Abstract

Tips and falls are the most prominent causes of wheelchair accidents that occur when driving on uneven terrains and less accessible environments. The Mobility Enhancement Robotic Wheelchair (MEBot) was designed to improve the stability of Electric Powered Wheelchairs (EPW) when driving over these environments. MEBot offers six independently height-adjustable wheels to control attitude of its seat over uneven and angled terrains. Its attitude control application uses an inertial measurement unit to detect seat angles changes to adjust each wheel-height accordingly. MEBot was compared to commercial EPWs in terms of EPW performance (seat angle changes and response time) and participant perception (satisfaction and task-load demand) towards each device. Ten participants drove their own EPW and MEBot for five trials each through driving tasks that replicated outdoor environments. Results showed less change in the pitch angle when driving up and down a 10° slope using MEBot (5.6 ± 1.6°, 6.6 ± 0.5°) compared to the participants’ own EPW (14.6 ± 2.6°, 12.1 ± 2.6°). However, MEBot required 7.8 ± 3.0 seconds to self-adjust to the minimum angle when driving over the tasks. Participants reported no difference in satisfaction and task load demand between EPWs due to similarities in comfort and ease-of-use. Improving the speed and efficiency of MEBot’s attitude control application will be addressed in future work based upon participants’ feedback.

Keywords: accessibility, terrain negotiation, wheelchairs, assistive technology, robotics, attitude control suspension

Introduction

Electric powered wheelchairs (EPW) are vital mobility devices used by people with physical limitations [1]. EPWs provide mobility and participation in the community to improve the quality of life [2]. The United States (US) Census Bureau’s Economics and Statistics Administration reported 5.5 million wheelchair users in 2014 [3]. Approximately 9–15% of this population benefits from an EPW [4]. Additionally, aging baby boomers and increasing life expectancy correlate to an annual growth of 5% in the EPW market in the US alone [5].

EPW users are exposed to different terrains which may include uneven surfaces, curb-cuts, and steps [6]. These environmental obstacles have an impact on EPW users’ driving performance which may cause loss of traction and stability leading to tips and falls and consequently hospitalization [7, 8]. A dynamics analysis of tips and falls has shown that shallower approach angles (25°) were the “most significant predicators of tipping for restrained passengers”, but tips were generally not affected by speed [9]. Chen et al performed a study with 95 participants in which 87% of wheelchair users reported having at least one tip or fall in the past three years [10]. Another study by Xiang et al reported 100,000 wheelchair user accidents in US hospital emergency rooms in a single year where 65% - 80% are attributable to tips and falls [11]. In 2005, it was estimated that a wheelchair-related accident, including rehabilitation, could cost $25,000-$75,000 [6]. The cumulative medical- cost inflation in the US since 2005–2018 is 49.98% [12, 13]. Therefore, as of 2018, the estimated costs could be $37,500 to $112,500 for a wheelchair-related incident.

Conventional EPWs exist in front-, mid-, and rear-wheel drive configurations each with different advantages to tackle environmental obstacles. A study conducted by Koontz et al found that front-wheel drive EPWs are intuitive for maneuverability and can navigate in a variety of terrains, mid-wheel drive EPWs are favorable to maneuver in confined spaces, and rear wheeled drive EPWs are commonly known for driving at higher speeds [14]. However, Salatin et al reported that intermittent loss of traction in EPW drive wheels can cause users to get stuck or slip when traversing obstacles, often making the EPWs unstable [7]. EPWs provide powered seat tilt function for pressure relief [15, 16]. Additionally, this feature is used to adjust the user’s weight distribution while driving over slope transitions to maintain stability; however, the user is required to manually control their body from tilting to each side of their wheelchair. There are currently devices in research and development (R&D) such as the RT-Mover which has a range of motion of ± 30° pitch and roll but has limited indoor mobility due to its large footprint [17]. Two commercially available devices (iBot and Observer Maximus) offer attitude control; but limited in the pitch direction [18, 19]. Attitude control suspension lifts are equipped in some cars to keep the chassis level when weight concentrated on the rear causes the front of the car to elevate, increasing stress on the brakes, tires, and other components of the vehicle [20]. The same principle can be applied to EPW technology to keep its seat leveled and increase EPW stability. The Mobility Enhancement Robot (MEBot) wheelchair was developed to address the driving limitations of EPW users when facing environmental obstacles by incorporating an attitude control suspension system. The goals of this study were to evaluate the driving performance of the MEBot’s attitude control application and participants’ perceptions towards the application in a laboratory environment. The hypotheses for this study were formed in terms of safety, effectiveness, satisfaction, and usability. We hypothesized that MEBot will have a lower change in seat angle compared to the participant’s wheelchair (safety) (Hypothesis 1) when driving in simulated outdoor environments. Additionally, the MEBot’s leveling time will at least keep up with or be faster than the average walking speed of 0.9 m/s when negotiating the driving tasks (effectiveness) (Hypothesis 2). Last, EPW users will rate satisfaction higher (Hypothesis 3) and experience lower workload demand (usability) (Hypothesis 4) when using MEBot compared to their own EPW. The Methods section will describe the hardware and software design of the MEBot attitude control application followed by a description of the evaluation protocol. The results section will present a comparison between MEBot and participants’ EPW in terms of driving performance and participants’ perception. Last, the benefits and limitations of the MEBot attitude control will be highlighted in the Discussion section, followed by recommendations and future work.

Method

MEBot Mechanical Design

MEBot includes six independent height-adjustable wheels, an interchangeable drive wheel configuration (front-, mid-, and rear-wheel drive), and a footprint similar to conventional EPWs [21]. The drive wheel configuration enables traction compensation features, such as repositioning a slipping wheel — e.g. on ice or wet grass to an area with better traction, or maintaining the maximum proportion of the wheelchair’s weight over the driving wheels when on moderately slippery surfaces [7].

MEBot incorporates similar features to EPWs such as recline, tilt-in-space for pressure relief, and seat elevation (Figure 1) [22]. Additionally, MEBot provides advanced mobility applications such as climbing/descending curbs up to 20 cm (8.0 in.) height to enhance accessibility and maintain its seat attitude over uneven terrain to reduce the risk of tips and falls [23]. MEBot was developed by following a participatory action design process involving clinicians, engineers, and end-users [24, 25]. The first generation of MEBot was a proof-of-concept to meet EPW users’ needs when driving in everyday environments [7, 26]. MEBot’s advanced applications were presented to a focus group of EPW users in which 83% of them agreed that they would use the MEBot seat-leveling application to tackle uneven terrains [24]. Additionally, 34.8% of users reported that they had tipped over with their EPWs in common outdoor environments. EPW users suggested mechanical changes to improve MEBot [27]. These changes led to a second-generation which increased its range of motion to maintain its base leveled at angled slopes of ± 20° fore/aft and laterally (Figure 1).

