Abstract

Food waste has been identified as one of the major factors that constitute numerous anthropogenic activities, especially in developing countries. There is a growing problem with food waste that affects every part of the waste management system, from collection to disposal; finding long-term solutions necessitates involving all participants in the food supply chain, from farmers and manufacturers to distributors and consumers. In addition to food waste management, maintaining food sustainability and security globally is crucial so that every individual, household, and nation can always get food. “End hunger, achieve food security and enhanced nutrition, and promote sustainable agriculture” are among the main challenges of global sustainable development (SDG) goal 2. Therefore, sustainable food waste management technology is needed. Recent attention has been focused on global food loss and waste. One-third of food produced for human use is wasted every year. Source reduction (i.e., limiting food losses and waste) and contemporary treatment technologies appear to be the most promising strategy for converting food waste into safe, nutritious, value-added feed products and achieving sustainability. Food waste is also employed in industrial processes for the production of biofuels or biopolymers. Biofuels mitigate the detrimental effects of fossil fuels. Identifying crop-producing zones, bioenergy cultivars, and management practices will enhance the natural environment and sustainable biochemical process. Traditional food waste reduction strategies are ineffective in lowering GHG emissions and food waste treatment. The main contribution of this study is an inventory of the theoretical and practical methods of prevention and minimization of food waste and losses. It identifies the trade-offs for food safety, sustainability, and security. Moreover, it investigates the impact of COVID-19 on food waste behavior.

Keywords: Bioenergy, COVID-19, GHG emissions, Biofuels, End hunger, Minimization

Introduction

Food is an essential human requirement, and food waste is the world’s biggest issue. According to the United Nations International Children’s Emergency Fund (UNICEF) 2011 report, approximately 21,000 people perish daily due to hunger-related problems. One out of every nine people worldwide sleeps hungry. On the other hand, nearly one-third of all food produced is sent to landfills (Singh et al. 2022). An estimated 222 million tons of food is wasted every year in the developed world. This is almost as much as the entire net food production of Sub-Saharan Africa. An estimated 222 million tons of food is wasted every year in the developed world. This is almost as much as the entire net food production of Sub-Saharan Africa (SSA) (230 million tonnes) (Boon and Anuga 2020). Food waste is caused by various reasons, including food production, area, lifestyle, industrialization, and consumer acceptance. Food waste and food losses are frequently used interchangeably, but are they the same? When we talk about “food loss,” it takes place in the supply chain after harvesting (postharvesting stages like handling, transport, storage, and distribution), and before reaching the consumer, it is specifically the reduction in the quantity of food (Kour et al. 2023) while the term “food waste” refers to the loss of items meant for consumption by humans that are later deteriorated, eventually lost, and discharged as landfill (Rather et al. 2022a; Pandey et al. 2021). It is mainly caused by consumer behavior and retail operations. The food is acceptable for other purposes; however, it is thrown before eating. Food waste is primarily a concern in developed nations, as most food is thrown away at the retail or consumer level. Curtailing food waste will automatically reduce crop production and thus water is needed for agriculture. Water is generally polluted due to industrial effluent or a lack of appropriate sanitary facilities. Water pollution is also caused by inconsiderate human behavior, such as dumping trash and other waste into water resources such as a river or a lake (Rather et al. 2022a, 2023g). Traditional water treatment and discharge methods are no longer viable because they rely heavily on a centralized system (Thines et al. 2017). Many studies have been reported to find different applications, including fruit-based waste materials and various carbon nanomaterials as adsorbents for wastewater treatment (Solangi et al. 2021; Lingamdinne et al. 2020; Dehghani et al. 2021). Developing countries suffer from food loss due to poor postharvest facilities. Most food is wasted in the supply chain during manufacture or different processing steps (FAO 2011).

What lies ahead of food waste is its management, treatment, and utilization. Different methods have been optimized to control and adequately utilize the waste, including extracting important nutrients from leachate. In third-world countries, the number of studies on food waste management is growing gradually (Filimonau and Delysia 2019; Rather et al. et al.2022b; Khan et al. 2022). But, a few exceptions in analysis from the food service industries and national cuisines in most developing countries were excluded from it (Papargyropoulou et al. 2019; Filimonau et al. 2020). Food material is discharged across the food supply chain (FSC), involving all waste management sectors right from collection to its disposal. The impact of waste material formation (food waste or organic waste, food losses) on all sectors engaged in food production, distribution, and consumption will be highlighted under the FSC system (Girotto et al. 2015; Pfaltzgraff et al. 2013). An FSC commences with agricultural food production, which includes both husbandry and farming wastes, as well as sub-products comprising organic waste (such as manure or cornstalks), food loss, and food waste (low-quality fruits and vegetables, unwanted productions left in the field, products or co-products with lower or absent commercial values). Food waste reduction starts with eliminating unwanted surplus food and thwarting food overproduction and glut (Papargyropoulou et al. 2014; Girotto et al. 2015). Moreover, the waste is utilized in the industrial sector and animal feed in the food waste hierarchy. Several industrial-scale alternatives exist, from using waste for energy generation via anaerobic digestion (e.g., bio-methane or bio-hydrogen productions) to producing particular chemical compounds as precursors for plastic material manufacture, medicinal, or chemical uses. Composting can help replenish nutrients or sequester carbon by generating humic chemicals. Composting has the potential to be utilized to remediate food waste (FW) and industrial process wastes (e.g., digestate). The final and least desired alternative is landfilling or incineration. Composting, landfills, and incineration are some of the most common conventional disposal methods, but they come with a number of negative health and environmental consequences (such as odors, leachate, groundwater pollution, and global warming). It is urgent that we find a sustainable and environmentally friendly solution for the valorization of food wastes in order to address the drawbacks of traditional approaches and prevent the loss of valuable organic food resources (Kumar et al. 2022; Alam et al. 2022).

The Global Food Policy has reexamined food insecurities as COVID-19 resulted in detrimental health consequences. Most of the low-and-middle-income countries (LMICs) are entirely dependent on jobs in the farming sector. Still, the adverse situation of COVID-19 has resulted in lockdown conditions, thereby contributing to job insecurities, which leads to food loss and food waste and thus decreases perishable nutritious food stocks. This problem has corresponded with a drop in demand for fresh, healthful foods, as many people can no longer afford them. Due to a lack of access to refrigerators, many LMICs began stocking up on non-perishable, relatively inexpensive food (Diabetes 2021; Rather et al. 2022c). COVID-19 has been a potential threat to humans’ health since its outbreak and has ceased all outdoor activities in one way or another (Aldaco et al. 2020). Lockdown tactics impact many supply chains, resulting in a slowing of economic growth or an impending catastrophe. Food supply chains are not immune to these disruptions. Indeed, COVID-19 has wreaked havoc on food security, access, and food loss and waste (FLW) from the pandemic’s start (Baig et al. 2019; Aldaco et al. 2020).

This review explores and discusses some tradeoffs between food security, sustainability, and safety. It discusses the impacts of food waste at different levels and various novel approaches for treating food waste and its conversion to energy. The last section of this paper elaborates on food waste source reduction strategies and the potential for mitigating climate change. Moreover, it discusses the status of the food system and various behavioral changes during the COVID-19 pandemic.

Waste generation

Food waste (FW) is on the rise and is not confined to industrialized countries. The Food and Agriculture Organization provided data on FW generation from various world regions, implying that FW generation occurs on an equivalent scale in both industrialized and developing countries (FAO 2011). Nonetheless, major disparities exist between developed and developing nations. More than 40% of food losses occur at the postharvest and processing stages in developing countries, whereas 40% of losses occur at the retail and consumer levels; hence, the industrialized world loses much more food on a per-capita basis than developing countries (FAO 2011; Boon and Anuga 2020; Khan et al. 2021) and may be attributed to harvesting procedures, storage, and cooling facilities in developing countries in challenging environmental conditions, packaging, marketing systems, and infrastructure, all facing financial, administrative, and technological constraints. In contrast, the reason for the same in developed countries is that customer behavior and poor coordination among the many supply chain participants and farmer-buyer sales deals may lead to agricultural crop waste. Food may be wasted due to quality requirements, with food products that do not suit the acceptable form or look being rebuffed. On a retail level, insufficient preparation and the expiration of “best before dates” result in enormous volumes of waste when paired with customers’ often irresponsible attitude (FAO 2011).

