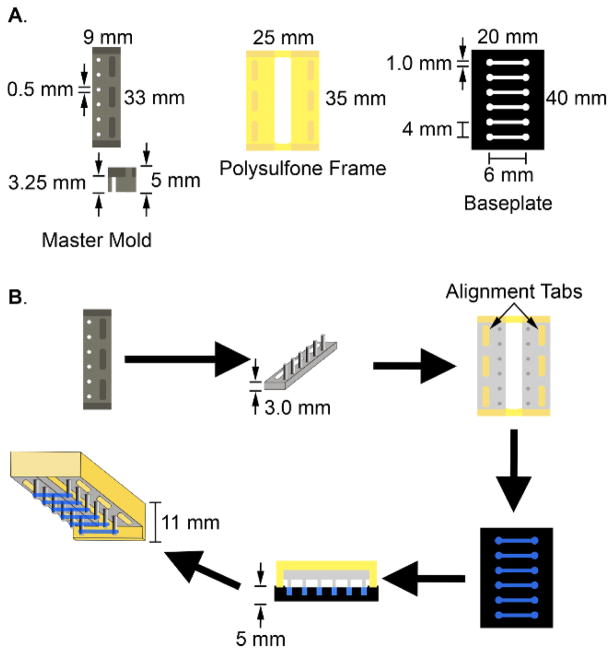

Figure 3. Schematic of the multi-tissue bioreactor and the cardiac tissue engineering process.

Construction of the multi-tissue bioreactor requires three components (A): 1) a polytetrafluoroethylene master mold 9 x 33 x 5 mm3, with 6 evenly spaced holes 0.5 mm in diameter; 2) a 25 x 35 x 11 mm3 polysulfone frame to hold the PDMS posts during tissue construction and culture; and 3) a 20 x 40 x 5 mm3 black polytetrafluorethylene baseplate with 6 wells of 6 x 1 x 1 mm3 dimensions, spaced 4 mm apart along its length. To create human engineered cardiac tissues (B), the PDMS posts are fabricated by PDMS soft lithography using the polytetrafluorethylene master mold, two of which are then pressed onto the tabs of the polysulfone frame to form 6 pairs of force-sensing cantilever posts. The tissue solution is pipetted into the wells in the black polytetrafluorethylene baseplate. The frame and posts are then inverted and aligned on the polytetrafluorethylene baseplate so that one pair of posts enters each well containing the tissue mix. After 48 hr, the baseplate is removed and the defined tissues are cultured on the posts, remaining inverted in NBS media.