Abstract

Carbon dioxide (CO2) is a major greenhouse gas released by gas turbine power plants that is hazardous to the environment. Hence, it is vital to investigate the operational conditions that influence its emissions. Various research papers have utilized a variety of techniques to estimate CO2 emissions from fuel combustion in various power plants without taking into account the environmental operational characteristics which in turn may have a significant effect on the obtained output values. Therefore, the purpose of this research is to assess the carbon dioxide emissions while considering both external and internal functioning characteristics. In this paper, a novel empirical model for predicting the feasible amount of carbon dioxide emitted from a gas turbine power plant was developed based on ambient temperature, ambient relative humidity, compressor pressure ratio, turbine inlet temperature and the exhaust gas mass flow rate. The predictive model developed shows that the mass flow rate of CO2 emitted has a linear relationship with the turbine inlet temperature to ambient air temperature ratio, ambient relative humidity, compressor pressure ratio, and exhaust gas mass flow rate with a determination coefficient (R2) of 0.998. Results obtained shows that rise in ambient air temperature and air fuel ratio led to increase in CO2 emission, while increase in ambient relative humidity and compressor pressure ratio resulted in reduction of CO2 emission. Furthermore, the average emission of CO2 obtained for the gas turbine power plant was 644.893kgCO2/MWh and 634, 066, 348.44kgCO2/yr, of which the latter is within the guaranteed values of 726, 000, 000 kgCO2/yr. Thus, the model can be utilized to perform an optimal study for CO2 reduction in gas turbine power plants.

Keywords: Carbon dioxide emission, Evaluation, Gas turbine, Modelling, Operating parameters

Nomenclature

Abbreviation/symbol

- AFR

Air Fuel Ratio

- CC

Combustion chamber

- CIT

Compressor Inlet Temperature (0C, K)

- CO2

Carbon dioxide

- cp

Specific heat capacity at constant pressure (kJ/kg K)

- EIA

Environmental Impact Assessment

- GHG

Greenhouse gas

- GT

Gas turbine unit

- HR

Heat rate (kJ/kWh)

- IEA

International Energy Agency

- IFC

International Finance Corporation

- ISO

International Standard Organization

- LF

Load factor (%)

- LHV

Lower heating value (kJ/kg)

- LNG

Liquefied Natural Gas

- M

Molar mass (kg/kmol)

- ṁ

Mass flow rate (kg/s)

- Molar flow rate (kmol/s)

- n

Number of moles

- NOx

Nitrogen oxides

- OPT

Operation Time (s, h)

- p

Pressure (bar)

- P

Power (MW)

- rp

Compressor Pressure ratio

- T

Absolute temperature (0C, K)

- TIT

Turbine Inlet Temperature (0C, K)

- X

Mole fraction

Greek Symbols

- Carbon dioxide Emission Rate (kg/MWh)

- Relative Humidity

- ɳc

Compressor isentropic efficiency

- ɳnet

Net Thermal Efficiency

- γ

Specific heat capacities ratio

- λ

Fuel air ratio

- ρ

Density (kg/m3)

Subscripts

- a

Air

- AC

Air compressor

- Amb

Ambient

- CC

Combustion chamber

- da

Dry air

- f

Fuel

- g

Exhaust gas

- gen

Generator

- GT

Gas turbine

- Mech

Mechanical

- T

Turbine

- V

water vapour

1. Introduction

In the past decades, the environment has been degraded due to various technological innovations. The environmental issues posed by technological advances are of concern to individuals and companies around the world. From a wider impact and policy perspective on environmental degradation, greenhouse gas (GHG) emissions are the most significant environmental issue for industries, while recognizing that other environmental impacts are potentially significant, especially at the local level [1,2]. Due to the effect of GHG on the environment, the Conference of the Parties (COP21) on Climate Change held in Paris had set an objective to maintain the average ambient air temperature below 1.5 °C. To achieve the said objective, the United Nations [3]and Abdallah & El-Shennawy [4] recommended that the determination of CO2 emissions from power plants is crucial because the power plant and other industries that supply and consume energy are major sources of CO2 emissions, which led to a rise in ambient air temperature. Again, carbon dioxide has been said to be the most important greenhouse gas [[5], [6], [7]]. The burning of fossil fuels is responsible for 73% of the CO2 emitted into the atmosphere [8]. The continued utilization of fossil fuels such as coal, natural gas, petroleum products, etc. To meet most of the world's energy demand will increase the amount of CO2 emitted into the environment and hence keep increasing the Earth's ambient temperature [9,10]. The aforementioned fact has spurred governments, private companies, and research bodies to look at energy techniques that will help lower the effect of natural gas and oil sectors' environmental impact on the total budget of carbon dioxide emissions [11]. While the request for alternative energy recourses is on, the reliance on fossil fuel for power generation will continue because of its extensive infrastructure for fuel production and distribution [12].

In the case of natural gas, relevant studies such as Yousefi et al. [13]; Ayaz et al. [14]; Kim et al. [15] have shown that natural gas combustion mainly emits carbon dioxide, nitrous oxide, and sometimes methane when unburnt. Also, it has been established that natural gas emits less carbon dioxide than coal [6,16]. Environmental researchers have categorized carbon dioxide (CO2) as the most notable anthropogenic ozone-harming substance [[17], [18], [19]]. Memon et al. [20] stated that CO2 emission effects from fossil fuels is the reason researchers are interested in exploring various environmental impact mitigation strategies while considering the use of fossil fuels for power generation. This provided an opportunity to investigate its emissions and suggest ways to reduce them.

Gas turbine (GT) power plants generate exhaust gases apart from electricity production. The flue gas emitted into the power plant's surroundings contains carbon dioxide and other gases which pollute the air and contribute to GHG [21]. Saravanamutto et al. [22] stated in their book that a large amount of excess air is needed in gas turbine combustible engines, which leads to considerable oxygen in the exhaust gases. The work also explains that the exhaust of any gas turbine consists mainly of CO2, H2O, O2, and N2, and the combustion products can be expressed as either gravimetric (by mass) or molar (by volume) composition. With this explanation, CO2 is the main gas emitted by gas turbine power plants that is harmful to the environment.

In light of the aforementioned, various approaches have been used in many research works on how CO2 emissions are estimated from the combustion of fuel in different power plants. The United States Environmental Protection Agency (USPEPA), the Intergovernmental Panel for Climate Change (IPCC), and IEA have deplored the emission factors to predict the emission of CO2. Also, the study on CO2 emissions by Manceralla and Chicco [23]; Kazemi et al. [24]; and Sousa et al. [25] stated that the use of the CO2 emission factor to evaluate the power plant's emissions of CO2 is on the increase. The emission factor has been used in previous work because it is easy to compute CO2 emissions from power plants. However, the issue of a particular power plant location was not considered because environmental location parameters were not considered. Qader et al. [26] developed a model using Holt's, Gaussian Process Regression, and neural network methods for the estimation of CO2 emitted from a power plant in Bahrain. This particular model was mainly based on time series, which again has a deficiency of particular environmental parameters such as ambient temperature and relative humidity. Zhao et al. [27] used the econometrical method to estimate CO2 and Nassar et al. [28] utilized the method of life cycle assessment to estimate the emission of CO2 from a power plant that uses diesel in Libya. In addition, many other studies, such as Wang et al. [29]; Wang & Song [30], used the aggregate carbon intensity to determine the emission of CO2 from power plants.