Figure 1:

MEBot configuration upon obstacles

To ensure the MEBot’s safety, a kinematic stability analysis was performed following the ISO/RESNA wheelchair standards in which MEBot maintained its center of mass within its wheel footprint [21]. A user evaluation was performed with 12 active EPW users who drove MEBot and their own EPW over a driving course and compared both chairs in terms of device performance and user satisfaction [28]. The study reported the usefulness of MEBot’s seat leveling application when driving on steep ramps and curb-cuts; on the other hand, participants reported high effort and workload in terms of mental demand to operate MEBot due to the complexity of its interface and recommended automation of the application to address these issues. In a survey study, Dicianno et al showed similar feedback in which 50.2% of 500 veterans with disabilities highlighted the need to develop wheelchairs that can self-adjust or can assist with overcoming obstacles [29]. Therefore, the MEBot seat-leveling application was optimized to automatically adjust its seat on uneven terrains and reduce user’s cognitive demand.

Electronics Design

MEBot uses six active height-adjustable wheels operated by pneumatic actuators (Bimba, IL, USA) and twelve 3-position closed-loop valves (SMC, CA, USA). This feature provides 3 Degrees of Freedom (DoF) to control vertical translation (seat elevation) and rotation in the pitch and roll directions. Built-in position sensors measure the movement of each pneumatic actuator which is transformed into the wheel’s height (Figure 2). Its driving mechanism uses a commercial joystick R-NET controller (Curtis-Wright, PA, USA). The driving mechanism is mounted to the mainframe via a horizontal sliding platform controlled by two DC motors (Dumore, WI, USA) to adjust its drive-wheel configuration. The drive wheels are equipped with incremental encoders (US-Digital, WA, USA) to monitor the wheelchair speed and acceleration. Additionally, an inertial measurement unit (IMU) with 9-DoF (Adafruit, NY, USA) is attached under the seat to monitor the pitch and roll seat angles. Each sensor is fed to the main computer Cortex-A53@1.4GHz (Raspberry PI Foundation, UK). High-powered devices such as air valves, DC motors, and R-NET controller were powered by 24 V gel cell batteries; while low-powered electronics, including sensors and main computers, were powered by a 5V voltage regulator. The combination of multiple sensors and actuators allows users to perform MEBot mobility applications. Additionally, a keypad, consisting of five switches (SW 1…5), allowed users to select any of the four advanced mobility applications: power seat functions (SW1), curb ascending mode (SW2), curb descending mode (SW3), and attitude control mode (SW4). SW5 was used to operate the curb ascending and descending mode. SW5 was not used for this study. The keypad was created to reduce EPW users’ cognitive demand when operating MEBot applications. Once the attitude control mode was selected, MEBot would automatically level its seat on steep hills and cross slopes to prevent tips or falls [30].

Figure 2:

Electronics diagram of the MEBot attitude control

Attitude control Algorithm

MEBot can be configured to front-, mid-, or rear-wheel drive position. Front-wheel drive was chosen for the attitude control application due to its benefits when driving outdoors [14]. Front-wheel drive was chosen based on prior literature that supports this wheel drive configuration for outdoor environments to maintain stability and traction [31].

An initial position matrix is defined by the driving and rear wheels positions in the local coordinates. These coordinates are located in relation to the IMU location placed in the front of the frame and half of its maximum ground clearance. The seat angle error is determined by comparing the angle of the wheelchair’s frame obtained by the IMU and the angle of a plane defined by the cross-product of the wheel height positions [21, 32]. The pitch and roll angle differences are fed into a transformation matrix which is multiplied by the current wheel position to obtain the desired wheel position and to maintain the seat within the angle threshold. Attitude control is only activated when the seat angles exceed an angle threshold of ± 2.5° in the pitch and roll directions [22]. This criterion was based on the Americans with Disabilities Act (ADA) guidelines which state that an accessible slope should be a 1:12 height-to-length ratio (4.7° slope) with a safety factor of 2 [33].

Inclusion/ Exclusion Criteria

To evaluate the attitude control application, a usability evaluation was performed with EPW users comparing MEBot to their own EPWs. The study was performed at the National Veterans Wheelchair Games (NVWG) in Orlando, Florida, and the Human Engineering Research Laboratories (HERL) in Pittsburgh, Pennsylvania. Participants were older than 18 years old, weighed less than 113.4 kg (250 lbs.), were able to tolerate sitting for 3 hours, had at least 1 year of experience using a power wheelchair indoor and outdoor environment, and were properly fitted with the test wheelchair. Participants with back, pelvic, or thigh pain limiting their sitting tolerance were excluded. The study was approved by the Veterans Affairs Pittsburgh Healthcare System Institutional Review Board.

Experimental Setup

The driving tasks replicated real-world environments that EPW users encounter daily. The tasks included: going up and down a 10° slope, a compound slope (an 8° cross slope and curb-cuts), and a series of potholes (maximum diameter 12 inches and 1 inch in depth). The 10° slope simulated conventional incline and decline ramps that were non-compliant with ADA standards but used as part of the ANSI/RESNA wheelchair standards Section 2: Dynamic stability [33, 34]. The compound slope simulated a combination of cross slopes and ± 18° curb cuts used at the Cybathlon competition, where people with disabilities compete against each other in driving tasks of daily life with assistive technology [35]. Each of the segments for the compound and ramp slopes measured 1.8-meters in length. The third task simulated a series of potholes based upon a wheelchair skills test and which was 30.48 cm (12 in.) in diameter and 2.54 cm (1 in.) deep (Figure 3) [36].

Figure 3:

Outdoor Driving Tasks: (a) ± 10° slope, (b) Compound Slope, (c) Potholes

Protocol

The researcher first briefed and screened each participant to ensure that they consented with the study and met the eligibility criteria. All participants were required to complete a demographics questionnaire. To reduce learning bias, the starting EPW was randomized before the protocol. If MEBot was selected first, participants received a demonstration and training of MEBot features. MEBot used a commercial EPW controller with a joystick that participants were familiar with. Participants were trained and asked to drive around the facilities and training course to get accustomed to MEBot until the researchers were comfortable with the participant’s driving skills. Later, participants were asked to attempt each of the three tasks over 5 trials with both MEBot and their EPWs (Figure 4). Participants were asked to complete the Quebec User Evaluation of Satisfaction of Assistive Technology (QUEST) [37] prior and post executing the tasks with each EPW. At the end of the study, participants were asked to rate each EPW using the National Aeronautics and Space Administration-Total Load Index (NASA-TLX) [38]. All participants were asked to drive both EPWs at a constant speed comfortable to them throughout the tasks. The video link (https://youtu.be/5qolDq49cUM) demonstrates MEBot’s attitude control functions.

