Abstract

Recently, total inward leakage (TIL) for filtering facepiece and elastomeric half-mask respirators (EHRs) was measured according to the International Organization for Standardization (ISO) test method standard 16900–1:2014 that showed larger TIL for corn oil aerosol than for NaCl aerosol. Comparison of TIL measured for different aerosols for higher protection level respirators is lacking. The objective of this study was to determine TIL for EHRs, full-facepiece respirators, and loose-fitting and tight-fitting powered air-purifying respirators (PAPRs) using NaCl and corn oil aerosols to compare. TIL was measured for two models each of EHRs, full-facepiece respirators, and loose-fitting and tight-fitting PAPRs. After fit testing with a PortaCount (TSI, St. Paul, MN) using the Occupational Safety and Health Administration (OSHA) protocol, eight subjects were tested in the NaCl aerosol chamber first and then in the corn oil aerosol chamber, while another eight subjects tested in the reverse order. Subjects were randomly assigned to one of the two groups. TIL was measured as a ratio of mass-based aerosol concentrations inside the mask to the test chamber while the subjects performed ISO 16900–1-defined exercises using continuous sampling methods. The concentration of corn oil aerosol was measured with one light scattering photometer, alternately, and NaCl aerosol was measured using two flame photometers. Results showed the geometric mean TIL for EHR was significantly (p < 0.05) larger for corn oil aerosol than for NaCl aerosol. EHR models equipped with P100 filters showed relatively smaller TIL values than the same models with N95 filters showing that TIL was inversely related to filter efficiency. Interestingly, TIL was significantly (p < 0.05) larger for NaCl aerosol than for corn oil aerosol for PAPRs, but not for full-facepiece respirators. TIL was inversely related to fit factors of respirator types. Overall, filter efficiency and faceseal leakage determine TIL. The relative trends in TIL for the two aerosols’ test methods differ between respirator types indicating that generalization of TIL for respirator types may not be appropriate when using different test agents.

Keywords: Aerosol, air-purifying respirators, efficiency, faceseal, filter penetration, total inward leakage

Introduction

The International Organization for Standardization (ISO) developed the ISO 16900 standard titled “Respiratory protective devices—Methods of test and test equipment” consisting of 14 parts including Part 1. Determination of inward leakage for respirators using test agents such as sodium chloride (NaCl) aerosol, corn oil aerosols, and sulfur hexafluoride gas (SF6) (ISO 2014). TIL represents both filter penetration and faceseal leakage of respiratory devices and is measured as a ratio of test agent concentration inside of the device to outside of the device. In general, TIL is measured using human subjects and test agents, incorporating specified body movements, at a specified metabolic work rate. TIL measured in the laboratory may represent an estimate of the performance level of respirators for protection against hazardous aerosols in workplaces. In the ISO respiratory protective device (RPD) scheme, TIL is used as a performance requirement to determine the protection class (PC) of RPDs (ISO 2021). PC is a numerical designation from PC1 to PC6 allocated to an individual RPD based upon laboratory testing indicating its relative protection level. The ISO RPD scheme classifies RPDs into six PCs based on the TIL value measured in the laboratory (Table 1) (ISO 2021). PC is based on laboratory performance, and not the type of RPD. This scheme of classification is different from the OSHA assigned protection factor, which represents the level of protection from airborne exposure each class of respirators is expected to provide. The ISO RPD scheme PC is used to determine the ISO RPD protection level (PL), which is used to select and use RPD, in accordance with ISO 16975 Part 1 (ISO 2016) and Part 3 (ISO 2017). The PL is representative of the protection that is expected to be provided to wearers when used within an effective respiratory protection program as described in the ISO 16975:2016 standard.

Table 1.

Total inward leakage (TIL), protection class (PC), and protection level (PL).

| Total Inward Leakage (TIL) Min-Max (%) | Protection Class (PC)a | Nominal Protection Factor (NPF)b | Safety Factor | Protection Level (PL)c |

|---|---|---|---|---|

| 5.0–20.0 | PC1 | 5 | 1.25 | 4 |

| 1.0–5.0 | PC 2 | 20 | 2 | 10 |

| 0.1–1.0 | PC 3 | 100 | 3.33 | 30 |

| 0.01–0.1 | PC 4 | 1,000 | 4 | 250 |

| 0.001–0.01 | PC 5 | 10,000 | 5 | 2,000 |

| <0.001 | PC 6 | 100,000 | 10 | 10,000 |

ISO classification of respirators.