Furthermore, Memon et al. [20] and Memon et al. [31] investigated the CO2 emission for simple and regenerative gas turbine power plant configurations, deploying the combustion equation. These studies considered changes in operating parameters such as compressor inlet temperature, compressor pressure, and turbine inlet temperature with CO2 emission. The results obtained were used to develop models using regression analysis for predicting CO2 emissions. Their results showed that the investigated operating parameters have an important effect on the performance of the cycle and the emission of CO2. Though these studies considered operating parameters, important parameters such as relative humidity and exhaust gas mass flow rate that critically influence gas turbine power plants performance were not considered in their predicting models. For other models developed, Ibrahim et al. [32] deployed statistical tools to develop a novel model for predicting the optimum performance of GT power plant. The model obtained was satisfactory with a coefficient of determination (R2) value of 0.985. Also, Kwasi-Effah et al. [33] developed a novel model for accumulation of heat prediction in a solar thermal application with thermal storage medium. The R2 value of 0.783 was obtained for the developed model. Likewise, Oyedepo et al. [34] studied the CO2 emissions of 11 selected GT power plants using the combustion equation. The study analyzed the variation of CO2 emissions with turbine inlet temperature (TIT) and exergy efficiency. Findings from the work showed that an increase in the exergetic efficiency of the GTs plant resulted in a reduction in CO2 emission. Moreso, Kanbur et al. [35] also used the combustion equation method to analyze the CO2 emissions of a combined cycle for a small-scale LNG cold plant. The findings from the environmental analysis revealed that the combined cycle system had a lesser CO2 emission rate than the single GT system because it produced a more energy rate while both systems emitted the same amount of CO2 into the atmosphere. Also, Karapekmez and Dincer [36] evaluated the emission of CO2 from various fuels and stated that wood and sawdust are rewarding alternative fuels because of their biofuel nature. Steen [37] reported that the discharge of CO2 from fossil fuel-fired gas power plants was found to be reduced with an increase in its thermal efficiency. Also, research work on carbon dioxide emissions from fuel consumption in Iran was carried out by Lotfalipour et al. [38] and it's revealed that carbon dioxide emissions will increase by 2.1 times as of 2025. Additionally. Fofrich et al. [39] stated in their research work that to maintain global warming at a temperature below 2 °C, an ambitious way of mitigating climate change problems from power facilities needs to be studied by continuous monitoring of carbon dioxide from power plant facilities. More so, the need to reduce gas turbine CO2 emission was emphasized by Choudhary et al. [40].

In the evaluation of CO2 emissions, an average carbon dioxide emission intensity or rate for simple open gas turbines has been determined by EIA [41] as 557 g CO2/kWh. Fofrich et al. [39] also mentioned in their paper that the carbon dioxide emission rate varies from 274 to 720 g CO2/kWh depending on technology and region. Gas turbine power plants are sensitive to environmental parameters such as, ambient air pressure, ambient air temperature and ambient air relative humidity [[42], [43], [44], [45]]. These parameters were not considered in modelling and evaluation of CO2 emission by previous studies reviewed. So, in evaluating and predicting CO2 emissions in GT power plants, these parameters require to be included for holistic study.

Additionally, the SGT5–2000E GT model considered for this study has a good record of controlling negligible low NOx and CO emissions [46,47]. So, the major exhaust constituent that has been flared is CO2, as mentioned by Saravanamuttoo et al. [22]. To advance the frontier of knowledge in CO2 emission studies, this makes it necessary to develop an empirical model for predicting CO2 emission considering both internal and external parameters of a 153 MW GT Power Plant, that has not been earlier studied. Hence, the present study intends to model and evaluate the variation of the CO2 emissions with operating parameters (ambient air temperature, ambient relative humidity, compressor pressure ratio, turbine inlet temperature and exhaust gas mass flow rate) for the power plant. The objectives of the study are to develop and validate a gas turbine model which will be used for the study; develop an empirical model for predicting CO2 emission based on operating parameters for a gas turbine power plant; and evaluate the effect of ambient air temperature, thermal efficiency and turbine inlet temperature on the annual CO2 emission rate from the gas turbine power plant. Furthermore, the study will also compare the actual CO2 emitted during this period with the CO2 emission specified by the manufacturer and other available literature.

2. Methodology

2.1. Description and operation of the 153 MW ga turbine power plant

The gas turbine considered for this study is the SGT5-2000E GT power plant located in Benin City, Edo State, Nigeria. The natural gas use to powered the gas turbine power was supplied by Nigeria Gas Company (NGC) pipeline network in partnership with Seplat Nigeria Limited. The manufacturer-installed capacity of model SGT5-2000E was 153 MW output power at this site with a net heat rate value of 10,528 kJ/KWh at 26 °C [48].

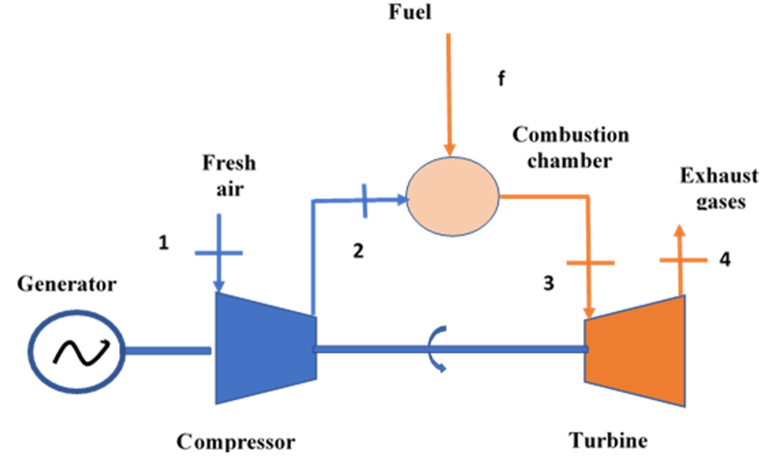

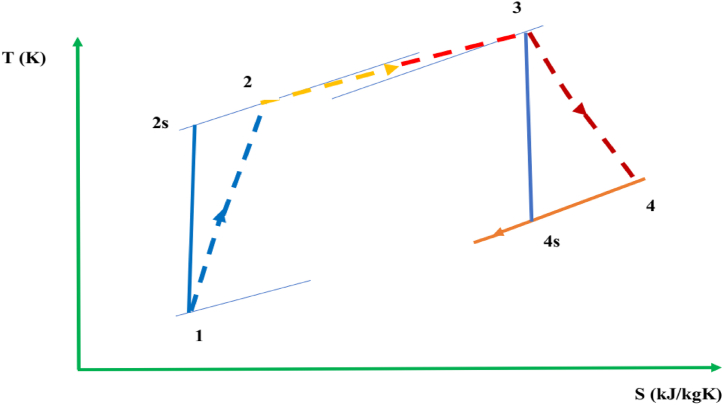

The considered model consists of single casing design, a single shaft, two side flanges, a high capacity, two silo-type combustors, a 4 -stage turbine and a 16 – stage axial compressor. The generator is attached to the side of the compressor (cold end) which is air-cooled. One advantage of this Siemens gas turbine model is that its arrangement permits easy attachment of HRSG, unlike other models where the generator is coupled to the turbine side. The SGT5-2000E model efficiently burn a mixture of fuel and compressed air to control CO and NOx emissions because of its good combustion chamber. The combusted products, which include carbon dioxide, water vapour, and oxygen, are emitted into the power plant's surroundings through the stack. The Siemens Gas Turbine Power Plant operates on the Brayton cycle. Fig. 1, Fig. 2 represent the schematic and specific temperature-entropy (T-s) diagrams of the SGT5-2000E gas turbine power plant respectively.

