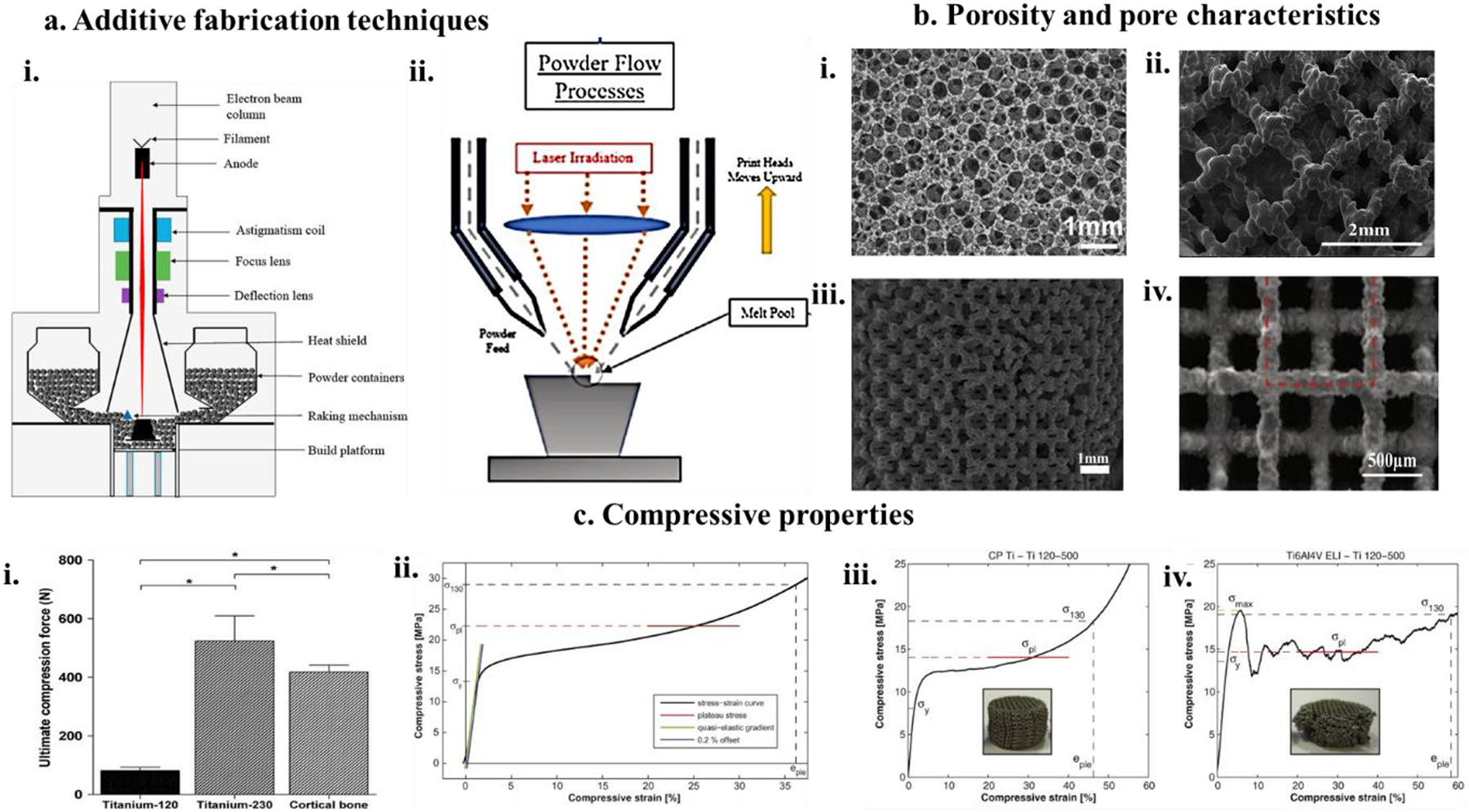

Figure 4. a. Schematic representation of metal implant additive manufacturing techniques,

i) Powder Bed Fusion (PBF) implant fabrication involves the use of an electron beam or high energy laser to melt powder particles on a metal powder bed to fabricate the desired shape and structure of implants81, ii) Directed Energy Deposition (DED) fabrication involves metal powder flow through multiple nozzles and simultaneously being exposed to a high energy laser beam which forms a metal melt pool on the substrate gradually taking shape through layer-wise deposition of molten metal and rapid cooling81. b. Pore properties of fabricated metal structures, i) SEM micrograph of 80% porous Ti sponge sheet fabricated using slurry foaming showing similar pore characteristics as cancellous bone82. ii) Shows the interconnected pore structure of a Ti metal cage 3D printed using electron beam melting technology with a trabecular pore diameter of 413 ± 78 μm. Pores > 300 μm are suitable for bone ingrowth and fusion with metal cage83, iii) Selective laser molten (SLM) porous Ti structures with 230 μm strut size and 500 μm pore size84, iv) SLM fabricated 80% porous Ta implants85. c. Compressive properties of additively manufactured porous metal structures for biomedical applications i) porous Ti with 230 μm strut size and 68% porosity86, ii) Ta structures with 80% porosity85, iii and iv) CpTi and Ti6al4V-ELI structures with 120 μm and 500 μm pore size, respectively87.