Abstract

Biomimetic materials have emerged as attractive and competitive alternatives for tissue engineering (TE) and regenerative medicine. In contrast to conventional biomaterials or synthetic materials, biomimetic scaffolds based on natural biomaterial can offer cells a broad spectrum of biochemical and biophysical cues that mimic the in vivo extracellular matrix (ECM). Additionally, such materials have mechanical adaptability, microstructure interconnectivity, and inherent bioactivity, making them ideal for the design of living implants for specific applications in TE and regenerative medicine. This paper provides an overview for recent progress of biomimetic natural biomaterials (BNBMs), including advances in their preparation, functionality, potential applications and future challenges. We highlight recent advances in the fabrication of BNBMs and outline general strategies for functionalizing and tailoring the BNBMs with various biological and physicochemical characteristics of native ECM. Moreover, we offer an overview of recent key advances in the functionalization and applications of versatile BNBMs for TE applications. Finally, we conclude by offering our perspective on open challenges and future developments in this rapidly-evolving field.

Keywords: Biomimic, Scaffold, Biosynthesis, Natural biomaterial, Tissue engineering

Background

Tissue engineering (TE) aims to restore, preserve, or enhance the structure and function of defective tissues or organs by integrating biological cues and bioscaffold strategies [1–3]. Bioscaffolds provide a niche for cells by imitating the composition, structure and properties of the in vivo extracellular matrix (ECM) and offer cells a broad spectrum of biological and physicochemical cues. The ECM acts as a biomass network that combines softness, toughness and elasticity to provide mechanical support and structural integrity to tissues and organs. It is mainly composed of a polysaccharide matrix with a variety of embedded proteins, such as collagen, elastin, and fibronectin. The ECM’s three-dimensional (3D) hierarchical microstructure and electromechanical nature play an essential role in its transport properties, cellular communication, mechanotransduction, and growth factor signaling by interacting with cell surface receptors, as well as binding growth factors and other signaling molecules.

Natural biomaterials derived from renewable resources, such as plants, animals and microorganisms, exhibit a large diversity of unique yet complex constituents, microstructures, and physiological properties. Such materials offer a biological support suitable for cell attachment and growth with a diverse set of functions in their native setting [2, 4]. Thus, natural biomaterials, when repopulated with autologous or genetically engineered cells, can serve as the ideal template for the design of living implants for specific applications in TE and regenerative medicine. Consequently, they are a good choice for biomimetic TE scaffolds due to their shape and mechanical adaptability, microstructure interconnectivity and inherent bioactivity, which mimics the native ECM. In addition, these biomimetic natural biomaterials (BNBMs) possess well-defined molecular structures and plentiful active sites enabling further functional modification and/or anchoring with other materials, enabling the preparation of an overwhelming variety of customized products with desirable properties and fine-tuned functions.

However, natural materials face several limitations, such as batch variability, rapid degradation, weak mechanical properties and limited processability, which slow their clinical translation. To mimic the natural ECM, BNBMs-based scaffolds can be tailored to provide superior physicochemical, mechanical and biological properties, thus supporting cell infiltration, adhesion, differentiation, as well as the transport of oxygen and nutrients.

This review provides an overview of the recent progress in the application of BNBMs for TE, including advances in their preparation, functionality, potential applications and future challenges. Several excellent reviews have been published on biomimetic materials [1–3] or natural biomaterials [4–6], but this is a rapidly-emerging field, and new summaries are always in demand. In addition, past reviews have not focused on the biomimetic strategies from the perspective of composition, structure, and performance. By contrast, the present review provides an inclusive outline of the up-to-date BNBMs for TE. In the remainder of this review, we provide a brief introduction of various BNBMs and highlight recent advances in their fabrication. Then we discuss how controllable alteration of BNBMs with a variety of substantial ECM-mimicking properties, such as electrical activity, biomechanical adaptiveness, or stimulus responsiveness, can be developed and employed to endow natural biomaterials with additional possibilities, leading to further therapeutic effects. Additionally, we review the methodologies used to create various functional natural biomaterials, with a specific emphasis on biomimetic approaches and microstructural hydrogels for cell orientation. Finally, we outline the functionalization of BNBMs for TE applications. We conclude the review with an outlook on the application of BNBMs in TE.

Biosynthesis and engineering of natural biomaterials

BNBMs are used extensively in TE due to their nontoxicity, non-genotoxicity and non-teratogenicity to native healthy tissue, and excellent bioactivity including promotion of cell proliferation, adhesion, migration and mediation of cell differentiation. The main BNBMs used in TE and regenerative medicine include 1) biopolyesters such as polylactic acid (PLA), polyhydroxyalkanoates (PHAs) and their derivatives, 2) polysaccharides such as hyaluronic acid (HA), alginate, cellulose and chitosan, as well as 3) polypeptides and proteins such as collagen, gelatin, fibroin, poly-glutamic acids (PGA) and antimicrobial peptides (AMPs). The molecular structures of these representative BNBMs are shown in Fig. 1.

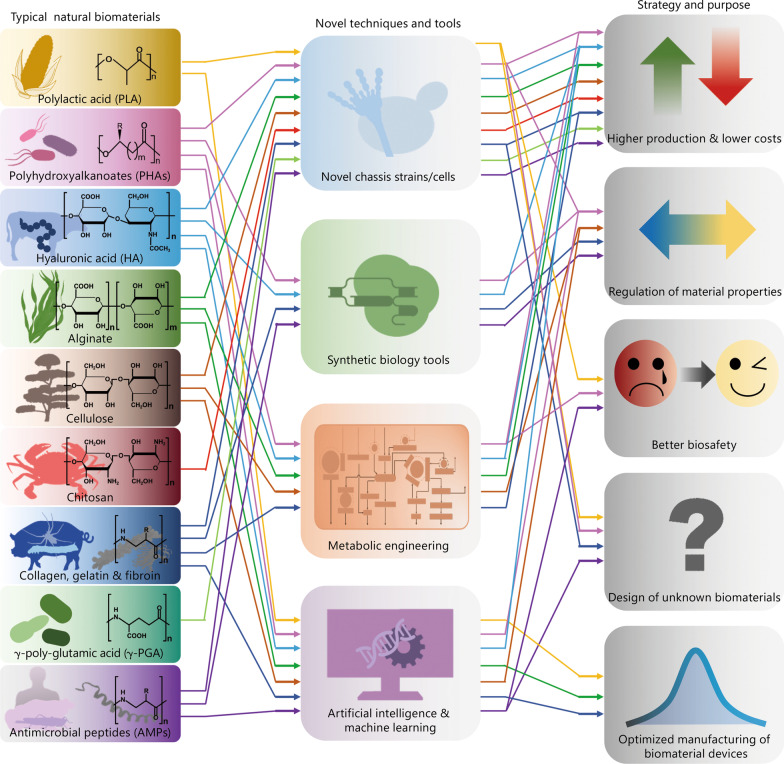

Fig. 1.

Correlation diagram of multiple strategies and purposes of natural biomaterials for tissue engineering (TE) and regenerative medicine based on novel techniques and tools in recent years. Typical natural biomaterials include biopolyesters of polylactic acid (PLA), polyhydroxyalkanoates (PHAs) and their derivatives (e.g., PLGA, PHA-PLA); polysaccharides of hyaluronic acid (HA), alginate, cellulose and chitosan, proteins and poly (amino acid)s of collagen, gelatin, fibroin, γ-poly-glutamic acid (γ-PGA) and antimicrobial peptides (AMPs), respectively. Novel techniques and tools contain novel chassis strains/cells for biosynthesis, synthetic biology tools, metabolic engineering, artificial intelligence and machine learning, respectively. The strategies for optimized natural biomaterials are higher production and lower costs, regulation of material properties, better biosafety, design of unknown biomaterials, and optimized manufacturing of biomaterial devices, respectively. PLGA poly (lactic-co-glycolic acid), PHA-PLA polyhydroxyalkanoate-polylactic acid

Biopolyesters based BNBMs

PLA is a highly versatile, biodegradable and biocompatible aliphatic polyester. PLA is one of the most widely used biopolyesters and is often applied for the repair of various tissues or deployed for drug delivery. Pure PLA is generally obtained via chemical ring-opening polymerization of lactide, which in turn is commonly derived from lactic acid (LA) produce through microbial fermentation or extraction of materials with high sugar content (such as molasses, whey, bagasse or potato and other cellulose and starch-containing materials) [7, 8]. To regulate the rapid degradation of LA and avoid inflammation due to acidification, glycolide was introduced into PLA to form poly (lactic-co-glycolic acid) (PLGA). Studies have shown that a higher ratio of glycolide units resulted in a more hydrophilic polymer with increased degradation rates [9–11]. In addition, PLA (or its derivatives with a higher molecular weight) showed greater mechanical strength and slower degradation, making them excellent candidates for hard tissue repair, such as 3D printed TE scaffolds for bone and spinal injury [12, 13]. Interestingly, they have also been prepared as fibers for the repair of skin and other soft tissues, as well as microspheres for minimally invasive treatment [14, 15].