Fig. 1.

A typical schematic diagram of SGT5 – 2000E gas turbine power plant.

Fig. 2.

The T-s Diagram of SGT5 – 2000E Gas Turbine Power Plant Cycle.

Part of the power mechanical power produced by turbine is utilized by the air compressor, while the rest is converted to electrical power by the 3000-rpm generator. The synchronized electrical power is fed into the public power grid [49].

2.2. Thermodynamic model equations

The thermodynamic model equations used for the modelling of carbon dioxide emissions from the gas turbine power plant are illustrated in Equations (1), (2), (3), (4), (5), (6), (8), (9), (10), (11), (12), (13), (14). Also, the composition and properties of the fuel (natural gas) used to fire the gas turbine power plant are presented in Table 1.where is the fuel mass flow rate and Mf is fuel molar mass

Table 1.

| (1) |

| S/N | Name of Constituent | Formula of Constituent | Molar fraction (Volumetric) (xf) | Molar mass of Constituent (Mi) (kg/kmol) |

|---|---|---|---|---|

| 1 | Methane | CH4 | 0.87721 | 16 |

| 2 | Ethane | C2H4 | 0.03658 | 30 |

| 3 | Propane | C3H8 | 0.03031 | 44 |

| 4 | Normal –Butane | C4H10–N | 0.003325 | 58 |

| 5 | Iso – Butane | C4H10–I | 0.003318 | 58 |

| 6 | Normal – Pentane | C5H12–N | 0.002157 | 72 |

| 7 | Normal – Hexane | C6H14–N | 0.000448 | 86 |

| 8 | Iso – Pentane | C5H12–I | 0.002352 | 72 |

| 9 | Carbon (IV) Oxide | CO2 | 0.02722 | 44 |

| 10 | Nitrogen | N2 | 0.01708 | 28 |

The molar flow rate of air (na) in kmol/s was calculated as expressed in Equation (2).

| (2) |

where, is the mass flow rate of air as obtained from the 153 MW GT Power Plant.

The fuel air ratio, was calculated as shown in Equation (3).

| (3) |

In the various computations, the air chemical compositions were assumed to be carbon (IV) oxide, water vapour, and nitrogen, and all gases were assumed to be ideal gases [51], respectively. The relationship between the chemical contents of the fuel, as presented in Table 1, air, and exhaust gases, is indicated in the combustion reaction that took place in the combustor, as illustrated in Equation (4).

| (4) |

where xa is the molar fraction of the air components, xp is the molar fraction of combustion products components, and λ is the fuel-air ratio of the power plant. The combustion equation was obtained from Bejan et al. [51] where more details can be found.

Applying carbon, hydrogen, oxygen and nitrogen balance to solve the combustion reaction expressed in Equation (4). The molar fraction of carbon (IV) oxide xpCO2, water vapour xpH2O, oxygen xpO2 and nitrogen xpN2 were computed as shown in Equations (5), (6), (7), (8) respectively.

| (5) |

| (6) |

| (7) |

| (8) |

The molar flow rate of the exhaust gases was evaluated by applying Equation (9).

| (9) |

The mass flow rate of each constituent of the product or exhaust gases was computed by using Equation (10) [52,53].

| (10) |

where naco2, naO2 and naN2 are the molar values for carbon dioxide, oxygen and nitrogen, which are 0.0003058, 0.20988789 and 0.78980632 respectively as gotten from Kanbur et al. [53].

The compressor pressure ratio (rp) was determined by applying Equation (11) as obtained from Refs. [49,54,55].

| (11) |

The Air fuel ratio (AFR) was evaluated by using Equation (12).

| (12) |

Equation (13) was used to obtain the net efficiency of the GT Power plant [54].

| (13) |

The GT power plant net heat rate was evaluated applying Equation (14) [48].

| (14) |

2.3. The SGT5 – 2000E GT power plant modelling and simulation

The installed parameters of the 153 MW GT Power Plant model are given in Table 2 as obtained from Azura [50,56], which is used as the roof profile for the simulation. Fig. 3 represents the structure of the GT Power Plant executed with Ebsilon Professional. Summary of data obtained from the 153 MW Ga Turbine Power Plant between December 2017 and December 2021 as presented in Table 3 was used for off design conditions during modelling and simulation process.

Table 2.

Nominal conditions for the gas turbine power plant.

| S/N | Variables | Quantities |

|---|---|---|

| 1 | Net Power Output (MW) | 153 |

| 2 | Net Heat Rate(kJ/kWh) | 10,528 |

| 3 | Ambient air temperature (0C) | 26 |

| 4 | Ambient air pressure (bar) | 1.013 |

| 5 | Turbine Exhaust Temperature (0C) | 557.50 |

| 6 | Exhaust mass flow (kg/s) | 506 |

| 7 | Compressor pressure ratio | 11.44 |

| 8 | Relative Humidity (%) | 70 |

| 9 | Lower Heating Value (MJ/kg), LHV | 45.011 |

| 10 | Annual CO2 Emission (kg) | 726,000,000 |

Fig. 3.

Topology of the SGT5 – 2000E for installed condition.

Table 3.

Summary of Operating data from the power plant.

| S/N | Variables | Quantities |

|---|---|---|

| 1 | Ambient Temperature (0C), T1 | 20–35 |

| 2 | Ambient Relative Humidity (%), ɸ | 41.02–92 |

| 3 | Turbine Exhaust Temperature (0C), T4 | 531.5–549.3 |

| 4 | Compressor Inlet Pressure (bar), p1 | 1.011–1.013 |

| 5 | Compressor Outlet Pressure (bar), p2 | 10.898–11.071 |

| 6 | Mass flow rate of air (kg/s), | 480.34–514.40 |

| 7 | Mass flow rate of fuel (kg/s), | 10.28–11.41 |

| 8 | Net Power output (MW), Pnet | 140.869–159.272 |

The assumptions taken in modelling the power plant are.

-

(i)

Steady-state was assumed for the simulation as in Ref. [57], which means that the mass and other parameters within the various components and the boundary do not vary with time. Quasi steady state is assumed for compressor inlet air temperature because it depends on time which was assumed to steady at every hour.

-

(ii)

Transient effects of start-up and shutdown during operations were neglected because the data obtained were recorded at times when the power plant are fully in operation without fault.

-

(iii)

The nominal pressure drops used in the Ebsilon Professional were obtained from the power plant. This was done in order to ensure that the pressures of the various fluids were more realistic.

