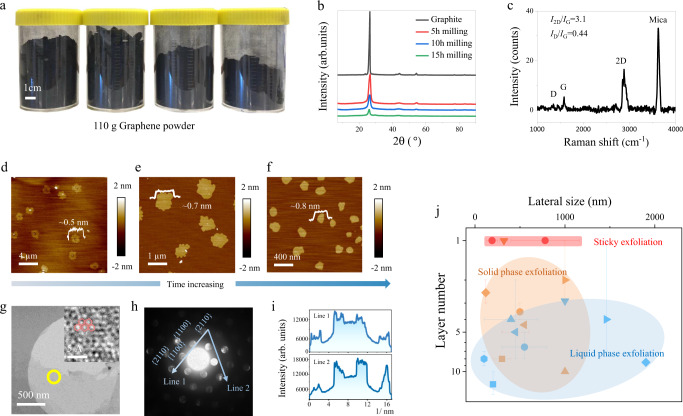

Fig. 1. The physical properties of the graphene nanosheets via sticky mechanical exfoliation.

a Photograph of the obtained 110 g graphene in powder form. b Powder X-ray powder diffraction (XRD) patterns of pristine graphite and graphene products after 5, 10, and 15 h milling. c Accumulated Raman spectrum of the graphene nanosheets after 15 h milling deposited on mica. Detailed characterization method can be found in supplementary S2.4. d–f Selected atomic force microscopy (AFM) height profiles of graphene exfoliated by 5, 10, and 15 h milling, respectively (from left to right). g High resolution transmission electron microscopy (HR-TEM) image of exfoliated graphene (inset, atomic resolution). Red hexagons highlight the graphene lattice. h Converged beam electric diffraction (CBED) of graphene indicated by the yellow circle in (e). Spot size: 9, convergence angle: ~15 milliard. i Diffraction spot intensity taken along the lines in (f). j Comparison of the obtained graphene in this work with other mechanical exfoliated graphene in terms of lateral size and layer number. Error balls indicate the data range provided in the references. (Detailed data in Supplementary Table 2.1.) Blue dots: liquid phase exfoliation; Orange dots: solid phase exfoliation; Red dots: this work.