Abstract

Recently, the concept of a circular economy for carbon neutrality is emerging. In particular, waste plastics are one of the key wastes, and efforts are being made to recycle them as energy rather than dispose of them. Accordingly, the technology of producing and utilizing pyrolysis oil from waste plastics attracts attention. As it is an early stage of technology development, however, there are not many demonstrations and papers that analyze the technology broadly. The goal of this study is to propose building a circular economy on a university campus through waste plastic pyrolysis oil technology. To show its feasibility, waste plastic pyrolysis oil technology is analyzed comprehensively from economic, environmental, and policy perspectives using the scenario analysis technique on the university campus level. A methodology of the scenario analysis technique enables predicting the uncertainties. Since plastic pyrolysis oil technologies and carbon neutrality are accompanied by many uncertainties, this technique is expected to be an appropriate methodology for this study. First, the amount of pyrolysis oil production from waste plastics from the campus is estimated. Then, the cost and carbon emissions from waste plastics are estimated if the pyrolysis oil technology is used instead of the traditional waste disposal process. As a result, the total economic profits of up to 425,484,022 won/year (354,570.01 $/year) are expected when a circular economy is built using waste plastic pyrolysis oil. In addition, it is also confirmed that greenhouse gas (GHG) emissions can be reduced by up to 840,891 kgCO2eq/year. The waste plastic pyrolysis oil satisfies Korea’s gas pollutant standards and is consistent with the GHG reduction policy. It can be concluded that building a circular economy at the university campus level using waste plastic pyrolysis oil technology is suitable from economic, environmental, and policy perspectives.

Keywords: Waste plastic pyrolysis oil, Plastic recycling, Circular economy, Carbon credits, Scenario analysis

Introduction

Discussions on how to respond to the climate crisis are taking place worldwide. Accordingly, a low-carbon society is being emphasized, and the circular economy system is attracting attention. The circular economy refers to a new economic model for breaking away from the traditional economic model based on mass production, mass consumption, and mass disposal (Geissdoerfer et al., 2017). In the linear economy structure composed of raw material extraction, production, consumption, and disposal, various problems such as resource depletion and environmental destruction inevitably occur (Sariatli, 2017). To solve this issue, the circular economy concept is attracting attention, and various efforts are being made to realize it through large-scale investment and political support (Ranta et al., 2018). To make the net emission of carbon dioxide ‘0’, an economic structure in which resources can be continuously circulated is needed rather than the traditional linear economic structure that ends with a large amount of waste.

Plastics are one of the most widely used materials, and they emit a large amount of greenhouse gas (GHG) throughout the entire process from production to disposal (Sevigné-Itoiz et al., 2015). Plastics are widely used because of their light weight and excellent durability. However, most of the plastics are still disposed of by incineration or landfill, leading to large amounts of GHG emissions. It is also known that waste plastics emit various pollutants and group 1 carcinogens such as dioxin (Shibamoto et al., 2007). The decomposition of buried plastic takes more than 500 years (Urtuvia et al., 2014). Globally, the recycling rate of plastics is 0–30%, and a large amount is still incinerated or landfilled (Kosior et al., 2018).

The amount of waste plastics in South Korea continues to increase, which has a significant negative impact on the environment as most of them are incinerated or landfilled. As of 2018, when total household waste increased by about 10% in the last 10 years, household waste plastic increased by about 71.7%. The increase rate remained at 10.6% for five years until 2013, however, it increased sharply to 46.6% for the next 5 years (Korea's 'notorious' plastic use, there is no place to bury it anymore, Hankookilbo xxxx). In addition, as non-face-to-face daily life has been prolonged since COVID-19 and the rate of courier use and food delivery has increased rapidly, the amount of waste plastics has been increasing sharply (Janairo, 2021).

There are physical, thermochemical, and biological methods for recycling plastics without landfilling (Dai et al., 2022). To obtain oil from waste plastics, one of these methods is to use pyrolysis, which belongs to thermochemical technology. Waste plastic pyrolysis oil technology is a technology that recovers energy by heating polymer waste in a reducing atmosphere and decomposing it into light hydrocarbon compounds (Sekar et al., 2022). Pyrolysis technology is a thermal degradation process that decomposes polymers into small molecules by applying heat. Main products such as CO, H2, and hydrocarbons or liquid oil can be used as vehicle fuel after refining. The use of pyrolysis oil technology can reduce carbon emissions by recycling waste such as plastics and biomass (Yuliansyah et al., 2015). Moreover, the cost of incineration or landfill can be reduced, and even profits can be created by producing and selling pyrolysis oil. In addition to the general plastic pyrolysis technology mentioned above, there are new technologies under their development. One of the new variations of plastic pyrolysis technology is supercritical pyrolysis technology. This technology extracts naphtha, an initial raw material, by thermally decomposing mixed waste plastics using supercritical steam at high temperature and high pressure, and is being actively researched.

Waste plastic pyrolysis oil technology is at an early stage of development and demonstration level. In particular, the development of catalysts and processes for synthesizing pyrolysis oil using various waste plastics such as PET, HDPE, PVC, PP, and PS has been the main focus (Sharuddin et al., 2016). The techno-economic analysis was conducted for waste plastics based on chemical process model (Almohamadi et al., 2021), probabilistic economic model (Ibe & Kodera, 2021), and experiments (Lam et al., 2019). Life cycle assessment was reported on plant levels (Neha et al., 2022). In addition, comprehensive economic analysis research with wider perspectives than simple reactions and plants was mainly reported on the pyrolysis process for biomass, not waste plastic (Brigagão & O.d.Q.F. Araújo, J.L. de Medeiros, H. Mikulcic, N. Duic, 2019; Lee et al., 2020; Schalkwyk et al., 2020; Shahbaz et al., 2020; Shemfe et al., 2017; Sorunmu et al., 2020). The previously mentioned literature was limited to the economic and environmental analysis only within the scope of simple reactions and plants. However, for the commercialization of waste plastic pyrolysis oil technology, it is essential to be quantitatively analyzed and answered what advantages the technology has from economic, environmental, and policy aspects based on the circular economy models compared to the traditional waste disposal process.

