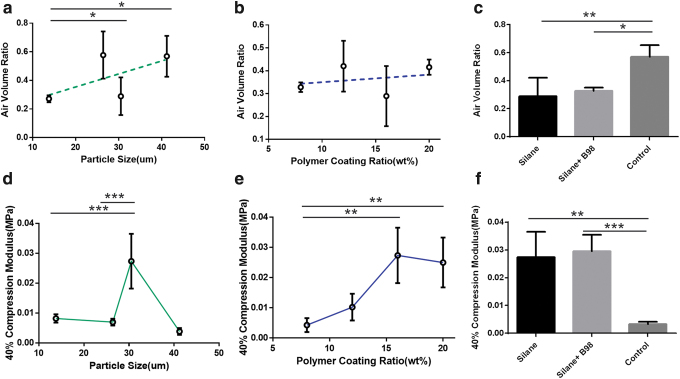

FIG. 8.

Air volume and green strength for the 3D-printed porous structure. (a–c) The air volume of the green parts, determined via microCT, reveals a positive correlation between particle size (nonvolatile ratio group) and the polymer coating ratio. In addition, the green parts printed with control powder (nonsilane treated) had a larger air volume within the structure than the green parts printed with the silane and silane+B98 groups (n = 4; mean ± SD; **p < 0.01; *p < 0.1). (d–f) The green strength, reported as 40% compression modulus, showed a maximum mean value when the median particle size was 30.5 μm. As the polymer coating ratio increased, the green strength also significantly increased, despite the decrease in packing density as evidenced by the greater air volume in green parts with higher polymer coating ratios. In addition, the green strength of the parts printed with the nonsilane-treated powder was significantly lower than the green strength of the parts printed with silane-treated powder (n = 4; mean ± SD; ***p < 0.001; **p < 0.01; *p < 0.1). CT, computed tomography. Color images are available online.