The FW generation problem has two aspects: prevention upstream and source segregation downstream. Prevention of generation is the fundamental step in a practical FW control approach. The inevitable resulting FW quantity must then be appropriately source-separated. The food supply chain is a merger of farmers and customers entangled with diverse food processing and marketing companies. As a result of globalization and industrialization, food supply chains have grown longer and more complicated, growing the risk of food spoilage (Ouda et al. 2016; Jeswani et al. 2021). There are numerous food waste causes, most of which depend on a particular stage where food is used, while specific reasons are universal to all supply levels of the food chain. Understanding and knowing about sources of food waste is important to tackle and frame a strategy for its prevention. Food waste is categorized into the following forms depending on where it occurs in the food supply chain.

Production of food wastes

In the food supply chain (FSC), primary production embodies the pre-harvest (animal, fisheries farming, and agricultural) and postharvest (handling, processing, and storage) operation chain. Natural factors that include harsh weather, spoilage, or any pest infestation are the core causes of food waste at the farm level (Bond et al. 2013; Nicastro and Carillo 2021). Significant agricultural losses are found in third-world countries (FAO 2011). Moreover, challenges such as obsolete harvesting methods, paucity of transportation, insufficient storage facilities, inadequate infrastructure, and restricted preservation techniques increase postharvest losses in third-world nations (Buchner et al. 2012; Halloran et al. 2014; Jeswani et al. 2021).

On the other hand, industrialized nations show significantly low levels of food wastage because of advanced harvesting techniques, adequate infrastructure, and better agronomic expertise. Surplus production, volatile market pricing, quality control requirements, and esthetics, on the other hand, are some of the prime causes of food waste in affluent nations (Bond et al. 2013; El Sheikha and Ray 2022). The COVID-19 issue, which is still occurring at the time of writing, is also expected to escalate food waste on farms due to a lack of labor, notably in wealthy countries that rely on imported seasonal work, such as agricultural workers (Jeswani et al. 2021). Furthermore, commodities that do not fulfill quality parameters or product appearance which are used in food marketing guidelines (size, shape, and weight) generally become trash, especially true with fresh produce (Waitt and Phillips 2016; Porter et al. 2018). Also, the ill-government policies of encouraging farmers to grow certain crops in excess without proper knowledge or providing farmers with bad quality seeds which fail to yield quality products result in food waste at the initial level of the supply chain. The estimation of food waste from different sources in the household area, food service, and retail across the countries sector-wise is shown in Table 1.

Table 1.

Sector-wise estimates of food waste in countries with high confidence

| Household | Food service | Retail | Total | |

|---|---|---|---|---|

| Australia | Australia | Australia | ||

| Austria | Austria | Austria | ||

| Canada | China | Denmark | ||

| Denmark | Denmark | Germany | ||

| Germany | Estonia | Italy | ||

| Ghana | Germany | New Zealand | ||

| Malta | Sweden | Saudi Arabia | ||

| Netherlands | UK | Sweden | ||

| New Zealand | USA | UK | ||

| Norway | USA | |||

| Saudi Arabia | ||||

| Sweden | ||||

| UK | ||||

| USA | ||||

| Global average food waste % | 61 | 26 | 13 | 100 |

| 2019 total (million tons) | 569 | 244 | 118 | 931 |

Handling and storage of wastes

These types of wastes occur due to negligence during the handling of food commodities from farm to store or from store to markets/processing units. It is mainly an issue in most third-world countries due to inadequate facilities and knowledge of handling different commodities. The absence of sufficient handling and storage facilities for fresh produce, poultry, and meat items contributes significantly to food loss, particularly in underdeveloped countries. Underdeveloped nations account for 19% of fruit and vegetable loss (FAO 2011). These foods can spoil quickly in warmer climes, necessitating adequate cold storage after catching, slaughtering, or harvesting.

Furthermore, failure in grain storage or pulse crops stored in air-tight containers where pests and moisture can enter potentially contaminates the crop with mold, toxins, or pests (Mishra et al. 2021). This frequently means that farmers must sell their whole crop immediately after harvest, resulting in lower prices due to increased supply. Thus, in low-income nations, adopting and investing in technology that allows for the safe storage and handling of fresh vegetables and grains may assist in preventing food waste. Fresh fruits and vegetables must be handled carefully after harvest and during transportation, as they can be bruised or blemished easily, rendering them nonsalable (Adegbola et al. 2011; Badran et al. 2017; Yadav et al. 2021). Sacks and bags commonly transport goods in underdeveloped nations; however, they offer little protection (Rahman et al. 2019). Plastic crates, for example, provide additional crop protection, can be reused for up to five years, and can frequently make menial work more accessible due to their convenient size and availability of handles (Kosseva 2020).

Processing food wastes

These wastes are the main contributors to the overall food waste. The prime reason behind it is inefficient processing unit operations to remove the edible and inedible parts from food and inefficient handling processes. Most processing wastes are accounted for inedible parts, including peel, eyes, and skin. And these inedible wastes are distinctly rich in proteins, carbohydrates, antioxidants, fats, and chemical or biological oxygen demand. The foodstuff experiences different processing steps during its manufacturing or processing, such as trimming, peeling, cutting, slicing, milling, cooking, boiling, and packing, owing to inefficiencies and a lack of quality assurance standards (Bakalis et al. 2020; Morrow et al. 2019; Dora et al. 2020). Flaws in devices that apply or remove heat, such as distillation, sterilization, or cooling, exacerbate the danger of bacterial contamination and, as a result, spoil food ((Mena et al. 2014). Food manufacturers, like peasants, must meet retailer specifications based on physical appearance, size, weight, and quality criteria (FAO 2011). As a result, producers may discard things that do not satisfy these specified quality standards and are not esthetically acceptable to customers (Buchner et al. 2012).

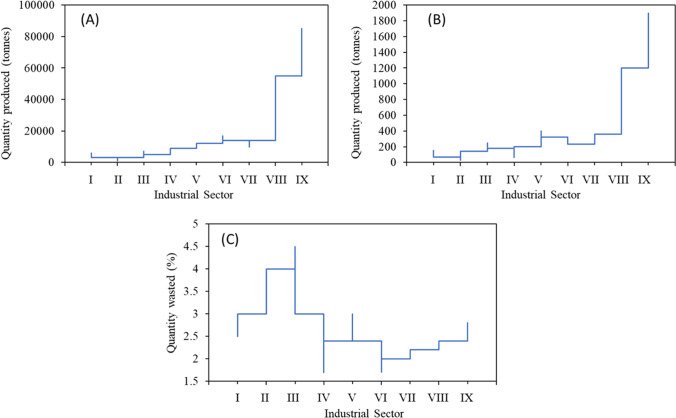

Moreover, the reason for waste produced in manufacturing and processing is inconsiderable: unhealthy animals, contaminations, quality rejections, laws, and management-related issues. The primary causes of meat product waste are poor prognosis, inventory management, and planning (Mena et al. 2014). Some wastes include fruit pomace produced during wine or juice production, and whey produced during cheese production is innate to the process. Though these may be used as fodder, their utilization is restricted due to their low nutrient quality (Kosseva 2020; Kour et al. 2023). The estimated food waste concerning quantity produced (MT), quantity wasted (MT), and quantity wasted (%) is shown in Fig. 1. Two main policy implications were highlighted by the figure, demonstrating the significance of the aforementioned findings. To begin, the environmental impacts of food waste should be taken into account when formulating prevention strategies and targets rather than just the volume of waste. Meat, fish, rice, and cheese, for instance, have more negative effects on the environment than vegetables. As a result, minimizing the waste of high-impact products is a sensible strategy for minimizing the negative effects of human food consumption on the environment. Second, opportunities exist at every stage of the food supply chain, so policies aimed at reducing food waste should consider the entire system. Some problems with the quality of the available data have also been brought to light by the study. The total estimated food waste concerning the quantity produced is about 9000 MT in the industrial sector, the highest food waste estimation is about 6000 MT from the Beverage industry sector, and the lowest food waste estimation is about 1000 MT from the meat and meat product production, processing, and preservation respect to the quantity produced. The total food waste estimation concerning the amount wasted is about 2000 MT, and the highest food quantity waste estimation is about 1300 MT in the beverage industry, and the lowest food quantity waste estimation is about 15 MT from the industrial sector in meat and meat product production, processing, and preservation. The total quantity of waste in the industrial sector with respect to percentage was 2.6%. The highest quantity of waste was 4.5% produced from fruit and vegetable production and preservation. The lowest amount of waste was 1.7% from the production of grain and starch products.

Fig. 1.

