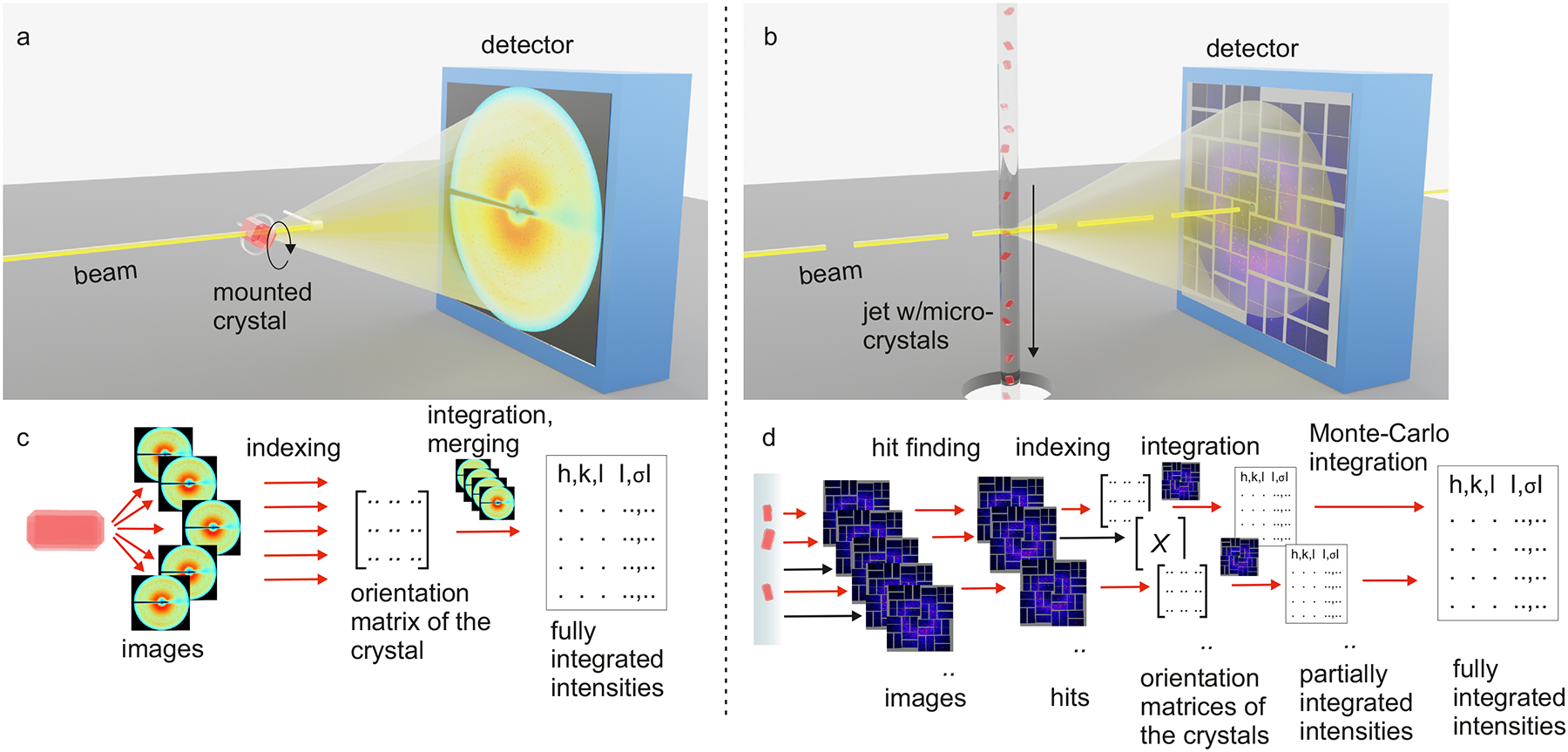

Fig. 1 |. Differences in experimental crystallography setups.

a, c | conventional rotation crystallography. b, d | SFX with sample delivery by high viscosity extrusion. In conventional MX, a single crystal (red) is mounted in a loop, kept at 100 K using a cryogenic nitrogen stream and rotated during sequential exposures, panel a. Consecutively acquired diffraction patterns are indexed, giving an orientation matrix of the crystal in the laboratory coordinate system, which is used to integrate the reflection intensities, panel c. In SFX, many microcrystals are sequentially delivered to the pulsed X-ray beam in random orientations, and a detector image is acquired for each XFEL pulse, panel b. A Bragg diffraction pattern containing partial intensities will only be produced when a crystal is present in the interaction region at the same time as an X-ray pulse arrives, panel d. Images containing a diffraction pattern are selected in a process called “hit finding”. The hit rate is the ratio of pattern-containing frames to the total number of collected frames. Hits are individually indexed, which is not always successful. The ratio of indexed patterns to the total number of hits is the indexing rate, panel d. Individual indexed diffraction patterns are integrated, and the resulting intensities are merged by Monte-Carlo integration.