Figure 4:

Study protocol

Variables

To compare EPWs’ driving performance, the maximum seat angles deviation (pitch and roll) from a the horizontal plane was measured with an IMU sensor placed on MEBot and participant’s own EPW. The IMU was located near the seat post of each participant’s EPW which represented the center of the chair to obtain symmetric angle measurements. Also, the seat post offers a rigid structure to reduce sensor noise. The IMU’s pitch and roll values were calibrated to zero (parallel to the horizontal ground) before starting the protocol. The IMU sampling rate was at 100 Hz and a complementary filter was used to obtain the pitch and roll angles from the accelerometer and gyroscope readings. The response time was defined as the time required from the beginning of the task for the seat angle to come back within the threshold region of ± 2.5°. EPWs are often a primary means of mobility over long distances. High speeds up to 2.7 m/s would be appropriate when not amongst pedestrians, and pelican crossings (HAWK beacons) are typically set at 0.9 m/s to account older adults walking speed [39, 40]. Hence it was used as a reference standard for MEBot’s attitude control ability as EPW users would keep up with the flow of human traffic at minimum speed when adjusting through obstacles [40, 41]. To ensure participants’ safety, the speed of the wheelchair was maintained at a reasonable rate.

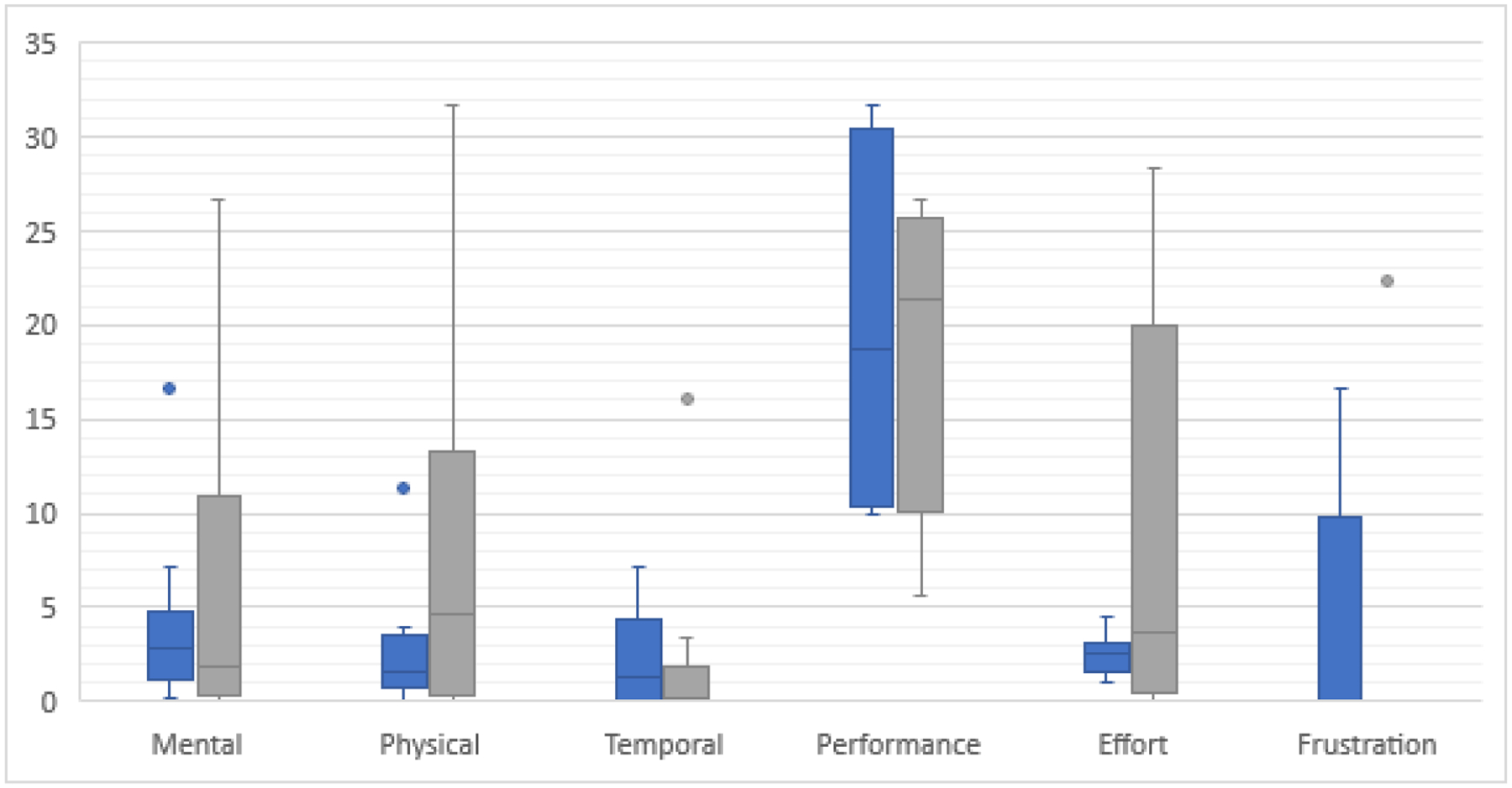

NASA-TLX

The NASA-TLX is a workload measurement tool based on 6 subscales: mental demand, physical demand, temporal demand, performance, effort, and frustration [38]. These can be clustered into three categories; objective demand, behavior, and psychological impact [42]. The six subscales were evaluated individually to compare MEBot results against the participant’s own EPWs.

The overall workload score was calculated by multiplying each raw value by the weight given to that factor by the participant. The sum of the weighted scores was then divided by 15 (total weights) to give an absolute workload score, which ranged between 0 and 100 [43]. Additionally, participants were allowed to provide comments on each subscale.