Representing the estimated food waste concerning A quantity produced in metric tonnes (MT), B quantity wasted (MT), and C quantity wasted (%). And the industrial sector includes I meat and meat product production, processing, and preservation; II fish and fish product production and preservation; III fruit and vegetable production and preservation; IV manufacturing vegetable and animal oils and fats; V dairy products and ice cream industry; VI production of grain and starch products; VII manufacture of other food products; VIII beverage industry

Distribution of food wastes

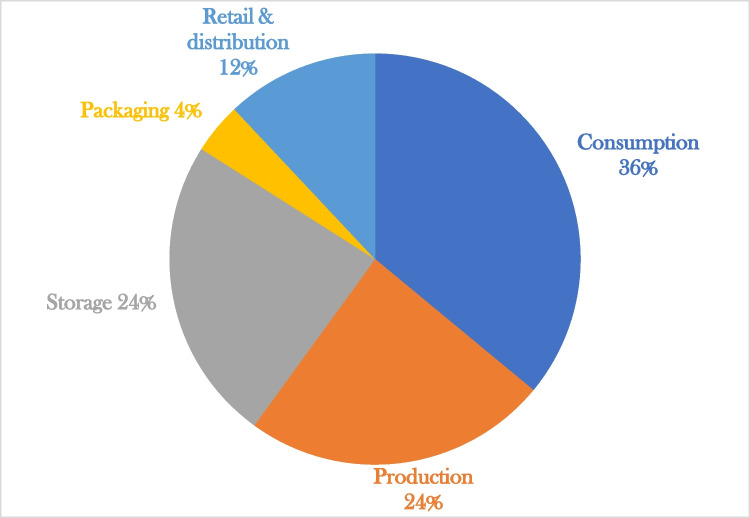

The distribution of global food waste from production to consumption in developing and developed countries is mentioned in Fig. 2 in detail with percentage consumption, production, storage, packaging, and retail and distribution. These food wastes are subject to inefficient planning of stocks which leads to overstocking in markets followed by unpopular consumer preference and larger food portion sizes which ultimately result in leftovers at a large scale and consumer attitude of not taking leftovers/discarded food due to consumer preferences. Distribution centers, wholesalers, retailers, and allied transport are included in the distribution stage. Perishable commodities are the root cause of waste during storage and distribution. Products that need chilling or freezing for enhanced shelf life are particularly difficult to manage as inadequate cold chain management methodologies result in significant food waste (Jeswani et al. 2021).

Fig. 2.

Distribution (%) of global food waste from production to consumption in developing and developed countries.

Source: adapted from the High-Level Panel of Experts on Food Security and Nutrition Losses, H.F, 2014; Sridhar et al. 2021

Moreover, dents or damages during the lifting and carrying of commodities make them inadmissible later in the supply chain. Poor record-keeping of items that have reached the end of their shelf life, rendering them unfit for sale and consumption, leads to food waste (Jeswani et al. 2021). Food waste at the retail level is more complex and varies with the product when compared to other distribution activities. Overstocking as a result of inaccurate projections, inadequate shelf stock rotation and the expiration of “best before” dates, items removed from the cold chain, insufficient storage facilities, and inadequate packaging are among them (de Moraes et al. 2020; Mena et al. 2014). Employees who are not adequately trained might contribute to food waste due to inadequate stock rotation practices (Canali et al. 2016). Retailers may mitigate such issues and the economic impact of food waste by making special offers and discounts (Schneider 2014). Growing populations and more advanced economies have focused the world’s attention on the issue of wasted food to unprecedented levels. The World Bank and the FAO estimate that each year, over 1.33 billion tons of food are lost or wasted around the world. If this trend continued, annual waste generation would increase to 2.2 billion tons. The percentage of food that is wasted around the world at each stage of the value chain, from production to consumption, is displayed in Fig. 2. In countries with higher incomes, dairy products account for nearly 17% of food waste, while in countries with lower incomes, roots and tubers account for 13%.

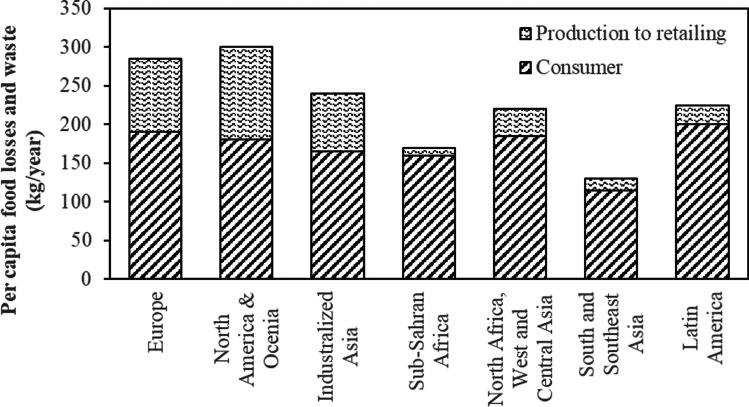

Consumer/household food wastes

Like agricultural waste, the percentage of household food waste is much higher in industrialized countries than in third-world countries. As per FAO (2011), the prime cause of food waste in industrialized countries is enough money to afford such wastage, and food loss in different regions of the world is mentioned in Fig. 3, while developing countries do not have such income, resulting in the prevention of doing so (Wani et al. 2018a; Buchner et al. 2012). According to FAO data, there is little difference between developed and developing nations in terms of waste and losses per capita at the final stages of consumption, with the exception of Southeast Asian nations. The amount of food that is wasted at the retail level is the main dividing line between developed and developing nations. This garbage generates between 95 and 115 g per person per year in the European Union and North America. There is only about 6–11 kg of food wasted per person in Southeast Asia and Sub-Saharan Africa. Throughout its production, processing, distribution, retail, and consumption phases, food is lost and wasted at a staggering rate. The production, processing, and distribution phases account for the vast majority of food waste in developing nations. In developed countries, food waste occurs primarily at the retail and consumption stages as a result of consumption patterns and expectations rather than a lack of infrastructure. In Europe, North America, and Oceania, annual per capita food waste is between 95 and 115 kg. Those in South and Southeast Asia, as well as Sub-Saharan Africa, only gain 6–11 kg annually. These visuals present condensed data from a 2011 study.

Fig. 3.

Food loss in different regions (FAOSTAT 2020)

Furthermore, studies reveal that developed countries produce more household waste as they have high income per capita than developing countries (Secondi et al. 2015). These wastes are generated after the FSC (food supply chain) at the hands of consumers/humans. The prime causes behind this are unplanned and excess buying of products, discarding products based on labeling/expiry date, improper storage of food items, especially perishable ones, and discarding behaviors.

Impacts of food waste

Food wastes threaten human health and the environment and the ubiquitous utilization of different useful sources in producing not consumed food. Poor management of decomposing food wastes leads to the emission of greenhouse gases (GHGs) and contamination of water bodies by mineral and leachate runoff which can act as a vector for diseases and various health hazards.

Waste management and sustainability concepts

The waste hierarchy principles were first established in the 1970s in the European Policy, with the 1975 Waste Directive and the EU’s 1977 Second Environment Action Program. The concept of waste hierarchy was accepted globally as the primary waste management framework after its clear definition given by the European legislation in the Community Strategy for Waste Management in 1989. The waste hierarchy guides the most environmentally friendly EoL treatment (Teigiserova et al. 2020). Asian countries, including Japan, promoted additional frameworks for waste management that have taken a similar line while highlighting the three Rs: reduction, reuse, and recycle (Sakai et al. 2011; Rather et al. 2022d). The objective of the hierarchy is to classify solutions that achieve the best environmental outcome overall; “prevention” at the top of the pyramid is the most advantageous option, whereas “disposition” at the bottom is the least valuable. The prediction (prevention) at the head of the hierarchy pyramid indicates the utmost effort to keep edible food edible. This can be accomplished through a variety of alleyways at the source, such as improved systematization and executive tools (at the manufacturing, processing, and retail levels) or by focusing on customer learning, behavior, and utilization routine at the customer level (Papargyropoulou et al. 2014; Garrone et al. 2014; Teigiserova et al. 2020; Rather et al. 2022e).

Prediction is followed by another level that depicts reuse for human consumption, and surplus food is directly reused for consumption. Furthermore, it is a component of prevention strategies or studies (Garrone et al. 2014; Mourad 2016; Teigiserova et al. 2020). Because food is perishable, the reuse of unused food is strictly governed by safety and hygiene standards, which can lessen the amount of reused food and, as a result, increase FW (Priefer et al. 2016; Teigiserova et al. 2020). Recycling is the third hierarchy level, and it is frequently confused with recovery, even though both are distinct categories. Anaerobic digestion, for example, is used in both recovery (as energy recovery) and recycling (Herszenhorn et al. 2014; Xin et al. 2018; Braguglia et al. 2018). Food redistribution is called recovery whereas FW stands for fodder (Garrone et al. 2014; Mourad 2016).

