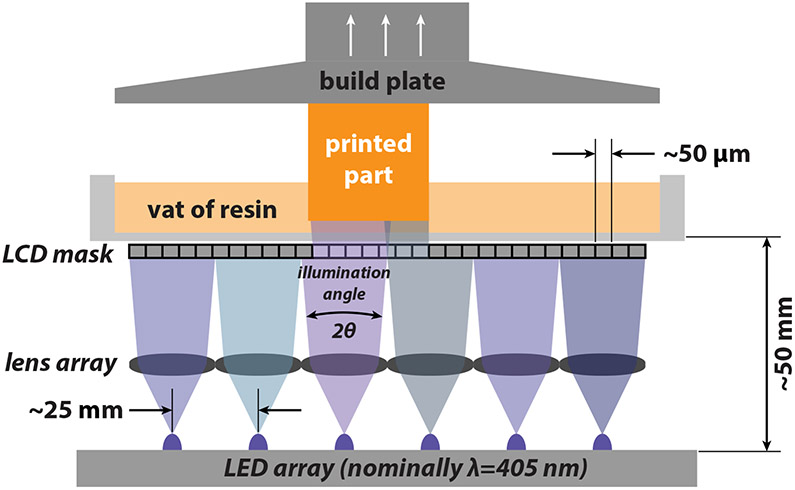

Figure 1:

A schematic of a LCD-based vat photopolymerization (VP) printer. The spatial extent of the photopolymerization in each layer is controlled by a programmable LCD mask. The LCD is illuminated by an array of light emitting diodes (LEDs) which are collimated by an array of lenses. In a typical LCD-based VP system the LEDs are spaced out by ca. 25 mm, and have a nominal emission wavelength of 405 nm. The LCD pixel pitch is ca. 50 μm and the total optical pathlength between the LED and the resin is on the order of 50 mm. Notably, because an array of LEDs and lenses are used to illuminate the resin, any variation in LED emission (intensity and/or spectrum) is transferred to the build plane. In addition, individual pixels may be illuminated differently depending on where they are positioned with respect to the LEDs/lenses.