The main goal of this study is to break away from the existing method of mass landfilling and incineration of waste plastics and to circulate waste plastics as a resource, forming a sustainable campus by constructing a circular economy. For the quantitative feasibility assessment, the circular economy models based on the waste plastic pyrolysis oil technology was evaluated from economic, environmental, and policy perspectives, which has not been reported on the university campus level. In this process, there are uncertainties expected, such as development of pyrolysis oil technology, the amount of waste plastic from the university, and changes in greenhouse gas emissions, thereby making a scenario analysis method to be chosen for this work. To achieve the research goal, a small-scale circular economy scenario for a university campus, a good example of a small community, was constructed and analyzed as a case study. The scenario was established for Ewha Womans University, a leading university for a circular economy system in South Korea. Detailed sub-goals and steps of the work can be summarized as follows: first, the amount of waste plastic and its disposal methods were explored. After that, a campus circular economy scenario was proposed, and the pyrolysis oil production and cost were estimated based on the scenario. Then, the economic profits of the produced pyrolysis oil were quantitatively evaluated. In addition, the environmental feasibility was evaluated by estimating the amount of GHG, pollutant solids, and gas for the waste plastic pyrolysis oil production. The consistency of the circular economy based on waste plastic pyrolysis oil technology with government policy was also discussed. Finally, risk assessment on the scenario was conducted based on SWOT analysis. Through this study, the feasibility of waste plastic pyrolysis oil technology to establish a circular economy was comprehensively analyzed from economic, environmental, and policy perspectives.

Methodology

Concepts of the scenarios analysis

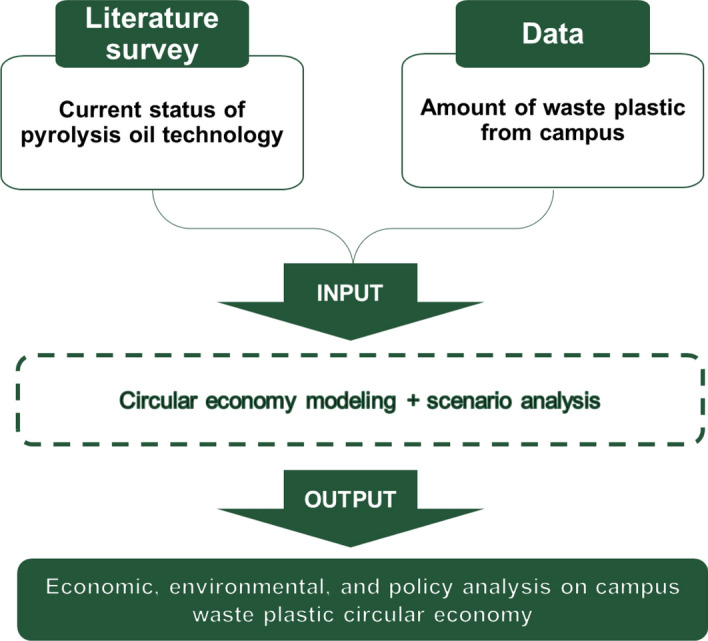

Scenario analysis is a tool for strategic planning for organizations to help understand how it might perform in uncertain and different future states (Maack, 2001). The scenario is defined as a possible future situation. The scenario is not a complete description of the future, but focuses on the parameters which has a possible impact on the future (Kosow & Gaßner, 2008). Scenario analysis techniques can be used to examine the key uncertainties, impacts, and interactions that are expected to shape the future. The purpose of the scenario in this research was to examine whether applying waste plastic pyrolysis oil technology to a small-scale circular economy of the university campus is feasible from an economic, environmental, and policy point of view. A research model was established as shown in Fig. 1. First, the current status of pyrolysis oil technology was identified through a literature survey, and data available for this study was explored. Afterward, the scenario analysis was conducted based on the circular economy scenario for the Ewha Womans University campus. By analyzing the results, the feasibility of the circular economy scenario was quantitatively investigated and discussed.

Fig. 1.

Research model for waste plastic pyrolysis oil for university campus

For this study, scenario components were selected as shown in Fig. 2. The number of waste plastics, and yield of pyrolysis oil was utilized to evaluate the amount of pyrolysis oil production from the waste plastics from the university campus. For the economic analysis, pyrolysis oil unit price and pyrolysis oil production unit cost per amount of waste plastic were considered, and pyrolysis oil net value, campus shuttle bus fuel replacement, and carbon credit values were evaluated. For the environmental analysis, the GHG reduction factor and pollutant substances emission ratio of the waste plastic pyrolysis oil technology were considered, and GHG reduction pollutant substance emissions were evaluated. For the policy analysis, the consistency of the waste plastic pyrolysis oil technology with the policy of South Korea was discussed. However, it was not considered a component of the scenario analysis because of the difficulty in quantitative evaluation.

Fig. 2.

Components of waste plastic pyrolysis oil scenario for university campus

Assumptions of the scenarios

The most ideal case and non-ideal case were set as listed in Table 1. In scenario 1, an ideal case, high production yield, and low production cost were assumed to produce pyrolysis oil economically. A high GHG reduction factor was set to maximize the GHG emission reduction, and a high pyrolysis oil net value was assumed to maximize the profits from pyrolysis oil sales. Scenario 2 is a non-ideal case with low production yield, high production cost, low GHG reduction factor, and low pyrolysis oil net value.

Table 1.

Two scenarios for the waste plastic pyrolysis oil analysis

| Scenario | Assumptions |

|---|---|

| Scenario 1 | Ideal case: high production yield, low production cost, high GHG reduction factor, high pyrolysis oil net value |

| Scenario 2 | Non-ideal case: low production yield, high production cost, low GHG reduction factor, low pyrolysis oil net value |

Table 2 shows the detailed assumptions for scenario 1 and 2, respectively. In Scenario 1, yield 1, production cost 1, unit price 1, and reduction factor 1 were selected for the scenario analysis. In scenario 2, yield 2, production cost 2, unit price 2, and reduction factor 2 were used.

Table 2.

