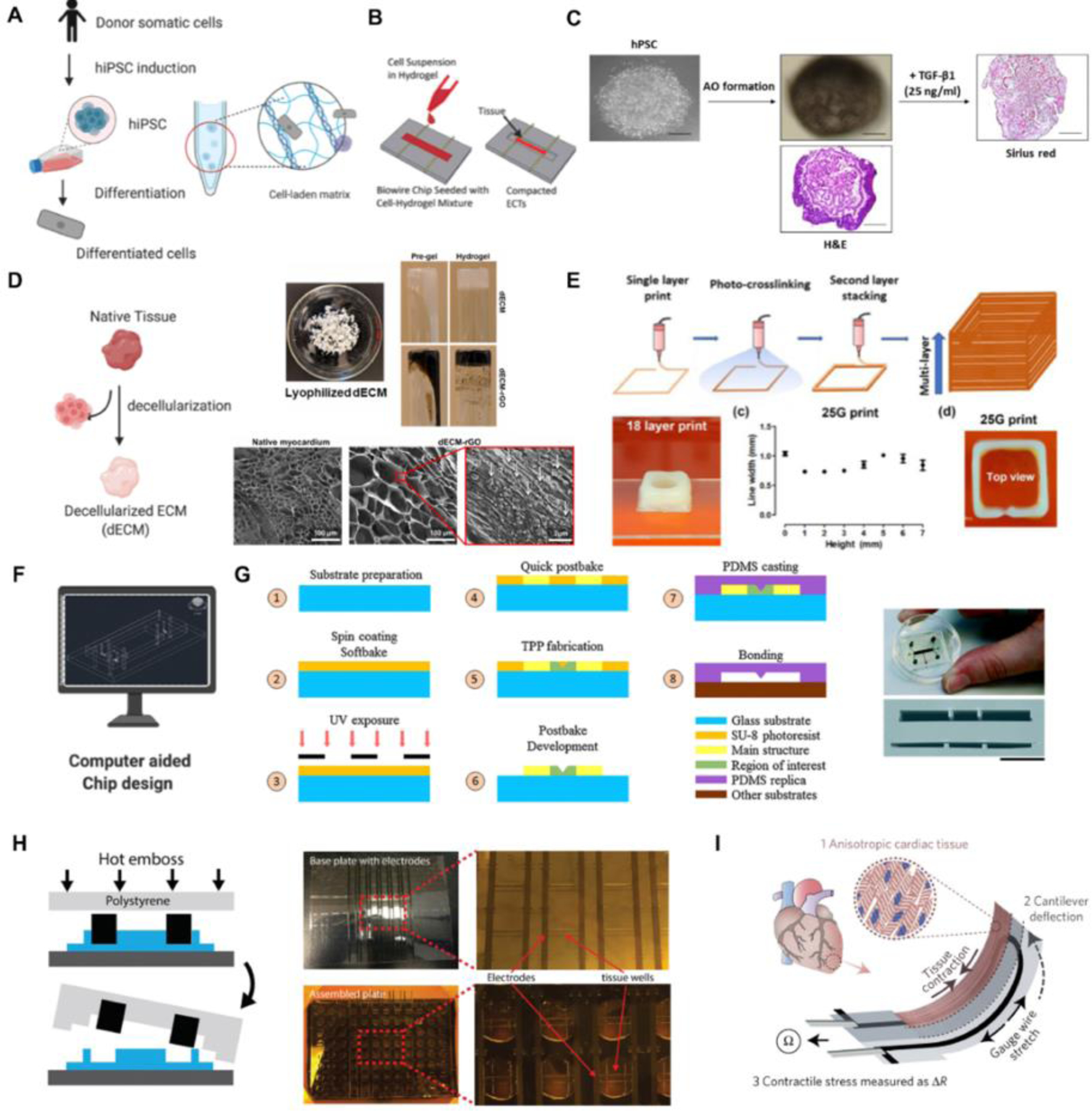

Figure 3. Engineering strategies for tissue construction and platform fabrication.

(A) Stem cell differentiation and cell encapsulation for the construction of engineered tissues. (B) Cell seeding for the construction of an engineered cardiac model on Biowire platform, reproduced with permission[17]. (C) Organoid formation through self-aggregation for fibrotic disease modeling, reproduced with permission [124]. (D) Construction of cardiac tissues with hydrogels comprised of ECM from porcine hearts, reproduced with permission [125]. (E) A multi-layer tissue model constructed with 3D bio-printing, reproduced with permission [125]. (F) Platform design using computer-aided tools. (G) Soft lithography and replica modeling procedures for the microfabrication of a PDMS device, reproduced with permission [126]. (H) Hot embossing process for the microfabrication of a scalable 96-well plate platform using tissue culture grade polystyrene, reproduced with permission[53]. (I) Microfabrication of an instrumented cardiac device via multi-material 3D printing, reproduced with permission [127].