The turbine model for a 153 MW gas-fired power plant (SGT5 – 2000E) includes an air compressor, combustor, gas turbine, and generator, which were modelled by linking the selected various components together as shown in Fig. 3 The SGT5-2000E model installed performances were obtained using the installed parameters of the ambient temperature of 26 °C and ambient air pressure of 1.013 bar and other variables from Table 2A “general input value” was used to set the nominal flue gas mass flow rate and temperature while adjusting the pressure ratios of the gas turbine components. Compressor and turbine isentropic efficiencies from the power plant manual of 90% and 85%, respectively, were used. This was done because the mass flow rates of fuel and air were not provided, which will be obtained after the model simulation. Generator and mechanical efficiencies of 98.5% and 99%, respectively, which were obtained after a series of iteration processes, were used for the modelling. The fuel composition and LHV were entered correspondingly. Subsequently, entering all the necessary values and running the model, the fuel and air mass flow rates were obtained at nominal conditions for the gas turbine.

The simulation was repeated using the obtained mass flow rates of fuel and air without the installed exhaust mass flow rate and temperature as shown in Fig. 3. This was done so that the air mass flow rate and fuel mass flow rate entering the compressor and combustor, respectively, could determine the performance of the gas turbine under different inlet conditions and partial loads. This formed the root profile for this model, which made it possible to enter the new values of air for off-design conditions applying the “boundary value input”. The modelling of the 153 MW GT Power Plant for the installed condition using Ebsilon is presented in Fig. 3.

2.4. Ebsilon model validation

The built model is used to monitor the performance of existing gas turbine power plants. The values obtained were validated with the 153 MW Ga Turbine Power Plant installed capacity data using the power generated and heat rate. The percentage errors of the model observed were calculated using Equation (15) [[58], [59], [60], [61]].

| (15) |

where AD and MD are actual data and model data obtained.

2.5. Off-design modelling for the SGT5 – 2000E gas turbine

When a gas turbine is operating at design conditions, it is sometimes called rated condition or 100% design condition. When a power plant is operated outside its nominal specifications, this is called an “off-design condition”. Off-design conditions can occur if ambient air conditions such as temperature or humidity change, or if the power produced by the turbine falls below or above its rated power. Off-design models were run by changing the ambient temperature and relative humidity when the output power deviated from rated conditions. The Ebsilon Professional software was used to model the 153 MW gas-fired power plant output power and thermal efficiency variation with ambient air temperature, as shown in Fig. 4.

Fig. 4.

Topology of azura edo SGT5 – 2000E for off-design conditions.

Power plant performance is affected by changing environmental conditions. The deviations in performances of the power plant that occur are owing to changes in the air properties entering the air compressor, such as relative humidity and temperature. Different ambient air densities and mass flow rates were computed applying Equations (16), (17), respectively, for various ambient air temperatures as expressed by Egware et al. [48].

| (16) |

| (17) |

where TN is the absolute temperature, ρN is the density and ṁN is air mass flow rate for the nominal condition; Ti is the absolute temperature, ρi is the density and ṁi is air mass flow rate for the off-design condition [48].

The net power output, net thermal efficiency, and mass flow rate of CO2 emitted from the GT power plant due to change in ambient air temperature and relative humidity were obtained from Ebsilon simulated model. The carbon dioxide emission from gas turbine power plant is a function of the following parameters which include; ambient air temperature, compressor pressure inlet and outlet pressures, turbine inlet temperature, relative humidity, exhaust gas mass flow rate Saravanamuttoo et al. [22] as shown in Equation (18).

| (18) |

Where , TIT to ambient air temperature ratio, , and compressor pressure ratio, .

The values of the mentioned independent variables obtained from the simulated Ebsilon model was used for the in the regression model.

2.6. Regression model

The regression analysis model was developed to predict the mass flow rate of CO2 emitted from the gas turbine power plant. The ambient air temperature, compressor pressure ratio, relative humidity, turbine inlet temperature and exhaust gas mass flow rate were considered independent variables, while the mass flow rate of CO2 emitted is the dependent variable.

Therefore, to predict the CO2 mass flow rate emitted, the β parameters in Equation. (19) must be evaluated for minimum value of the sum of the square of the differences between the observations Yi and the actual curve [33].

| (19) |

The coefficients βo and that minimize the square of the distance between the curve and the point as expressed in Equations (20), (21) respectively as expressed in Ref. [33].

| (20) |

| (21) |

Equations (22), (23) was used to compute the coefficient of correlation and the standard error obtained [33];

| (22) |

| (23) |

The determination coefficient (R2) was computed by applying Equation (24) [33].

| (24) |

2.7. Evaluation of CO2 emission rate

The mass of carbon dioxide emission rate in terms of kg/kWh and annual mass of carbon dioxide discharged was computed by applying Equations (25), (26) respectively [35,62,63].

| (25) |

| (26) |

where LF = 0.75 and OPT = 8760 h s are load factor and operation time for the 153 MW Power Plant for one year respectively.

3. Results and Discussion

3.1. Model validation and variation of CO2 emission with the operating parameters

In this study, Ebsilon Professional software was deployed to model and simulate the SGT5-2000E model GT power plant. Table 4 shows the validated results for the installation conditions of the SGT5 – 2000E model developed by Ebsilon. Equation (15) was used to calculate the per cent deviation or error between model and design data. This is to confirm that there is consistency between model developed and the installed design data that form the root profile of the model. Thus, the developed model was used to evaluates CO2 emissions, net power output, net heat rate, and net thermal efficiency.

Table 4.

Model validation results for installed data.

| S/N | Parameters | Design | Model | Deviation | %Error |

|---|---|---|---|---|---|

| 1 | Net Power Output (MW) | 153 | 151.645 | 1.355 | 0.885621 |

| 2 | Net Heat Rate(kJ/kWh) | 10,528 | 10,858 | −330 | −3.1345 |

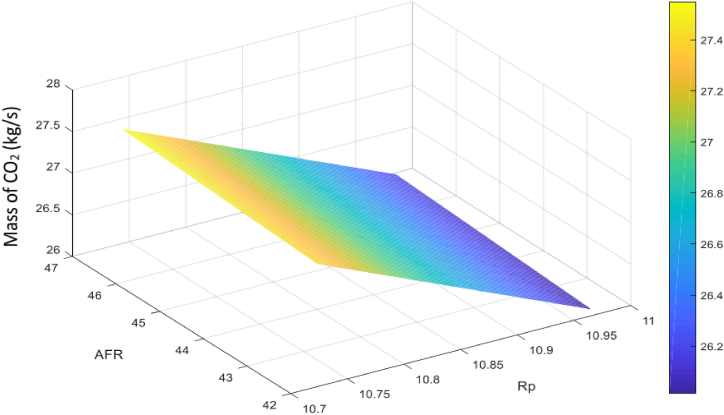

After the validating the model, the off-design conditions were carried out to ascertain the behaviour of CO2 with ambient relative humidity, ambient temperature, compressor pressure ratio, exhaust gas mass flow rate, TIT, net power out and net thermal efficiency of the gas turbine power plant. The off-design condition was also validated to show how the model mimic the actual gas turbine power plant as presented in Fig. 5. The results of carbon dioxide emission variation with ambient temperature and relative humidity; air fuel ratio and compressor pressure ratio are presented in Fig. 6, Fig. 7 respectively.

Fig. 5.

Model Validation for change in Ambient Air Temperature with Net Power Output.