Different from PLA and its derivatives, PHAs, another bio-polyester with similar chemical structure (Fig. 1), can only be biosynthesized by microorganisms, including natural and engineered bacteria [16, 17]. Due to their excellent biodegradability, biocompatibility, non-teratogenicity and non-carcinogenicity, various PHAs have been incorporated into a series of biomedical devices for tissue repair and drug delivery. For example, some PHAs have been developed into injectable stem cell carriers [18], 3D in vitro cell culture carriers [19] bone TE scaffolds, nano-carriers for anti-osteoporosis therapy in microgravity [20], as well as for directional bone induction [21], immunoregulation [22] and bionic COVID-19 vaccines [23]. The multiple structures and compositions of PHAs result in a range of mechanical properties and biodegradation rates, as well as PLA with relatively uniform characteristics, which can be adapted to the mechanical and biochemical microenvironments of different tissues. In contrast to faster LA (pKa = 3.86) release from PLA or PLGA, PHAs generally have slow biodegradation and release moderately acidic biodegradable monomers and oligomers of 3-hydroxybutyrate (3HB, pKa = 4.41). Notably, 3HB is a natural metabolite that is present in human blood at concentrations of 0.03–0.1 mg/ml and exhibits a mild irritant effect that diminishes acid load, thereby reducing cellular and tissue reactions resulting in limited local inflammation.

Polysaccharides based BNBMs

HA is a non-sulfated glycosaminoglycan and a highly hydrated polyanionic macromolecule, which is an essential component of the ECM and mediates its function in tissue repair, signaling, and morphogenesis [24]. Due to the hydrophilic properties of this highly negatively charged polysaccharide, HA can imbibe water to achieve considerable mechanical robustness. As an essential component of the endogenous or synthetic ECM, HA has been proven to be effective at inducing cellular proliferation [25, 26]. In contrast to animal tissue, which has potential pathogenicity and limited sources, HA is easily synthesized on a large scale using various engineered bacteria such as Lactococcus lactis [27], Pichia pastoris [28] and Streptococcus [29], which avoided the residue of pathogens in animals. As a consequence, HA-related products have been widely applied in the pharmaceutical, cosmetic and food industries [30–33].

Alginate, composed of β-D-mannuronic and α-L-guluronic acid residues, is mainly found in brown seaweed and has been included in the U.S. Pharmacopoeia since 1938 [34, 35]. In addition to the food industry, alginates are currently used in TE due to their excellent hydrophilicity, biosafety and inexpensiveness [36–38]. Alginate scaffolds can provide a long-term cell culture support [39] and flat alginate fibers with grooves support myoblast attachment and spreading [40, 41]. Biosynthesis of bacterial alginates using Pseudomonas aeruginosa (P. aeruginosa) or other microbes is possible, but commercially available alginates are currently derived only from algae [42].

Cellulose is a linear polysaccharide consisting of a chain of several hundred to many thousands of (1 → 4)-β-glucopyranose units, with cellobiose as the dimeric repeating unit [43]. As an important structural component of green plants [44, 45] and some microorganisms [46], it is the most abundant biomaterial on earth. Cellulose is odorless, hydrophilic, biodegradable, biocompatible, and insoluble in water and most organic solvents. The amorphous parts of cellulose are biodegradable in the human body and can be used to regulate the degradation rate of TE scaffolds. In addition, bacterial cellulose (BC) has high water retention and elasticity. It has been approved by the Food and Drug Administration for the clinical usage in wound dressings with incomplete degradation [47]. In contrast to cellulose derived from plant and bacteria, cellulose of animal origin (such as sea squirt cellulose) is more attractive due to its molecular weight, mechanical properties, water holding capacity, water and air permeability and thermal stability [48].

Chitosan is an analogous structure of glycosaminoglycan prepared by partial deacetylation of chitin [49]. Chitosan contains positive charges (zeta potentials of + 20– + 40 mV) and shows potential antibacterial ability, cell adhesion activity and low toxicity. Pure chitosan has been fabricated into nanoparticles, films, sponges, fibers, scaffolds and hydrogels, all of which are commonly used for tissue regeneration and construction [50, 51]. Chitosan-based nano-carriers have been developed for drug delivery in cancer therapy [52, 53]. The introduction of chitosan into a biopolymeric scaffold (i.e., PLA/chitosan scaffolds) results in improved mechanical and biological functionality [54]. On the other hand, chitosan provides better stability, mechanical strength, and biocompatibility in diverse composite scaffolds of proteins or keratin [41, 55, 56].

Polypeptides and proteins based BNBMs

Collagen consists of a triple helical region composed of three polypeptide strands and two non-helical regions at both ends of the helix [57, 58]. It can be extracted on a large scale from diverse animal by-products such as cattle hides and pigskin. In addition to extraction from animal tissues, a recombinant production system based on yeast has been recently explored [59–62]. Some monodisperse gelatin-like polymers have also been obtained from recombinant protein biosynthesis systems based on engineered microorganisms. Gelatin is another combination of heterogeneous, animal-derived peptides that have a net charge based on environmental pH and gelatin type [59]. Fibroin, which mainly contains repeating amino acid sequences of Gly-Ala-Gly-Ala-Gly-Ser and Gly-Ala-Gly-Ala-Gly-Tyr [60], is also an extensively studied insoluble protein present in silk from silkworms and spiders [61]. A variety of collagen, gelatin and fibroin devices have been developed and applied in medical, pharmaceutical and cosmetics applications for more than a century [62].γ-poly-glutamic acid (γ-PGA) is an anionic polypeptide that has been applied in medicine due to its good water-solubility, biocompatibility, biodegradability and edible properties [63, 64]. Production of γ-PGA relies almost entirely on Bacillus species, but the high cost of microbial fermentation processes limits its widespread application in the industry. Recently, several approaches have been exploited to improve the fermentation processes, including novel wildtype strains, recombinant strains, as well as optimization of the culture media and fermentation conditions [65]. For example, we reported a metabolically engineered Corynebacterium glutamicum (C. glutamicum), which was capable of producing up to 11.4 g/L of γ-PGA from glucose [66]. Thus, the production cost of γ-PGA is greatly reduced, which provides the possibility of its wide application.

AMPs are a class of active oligopeptides with positive charges and amphiphilic structures [67] that have broad-spectrum activity against bacteria, fungi, viruses and parasites, and influence the host immune responses [68, 69]. Natural AMPs are found in microorganisms, plants, invertebrates, fish, amphibians, reptiles, birds and mammals [70]. However, most AMPs are currently biosynthesized for AMP-BioDesign 1.0 by relying on engineered microbial chassis cells [71]. AMPs can increase the permeability of the cell membrane and then destroy its homeostasis, resulting in the cell lysis of targeted pathogens. Some AMPs are transported without damaging the cell membrane and interfere with important targets inside the cell [71].

BNBMs by novel biosynthesis methods

The properties of BNBMs are difficult to alter because the natural biosynthetic mechanisms are difficult to elucidate, imitate, or adjust. With the development of new technologies, such as novel chassis strains/cells for biosynthesis, synthetic biology, metabolic engineering, artificial intelligence (AI) and machine learning (ML), the large-scale production of BNBMs with a lower cost, tunable properties and better biosafety can be realized by reprogramming in natural or engineered biosynthesis and should also enable the design of novel previously unknown materials by combining desired domains in vivo and with natural templates.

Novel chassis strains/cells for BNBMs

Common model microbial chassis cells include Saccharomyces cerevisiae (S. cerevisiae), Escherichia coli (E. coli), Bacillus subtilis (B. subtilis) and Corynebacterium glutamicum (C. glutamate), which have been used to biosynthesize LA (i.e., PLA precursor), PHAs, HA, alginate, cellulose, chitosan collagen, fibroin, γ-PGA and AMPs. The synthesis of these biomaterials by microorganisms avoids the problems of traditional extraction from animal tissues, such as pathogens clearance. Using genetic tools, some non-model microorganisms have been employed as novel chassis strains/cells to produce BNBMs. For example, Halomonas bluephagenesis (H. bluephagenesis), a novel halophilic chassis strain, can achieve continuous PHA synthesis under non-sterile conditions at high salt concentrations [72]. PHA [73] and HA [74] were both produced using in engineered C. glutamicum, an organism free of exotoxins and endotoxins. PLA also can be produced by engineered bacteria [75], which has led to its extensive medical use.

Moreover, Chlamydomonas reinhardtii (C. reinhardtii) is a new single-celled green alga with a short growth cycle, which often exhibits more stable protein expression for AMPs [71]. Most cellulose has been produced in Acetobacteraceae, Gluconacetobacter and Komagataeibacter [76]. In recent years, biosynthetic silk protein has been obtained using several model organisms such as E. coli [77], B. subtilis [78], S. cerevisiae [79] and Chinese hamster ovary cells [80].