QUEST

QUEST is an assessment tool to measure user satisfaction with assistive technology [44] ranking 8 questions on a 5-point Likert scale from “Not Satisfied at all”, “Not very satisfied”, “More or less satisfied”, “Satisfied” to “Very Satisfied”. Additionally, QUEST provides 4 questions to measure assistive technology with respect to service delivery; however, this component was irrelevant to the study. Scores on QUEST subdomains were calculated individually. These subdomains were dimensions, weight, ease of adjustment, safety, durability, ease of use, comfort, and if the device was effective for the participant’s needs. The assessment tool was used for both EPWs and completed prior and post executing each task. Completing QUEST in this format allowed for differences to be highlighted between the participant’s initial perception of the EPW and their experience. Further, the QUEST assessment tool contains a comments section to allow participants to add further details of each subdomain.

Data Analysis

Excel Software 365 (Microsoft, WA) was used to tabulate data and statistical analyses were performed using Statistical Package for the Social Science (SPSS Inc., Version 25, IL). Alpha level was set at 0.05 for all comparisons.

Initial statistical analyses included a descriptive analysis of the demographics questionnaire and the outcome measures results using standard descriptive summaries (e.g., means, standard deviation, median, interquartile range (IRQ), and ranges) and graphical techniques such as box plots.

Hypothesis 1 tested the safety of EPWs by comparing the maximum angle changes in their seat (pitch and roll direction). The absolute values of the maximum seat angles were recorded for both the 10° slope and compound slope for three waypoints (going up, over, and down the slopes). The analysis of maximum pitch and roll provides the extreme seat angle measurements, thus the use of absolute deviations means and minimum to maximum ranges. The maximum positive and negative seat angle changes were analyzed for the pothole driving task since the direction of the EPW deviated due to sudden drops from the potholes. A paired t-test was used to compare the mean and standard deviation seat angle changes between EPWs.

Hypothesis 2 evaluated the average time that MEBot required to reach the seat angle threshold throughout the five trials in each task. The same timestamps to determine the seat angle changes were used for each task and compared to the average walking speed of 1.43m/s [45]. Analyzing each timestamp illustrates MEBot’s ability to maintain attitude while transitioning from different angled planes.

Hypothesis 3 & 4 used a Wilcoxon Signed Rank test to compare QUEST and NASA-TLX subdomains as they did not meet the normality test [46]. The medians and quartile ranges were used to provide a descriptive analysis of the collected data.

Results

Demographics & EPW Usage

Ten participants completed the study (8 males, 2 females) with an average age of 59.3 ± 12.6 years (Table 1). Participants reported using EPWs for average usage of 11.6 ± 7.3 years and their current EPW for average usage of 4.6 ± 4.5 years. Additionally, participants reported an average EPW usage of 11.1 ± 5.6 hours per day in total and nearly 6 days per week outdoors (Table 1). Seven participants used a mid-wheel drive EPW, two used a front-wheel drive, and one used a rear-wheel-drive EPW.

Table 1:

Participant Electric Powered Wheelchair Usage

| Participant ID | Usage of an EPW (yrs.) | Usage of current EPW (yrs.) | Usage of EPW per day (hrs) | Usage of an EPW outside the home (days/week) | EPWs | Model | Drive Configuration |

|---|---|---|---|---|---|---|---|

| 1 | 7 | 1 | 9 | 6 | Quantum | Q Edge 2.0 | Mid-wheel |

| 2 | 4 | 4 | 8 | 7 | Quickie | QM-710 | Mid-wheel |

| 3 | 20 | 1 | 6 | 5 | Permobil | M400 | Mid-wheel |

| 4 | 8 | 5 | 15 | 7 | Permobil | M300 | Mid-wheel |

| 5 | 6 | 1 | 18 | 7 | Quickie | QM-710 | Mid-wheel |

| 6 | 25 | 16 | 12 | 7 | Quickie | S-646 | Rear-wheel |

| 7 | 18 | 6 | 8 | 2 | Invacare | FDX | Front-wheel |

| 8 | 4 | 2 | 1 | 1 | Permobil | M300 | Mid-wheel |

| 9 | 13 | 5 | 18 | 7 | Permobil | M300 | Mid-wheel |

| 10 | 11 | 5 | 16 | 7 | Permobil | C400 | Front-wheel |

| Mean ± Std | 11.6 ± 7.3 | 4.6 ± 4.5 | 11.1 ± 5.6 | 5.6 ±2.3 |

EPW Driving Performance

Safety: Seat Angle Comparison

All participants completed each trial of the tasks using MEBot and their own EPW. The maximum pitch and roll were measured for all three tasks and trials. The mean, standard deviation, and p-values are displayed in Table 2. Participants’ own EPWs had a higher absolute seat angle deviation in the pitch direction (Pitch: 14.2° ± 4.0°) when going down the compound slope compared to MEBot (Pitch: 8.5° ± 2.0°). Both MEBot and participants’ own EPW had a greater roll angle change when driving over the compound slope (MEBot: 6.8° ± 1.3°, Own EPW: 8.8° ± 0.7°).

Table 2:

Seat Angle comparison

|

p < 0.05, statistically significant

Participants’ own EPW had a larger absolute seat angle deviation in the pitch direction than MEBot when going up and down the slope. The difference in pitch and roll seat angles when driving in the pothole showed no difference between both EPWs; however, participants’ EPW had a smaller change in the roll direction. The maximum pitch and roll seat angles denoted the largest positive angles while the minimum seat angles denoted the largest negative seat angles for the pothole task. MEBot had an average (out of the 5 trials) of largest minimum and maximum angle in the roll direction of −3.6° ± 1.1° and 3.9° ± 1.6°, respectively, compared to participant’s own EPW −1.6° ± 0.5° to 1.9° ± 0.4°.

Effectiveness- MEBot Attitude Control Time

The attitude control time was measured to evaluate the MEBot application’s effectiveness. showed the average time to level the seat at each waypoint of the compound slope and ± 10° slope for each participant and average leveling time for all trials. MEBot attitude control time was higher than the average walking time for each reference point on each task. MEBot required an average time of 8.1 ± 2.8 seconds to adjust its seat within the seat angle threshold that displayed the greatest variability and longest time for MEBot to adjust. The time taken for MEBot to settle over the compound yielded a time average and standard deviation of 7.8 ± 3.0 seconds. For example, results from Subject 7 showed that MEBot demonstrated an average of 2 seconds to level the seat up a ± 10° slope (Figure 5); however, traversing over and down the slope took 6.9 and 6.3 seconds respectively. Additionally, results from Subject 4 showed that MEBot leveled its seat during the 8° cross slope in contrast to the participant’s own wheelchair (Figure 6).