Fig. 6.

Variation of CO2 with ambient air temperature and relative humidity.

Fig. 7.

Variation of CO2 with rp and AFR.

Fig. 5 shows that the model mimics the actual performance of the gas turbine power plant because of the negligible variation observed Also, the average percentage error between the model and the actual net output power was −0.31% for the GT unit. Again, the validation results conform with the outcomes attained by Wallentinen [58] and Miguez Da Rocha [59] who utilized very similar software for their studies. Consequently, the model validation outcomes showed the adequacy and consistency of the developed model. Therefore, the results were used for the thermodynamic evaluation of the model power plant SGT5 – 2000E GT. Therefore, its outcomes were utilized in evaluating the thermodynamic performance for the SGT5 – 2000E GT model power plant.

A sensitivity analysis was performed for the independent variable parameters to examine the output response of the carbon dioxide emission from the gas turbine power plant. Fig. 6 shows the variation of carbon dioxide emissions with ambient relative humidity and ambient air temperature. The plot shows that the relative humidity decreases as the magnitude of CO2 increases, while the reverse is the case of the ambient temperature because it increases as the mass flow rate of carbon dioxide emission increases from the power plant. This is in agreement with results obtained by Teng and Chen [64]. The implication of this observation is that high-magnitude carbon dioxide emissions from gas turbine power have occurred at a high ambient temperature and low relative humidity of the environment. This can be minimized by introducing an air inlet cooling system to reduce the compressor's air inlet temperature and increase its relative humidity. Fig. 7 shows the variation of carbon dioxide emissions with the compressor pressure ratio and air-fuel ratio of the gas turbine power plant. The plot shows that the air-fuel ratio slightly increases and the compressor pressure ratio decreases as CO2 emissions from the power plant increase. It agrees with the statement made by Kruk-Gotzman [65]. This revealed that the gas turbine power plant emitted more carbon dioxide at a low compressor pressure ratio, and the AFR has less effect on the CO2 emission compared to the compressor pressure ratio. This can be improved by operating the gas turbine power plant at a high compressor pressure ratio.

3.2. Regression model

The data obtained from the off-design analysis was used to carry out a regression analysis that will be used to predict carbon dioxide emissions from gas turbine power plants. From the regression analysis, the empirical model for predicting the mass of carbon dioxide emission rate in gas turbine power plant is obtained as follows;

| (27) |

The predictive model obtained as shown in Equation (27) shows a linear relationship with the TIT to ambient temperature ratio, ambient air relative humidity, compressor pressure ratio, and exhaust gas mass flow rate with an R2 value of 0.998. The coefficient of determination (R2) obtained is satisfactory as stated by Ibrahim et al. [32] and Kwasi-Effah et al. [33].

Equation (27) can be used to predict the mass flow rate of carbon dioxide emissions from any related gas turbine power plant for a given ambient air temperature, ambient relative humidity, compressor pressure ratio, and exhaust gas mass flow rate. The model is valid for gas turbines within the range of 20–35 °C in a humid environment. One major advantage of this model is that it encompasses environmental and internal operating parameters in predicting the emission of carbon dioxide from gas turbine power plants.

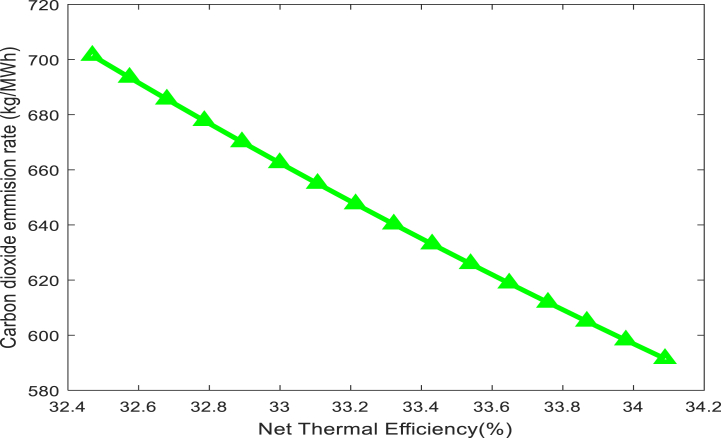

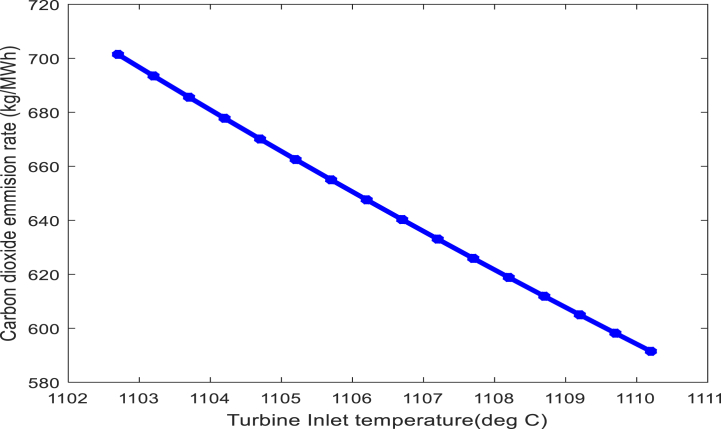

3.3. Carbon dioxide emission rate evaluation

The environmental variables evaluated are CO2 emission in kg/MWh of electricity generated and the mass of CO2 emitted annually for the GT unit. The variation of the CO2 rate emitted in kg/MWh and the mass of CO2 emitted per year with ambient air temperature are presented in Fig. 8, Fig. 9 respectively. Fig. 10 illustrates the variation of CO2 in kg/MWh with net thermal efficiency for the GT unit. Also, the change in turbine inlet temperature with carbon dioxide emission from the gas turbine power plant is presented in Fig. 11. The average results of the CO2 emission in kgCO2/MWh and the annual mass of CO2 emitted obtained from the environmental analysis of the 153 MW Ga Turbine Power Plant unit are presented in Fig. 12.

Fig. 8.

Variation of carbon dioxide emission rate in (kg/MWh) with ambient temperature.

Fig. 9.

Variation of carbon dioxide emitted per year with ambient temperature.

Fig. 10.

Variation of Carbon Dioxide Emission Rate in (kg/MWh) with Net Thermal Efficiency.

Fig. 11.

Variation of Carbon Dioxide Emission Rate in (kg/MWh) with Turbine Inlet Temperature.

Fig. 12.

Average amount of carbon dioxide emission rate for the gas turbine power plant.

As seen in Fig. 8, Fig. 9, the carbon dioxide emission rate in kg/MWh and annual emission increase with ambient air temperature. Thus, at high ambient air temperatures, more CO2 was emitted, so the air intake cooling system will be required to lower the CO2 emission from the 153 MW Ga Power Plant. Fig. 10 is a plot of the CO2 emission rate against net thermal efficiency for the GT unit. It was observed that the CO2 emission rate in kg/kWh decreases as the net thermal efficiency increases. This indicates that improved net thermal efficiency will reduce CO2 emissions by kg/MWh, which agrees with the work of Memon et al. [31] and Steen [37] and. Furthermore, the CO2 emission from the gas turbine power plant reduces as the turbine inlet temperature increases, as shown in Fig. 11. This is in agreement with what was mentioned by Oyedepo et al. [34]; Qi and Huang [66]; Pashchenko et al. [67].

