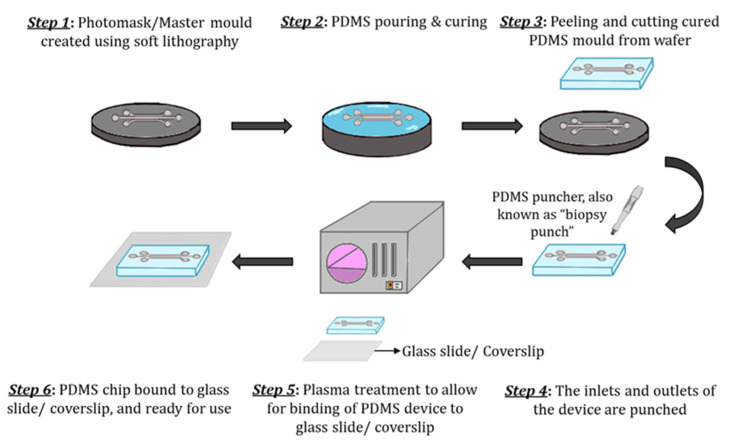

Figure 4.

Schematic of the step-by-step process of PDMS device fabrication. (Step 1) The master mould is created using soft lithography. (Step 2) The PDMS mixture (10:1 (base: curing agent)) is poured over the master mould and cured. (Step 3) The solidified PDMS is then cut and peeled from the master mould. (Step 4) The inlets and outlets are punched using a biopsy puncher. (Step 5) The PDMS chip and glass slide/coverslip are activated through plasma treatment. (Step 6) Finally, the PDMS chip is bound to a glass slide/coverslip and cured further for ~2–5 min at 75 °C and is ready to use.