Figure 5:

Subject 7 ‘s angle comparison results between MEBot vs own EPW when driving a ±10° slope

Figure 6:

Subject 4’s angle comparison results between MEBot and own EPW when driving over a compound slope

Participant’s perception towards both EPWs

Usability- NASA-TLX

The NASA-TLX results are reported in Table 3. No statistically significant differences were detected. Participants showed less physical demand using MEBot (median: 1.64, IQR: 0.77 – 3.5) than their own EPWs (median: 4.6, IQR: 0.3 – 13.34) when performing the driving tasks, however, participants experienced higher mental demand using MEBot (median: 2.84, IQR: 1.17 – 4.8) than their own EPWs (median: 1.9, IQR: 0.3 – 10.84). The average overall weighted score favored the participants’ own EPWs (45.70 ± 25.15) over MEBot (35.28 ± 9.44). The frustration weighted workload scores had equated to zero for all the participants except for one participant (median: 16.67; IQR: 0 – 9.80 and median: 22.33; IQR: 0) when using MEBot and the participant’s own EPW. The disparity was shown in Figure 7.

Table 3.

MEBot attitude control time.

| MEBot |

|

|

||||

|---|---|---|---|---|---|---|

| Participant (Distance) | Up (0.46 m) | Over (1.73 m) | Down (1.73 m) | Up (1.8 m) | Over (1.22 m) | Down (1.8 m) |

| SI | n/a | 1.2 | 3.5 | 2.5 | 4.6 | 14.5 |

| S2 | n/a | 7.8 | 11 | 1.9 | 4.6 | 9.6 |

| S3 | n/a | 13.8 | 8.5 | 2.3 | 6.5 | 9 |

| S4 | n/a | 6.4 | 4.1 | 2.2 | 3.9 | 5.6 |

| S5 | n/a | 8.1 | 5.3 | 2.6 | 4.5 | 6.5 |

| S6 | n/a | 8.1 | 7.1 | 2.7 | 5.6 | 9.5 |

| S7 | n/a | 8.7 | 5.3 | 2 | 6.9 | 6.3 |

| S8 | n/a | 7 | 5.9 | 2.1 | 5.5 | 6 |

| S9 | n/a | 8.5 | 8.5 | 2.6 | 2.6 | 8.4 |

| S10 | n/a | 8.1 | 5.6 | 2.5 | 2.7 | 5.4 |

| Mean ± Std | n/a | 7.8 ± 3.0 | 6.5 ± 2.3 | 2.3 ± 0.3 | 4.7 ± 1.5 | 8.1 ± 2.8 |

| Average Walking Time per waypoint (Seconds) at 0.9 m/s | n/a | 1.92 | 1.92 | 2 | 1.36 | 2 |

Figure 7:

NASA-TLX Subscale Comparison between MEBot (blue) and participants’ own EPW (grey)

Satisfaction- QUEST

The comparison between the EPWs after the participant completed the driving course created the pooled ranking between the two dependent variables to provide the p-value. Table 5 and show no significant differences in each QUEST subdomain between EPWs with low standard deviations. The QUEST results in showed a ceiling effect which may be why it was not possible to support the fourth hypothesis. The comments stated by participants on each of the subdomains were more critical of their own EPW than MEBot. Participants reported lower safety score after driving over the tasks with their EPW compared to before driving over the tasks. Participant’s satisfaction towards MEBot didn’t show a significant difference before and after driving over the tasks, but the information can be used to improve MEBot performance over these obstacles and prevent user’s critical perception of the obstacle.

Table 5:

QUEST Subscale Comparison

| QUEST | MEBot | Own EPW | ||

|---|---|---|---|---|

| Mean ± Std Dev | p-value | Mean ± Std Dev | p-value | |

| Dimensions (PRE) | 4.4 ± 0.7 | 1.00 | 4 ± 1.3 | 0.79 |

| Dimensions (POST) | 4.2 ± 0.9 | 4.2 ± 0.8 | ||

| Weight (PRE) | 4.4 ± 0.7 | 0.32 | 4.3 ± 1.1 | 0.45 |

| Weight (POST) | 4.5 ± 0.5 | 4 ± 1.2 | ||

| Adjustment (PRE) | 3.6 ± 0.9 | 0.48 | 4.2 ± 1.3 | 0.71 |

| Adjustment (POST) | 4 ± 0.9 | 4.4 ± 0.5 | ||

| Safe (PRE) | 3.4 ± 0.7 | 0.66 | 4.4 ± 0.7 | 0.24 |

| Safe (POST) | 3.5 ± 1.4 | 3.9 ± 1.2 | ||

| Durability (PRE) | 3.7 ± 1.2 | 0.78 | 4.1 ± 1 | 0.71 |

| Durability (POST) | 3.7 ± 0.9 | 4 ± 1.3 | ||

| Easy (PRE) | 4 ± 0.7 | 0.74 | 4.6 ± 0.5 | 0.66 |

| Easy (POST) | 4 ± 0.7 | 4.5 ± 0.5 | ||

| Comfort (PRE) | 3.3 ± 0.9 | 0.85 | 4 ± 1.3 | 0.28 |

| Comfort (POST) | 3.5 ± 0.7 | 3.6 ± 1.3 | ||

| Effective (PRE) | 3.9 ± 0.8 | 0.58 | 4.1 ± 1.3 | 0.06 |

| Effective (POST) | 3.7 ± 1 | 3.5 ± 0.9 | ||

Discussion

Hypothesis 1 was supported in that MEBot maintained the seat closer to level than the participant’s own EPW for all the obstacles. However, the time it took for MEBot to return below the threshold (± 2.5°) of seat levelness was longer than the time required to complete each obstacle at average walking speed (hypothesis 2). The delayed responses in the attitude control caused MEBot to overcorrect after driving over each obstacle resulting in an oscillation of the seat angle. Furthermore, challenges with the pneumatics system included the non-linear response of the air valves and variability of air consumption that was affected by the participant’s mass, weight distribution, air tank volume, and air tank temperature. The lag in the system is where MEBot’s maximum pitch change in each direction was significantly lower than conventional EPW’s when changing planes; therefore, MEBot and its user would remain stable throughout the entire range of motion of the MEBot attitude control application. For obstacles with sufficiently long travel, such as ± 10° slope as tested in this study, the seat angle on MEBot will be in the same orientation as the slope and will initially be at the same seat angle as conventional EPWs. MEBot will correct its seat angle to be level as it proceeds along the obstacle. On transitions or bumps, the lag in the system could cause a mirror effect in the MEBot’s pitch angle. For example, if MEBot were to rapidly traverse a speed bump, MEBot could, depending on the rate of travel, adjust to the posterior tilt after the front wheels are already over the obstacles resulting in anterior tilt on the level surface. Anterior tilt on a down ramp would only be worse than a conventional EPW if immediately proceeded by an upward slope or significant bump. This effect is observed in Figure 5 when driving from ±10° slope to a flat surface.

