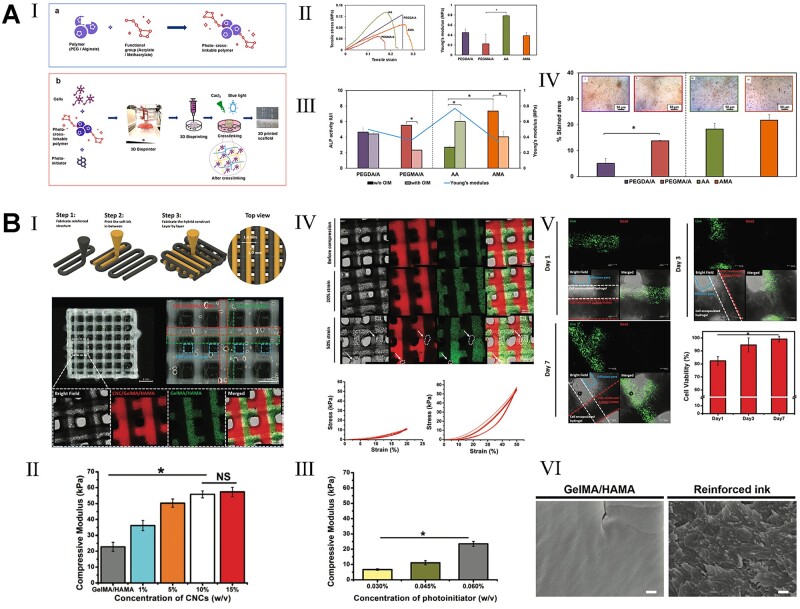

Figure 9.

Mechanical reinforcement of composite polymers for 3D printing [329, 339]. (A: I. Overall 3D bioprinting process to fabricate functional PEG diacrylate (PEGDA) or PEG dimethacrylate (PEGMA)-Alg acrylate (AA) or alg ormethacrylate (AMA) crosslinked scaffolds. II. Stress-strain curve and young’s modulus (MPa) value of different hydrogels indicated the functionalized PEG and alginate gels exhibited high mechanical strength compared with natural materials. III. The ALP activities of functionalized hydrogels demonstrated the favorable osteogenic effects with any additive agents. Reproduced with permission from Ref. [339] Copyright 2021 Elsevier. B: I. Illustration of the hybrid printing procedure and the observation of the hybrid printed construct (the hybrid printed constructs were fabricated using the two hydrogel inks: cellulose nanocrystals (CNCs)-reinforced GelMA/HLAMA and GelMA/HLAMA inks, which were defined in the optical microscopic image by red dotted lines and green dotted lines, respectively.) II–III. Compression test for the optimal concentration of GelMA/HLAMA, reinforced hydrogel and photoinitiator. IV. Mechanical results of hybrid printed construct after cyclic compression (structural integrity was retained after 10 cycles of compression with 20% strain. After 10 cycles of compression with 50% strain, the structural defects appeared as marked by the white arrow and dot line). V. Cells remained high viability of 82.4 ± 3.3% at day 1 and reached to 99.1 ± 2.2% at day 7. VI. SEM observation of GelMA/HLAMA ink. Reproduced with permission from Ref. [329] Copyright 2020 John Wiley and Sons.)