List of assumptions

| Item | Type | Value | Unit | Source | Remarks | |

|---|---|---|---|---|---|---|

| Basic | Amount of waste plastic | – | 591.51 | ton/year | Internal Data of Ewha Womans University (2022) |

Ewha Womans University Waste Disposal Statement for 2021 |

| Yield of pyrolysis oil | Yield 2 | 0.43 | – | Ma & Zhong (2018), Phae et al. (2005), Pyrolysis Plant For Sale, Beston Group Co. & Ltd (2022), Krüger (2020) |

Estimation based on literature and company reports (including BASF, BESTON) |

|

| Yield 1 | 0.77 | – | Ma & Zhong (2018), Phae et al. (2005), Pyrolysis Plant For Sale, Beston Group Co. & Ltd (2022), Krüger (2020) |

Estimation based on literature and company reports (including BASF, BESTON) |

||

| Economic | Pyrolysis oil production unit cost per amount of waste plastic | Production cost 1 |

51,120 (42.6) |

₩/ton ($/ton) |

Ma & Zhong (2018) | $42.6/ton, $1 = ₩1200 |

| Production cost 2 |

99,960 (83.3) |

₩/ton ($/ton) |

Pyrolysis Plant For Sale, Beston Group Co. & Ltd (2022) | $83.3/ton, $1 = ₩1200 | ||

| Traditional waste plastic disposal unit cost | – |

297,000 (24,750) |

₩/ton ($/ton) |

Disposal unit price for each type of waste for calculating the insurance money for waste disposal (2021–259) 2022) | Disposal unit price for each type of waste for calculating the insurance money for waste disposal (2021–259) | |

| Pyrolysis oil unit price | Unit price 1 |

700 (0.583) |

₩/liter ($/liter) |

Oh (2006) | – | |

| Unit price 2 |

330 (0.275) |

₩/liter ($/liter) |

Ma & Zhong (2018) | $224/ton, $1 = ₩1200 | ||

| Shuttle bus fuel cost | - |

24,857,570 (20,714.642) |

₩/year ($/year) |

Kwon et al. (2020) |

Annual travel distance 132,988 km, mileage 10.7 km/L, Fuel price: ₩2000/L |

|

| Carbon credit price | – |

22,400 (18.667) |

₩/tCO2eq ($/tCO2eq) |

(Ets Market Information Platform et al. (2022) | Price as of May 27, 2022 | |

| Environmental | GHG emission factor for traditional waste plastic disposal | – | 1777 | kgCO2eq/ton | Krüger (2020) | Estimation from BASF |

| GHG reduction factor for waste plastic pyrolysis oil | Reduction factor 1 | 0.80 | - | Antelava et al. (2019), “Plastic responsible for marine pollution, good material if recycled well” [H.eco Forum (2022), Climate Crisis & the Sea ⑤ (2022) | Estimation from SK geocentric | |

| Reduction factor 2 | 0.58 | – | Krüger (2020) | Estimation from BASF | ||

| Pollutant substances emission from waste plastic pyrolysis oil production | – | – | – | Yongtai (2011), Nho et al. (2006) | Listed in Table 8 and 9 |

Economic and environmental analysis

Based on the previous scenario components and assumptions, the following equations were established to conduct an economic and environmental analysis.

| 1 |

Environmental analysis—GHG reduction by utilizing pyrolysis oil technology

| 3 |

| 4 |

Economic analysis—profits by utilizing pyrolysis oil technology

Sensitivity analysis

Because the waste plastic pyrolysis oil technology is in the early stages of development, there are many uncertainties. Sensitivity analysis was conducted to understand the effects of various assumptions on the economic feasibility of constructing a circular economy based on waste plastic pyrolysis oil. More precisely, the sensitivity analysis's purpose was to determine the change of scenario result values as the degree of scenario component values changes. For this purpose, the analysis was conducted based on the values shown in Table 3. To find out how much influence each assumption has, the effects on the final yield were analyzed when each concerning variable was changed at the same rate. The reference value was set based on the scenario, and high and low values were determined by introducing weights of 0.5 and 1.5, respectively.

Table 3.

Assumptions for sensitivity analysis

| Assumptions | Unit | Low value (− 1.0) | Reference value (0.0) | High value (1.0) |

|---|---|---|---|---|

| Amount of waste plastic | Ton/year | 295.76 | 591.51 | 887.27 |

| Yield of pyrolysis oil | – | 0.43 | 0.60 | 0.77 |

| Pyrolysis oil production unit cost per amount of waste plastic | ₩/ton ($/ton) | 51,120 (42.675) | 75,540 (62.95) | 99,960 (83.3) |

| Pyrolysis oil unit price | ₩/L ($/L) | 330 (0.275) |

515 (0.42) |

700 (0.58) |

| Shuttle bus fuel cost | ₩/year ($/year) | 12,437,785 (10,364.82) | 24,875,570 (20,729.64) | 37,313,355 (31,094.46) |

| Carbon credit price | ₩/tCO2eq ($/tCO2eq) | 11,200 (9.33) | 22,400 (18.66) | 33,600 (28) |

| GHG reduction factor | – | 0.6 | 0.7 | 0.8 |

Results and discussion

Economic analysis on pyrolysis oil synthesis from plastics

The economic value of pyrolysis oil obtained from the annual waste plastic was calculated as shown in Table 4. The value of pyrolysis oil was ₩361,101,017/year ($300,917.51/year) for Scenario 1, and ₩43,879,101/year ($36,565.91/year) for Scenario 2. The pyrolysis oil net value was the economic value of pyrolysis oil itself. However, in this study, circular economy scenarios based on waste plastic pyrolysis oil were constructed. Accordingly, an additional comprehensive economic analysis was performed considering the replacement of campus shuttle bus fuel and pyrolysis oil sales revenue of carbon credits.

Table 4.

Economic analysis results for plastic pyrolysis oil analysis

| Item | Scenario | Value | Unit | Equation | ||

|---|---|---|---|---|---|---|

| Pyrolysis production | Pyrolysis oil production | Scenario 1 | 455.46 | ton/year | Equation 1 | |

| Scenario 2 | 254.35 | ton/year | ||||

| Pyrolysis oil production cost | Scenario 1 | 30,237,991 (25,198.32) | ₩/year ($/year) | Equation 5 | ||

| Scenario 2 | 59,127,340 (49,272.78) | ₩/year ($/year) | ||||

| Traditional waste plastic disposal cost | – | 175,678,470 (146,398.72) | ₩/year ($/year) | Equation 6 | ||

| Economic analysis | Pyrolysis oil net value | Scenario 1 | 361,101,017 (300,917.51) | ₩/year ($/year) | Equation 2 | |

| Scenario 2 | 43,879,101 (36,565.91) | ₩/year ($/year) | ||||

| Campus circular economy | 1. Shuttle bus fuel cost reduction by utilizing pyrolysis oil | Scenario 1 | 24,172,695 (20,143.91) | ₩/year ($/year) | Equation 7 | |

