Abstract

High-speed rail has been operating in more than 25 countries (mainly in Asia, Europe and North America), and has become an important part of global economic development. However, the cleaning and maintenance of high-speed rail is a comprehensive task, which may easily cause environmental pollution. This study aims to analyze and improve the sustainability of the formulation and production process of a concentrated complex enzyme detergent used as the maintenance agent for high-speed trains via the life cycle assessment (LCA) method. The eFootprint software system with built-in China, European and Swiss Ecoinvent databases was used to establish the LCA model with the system boundary being from cradle to gate. The LCA model showed that the production of 1 kg of concentrated detergent generates the global warming potential of 2.53 kg CO2 eq, and other environmental emissions including acidification potential of 0.01 kg SO2 eq, eutrophication potential of 3.76E-03 kg PO43−eq, inhalable inorganic matter of 3.17E-03 kg PM2.5 eq, ozone depletion potential of 5.3E-06 kg CFC-11 eq, photochemical ozone formation potential of 3.44E-03 kg NMVOC eq, primary energy demand of 3.17 MJ, abiotic depletion potential of 4.97E-6 kg antimony eq, and water use of 0.84 kg. LCA results are not strongly dependent to the assumptions of the research, and the uncertainties of LCA results are between 8 and 16%, which is mainly due to the regional differences in technology sources, the year of technical data collection, and the representativeness of technology collection companies. Carbon footprint analysis showed that the production processes of enzyme stabilizer (glycerol) and surfactants contributed the most, while changes in power consumption during production and transportation distance of raw materials had limited effect on total carbon emissions. Therefore, the formulation of the concentrated complex enzymatic detergent was improved based on the LCA results. The new formulations with less enzyme stabilizer showed similar detergency to the original formulation. The new formulations could reduce carbon emissions by 5,500–9,200 tons per year and save between $4.4 and $7.4 million in annual production of 10,000 tons.

Supplementary Information

The online version contains supplementary material available at 10.1007/s10668-023-03122-2.

Keywords: Concentrated compound enzyme detergent, Life cycle assessment, Carbon footprint, Enzyme stabilizer, Formulation

Introduction

The global detergent industry has gradually formed a relatively complete industrial system (Al-Ghanayem & Joseph, 2020). With the rapid development of science and technology and the petrochemical industry, the production of detergents has reached an unprecedented peak. According to Fortune Business Insights, in 2020, the global household cleaning (HHC) products market was $221.32 billion (2020 US dollar)(Vochozka et al., 2020), which is projected to grow from $235.76 billion in 2021 to $320.82 billion in 2028 at a compound annual growth rate of 4.5% in forecast period (Fortune Business Insights, 2021). The increasing demand for HHC products is partly because of emergence of COVID-19 pandemic (Maceno et al., 2022), population growth and the need for organic cleaning products, and partly because of the huge potential market in developing countries.

Since the Tokaido Shinkansen's first high-speed rail (HSR) system began operating in Japan in 1964, HSR has operated in a number of countries, mainly in Europe, Asia, and North America. The world HSR network is expected to more than double the 2014 length by 2025 (Zhang et al., 2019). China has the largest network of high-speed railways in the world, which is followed by European countries and Japan. High-speed rail has now become an important part of economic development in many countries. It not only promotes the transportation and railway industry, but also promotes macro-economic in high- and upper-middle-income countries (Bhatt & Kato, 2021). With the rapid development and export of high-speed rail, the maintenance of locomotive and mainline has become an important industry in the economy of the HSR-associated production industry, forming an important part of the modern high-end equipment maintenance industry and the modern cleaning market.

The cost of each carriage of the HSR train is expensive, which is about $20 million (Lawrence et al., 2019). HSR trains usually operate during the day. At night, locomotives, train bodies, undercarriage, high-voltage electrical lines, engines, etc. need to be carefully maintained to eliminate fatigue and hidden dangers and ensure normal travel the next day. The maintenance of high-speed trains includes cleaning, lubrication, antifreeze and rust prevention (Lin et al., 2019). The requirements for cleaning high-speed trains are strict, and it is necessary to decontaminate without harming the surface and mechanical properties of the train body. China's National High-speed Railway Corporation stipulates that high-speed trains must be cleaned and maintained every 4,000 km, and almost all parts such as the exterior of the train body and the interior of the train should be cleaned. The cleaning and maintenance of high-end equipment such as HSR is a comprehensive task. HSR dirt includes heavy dirt on locomotives, dirt on train interiors and floors, dirt on toilets, dirt on air conditioners, dirt on electrical equipment, and so on (Zhang et al., 2021). The variety of pollution sources and complex structure determine the diversity and complexity of the cleaning agent. At present, the cleaners on the market are mainly high pH alkaline cleaners. Although the formulation of ordinary cleaners is stable, they are not specific designed (Gong et al., 2022). For example, washing with hard water will be worse, (i.e., the dirt will not be cleaned thoroughly), and it will easily cause environmental pollution and other problems (Danby et al., 2018; Li et al., 2021). The existing cleaning agents with professional cleaning functions have a narrow cleaning range, and also have disadvantages such as high cost, slow cleaning of dirt, damage to solid surface paint, and harmful solvents.

This study conducted a life cycle assessment (LCA) study on a concentrated complex enzyme detergent (Model TL1003-1) developed by Suqian Dunjia Biotechnology Co., Ltd. (Jiangsu, China) in cooperation with the University. LCA is a methodology for assessing environmental impacts associated with all the stages of the life cycle of a commercial product, process, or service. The LCA method must be in accordance with ISO 14040 and ISO 14044, which specify a characterization model for each category indicator and are based on precise standard environmental mechanisms and repeatable verification (Chang & Huang, 2022). The formulation of this detergent product has efficient penetration, stripping, dissolution and decontamination functions, so it can effectively remove heavy stains such as oil stains, insect carcasses, animal feces, plant fruit dirt and other stains from high-speed train bodies and interiors. The market demand for cleaning agents for high-speed trains exceeds 100,000 tons per year, and this complex enzyme detergent has a good profit margin. If the formulation is further improved through research and development, and the technical advantages and cost advantages of the products are improved, the market share of cleaning agents for high-speed trains can be increased. The target market share is 40%. Therefore, by optimizing the formulation and production process of HSR cleaners, more profits can be brought to the enterprise and the risk of bankruptcy can be reduced (Durana et al., 2021a; Kliestik et al., 2022).

To evaluate and improve existing product formulations from a life cycle perspective, this study involves life cycle inventory analysis of all raw materials and production processes, assessment and interpretation of the LCA results including nine environmental indicators, and experimental tests of new formulations.

Materials and methods

Material

The ISO standards for LCA require the definition of goal and scope, functional units, system boundaries, life cycle inventory analysis, life cycle impact assessment and interpretation of results. The research object of this study is the concentrated compound enzyme detergent of model TL1003-1 produced by Suqian Dunjia Biotechnology Co., Ltd. It is used as a HSR maintenance agent, which belongs to one of the special series of cleaning agent products for cleaning, anti-rust, anti-freezing and lubricating maintenance of the HSR train. This phosphorus-free product is compounded with biologically active enzymes, surfactants and additives. It has a strong ability to remove inorganic and organic dirt on the train body surface, as well as its interior parts. Its form is suspension. The functional unit in this LCA study is 1 kg concentrated complex enzyme detergent product. The representation of time and geography is 2020 and China, respectively.

Scope definitions

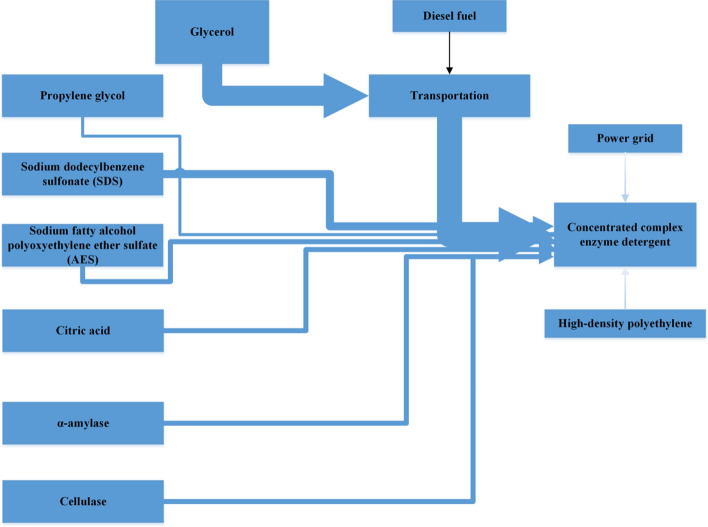

System boundaries in LCA must be relevant in relation to the purpose of the study, which is to improve the formulation and the sustainability of the production process. Therefore, the initial choice of the system boundary for this study is "from cradle-to-gate." The system encompasses all upstream chemical manufacture processes, raw material transportation, and detergent manufacturing and packaging processes. As shown in Fig. 1, the foreground process includes the production of amylase, cellulase, glycerol, sodium dodecylbenzene sulfonate (SDS), sodium fatty alcohol polyoxyethylene ether sulfate (AES), and citric acid. Background processes include power grids, natural gas, transportation, propylene glycol, high-density polyethylene, and other chemicals. To further expand the scope of this study, downstream washing and wastewater treatment processes are also evaluated in Sect. 3.9.