Synthetic biology tools for BNBMs

Synthetic biology is a novel interdisciplinary field involving mathematics and systems biology that has been utilized to design new biological parts and biosystems to improve the properties of microorganisms and their products [71]. Various bio-tools, such as clustered regularly interspaced short palindromic repeats (CRISPR)—CRISPR associated protein 9 (CRISPR-Cas9), optimization of ribosomal binding sites and novel genetic elements have been introduced in recent years. These bio-tools can promote the biosynthesis of various natural biomaterials, reduce the cost, and adjust their physical properties.

The CRISPR-Cas9 tools, especially the CRISPRi systems, have been used successfully to control the biosynthetic flux of the PHA pathway and adjust the molecular weights and composition of the products. By simultaneously manipulating multiple genes in E. coli via CRISPRi, expressions of the prpC gene encoding 2-methylcitrate synthase can be changed to regulate the 3-hydroxyvalerate content in P(3-hydroxybutyrate-co-3-hydroxyvalerate) (PHBV) copolymers from less than 1 to 13% [81] and generate P34HB with 1.4 to 18.4 mol% of 4HB [82]. Similarly, the molecular weight of HA was increased by decreasing the expression of FtsZ (initiating cell division) and changing the distribution of cardiolipin in the membrane of Bacillus subtilis [83]. The CRISPR-Cas9-initiated fixed-point strategy was employed to successfully incorporate spider silk protein genes into the Bombyx mori genome, resulting in fibers that are as strong as native spider silk, with a high tensile strength of 1.2 GPa [84].

Using the CRISPR-Cas9 system, the function of endogenous genes was disrupted in BM-N cells with a mutation frequency of 30 – 40%. Similarly, zinc-finger nucleases have been used to insert the human lysozyme gene into the bovine β-casein locus, leading to human lysozyme knock-in in approximately 1% of the treated bovine fetal fibroblasts. The milk secreted by the resulting transgenic cows could kill Staphylococcus aureus (S. aureus) [85]. The cell-free biosynthesis system is an efficient way to produce rare, easily degradable or toxic AMPs, such as cecropin P1 with 31 amino acid residues and human beta-defensin 2 (hBD-2) [86].

The optimization of ribosomal binding sites increased PHB accumulation to 92% of cell dry weight [87] and achieved a high HA yield of 8.3 g/L [88]. Novel T7-like RNA polymerase-promoter pairs were designed to overexpress the PHB operon and cell-elongation cassette (i.e., minCD) under isopropyl-β-D-thiogalactopyranoside induction, resulting in an increase of PHB accumulation and cell lengths in H. bluephagenesis [89]. Furthermore, recombinant collagens (rCols) produced using synthetic biology techniques have attracted increasing attention, since the structure of collagen can be modified with functional protein fragments [90].

Metabolic engineering for BNBMs

Metabolic engineering is also a relatively new and interdisciplinary field that draws from metabolic flux optimization, outer membrane permeabilization, cell morphology engineering, and chromosomal integration to manipulate microorganisms to more efficiently produce natural biomaterials at low costs.

PHA-accumulation can be increased in engineered microorganisms via oxygen limitation with alcohol dehydrogenase (PadhE) [91], prevention of succinate semialdehyde loss by gabD-knocking out [92], intercepting the 2-methyl-malonyl-CoA to 2-methylcitrate cycle (MCC) [93, 94], overexpression of NADH (or NADPH) synthesis enzymes (e.g., UdhA) [92, 93], weakening the beta-oxidation cycle by fadA B-knockout [92], chromosomal integration of PHA synthetase [93, 95], inhibition of fission ring protein FtsZ or weakening of cell skeleton protein MreB [96], and OM-defective halophilic H. bluephagenesis strains with a low endotoxin content for better biosafety [97]. Similarly, a strong oxygen supply can both influence metabolic fluxes toward PHB and alginate synthesis in Azotobacter vinelandii (A. vinelandii) cells due to alginate acetylation [98]. Optimized carbon/nitrogen molar ratios in both the batch and feeding media for E. coli BL21 resulted in the highest dry-cell density (67.2 g/L dry cell weight) and human-like collagen production (10.8 g/L) [99]. Notably, BC from the glycerol medium showed the highest tensile strength at 83.5 MPa, with thinner fibers and lower porosity, compared with BC from glucose and fructose medium. These findings illustrate that some biomaterial properties can be regulated using different carbon sources [100].

Furthermore, due to weak promoter substitution or plasmid overexpression, DivIVA and FtsZ genes were regulated for HA synthesis in C. glutamicum, which generated different shapes including small-ellipsoid-like (DivIVA-reduced), bulb-like (DivIVA-enhanced), long-rod (FtsZ-reduced) and dumbbell-like (FtsZ-enhanced) cells [101].

AI and ML

A variety of prediction algorithms based on AI and ML can be established to analyze and learn the patterns of natural biomaterials, after which the algorithm can be used to find relevant characteristics and rules. Eventually, a combination of AI and ML may lead to the prediction and accurate design of completely novel, previously unknown functional biomaterials with a variety of TE applications. The N-terminal residues of known AMPs were used to predict new AMPs via neural network, quantitative matrices and support vector machine learning, which showed accuracies of 88.17%, 90.37% and 92.11%, respectively [102]. Using quantitative structural-activity relationships, initial high-throughput measurements of over 1400 random peptides in artificial neural network models were conducted and subsequently used to screen an in-silico library of approximately 100,000 peptides [103].

Another future utilization of AI may be to predict important factors for metabolic engineering, such as expression of multiple genes in a pathway [104], plasmid architecture [105], as well as the simplification of protein engineering [106] and pathway design [107], which improves the accuracy and fidelity of target product synthesis [108].

As AI and ML technology advances, the characteristics of biomaterials blends, composites, or novel materials could be predicted and categorized by AI and ML [109–111]. For example, ML predicted the glass transition temperature of PHA-based polymeric materials and the location of PHA-accumulating bacteria in a mixed microbial culture. Similarly, the tensile strength of PLA fused deposition models was accurately estimated by an artificial neural network [112]. Enzymatic kinetics of cellulose hydrolysis in a heterogeneous system have been described by an artificial network and compared using response surface methodology [113] (Table 1).

Table 1.

Synthesis strategy, methods and results of natural biomaterials based on novel techniques and tools

| Strategies | Natural biomaterials | Methods, the involved strains or cells, and results | References |

|---|---|---|---|

| Novel chassis strains/cells | γ-PGA | Produced in engineering bacteria for high production | [66] |

| AMPs | Produced in C. reinhardtii for stable expression of AMPs | [71] | |

| PLA & PLGA | Produced in engineered E. coli | [72] | |

| PHAs | Produced in H. bluephagenesis under high salt concentration and non-sterile conditions | [72] | |

| PHAs | Produced in engineered C. glutamicum for PHAs with free exotoxins and endotoxins | [73] | |

| HA | Produced in engineered C. glutamicum for HA with free exotoxins and endotoxins | [73] | |

| Alginate | Produced in engineering bacteria for high production | [96] | |

| Cellulose | Produced in Acetobacteraceae, Gluconacetobacter and Komagataeibacter for a large proportion of cellulose | [76] | |

| Collagen | Produced in engineering bacteria for high production | [99] | |

| Fibroin | Produced in engineered B. subtilis, S. cerevisiae and Chinese hamster ovary cells | [78–80] | |

| Synthetic biology tools | PHAs | Manipulated the PHA synthesis-related genes via CRISPR-Cas9 | [94] |

| Increased the production of PHB via optimization of ribosomal binding site | [87] | ||

| HA | Increased the production of HA via optimization of ribosomal binding site | [88] | |

| Fibroin | Incorporated spider silk protein genes into the Bombyx mori genome via CRISPR-Cas9 | [84] | |

| AMPs | Inserted hLYZ gene into the bovine β-casein locus via zinc finger nucleases | [85] | |

| AMPs | Produced cecropin P1 with 31 amino acid residues and hBD-2 in cell-free biosynthesis system | [86] | |

| Metabolic engineering | PHAs | Increased the production of PHA via PadhE, GabD, MCC, UdhA, FadA, FadB, FtsZ and MreB | [91–94, 96] |

| HA | Regulated HA via genes DivIVA and FtsZ down or up | [101] | |

| Collagen | Increased the production of human-like collagen via optimization of carbon/nitrogen molar ratios | [99] | |

| Alginate | Metabolic flux analysis shows higher production of alginate acetylation in the cultures with limited oxygen | [98] | |

| Cellulose | Biomaterial properties of bacterial cellulose can be regulated through metabolic flux | [100] | |

| AI & ML | AMPs | Predicted new AMPs via neural network | [102] |

| HA | Predicted multiple genes expression in a pathway of HA based on AI | [108] | |

| HA | Simplified pathway design of HA via AI | [108] | |

| PHAs | Predicted the Tg of PHAs via recurrent neural network | [108, 109] | |

| Cellulose | Predicted the location of PHA-accumulating bacteria in a mixed microbial culture by recurrent neural network | [111] | |

| Collagen | Deduced the tensile strength of PLA fused deposition models by Taguchi L9 orthogonal array | [108] | |

| Cellulose | Enzymatic kinetics of cellulose synthesis was described by artificial neural networks | [113] |