| Scenario 2 | 22,459,460 (18,716.21) | ₩/year ($/year) | ||||

| 2. Pyrolysis oil sales revenue | Scenario 1 | 382,475,377 (318,729.48) | ₩/year ($/year) | Equation 8 | ||

| Scenario 2 | 98,828,664 (8,257.22) | ₩/year ($/year) | ||||

| 3. Carbon credit salesrevenue | Scenario 1 | 18,835,950 (15,696.62) | ₩/year ($/year) | Equation 9 | ||

| Scenario 2 | 13,656,064 (11,380.05) | ₩/year ($/year) | ||||

| Total profit by establishing waste plastic circular economy (1 + 2 + 3 − pyrolysis production cost) | Scenario 1 | 425,484,022 (354,570.01) | ₩/year ($/year) | - | ||

| Scenario 2 | 134,944,188 (112,453.49) | ₩/year ($/year) |

Shuttle bus fuel substitution

The shuttle buses of the campus are powered by diesel fuel, and a total of four are currently in operation. The on-campus shuttle bus travels 132,988 km/year and therefore requires about 12,429 L (= 10,316 kg) of fuel. The annual shuttle bus fuel cost reduction by utilizing pyrolysis oil instead of diesel fuel was estimated through Eq. 2 as follows:

Scenario 1: 24,857,570-(10,316 × 51,120) / (0.77 × 1000) = 24,172,695 ₩/year (20,143.91 $/year)

Scenario 2: 24,857,570-(10,316 × 99,960) / (0.43 × 1000) = 22,459,460 ₩/year (18,716.21 $/year)

As can be seen from the above equation, most of the shuttle bus fuel cost of 24,857,570 ₩/year (20,714.64 $/year) could be reduced by using waste plastic pyrolysis oil. As shown in Table 5, these results were attributed to the low pyrolysis oil production cost. The waste plastic pyrolysis oil utilizes waste plastic, leading to low pyrolysis oil production costs, while conventional diesel fuel price is much more expensive than the pyrolysis oil production cost.

Table 5.

Cost reduction by utilizing waste plastic pyrolysis oil for shuttle bus

| Scenario | Shuttle bus fuel cost (₩/year) ($/year) | Pyrolysis production cost for shuttle buses (₩/year) ($/year) |

|---|---|---|

| Scenario 1 |

24,857,570 (20,714.64) |

684,875 (570.72) |

| Scenario 2 |

2,398,110 (1998.42) |

Pyrolysis oil sales revenue

The profits of selling the remaining fuel after some portion of pyrolysis oil was utilized as shuttle bus fuel was calculated. As shown in Table 6, for Scenario 1, the remaining pyrolysis oil was 426 tons/year, while 339 tons/year for Scenario 2. Assuming that all of the remaining pyrolysis oil was sold as fuel, the sales revenue was as follows.

Scenario 1 (700 ₩/L): 382,475,377 ₩/year (318,729.48 $/year)

Scenario 2 (330 ₩/L): 98,828,664 ₩/year (82,357.22 $/year)

Table 6.

Residual waste plastic pyrolysis oil for sale

| Scenario | Pyrolysis oil production (ton/year) | Amount of pyrolysis oil used for shuttle buses (ton/year) | Residual amount (ton/year) |

|---|---|---|---|

| Scenario 1 | 436 | 10 | 426 |

| Scenario 2 | 349 | 10 | 339 |

Carbon credit sales revenue

Another economic value of waste plastic pyrolysis oil for a circular economy was securing carbon credits through GHG reduction. Because waste plastics were utilized as a pyrolysis oil instead of disposal, GHG emissions from the waste plastic could be reduced. In South Korea, the amount of GHG reduction can be recognized as a carbon credit (Leading circular economy & carbon neutrality by pyrolysis of waste plastics, Ministry of Environment, 2020). The carbon credit price is ₩22,400/tCO2eq ($18.66/tCO2eq) as of May 27, 2022 (Ets Market Information Platform et al., 2022). As shown in Table 7, the economic value corresponding to the amount of GHG reduction was calculated to be ₩18,835,950/year ($15,696.62/year) and ₩13,656,064/year ($11,380.05/year) for scenarios 1 and 2, respectively.

Table 7.

Greenhouse gas (GHG) emission and price of carbon credit

| Scenario | GHG reduction (kgCO2eq/year) | Carbon credit sales revenue (₩/year) ($/year) |

|---|---|---|

| Scenario 1 | 840,891 |

18,835,950 (5696.62) |

| Scenario 2 | 609,646 |

13,656,064 (11,380.05) |

Through the above scenario analysis, it was confirmed that the economic value of waste plastic pyrolysis oil itself was ₩43,879,101—₩361,101,079/year ($36,563.41—$300,917.56/year). However, when pyrolysis oil was used to build a university campus circular economy, it showed a higher economic value of ₩134,944,188—₩425,484,022/year ($112,453.49—$354,570.01/year) as shown in Fig. 3. These results were attributed to replacing conventional fossil fuels, selling pyrolysis oil, and selling carbon credits. Therefore, it could be concluded that building a circular economy even in a small community of university campus can have up to about 1–3 times of economic value compared to simply producing and selling pyrolysis oil itself.

Fig. 3.

Economic analysis on waste plastic pyrolysis oil for university campus

Sensitivity analysis on waste plastic pyrolysis oil

Sensitivity analysis was performed to analyze the effect of each assumption on the results. As can be seen in Fig. 4, it was confirmed that the amount of waste plastic, which is a raw material that directly affects pyrolysis oil production, and the yield of pyrolysis oil showed a great influence on the economic value when establishing a circular economy. In other words, it is expected that greater economic value can be created if a larger-scale circular economy system is built beyond the university campus level or if the yield of pyrolysis oil is improved through the development of new technologies.

Fig. 4.

Sensitivity analysis on waste plastic pyrolysis oil for university campus

It was also confirmed that the pyrolysis oil unit price and the shuttle bus fuel cost had a direct impact on the economic value of the circular economy. Pyrolysis oil unit price was expected to increase by diversifying future application fields and improving fuel quality. In the case of on-campus shuttle bus fuel cost, the effect was not large because the amount of fuel used for the shuttle bus on the university campus was not large. However, it was expected that it can have a larger impact in the future if a circular economy is built at the village and city level.

The price of carbon credits is a value that can vary depending on regulations and market fluctuations. Therefore, if regulations are gradually strengthened in the future, there is a possibility that the increase in the price of carbon credits can have a significant impact on economic value. The GHG reduction factor is related to the maturity of pyrolysis oil technology. If the GHG reduction factor is increased through the development of new technology, a larger amount of carbon emission can be reduced and further economic value can be created.