Fig. 1.

System boundary of the concentrated complex enzyme detergent

The trade-off rules used in this study are based on the weight ratio of raw material to the product weight or the total process input. Specific rules are as follows:

When the weight of ordinary material is less than 1% of the product weight and the weight of material containing rare or high purity components is less than 0.1% of the product weight, the upstream production data of the material can be ignored. The total weight of negligible material must not exceed 5%.

The material can be ignored if the low value waste is used as raw materials, such as fly ash, slag, straw, garbage and other upstream production data. The production equipment, plant, living facilities and other emissions are ignored.

In this study, the eFootprint software system was used to establish a life cycle model of the concentrated complex enzyme detergent and calculate the LCA results. The eFootprint software system is an online LCA analysis software developed by IKE Environmental Technology Co., Ltd (China). It complies with ISO 14040, ISO 14044, ISO/TS 14,048 standards (Wang & Zhu, 2021), and supports full life cycle process analysis and has built-in China Life Cycle Basic Database (CLCD), European ELCD database and Swiss Ecoinvent database (Qian et al., 2022). The CLCD database is an industry average database based on the core model of China's basic industrial system life cycle. The CLCD database includes inventory data sets of major domestic energy, transportation, and basic raw materials. The calculated environmental indicators include global warming potential (GWP), acidification potential (AP), eutrophication potential (EP), inhalable inorganic matter (RI), ozone depletion potential (ODP), photochemical ozone formation potential (POFP), primary energy demand (PED), abiotic depletion potential (ADP), and water use (WU), which are summarized in Table S1 of the supporting material. The background data sources of this LCA study are summarized in Table S2.

Data collection

Production of the concentrated complex enzyme detergent

Main data sources are collected via enterprise surveys, the literature (Kim & Park, 2020; Melián et al., 2023), and chemical process simulation. The surveyed company is Suqian Dunjia Biotechnology Co., Ltd. (Jiangsu, China), which is producing annually 10,000 tonnes of TL1003-1 concentrated compound enzyme detergent. The base year is 2020, and the origin is China. The major process equipment includes 2000-L reactors (BMT-F2000L, Guangzhou Senmeite Light Industry Machinery Manufacturing Co., Ltd., Guangdong, China), steam generator (Type A, Peiyu Machinery Manufacturing Co., Ltd., Shanghai, China), 1000-L storage tanks (GXCG-1000L, Guangzhou Guanxin Light Industry Machinery Manufacturing Co., Ltd., Guangdong, China), and 100-L 4 kW vacuum homogenizer (YK-100, Yodi Machinery Equipment Co., Ltd., Shanghai, China), (Figure S1). A simplified process flow chart of the concentrated compound enzyme detergent is shown in Figure S2. Main raw materials include organic chemicals and enzymes. The main energy consumption is electricity. The life cycle inventory (LCI) data of the process is summarized in Table 1.

Table 1.

LCI data of the production of the concentrated complex enzyme detergent

| Type | List name | Quantity | unit | Upstream data source | Use/emission reasons |

|---|---|---|---|---|---|

| Product | Concentrated complex enzyme detergent | 1 | kg | – | – |

| Raw material | Amylase | 0.0032 | kg | Foreground process data | |

| Raw material | Cellulase | 0.0032 | kg | Foreground process data | |

| Raw material | Propylene glycol | 0.05 | kg | CLCD-China-ECER 0.8 | |

| Raw material | AES | 0.16 | kg | Foreground process data | |

| Raw material | SDS | 0.17 | kg | Foreground process data | |

| Raw material | Citric acid | 0.02 | kg | Foreground process data | |

| Raw material | Glycerol | 0.6 | kg | Foreground process data | |

| Raw material | HDPE | 0.02 | kg | CLCD-China-ECER 0.8 | |

| Energy | Electricity | 0.06 | MJ | CLCD-China-ECER 0.8 | |

| Environmental emission | water vapor | 8.40E-04 | kg | Boiler blowdown | |

| Environmental emission | Suspended solids, unspecified | 9.33E-05 | kg | emission (water body) | |

| Environmental emission | biological oxygen demand | 0.0001 | kg | emission (water body) | |

| Environmental emission | Chemical oxygen demand | 0.0001 | kg | emission (water body) |

In the baseline model, only the transportation of glycerol that accounts for 60% of the total product mass was considered. The transport distance is assumed to be 200 km, which is close to the average transport distance (175.6 km, 2020) of domestic goods in China (National Bureau of Statistics of China, 2021). The upstream data sources of transportation data are all from the CLCD database.

Production of fatty alcohol ether sulfate (AES)

The process boundary is from cradle to gate. The main data sources are the CLCD database, Ecoinvent database and the literature (Munkajohnpong et al., 2020; Myers, 2020). The origin is China, and the base year is 2019. The production scale is 1000 t/d. AES is a detergent with high solubility and low sensitivity to water hardness. AES can be prepared by the ethoxylation of alcohols to form alcohol ethoxylate, and these ethoxylated alcohols are further sulfonated to produce the final detergent. A schematic diagram of the production process of AES from alcohol ethoxylate is provided in Figure S3.

Production of sodium dodecyl benzene sulfonate (SDS, LAS)

The process boundary is from cradle to gate. The main data sources are the CLCD database, Ecoinvent database and the literature (Ivanchina et al., 2021; Shokri & Karimi, 2021). The origin is China and the base year is 2011–2016. The production scale is 1000 t/d. The principle of preparation of SDS is that alkylating agent reacts with benzene to form alkylbenzene, which is then sulfonated and neutralized. In this production process, dodecylbenzene (a linear alkylbenzene, LAB) is used as raw material, and sulfur trioxide is used as sulfonating agent (Figure S4). Dodecylbenzenesulfonic acid is synthesized by sulfonation in the reactor, and then sodium hydroxide is added for neutralization reaction to form the final product.

Production of citric acid

Citric acid is an organic acid with a global market value of 3.6 billion US dollars, which is widely used in the food, pharmaceutical, biomedical, textile, and leather industries (Reena et al., 2022). The production of citric acid is one of the oldest industrial fermentations, which is predominantly produced by Aspergillus niger due to its higher yield and ability to ferment various low-cost feedstock (Mores et al., 2021). The process boundary of this part of LCA model is from cradle to gate. The main sources of LCI data of citric acid production are the GREET database and the literature (Tong et al., 2021). GREET (Greenhouse gases, Regulated Emissions, and Energy use in Transportation) is a full life cycle model sponsored by the Argonne National Laboratory (U.S. Department of Energy’s Office of Energy Efficiency and Renewable Energy). The data used in this study represents industry average data. The origin is China, and the base year is 2019. The production scale is 10 t/d. The technology includes that Aspergillus niger uses starch as a raw material to ferment to produce citric acid (Figure S5). The technology also includes the use of corn as raw material, the use of jet liquefaction technology to liquefy the corn syrup after the corn is crushed and mixed, the liquefied mash is filtered to obtain the liquefied clear liquid, and the liquefied clear liquid enters the fermentation section. Finally, the advanced absorption method is used to extract citric acid.

Production of amylase

Amylases are important hydrolase enzymes which have been widely used since many decades (Movahedpour et al., 2022). Bacillus species including B. amyloliquefaciens and B. licheniformis are widely used for commercial production of the enzyme (Ngalimat et al., 2021). In this part of LCA model, the α-amylase is produced by biological fermentation using glucose as the feedstock, and the process boundary is from cradle to gate. The main data sources are the GREET database and the literature (Dunn et al., 2012; Nogueira et al., 2022). The data used in this study represents industry average data. The origin is China, and the base year is 2020. The production scale: 1 t/d.

