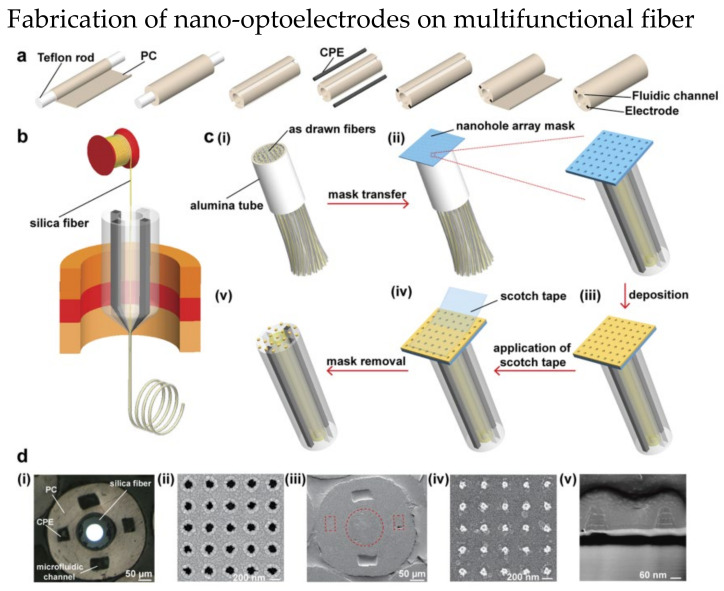

Figure 16.

Fabrication steps of nano-optoelectrodes on multifunctional fiber probe. (a) Fabrication of preform with two conductive polymer electrodes (CPE) and two optofluidic channel. (b) A silica fiber was inserted into the hollow core of the preform before the fiber drawing process. (c) The process of combining nano−optoelectrodes on the fiber tips. (i) multiple fibers were packed together in an alumina tube and cut. (ii) After the top surface of fiber bundle was polished, a nanohole array mask was placed on it. (iii) Layers of Ti, Au, and Ag were deposited to the fiber bundle. (iv) A scotch tape was used to remove the nanohole array mask. (v) The final fiber with nanostructures. (d) Images of multifunctional fiber. (i) Optical image of the fiber bundle after polishing. SEM image of (ii) the nanohole array mask, (iii) fiber end, (iv) nano−optoelectrodes on the fiber end (v) cross−sectional of nano−optoelectrodes. Reprinted with permission from [125]. Copyright 2021, American Chemical Society.