NPF = 100%/Maximum TIL (%) for each PC.

PL = NPF/Safety factor (safety factor assigned based on experience and professional judgment on the performance of a respirator).

In developing the ISO RPD scheme, it was assumed that different test agents produce similar TIL values (ISO 2021). However, TIL measurement can be influenced by characteristics of test agents such as aerosol size and charge as well as detection methods. In a previous study, NIOSH determined the TIL values for four different respirator types using NaCl and corn oil aerosols side-by-side in two separate chambers and compared the results (Rengasamy et al. 2018). TIL for filtering facepiece respirators (FFRs) (European certified FFP1, NIOSH approved N95 and P100), and elastomeric half-mask respirators (EHRs with N95 filters) were measured while the test subjects performed a set of simulated exercises described by the ISO standard 16900–1 (ISO 2014). A comparison of TIL values for the two aerosols showed relatively larger TIL values for corn oil aerosol than for NaCl aerosol across all respirator models (Rengasamy et al. 2018). The higher TIL for corn oil aerosol was partially attributed to its electrically neutral charge status as measured by an electrometer. The neutrally charged corn oil aerosol more easily passed through the filter media giving a larger TIL value than NaCl aerosol. NaCl aerosol is highly charged and more easily captured by electrostatic filter media resulting in relatively smaller TIL value. The results indicated that the corn oil aerosol method is a relatively conservative method for TIL measurement for lower protection level respirators such as filtering facepieces and EHRs with N95 filters (Rengasamy et al. 2018).

The geometric mean (GM) TIL determined for EHRs in the previous study decreased with the increasing protection level of respirator types from FFP1, to N95, to P100 filtering facepieces, and finally to elastomeric respirators with N95 filters (Rengasamy et al. 2018). Based on the results, it was predicted that TIL values for higher protection level respirator types may be smaller and closer to each other and present difficulty in assigning correct PC or PL. One possible reason is that TIL determination by flame photometry and light scattering photometry used for NaCl and corn oil aerosol methods, respectively, may not be sensitive enough at smaller TIL values. For example, light scattering photometry does not accurately measure particles smaller than 100 nm (Eninger et al. 2008).

The relationship between PL derived from TIL and the Occupational Safety and Health Administration (OSHA) assigned protection factor (APF) is not well understood. APF is defined as the workplace level of respiratory protection that a respirator or class of respirators is expected to provide to employees when the employer implements a continuing, effective respiratory protection program as specified by the 29 CFR 1910.134 standard. APF accounts for all expected sources of leakage including filter media, faceseal, and other sources. OSHA evaluated the results of several workplace protection studies and specified APFs to various types of respirator classes (OSHA 2006). The OSHA APFs for EHRs is 10. An APF of 10 implies that the respirator wearer is expected to have no more than one-tenth of the atmospheric ambient particles inside the respirator. For example, the APFs for tight-fitting EHR, tight-fitting full-facepiece, tight-fitting PAPR and loose-fitting PAPR respirators are 10, 50, 1,000, and either 25 or 1,000 (based on the manufacturer’s ability to show an APF of 25 or 1,000 from their studies), respectively. In contrast, PL is derived from TIL (representing penetration of contaminants through filter media, face seal and other components) measured in the laboratory settings. Comparison of PL with APF of these respirator classes may provide only estimates of respirator performance levels.

Previous research showed relatively larger TIL values for corn oil aerosol than for NaCl aerosol for filtering facepiece respirators and EHRs (Rengasamy et al. 2018). In this study, investigators tested EHRs with P100 filters, and higher protection level full-facepiece respirators and PAPRs (tight-fitting and loose-fitting) to examine if differential effects were also present. Two models each of four different respirator types, worn by human subjects, were tested in NaCl and corn oil aerosol test chambers, side-by-side. TIL measured for the two aerosols was used to assign PCs, and the corresponding PLs were obtained and compared for each respirator model for all four respirator types. A respirator model with relatively lower TIL and thus higher PC and PL is expected to provide higher level of protection in workplaces. The authors hypothesize that TIL for corn oil aerosol will be larger than NaCl aerosol for all types of respirators. Also, the PCs and PLs will be different for the two models of each respirator type for the two aerosols.