Production of cellulase

Cellulases are the enzymes that hydrolyze β -1, 4 linkages in cellulose chains, which are produced by fungi, bacteria, protozoans, plants, and animals (Suhag, 2022). Most of the cellulases exploited for industrial applications are from filamentous fungi such as Trichoderma, Penicillium, Fusarium, Humicola, Phanerochaete (Naher et al., 2021). Most reports of microbial production of cellulase utilize the submerged fermentation technology. The widely studied organism for cellulase production, T. reesei, has also been tested primarily in liquid media. In this part of LCA model, the cellulase is produced by biological fermentation using glucose as the feedstock, and the process boundary is from cradle to gate. The main data sources are the GREET database and the literature (Wang et al., 2012). The data represent industry average data. The origin is China, and the base year is 2020. The production scale is 1 t/d.

Production of glycerol

The function of glycerol in the formulation is both an enzyme stabilizer and a solution (Braham et al., 2021). The process boundary for the glycerol production is from cradle to gate. The main data sources are the USLCI database and the literature (Feraldi et al., 2011; Yang & Rosentrater, 2021). The data represent industry average data. The origin is USA, and the base year is 2020. The production scale is 4000 t/d. Glycerol is prepared from natural oils (Figure S6). The main raw materials are crude palm kernel and methanol with the main energy consumption being from biomass, diesel, natural gas, and electricity.

Integrity description, assumptions and limitations

In this study, mass balance and energy balance calculations were performed on the production process of concentrated complex enzyme detergent according the unit operations. A literature study was conducted on the emission data of the production process, and the average value of multiple literatures was used. The possible increase in power consumption during the production improvement process is discussed in detail in Sect. 3.3 of Carbon footprint analysis of power consumption. At the same time, some components that account for less than 0.5% by mass, such as boric acid and calcium dioxide, are ignored. The amylase and cellulase data sets use the production process emission data in the public database, and the raw materials and electricity consumption are domesticized. The uncertainties of environmental impacts of the production process were quantitatively evaluated in the eFootprint system using the CLCD quality assessment method, which is a quality assurance method based on Taylor series expansion (Ding et al., 2022).

This study calculated the results of 9 environmental impact indexes of the production process of the concentrated complex enzyme detergent. During the simulation of the chemical process, only the energy consumption of the core equipment was calculated. It’s assumed that when the number of major equipment increases, only electricity is consumed, and process emissions are not increased.

The production processes of amylase, cellulase, and citric acid are all fermentation processes. The LCA model assumes that the fermentation strain used has the same production efficiency as the published literature or public database, i.e., the process and the emissions are the same. For the three production processes of glycerol, AES, and SDS, it is assumed that the production technology used is the same as that in the other LCA databases and literature, and the emissions are the same. The model assumption description of each unit operation is shown in Table S3.

Experimental determination of detergency

The detergency is the ability of detergent to remove stains, which is a common indicator of the washing performance. According to the national standard of P. R. China GB/T13174-2008 "Determination of Detergent Power and Cycle Washing Performance of Detergents for Clothing," the detergency is calculated by using following equation.

| 1 |

in which R is the detergency of the detergent, F0 is the weight of the empty sample holder (such as stainless steel and white cloth), F1 is the weight of the sample before washing, and F2 is the weight of the sample after washing.

Results and discussion

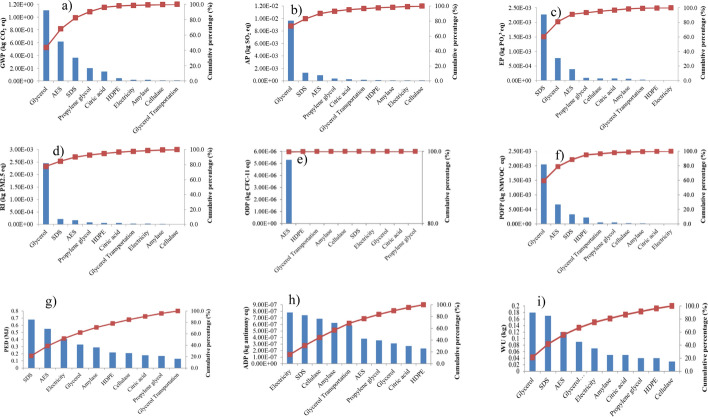

LCA results and analysis of process cumulative contribution

Table 2 shows the LCA results of the production of 1 kg concentrated composite enzyme detergent. Cumulative contribution results of the production process are illustrated in Fig. 2. The cumulative contribution of a process refers to the cumulative value of the direct contribution of the process and the contribution of all upstream processes (i.e., the contribution of raw material consumption). Since the process usually contains multiple inventory data, the process contribution analysis is actually the accumulation of the sensitivity of multiple inventory data. According to the LCA results (Fig. 2), the three processes that contribute the most to the environmental impacts are the production of glycerol, the production of AES, and the production of SDS. It can be seen that the environmental emissions from the detergent product manufacturing process are lower, because the production process mainly uses most of the physical action equipment and heat exchangers (Figures S1 and S2). Therefore, the main source of environmental emissions is the production process of raw materials.

Table 2.

LCA results of the concentrated complex enzyme detergent (1 kg)

| Indicator | Unit | Results |

|---|---|---|

| GWP | kg CO2 eq | 2.53 |

| AP | kg SO2 eq | 0.01 |

| EP | kg PO43−eq | 3.76E-03 |

| RI | kg PM2.5 eq | 3.17E-03 |

| ODP | kg CFC-11 eq | 5.3E-06 |

| POFP | kg NMVOC eq | 3.44E-03 |

| PED | MJ | 3.17 |

| ADP | kg antimony eq | 4.97E-06 |

| WU | Kg | 0.84 |

Fig. 2.

LCA results of concentrated complex enzyme detergent a GWP, b AP, c EP, d RI, e ODP, f POFP, g PED, h ADP, iWU

Nielsen et al. (Nielsen et al., 2013) compared several environmental indicators of compact detergents with ordinary laundry detergent. The results showed that 1 kg of compact detergent will generate GWP of 2.32 kg CO2 eq, AP of 8.8 mg SO2 eq and EP of 3.6 mg PO43−eq during its entire life cycle. The surfactant content of the detergent and the washing practice of users are significant factors affecting the environmental emissions of the product. Their results are close to the results of this study. The main deviations of calculation results are due to the water content of the compact detergent which is 26.7% of total weight. Kim and Park (Kim & Park, 2020) studied the environmental emissions of containers for 10,000 loads of liquid detergent. Assuming that one load of liquid is approximately two tablespoons (28.3 g), the container for 1 kg detergent will generate GWP of 0.5 kg CO2 eq, which also justifies our calculations.

Sensitivity analysis of inventory data

Inventory data sensitivity was preformed to analyze the LCA results, which refers to the corresponding indicator change rate caused by the unit change rate of inventory data. By analyzing the sensitivity of the inventory data to each indicator and cooperating with the improvement potential evaluation, the most effective improvement points can be identified. The carbon footprint sensitivity analysis (Table 3) showed that the top three production processes of the active components with the greatest impact are glycerol, AES, and SDS. Therefore, the sensitivity analysis confirmed that the main source of environmental emissions of this product formulation is the production process of three raw materials.

Table 3.

Sensitivity of inventory data*

| Process/chemical | Parent process | GWP (%) | AP (%) | EP (%) | RI (%) | ODP | POFP (%) | PED (%) | ADP (%) | WU (%) | Average sensitivity (%) |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Glycerol production | Detergent production | 43.65 | 73.29 | 20.39 | 77.64 | 3.10E-06 | 59.46 | 7.03 | 2.35 | 5.53 | 32.15 |

| AES production | Detergent production | 24.34 | 7.04 | 10.32 | 5.56 | 99.88% | 19.47 | 9.78 | 3.14 | 9.17 | 20.97 |

| SDS production | Detergent production | 14.45 | 9.96 | 60.38 | 7.07 | 9.36E-06 | 9.61 | 21.20 | 7.10 | 16.73 | 16.28 |

| HDPE | Detergent production | 1.70 | 1.13 | 0.36 | 2.02 | 0.09% | 6.48 | 25.93 | 60.30 | 45.77 | 15.98 |

| Tetrachloromethane | AES Production | 0% | 0 | 0 | 0 | 99.88% | 0 | 0 | 0 | 0 | 11.10 |

| Nitrogen oxides | Glycerol production | 0 | 29.81 | 19.45 | 22.59 | 0% | 0 | 0 | 0 | 0 | 7.98 |

| Sulfur dioxide | Glycerol production | 0 | 41.10 | 0 | 13.39 | 0% | 12.80 | 0 | 0 | 0 | 7.48 |