Despite the urgent need to weigh up the social and economic repercussions, Member States and the environmental impacts under the European Waste System Directive. As a framework, waste hierarchy seeks to give the most preferred ecological alternative. Several economists have criticized the hierarchy of waste, arguing that waste hierarchy should be used as an amenable protocol for developing a strategy for waste (Bano et al. 2018).

Sustainable production and consumption

In United Nations Environmental Program, Sustainable consumption and manufacturing (SCP) was stated as “the production and consumption of products and services that respond to basic requirements and thereby increase the value of life while reducing the use of natural resources, hazardous materials, waste, and pollutant emissions throughout the life span so that future generations are not jeopardized.” In this context, the SCP approach is viewed as a feasible implementation action plan to achieve long-term growth that encompasses the economy, culture, and environment by leveraging technical and social innovation. The strategies included in SCP policies aim to meet humans’ basic needs, decouple environmental degradation from economic growth, and avoid the rebound effect, which describes the situation in which the adverse effects of increased consumption counterbalance the benefits of increased technological advancement and efficiency (Barrett and Scott 2012; Bengtsson et al. 2018). SCP’s main approaches target the demand for goods, supply, and services by minimizing production and consumption’s detrimental consequences. Furthermore, including sustainable production on the supply side and sustainable consumption on the demand side of human economic activities is a cornerstone idea of SCP.

Food security and food sustainability

Food security and food sustainability are two concepts that share many attributes. Many systematic disciplines and other general groups have used these broad concepts, including administrative and NGOs, which frequently come up with their definitions. They have been advanced in different arenas by international negotiations for the international community with common objectives. The concept of food security and sustainability has progressed and extended during the previous few decades. The idea of food security initially only underlined the availability and production of food. It soon grew to include physical, socio-cultural, and economic availability of food, its consumption, and lastly, the stability of all of these amounts. On the other hand, sustainability is defined as “development that meets current demands without jeopardizing future generations’ ability to satisfy their own needs” (FAO 2009; Padder et al. 2022a, b; Salvatory 2022). It also includes a time dimension that aids in determining how to weigh commutation between environmental vs. social and economic issues and assimilating long-term social and economic dimensions (Berry et al. 2015; Nizami et al. 2017).

Furthermore, while the pandemic’s long-term influence on all aspects of food security cannot be predicted, the short- and mid-term effects of COVID-19 on food systems may be quantified. COVID-19 has an immediate impact on bean output, affecting food supply and consumption. As a result, bean farmers were asked how the epidemic affected household food consumption. Farmers were asked if the outbreak affected how frequently they consumed food. The combined findings show that most Eastern African families ate twice throughout the episode. According to the data, Uganda was the most affected country in Eastern Africa, with all questioned farmers indicating that they only ate once a day throughout the epidemic. The immediate impact of COVID-19 on the food chain and government containment efforts are communicated in many ways. Seven COVID-19-related food consumption shocks were found by farmers who verified that the pandemic influenced food consumption patterns.

As a result of the epidemic and control procedure, food shortages occurred in Uganda and Kenya. This might be because of distribution and production challenges that arose during the epidemic. Second, millions of jobs have been destroyed (World Bank 2020; Nchanji and Lutomia 2021), and livelihoods and food consumption were not spared (Fox and Signé 2020). Over 3%, 20%, and 36% of farmers in Kenya, Uganda, and Burundi lost revenue during the epidemic, creating shifts in food consumption patterns. According to Nchanji and Lutomia (2021), the significant repercussions of coronavirus and government restrictions in Southern Africa were access to farmworkers and farm inputs. Another effect of the pandemic on bean yield, according to which around 27% of farmers, is the inability to acquire agricultural financing. Access to seed and product markets was another issue in the Southern Africa subregion.

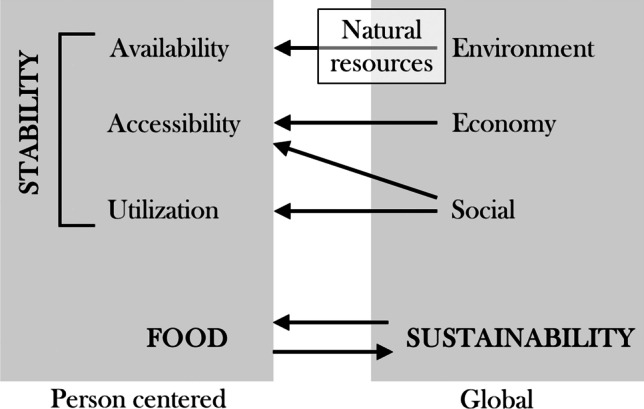

The development of food security and sustainability

“Food security” was coined during worldwide food shortages over 45 years ago. It initially ensured food supply and later price stability of essential food commodities globally and locally. It resulted from the instability of prices of food commodities in the early 1970s, followed by the fluctuation in currency and energy markets, in addition to certain unfavorable conditions. Due to famines, starvation, and food scarcity, it is necessary to be familiar with the censorious requirements and attitudes of more susceptible and afflicted individuals. (Campi et al. 2021). The 1974 World Food Conference resulted in a new definition of food security: “the availability of an adequate global food supply of vital commodities at all times to ensure a constant increase of food consumption and to compensate for changes in production and price” (Burchi and Muro 2016; Bhat et al. 2021). The blame for the crisis was put on the economic sciences that changed the structure of food industries at a global level. Though usage and stability are not mentioned explicitly in this definition, they are mostly hidden in the phrase “at all times.” The interpretation emphasizes the demand for increased production because macronutrient hunger was estimated to affect 25% of the world’s population. Future food security can be seen as contingent upon sustainability. Access to food is contingent on factors such as the local climate, the state of the environment, and the availability of natural resources. Access to food for all requires long-term economic and social stability (see Fig. 4). Food consumption is also affected by factors related to social sustainability. The stability of the systems is dependent on the consistency of the other dimensions of food security, and all three of sustainability’s pillars—social, economic, and environmental—work together to guarantee this. On the other hand, food security is increasingly considered a condition for sustainability (García-Díez et al. 2021).

Fig. 4.

The linkages and interrelationships between food security and sustainability

Incorporation of sustainability in food security

The history of sustainability is comparable to that of food security. Evaluating a system’s robustness over time without jeopardizing future generations’ ability to meet their own needs is sustainability. Though food security is an individual-centered concern, ecological and environmental tenability factors drive both regionally and globally. Sustainability is thought to be a prerequisite for persistent food security. The environment, particularly climate, and the availability of natural resources are prerequisites for the availability and preservation of food and biodiversity (Gomez-Zavaglia et al. 2020). For everyone to access food, economic and social sustainability are required. In addition, social sustainability is an essential aspect of food consumption. The three dimensions of sustainability collaborate to ensure the system’s stability, dependent on the other dimensions of food’s fidelity. Contrarily, food security is increasingly seen as a requirement for long-term viability. According to the Committee on World Food Security (2012), WFS; United Nations System High-Level Task Force on Global Food Security 2021, food and nutrition security is built on four pillars.

Food availability: the availability of ample amounts of food regularly. Food production status, food stock levels, and gross trade influence food availability. The mere existence of sufficient food does not guarantee that an individual will obtain and consume it. Food must also be available to humans (Farrukh et al. 2020).

Food access: acquiring enough food for a healthy diet. Three elements, namely affordability, preference, and distribution, describe the accessibility to food. All aspects of accessibility include economic access (i.e., buying capability), physical availability (i.e., transport and facilities), and social-cultural access and desires. Concerns about food access necessitate a greater emphasis on food costs, wages, spending, and markets.

Food utilization: built on food safety, nutritional and social value, and appropriate use of food. Utilization leads to feeding, food preparation, diversity in diet, and fair distribution of intra-household food. It is also about ensuring sufficient power and nutrition from the food consumed by individuals or households. (FAO 2011; Farrukh et al. 2020).

Stability: food availability, accessibility, and consumption It demonstrates how a country, person, or home is always food secure (Farrukh et al. 2020). Crisis and disruptions such as political unrest, extreme climatic conditions, and fiscal factors impact long-term food security.