Materials and methods

Respirators

TIL was measured for two models each of NIOSH approved EHR, full-facepiece respirators, and tight-fitting and loose-fitting PAPRs. Table 2 shows respirator types, manufacturers, models, and filters used in the study. These respirators were selected based on the respirator models used in previous NIOSH studies and the availability of the devices on the market.

Table 2.

Respirator types and models tested for total inward leakage measurement (elastomeric half-mask respirator (EHR), full-facepiece respirator (FFPR), tight-fitting powered air-purifying respirator (PAPR), and loose-fitting PAPR).

| Respirator | Manufacturer | Model | Cartridge/Filter | Sizes |

|---|---|---|---|---|

| EHR | A) MSA | Comfo Classic | P100 Cartridges | S, M, and L |

| EHR | B) North | 7700 | P100 Filters | S, M, and L |

| FFPR | C) MSA | Advantage 3000 | P100 Filters | S, M, and L |

| FFPR | D) 3 M | 7800 | P100 Filters | S, M, and L |

| PAPR (Tight-Fitting) | E) MSA | Advantage 4000 | High Efficiency Cartridge Filter, Model 4100 FFR | S, M, and L |

| PAPR (Tight-Fitting) | F) Bullard | EVA | High Efficiency Particulate Filter, Spectrum Series FFR | S and M/L |

| PAPR (Loose-Fitting) | G) 3 M | Air-Mate | High Efficiency Particulate Filter, BE Series Hood | One-Size- Fits-All |

| PAPR (Loose-Fitting) | H) Bullard | EVA | High Efficiency Particulate Filter, CC20 Series Hood | One-Size- Fits-All |

NaCl and corn oil aerosol test chambers

TIL values for corn oil and NaCl aerosols were determined in two separate chambers as described previously (Rengasamy et al. 2018). An MSP Corporation Model 2045-S High Output Aerosol Generator (MSP Corp., Shoreview, MN) generated the corn oil aerosol which was then passed into an aerosol chamber (3.05 L × 3.05 W × 2.74H m). The corn oil aerosol was injected by the aerosol generator into the vertical section of a 20.3 cm diameter duct approximately 213 cm upstream of a horizontal header connected to the intake plenum. The corn oil aerosol/air mixture then flowed into the corn oil chamber through four vents (0.3H × 2.1 W m) equally spaced on the aerosol inlet plenum. The dimensions of the NaCl aerosol chamber were 2.43 L × 3.05 W × 2.74H m. NaCl aerosol was generated using a 2% salt solution by an SFP Services (Dorset, UK) 4100/250 F single collision atomizer with an integral fan. The air supplied by the fan helped convey the NaCl aerosol into the chamber through a 20.3 cm diameter duct to the chamber approximately 5.8 m downstream of the NaCl aerosol generator. A common air lock entryway was shared between the two chambers. The interior/exterior walls of the chambers were covered with fiberglass reinforced plastic (Class C Fire Rating) to facilitate ease of cleaning.

Test subjects

A panel of 16 subjects (18–50 years old) consisting of both men and women were selected for testing each respirator model. Only 16 subjects who passed a standard OSHA quantitative fit test protocol using a PortaCount-Plus quantitative fit tester were selected for the TIL study. All subjects were from a pool of ~100 subjects, who periodically participate in NIOSH fit test studies; thus, subjects had experience wearing respirators. The NIOSH bivariate panel (NIOSH Panel) was used for placement of test subjects in specific face length by face width cells (Zhuang et al. 2008). The NIOSH Panel has 10 cells and covers face lengths from 98.5 to 138.5 mm and face widths from 120.5 mm to 158.5 mm. Each of the 10 cells contained at least one subject. All subjects were medically cleared using a modified OSHA Respirator Medical Evaluation Questionnaire, with questions taken from Appendix C of the 29 CFR Part 134 Respirator Standard. The NIOSH Human Subjects Institutional Review Board approved this study (Protocol# HSRB14-NPPTL-02) and all subjects gave written consent to participate.