Greenhouse gas emission from waste plastics pyrolysis oil

As shown in Fig. 5, it was estimated that about 1,033,277 kgCO2eq of GHG was emitted when 591.51 tons of waste plastic was incinerated through the traditional disposal process. On the other hand, when pyrolysis oil technology was applied, GHG emission was estimated as 206,455—433,556 kgCO2eq. In the case of pyrolysis oil from waste plastics, a considerable amount of GHG that would have been incinerated and emitted into the atmosphere in the form of gas remains in the form of pyrolysis oil. For this reason, GHG emissions could be reduced to about 19.98%—41.96%% compared to the traditional disposal process. In addition, because pyrolysis oil can be used as a replacement for fossil fuels, it is expected that additional GHG emission reduction is possible. According to the US Environmental Protection Agency (EPA), a typical passenger car emits 46,000 kg of carbon dioxide per year. Using this information as a tool for comparison, it can be said that using plastic pyrolysis oil technology can reduce the amount of carbon dioxide emitted by about 13–18 cars per year on average.

Fig. 5.

Greenhouse gas (GHG) emission of conventional incineration and waste plastic pyrolysis scenarios

Discussion on pollution, government policy, and risk analysis

Pollution from waste plastics pyrolysis oil

Table 8 shows the major metals contained in waste plastic pyrolysis oil. The amounts of the heavy metals—Pb and Cr, the solid pollutant substances generated in the pyrolysis process, are approximately 0.00005 and 0.0003wt%, respectively (Yongtai, 2011). This was the number of pollutant substances that satisfied the criteria for good recycled products established by the Korean Agency for Technology and Standards (KATS) (Announcement of notice of enactment, revision of good recycled product (GR) quality certification standards (draft) and collection of opinions, Korean Agency for Technology and Standards (KATS) 2021). However, because there are not many reports on the component analysis of various heavy metals such as Cd and Hg, further studies are required for more pollutant substances.

Table 8.

Major metals from plastic pyrolysis oil

| Materials | Unit | Solid pollutants | |

|---|---|---|---|

| Measured value (Yongtai, 2011) | Criteria (Announcement of notice of enactment, revision of good recycled product (GR) quality certification standards (draft) and collection of opinions, Korean Agency for Technology and Standards (KATS) 2021) | ||

| Pb | wt % | < 0.00005 | 0.1 |

| Cr | wt % | < 0.0003 | 0.1 |

| Zn | wt % | < 0.000001 | – |

Pollutant gases generated from the pyrolysis process must satisfy the emission gas regulations of Korea. The exhaust gas generated from the pyrolysis oil process includes SO2, NO2, HCl, and dioxins (Nho et al., 2006). Table 9 shows the content of the pollutant exhaust gas and the Korean air pollutant emission standard. As can be seen from the table, the pyrolysis oil production process met the criteria except for NO2.

Table 9.

Gas pollutants from plastic pyrolysis oil

| Materials | Unit | Gas pollutant from pyrolysis oil production | |

|---|---|---|---|

| Measured value (Yongtai, 2011) | Criteria | ||

| SO2 | ppm | < 14 | < 30 (Emission criteria for air pollutants & Ministry of Environment, 2022) |

| NO2 | ppm | < 111 | < 70 (Emission criteria for air pollutants & Ministry of Environment, 2022) |

| HCl | ppm | < 0.003 | < 15 (Emission criteria for air pollutants & Ministry of Environment, 2022) |

| Dioxin | ng-TEQ/sm3 | < 0.0026 | 0.1 (Permissible emission standards for residual pollutants, 2022) |

For the production of pyrolysis oil, waste plastics are pyrolyzed, and substances that can be used as pyrolysis oil are separated through distillation. Only the residual gases are exhausted. In this process, because most of the chemical components of waste plastics are recycled in the form of pyrolysis oil, a small number of pollutants were emitted in the form of exhaust gas compared to the traditional disposal process such as incineration. However, it was also confirmed that a large amount of NO2 above the criteria values were generated during the pyrolysis oil production. Therefore, it was believed that additional NO2 treatment processes such as selective catalytic reduction (Chen et al., 2004; Yan et al., 2016) are required to meet the regulation of South Korea.

The policy of pyrolysis oil synthesis from plastics

Waste plastic pyrolysis oil technology is considered one of the essential technologies for carbon neutrality and the circular economy. As shown in Table 10, on December 24, 2020, the Ministry of Environment announced the “Measures to de-plasticize household waste” (Measures for plastic free of household waste & Ministry of Environment, 2022). It was announced to reduce plastic production and consumption, expand the recycling of collected plastics, and ultimately transition to a plastic-free society. In addition, in 2021, the Ministry of Environment announced: “Leading circular economy and carbon neutrality by pyrolysis of waste plastics” (Leading circular economy & carbon neutrality by pyrolysis of waste plastics, Ministry of Environment, 2020). The goal was to realize a circular economy and carbon neutrality by increasing the proportion of waste plastic pyrolysis oil production from the current 0.1% to 3.6% in 2025 and 10% in 2030. For this transition, the Regulations of the Waste Management Act were revised to enact the law related to the pyrolysis oil industry (Waste Management Act Enforcement Rules & Ministry of Environment, 2022). As a result, pyrolysis facilities, that were previously classified as incineration facilities, were re-classified as recycling facilities. The demand for advanced recycling and stable waste treatment is expected to increase, and accordingly, the commercialization of waste plastic pyrolysis oil technology is also expected to be boosted.

Table 10.

Korean government policy on plastic pyrolysis oil

| Policy | Details |

|---|---|

| Measures to de-plasticize household waste | 10 public facilities (pyrolysis facilities) that produce fuel by pyrolyzing waste vinyl and residues by 2025 |

| Leading circular economy and carbon neutrality by pyrolysis of waste plastics | Realization of a circular economy and carbon neutrality by increasing the proportion of waste plastic pyrolysis from the current 0.1% to 3.6% in 2025 and 10% in 2030 |

| Part of the Enforcement Decree and Enforcement Regulations of the Waste Management Act | The pyrolysis facility, which was previously classified as an incineration facility, being included in the recycling facility in the future |

SWOT analysis

SWOT analysis is an analysis technique that analyzes strengths, weaknesses, opportunities and threats to diagnose situations and evaluate risks. In this study, SWOT analysis was performed on the model that builds a circular economy in a university campus using waste plastic pyrolysis oil technology. The result is shown in Table 11. The strength of this model was its positive economic and environmental effects. On the other hand, the weakness was mainly related to technological maturity. As an opportunity factor, the importance of carbon neutrality is emerging, and the threat was the fluctuations of the energy market. Based on the analysis, possible strategies to manage the risks were proposed by considering the combined S–O, S-W, T-S, and T-W.