PLA Polylactic acid, PLGA Poly (lactic-co-glycolic acid), E. coli Escherichia coli, PHAs Polyhydroxyalkanoate, PHB Polyhydroxybutyrate, HA Hyaluronic acid, γ-PGA Gamma-poly-glutamic acid, AMPs Antimicrobial peptides, hLYZ Human lysozyme, hBD-2 Human beta-defensin 2, Tg Glass Transition temperature, AI Artificial intelligence, ML Machine learning, H. bluephagenesis Halomonas bluephagenesis, C. glutamicum Corynebacterium glutamicum, CRISPR-Cas9 Clustered regularly interspaced short palindromic repeats—CRISPR associated protein 9, adhE Alcohol dehydrogenase, GabD Succinate-semialdehyde dehydrogenase, MCC 2-Methylcitrate cycle, UdhA Pyridine nucleotide transhydrogenase, FadA Acetyl-CoA C-acyltransferase, FadB Fatty acid oxidation complex subunit alpha, FtsZ Cell division protein, MreB Rod shape-determining protein

In addition, AI and ML have been used to help optimize the manufacturing of medical devices by optimizing numerous prilling process variables. AI and ML have been deployed in the fabrication of alginate core-shell beads of sunflower oil [114], PLGA microparticles produced by diverse microfluidic systems either in the form of single or multiple particles [115], as well as the classification and selection of fish gelatin packaging films produced with palm oil and plant essential oils [116].

Rational design and preparation of BNBMs enabling with ECM featured properties

Ideal TE scaffolds offer an ECM-mimetic environment for cell growth and tissue repair. Therefore, properties of the ECM, such as electro-conductivity, tissue-adaptive biomechanical properties, interfacial properties, stimulus responsiveness, mechano-electric coupling capacity, and so on, should be considered in the rational design process. As shown in Fig. 2, the development of BNBMs that mimic various biological and physicochemical characteristics of the natural ECM may have additional functionalities and enhanced therapeutic effects. Here, we summarized the design principles and preparation strategies of BNBMs with that mimic ECM features.

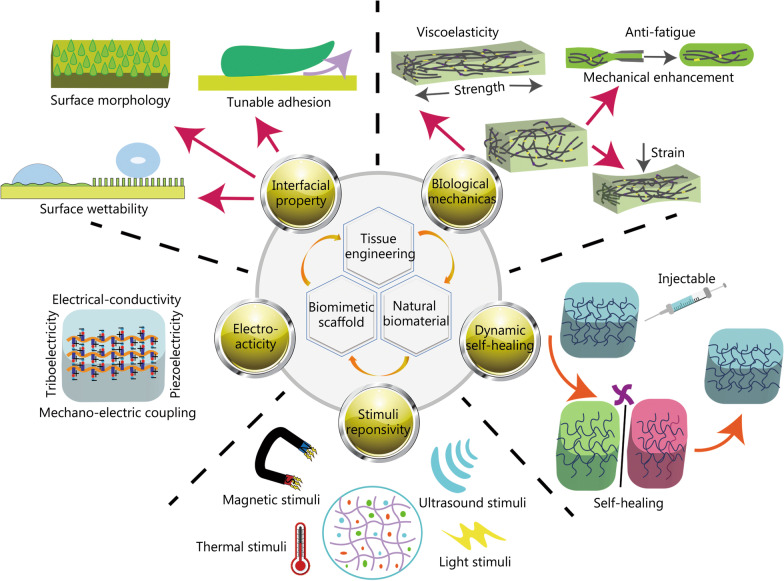

Fig. 2.

Schematically showing the rational design and preparation of biomimetic natural biomaterials (BNBMs) enabling with featured properties mimicking the tissue extracellular matrix (ECM)

Biomimetic design of electroactive BNBMs

Electroconductivity is one of the most essential features for normal electrophysiological activities and functions. As a consequence, to improve the electrical conductivity or electro-activity of BNBMs are crucial for mimicking the conductive coupling and electrostimulation of the native ECM [117]. The development of biocompatible and electroconductive BNBMs has been proposed to enhance the growth of electrical-active cardiac, neural, and musculoskeletal cells [117, 118]. One main challenge in matching scaffold conductance to that of local tissue is that most scaffolds use high-conductivity materials that are not biocompatible at high concentrations and can induce cell apoptosis or immune rejection [119]. Researchers have utilized conducting polymers (e.g., polyaniline and polypyrrole [120, 121]), nano-metallic wires, rods or dots [122], and carbon-based materials (such as carbon nanotubes [123], graphene [119]) to enhance the electrical conductivity of natural materials. Some of these materials have been successfully applied in experimental animal models and exhibited excellent biocompatibility. Very recently, Wang et al. [123] developed a novel conductive injectable hydrogel as functional cardiac patches to repair infarcted myocardium in rats and minipigs. These brand-new electroactive BNBMs based on elastin and carbon nanotubes are proposed to reconstruct electroconductive coupling, restore the electrophysiology of infarcted myocardium and promote cell proliferation [124]. The potential of BNBMs with enhanced electrical conductivity in TE and regenerative medicine is strengthened, and it is expected to enable better therapeutic performance for various bioapplications.

The mechano-electrical coupling (MEC) property is another electroactive feature by which an acute electrical feedback can be generated by the local mechanical environment and cellular electrophysiology through mechanosensitive subcellular components. Systems with MEC electroactive capacity can convert external mechanical energy into internal electric energy for the living organisms through a tissue-specific energy dissipation mechanism. Thus, the MEC property is an important functional characteristic for both biomechanical and biophysical behaviors of living systems. Enabling MEC properties in tissue scaffolds is of particular interest in organs necessitating biological MEC, such as the heart, bone, periodontium, and nervous tissues. In the case of cardiac tissue, normal heart rhythm requires the coordinated activity of numerous cardiac cells, with their rapid response and harmonious adaptation to changes in electrophysiological demands [124]. A key element in the turn-by-turn control and restoration of cardiac function is the restructuring of the electro-conductive coupling microenvironment and recovery of the electromechanical self-regulating mechanism [125].

Furthermore, the BNBMs with piezoelectric features can enable the integrated design of in vivo diagnostic and treatment tools, which opens a new field of research in BNBMs. Natural piezoelectric materials mainly include bone, wood, collagen, and spider silk [126–133], which not only have good biocompatibility, but also can be used for biosensing and biological power generation after modification [134–136], to achieve local motor/electrical coupling and maintain electrophysiological balance [137, 138]. Research has shown that many unmet healthcare needs, including biosensing, health monitoring, and repair of myocardial infarction, stand to benefit from expanding the fabrication and understanding of piezoelectric BNBMs.

In addition, the triboelectric effect, originating the bioelectricity through mechanical friction between two moving objects also endow the electroactive capacity of BNBMs [139, 140]. During the process of sliding, opposite charges are generated on the interface of the sliding materials. Charge accumulation and generation varies based on the composition and structure of the materials in motion, the surface area in contact, and the force applied during motion [141]. Researchers developed a series of composite triboelectric devices using natural biological materials with good cytocompatibility, such as cellulose [142], polyvinyl alcohol (PVA)/Ag [143], and spider silk/PVDF [144]. Moreover, since the charge generation phenomenon occurs mainly on the nanoscale, many triboelectric materials can be fabricated into various micro and nanoscale wearable devices to construct self-powered systems. Among these, the triboelectric nanogenerators are the most famous example of energy harvesting based on the triboelectric effect [141, 142]. These triboelectric materials and devices have enormous potential for human–machine interactions, health monitoring, peripheral nerve restoration, smart wearables and other medical applications [143, 144].

Design of BNBMs with suitable biomechanics

Substantial studies over the past 20 years have established that the mechanical properties of the ECM affect cellular proliferation, growth, migration, differentiation and other behaviors. A successfully designed for BNBMs thus has to fit the mechanical requirements of the implant location and their cellular microenvironment. Through the intensive study of the mechanical characteristics of native ECM in different tissues, researchers gradually began to explore the biomimetic biomechanical design of BNBMs in terms of cytocompatibility, proliferation and tissue repair for potential applications in modern TE and regenerative medicine [145–147]. The poor mechanical performance of most original natural materials greatly restricts their application as scaffolds prospects. It is therefore of great significance to improve the biomechanical properties of BNBMs. To this end, Gong et al. [148] presented the construction of a double network hydrogel with high strength, offering a novel strategy for designing mechanically reinforced scaffolds. Strategies for improving mechanical strength based on an interpenetrating polymer network (IPN) or semi-IPN [149, 150], nanoreinforcement [151] and so on, were utilized to obtain scaffolds with the desired mechanical performances. Many studies have shown that nanocomposite reinforced BNBMs not only have an excellent toughening and reinforcing effect on polymeric bulk materials, but also bring additional benefits such as the inhibitory effect of nanomaterials on the generation of crazes and fatigue crack propagation [151]. Moreover, many biomimetic structural designs, such as honeycomb structures [152, 153], layer-by-layer stacking [154], and nacre-like mineralization [155, 156] have been developed to enhance the mechanical properties of scaffolds, which will be detailed later in "Biomimetic structural materials and their fabrication" Section.