Global reasons for concern about food security

It is commonly said that there is enough food to feed the entire planet, measured in calories per capita, if it were distributed more evenly. As per this analysis, distributive justice regarding food security is a matter of distributive justice. The dare is to build markets and work more resourcefully to stabilize barriers to effective distribution and lift productivity for the future. Food security can be achieved only if the food systems become sustainable. Therefore, sustainability is the basis of food production and ensuring healthy consumption. Climate change requires adaptation and mitigation; water stress, pressure on land use, finite fossil fuel sources, requirements for increasing soil fertility, and a rising population to nine billion by 2050 are some strains at the forefront. The UK government’s chief scientific adviser Professor John Beddington has verbalized the upcoming perfect storm of rising demand, stagnant production, and climate change.

Source reduction: reduction of waste and losses

Food security a question of indemnity?

There is a need for novel ways to look at food sustainability and security. One of the outcomes of such a move in food policy is focusing on zero hunger and nutrition. Change in perspective opens up a new way of considering food and its long-term sustainability. A question arises: should food security be viewed as an indemnity issue; what amount should we pay in premiums to ensure that we don’t go hungry, obtain the proper nutrients, and keep foodborne diseases at bay in the future? The epithet mega-watt sparks a new notion (Majumdar et al. 2018). Because the essential eco-friendly watt is the one that is not lost or wasted, energy conservation expenditures were just as effective as investments in increased production capacity. Is it possible to apply the same approach to food security and sustainability, for example, mega foods? An investment made in reducing food waste will be equivalent to a more significant food production capacity investment. As a result, decreasing food waste and food losses from the farm to the plate will be an essential component of the long-term solution for sustainably feeding 10 billion people.

Source reduction: using novel IT and AI solutions

There is a need to cut down on food waste losses to accomplish sustainability. This proposal is in line with the goals of lowering resource consumption and environmental impact. In contrast, the customers desire to buy their required food whenever convenient. Certain food businesses face difficulties receiving suitable inventory policies, i.e., reordering foods and maintaining appropriate stock levels. Moreover, food businesses and retailers face problems in allocating resources which is the current challenge of eliminating food waste and stock-outs. In addition to inaccurate sales forecasting, the incorrect ordering of products results in food waste and stock-outs (Kayikci et al. 2022; Bano et al. 2022a). The factors such as season, weather, event, price, promotions or discounts, characteristics of products, and the number of consumer visits are linked to the demand for food put up for sale in stores. Few standard statistical model assumptions are being violated because of the volatile time series in food retail and the changing skewness over time.

Here arises a question: is there any possibility of using predictive models, neural networks, machine learning, and expert systems to predict demand for food by various food business operators? Or is there any possibility of fine-tuning the supply chain and demand projections, minimizing the stock-outs and food waste? The daily sales of perishable commodities could be forecasted using the seasonal autoregressive model, forecasting models with integrated moving averages, and external variable models (Hussain et al. 2021; Haselbeck et al. 2022). Using two or more models with diverse investigative approaches would improve forecast accuracy. Prediction of good demand at convenience stores for fresh food is possible by combining moving averages with the backpropagation neural networks.

Moreover, better predictions for food materials will possibly be made using huge data approaches, including remote sensing images, metrology, genetic information, laboratory findings, and historical production statistics (Gounden et al. 2015). To benefit from these promising data models, food quality and food safety contemplations must be included. In the age of big data, there are concepts for food security that are complementary and competitive (Ropodi et al. 2016; Nychas et al. 2016; Bano et al. 2022b). Multidisciplinary approaches to food quality and safety should improve the food business’s tools (Ropodi et al. 2016). Complicated and opaque processes like machine learning and computational intelligence could be used to analyze these massive data volumes in real time (Beylot et al. 2013; Ropodi et al. 2016). Lack of precision means complex evidence-based recommendations and interpretation of results. However, raw applications regarding forecasting food supply and demand by monitoring the food chain from the farm to the plate and disregarding the concern related to food safety could be a way to the disaster. Therefore, great statistical strategies must be included in food safety considerations.

Moreover, the benefits possibly will include food waste reduction, food safety assurance, and reassurance of trust between the food industry and consumers. Furthermore, it will be beneficial if a shift from destructive testing toward automated monitoring, non-destructive or non-invasive based on sensors, is made. The sensors monitor production instantaneously and are implemented quickly on-site. The vast amount of high throughput, analytical as well, and metadata that is collected with such devices will automatically provide a holistic sight of both spoilage as well as decaying processes of the variety of food processes across a wide range of storage conditions (packaging and temperature) allowing for better food supply forecasting. The current available online knowledge would also provide endless benefits for the food industry.

Shelf lives “best before date” and “use by date”: source reduction by intelligent labeling

In the case of food pieces of stuff, the important food quality management tool is the “best before date.” Food commodities’ shelf life is labeled “use by date” or “best before date.” The food industries give complete assurance of the quality and safety of food consumed before its “best before date” and provide cold or dark storage instructions. Once the food passes through its “best before date,” it is still acceptable, with deteriorated quality. Consumers usually consider the food unsafe and unfit for consumption resulting in the throwing away of food as waste. This is because of consumers’ confusion about interpreting “best before” and “use by” dates as hazardous “after those dates.” In the case of use by date, the food industry guarantees food safety, and then only consumers can discard the food. The food must adhere to the microbiological safety guidelines of the end product on the last “use by date.” Microbiological safety guidelines are legally enforceable in the European Union (E.U.) [Commission Regulation (E.C.) No 2073/2005]. Governments’ capacity to mitigate famines by importing food from other countries, for example, should be based on the amount of listeria. Food safety requires confidence, and block-chains usage could help build that trust while speeding up the process.

Intelligent labeling and sensors

Among the most significant opportunities for decreasing food waste and enhancing food security are using sensors and intelligent packaging (Newsome et al. 2014). The sensors are categorized into four major classes—freshness sensors, gas sensors for food package integrity, identification tags like radio-frequency identification tags, and time–temperature indicators (TTI). Now temperature violation at any point along the distribution chain could be detected by TTI permitting lively dating of a food product’s shelf life. Cheating a consumer by replacing labels of “use by dates” has become difficult for business operators as TTI indicators quickly show the condition of foodstuff by the color on its strip. If the color has turned red, the food is unpalatable, while yellow indicates declined food quality. There are also freshness indicators that monitor the freshness of the product simply by reacting to metabolites generated by the food product. For each foodstuff, freshness indicators need to be calibrated. Gas sensors check the food packaging integrity, changes in gas metabolites, and leakages of protective atmospheres (Ghaani et al. 2016; Malik et al. 2018). Commercializing sensors globally needs to be cheap, reusable, reversible, and long-lasting. There are RFID tags that help trace and track foodstuffs as it gives real-time data regarding the identity of the food chain and the food product. RFID tags also provide complete data to analyze food waste sources and losses. Moreover, food frauds in food production that emerged a few years back could be controlled by these tags (Evans 2011; Manning and Soon 2016).

Source reduction: reduction of food losses by the intensification of food production

As per Rockström et al. (2017), the long-term sustainability criteria must be aligned with the development of food production. Agriculture must operate within its environmental constraints to be long-term sustainable. This approach’s fundamental considerations include resource footprints and resilience, ecological and social elements of food security, and advances in the lives of global food production systems. Both aquaculture and agriculture are considered drivers of global climatic and environmental change, and they should change their focus to become the foundation for global sustainability. Food security resilience and its ability to deal with the stress and shocks in food production and distribution severely raise the risk of hunger, foodborne diseases, and malnutrition. The binary challenge of shrinking arable land and increasing the global population (Gerhardt et al. 2020). As per Johnson et al. (2018), the loss percent of the edible vegetable in the fields is more than half of its production. These losses are due to failures at different levels, such as at the harvest, supermarkets (e.g., wrong, shaped cucumbers), and uneven crop ripening. This suggests a simple technique to increase the available food and improve food security while posing a few hazards, such as food safety.

Furthermore, sustainability will show improvement as doubling the plant food amounts supplied to consumers will require the same amount of footprints in labor, fertilizer, chemicals, and irrigation water. The second strategy may replace traditional meat products with innovative animal proteins generated from insect-fed food waste and byproducts. The third option is increasing resilience by moving down the food chain and ingesting grains destined for animal feed. Food security and sustainability would improve reasonably if animal production depended on feeds only and was not accessible for human utilization (i.e., grasslands and pastures). It means for high-quality protein supply ensuring future food security, and the significant contributors would be the Nigerian production of beef, mutton, and milk. Due to increased animal nutrition, health, and illness prevention, animal production intensification might considerably contribute to low and middle-income countries’ sustainable development (Canali et al. 2016; Dora et al. 2020).