Table 11.

SWOT analysis on waste plastic pyrolysis oil technology

|

S (Strengths) Pro-environmental technology by reducing CO2 emission Plastic recycle process Profitability |

W (Weaknesses) New technology (immature technology) Lack of reliable economic analysis Limited large-scale demonstration |

|

|

O (Opportunities) World trend—carbon neutrality Increasing waste plastics Era of globalization—more international climate cooperation |

The global trend of carbon neutrality can increase the usage of low carbon technology of waste plastic pyrolysis oil In COVID-19, waste plastic (e.g. medical waste, takeaway garbage) is rapidly increasing, so waste plastic pyrolysis oil technology can be used to deal with waste plastics |

In the era of globalization, there are more international cooperation, which can boost the technology development and economic analysis With increasing waste plastics, the demand for large-scale demonstration can increase |

|

T (Threats) Unstable energy supply (e.g. Russia-Ukraine war) Continuation of fossil fuel usage Government policy change |

Because of the unstable energy supply, various energy sources such as waste plastic pyrolysis oil can be needed To reduce CO2 emission, waste plastic oil technology can be supported by government policy |

Waste plastic pyrolysis oil technology can be developed to lessen unstable energy supply and reduce fossil fuel usage Waste plastic pyrolysis oil technology can be demonstrated to induce the support from government policy |

Implications and limitations

In this study, the feasibility of constructing a circular economy using pyrolysis oil technology was analyzed from economic and environmental perspectives. As a result, the economic profit was estimated as ₩134,944,188/year—₩425,484,022/year ($112,453.49—$354,570.01/year). The carbon dioxide emission could be reduced by 609,646—840,891 kgCO2eq/year. Through this analysis, it was possible to confirm that the circular economy scenario of this study is feasible. In addition, environmental pollution, policy status, and SWOT analysis, which must be considered in building a circular economy, were performed. Through the study, the application of waste plastic pyrolysis oil technology was confirmed to satisfy environmental standards and conforms to Korean policy. The strengths, weaknesses, opportunities, and threats of this scenario were analyzed and possible strategies to reduce the risks were proposed. It was comprehensively revealed that the waste plastic pyrolysis oil-based circular economy is a feasible scenario. The recommendations resulting from this work can be summarized explicitly as follows: 1. The economic feasibility of the demonstration of a small-scale circular economy based on waste plastic pyrolysis oil was verified through scenario analysis, 2. To maximize the economic feasibility, selection of the place with large amount of waste plastic was essential, 3. The improvement in the yield of waste plastic pyrolysis oil was important to increase economic feasibility, 4. Establishment of a circular economy was consistent with Korea’s pollutant regulations and policies, 5. Risk analysis and management measures based on SWOT analysis was proposed.

However, there are still some limitations. First, the circular economy scenario of this work was established within the scope of university campus, and external facilities investment for the waste plastic pyrolysis oil plants was not considered (i.e., existing waste plastic pyrolysis oil plants were assumed to be used). To analyze the scenario more accurately, the investment cost for the waste plastic pyrolysis oil technology should be considered. However, because the waste plastic pyrolysis oil technology is in the early stage of the research and development, it was challenging to obtain a reliable expected investment yet. Second, as carbon neutrality and GHG emission regulations are strengthened worldwide in the future, the construction of this circular economy is expected to expand to the city and even national level. Therefore, in the follow-up study, it is necessary to expand the circular economy scenarios to a large scale. Third, this study has a limitation in that scenario analysis was conducted only in the case of South Korea. It is expected that more reliable research results can be obtained if a vast amount of global status, data, and policy are collected. Last, this study was conducted based on conventional waste plastic pyrolysis oil technology only. Recently, various new technologies such as supercritical pyrolysis technology have been proposed (Bai et al., 2019; Goto et al., 2006). However, Supercritical pyrolysis technology is more economical than conventional pyrolysis technology because it has a higher yield of pyrolysis oil. However, as it is still an early-stage technology, it was difficult to obtain the data required for economic and environmental analysis.

Conclusion

This study proposed and analyzed a university campus circular economy scenario based on pyrolysis oil technology utilizing waste plastics. It was confirmed that the economic value of ₩134,944,188/year—₩425,484,022/year ($112,453.49—$354,570.01/year) could be created through the construction of the campus circular economy. In particular, when the circular economy was built on a university campus, not only the value of the pyrolysis oil itself but also greater profits could be created by replacing the fuel for the campus shuttle bus, selling pyrolysis oil and carbon credits. In terms of the environment, waste plastic pyrolysis oil technology significantly reduced GHG emissions by 609,646—840,891 kgCO2eq/year. In terms of policy, it was confirmed that it was in line with South Korea’s de-plasticization policies such as measures to de-plasticize household waste, leading circular economy and carbon neutrality by pyrolysis of waste plastics, and the Enforcement Decree and Enforcement Regulations of the Waste Management Act.

Waste plastic pyrolysis oil technology is in the early stages of R&D and demonstration. The research on basic chemical reactions has been mainly conducted. In this study, a circular economy scenario model based on waste plastic pyrolysis oil was proposed for a small-scale economy of the university campus. In the future, the results of this study can be applied to larger-scale circular economy models on a village, city, and national level.

Acknowledgements

This research was supported by the Specialized university program for confluence analysis of Weather and Climate Data of the Korea Meteorological Institute (KMI) funded by the Korean government (KMA).

Data availability statement

The datasets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

Declarations

Conflict of interest

The authors have no conflicts of interest to declare that are relevant to the content of this article.

Footnotes

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Hayoung Park, Kayoung Kim, Mirae Yu and Zhihao Yun have equally contributed to have this work.