The average emission of CO2 rate for the gas turbine unit varies from 591.50 to 701.46 kg CO2/MWh during the period of this study, as presented in Fig. 12. The power plant average of 644.893 kg CO2/MWh, which is in the range value of 214–720 kgCO2/MWh obtained from various studies as mentioned by Fofrich et al. [39]; Von Wald [68] and Barquín del Rosario [69]. The average value is on the high side of the mentioned range, which means CO2 capture technology will be encouraged to reduce its emission rate. The average mass of CO2 emitted annually as shown in Fig. 12 ranges from 618, 946, 501.58 kg to 649, 208, 301.04 kg with a station average of 634, 066, 000 kg (634.066 kton CO2). Also, the station average is less than the guaranteed value of 726, 000, 000 kgCO2 annually. The results obtained indicate that the 153 MW Ga Turbine Power Plant has a good carbon dioxide emission rate. However, the values obtained are still higher than the International Finance Council (IFC) performance standard recommendation of 100, 000, 000 kg CO2/yr as stated by Azura EIA [56] and Herremans and Tyler [70]. So, there is a need to reduce the quantity of CO2 emissions from the power plant.

This research work has shown that the 153 MW gas power plant's emission can be reduced in two ways. By enhancing the most ineffective components, such as reducing the temperature of the air flowing into the compressor and using the least sufficient flow rate of fuel to ensure its maximum burning. Also, the reduction in the net CO2 emission rate will be achieved by improving the overall plant thermal efficiency. Additionally, the incorporation of inlet air cooling systems will help to maintain a low compressor air inlet temperature and reduce carbon dioxide emission; since low CO2 is emitted at a low ambient air temperature.

4. Conclusion and recommendation

In this study, the carbon dioxide emission model and analysis of the 153 MW gas turbine power plant have been carried out using the data from the power plant. An empirical model for predicting the feasible amount of carbon dioxide emitted from a gas turbine power plant was developed based on ambient temperature, ambient relative humidity, compressor pressure ratio, and the exhaust mass flow rate. The summary of findings from the study are as follows.

-

•

The validation error values of 0.886% and −3.135% for the design and −0.31% for off – design conditions were obtained for the developed gas turbine power plant, which ascertained that the gas turbine model used for the obtained the CO2 emission data was good.

-

•

After validation the sensitivity analysis results obtained shows that rise in ambient air temperature and air fuel ratio led to increase in mass flow rate of CO2 emission, while increase in ambient relative humidity and compressor pressure ratio resulted in reduction of CO2 emission mass flow rate.

-

•

The predictive model developed shows that the mass flow rate of CO2 emitted has a linear relationship with the turbine inlet temperature to ambient air temperature ratio, ambient relative humidity, compressor pressure ratio, and exhaust gas mass flow rate with a coefficient of determination (R2) of 0.998. The value of R2 obtained revealed that the model developed is good.

-

•

The carbon dioxide emission rate in kg/MWh and annual emission increase with ambient air temperature. It was observed that the CO2 emission rate in kg/kWh decreases as the net thermal efficiency increases. The CO2 emission from the gas turbine power plant reduces as the turbine inlet temperature increases. The average emission of CO2 obtained for the gas turbine power plant was 644.893kgCO2/MWh and 634, 066, 348.44kgCO2/yr, of which the latter is within the guaranteed values of 726, 000, 000 kgCO2/yr.

The CO2 emission rates obtained were within the range of the installed data but higher than the IFC standard. The study also showed that the emission of CO2 in kgCO2/MW annually was affected by the ambient air temperature, TIT, and net thermal efficiency. To address the adverse effects of ambient air temperature and relative humidity on carbon dioxide emission, the integration of an air intake cooling system should be encouraged. Further study on carbon capture techniques, can be considered to reduce the carbon dioxide emission from power plants to maintain IFC standards. Also, the model is valid for humid region, consequently, similar study can be recommended for arid and temperate regions. Hence, the model should be recommended in selecting parameters that affect CO2 emission for gas turbine modelling.

Author contribution statement

Henry Okechukwu Egware: Conceived and designed the experiments; Performed the experiments; Contributed reagents, materials, analysis tools or data; Wrote the paper.

Collins Chike Kwasi-EffahConceived designed the experiments; Performed the experiments; Analyzed and interpreted the data; Contributed reagents, materials, analysis tools or data.

Funding statement

This research did not receive any specific grant from funding agencies in the public, commercial, or not-for-profit sectors.

Data availability statement

The data that has been used is confidential.

Declaration of interest's statement

The authors declare no conflict of interest.

Acknowledgment

The authors wish to appreciate the support of the Azura Edo Power Plant and Nigerian Bulk Electricity Trading (NBET) staff for their cooperation. We are indeed grateful to STEAG Energy Services GmbH, Germany for the provision of the Ebsilon Professional Software academic license used in this study.

References

- 1.Li S., Niu L., Yue Q., Zhang T. Trajectory, driving forces, and mitigation potential of energy-related greenhouse gas (GHG) emissions in China's primary aluminum industry. Energy. 2022;239 [Google Scholar]

- 2.Zhu S., Mac Kinnon M., Soukup J., Paradise A., Dabdub D., Samuelsen S. Assessment of the greenhouse gas, Episodic air quality and public health benefits of fuel cell electrification of a major port complex. Atmos. Environ. 2022;275 [Google Scholar]

- 3.United Nations . 2015. Report of the Conference of the Parties on its Twenty-First Session. held in Paris from 30 November to 13 December. (Accessed) [Google Scholar]

- 4.Abdallah L., El-Shennawy T. Evaluation of CO2 emission from Egypt's future power plants. Euro-Mediterranean J. Environ. Integrat.-Mediterranean Journal for Environmental Integration. 2020;5(3):49. doi: 10.1007/s41207-020-00184-w. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 5.Brink C. Wageningen University and Research; 2003. Modelling Cost-Effectiveness of Interrelated Emission Reduction Strategies: the Case of Agriculture in Europe. [Google Scholar]

- 6.Allam R.J., Palmer M.R., Brown G.W., Jr., Fetvedt J., Freed D., Nomoto H., Itoh M., Okita N., Jones C., Jr. High efficiency and low cost of electricity generation from fossil fuels while eliminating atmospheric emissions, including carbon dioxide. Energy Proc. 2013;37:1135–1149. [Google Scholar]

- 7.Carapellucci R., Giordano L., Vaccarelli M. The use of biomass to reduce power derating in combined cycle power plants retrofitted with post-combustion CO2 capture. Energy Convers. Manag. 2016;107:52–59. [Google Scholar]

- 8.Lokhorst A., Wildenborg T. Introduction on CO2 Geological storage-classification of storage options. Oil Gas Sci. Technol. 2005;60(3):513–515. [Google Scholar]

- 9.Yu J., Corripio A.B., Harrison D.P., Copeland R.J. Analysis of the sorbent energy transfer system (SETS) for power generation and CO2 capture. Adv. Environ. Res. 2003;7(2):335–345. [Google Scholar]

- 10.Demirbas A. Hazardous emissions, global climate change and environmental precautions. Energy Sources B Energy Econ. Plann. 2006;1(1):75–84. [Google Scholar]