Recent work has shown that the viscoelastic properties of the matrix can modulate these fundamental cellular processes and promote behaviors not observed in 2D and 3D in vitro cultured hydrogel systems [157]. These results indicate that BNBMs which match synthetic and natural ECM mechanics may improve the translational aspect of constructing tissue-specific in vitro cell or tissue models and TE applications. Generally, BNBMs with viscoelastic properties are based on biomimetic hydrogels with dynamic cross-linked networks containing multiplex covalent and non-covalent interactions, such as dynamic covalent acylhydrazone bonds, borate bonds, thioesters, guest-host complexes or electrostatic interaction [158–163]. For instance, a viscoelastic HA-based hydrogel can be formed with hydrazone covalent bonds as well as weak guest-host or hydrogen bond cross-links [162, 163]. With the introduction of weak noncovalent bonds into these covalent cross-linking networks, the viscoelasticity can be tuned independently by tuning the molecular weight of the polymeric constituents, the affinity of non-covalent interactions, the ratio between non-covalent and covalent bonds, and coupling of inert molecules to the constituent polymers as spacers [162–165].

In some TE applications, such as the regeneration of heart valves, bones and teeth, fatigue resistance is crucial for reliable and long-term replacement. Hence, TE scaffolds for such anatomies require fatigue resistant materials. Early on, researchers studied the underlying anti-fatigue mechanism of hydrogel and elastomeric systems and demonstrated that when the number of polymer chain entanglements exceeds the cross-linking point, the material’s toughness increases and the material exhibits anti-fatigue properties [166, 167]. The fatigue resistance of soft materials can be effectively enhanced through the introduction of additional structures, such as crystals [167], composites [168], and ordered folding units [169], into the original cross-linking network structure. Hydrogels with hierarchical structures were proven to exhibit higher fatigue resistance due to the synergistic effects between different scales. The biomimetic design and mechanism study for BNBMs with fatigue resistance enhanced our understanding of the fatigue failure behavior of biological tissues with complex hierarchical structures. With the burgeoning development of advanced material preparation and structural design strategies, various strategies for tough and fatigue-resistant BNBMs based on hierarchical microstructures are presented as promising for tissue-specific applications.

In addition, the injectability of BNBMs based mechanical responsiveness (such as shear thinning, stress relaxation, creep, relaxation, etc.) offers convenience and accessibility for in situ moldability, minimally invasive surgery, drug delivery, precise tissue targeting, and uniform material distribution. Therefore, injectable hydrogels are popular and widely used in biomedical applications such as TE and drug delivery. In recent years, in situ cell injection therapies are gradually being used in clinical settings, in which BNBMs play a pivotal role as a protective niche for cells. A variety of methods focusing on chemical [170–172], physical [173, 174], and multiple synthetic strategies [175, 176] were presented for preparing injectable hydrogels. Physically cross-linked injectable hydrogels rely on the involvement of tenuous intermolecular associations and reversible non-covalent bonds, which are in response to an environmental condition such as temperature, pH, ionic strength, or the existence of opposite ions during network configuration. By contrast, chemically cross-linked injectable hydrogels can in situ gel through forming irreversible covalent polymer networks from a soluble precursor using cross-linking agents or enzymes. The rapid and in situ-forming injectable hydrogels also facilitate the encapsulation and controlled release of living cells and bioinks and endow the capacity to match irregular defects.

Biomimetic interfacial engineering of BNBMs

A precise host tissue-biomaterial interface is capable of regulating the cell-biomaterial interactions and the desirable performance of biomaterials in biological environment. Surface and interface engineering have been widely studied to tailor desired behaviors and functionalities into biomaterials to achieve better clinical performance. Thus, the interfacial engineering approaches as well as critical factors that determine tissue-specific functionality for BNBMs should be considered.

Surface wettability is the primary factor for dominating the protein adsorption, cell adhesion and other subsequent behaviors due to the essence of the dynamic liquid cell environment [177]. Superwettable (superhydrophobic, superhydrophilic and superslippery) surfaces are the most representative biomimetic examples for biological surfaces and interfaces to regulate the biomolecule and cellular adhesion behaviors [177]. The wettability of a material’s surface is determined by its surface morphology (surface roughness, microstructure) [178, 179] and inherent properties of the material (surface energy) [179]. Tuning methods of surface wettability are mainly divided into physical methods (such as plasma treatment, templating, spraying), chemical methods (electrochemical, self-assembly) and combined physicochemical methods (vapor deposition, etching). For instance, the introduction of an anisotropic striped surface pattern [178] and photo-induced gradient cross-linking layers enabled tunable surface wettability and creation of gradient soluble factors, cells, and microspheres in 3D hydrogels [179].

Moreover, to tailor the surface adhesion or anti-adhesion to a cell is one of the essential requirements for specific-propose tissue repair. For resisting undesirable adhesion and preventing adverse tissue-synechia, current anti-adhesion strategies mainly focus on pharmaceutical treatment and physical barriers or functional implant coating with the capability of inhibiting fibroblasts and anti-inflammation [180]. Contrary to antiadhesive materials, it may be favorable in many cases to form stable and firm wet tissue adhesion or even mucoadhesion performances. Wet adhesion presents a challenging task because when wet tissual interfaces interact, water separates the biomolecules on both surfaces and prevents tissue-material interactions, resulting in sharp decrease of tissue-material adhesion. In order to maximize the clinical utility, various biomimetic approaches have been adopted to enhance or optimize the integrin-mediated cellular interactions and adhesion, including incorporation or surface modification with bioactive molecules or bioadhesive ECM motifs, and macro- or nano-scale patterning of the biomaterials [181].

Besides the above-mentioned benefit on biomechanical properties, the topographical cues, such as surface microstructure, on TE scaffolds has significant influence increasingly become a focus of studies in recent years. Some technical approaches such as 3D printing [182], photolithography [183], plasma spraying [184], ion implantation [185], etc., have also been widely used for preparing hierarchical microstructured BNBMs. Scaffold-tissue interactions are critical for guiding and modulating favorable cellular and structural outcomes. Therefore, the surface microstructures of scaffolds are often designed and constructed aiming to improve biomechanical properties and bioactivity at the cellular and tissual level [186, 187]. Inspired by native wrinkle microstructures, Hou et al. [188, 189] developed a series of dynamic surface wrinkle microstructures, and systematically investigated the formation principles to assess the potential for wider biological applications of dynamic microstructures.

In addition, there are a large number of biointerfaces abundant in biological systems, for example, bone-to-connective tissues (ligaments, tendons, and cartilages) interfaces, which are responsible for transferring loads between tissues with significantly discrepant properties and functions. To modulate and biomimetic construct such natural tissue interfaces with unique microstructural properties and characteristics is beneficial for repairing gradient-connection tissues and achieving perfect therapeutic performance between tissues [190].

Tunable properties of BNBMs based on stimulus responsiveness, self-healing, or injectable properties

BNBMs capable of self-healing and responding to external stimuli (including acoustic [191], magnetic [192], light [179], pH [193], thermal [194] stimulation) make them possible to recapitulate the ECM-mimetic dynamic environment ex vivo and achieve controllable manipulation of physical and biochemical cues to the cell and tissue. To this end, researchers have presented a series of stimulus-responsive technologies and material systems (e.g., hydrogels with cells, growth factors, microspheres, etc.) for TE applications. For instance, magnetically responsive BNBMs prepared by introducing magnetic nanoparticles (MNPs) into hydrogel networks are advantageous in biological applications considering their rapid magnetic response, precise spatiotemporal control, and non-invasive remote operation [195]. The preparation methods of magnetically responsive hydrogels mainly include the following: 1) MNPs are mixed with the hydrogel precursor solution [192]; 2) MNPs are co-precipitated in the prefabricated hydrogel matrix [196]; and 3) MNPs are used as hydrogels cross-linking agents [197]. In addition, a magnetic patterning approach has been applied to construct complex tissue-engineered articular cartilage with a depth-dependent cellular structure similar to native cartilage [198].

The sound sensitivity of BNBMs opens a novel avenue for sonodynamic therapies. This effective acoustic-based method combining the low-intensity ultrasound and drugs (acoustic sensitizers) has been recognized as a promising approach for drug delivery and scaffold morphology modulation. Researchers mainly combine sonosensitizers (such as porphyrin analogs) with natural biomaterials to prepare sound-responsive scaffolds and apply them to TE and regenerative medicine [191]. Some acoustically responsive scaffolds were utilized to achieve sequential delivery of different growth factors encapsulated in a perfluorocarbon emulsion by simply controlling the acoustic parameters [199].