References

- Almohamadi H, Alamoudi M, Ahmed U, Shamsuddin R, Smith K. Producing hydrocarbon fuel from the plastic waste: Techno-economic analysis. Korean Journal of Chemical Engineering. 2021;38:2208–2216. doi: 10.1007/s11814-021-0876-3. [DOI] [Google Scholar]

- Announcement of notice of enactment/revision of good recycled product (GR) quality certification standards (draft) and collection of opinions, Korean Agency for Technology and Standards (KATS). Retrieved July 29 2021, from https://www.kats.go.kr/content.do?cmsid=239&_dc=1498035892088&mode=view&page=8&cid=22516.

- Antelava A, Damilos S, Hafeez S, Manos G, Al-Salem SM, Sharma BK, Kohli K, Constantinou A. Plastic solid waste (PSW) in the context of life cycle assessment (LCA) and sustainable management. Environmental Management. 2019;64:230–244. doi: 10.1007/s00267-019-01178-3. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Bai B, Jin H, Fan C, Cao C, Wei W, Cao W. Experimental investigation on liquefaction of plastic waste to oil in supercritical water. Waste Management. 2019;89:247–253. doi: 10.1016/j.wasman.2019.04.017. [DOI] [PubMed] [Google Scholar]

- Brigagão GV, Araújo ODQF, de Medeiros JL, Mikulcic H, Duic N. A techno-economic analysis of thermochemical pathways for corncob-to-energy: Fast pyrolysis to bio-oil, gasification to methanol and combustion to electricity. Fuel Processing Technology. 2019;193:102–113. doi: 10.1016/j.fuproc.2019.05.011. [DOI] [Google Scholar]

- Chen J-C, Wey M-Y, Yeh C-L, Liang Y-S. Simultaneous treatment of organic compounds CO, and NOx in the incineration flue gas by three-way catalyst. Applied Catalysis B: Environmental. 2004;48:25–35. doi: 10.1016/j.apcatb.2003.09.004. [DOI] [Google Scholar]

- Dai L, Zhou N, Lv Y, Cheng Y, Wang Y, Liu Y, Cobb K, Chen P, Lei H, Ruan R. Pyrolysis technology for plastic waste recycling: A state-of-the-art review. Progress in Energy and Combustion Science. 2022;93:101021. doi: 10.1016/j.pecs.2022.101021. [DOI] [Google Scholar]

- Disposal unit price for each type of waste for calculating the insurance money for waste disposal (2021–259), Ministry of Environment. Retrieved July 15 2022, from https://www.law.go.kr/LSW/admRulBylInfoP.do?admFlag=0&directYn=Y&bylSeq=1792018&admRulSeq=2100000038780.

- Emission criteria for air pollutants, Ministry of Environment. Retrieved June 30 2022 https://www.law.go.kr/%EB%B2%95%EB%A0%B9/%EB%8C%80%EA%B8%B0%ED%99%98%EA%B2%BD%EB%B3%B4%EC%A0%84%EB%B2%95%EC%8B%9C%ED%96%89%EA%B7%9C%EC%B9%99.

- KRX ETS Market Information Platform, Korea Exchange (KRX). Retrieved May 27 2022, from https://ets.krx.co.kr/main/main.jsp.

- Geissdoerfer M, Savaget P, Bocken NM, Hultink EJ. The circular economy–A new sustainability paradigm? J Cleaner Prod. 2017;143:757–768. doi: 10.1016/j.jclepro.2016.12.048. [DOI] [Google Scholar]

- Goto M, Sasaki M, Hirose T. Reactions of polymers in supercritical fluids for chemical recycling of waste plastics. Journal of Materials Science. 2006;41:1509–1515. doi: 10.1007/s10853-006-4615-2. [DOI] [Google Scholar]

- Ibe H, Kodera Y. A probabilistic economic model and sensitivity analysis of fuel-oil production from plastic waste. Journal of Material Cycles and Waste Management. 2021;23:449–460. doi: 10.1007/s10163-020-01159-3. [DOI] [Google Scholar]

- Internal Data of Ewha Womans University. (2022).

- Janairo JIB. Unsustainable plastic consumption associated with online food delivery services in the new normal. Cleaner Responsible Consumption. 2021;2:100014. doi: 10.1016/j.clrc.2021.100014. [DOI] [Google Scholar]

- Korea's 'notorious' plastic use, there is no place to bury it anymore, Hankookilbo, https://www.hankookilbo.com/News/Read/A2020122810050002703.

- Kosior E, Mitchell J, Crescenzi I. Plastics recycling. Plastic Environment. 2018;47:156–176. doi: 10.1039/9781788013314-00156. [DOI] [Google Scholar]

- H. Kosow, R. Gaßner, Methods of future and scenario analysis: overview, assessment, and selection criteria, DEU, 2008.

- Krüger, C. (2020) LCA ChemCyclingTM: CO2 emissions of pyrolyzed mixed plastic waste and the mass balance approach. BASF Corporate Sustainability.

- Kwon, H., Shin, S., Lee, H., Choi, Y., & Song, D. (2020) Electric vehicle-oriented energy storage system (ESS) establishment. 2020 Ewha climate∙energy project: campus, pp. 168–193.

- Lam SS, Mahari WAW, Ok YS, Peng W, Chong CT, Ma NL, Chase HA, Liew Z, Yusup S, Kwon EE. Microwave vacuum pyrolysis of waste plastic and used cooking oil for simultaneous waste reduction and sustainable energy conversion: Recovery of cleaner liquid fuel and techno-economic analysis. Renewable and Sustainable Energy Reviews. 2019;115:109359. doi: 10.1016/j.rser.2019.109359. [DOI] [Google Scholar]

- Leading circular economy and carbon neutrality by pyrolysis of waste plastics, Ministry of Environment. Retrieved December 14 2020, from https://me.go.kr/home/web/board/read.do?boardMasterId=1&boardId=1420640&menuId=286.

- Lee J-C, Lee B, Ok YS, Lim H. Preliminary techno-economic analysis of biodiesel production over solid-biochar. Bioresource Technology. 2020;306:123086. doi: 10.1016/j.biortech.2020.123086. [DOI] [PubMed] [Google Scholar]

- Ma J, Zhong Q. Comparison of operating pyrolysis processes in china, Department of Earth and Environmental Engineering, Fu Foundation School of Engineering & Applied Science. Columbia University; 2018. [Google Scholar]

- Maack, J.N. (2001). Scenario analysis: A tool for task managers, Social analysis selected tools and techniques. 62.

- Measures for plastic free of household waste, Ministry of Environment. Retrieved December 24 2022, from https://me.go.kr/home/web/board/read.do?boardMasterId=1&boardId=1420640&menuId=286.