| Nitrogen | SDS production | 0 | 0 | 57.98 | 0 | 0% | 0 | 0 | 0 | 0 | 6.44 |

| Carbon dioxide | Glycerol production | 42.90 | 0 | 0 | 0 | 0% | 0 | 0 | 0 | 0 | 4.77 |

| Electricity | SDS production | 2.22 | 2.22 | 0.52 | 2.68 | 9.36E-06 | 0.61 | 21.20 | 7.10 | 6.33 | 4.76 |

| Non-methane volatile organic compounds | Glycerol production | 0 | 0 | 0 | 0 | 0% | 42.33 | 0 | 0 | 0 | 4.70 |

| Inhalable particulate matter (PM10) | Glycerol production | 0 | 0 | 0 | 34.20 | 0% | 0 | 0 | 0 | 0 | 3.80 |

| Propylene Glycol | Detergent production | 8 | 2.95 | 2.27 | 2.65 | 2.32E-06 | 1.51 | 5.25 | 1.76 | 4.14 | 3.17 |

| Amylase | Detergent production | 0.66 | 0.84 | 1.61 | 0.85 | 6.97E-05 | 0.65 | 9.15 | 5.81 | 4.87 | 2.72 |

| Citric acid | Detergent production | 5.80 | 2.19 | 1.76 | 1.83 | 2.49E-06 | 0.29 | 5.63 | 1.89 | 4.44 | 2.65 |

| Carbon dioxide (fossil fuel source) | AES production | 20.91 | 0 | 0 | 0 | 0% | 0 | 0 | 0 | 0 | 2.32 |

| Cellulase | Detergent production | 0.38 | 0.54 | 1.82 | 0.42 | 6.80E-05 | 0.77 | 6.45 | 6.49 | 2.37 | 2.14 |

| Glycerol-Heavy Diesel Truck Transportation (30t)-China | Detergent production | 0.35 | 1.34 | 0.84 | 1.06 | 0.01% | 1.55 | 2.62 | 8.92 | 0.71 | 1.93 |

| Non-methane volatile organic compounds | AES production | 0 | 0 | 0 | 0 | 0% | 12 | 0 | 0 | 0 | 1.33 |

| CO2 | SDS production | 10.88 | 0 | 0 | 0 | 0% | 0 | 0 | 0 | 0 | 1.21 |

| Nitrogen oxides | AES production | 0 | 3.74 | 2.44 | 2.83 | 0% | 0 | 0 | 0 | 0 | 1.00 |

| Sulfur dioxide | SDS production | 0 | 4.86 | 0 | 1.59 | 0% | 1.52 | 0 | 0 | 0 | 0.89 |

| Nitrogen | AES production | 0 | 0 | 7.40 | 0 | 0% | 0 | 0 | 0 | 0 | 0.82 |

| Non-methane volatile organic compounds | SDS production | 0 | 0 | 0 | 0 | 0% | 7.21 | 0 | 0 | 0 | 0.80 |

| Carbon dioxide (fossil fuel source) | Propylene glycol production | 6.73 | 0 | 0 | 0 | 0% | 0 | 0 | 0 | 0 | 0.75 |

| Nitrogen oxides | SDS production | 0 | 2.70 | 1.76 | 2.05 | 0% | 0 | 0 | 0 | 0 | 0.72 |

| n-butane | AES production | 0 | 0 | 0 | 0 | 0% | 6.49 | 0 | 0 | 0 | 0.72 |

| Inhalable particulate matter (PM2.5) | Glycerol production | 0 | 0 | 0 | 6.48 | 0% | 0 | 0 | 0 | 0 | 0.72 |

| CO2 | Citric acid production | 4.84 | 0 | 0 | 0 | 0% | 0 | 0 | 0 | 0 | 0.54 |

*This table lists the inventory data with sensitivity > 0.5%

Because glycerol in this detergent acts as an enzyme stabilizer and a solvent, it accounts for the highest proportion in the originally designed formulation. Based on the LCA results, it is recommended to reduce the use of glycerol to further reduce the carbon footprint of this product. AES and SDS as surfactants are necessary active ingredients in detergent products. It is recommended to use a cleaner production process to partially replace such products or develop cleaner production processes.

Golsteijn et al. (Golsteijn et al., 2015) compared the LCA of six household detergent product categories in Europe including hand dishwashing detergents, compact laundry detergents, window glass trigger spray, bathroom trigger spray, acid toilet cleaners, and bleach toilet cleaners. Through the evaluation and sensitivity analysis, it was concluded that product usage and surfactant selection and dosage were the main drivers of emissions. Their research conclusions are comparable with the results of this study.

Carbon footprint analysis of electricity consumption

In the original model, the energy consumption of heating, stirring, cooling, and pumping materials in the production process is considered. The power consumption is estimated as 0.065 MJ. The simulated production process did not consider the energy consumption of the vacuum homogenization and filtration process. After adding these two unit operations, it is estimated that the total energy consumption is about 0.1 MJ.

Table 4 shows the impact of increasing power consumption from 0.065 MJ to 1 MJ on total carbon emissions. It can be seen that when the energy consumption increases to 0.1 MJ, the total carbon emissions only increase by 0.4%. When electricity consumption further increases 10 times to 1 MJ, carbon emissions will increase by about 10%. Therefore, under the premise of paying attention to energy conservation in the production process, electricity consumption has little effect on the carbon footprint.

Table 4.

Effect of electricity consumption on carbon footprint

| Electricity consumption (MJ) | Production process GWP (kg CO2 eq) | Total GWP (kg CO2 eq) | Change ratio (%) |

|---|---|---|---|

| 0.065 | 1.71E-02 | 2.53E + 00 | – |

| 0.1 | 2.64E-02 | 2.54E + 00 | + 0.40 |

| 0.5 | 1.32E-01 | 2.64E + 00 | + 4.35 |

| 1 | 2.64E-01 | 2.78E + 00 | + 9.88 |

Carbon footprint analysis of transportation distance

In the original model, only the transportation of glycerol, which accounts for 60% of the mass of the component, was considered. The transportation distance was 200 km, which is close to the average transport distance of 175.6 km of domestic goods in China. The calculated results (Table 5) showed that if the transportation distance is increased to 2000 km, the total carbon emissions increase by 3.16%. When taking into account the transportation of all raw materials, and assuming a transportation distance of 200 km, the total carbon emission increases by only 0.11%. Therefore, transportation distance has little effect on total carbon emissions.

Table 5.

Effect of transportation distance on carbon footprint

| Transportation distance (km) | Transportation GWP (kg CO2 eq) | Total GWP (kg CO2 eq) | Change ratio (%) |

|---|---|---|---|

| 200 | 8.74E-03 | 2.53 | – |

| 500 | 2.18E-02 | 2.54 | + 0.40 |

| 1000 | 4.37E-02 | 2.56 | + 1.19 |

| 2000 | 8.74E-02 | 2.61 | + 3.16 |

| 200 for all raw materials | 1.46E-02 | 2.532 | + 0.11 |

Carbon footprint analysis, experimental testing and cost saving of suggested product formulations

According to the results of LCA analysis, three improvements to the original product formulation were proposed (Table S4). In the suggested formulation 1, the content of the enzyme stabilizer glycerol is reduced by adding soft water, and the final product is a concentrated detergent with 70% active ingredient content. The suggested formulation 2 reduces the active ingredients content of the concentrated detergent to 50% by reducing the amount of enzyme stabilizer and adding water. The suggested formulation 3 increases the content of AES and SDS, and reduces the content of glycerol to 50% of the original formulation. The effect of suggested formulations on the carbon emission is shown in Table 6.

Table 6.