The z-acceleration in both wheelchairs were collected to measure participants’ comfort. The maximum z-acceleration was observed in the transition between surfaces. For example, both EPWs showed a similar acceleration of 11.9m/s2 and 10.9 m/s2 when driving up the 10° slope and down the compound slope, respectively. Also, a higher acceleration of 12.6 m/s2 was observed in participants’ EPWs compared to MEBot, 10.9 m/s2, when driving down the 10° slope and driving up the compound slope. This effect could be associated with the active dampening adjustment in pneumatic actuators compared to shock absorbers used in commercial EPWs. On the other hand, an average acceleration of 9.8 ± 1.0 m/s2 was observed in MEBot after crossing the transition to a flat surface which lasted as long as the required time to level the seat. This effect was associated with the constant adjustment to level the seat and non-linear control of pneumatics which sometimes caused unnecessary adjustment. While MEBot can level the seat, proper dampening adjustment is necessary to improve EPW users’ comfort when facing these environments.

The NASA-TLX subscale scores were not statistically different between the EPWs; therefore, hypothesis 3 was not supported based upon the results. However, participants had the option of adding their own comments when evaluating each of the subscales. Participants provided comments about their EPW only such as “Frustrated when driving through the compound slope,” temporally demanding due to “lack of space to do the task” and “potholes were physically demanding.” MEBot comments included: “Easy to use buttons,” “Safe and comfortable on the slopes, “too much movement,” and “Noise from the pneumatics adjusting”. Comments of their EPW included, “Not comfortable on potholes,” “Unsafe when driving through compound slopes” and “Slopes were harder to tackle than the potholes.” Overall, hypotheses 3 and 4 demonstrated that the MEBot was not statistically different than the participant’s own EPW.

Potential Limitations

Participants were constantly observed by the researchers to instruct participants and ensure their safety. The presence of researchers and other potential participants could alter their driving behavior (Hawthorne Effect) [47]. To reduce this effect, participants were scheduled at different times to limit other participants from observing each other. MEBot was a new EPW for the participants involved which may have influenced their driving behavior. To mitigate this, MEBot’s driving and seating configurations were adapted for each participant. However, seventy percent of the participants were mid-wheel drive EPW users and MEBot was configured to front-wheel drive, which could have affected their driving behavior [48].

Other study limitations included the sample size and limitations in qualitative outcome measures. Likert scale questionnaires like the QUEST questionnaire have the likelihood of a ceiling effect, making it difficult to differentiate participants’ satisfaction between each EPW score [49]. Also, the low power of the study limited the ability to detect statistically significant differences. To complement these results, seat angle changes and task load demand results were obtained to analyze the safety and satisfaction of the devices. Also, participants’ feedback was obtained for further implementation of the MEBot attitude control application. Virzi et. al suggested that 80% of usability problems can be detected with just 4 or 5 participants from a usability evaluation [50]. The usability problems were highlighted from both written responses in the questionnaires and execution of the study. The feedback highlighted mechanical and software changes that should be addressed such as the unnecessary pneumatic movements to constantly maintain the seat leveled and the long settling time of the pneumatics to reach the desired seat angles in MEBot.

Conclusion & Future Work

The MEBot attitude control application enhanced the stability of EPW users by maintaining the seat level as compared to commercial EPWs when negotiating through each task. Even though the results on participants’ perceptions did not rise to the level of statistical significance, participants’ comments towards both EPWs highlighted the importance of increasing EPW stability when driving and provided feedback to make MEBot a more practical chair for real-world use. The NASA-TLX and QUEST showed similar satisfaction scores towards both wheelchairs can be interpreted as participants were equally satisfied with MEBot compared with their EPW.

The use of pneumatic actuators to operate the attitude control demonstrated that they are difficult to control and regulate as the pressure in the storage tank decreases. The next iteration of MEBot will utilize Electro-Hydraulic Actuators (EHA) instead of pneumatic actuators to address the hindrances identified in this study. EHA in series with shock absorbers may enable better control and smoother ability to maintain the wheelchair seat leveled. This new approach should provide controllable active and passive suspension for different terrains and angled surfaces. Additionally, the movement of the driven wheels along the x-plane could incorporate attitude control in three-wheel configurations. This feature could re-distribute the center of mass of the system creating traction when in contact with an obstacle. Furthermore, terrain pre-planning could improve the efficiency of the attitude control application. For example, using a combination of Light Detection and Ranging (LIDAR) sensor and a fisheye camera could be used to map the terrain in advance, enabling some preparatory actions before obstacles are encountered. Future work will include increasing the sample size and evaluating MEBot’s driving performance in real-world environmental conditions.

Table 4:

QUEST EPW Comparison

| QUEST | MEBot vs OWN EPW |

|---|---|

| P-value | |

| Dimension | 0.89 |

| Weight | 0.19 |

| Adjustment | 0.16 |

| Safe | 0.52 |

| Durability | 0.52 |

| Easy | 0.10 |

| Comfort | 0.48 |

| Effective | 0.75 |

Highlights.

Electric Powered Wheelchair (EPW) users are at risk of tips and falls when driving in outdoor environments

MEBot increases the stability and safety of the user by adjusting its seat to ground changes

MEBot was compared to the participant’s own EPW in controlled outdoor tasks

MEBot maintained its seat leveled compared to commercial EPWs in uneven terrains

Participants reported no difference in satisfaction and task load demand between EPWs

Acknowledgments

The authors would like to thank the National Veterans Wheelchair Games’ staff for providing the venue for subject testing and Human Engineering Research Laboratories’ staff members in aiding with the development and evaluation of the MEBot wheelchair. The contents of this paper do not represent the views of the Department of Veterans Affairs or the United States Government. This work was funded by the VA Center for Excellence for Wheelchairs and Associated Rehabilitation Engineering (Grant #B9250-C), Craig H. Nielsen Spinal Foundation, and National Institute on Disability, Independent Living, and Rehabilitation Research NIDILRR-ARRT (Grant # 90AR5021).