Generally, pH, as one of the most basic factors and indicators for normal cellular and tissue microenvironments, may reflect a considerable variation of physiological status. Accordingly, BNBMs endowed with pH responsivity are capable of releasing bioactive cargos in response to physiological changes and thus enhanced function as tissue scaffolds. Many ionizable groups or acid-cleavable bonds are responsive to environmental pH changes, such as Schiff bases [193], hydrazone [200], acetal [201], and β-thiopropionate [202]. For example, Gan et al. [203] reported a pH-responsive surface-functionalized mesoporous silica nanoparticle system for simultaneously delivering both growth factor bone morphogenetic protein-2 and the drug dexamethasone for osseointegration.

Furthermore, the thermal-responsive BNBMs has received significant attention due to their controllable injection and drug release [204–207]. Most researchers have been focusing on the development of efficient and rapidly responsive thermosensitive biomaterials such as Pluronic F127 in a non-covalent manner, sodium chitosan/β-glycerophosphate, and furan dimer gelatin covalently cross-linked by click chemistry with maleimide-functionalized polyethylene glycol (PEG) [204]. It can be foreseen that these temperature-sensitive BNBMs have great promise for clinical therapeutic applications such as responsive on-demand antibiotic release to combat bacterial infection in wound dressings.

Researchers also focused on redox-responsive BNBMs to regulate excess reactive oxygen species or glutathione (GSH) in the human body, achieve redox balance, repair tissue damage, and kill tumor cells [208–210]. Kim et al. [209] prepared epidermal growth factor-loaded cysteamine-cross-linked BNBM scaffolds, utilizing cysteine to respond to GSH to achieve targeted release of bio-factor and enhance the desired therapeutic effect. The construction of this BNBM-based redox response system has broad prospects in the fields of tissue repair and cancer therapy.

Besides, many other factors can be also considered in the responsive design of BNBMs, such as enzymes, light, etc. For the former, growth factors can be released by modifying matrix metalloproteinases in BNBMs [210], or BNBMs can be prepared as nanozymes to release related factors through intracellular cascade reactions, thereby achieving tissue repair. For photoresponsiveness, designs such as photodynamic therapy and infrared-to-ultraviolet light conversion can be utilized for medical applications such as therapy and diagnosis.

Considering that the applications of BNBMs are diversified and often susceptible to mechanical disruption, the requirements for BNBMs in tissue-specific performance and challenges in various harsh physiological conditions have also increased. Inspired by the self-healing properties of human tissue after minor damage, self-healing BNBMs were designed and developed mainly based on non-covalent interactions (such as hydrogen bonds, van der Waals forces), weak covalent bonds (for instance, acylhydrazone bond), ionic complexes and other design methods [25, 41, 56, 179]. The self-healing properties endow BNBMs capable of catering to the clinical requirements and promising to replace the traditional brittle stents in the fields of orthopedics, heart, skin, and muscle repair [25, 41, 179].

Biomimetic structural materials and their fabrication

Microstructural properties should be considered when designing biomaterials for TE and regeneration because microstructure not only determines the mechanical properties of the biomaterials but also affects their interactions with cells and tissues [211–213]. When the materials are used in a damaged area, it is favorable to have a microstructure similar to that of the tissues to facilitate cell migration and infiltration. Additionally, bioactive molecules, such as drugs, growth factors and so on, can be integrated into the microstructure for synergistic therapeutic effects. Here, we summarized the typical topologies and fabrication strategies of structural biomaterials used in tissue regeneration, as shown in Fig. 3.

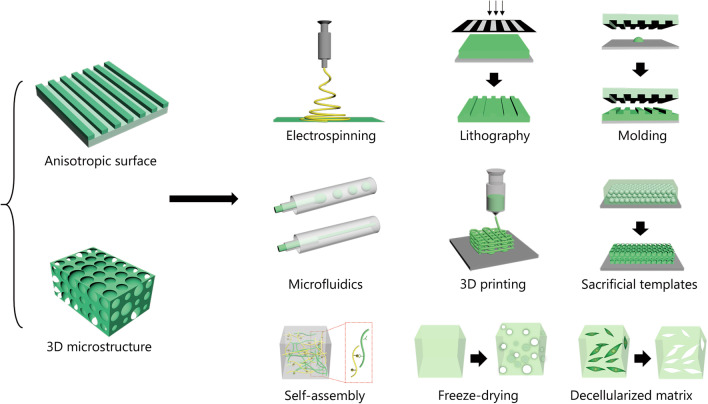

Fig. 3.

Typical topologies and fabrication strategies of the structural biomaterials

Biomimetic structures in tissue regeneration

Anisotropic surface

The surface of the biomaterial is in direct contact with the damaged area. Therefore, the surface features, especially the topology of the biomaterial, are critical in TE applications, especially in facilitating cell alignment and polarization. Anisotropic surfaces, such as aligned fibers, structural patterns, or oriented materials, enable the use of BNBMs as a tissue scaffold that leads to an orientation-dependent mechanical response. To date, many kinds of microstructures have been developed, including grooves, ridges, caves, convex patterns, and so on.

Grooves and ridges are the most commonly used anisotropic topography, and they can modulate cell polarization significantly. It is worth noting that although they can induce cell polarization at different scales, the mechanisms are different [178, 214]. When these groove and ridge patterns are used at the micro-scale, they provide spatial limitation to the cells and activate the formation of pseudopodia. However, when they are used at the nanoscale, they regulate the orientation of adhesomes by the myosin-based intracellular force. The depth of the grooves is another parameter that affects cell behavior. For example, deeper grooves caused increased differentiation, alignment and neurite elongation of murine neural progenitor cells [215].

Concavity is another typical micropattern for guiding cell behaviors. Chen et al. [216] cultured human osteosarcoma MG-63 cells on the substrates with concave patterns of different sizes. It was found that larger concaves patterns enhanced the proliferation of cultured cells because the substrate was suitable for cell attachment, while the smaller concave patterns promoted osteogenic differentiation due to the strong topological stimulation. Similarly, convex topology can improve the wettability and surface energy of the substrate, leading to enhanced capability in promoting cell adhesion, proliferation, differentiation, and achieved the best effect when the micropattern size is close to the size of cells [217].

3D microstructures

Although many advances have been made in patterning the microstructure of scaffolds, many of these advances have been in planar scaffolds [190, 194], which may not be suitable for the repair of volumetric defects. The absence of 3D microstructure within the biomaterial may limit the vascularization of the regenerated tissues and decrease the repair efficacy. Conversely, BNBMs with 3D microstructure allow cell infiltration as well as mass transfer, supporting vascularization and ECM deposition. It should be noted that the mechanical properties are also closely related to the pore interconnectivity. Therefore, it is crucial to find a balance between meeting the demands of mechanical properties without sacrificing advantageous biological effects. For example, researchers developed a series of porous microfluidic hydrogel particles based on BNBMs for tissue repair [218–220]. These biomaterials had porous structures for the loading and release of drugs, as well as inducing the proliferation and differentiation of cells. Dai et al. [221] designed a tissue scaffold using methacrylated hyaluronic acid for bone/cartilage tissue regeneration. The HA-based scaffold had radially oriented pores, which were used to recruit and orient cells. When the scaffolds were implanted at sites of cartilage defects in experimental animals, favorable cartilaginous regeneration was achieved.

Nanofiber scaffolds enable superior control and generation of microstructures. By tuning the parameters of electrospinning, scaffolds with controllable nano- and micro-structures can be readily prepared [222–224]. Rnjak-Kovacina et al. [225] presented an electrospun fibrous elastin-collagen composite scaffold for the regeneration of skin. The obtained materials not only maintained inherent bioactivity, but also had tunable microstructures. The synergistic effect of the natural materials and the optimal microstructure resulted in favorable cell attachment and proliferation.

Inverse opal scaffolds are biomaterials with ordered 3D porous microstructures [226–229]. The size of the interconnected pores is homogeneous and controllable, which results in the efficient transfer of nutrients and wastes, leading to a uniform distribution of cells. Additionally, the uniform pores make it possible to evaluate effects on cell infiltration [230]. It is also feasible to functionalize inverse opal scaffolds with drugs or signal molecules to enhance their therapeutic effects. For example, Osathanon et al. [231] prepared an inverse opal fibrin scaffold modified with alkaline phosphatase, which can promote bone formation, whereby significant mineral deposition and bone regeneration was observed on the scaffold.

Fabrication of biomimetic structural materials

Electrospinning

Electrospinning is a common technique that can generate polymer fibers with a desired size [232, 233]. There are three main components of electrospinning systems, including a high voltage power source that provides the electrostatic field, a material delivery system that delivers the material continuously, and a substrate that collects the generated fibers. When the system is running, polymer solution is extruded and forms a Taylor cone under an electric field. During spinning, the solvent is evaporated, and the jet is solidified. By adjusting the electrospinning parameters, including the solution’s viscosity, conductivity, and surface tension, as well as the electrostatic field, temperature, and humidity, the diameters of the fibers can be tuned from the nanoscale to microscale [234].