- 11.IEA . International Energy Agency; 2015. Energy and Climate Change, World Energy Outlook Special Report; pp. 1–200. [Google Scholar]

- 12.Devi A.D., Pushpavanam S., Singh N., Verma J., Kaur M.P., Roy S.C. Enhanced methane yield by photoreduction of CO2 at moderate temperature and pressure using Pt coated, graphene oxide wrapped TiO2 nanotubes. Results Eng. 2022;14 [Google Scholar]

- 13.Yousefi A., Guo H., Dev S., Liko B., Lafrance S. Effect of pre-main-post diesel injection strategy on greenhouse gas and nitrogen oxide emissions of natural gas/diesel dual-fuel engine at high load conditions. Fuel. 2021;302 [Google Scholar]

- 14.Ayaz S.K., Altuntas O., Caliskan H. Enhanced life cycle modelling of a micro gas turbine fuelled with various fuels for sustainable electricity production. Renew. Sustain. Energy Rev. 2021;149 [Google Scholar]

- 15.Kim W., Park C., Bae C. Characterization of combustion process and emissions in a natural gas/diesel dual-fuel compression-ignition engine. Fuel. 2021;291 [Google Scholar]

- 16.Mousavi B., Lopez N.S., Biona J.B., Chiu A.S., Blesl M. Driving forces of Iran's CO2 emissions from energy consumption: an LMDI decomposition approach. Appl. Energy. 2017;206:804–814. [Google Scholar]

- 17.Smith K.A., Ball T., Conen F., Dobbie K.E., Massheder J., Rey A. Exchange of greenhouse gases between soil and atmosphere: interactions of soil physical factors and biological processes. Eur. J. Soil Sci. 2003;54(4):779–791. [Google Scholar]

- 18.Stangeland A. A model for the CO2 capture potential. Int. J. Greenh. Gas Control. 2007 Oct 1;1(4):418–429. [Google Scholar]

- 19.Dey S., Dhal G.C. Materials progress in the control of CO and CO2 emission at ambient conditions: an overview. Mater. Sci. Eng. Technol. 2019;2(3):607–623. [Google Scholar]

- 20.Memon A.G., Memon R.A., Harijan K., Uqaili M.A. Thermo-environmental analysis of an open cycle gas turbine power plant with regression modeling and optimization. J. Energy Inst. 2014;87(2):81–88. [Google Scholar]

- 21.Odunlami O.A., Vershima D.A., Oladimeji T.E., Nkongho S., Ogunlade S.K. Advanced techniques for the capturing and separation of CO2–a review. Results Eng. 2022 [Google Scholar]

- 22.Saravanamuttoo H., Roger G.F.C., Cohen H., Straznicky P.V. sixth ed. Pearson Education Ltd; England: 2009. Gas Turbine Theory. [Google Scholar]

- 23.Mancarella P., Chicco G. Global and local emission impact assessment of distributed cogeneration systems with partial-load models. Appl. Energy. 2009 Oct 1;86(10):2096–2106. [Google Scholar]

- 24.Kazemi H., Bourkheili S.H., Kamkar B., Soltani A., Gharanjic K., Nazari N.M. Estimation of greenhouse gas (GHG) emission and energy use efficiency (EUE) analysis in rainfed canola production (case study: golestan province, Iran) Energy. 2016;116:694–700. [Google Scholar]

- 25.Sousa V., Bogas J.A., Real S., Meireles I. Industrial production of recycled cement: energy consumption and carbon dioxide emission estimation. Environ. Sci. Pollut. Control Ser. 2022 May 26:1–2. doi: 10.1007/s11356-022-20887-7. [DOI] [PubMed] [Google Scholar]

- 26.Qader M.R., Khan S., Kamal M., Usman M., Haseeb M. Forecasting carbon emissions due to electricity power generation in Bahrain. Environ. Sci. Pollut. Control Ser. 2021:1–2. doi: 10.1007/s11356-021-16960-2. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 27.Zhao X., Du D. Forecasting carbon dioxide emissions. J. Environ. Manag. 2015;160:39–44. doi: 10.1016/j.jenvman.2015.06.002. [DOI] [PubMed] [Google Scholar]

- 28.Nassar Y.F., Salem M.A., Iessa K.R., AlShareef I.M., Ali K.A., Fakher M.A. Estimation of CO 2 emission factor for the energy industry sector in Libya: a case study. Environ. Dev. Sustain. 2021:13998–14026. [Google Scholar]

- 29.Wang Y., Yan Q., Li Z., Baležentis T., Zhang Y., Gang L., Streimikiene D. Aggregate carbon intensity of China's thermal electricity generation: the inequality analysis and nested spatial decomposition. J. Clean. Prod. 2020;247 [Google Scholar]

- 30.Wang Q., Song X. Quantified impacts of international trade on the United States' carbon intensity. Environ. Sci. Pollut. Control Ser. 2022;29(22):33075–33094. doi: 10.1007/s11356-021-18315-3. [DOI] [PubMed] [Google Scholar]

- 31.Memon A.G., Harijan K., Uqaili M.A., Memon R.A. Thermo-environmental and economic analysis of simple and regenerative gas turbine cycles with regression modeling and optimization. Energy Convers. Manag. 2013;76:852–864. [Google Scholar]

- 32.Ibrahim T.K., Rahman M.M., Mohammed M.K., Basrawi F. Statistical analysis and optimum performance of the gas turbine power plant. Int. J. Automot. Mech. Eng. 2016;13(1):3215–3225. [Google Scholar]

- 33.Kwasi-Effah C.C., Ighodaro O., Egware H.O., Obanor A.I. A novel empirical model for predicting the heat accumulation of a thermal energy storage medium for solar thermal applications. J. Energy Storage. 2022 Dec 1;56 [Google Scholar]

- 34.Oyedepo S.O., Fagbenle R.O., Adefila S.S., Alam M.M. Thermoeconomic and thermoenvironomic modeling and analysis of selected gas turbine power plants in Nigeria. Energy Sci. Eng. 2015;3(5):423–442. [Google Scholar]

- 35.Kanbur B.B., Xiang L., Dubey S., Choo F.H., Duan F. Thermoeconomic and environmental assessments of a combined cycle for the small scale LNG cold utilization. Appl. Energy. 2017;204:1148–1162. [Google Scholar]

- 36.Karapekmez A., Dincer I. Comparative efficiency and environmental impact assessments of a solar-assisted combined cycle with various fuels. Appl. Therm. Eng. 2020;164 [Google Scholar]

- 37.Steen M. Institute for Advanced Materials, Joint Research Centre; European Commission: 2000. Greenhouse Gas Emissions from Fossil Fuel Fired Power Generation Systems. [Google Scholar]

- 38.Lotfalipour M.R., Falahi M.A., Ashena M. Economic growth, CO2 emissions, and fossil fuels consumption in Iran. Energy. 2010;35(12):5115–5120. [Google Scholar]

- 39.Fofrich R., Tong D., Calvin K., De Boer H.S., Emmerling J., Fricko O., Fujimori S., Luderer G., Rogelj J., Davis S.J. Early retirement of power plants in climate mitigation scenarios. Environ. Res. Lett. 2020 Aug 27;15(9) [Google Scholar]