Effect of suggested formulations on carbon emission (total and breakdown), detergency and cost savings

| Carbon emission (kg CO2 eq) | Original formulation | Suggested formulation 1 | Suggested formulation 2 | Suggested formulation 3 |

|---|---|---|---|---|

| Production of concentrated complex enzyme detergent (total) | 2.53 | 1.98 | 1.60 | 2.87 |

| Electricity | 1.71E-02 | 1.71E-02 | 1.71E-02 | 1.71E-02 |

| Amylase | 1.66E-02 | 1.66E-02 | 1.66E-02 | 1.66E-02 |

| Cellulose | 9.59E-03 | 9.59E-03 | 9.59E-03 | 9.59E-03 |

| Propylene glycol | 2.02E-01 | 2.02E-01 | 2.02E-01 | 2.12E-01 |

| AES | 6.16E-01 | 6.16E-01 | 6.16E-01 | 1.18E + 00 |

| SDS | 3.66E-01 | 3.66E-01 | 3.66E-01 | 6.84E-01 |

| Citric acid | 1.47E-01 | 1.47E-01 | 1.47E-01 | 1.47E-01 |

| Gylcerol | 1.10E + 00 | 5.56E-01 | 1.85E-01 | 5.56E-01 |

| Glycerol transportation | 8.74E-03 | 4.40E-03 | 1.47E-03 | 4.40E-03 |

| HDPE | 4.31E-02 | 4.31E-02 | 4.31E-02 | 4.31E-02 |

| Soft water | 0.00E + 00 | 2.02E-04 | 3.40E-04 | 0.00E + 00 |

| Change ratio of carbon emissions(%) | – | − 21.7 | − 36.7 | + 13.44 |

| Detergency | 86.1 ± 5.2% | 82.2 ± 7.1% | 83.5 ± 5.1% | N/A |

| Cost saving (%) | – | 29.6% | 49.6% | N/A |

For suggested formulations 1 and 2, when the amount of glycerol is reduced to 50% and 16.7% of the original formulation, carbon emissions can be reduced by 21.7% and 36.7%, respectively. With an annual production of 10,000 tons of concentrated compound enzyme detergent, carbon emissions in the production process are reduced by 5,500 to 9,200 tons. However, if glycerol is reduced while the amount of surfactants is relatively increased in the suggested formulation 3, the total carbon emissions will increase instead. This is because there is still a large amount of carbon emissions from the production processes of surfactants.

In terms of detergency, experimental tests showed that there is no statistical difference between the original formulation, suggested formulation 1, and suggested formulation 2. The detergency of all 3 formulations is about 83–86%. The possible reason is that the function of glycerol is mainly as an enzyme stabilizer. Therefore, decreasing the amount of the enzyme stabilizer does not significantly affect the performance of these products.

The price of ordinary train cleaning agent is $1000–1500/ton. This highly concentrated complex enzyme detergent is composed of biological enzymes, enzyme stabilizers and surfactants, and the cost is relatively high at ~ $1500/ton. However, in the cleaning process, the amount of compound enzyme cleaning agent added is only 0.1%, which is much lower than other cleaning agents, giving a better profit margin. By further reducing the stabilizer content in the formulation, the cost saving of suggested formulations 1 and 2 could reach 29.6% and 49.6%, respectively. With an annual production of 10,000 tons of concentrated compound enzyme detergent, the cost can be saved from 4.4 to 7.4 million US dollars. For a more in-depth discussion of the financial perspective of sustainable smart manufacturing based on Industry 4.0, more details can be found in the literature (Durana et al., 2021b; Kovacova & Lăzăroiu, 2021).

The technology on the new formulations has been transferred to Suqian Dunjia Biotechnology Co., Ltd. Suggested formulation 1 and suggested formulation 2 have been designated by the manufacturer as model numbers TL1003-2 and TL1003-3, respectively. Currently, the stability study of these 2 new formulations is still ongoing. For a more in-depth review of data visualization, Industry 4.0 wireless networks, smart factory performance and cognitive automation, more details can be found in the literature (Kovacova et al., 2022; Zvarikova et al., 2021).

Carbon footprint estimation of upstream glycerol production process

To trace the high impact factors on the carbon footprint, the carbon emissions of the three upstream production processes (glycerol, AES, and SDS) were further estimated. The carbon footprint of the glycerol production process is estimated using public data from the USLCI database. The database data are summarized in Table 7.

Table 7.

Carbon footprint estimation of glycerol production process (GWP/kg CO2 eq)

| Glycerol (1 kg) | Processed palm kernel oil (1 kg) | Crude palm kernel oil (1 kg) | Palm kernel (1 kg) | ||||

|---|---|---|---|---|---|---|---|

| Total carbon emissions | 2.48 | Total carbon emissions | 2.14 | Total carbon emissions | 1.93 | Total carbon emissions | 1.4 |

| Processed palm kernel oil | 1.45 | Crude palm kernel oil | 1.96 | Palm kernel | 1.49 | Palm kernel processing | 1.21 |

| Crude palm kernel oil | 0.477 | Diesel combustion | 0.085 | Electricity | 0.235 | Crop harvest | 0.179 |

| Natural gas combustion | 0.311 | ocean shipping | 0.082 | Diesel combustion | 0.102 | Truck transportation | 0.012 |

| Bituminous coal combustion | 0.144 | ocean shipping | 0.086 | ||||

| ocean shipping | 0.0734 | ||||||

| Methanol | 0.0391 | ||||||

The total carbon emission per 1 kg of glycerol is 2.48 kg, which mainly comes from processing palm kernel oil, crude palm kernel oil, and natural gas combustion for heating. The main carbon emission of processing palm kernel oil is derived from the production process of crude palm kernel oil, while the main carbon emissions of crude palm kernel oil production is due to the palm kernel production process. The main carbon emissions of palm kernel processing are generated from biomass burning for heating and energy consumption for crop harvesting. In summary, the carbon emissions in the production process of glycerol are mainly due to the biomass combustion for heating during palm kernel processing, and the secondary sources of carbon emissions include natural gas, bituminous coal, and diesel combustion for heating and as fuel. Therefore, it is recommended that the exhaust gas from the production process of glycerol should undergo strict absorption and purification before being discharged.

Carbon footprint estimation of upstream AES production process

AES is produced by further sulfonation of ethoxylated alcohols AE3 or AE7 (Schowanek et al., 2018). The carbon emission estimation of the production process needs to consider processes such as alcohol ethoxylate (AE3 or AE7), ethanol, sodium hydroxide, SO3, nitrogen, deionized water, sewage treatment, and electricity. Alcohol ethoxylates with three or seven ethylene oxide units (i.e., AE3/AE7) are formed by the reaction of C12-C15 petroleum fatty alcohols with ethylene oxide with a catalyst.

Petroleum fatty alcohols can be produced by ethylene alkylation using the Ziegler process with a hydrogenation catalyst of triethylaluminum, or by an oxo process using synthesis gas for hydroformylation of long-chain olefins. Normal olefins are produced by dehydrogenation of normal alkanes, which are synthesized from kerosene or natural gas in petroleum refining products. Ethylene oxide is synthesized by direct oxidation of ethylene catalyzed by silver. Ethylene is produced by cracking natural gas liquid and petroleum steam, while SO3 is produced by sulfuric acid evaporation method. Ethylene hydration method is used for ethanol production. The production process of deionized water uses distillation, ion exchange and reverse osmosis technologies. Nitrogen preparation uses air cryogenic separation technology. Sodium hydroxide is produced by sodium chloride electrolysis.

Due to the confidentiality of Ecoinvent database, the AES, AE3/AE7, and normal olefin datasets obtained do not provide detailed production process and chemical reaction measurement numbers. So, the carbon footprint contribution can only be estimated from the emission data per kilogram of raw materials (Table 8). Among these raw materials, AE3, AE7, and ethanol have the highest contribution to the carbon emissions. The carbon emissions of petroleum fatty alcohol and ethylene oxide, which are the main raw materials in AE production, are also significant. The carbon emission of petroleum fatty alcohol production mainly comes from normal olefin production and ethylene production, while the carbon emissions of ethylene oxide are from the production of ethylene, the chemical reactions, and natural gas combustion. Therefore, it is estimated that carbon emissions from normal olefin production mainly come from the petroleum refining process.

Table 8.

Carbon footprint estimation of AES production process (GWP /kg CO2 eq)

| Process | Carbon emission | Process | Carbon emission |

|---|---|---|---|

| AES (1 kg)e | 3.71 | Alcohol Ethoxylate-AE (1 kg) | |

| AE3 (1 kg) | 2.67b–4.3a | Petroleum Fatty Alcohol (1 kg) | 2.97d–4.41a |

| AE7 (1 kg) | 2.31b–3.04a | Ethylene oxide (1 kg) | 1.6b–2.03c |

| Ethanol (95%,1 kg)e | 2.79 | ||

| Sodium hydroxide (1 kg)e | 1.33 | ||

| SO3 (1 kg)e | 0.78 | Ethylene oxide (1 kg) c | 2.03 |

| Nitrogen (1 kg)e | 0.0822 | Ethylene production | 0.848 |

| Deionized water (1 kg)e | 1.61E-03 | Chemical reaction process | 0.667 |

| Wastewater treatment (1 kg)e | 9.39E-04 | Natural gas combustion for heating | 0.243 |

| Process | Carbon emission | Process | Carbon emission |

| Petroleum Fatty Alcohol (1 kg)a | 2.97 | Normal olefin(1 kg)a | 1.86 |

| Normal olefin productiona,d | 1.55 | ||

| Ethylene productiona,d | 0.257 | ||

| Thermal energy | – | Petroleum Refined Products as the feedstock of Normal Olefin Feedstock (1 kg)c | 0.52 |

| Crude oil extraction | 0.22 | ||

| Ethylene (1 kg)c | 1.08 | Electricity | 0.108 |

| Natural gas production | 0.52 | Ocean shipping | 0.0896 |

| Natural gas combustion for heating | 0.347 | Residual fuel oil combustion | 0.0843 |

| Petroleum refined products | 0.14 | Natural gas combustion for heating | 0.022 |

Data sources: (a) WebLCA/Ecoinvent3.1, (b) ERASM platform, (c) USLCI, (d) literature (Shah et al., 2016), (e) CLCD

In summary, the main carbon emissions of the AES production process are derived from petroleum refining, natural gas production, ethylene oxide reaction, and ethanol production process. It is recommended to use renewable fuels/raw materials instead of crude oil to achieve a cleaner production. The exhaust gas from the traditional production processes shall be strictly absorbed and purified before being discharged.