However, it should be noted that many solvents used for electrospinning are halogenated compounds, which have high toxicity and negative effects on the environment. To solve this problem, more biocompatible “green solvents” have been developed. For example, Zhou et al. [235] reported a collagen/hydroxyapatite (HAP) composite fiber with an excellent microstructure fabricated by electrospinning. Rather than using potentially cytotoxic organic solvents, they dissolved type I collagen in a solution of phosphate buffered saline (PBS)/ethanol. The solution was desalinated and co-electrospun with HAP to form collagen/HAP composite fibers, which exhibited not only better mechanical properties, but also had a microstructure similar to natural bone.

Lithography and molding

Lithography is a widely used technology capable of precisely fabricating intricate biomaterials. Like electrospinning, lithography is flexible in operation and relatively inexpensive. Photolithography and soft lithography are the most common lithography methods for preparing BNBMs [141, 183]. Photolithography uses ultraviolet (UV) irradiation to cure the photoresist layer through a photomask [236]. This strategy can produce materials with high throughput and thus, the cost of each patterned element is low [188, 237, 238]. However, several inherent weaknesses such as the wavelength and diffraction effect of the light may limit their application in developing microstructures with ultrahigh precision down to the nanometer scale. By contrast, soft lithography employs patterned molding or stamps with high resolution to prepare biomaterials with pre-designed patterns [239]. This method is simple, fast, and low-cost, while avoiding residues of initiators and free radicals which may remain in photolithography processes. These features allow it to be employed for constructing a variety of structural biomaterials. Moffa et al. [240] presented a micro-grooved scaffold with oriented fibers for engineering vessels. In this work, they prepared a patterned polydimethylsiloxane mold and used it as a template to form a microgrooved gelatin. Next, electrospinning technology was used to fabricate nanofibers on the gel in order to provide nanoscale cues. By tuning the collection parameters, the micro- and nano-scale topographic cues could be aligned in random, parallel, or perpendicular relative directions.

Microfluidics

Microfluidics is a technology that can precisely modulate fluids on the sub-millimeter scale [115, 241–245]. Because the dimensions of the fluids manipulated by microfluidics are at the microscale, their specific surface area increases and the fluids exhibit different behaviors from those of drops on a macroscopic scale [245]. Additionally, the microfluidic systems can integrate many channels, so that various fluid phases can simultaneously flow in the systems. Based on the diverse interactions among the fluid phases, various kinds of fibers and droplets can be generated [115, 224, 244]. Fibers are fabricated in microfluidic systems based on the concentric flow of a core and a sheath fluid via two channels, while droplets are generated by the action of liquid-liquid interfacial tension and shear force [245]. The biocompatibility of the fibers and droplets is determined by the fluids used in the fabrication process and their interactions with microfluidic chips. Surfactants are often used in the fabrication process to stabilize the fluid and the generated products, but they may have negative effects on cells. In some cases, photopolymerization is combined with microfluidic technologies, which may leave residual photoinitiators and free radicals. Therefore, the fibers and droplets prepared using these systems should be washed carefully before use.

Thanks to the ability to control fiber or droplet size during fabrication, microfluidic technology has tremendous potential for preparing BNBM-based functional scaffolds. For example, Yu et al. [246] developed a metal-organic framework (MOF)-loaded microfiber using microfluidics. In their work, various solutions were pumped into a coaxial capillary microfluidic chip and formed shell-ore microstructures via interactions between Ca2+ and sodium alginate, as well as nicotinic acid and Cu2+ or Zn2+ solutions. In a different approach, Yang et al. [247] integrated microfluidics with electrospray technology to fabricate stem cell-laden alginate hydrogel capsules. The fluids at the end of the microfluidic chip were cut into droplets composed of alginate shells and stem cell cores by the shear force of an electrostatic field. The shells gelled immediately when the droplets were collected in the calcium chloride solution. This unique core–shell structure provided a good microenvironment for cell culture and the following in vivo applications.

3D bioprinting

3D bioprinting is a novel technology for preparing biomaterials and is generally defined as the application of additive manufacturing in biomedical fields [38, 182, 248]. Biomaterial models are designed by computers before fabrication, while microfluidics and photopolymerization are often employed to manipulate the bioink to fabricate designed biomaterials layer-by-layer. Therefore, the biocompatibility of the prepared materials is mainly determined by the employed bioinks. According to the fabrication methods, 3D bioprinting can be classified into four categories of extrusion, inkjet printing, laser-induced forward transfer, and vat polymerization.

Since 3D bioprinting can prepare biomaterials with a programmed microstructure, it has been widely utilized to develop biodegradable scaffolds with suitable microstructure and spatial cell distribution [249]. Based on this strategy, Wang et al. [249] realized a living photosynthetic scaffold composed of microalgae, alginate, and gelatin methacrylate (GelMA) similar to natural tissues or organs using an extrusion strategy. They used gelatin fluid containing calcium chloride and the mixture solution of microalgae, alginate, and GelMA as the inner phase and outer phase, respectively. The cross-linking between Ca2+ and alginate formed the hollow fibers which were subsequently irradiated under UV light to photopolymerize the GelMA component. Furthermore, it was demonstrated that the resultant hydrogel fibers could be stacked in situ on tissue and form a 3D scaffold, indicating that this method could be a novel 3D bioprinting technology. Boland et al. [250] employed inkjet technology to prepare cell multilayers with 3D structures. They fixed a platform on an elevator stage which lowered after each printed layer and thus, the cross-linking could be continued until the elevator stage reached the bottom. By using this system, they acquired the 3D construct with the desired form and microstructure for cell culture. Vat polymerization is a 3D printing method which solidifies liquid ink in a layer-by-layer manner using photopolymerization, which can rapidly generate structural materials with high-resolution architectures. Due to these features, it has appealed to many researchers. For example, Wang et al. [251] employed this method to cross-link a bioink made of GelMA containing eosin Y photoinitiator under visible light irradiation. The formed hydrogel exhibited the designed shape and micropattern, while cells could adhere and proliferate well inside the hydrogel.

Sacrificial template

The fabrication of materials with a specific microstructure often requires machining technologies with high precision. Many of these technologies are difficult to operate at scale and are expensive. By contrast using materials that possess unique micro- or nano-structures as sacrificial templates to fabricate the biomaterials is an easy and feasible strategy [251, 252]. The pre-polymerization solution can infiltrate the small structure of the templates and form a polymer network after polymerization, after which suitable corrosives are employed to etch the templates. The resulting materials must be washed thoroughly before use for cell culture or in animals to remove the residual toxic reagents. For example, Zhang et al. [253] fabricated a hollow conduit with porous inner walls for drug loading and peripheral nerve regeneration. They used silica nanoparticles to form a thin film with periodic layers on the outside of a glass capillary. The thin silica film was used as template to obtain the natural protein-derived conduit by pre-gel infusion, UV irradiation, and sacrificial template etching. Kong et al. [254] combined the template with a photomask to prepare a hydrogel film for corneal stroma regeneration. In their work, the colloidal crystal film was infiltered with photopolymerizable natural polymer solution, and a photomask was added to the film prior to UV irradiation. After sacrificial template etching, the hydrogel film retained both the nanostructures inherited from the colloidal crystal array and the microscale grooves from the mask (Table 2).

Table 2.

Design principles, preparation methods, and applications of biomimetic natural biomaterials

| Modification | Biomaterials | Properties | Methods | Principles | Applications | References |

|---|---|---|---|---|---|---|

| Electroactive design | Collagen/chitosan | Conductivity | Loading with conductive substances or modification of electroactive functional groups | Electronic vacancy/movement, ionizable groups | Cardiac/skin/nerve/muscle tissue engineering, diagnosis | [117–125] |

| Collagen/PVDF/M13-bacteriophage | Piezoelectric | Loading with piezoelectric materials | Ordered nature of nano- or liquid-crystalline in biomaterials | Biosensing monitoring, health monitoring, dentistry, cardiac/skin tissue engineering | [126–138] | |

| Cellulose/silk | Triboelectric | Loading with triboelectric materials | Charges generated by friction | Human–machine interactions, health monitoring, peripheral nerve restoration, smart wearables | [139–144] | |

| Biomechanics design | Cellulose/collagen/alginate | Mechanical enhancement | Bionic structuring, multiple networks, doped nanomaterials | Nano enhancement, improving cross-linking density | Cartilage/bone/muscle tissue engineering | [148–156] |

| HA/collagen/alginate | Viscoelasticity | Chemical modification, mimics ECM dynamic mechanics | Abundant dynamic covalent bonds | Cell niche, mediating cell behavior, ophthalmology, drug delivery, tissue regeneration | [157–165] | |

| PVA/HA | Anti-fatigue | Adding crystals composites and ordered folding units, introduction of hierarchical structure | Multiscale design, polymer chain entanglements | Cardiac/skin/neuro/cartilage/bone/muscle tissue engineering, | [166–169] | |

| CMCS/PEG/HA | Injection | Chemical/physical modification | Weak (non-covalent) cross-linking, shear thinning | Drug delivery, in situ moldability, targeted therapy | [170–176] | |