- 40.Choudhary T., Sahu M.K., Sanjay R., Kumari A., Mohapatra A. SAE Technical Paper; 2018 Apr 3. Thermodynamic Modeling of Blade Cooled Turboprop Engine Integrated to Solid Oxide Fuel Cell: A Concept. [Google Scholar]

- 41.EIA . EIA, DOE; 1999. Analysis of the Climate Change Technology Initiative; p. 68. April 99, SR/OIAF/99-01. [Google Scholar]

- 42.Ibrahim T.K., Mohammed M.K., Al Door W.H., Al-Sammarraie A.T., Basrawi F. Study of the performance of the gas turbine power plants from the simple to complex cycle: a technical review. J. Adv. Res. Fluid Mech. Therm. Sci. 2019;57(2):228–250. [Google Scholar]

- 43.Zhang Y., Liu P., Li Z. Gas turbine off-design behavior modelling and operation windows analysis under different ambient conditions. Energy. 2023;262 [Google Scholar]

- 44.Abubaker A.M., Ahmad A.D., Singh B.B., Akafuah N.K., Saito K. Multi-objective linear-regression-based optimization of a hybrid solar-gas turbine combined cycle with absorption inlet-air cooling unit. Energy Convers. Manag. 2021;240 [Google Scholar]

- 45.Egware H.O., Onochie U.P., Itoje H. Effect of incorporating fogging inlet air cooling system: a case study of Ihovbor Thermal Power Plant, Benin City. Int. J. Ambient Energy. 2022;43(1):2173–2179. [Google Scholar]

- 46.Udeh G.T., Udeh P.O. Comparative thermo-economic analysis of multi-fuel fired gas turbine power plant. Renew. Energy. 2019;133:295–306. [Google Scholar]

- 47.Fu H. Doctoral dissertation, Georgia Institute of Technology); 2019. An Architecture-Based Growth Approach for Industrial Gas Turbine Product Development. [Google Scholar]

- 48.Egware H.O., Obanor A.I., Aniekwu A.N., Omoifo O.I., Ighodaro O.O. Modelling and simulation of the SGT5 – 2000E gas turbine model for power generation. J. Energy Technol. Environ. 2021;3(2):88–107. doi: 10.37933/nipes.e/3.2.2021.10. [DOI] [Google Scholar]

- 49.Egware H.O., Obanor A.I. The investigation of an SGT5-2000E gas turbine power plant performance in Benin City based on energy analysis. Energy Convers. Manag. X. 2022;16 [Google Scholar]

- 50.Edo Azura. 2017. Testing Manual for Azura Edo Power Plant. [Google Scholar]

- 51.Bejan A., Tsatsaronis G., Moran M.J. John Wiley & Sons; 1995 Dec 12. Thermal Design and Optimization. [Google Scholar]

- 52.Eastop T.D., McConkey . fifth ed. Dorling Kindersley; New Delhi, India: 2011. Applied Thermodynamics for Engineering Technologists. 8th Impression) [Google Scholar]

- 53.Kanbur B.B., Xiang L., Dubey S., Choo F.H., Duan F. Thermoeconomic and environmental assessments of a combined cycle for the small scale LNG cold utilization. Appl. Energy. 2017;204:1148–1162. [Google Scholar]

- 54.Egware H.O., Obanor A.I. Energy analysis of omotosho phase I gas thermal power plant. Inter. J. Eng. Technol. Sci. 2013;1(4):206–207. [Google Scholar]

- 55.Egware H., Obanor A., Itoje H. Thermodynamic evaluation of a 42MW gas turbine power plant. Int. J. Eng. Res. Afr. 2014;12:83–94. [Google Scholar]

- 56.Azura Edo Independent Power Project Environmental Impact Assessment. vol. 1. Prepared by Environmental Resources Management; 2013. Final Report January 2013. [Google Scholar]

- 57.Choudhary T. Novel and optimal integration of SOFC-ICGT hybrid cycle: energy analysis and entropy generation minimization. Int. J. Hydrogen Energy. 2017 Jun 8;42(23):15597–15612. [Google Scholar]

- 58.Wallentinsen B.S. NTNU; 2016. Concentrated Solar Power Gas Turbine Hybrid With Thermal Storage. Master's Thesis. [Google Scholar]

- 59.Da Rocha A.M. Fakultät für Maschinenwesen und Betriebswissenschaften, Technische Universität Wien; 2010. Analysis On Solar Retrofit In Combined Cycle Power Plants. Master thesis. [Google Scholar]

- 60.Matjanov E. Gas turbine efficiency enhancement using absorption chiller. Case study for Tashkent CHP. Energy. 2020;192 [Google Scholar]

- 61.Abbaspour H., Ehyaei M.A., Ahmadi A., Panahi M., Abdalisousan A., Mirzohosseini A. Energy, exergy, economic, exergoenvironmental and environmental (5E) analyses of the cogeneration plant to produce electrical power and urea. Energy Convers. Manag. 2021;235 doi: 10.1016/j.enconman.2021.113951. [DOI] [Google Scholar]

- 62.Barzegar Avval H., Ahmadi P., Ghaffarizadeh A.R., Saidi M.H. Thermo‐economic‐environmental multiobjective optimization of a gas turbine power plant with preheater using evolutionary algorithm. Int. J. Energy Res. 2011;35(5):389–403. [Google Scholar]

- 63.Altayib K. University of Ontario Institute of Technology; 2011. Energy, Exergy and Exergoeconomic Analyses of Gas-Turbine Based Systems (Doctoral Dissertation) M.Sc. thesis. [Google Scholar]

- 64.Teng T.P., Chen W.J. A compensation model for an NDIR-based CO2 sensor and its energy implication on demand control ventilation in a hot and humid climate. Energy Build. 2023 Feb 15;281 doi: 10.1016/j.enbuild.2022.112738. [DOI] [Google Scholar]

- 65.Kruk-Gotzman S., Ziółkowski P., Iliev I., Negreanu G.P., Badur J. Techno-economic evaluation of combined cycle gas turbine and a diabatic compressed air energy storage integration concept. Energy. 2023 Mar 1;266 [Google Scholar]

- 66.Qi Y., Huang D. Energy and exergy analysis of supercritical/transcritical CO2 cycles for water injected hydrogen gas turbine. Energy. 2022 Dec 1;260 [Google Scholar]

- 67.Qi Y., Huang D. Energy and exergy analysis of supercritical/transcritical CO2 cycles for water injected hydrogen gas turbine. Energy. 2022 Dec 1;260 [Google Scholar]

- 68.Von Wald G. Stanford University; 2021. Investigations in Emissions-Constrained, Integrated Gas-Electric Energy Systems. [Google Scholar]

- 69.Barquín del Rosario S. Faculty of Engineering and Sustainable Development, University of Gävle; 2022. The Future of Geothermal Energy in Europe. [Google Scholar]

- 70.Herremans I.M., Tyler M.E. 2018. Climate Change Policy as a Catalyst for Sustainable Energy Practice: Examples from Mainland Ecuador and the Galapagos. Sustainable Energy Mix in Fragile Environments: Frameworks and Perspectives; pp. 33–47. [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.

Data Availability Statement

The data that has been used is confidential.