Abbreviations:

- EPW

Electric Powered Wheelchair

- MEBot

Mobility Enhancement roBotic Wheelchair

- IMU

Inertial Measurement Unit

- QUEST

Quebec User Evaluation of Satisfaction with assistive Technology

- NASA-TLX

NASA Task Load Index

Footnotes

Publisher's Disclaimer: This is a PDF file of an unedited manuscript that has been accepted for publication. As a service to our customers we are providing this early version of the manuscript. The manuscript will undergo copyediting, typesetting, and review of the resulting proof before it is published in its final form. Please note that during the production process errors may be discovered which could affect the content, and all legal disclaimers that apply to the journal pertain.

Conflict of Interest

None

Ethical Approval

The study was approved by the Veterans Affairs Pittsburgh Healthcare System Institutional Review Board.

References

- [1].Mortenson WB, Hammell KW, Luts A, Soles C, Miller WC. The power of power wheelchairs: Mobility choices of community-dwelling of older adults. Scandinavian journal of occupational therapy. 2015;22:394–401. [DOI] [PMC free article] [PubMed] [Google Scholar]

- [2].Edwards K, McCluskey A. A survey of adult power wheelchair and scooter users. Disability and Rehabilitation: Assistive Technology. 2010;5:411–9. [DOI] [PubMed] [Google Scholar]

- [3].Taylor DM. Americans With Disabilities: 2014. Current Population Reports: U.S Department of Commerce; 2014. p. 70–152. [Google Scholar]

- [4].Flagg J Wheeled mobility demographics. Industry profile on wheeled mobility. 2009:7–29. [Google Scholar]

- [5].LaPlante MP, Kaye HS. Demographics and trends in wheeled mobility equipment use and accessibility in the community. Assist Technol. 2010;22:3–17. [DOI] [PubMed] [Google Scholar]

- [6].Gavin-Dreschnack D, Nelson A, Fitzgerald S, Harrow J, Sanchez-Anguiano A, Ahmed S, et al. Wheelchair-related Falls: Current Evidence and Directions for Improved Quality Care. Journal of nursing care quality. 2005;20:119–27. [DOI] [PubMed] [Google Scholar]

- [7].Salatin B Electric powered wheelchair driving outdoors: The identification of driving obstacles & strategies and the development of an advanced controller: University of Pittsburgh; 2011. [Google Scholar]

- [8].Corfman TA, Cooper RA, Fitzgerald SG, Cooper R. Tips and falls during electric-powered wheelchair driving: effects of seatbelt use, legrests, and driving speed. Archives of physical medicine and rehabilitation. 2003;84:1797–802. [DOI] [PubMed] [Google Scholar]

- [9].Erickson B, Hosseini MA, Mudhar PS, Soleimani M, Aboonabi A, Arzanpour S, et al. The dynamics of electric powered wheelchair sideways tips and falls: experimental and computational analysis of impact forces and injury. Journal of NeuroEngineering and Rehabilitation. 2016;13:20. [DOI] [PMC free article] [PubMed] [Google Scholar]

- [10].Chen W-Y, Jang Y, Wang J-D, Huang W-N, Chang C-C, Mao H-F, et al. Wheelchair-Related Accidents: Relationship With Wheelchair-Using Behavior in Active Community Wheelchair Users. Archives of Physical Medicine and Rehabilitation. 2011;92:892–8. [DOI] [PubMed] [Google Scholar]

- [11].Xiang H, Chany AM, Smith GA. Wheelchair related injuries treated in US emergency departments. Injury Prevention. 2006;12:8. [DOI] [PMC free article] [PubMed] [Google Scholar]

- [12].U.S Department of Labour. Measuring Price Change in the CPI: Medical care. Medical care in US city average 2005–2018: Bureau of Labor Statistics; 2019. [Google Scholar]

- [13].Sawyer B, Cox C. How does health spending in the U.S. compare to other countries? In: Foundation KF, editor. Average annual growth rate in health consumption expenditures per capita, US dollars, PPP adjusted. Peterson-Kaiser Health System Tracker: OECD Health Statistics database and the National Health Expenditure Accounts; 2018. [Google Scholar]

- [14].Koontz AM, Brindle ED, Kankipati P, Feathers D, Cooper RA. Design features that affect the maneuverability of wheelchairs and scooters. Arch Phys Med Rehabil. 2010;91:759–64. [DOI] [PubMed] [Google Scholar]

- [15].Ding D, Leister E, Cooper RA, Cooper R, Kelleher A, Fitzgerald SG, et al. Usage of tilt-in-space, recline, and elevation seating functions in natural environment of wheelchair users. Journal of rehabilitation research and development. 2008;45:973–83. [DOI] [PubMed] [Google Scholar]

- [16].Dicianno BE, Arva J, Lieberman JM, Schmeler MR, Souza A, Phillips K, et al. RESNA position on the application of tilt, recline, and elevating legrests for wheelchairs. Assistive Technology. 2009;21:13–22. [DOI] [PubMed] [Google Scholar]

- [17].Shuro Nakajima. RT-Mover: a rough terrain mobile robot with a simple leg–wheel hybrid mechanism. The International Journal of Robotics Research. 2011;30:1609–26. [Google Scholar]

- [18].Observer Mobility. Observer Mobility 4×4 Wheelchair. 2019.

- [19].Mobility Mobius. iBot. 2019.

- [20].Fijalkowski B Automotive Mechatronics: Operational and Practical Issues: Springer; 2011. [Google Scholar]

- [21].Candiotti JL, Sundaram SA, Daveler BJ, Gebrosky B, Grindle GG, Wang H, et al. Kinematics and Stability Analysis of a Novel Power Wheelchair When Traversing Architectural Barriers. Topics in spinal cord injury rehabilitation. 2017;23:110–9. [DOI] [PMC free article] [PubMed] [Google Scholar]

- [22].Candiotti JL, Wang H, Chung CS, Kamaraj DC, Grindle GG, Shino M, et al. Design and evaluation of a seat orientation controller during uneven terrain driving. Medical engineering & physics. 2016;38:241–7. [DOI] [PubMed] [Google Scholar]

- [23].Candiotti JL, Daveler BJ, Kamaraj DC, Chung CS, Cooper R, Grindle GG, et al. A heuristic approach to overcome architectural barriers using a robotic wheelchair. IEEE transactions on neural systems and rehabilitation engineering : a publication of the IEEE Engineering in Medicine and Biology Society. 2019;27:1846–54. [DOI] [PubMed] [Google Scholar]

- [24].Daveler BJ, Salatin B, Grindle GG, Candiotti JL, Wang H, Cooper RA. Participatory design and validation of mobility enhancement robotic wheelchair. Journal of rehabilitation research and development. 2015;52:739–50. [DOI] [PubMed] [Google Scholar]

