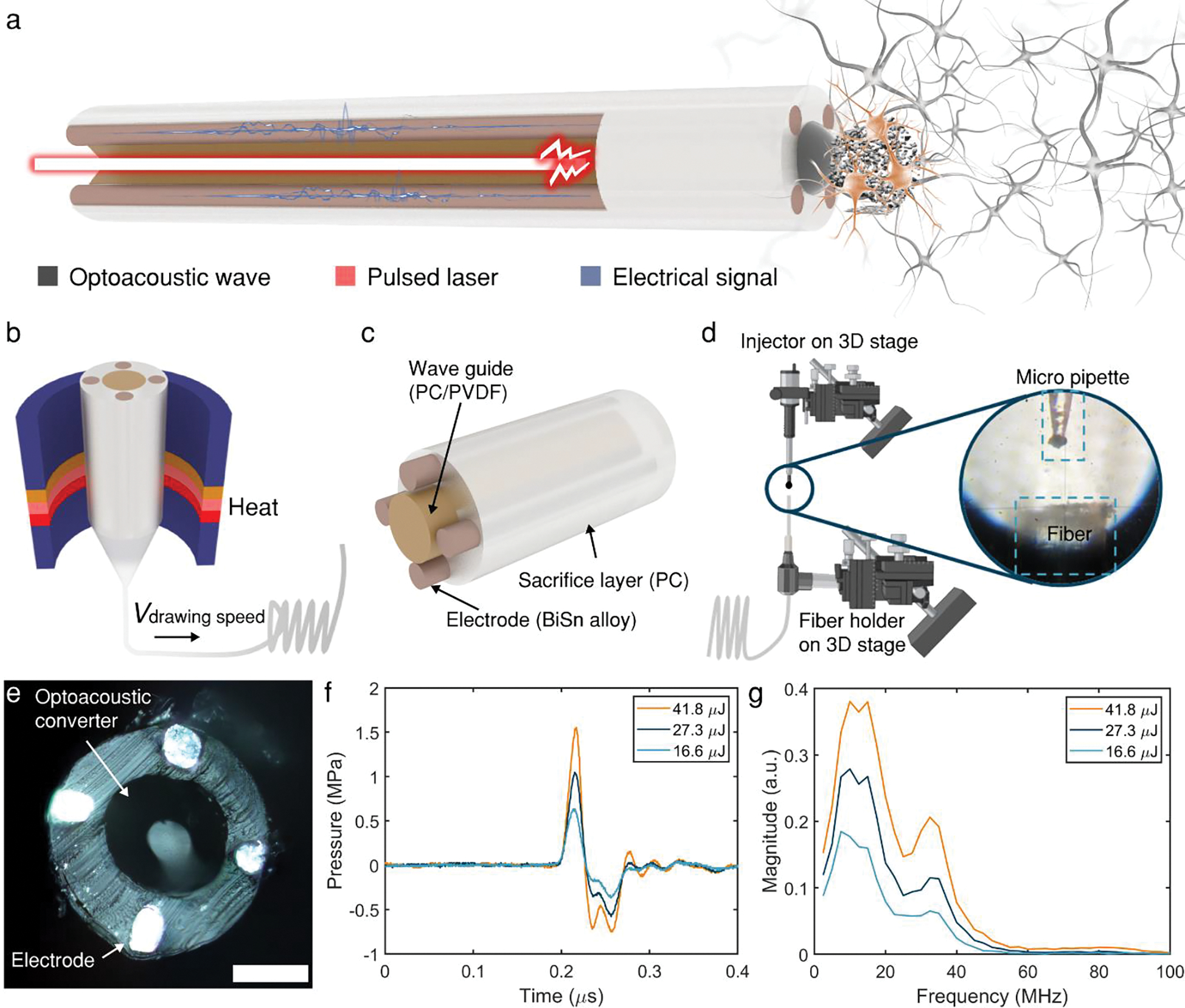

Figure. 1. Design, fabrication and characterization of mFOE.

a. Schematic of mFOE for bidirectional communication with neurons. Input laser pulse (red) is used to generate optoacoustic waves (black mesh next to the emitter at the mFOE tip) by the emitter. Neural activities are recorded by embedded electrodes (brown) as the output electrical signal (blue). Neurons stimulated are highlight in the tan color, in contrast to the unstimulated neurons in the gray color. b. Illustration of the thermal drawing process. c. Components of the multifunctional fiber, including a PC/PVDF waveguide, BiSn alloy electrodes and PC sacrifice layer. d. The selective deposition process for integrating the optoacoustic converter to the core wave guide in the multifunctional fiber. A pressure-driven micro-injector is used to control the volume of CS/PDMS deposited. 3D translation stages and microscope are used to control the deposition location. Zoom-in: The micro pipette was aligned to the center of the fiber under the microscope. e. Top view microscope image of the mFOE. Scale bar: 100 μm. f. Representative acoustic waveforms under different laser pulse energy recorded by a needle hydrophone. g. Frequency spectrum of acoustic waveforms shown in f.