Carbon footprint estimation of upstream SDS production process

SDS (LAS, HLAS) is produced by sulfonation of linear alkylbenzene (LAB) (Schowanek et al., 2018). The conventional production process of LAB is that hydrofluoric acid catalyzes the alkylation reaction of benzene and normal olefins. The production of normal olefins includes petroleum collection, petroleum refining (kerosene production), kerosene pre-fractionation and hydroprocessing, and normal paraffin separation. In the LCA process of the Ecoinvent database, one-third of benzene production is produced via pyrolysis gasoline (Pygas), while two-thirds is produced via the catalytic reforming of refined petroleum products. Pygas is a series of naphtha products with high aromatic content, and is a by-product of high-temperature naphtha cracking in the production of ethylene and propylene.

Due to the confidentiality of the database, Ecoinvent's Sodium Dodecylbenzene Sulfonate (LAS) dataset does not provide detailed documentation, but only provides basic input and output information (Table 9). It is estimated that the carbon emissions of LAS production are mainly derived from the production of linear alkyl benzene (LAB). The main raw materials of LAB including normal olefins and benzene also produce relatively high carbon emissions. Due to the different production technologies of benzene, the emission data given by different databases are quite different. According to the information provided by the USLCI database, it can be seen that when petroleum refined products and pygas are used as raw materials, the production of these raw materials is the main source of carbon emissions. Emissions from pygas production mainly come from the combustion of petroleum refined products and natural gas. The carbon emissions of the petroleum refining process have been analyzed in the previous Sect. 3.7, which are mainly caused by oil extraction, electricity, shipping, fuel heating, etc.

Table 9.

Carbon footprint estimation of LAS production process (GWP /kg CO2 eq)

| Process | Carbon emission | Process | Carbon emission | Process | Carbon emission |

|---|---|---|---|---|---|

| LAS (1 kg) | 1.75a | Benzene production (1 kg)c | 0.85 | Pygas production(1 kg)c | 0.619 |

| LAB (1 kg) | 2.13a | Petroleum refined products | 0.351 | Petroleum Refined Products | 0.256 |

| Pygas | 0.207 | Natural gas combustion | 0.232 | ||

| Normal olefin (1 kg) | 1.86a | Residual fuel oil combustion | 0.121 | Diesel/gasoline combustion | 0.1 |

| Benzene (1 kg) | 2.22a | Natural gas combustion | 0.094 | ||

| 1.81b | Sum of other processes | 0.0457 | |||

| 0.85c | Chemical reactions of production process | 0.03 |

Data sources (a) WebLCA/Ecoinvent3.1, (b) WebLCA/CLCD-China-ECER 0.8, (c) USLCI

The carbon footprint estimation of the LAS production process showed that its main carbon emissions are petroleum refining, natural gas production and fuel combustion. It is recommended that the exhaust gas generated in the production process is discharged after strict absorption and purification.

Downstream washing and wastewater treatment process evaluation

The concentrated complex enzyme detergent is designed for cleaning the dirt on the high-speed train. Before using the product in the train maintenance workshop of the railway bureau, the concentrated detergent needs to be diluted 1,000 times, i.e., 1 kg of detergent is diluted to 1 tonne. It is estimated that 1000 m2 train body can be cleaned by 1 tonne diluted detergent. As shown in Table 10, the concentration of active ingredient of the three formulations decreased to 1%, 0.7%, and 0.5% after dilution. In consideration of other cleaning processes (such as rinsing), the diluted wastewater concentration can reach the third-level standard for discharge to the second-level sewage treatment plant (China National sewage comprehensive discharge standard GB8978-1996). At present, the energy consumption of wastewater treatment plants is about 1.8–4.4 kWh/kg COD (Capodaglio & Olsson, 2020). According to the content of active components, the three formulations are equivalent to 1 kg COD, 0.7 kg COD, 0.5 kg COD. Even assuming that wastewater treatment is performed in an energy-efficient manner, the energy consumption required for the treatment is 2.8 MJ, 1.96 MJ, and 1.4 MJ, respectively. Based on the datasets of the power grid in the CLCD database, different regions and power generation methods in China are slightly different. Each 1 MJ of electricity will produce approximately 0.25–0.35 kg CO2 eq. In this study, an average value of 0.3 kg CO2 eq was used to calculate the carbon emissions caused by the electricity consumption of sewage treatment. The estimated carbon emissions based on electricity consumption of three formulations are 0.84, 0.588, and 0.42 kg CO2 eq, respectively. USLCI database reported that the municipal sewage treatment plant in US has a carbon emission of approximately 0.9–1.5 kg CO2 eq/ton sewage due to different treatment methods (National Renewable Energy Laboratory, 2021). Therefore, carbon emissions estimated in this study are comparable to data in the USLCI database, and the COD content in sewage has a significant impact on total carbon emissions. Minimizing the amount of enzyme stabilizer glycerol without compromising detergency will help reduce environmental emissions throughout the entire life cycle of this series of products.

Table 10.

Estimation of the impact of washing process and sewage treatment on carbon emissions

| Washing and sewage treatment | Original formulation (TL1003-1) | Suggested formulation 1 (TL1003-2) | Suggested formulation 2 (TL1003-3) |

|---|---|---|---|

| Active component content | 100% | 70% | 50% |

| Active ingredient content after dilution | 1% | 0.70% | 0.50% |

| Concentration of sewage (only the washing process is considered) | 1000 ppm | 700 ppm | 500 ppm |

| Energy consumption of sewage treatment (1.8kWh/kg COD) | 2.8 MJ | 1.96 MJ | 1.4 MJ |

| Carbon emission (kg CO2 eq) | 0.84 | 0.588 | 0.42 |

Data quality assessment results

Data quality represents the difference between the target representativeness of the LCA study and the actual representativeness of the data. The uncertainties of environmental impacts of the production process were quantitatively evaluated in the eFootprint system by using the CLCD quality assessment method. The data quality evaluation results are shown in Table 11. The uncertainties of LCA results are between 7.6% and 15.8%, which is mainly due to the regional differences in technology sources, the year of technical data collection, and the representativeness of technology collection companies.

Table 11.

LCA data quality assessment results

| Indicator (Unit) | LCA results | Uncertainty | Upper and lower limits of results (95% confidence interval) |

|---|---|---|---|

| GWP(kg CO2 eq) | 2.529 | 10.03% | [2.28,2.78] |

| AP(kg SO2 eq) | 1.322E-002 | 11.18% | [0.01,0.01] |

| EP(kg PO43−eq) | 3.764E-003 | 15.76% | [3.17E-03,4.36E-03] |

| RI(kg PM2.5 eq) | 3.165E-003 | 10.65% | [2.83E-03,3.50E-03] |

| ODP(kg CFC-11 eq) | 5.301E-006 | 14.98% | [4.5E-06,6.09E-06] |

| POFP(kg NMVOC eq) | 3.441E-003 | 9.76% | [3.11E-03,3.78E-03] |

| PED (MJ) | 3.171 | 10.46% | [2.85, 3.49] |

| ADP (kg antimony eq) | 4.97E-06 | 7.63% | [4.61E-6, 5.36E-6] |

| WU (kg) | 0.84 | 15.55% | [0.72, 0.98] |

Conclusions and recommendations

The life cycle analysis of the established LCA model for the TL1003-1 concentrated complex enzyme detergent shows that the GWP for the production of 1 kg of concentrated detergent is 2.53 kg CO2 eq, AP is 0.01 kg SO2 eq, EP is 3.76E-03 kg PO43−eq, RI is 3.17E-03 kg PM2.5 eq, ODP is 5.3E-06 kg CFC-11 eq, and POFP is 3.44E-03 kg NMVOC eq. The uncertainty of the results is between 7.6–15.8%. Carbon footprint (GWP) analysis showed that the production processes of glycerol, AES, SDS, propylene glycol, and citric acid contributed the most to the production process. Changes in power consumption during production and transportation distance of raw materials have limited effect on total carbon emissions. The average sensitivity analysis shows that the most influential processes are enzyme stabilizer and surfactants production, so they are the focus of process improvement.