Antimicrobials in food production: a case of unsustainable intensification

The use of antimicrobials intensifies animal production simply by fixing feed conversions and animal growth, i.e., zoo-technical service. The method is associated with substantial industrial production systems wherein antimicrobials are used as raw materials. One of the controversies rose when Swedish joined E.U. in 1995 and banned zoo-technical antimicrobials. The Swedish Commission on Antimicrobial Feed Additives SOU, 1997, concluded that even as antimicrobial use intensifies animal production and decreases footprints, such improvements cannot outweigh the negative consequences of antimicrobial resistance (AMR). With Regulation (E.U.) 2019/4, the E.U. has outlawed antimicrobials for growth promotion and prevention after more than 20 years. The antimicrobials used in plant production are “tetracycline" and “streptomycin,” usually used as spray treatments for orchards. Streptomycin resistance has become extensive among bacterial plant diseases, exemplifying the general issues with utilizing antimicrobials as productivity boosters. As a result, together with biocontrol agents, resistant plants, and disinfectants, a new approach to antimicrobials in plant production is required (Nafees et al. 2023; Thakur and Rather 2023). As a result, we need biocontrol agents, disinfectants, and resistant plants as alternatives to antimicrobials in plant production.

Reprocess or redistribute food

Food redistribution is done through different food donation programs and food banks. Both are examples of urban mining (Schneider 2014; Wani et al. 2018b; May et al. 2020). Such events are significant for making food available to underprivileged and socioeconomic groups. Moreover, the foods that are being donated are close to their end shelf lives, and “use-by dates,” would specify an increased foodborne risk, while “best before “dates usually denote the decreased quality.

Food donations: liability concerns

Is it possible that liability concerns will limit people’s food donation or redistribution willingness? Well, an example will help us to understand it. For example, around 10% of every bread in Austrian supermarkets is rejected (Lebersorger and Schneider 2014). Only 7% of the abandoned bread is donated to food banks, accounting for less than 1% of bread production. One of the reasons might be the liability concerns of food business operators associated with the foodborne disease while donating perishable food items. Two developed countries USA and Italy implemented Good Samaritan laws to ease liability concerns. These laws are fruitful for donors as it protects them from liability. At the same time, they donate to such non-profit organizations and protect them from civil and criminal liability if the product contributed causes any harm to the needy beneficiary. To support this food donation, legislation on donating these food pieces of stuff without incurring penalties is needed.

Reprocessing of foodstuffs for human consumption

Reprocessing is when an item approaches its “best before” or “use by” dates; it is frozen or reheated. For example, beef chunks and salmon fillets are chopped to produce salmon or beef patties, then fried to extend their shelf life. Freezing items just before their use-by or best-before dates is another option. The third option is to reheat leftovers or utilize them as a raw material for a subsequent meal. A study was conducted by Swedish supermarkets (Fogelberg 2011) that found supermarkets have a chef who makes warm lunches and dinners a paying proposition. With this approach, the amount of food waste was significantly reduced. Moreover, customers got improved services, and business operators and supermarkets got another opportunity. The food planned to throw in the bin is now being processed into meals and sold to fetch more profits. In addition, hygiene standards were enhanced among both chefs and other employees. Once the food is processed and reheated, it would increase sales but leave food at risk. The growth of toxin-producing bacteria linked with delayed cooling and then warming of pea soup is a good example.

A typical example would be the growth of toxin-producing bacteria associated with delayed cooling and then warming of pea soup (Fogelberg 2011; Wani et al. 2018c). In Sweden, about 20% of reported cases of foodborne illnesses linked with bacteria-producing toxins (Bacillus cereus, Clostridium perfringens) had been reported (Vagsholm et al. 2020), whereas EFSA (European Food Safety Authority) indicated that 18.5% of foodborne outbreaks were connected to bacterial toxins in the E.U. in the year 2018 (EFSA (European Food Safety Authority 2019). Clostridium perfringens intoxications in food are associated with slow cooling and warming food such as pea soup with meat (Fogelberg 2011). Food reprocessing benefits food sustainability and security, but there must be no negative trade-offs with food security. As a result, food processing industry owners and operators must be trained.

Food quality loss or waste metrics

Food quality loss or waste (FQLW) is simply the loss of a food quality characteristic (nutrition, appearance, etc.) due to product deterioration in the food chain, from the harvest to its consumption. Various metrics have distinct consequences in terms of data requirements, measurement techniques, computation outputs, and discussion of data. Some measurements may be more meaningful based on the conditions or types of people involved and how FLW is measured.

FLW is expressed in the form of food mass. Caloric measures have been utilized in specific research, whereas economic units have been used in others. FQLW is more difficult to evaluate and quantify since it has various qualitative and nutritional properties that are not connected. With growing FQLW, there is often a loss of economic value, as in the case of a drop in prominent quality features (fresh products or expiration dates).

Food mass

At all levels of analysis, the most common method for metrics is the evaluation of FLW in mass, which is typically the most conveniently available and analogous data. This is consistent with the definition of FLW we employ in this research. It has been embraced by the majority of studies published to date, including the comprehensive FLW study (FAO 2011).

Calorie

Measuring FLW in calorie units is another option. Kummu et al. 2012 used the caloric content of various meals to transform FLW statistics as stated in mass in FAO (2011) into calories. As a result, the FLW of the energy-dense meals is given a higher “weight” in the FLW computation. This technique should not be confused with the one employed to assess efficient food systems, which is fundamentally distinct.

Nutritional value of food waste

The nutritional components are not fully accounted for by FLW accounting in mass: food amount can be retained (low FLW levels), but protein quality and nutrients are not always preserved. Hence, in this paper, we have proposed a new FQLW definition to account for scenarios where nutritional characteristics are lost without a corresponding FLW.

The FAO and Messe Düsseldorf GmbH created the Worldwide Initiative on Food Loss and Waste Reduction (also known as SAVE FOOD) in 2011, one of the most significant global efforts. “SAVE FOOD” facilitates and enables (i) making people aware; (ii) collaboration and coordination of global activities, and community organizations; (iii) policy, strategy, and evidence-based program creation; and (iv) technical support with funders, bilateral/multilateral bodies, banks, the public and commercial sectors, and community organizations. Moreover, this comprises technical and administrative support and capacity development (guidance) for food supply chain actors and organizations interested in food waste reduction and food loss, whether at the subsector or policy level. Loss assessments can be improved by integrating a food chain approach with a cost–benefit analysis. SAVE FOOD is performing several national–regional studies in the field that are needed to identify the most effective strategies for minimizing food loss and techniques that offer the highest returns on investment. The program also conducts research on the socioeconomic effects of food loss and waste and the political and regulatory environment that influences food loss and waste. Studies on grains, fruits and vegetables, roots and tubers, milk, and fish have already been undertaken in Kenya and Cameroon, and more will be conducted (FAOSTAT 2020). Globally, some case studies and initiatives on food waste generation and their effective management and environmental sustainability are listed below in Table 2.

Table 2.

Globally case studies and initiatives on food waste generation

| Country | Case study | Reference |

|---|---|---|

| China | “Empty Plate” Campaign raises awareness about food waste. Initially, the program focused on food consumption by the public, various receptions, and dinners. According to anecdotal evidence, since the campaign began, restaurant food waste has decreased significantly since January 2013. It includes national public media mobilization, including the state-run CCTV and several provincial T.V. stations, and a series of public advertisements aimed at reducing food waste | Losses 2014 |

| Republic of Korea | “Half-bowl” Campaign—to prevent food waste in restaurants, this ad encourages consumers to order half a rice bowl. By the end of the year, it was intended to have reduced restaurant FLW by 20%. Some firms developed a new food container with an additional layer inside to keep air and moisture out and halt the rotting process | Losses 2014 |

| Japan | “Extending delivery dates in Japan”—to reduce FLW, Japan tried to extend the delivery date. In Japan’s food industry, there is a “1/3 rule,” which states that more than one-third of food goods are not distributed to shops over their expiration date. The food delivery date will be extended to half of the expiry date by participating firms | Losses 2014 |

| UK | “Love Food Hate Waste”—in just 6 months, food waste in West London was reduced by 14% due to this effort. The “4 E’s” behavioral change paradigm was used to construct the campaign and approach: enabling individuals to make a difference, motivating action, participating in the community, and exemplifying what others are doing. Families who reported they were aware of the commercial and other food-waste messaging and claimed to do anything different reduced avoidable food waste by 43%, a statistically significant difference | (WRAP 2013) |

| Netherlands |

“Food Battle”—this campaign aimed to reduce family food waste. Recognizing that knowledge alone is insufficient encourages individuals to feel the amount of food wasted at home physically. This entailed maintaining a 3-week journal on how much food was wasted and providing practical advice and specific solutions. A unique component of the Food Battle intervention is the influence of the social environment (neighbors, sociological groupings, shopping places, etc.). In the Netherlands, the first Food Battle resulted in participants wasting 20% less food over 3 weeks In 2014, the second Food Battle, staged in partnership with the national women’s organization Vrouwen van Nu, resulted in a 30% reduction in edible food waste |

