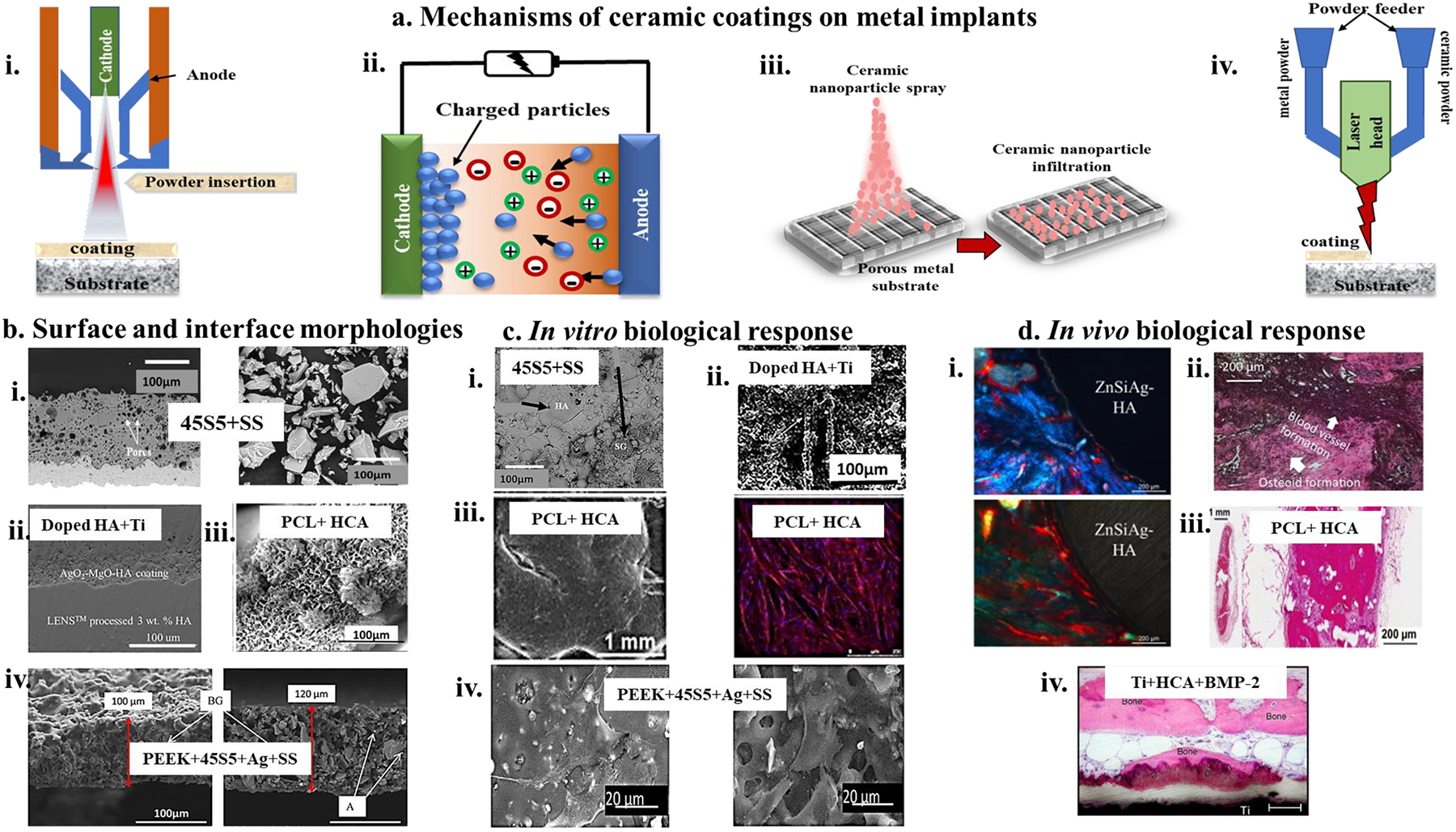

Figure 10. a. popular mechanisms of effective ceramic coatings on metal surfaces,

i) Plasma-spray coating molten ceramic powder particles onto the surface of a heated material to-be-coated. The ceramic powder is injected into the high-temperature plasma, ii) Electrophoretic deposition technique involves the deposition of charged ceramic particles in a colloidal solution onto a conducting metal surface, iii) infiltration process involves the use of nanoscale ceramic particles into porous metal network resulting in entrapment of the ceramic nanoparticles and coating the metal, iv) DED additive manufacturing technique involves premixing ceramic and metal powders to coat metal surfaces under high-temperature laser melting and rapid solidification. b, Morphologies of coating surfaces and coating-substrate interfaces, i) (left) interfacial SEM micrograph and (right) micrograph of the particle size distribution of 45S5 bioglass coated on stainless steel (AISI 304) with the fine dry ground (DR) particle size less than 63μm. DR63 powder coating revealed fewer cracks and pores at the interface due to decreased temperature gradient during cooling339, ii) Interfacial microstructure of Ag-oxide and Mg-oxide doped HA-coated on DED fabricated Ti+3%HA substrate showed well-bonded coating with the substrate with no cracks and delamination299, iii) CaP deposition using immersion in simulated body fluid on polycaprolactone (PCL) coated metal substrate reveals nanotextured HCA like layer formation on PCL strands305, iv) Cross-section microstructure of 45S5 and silver particles embedded in PEEK coated on SS316L, shows uniform co-deposition of 45S5 and Ag particles and homogenous microstructure from SEM (left) as well as a backscattered image (right)340. c, in vitro cellular activity on coated metal surfaces, i) 45S5 coating on AISI 304 substrate shows the formation of a uniform layer of HA after 7-day immersion in SBF, indicating enhanced bioactivity339, ii) Doped HA coating on DED processed Ti64 surfaces shows not only well-attached osteoblasts but also differentiation of osteoblast at day 11 on these increased biocompatible coated metals299, iii) At week-8, HCA coated PCL strands shows cell sheet formation around each strand of PCL when exposed to a basal media305, iv) PEEK and bioglass composite on SS316L exhibited well-spread MG63 osteoblast-like cell on the surface at 4 days after incubation, with no evident detrimental effect from Ag addition in the coating340, d, in vivo dynamic biological response, i) Tissue integration within the doped HA coating on Ti64 can be seen in week 10 with ZnSiAg HA-coated Ti64 indicating better osseointegration. The higher osteoid formation is seen with HA; however, ZnSiAg-HA has a higher total bone formation300, ii) H&E staining of rat explant section reveals new bone formation and angiogenesis for HA-coated Ti64 with natural medicinal compound curcumin doping in the HA matrix341, iii) Mineralized bone filling pores of HA+ PCL coated scaffolds at 8 weeks implantation in athymic rats305, iv) High-magnification image of Ti discs coated with HCA and BMP-2, showing bone tissue in direct contact with the coating and within the surrounding connective tissue298.