- Neha S, Ramesh KPK, Remya N. Techno-economic analysis and life cycle assessment of microwave co-pyrolysis of food waste and low-density polyethylene. Sustainable Energy Technologies and Assessments. 2022;52:102356. doi: 10.1016/j.seta.2022.102356. [DOI] [Google Scholar]

- Nho N, Shin D, Park S, Lee K, Kim K, Jeon S, Cho B. Process development of pyrolysis liquefaction for waste plastics. New Renew Energy. 2006;2:118–125. [Google Scholar]

- Oh SC. [New business introduction] waste plastic oil pyrolysis oil business. News Information Chemical Engineering. 2006;24:18–23. [Google Scholar]

- Permissible emission standards for residual pollutants. Retrieved June 30 2022, from https://www.law.go.kr/%EB%B2%95%EB%A0%B9/%EC%9E%94%EB%A5%98%EC%84%B1%EC%98%A4%EC%97%BC%EB%AC%BC%EC%A7%88%EA%B4%80%EB%A6%AC%EB%B2%95%EC%8B%9C%ED%96%89%EA%B7%9C%EC%B9%99.

- Phae C-G, Kim Y-S, Jo C-H, Pyoun U-S. Assessment of practical use of recycling oil from the pyrolysis of mixed waste plastics. Journal of Energy Engineering. 2005;14:159–166. [Google Scholar]

- “Plastic responsible for marine pollution, good material if recycled well” [H.eco Forum 2022-Climate Crisis and the Sea ⑤], The Korea Herald. Retrieved July 15 2022, from http://news.heraldcorp.com/view.php?ud=20220518000383.

- Pyrolysis Plant For Sale, Beston Group Co., Ltd. Retrieved July 15 2022, from https://bestoncompany.com/pyrolysis-plant-for-sale/#4.

- Ranta V, Aarikka-Stenroos L, Ritala P, Mäkinen SJ. Exploring institutional drivers and barriers of the circular economy: A cross-regional comparison of China, the US, and Europe. Resources, Conservation and Recycling. 2018;135:70–82. doi: 10.1016/j.resconrec.2017.08.017. [DOI] [Google Scholar]

- Sariatli F. Linear economy versus circular economy: A comparative and analyzer study for optimization of economy for sustainability. Visegrad J Bioecon Sustain Dev. 2017;6:31–34. doi: 10.1515/vjbsd-2017-0005. [DOI] [Google Scholar]

- Sekar M, Ponnusamy VK, Pugazhendhi A, Nižetić S, Praveenkumar T. Production and utilization of pyrolysis oil from solidplastic wastes: A review on pyrolysis process and influence of reactors design. Journal of Environmental Management. 2022;302:114046. doi: 10.1016/j.jenvman.2021.114046. [DOI] [PubMed] [Google Scholar]

- Sevigné-Itoiz E, Gasol CM, Rieradevall J, Gabarrell X. Contribution of plastic waste recovery to greenhouse gas (GHG) savings in Spain. Waste Management. 2015;46:557–567. doi: 10.1016/j.wasman.2015.08.007. [DOI] [PubMed] [Google Scholar]

- Shahbaz, M., AlNouss, A., Parthasarathy, P., Abdelaal, A. H., Mackey, H., McKay, G., & Al-Ansari, T. (2020). Investigation of biomass components on the slow pyrolysis products yield using Aspen Plus for techno-economic analysis. Biomass Conversion and Biorefinery. pp. 1–13.

- Sharuddin SDA, Abnisa F, Daud WMAW, Aroua MK. A review on pyrolysis of plastic wastes. Energy Conversion and Management. 2016;115:308–326. doi: 10.1016/j.enconman.2016.02.037. [DOI] [Google Scholar]

- Shemfe M, Gu S, Fidalgo B. Techno-economic analysis of biofuel production via bio-oil zeolite upgrading: An evaluation of two catalyst regeneration systems. Biomass and Bioenergy. 2017;98:182–193. doi: 10.1016/j.biombioe.2017.01.020. [DOI] [Google Scholar]

- Shibamoto, T., Yasuhara, A., & Katami, T. (2007). Dioxin formation from waste incineration. Reviews of Environmental Contamination and Toxicology. pp. 1–41. [DOI] [PubMed]

- Sorunmu Y, Billen P, Spatari S. A review of thermochemical upgrading of pyrolysis bio-oil: Techno-economic analysis, life cycle assessment, and technology readiness. Gcb Bioenergy. 2020;12:4–18. doi: 10.1111/gcbb.12658. [DOI] [Google Scholar]

- Urtuvia V, Villegas P, González M, Seeger M. Bacterial production of the biodegradable plastics polyhydroxyalkanoates. International Journal of Biological Macromolecules. 2014;70:208–213. doi: 10.1016/j.ijbiomac.2014.06.001. [DOI] [PubMed] [Google Scholar]

- van Schalkwyk DL, Mandegari M, Farzad S, Görgens JF. Techno-economic and environmental analysis of bio-oil production from forest residues via non-catalytic and catalytic pyrolysis processes. Energy Conversion and Management. 2020;213:112815. doi: 10.1016/j.enconman.2020.112815. [DOI] [Google Scholar]

- Waste Management Act Enforcement Rules, Ministry of Environment. Retrieved July 8 2022, from https://www.law.go.kr/%EB%B2%95%EB%A0%B9/%ED%8F%90%EA%B8%B0%EB%AC%BC%EA%B4%80%EB%A6%AC%EB%B2%95%EC%8B%9C%ED%96%89%EA%B7%9C%EC%B9%99.

- Yan Q, Yang R, Zhang Y, Umar A, Huang Z, Wang Q. A comprehensive review on selective catalytic reduction catalysts for NOx emission abatement from municipal solid waste incinerators. Environmental Progress & Sustainable Energy. 2016;35:1061–1069. doi: 10.1002/ep.12328. [DOI] [Google Scholar]

- Yongtai, S. (2011). Accelerated development of waste plastic oil industry. Resource Recycle, pp. 48–51.

- Yuliansyah AT, Prasetya A, Ramadhan MA, Laksono R. Pyrolysis of plastic waste to produce pyrolytic oil as an alternative fuel. Int J Technol. 2015;7:1076–1083. doi: 10.14716/ijtech.v6i7.1241. [DOI] [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.

Data Availability Statement

The datasets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.