(Bos-Brouwers et al. 2013) |

| Denmark | Stop wasting food—consumers developed this consumer campaign against food waste in Denmark for consumers by a non-governmental organization (NGO). It aims to raise awareness among people by organizing campaigns, mobilizing the media, and fostering discussions, debates, and other events to reduce FLW. It encourages customers to take action and take personal steps like preparing leftovers, purchasing more wisely, and distributing excess food. It contributes to the Danish Minister of the Environment’s Initiative Group Against Food Waste | Losses 2014 |

Current food waste treatment methods: novel approaches

The five basic treatment strategies commonly used in developed countries are composting or natural fertilizer, livestock feeding, incineration, landfills, and anaerobic digestion. According to the literature, landfills and open dumps are the most prevalent food waste disposal methods due to their high usage rates (Thi et al. 2015; Rather et al. 2022f). The recorded statistics on current food waste treatments in developing countries show dumps or landfills (90% use) and compositing (1 to 6%) as a widely used methods. Anaerobic digestion (0.6%) and animal feeding and incineration treatments are barely used. To help meet the growing demand for energy around the world, the anaerobic digestion method has emerged as a viable option.

Application I: animal feeding

A range of food waste items from various sources and kinds are employed in feeding trials. These food wastes are divided into three categories: (i) manufacturing co-products/byproducts, which usually comprise consistent and well-known constituents like wheat middlings and oilseed meals; (ii) refusals/residuals from processed foods, such as those from industrial bakeries or produce packing plants sites; (iii) a tangle of discarded food from food service establishments (e.g., cafeterias, restaurants), the contents of which are uncertain. This is because manufacturing co-products/byproducts and food-processing refusals/residues are commonly employed in animal feed. For example, in the USA, 10.9 million tons of milling co-products, 30.4 million tons of oilseed meals, 2.5 million tons of animal proteins, and an estimated 27 million tons of brewing and ethanol co-products are given to livestock animals each year (Ferguson 2016). This feeding approach is helpful because of the economies of scale and the predictability of the quality and amount of waste materials. Indeed, in the USA, industrial by-products are not included in food waste statistics (ReFED 2016). Contrarily, food waste occurring during the consumption phase provides the most significant challenge since it is the largest waste stream formed in the food chain. Given its enormity and the limits of alternative management methods, its recovery and treatment for feeding animals are significant.

Local legislation in several nations with solid demand for livestock feed, like South Korea, Taiwan, and Japan, encourages food waste to feed animals, accounting for 33%, 81%, and 72% of the overall FW generation (Thi et al. 2015). On the contrary, developing countries do not practice the segregation and collection of food waste, thereby mixing food waste with municipal solid waste, which could not be decontaminated and utilized as animal feed.

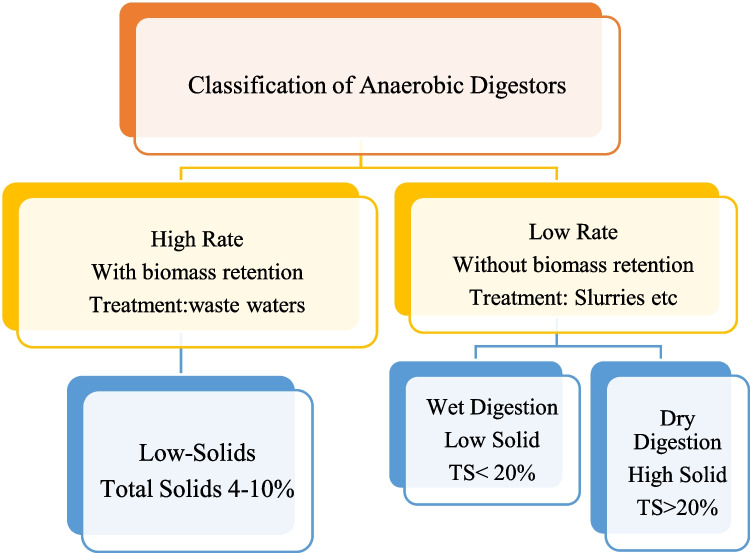

Application II: anaerobic digestion

From 2006 onwards, the EU and many developed countries of Asia widely accepted anaerobic digestion (AD) as a food waste treatment (Abbasi et al. 2012; Sharma et al. 2022). On the contrary, AD is hardly applied to manage food waste. Various institutes and NGOs in China and India established different anaerobic digesters for food waste treatment at residential and industrial levels (Rodriguez-Jiménez et al.2022). Several institutes use pilot-scale anaerobic digester and biogas plants installed in India. About twenty anaerobic digestive projects are being planned or implemented in China for municipal solid wastes, food wastes, and manures. However, the full scale of anaerobic digestive plants based on food abutments has still to be established. Inadequate operations or management regulations do not function adequately in the majority of the anaerobic digesters due to technical failures (Thi et al. 2015). Some countries like Indonesia, Vietnam, and the Philippines generally assimilate anaerobic digestion with compositing to dispose of food waste in landfill sites (Kim 2016).

Meanwhile, Thailand and Jamaica have important success through anaerobic digestion and the aerobic composting process for various food waste treatments. Jamaica has a group of biogas Carib Share that treats food waste through anaerobic digestion to generate power for agrarian societies (Meghan 2014). Enzymatic hydrolysis, acid synthesis, and gas production are the three steps of anaerobic digestion.

Application III: composting

In developing countries, compositing is considered the most efficient form of waste disposal. Around 70 composite plants handle the mixed urban waste in India, generating approximately 4.3 million tons each year by recycling up to 5.9% of total FW. In Vijayawada and Suryapetare, two plants are recognized for handling the source’s organic waste (Annepu 2012; Bano et al. 2021). Compositing is a common approach in Thailand to treat organic solid waste. The production of organic fertilizer and biogas was done by composting around 0.59 million tonnes of food waste (Zhang et al. 2014; Thi et al. 2015).

The Malaysian government has taken vermicompost as a primary national policy to produce bio-fertilizer utilizing FW (Wani et al. 2018d). However, there are still a few inefficiencies in composting output induced by unprocessed waste feedstock, which is a consequence of most developed countries’ incomplete source-segregated food waste schemes. Therefore, composite markets are weak, and food waste composts must compete with chemical fertilizers, which causes problems in composite facilities’ operations and investment. Increased communication, knowledge diffusion, and training about how to build resilience and improve food waste reduction practices among different actors can result from the implementation of food waste reduction initiatives by non-governmental organizations and retailer associations.(de Oliveira et al. 2022).

Application IV: incineration

Incineration is the most effective way to reduce waste volumes and demand for sites. This technique is used in high-income nations, including Singapore and America (Roy and Tarafdar 2022) and countries such as Ethiopia, Bangladesh, and India have recently taken initiatives to adopt incineration plants although with small-scale capacity (Kabir et al. 2022). It is an invasive investment requiring much upkeep compared to other treatments. In addition, the control of gas emission residues involves the application of expensive instruments with highly technical operations. However, this method is unusual for treating food waste in developing countries like Brazil and Ukraine (Thi et al. 2015).

Application V: landfill

The special food waste treatment techniques in developing countries which are estimated to dispose of 90% of total food waste are open dumps and landfills. Several new landfills have been built to capture potentially harmful landfill gas emissions and convert them to biofuel (Sufficiency et al. 2022). Many countries have been found to disposal of unsorted food waste from waste through landfill sites, including Malaysia, Romania, Brazil, Mexico, Southern Africa, China, Turkey, Costa Rica, Belarus, Jamaica, Ukraine, Vietnam, and Nigeria, estimating that about 20 to 80% of food waste generated globally has not been segregated from the solid waste by municipal governmental authorities. As per various pieces of literature, the landfill method is considered a realistic method for food waste treatment because of its biodegradability and the potential to produce disease vectors. Moreover, it has been found that there is an increase of 8% in the emission of greenhouse gases.

Energy generation by food wastes

Food waste is simply recycled, treated with different processes, and deposited in most developing countries and does not generate any resource in return. Such practices pose a serious ecological risk and are not economically sustainable for food waste management. Table 3 represents the various methods for converting food waste to energy, including their products and uses in most developed and developing countries, particularly in generating resources.