- [25].Wang HCR, Chung C, Candiotti JL, Grindle GG, Pearlman JL, Daveler BJ. Mobility Enhancement Wheelchair. United States of America: University of Pittsburgh, US Department of Veterans Affairs; 2017. [Google Scholar]

- [26].Wang H, C JL, Shino M, Chung CS, Grindle GG, Ding D, et al. Development of an advanced mobile base for personal mobility and manipulation appliance generation II robotic wheelchair. The journal of spinal cord medicine. 2013;36:333–46. [DOI] [PMC free article] [PubMed] [Google Scholar]

- [27].Candiotti JL, Kamaraj DC, Daveler B, Chung CS, Grindle GG, Cooper R, et al. Usability Evaluation of a Novel Robotic Power Wheelchair for Indoor and Outdoor Navigation. Arch Phys Med Rehabil. 2019;100:627–37. [DOI] [PMC free article] [PubMed] [Google Scholar]

- [28].Candiotti JL. Design Development and Usability Evaluation of Control Algorithms of a Mobility Enhancement Robotic Wheelchair (MEBot): University of Pittsburgh; 2018. [Google Scholar]

- [29].Dicianno BE, Joseph JM, Eckstein S, Zigler CK, Quinby E, Schmeler MR, et al. The Voice of the Consumer: A Survey of Veterans and Other Users of Assistive Technology. Mil Med. 2018;183:e518–e25. [DOI] [PMC free article] [PubMed] [Google Scholar]

- [30].Candiotti J, Wang H, Chung C-S, Kamaraj DC, Grindle GG, Shino M, et al. Design and evaluation of a seat orientation controller during uneven terrain driving. Medical engineering & physics. 2016;38:241–7. [DOI] [PubMed] [Google Scholar]

- [31].Ding D, Cooper RA. Electric powered wheelchairs. IEEE Control Systems Magazine. 2005;25:22–34. [Google Scholar]

- [32].Sundaram SA, Candiotti JL, Wang H, RA C. Development And Simulation Of A Self-Leveling Algorithm For The Mobility Enhancement Robotic Wheelchair. Rehabilitation Engineering and Assistive Technology Society of North America,. Arlington, Virginia: 2016. [Google Scholar]

- [33].Americans with Disabilities Act (ADA). Accessible Routes- Slopes. Slopes: United States Access Board; 2010.

- [34].Rehabilitation Engineering & Assistive Technology Society of North America (RESNA). Additional Requirements for wheelchairs (including Scooters) with Electrical Systems. Volume 2: American National Standard for wheelchairs; 2009. [Google Scholar]

- [35].Riener R The Cybathlon promotes the development of assistive technology for people with physical disabilities. Journal of NeuroEngineering and Rehabilitation. 2016;13:49. [DOI] [PMC free article] [PubMed] [Google Scholar]

- [36].Rushton PW, Kirby RL, Routhier F, Smith C. Measurement properties of the Wheelchair Skills Test – Questionnaire for powered wheelchair users. Disability and Rehabilitation: Assistive Technology. 2016;11:400–6. [DOI] [PMC free article] [PubMed] [Google Scholar]

- [37].Demers L, Weiss-Lambrou R, Ska B. The Quebec User Evaluation of Satisfaction with Assistive Technology (QUEST 2.0): An overview of recent progress. Technology and Disability. 2002;14:101–5. [Google Scholar]

- [38].Hart SG. NASA task load index (TLX). Volume 1.0; Paper and pencil package. Moffett Field, CA United States: NASA Ames Research Center; 1986. [Google Scholar]

- [39].Duim E, Lebrão ML, Antunes JLF. Walking speed of older people and pedestrian crossing time. Journal of Transport & Health. 2017;5:70–6. [Google Scholar]

- [40].Cooper RA, Thorman T, Cooper R, Dvorznak MJ, Fitzgerald SG, Ammer W, et al. Driving characteristics of electric-powered wheelchair users: How far, fast, and often do people drive? Archives of Physical Medicine and Rehabilitation. 2002;83:250–5. [DOI] [PubMed] [Google Scholar]

- [41].Himann JE, Cunningham DA, Rechnitzer PA, Paterson DH. Age-related changes in speed of walking. Med Sci Sports Exerc. 1988;20:161–6. [DOI] [PubMed] [Google Scholar]

- [42].Hart SG, Stavenland LE. Development of NASA-TLX (Task Load Index): Results of empirical and theoretical research. In: Hancock PA, Meshkati N, editors. Advances in Psychology 1988. p. 139–83. [Google Scholar]

- [43].Noyes JM, Bruneau DPJ. A self-analysis of the NASA-TLX workload measure. Ergonomics. 2007;50:514–9. [DOI] [PubMed] [Google Scholar]

- [44].Demers L, Weiss-Lambrou R, Ska B. Development of the Quebec User Evaluation of Satisfaction with assistive Technology (QUEST). Assistive Technology. 1996;8:3–13. [DOI] [PubMed] [Google Scholar]

- [45].Bohannon RW, Williams AA. Normal walking speed: a descriptive meta-analysis. Physiotherapy. 2011;97:182–9. [DOI] [PubMed] [Google Scholar]

- [46].RC B, Higgins JJ. Comparison of the power of the paired samples t test to that of Wilcoxon’s signed-ranks test under various population shapes. Psychological Bulletin. 1985;97:119. [Google Scholar]

- [47].McCambridge J, Witton J, Elbourne DR. Systematic review of the Hawthorne effect: new concepts are needed to study research participation effects. Journal of clinical epidemiology. 2014;67:267–77. [DOI] [PMC free article] [PubMed] [Google Scholar]

- [48].Tsiotras P, Cowlagi RV. Achieving Increased Mobility and Autonomy for Ground Vehicles Over Rough Terrain. In: Defense UDo, editor. Defense Technical Information Center. Virginia: Georgia Institute of Technology, Atlanta School of Aerospace Engineering,; 2008. [Google Scholar]

- [49].Voutilainen A, Pitkäaho T, Kvist T, Vehviläinen-Julkunen K. How to ask about patient satisfaction? The visual analogue scale is less vulnerable to confounding factors and ceiling effect than a symmetric Likert scale. Journal of advanced nursing. 2016;72:946–57. [DOI] [PubMed] [Google Scholar]

- [50].Virzi RA. Refining the Test Phase of Usability Evaluation: How Many Subjects Is Enough? Human factors. 1992;34:457–68. [Google Scholar]