The LCA analysis of suggested product formulations (TL1003-2 and TL1003-3) showed that when the amount of enzyme stabilizer glycerol is reduced to 50% and 16.7% of the original formulation, carbon emissions can be reduced by 21.7% and 36.7%, respectively. The detergency of two suggested product formulations were experimentally tested and showed a similar performance to the original formulation. The newly improved formulations have been transferred to the manufacturing plant for production. The Environmental Protection Agency (China) will continue to monitor the environmental emissions of new formula production in accordance with the law, and we will further follow up the pollution emission data of the new product production process.

Estimates of carbon emissions from major upstream production processes show that carbon emissions mainly come from biomass combustion, petroleum refining, natural gas production, chemical reactions, natural gas combustion, bituminous coal combustion, diesel combustion for heating and as fuel. Estimation of carbon emissions from downstream washing and wastewater treatment processes shows that the COD content in wastewater has a significant impact on total carbon emissions. While detergent manufacturers are not responsible for environmental emissions from the production of raw materials, it is recommended that additives with higher emissions be minimized without compromising detergency. In addition, surfactants with a cleaner production process may be used to reduce carbon footprint. For example, renewable energy can be used to replace crude oil for carbon (tax) credits or as carbon sinks. Fermentation is recommended used to produce some of raw materials, such as ethanol. Exhaust gas from the traditional production process shall be strictly absorbed and purified before being discharged. The recycling of HDPE packaging material also needs attention.

Supplementary Information

Below is the link to the electronic supplementary material.

Acknowledgments

The authors are thankful to Professor Dr. Hongtao Wang of Sichuan University for his suggestions on improving the research.

Author contributions

Conceptualization was contributed by BZ, CY; methodology was contributed by CY, RL; formal analysis and investigation were contributed by YG, YQ, JL, BY, DSZ; writing—original draft preparation, was contributed by BZ, CY; writing—review and editing was contributed by DSZ, BW; funding acquisition was contributed by CY, YD; Resources were contributed by BZ, YD; supervision was contributed by BZ.

Funding

This work was partially supported by the Fund of Wuhan Institute of Technology, the Heilongjiang Provincial Postdoctoral Science Foundation (LBH-Z19040) and Fund for Distinguished Scholars of Northeast Agricultural University.

Data availability

The data are included in the article and supporting materials. Additional information can be acquired by contacting the corresponding author.

Code availability

Not applicable

Declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Ethical approval

No conflicts, informed consent, human or animal rights applicable.

Consent for publication

All authors agree to publish this article in Environment, Development and Sustainability.

Footnotes

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

References

- Al-Ghanayem AA, Joseph B. Current prospective in using cold-active enzymes as eco-friendly detergent additive. Applied Microbiology and Biotechnology. 2020;104:2871–2882. doi: 10.1007/s00253-020-10429-x. [DOI] [PubMed] [Google Scholar]

- Bhatt A, Kato H. High-speed rails and knowledge productivity: A global perspective. Transport Policy. 2021;101:174–186. doi: 10.1016/j.tranpol.2020.12.006. [DOI] [Google Scholar]

- Braham SA, Siar EH, Arana-Peña S, Bavandi H, Carballares D, Morellon-Sterling R, de Andrades D, Kornecki JF, et al. Positive effect of glycerol on the stability of immobilized enzymes: Is it a universal fact? Process Biochemistry. 2021;102:108–121. doi: 10.1016/j.procbio.2020.12.015. [DOI] [Google Scholar]

- Capodaglio AG, Olsson G. Energy issues in sustainable urban wastewater management: use, demand reduction and recovery in the urban water cycle. Sustainability. 2020;12:266. doi: 10.3390/su12010266. [DOI] [Google Scholar]

- Chang C-C, Huang P-C. Carbon footprint of different fuels used in public transportation in Taiwan: A life cycle assessment. Environment Development and Sustainability. 2022;24:5811–5825. doi: 10.1007/s10668-021-01685-6. [DOI] [Google Scholar]

- Danby SG, Brown K, Wigley AM, Chittock J, Pyae PK, Flohr C, Cork MJ. The effect of water hardness on surfactant deposition after washing and subsequent skin irritation in atopic dermatitis patients and healthy control subjects. The Journal of Investigative Dermatology. 2018;138:68–77. doi: 10.1016/j.jid.2017.08.037. [DOI] [PubMed] [Google Scholar]

- Ding J, Hu X, Feng Z, Dong L. Environmental life cycle assessment of monosodium glutamate production in China: Based on the progress of cleaner production in recent ten years. Science of the Total Environment. 2022;818:151706. doi: 10.1016/j.scitotenv.2021.151706. [DOI] [PubMed] [Google Scholar]

- Dunn JB, Mueller S, Wang M, Han J. Energy consumption and greenhouse gas emissions from enzyme and yeast manufacture for corn and cellulosic ethanol production. Biotechnology Letters. 2012;34:2259–2263. doi: 10.1007/s10529-012-1057-6. [DOI] [PubMed] [Google Scholar]

- Durana P, Michalkova L, Privara A, Marousek J, Tumpach M. Does the life cycle affect earnings management and bankruptcy? Oeconomia Copernicana. 2021;12:425–461. doi: 10.24136/oc.2021.015. [DOI] [Google Scholar]

- Durana P, Perkins N, Valaskova K. Artificial intelligence data-driven internet of things systems, real-time advanced analytics, and cyber-physical production networks in sustainable smart manufacturing. Economics Managment and Financial Market. 2021;16:20–30. doi: 10.22381/emfm16120212. [DOI] [Google Scholar]

- Feraldi, R., Huff, M., Sauer, B., Schneider, S., Cashman, S., Molen, A., Littlefield, J., Franklin, W., et al. (2011) Cradle-to-Gate life cycle inventory of nine plastic resins and four polyurethane precursors. https://www.americanchemistry.com/better-policy-regulation/plastics/resources/cradle-to-gate-life-cycle-inventory-of-nine-plastic-resins-and-four-polyurethane-precursors. Accessed 02/02/2023

- Fortune Business Insights (2021) Household cleaning products market size, share & COVID-19 impact analysis, by product type (laundry detergents, surface cleaners, dishwashing products, toilet cleaners, and others), and regional forecast, 2021–2028. https://www.fortunebusinessinsights.com/household-cleaning-products-market-103286. Accessed 02/02/2023

- Golsteijn L, Menkveld R, King H, Schneider C, Schowanek D, Nissen S. A compilation of life cycle studies for six household detergent product categories in Europe: the basis for product-specific A.I.S.E. charter advanced sustainability profiles. Environmental Sciences Europe. 2015;27:23. doi: 10.1186/s12302-015-0055-4. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Gong Y, Yang C, Qu Y, Li J, Yang B, Ding Y, Zhang B. Life cycle assessment of a coke cleaning agent. Trends Renewable Energy. 2022;8:67–83. doi: 10.17737/tre.2022.8.1.00142. [DOI] [Google Scholar]

- Ivanchina E, Ivashkina E, Dolganova I, Dolganov I, Solopova A, Pasyukova M. Influence of flowrate and composition of the alkanes dehydrogenation process feedstock on by-products concentration in the linear alkylbenzene sulfonic acid manufacturing technology. Catalysis Today. 2021;378:231–239. doi: 10.1016/j.cattod.2020.12.010. [DOI] [Google Scholar]

- Kim S, Park J. Comparative life cycle assessment of multiple liquid laundry detergent packaging formats. Sustainability. 2020;12:4669. doi: 10.3390/su12114669. [DOI] [Google Scholar]

- Kliestik T, Zvarikova K, Lăzăroiu G. Data-driven machine learning and neural network algorithms in the retailing environment: Consumer engagement, experience, and purchase behaviors. Economics Management and Financial Market. 2022;17:57–69. doi: 10.22381/emfm17120224. [DOI] [Google Scholar]

- Kovacova M, Lăzăroiu G. Sustainable organizational performance, cyber-physical production networks, and deep learning-assisted smart process planning in Industry 4.0-based manufacturing systems. Economics Managment and Financial Market. 2021;16:41–54. doi: 10.22381/emfm16320212. [DOI] [Google Scholar]