| Interface design | PEG/gelatin | Superhydrophilicity or superhydrophobicity | Plasma treatment, template, spraying, electrochemical, self-assembly, vapor deposition, etching | Surface roughness, surface energy | Cell culture/gradient scaffold construction, skin repair, dentistry, artificial vascular | [177–179] |

| Retinin | Anti-adhesion | Chemical modification, spraying, | Physical barriers, reduced contact area/surface energy | Abdominal wall defect treatment, anti-protein adsorption | [180] | |

| PEG/Chitosan | Wet adhesion | Chemical modification, electrochemical, etching | Electrostatic interaction, Strong water absorption | Wound dressing, preventing infection, wet tissue adhesion, wound closure hemostasis | [181] | |

| Stimulus responsiveness design | PEG/PVA/MNP | Magnetic field response | Embedding magnetic nanomaterials | Moving charge or changing electric field | Cartilage/bone tissue engineering, diagnosis | [192, 195–198] |

| Porphyrin/fibrin | Sound sensitivity | Embedding sonosensitizers nanomaterials | High acoustic sensitization activity | Controlled drug release, tissue engineering, | [191, 199] | |

| PEO/chitosan | pH sensitivity | Chemical modification | Ionizable groups or acid-cleavable bonds | Targeted drug delivery, tissue regeneration | [193, 200–203] | |

| Chitosan/gelatin | Temperature sensitivity | Adding thermosensitive polymers | Low glass transition temperature | Drug delivery, tissue regeneration, injection-based cell therapy | [204–207] | |

| GSH/mussel/DTT | Redox response | Chemical modification, physical doping | Redox-responsive chemical bonds, cascade response | Targeted drug delivery, cancer treatment | [208, 209] | |

| Self-healing design | PAA/gelatin/SA | Rapid self-healing | Chemical modification, ion complexation | Weak sacrificial links | Skin/nerve/muscle/cartilage tissue repair | [179] |

| Microstructure design | HAP/HA/PLGA/collagen | Anisotropic surface | Electrospinning, lithography and molding, microfluidics, 3D printing, sacrificial templates, self-assembly, freeze-drying | Surface roughness, microscale effects, topology | Guiding cell fate, nerve/bone tissue regeneration | [214–231] |

| Collagen/carrageenan | 3D microstructure | Vascularization, drug release, transfer of nutrients and wastes, mediating cell fate, cartilage/skin/bone tissue engineering | [235–254] |

PVDF Polyvinylidene difluoride, ECM Extracellular matrix, PVA Polyvinyl alcohol, HA Hyaluronic acid, CMCS Carboxymethyl chitosan, PEG Polyethylene glycol, HAP Hydroxyapatite, PLGA Poly (lactic-co-glycolic acid), MNPs Magnetic nanoparticles, PEO Polyethylene oxide, GSH Glutathione, DTT Dithiothreitol, PAA Polyacrylic acid, SA Sodium alginate

Bio-inspired self-assembly or self-organization

Self-assembly can be used to form stable structures through non-covalent interactions among molecules including hydrogen bonding, electrostatic force, and Van Der Waals force [190, 255–259]. For example, peptides with complementary chemical and spatial structures can self-assemble into fibers [260]. Furthermore, fibers can be organized to form hydrogels with specific nanopores [261]. These biomimetic self-organization strategies avoid toxic chemical reagents (such as chemical cross-linker), while the fibers and hydrogels degrade into nontoxic small molecules. Kumar et al. [262] used self-assembling peptides to form nanofibrous hydrogel scaffolds that facilitated angiogenesis. They employed a multi-domain vascular endothelial growth factor 165 (VEGF-165) mimicking peptide named SLanc. The scaffold could be dissolved in deionized water and rapidly form hydrogels when mixed with negatively charged multivalent ions.

There are several studies demonstrating that BNBMs can also be developed by the self-assembly of ECM secreted by cells. L’Heureux et al. [263] demonstrated that fibroblasts could form an ECM substrate with suitable mechanical strength by in vitro cell culture. Based on this cell culture system, they prepared a large quantity of cell-assembled ECM and explored its clinical applications, such as ECM yarns for surgical sutures.

Freeze-drying

Freeze-drying, also known as lyophilization, can be used to prepare porous biomaterials from polymeric solutions without additional cross-linkers and thus, can be employed for preparing materials with superb biocompatibility [264, 265]. The preparation process of freeze-drying includes three steps: dissolving polymers in water to acquire a polymer solution, freezing the solution in a container or a mold, and removing the ice from the frozen solution with a lyophilizer. When water is frozen, it acts as porogen. Accordingly, the porosity and pore size of the materials is dependent on the rate and method of freezing as well as the freeze-drying parameters. Rapid freezing hinders the formation of large ice crystals and results in small pores. Wang et al. [266] prepared a series of frozen scaffolds based on natural biomaterials for the repair of myocardial infarction. It is worth noting that a high vacuum is generally necessary to maintain pores during sublimation. If the vacuum is lost prior to the complete removal of ice, the scaffold may collapse on itself. Stokols et al. [267] explored the feasibility of freeze-drying agarose to form a scaffold with uniaxial linear pores for repairing spinal cord injury. Although the scaffold was not cross-linked with any chemical strategies, it remained stable under physiological conditions for a long time.

Decellularized matrices

Decellularization is a technique that removes all cells from a natural tissue via physical, chemical, or biological methods and leaves behind only the ECM of the tissues or organs [268]. The resulting scaffolds are also called decellularized ECM (dECM), and they may be favorable options for tissue regeneration since they retain the original tissue microstructure. Theoretically, recellularization of dECM scaffolds can recover the physiological functions of the decellularized organs due to their similarities to physiological composition and microstructure, which endows them with excellent biocompatibility after removal of the decellularizing solvents [269, 270]. For example, Ott et al. [269] perfused heart tissue with a mixed solution of heparinized PBS and adenosine followed by sodium dodecyl sulfate. After washing with deionized water, Triton-X100, and PBS containing antibiotics, the structurally functional, yet decellularized heart was obtained. Using a similar perfusion method, other organs, such as liver, have been successfully decellularized [270].

Interestingly, decellularized matrices can retain some of their physiological function without recellularization. Xu et al. [271] presented a liver-mimetic detoxication device using polydiacetylene nanoparticle-functionalized decellularized liver scaffolds. The decellularized scaffold provided 3D architecture for nanoparticle immobilization and blood perfusion and could remove pore-forming toxins from the blood.

Since decellularized tissues are derived from native tissues, they have many advantages over synthetics scaffolds [272, 273]. Since the components and microstructure of the ECM are dependent on their source organs, the physical structure and chemical composition of dECM from different tissues are distinct and arguably more suitable for specific applications. Singelyn et al. [274] dissolved decellularized porcine myocardial tissues using pepsin to form an injectable solution, which could form nanofibrous hydrogels when treated with heat. When the solution was injected into experimental animals, it formed a hydrogel capable of facilitating cell infiltration in vivo. In another study, Hong et al. [275] confirmed the capability of decellularized brain tissue hydrogel to promote the repair of spinal cord injury. Further studies of decellularized tissue hydrogels from dermal [276], bone [277], and blood vessels [278] indicate this strategy is suitable for regenerating various tissue types.

Application of BNBMs for TE and regenerative medicine

Applications of component-mimetic biomaterials

Collagen is the main component of ECM in all connective tissues in the body, and more than 27 types of collagen were found to play critical role in supporting mechanical stresses such as tendon, skin, cartilage, and bone tissues. Collagen-based scaffolds are enlightened to treat various tissue injuries. For example, Rho et al. [279] prepared collagen nanofiber membranes by electrospinning to promote the migration of keratinocytes at the early stage of wound healing. Compared with 2D collagen membranes, 3D collagen scaffolds are better candidates for skin regeneration. Ahn et al. [280] developed 3D porous collagen scaffolds with controlled pore sizes. The 3D scaffolds sustained uniform fibroblast dispersion and complete coverage with keratinocytes, similar to that of full thickness skin. Similarly, Ng et al. [281] applied the macromolecular crowding to 3D bioprinting and fabricated a 3D hierarchical porous collagen-based hydrogel scaffold, which could be a potential substrate for skin wound healing and skin TE.

Similar to skin, tendon and ligaments are also mainly composed of collagen fibers [281]. Tendinous and ligamentous collagen fibers are remarkably strong, having one of the highest tensile strengths among soft tissues in humans. However, reconstructed collagen fibers are usually too weak to support daily load bearing. To overcome the current shortcomings of tendon repair scaffolds, Francis et al. [282] developed a new electrospun tendon mimetic material consisting of aligned poly (D,L-lactide) (PDLLA) and type I collagen fibers. The addition of PDLLA significantly improved the mechanical properties of the synthetic scaffold. This study further confirmed the necessity of maintaining cell orientation, which resulted in the upregulation of tendon-related genes after three days of co-culture with human stem cells.