Table 3.

Various methods for converting food waste to energy

| Current technology | Advantages | Challenge | Primary products | Application |

|---|---|---|---|---|

| Anaerobic digestion |

Treatment of high-moisture biomass feedstock with this technology is common Lower CO2 production than a landfill with a greater CH4 concentration |

Not suited for all types of trash (especially waste with little organic content) System stability has deteriorated |

Biogas | Electricity, fertilizers, biorefineries |

| Compositing |

Waste stabilization and volume reduction To create an efficient yield, soil conditioners are required |

Appropriate for the composting process It necessitates labor Nutritional losses and odor problems as a result of the process |

Compost | Heat energy, fertilizers |

| Incineration |

Reductions in mass and volume of up to 70 to 80% are possible High-calorie content Has the ability to treat large amounts of waste in a short length of time |

Toxic compounds are produced, resulting in pollution of the air and water High initial investment costs |

Heat | Heat energy, electricity |

| Landfills |

No expert labor is required Least cost Any type of land can be used Natural resources are returned to the earth |

Pollution of the soil and groundwater It necessitates a significant amount of land Excessive emissions of greenhouse gases (GHGs) Treatment of leachates is expensive Increased transportation prices |

Landfill gas | Electricity |

Anaerobic digestion

Many biogas and electricity generation studies were recently conducted to develop a more feasible and economical way of managing food waste and recovering energy. Anaerobic digestion (AD) has become a popular approach to reducing volume and energy recovery. To maximize methane production, a two-step anaerobic digester separates hydrolysis and fermentation from a methanogenic final stage in anaerobic digestion to optimize biogas production (methane). Feeding food waste into a digester increases methane generation: the more significant the methane load concentration, the greater the energy production. Without oxygen, waste is decomposed at different time–temperature combinations in the digesters. Biogas is collected in storage tanks and desulphurized to reduce the biogas sulfur content. Biogas is further processed following application and competence rules.

There are four main stages to anaerobic digestion: hydrolysis, acidogenesis, acetogenesis, and methanogenesis; AD is the disintegration of organic compounds in digestors. Hydrolysis breaks organic matter into simple sugar, fatty acids, and amino acids. The products are then fermented in acidogenesis into volatile fatty acids and alcohol. The fermented products undergo conversion in acetogenesis, leading to carbon dioxide, hydrogen, and ammonia. Biogas is produced from acetate acid and hydrogen in the final stage of methanogenesis. Figure 5 shows the following steps. Anaerobic digestion is done at different time–temperature combinations with optimal temperatures ranging from 55 to 60 °C (thermophilic) and 35–40° C (mesophilic) (Oreggioni et al. 2017). Most of the global food waste is handled in mesophilic ranges. Such installations need less heat and are easily managed. The anaerobic digesters are classified into different categories depending on the components of foods, which are listed in Fig. 5. The main drawback of A.D. is the acidity (pH < 5) developed by the production of volatile fatty acids (VFA), which can end the whole digestion process. However, this procedure has been highly appreciated.

Fig. 5.

Classification of different anaerobic digesters for waste conversion

Microbial fuel cells

The bioelectric system of microbial fuel cells (MFCs) directly converts stored chemical energy into electricity from food waste. The electrochemically active microorganisms in this procedure aid in the catalysis of the organic reaction by acting as an electron acceptor in an electronic diode. Unlike AD, MFCs are less acidic (low pH) and low temperature and susceptible to an acidic environment. It is more appropriate for treating low-strength organic compounds VFAs (volatile fatty acids). VFAs are very much present in hydrolysis and acidic stages due to leachate production (Xu et al. 2011; Padder et al. 2021). Therefore, it is better to use MFCs to transform VFA into electrical energy instead of the last methanogenic phase of biogas production. Several organic feedstocks in MFCs have been driven by electrical production, from simple organic products such as glucose, acetate, and butyrate to complex organic pieces like starch, protein, and meat processing waste.

Current state of the food system (during COVID-19)

According to Caiazza and Bigliardi 2020, a value chain becomes an economic and social reality during a pandemic. Food hoarding has been reported in the media in many nations, with photographs of bare shop shelves and stretched internet delivery unable to meet demand. The closure of the majority of catering firms resulted in significant food waste and financial losses. As the situation intensifies, big food corporations have issued dire warnings about disrupted supply lines and, as a result, food waste. In contrast, records show that food was purchased from supermarkets 50% of the time before the outbreak and food services 50%. Almost all food purchases are now made in supermarkets (at least for the middle class). It is worth mentioning that food chains may have to deal with fluctuating and growing demand.

Another point to consider is the food truck traffic in France, which accounts for around 5% of total traffic. Consumer behavior or purchase patterns have also changed, according to reports. There is some indication that customers did not “stockpile” to the supposed initial level; there was an average rise of 15% in the amount spent each visit, although the number of trips decreased. This shift might be due to more people making meals for themselves and their families. When compared to other countries, the USA produced less food waste, according to Rodgers et al. (2021). When the limits were implemented, gender, age, and perceived financial security were all considered; logistic regression found that Americans have had a more significant food waste reduction since the pandemic than Italians.

According to Waugh, the UK produces 90,000 tons of flour each week. The majority goes to commercial bakeries and other food manufacturers (supplied in tankers or 16 kg or 25 kg sacks), and only 4% goes to stores and supermarkets. The current estimates of 3000 tons of flour per week, or two million 1.5 kg bags, or one bag per family every 14 weeks, have altered dramatically. Baking at home grew popular as a family activity, and bakeries became scarce. The issue of food insecurity, which affects a substantial portion of the population, is one of the primary challenges that COVID-19 has identified. As a result of the lockdown, many of the social programs that were in places, such as school meals and family/grandparent support, have been halted. This has put the most vulnerable members of our communities in grave danger (because of hunger). Food insecurity among low-income households was exacerbated by induced unemployment. Programs that give back to the community, whether they be charities, food banks, or financial incentives and measures, have addressed the problem in certain nations. Nonetheless, it is a major source of concern (Vidal-Mones et al. 2021).

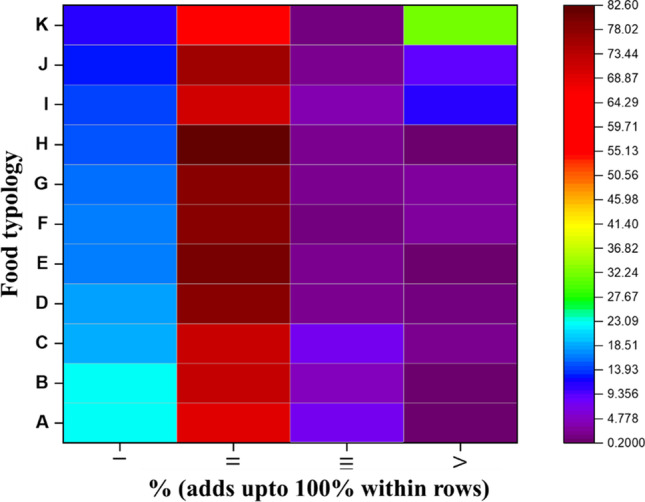

Furthermore, a higher priority for health concerns when making food selections and more frequent cooking and avoiding shops were linked to a lower likelihood of food waste. Scarcity and an increased reliance on cooking may prompt people to think about their food waste habits. Beyond the epidemic, more research should be done to see how these elements may be targeted to prevent food waste. According to food typologies, the changes in domestic food waste during the COVID-19 lockdown, including fruits, vegetables, bread, dairy, and eggs (Fig. 6). This study investigated how these changes in consumers’ daily lives influenced food waste generation at the household level. The changes in domestic food waste during the COVID-19 lockdown according to food typologies, including fruits, vegetables, bread, dairy, and eggs, besides this highest food waste generation in rice, pasta, 82.60%, eggs and dairy, 78.2%, meat, and fish, drinks, 73.44%, vegetables, 68.87%, biscuits and bread, 64.29%, precooked meals, 59.71%, fruits, 0.2%, etc., resulted from respondents’ self-reports of the amount of food that was wasted before and during the lockdown, as well as their explanations for how they handled their food supply during that time.

Fig. 6.

Changes in domestic food waste owing to COVID-19 according to food typologies during the lockdown. The food typology represents A fruits, B vegetables, C bread, D dairy, E eggs, F fish, G meat, H rice and pasta, I biscuits, J drinks, K precooked meals. And percentages within rows include I less than before, II same as before, II more than before, IV we do not eat this food

Potential for mitigating climate change