- Kovacova M, Machova V, Bennett D. Immersive extended reality technologies, data visualization tools, and customer behavior analytics in the metaverse commerce. Journal of Self-Governance and Management Economics. 2022;10:7–21. doi: 10.22381/jsme10220221. [DOI] [Google Scholar]

- Lawrence M, Bullock R, Liu Z. China's high-speed rail development. World Bank Publications; 2019. [Google Scholar]

- Li Y, Ma S, Fang X, Wu C, Chen H, Zhang W, Cao M, Liu J. Water hardness effect on the association and adsorption of cationic cellulose derivative/anionic surfactant mixtures for fabric softener application. Colloids and Surface, A. 2021;626:127031. doi: 10.1016/j.colsurfa.2021.127031. [DOI] [Google Scholar]

- Lin B, Wu J, Lin R, Wang J, Wang H, Zhang X. Optimization of high-level preventive maintenance scheduling for high-speed trains. Reliability Engineering and System Safety. 2019;183:261–275. doi: 10.1016/j.ress.2018.11.028. [DOI] [Google Scholar]

- Maceno MMC, João S, Voltolini DR, Zattar IC. Life cycle assessment and circularity evaluation of the non-medical masks in the Covid-19 pandemic: A Brazilian case. Environment Development and Sustainability. 2022 doi: 10.1007/s10668-022-02388-2. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Melián EP, Santiago DE, León E, Reboso JV, Herrera-Melián JA. Treatment of laundry wastewater by different processes: Optimization and life cycle assessment. Journal of Environmental Chemical Engineering. 2023;11:109302. doi: 10.1016/j.jece.2023.109302. [DOI] [Google Scholar]

- Mores S, Vandenberghe LPdS, Magalhães Júnior AI, de Carvalho JC, de Mello AFM, Pandey A, Soccol CR. Citric acid bioproduction and downstream processing: Status, opportunities, and challenges. Bioresource Technology. 2021;320:124426. doi: 10.1016/j.biortech.2020.124426. [DOI] [PubMed] [Google Scholar]

- Movahedpour A, Asadi M, Khatami SH, Taheri-Anganeh M, Adelipour M, Shabaninejad Z, Ahmadi N, Irajie C, et al. A brief overview on the application and sources of α-amylase and expression hosts properties in order to production of recombinant α-amylase. Biotechnology and Applied Biochemistry. 2022;69:650–659. doi: 10.1002/bab.2140. [DOI] [PubMed] [Google Scholar]

- Munkajohnpong P, Kesornpun C, Buttranon S, Jaroensuk J, Weeranoppanant N, Chaiyen P. Fatty alcohol production: An opportunity of bioprocess. Biofuels, Bioproducts and Biorefining. 2020;14:986–1009. doi: 10.1002/bbb.2112. [DOI] [Google Scholar]

- Myers D. Surfactant science and technology. 4. Wiley; 2020. [Google Scholar]

- Naher L, Fatin SN, Sheikh MAH, Azeez LA, Siddiquee S, Zain NM, Karim SMR. Cellulase enzyme production from filamentous fungi Trichoderma reesei and Aspergillus awamori in submerged fermentation with rice straw. J Fungi. 2021;7:868. doi: 10.3390/jof7100868. [DOI] [PMC free article] [PubMed] [Google Scholar]

- National Bureau of Statistics of China (2021) Average distance of road cargo transportation (km). https://data.stats.gov.cn/easyquery.htm?cn=C01. Accessed 02/02/2023

- National Renewable Energy Laboratory (2021) US Life cycle inventory datebase. https://www.nrel.gov/lci/. Accessed 02/02/2023

- Ngalimat MS, Yahaya RSR, Baharudin MMA-a, Yaminudin SM, Karim M, Ahmad SA, Sabri S, A review on the biotechnological applications of the operational group Bacillus amyloliquefaciens. Microorganisms. 2021;9:614. doi: 10.3390/microorganisms9030614. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Nielsen AM, Li H, Zhang H. Compact detergents in China—a step towards more sustainable laundry. A life cycle assessment of four typical chinese detergents. Household Pers Care Today. 2013;8:30–35. [Google Scholar]

- Nogueira GP, Capaz RS, Franco TT, Dias MOS, Cavaliero CKN. Enzymes as an environmental bottleneck in cellulosic ethanol production: Does on-site production solve it? Journal Cleaner Production. 2022;369:133314. doi: 10.1016/j.jclepro.2022.133314. [DOI] [Google Scholar]

- Qian H, Song G, Lv L, Cheng Y, Zhang L, Chen J. The comparative life-cycle environmental effects of chemical feedstock change driven by energy system transition: A case study from China's ethylene glycol industry. Journal Cleaner Production. 2022;355:131764. doi: 10.1016/j.jclepro.2022.131764. [DOI] [Google Scholar]

- Reena R, Sindhu R, Athiyaman Balakumaran P, Pandey A, Awasthi MK, Binod P. Insight into citric acid: A versatile organic acid. Fuel. 2022;327:125181. doi: 10.1016/j.fuel.2022.125181. [DOI] [Google Scholar]

- Schowanek D, Borsboom-Patel T, Bouvy A, Colling J, de Ferrer JA, Eggers D, Groenke K, Gruenenwald T, et al. New and updated life cycle inventories for surfactants used in European detergents: Summary of the ERASM surfactant life cycle and ecofootprinting project. International Journal of Life Cycle Assessment. 2018;23:867–886. doi: 10.1007/s11367-017-1384-x. [DOI] [Google Scholar]

- Shah J, Arslan E, Cirucci J, O'Brien J, Moss D. Comparison of Oleo- vs petro-sourcing of fatty alcohols via cradle-to-gate life cycle assessment. Journal of Surfactants and Detergents. 2016;19:1333–1351. doi: 10.1007/s11743-016-1867-y. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Shokri A, Karimi S. A review in linear Alkylbenzene (LAB) production processes in the petrochemical industry. Russian Journal of Applied Chemistry. 2021;94:1546–1559. doi: 10.1134/S1070427221110094. [DOI] [Google Scholar]

- Suhag M. Bioethanol production technologies: commercial and future perspectives. In: Kothari R, Singh A, Arora NK, editors. Biomass, bioenergy & Bioeconomy. Singapore: Springer; 2022. pp. 117–139. [Google Scholar]

- Tong Z, Tong Y, Wang D, Shi Y-C (2021) Whole Maize Flour and Isolated Maize Starch for Production of Citric Acid by Aspergillus niger: A Review. Starch - Stärke:2000014. doi:10.1002/star.202000014

- Vochozka M, Rowland Z, Suler P, Marousek J. The influence of the international price of oil on the value of the EUR/USD exchange rate. Journal of Competitiveness. 2020;12:167. doi: 10.7441/joc.2020.02.10. [DOI] [Google Scholar]

- Wang C, Zhu L. Life cycle assessment of coal-to-liquid process. Environment Development and Sustainability. 2021;23:14453–14471. doi: 10.1007/s10668-021-01252-z. [DOI] [Google Scholar]

- Wang M, Han J, Dunn JB, Cai H, Elgowainy A. Well-to-wheels energy use and greenhouse gas emissions of ethanol from corn, sugarcane and cellulosic biomass for US use. Environmental Research Letter. 2012;7:045905. doi: 10.1088/1748-9326/7/4/045905. [DOI] [Google Scholar]

- Yang M, Rosentrater KA. Cradle-to-gate life cycle assessment of structural bio-adhesives derived from glycerol. International Journal of Life Cycle Assessment. 2021;26:799–806. doi: 10.1007/s11367-020-01733-9. [DOI] [Google Scholar]

- Zhang A, Wan Y, Yang H. Impacts of high-speed rail on airlines, airports and regional economies: A survey of recent research. Transport Policy. 2019;81:A1–A19. doi: 10.1016/j.tranpol.2019.06.010. [DOI] [Google Scholar]

- Zhang L, Liu C, Li F, Qiao W. Performance improvement of cleaning formulations for the exterior surface of high-speed trains. Journal of Surfactants and Detergents. 2021;24:99–109. doi: 10.1002/jsde.12464. [DOI] [Google Scholar]

- Zvarikova K, Rowland M, Krulicky T. Sustainable Industry 4.0 wireless networks, smart factory performance, and cognitive automation in cyber-physical system-based manufacturing. Journal Self-Governance Manage Econ. 2021;9:9–20. doi: 10.22381/jsme9320211. [DOI] [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.

Supplementary Materials

Data Availability Statement

The data are included in the article and supporting materials. Additional information can be acquired by contacting the corresponding author.

Not applicable