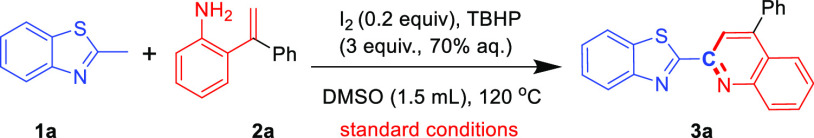

Table 1. Optimization of the Reaction Conditionsa.

| entry | changes from the standard conditions | yield (%)b |

|---|---|---|

| 1 | none | 78 |

| 2 | KI (0.2 equiv) as the catalyst | trace |

| 3 | NaI (0.2 equiv) as the catalyst | trace |

| 4c | I2 (0.2 equiv) as the catalyst | 52 |

| 5 | TBAI (0.2 equiv) as the catalyst | 27 |

| 6 | NIS (0.2 equiv) as the catalyst | 47 |

| 7 | I2 (0.1 equiv) as the catalyst | 49 |

| 8 | I2 (0.3 equiv) as the catalyst | 53 |

| 9 | DMF as the solvent | 15 |

| 10 | MeCN as the solvent | 20 |

| 11 | NMP as the solvent | 43 |

| 12 | toluene as the solvent | trace |

| 13 | temp = 100 °C | 45 |

| 14 | temp = 140 °C | 50 |

| 15 | TBHP (2 equiv) | 52 |

| 16 | TBHP (4 equiv) | 60 |

| 17 | no catalyst | trace |

| 18 | no oxidant | trace |

Reactions were performed on a 0.3 mmol scale, 1a (0.3 mmol) and 2a (0.54 mmol.).

Isolated yield.

2 equiv of TBHP was used.