Fit testing

All subjects performed a quantitative respirator fit test followed by a TIL test in the two aerosol chambers for a period of about 60 min with two 5-min breaks. All respirator models were fit tested except the loose-fitting PAPRs, which by nature do not require fit testing. Tight-fitting PAPRs were fit tested as per manufacturer’s instructions using fit testing adapters. Fit testing was done in a room adjacent to the TIL test chambers prior to TIL testing. Subjects were fit tested using a standard OSHA fit test protocol with a PortaCount Pro + Model 8038 (TSI, Inc., Shoreview, MN), with the N95-Companion mode turned off. Test subjects were given training on each respirator model’s donning and user seal check procedures according to the instructions supplied by the respirator manufacturer. The test administrator observed the subjects and instructed them to don the respirator correctly. Subjects were permitted to adjust the respirator before fit testing but not allowed to re-adjust the respirator fit until the completion of the TIL test in the two test chambers. Subjects performed the eight exercises described in the standard OSHA fit test protocol (OSHA 1998). The eight exercises were performed in the following order: (1) normal breathing, (2) deep breathing, (3) turning head side to side, (4) moving head up and down, (5) talking (recitation of the “rainbow” passage), (6) grimace, (7) bending over, and (8) normal breathing. The duration of each fit test was approximately 8 min. At the end of the test, the PortaCount calculated the fit factor (FF) for each individual exercise (FFi) and provided a harmonic mean FF for seven exercises, except the grimace exercise. After fit testing, the subject continued to wear the respirator with the sampling tube removed, left open for approximately <1 min and reconnected in the first aerosol test chamber.

TIL measurement using test subjects

Before testing, the 16 test subjects were randomly assigned into two groups of eight each. Eight subjects were tested in the NaCl aerosol chamber first and then in the corn oil aerosol chamber. The other eight subjects were tested to measure TIL in the corn oil chamber before the NaCl chamber. Subjects were tested in the two aerosol chambers in random order. Once the 16 subjects were determined, they were numbered 1–16. Odd-numbered subjects performed tests in the NaCl chamber first, followed by the corn oil chamber. Even-numbered subjects were tested in the corn oil chamber first, then in the NaCl chamber. After the test subject entered the chamber, the sample tubing was connected to the respirator and the subject stood on the nonmoving treadmill for about 2 min to prepare the equipment for measurement. The test subject performed the exercise regimen continuously for about 18 min as specified in the ISO 16900–1. The ISO-defined exercises are: (1) acclimatization (3 min), (2) standing still (2 min), (3) reach up and down (2 min); (4) squatting (1 min), (5) hands and knees, head rotation (2 min), (6) walk (2 min), (7) walk, head rotation (2 min), (8) walk, speaking (2 min), and (9) standing still (2 min). The TIL for each exercise and for the entire test regimen were measured. After measuring TIL in the first aerosol test chamber, the sampling tube was removed and left open, the test subject exited the chamber, continued to wear the device without any adjustment or repositioning for a resting period of 5 min, and then entered the second test chamber for testing. The sampling tube was reconnected to the respirator in the second test aerosol chamber. The subject continued testing in the second testing chamber following the same exercise regimen as in the previous chamber.

A continuous sampling method was used to measure the aerosol concentration inside the mask and the concentration outside the mask. That is, the aerosol sample was withdrawn continuously for analysis during the entire test. In the case of NaCl aerosol testing, the in-mask aerosol sample was withdrawn at 1 liter per minute and was mixed with filtered air at 1 liter per minute (used to reduce the relative humidity of the exhaled sample) at a distance of 22 cm downstream of the sample point. Corn oil aerosol was not diluted for TIL measurement. The upstream and downstream samples of NaCl aerosol were measured using two flame photometers (SFP Services, Type 1250, Dorset, UK). The upstream and downstream samples of corn oil aerosol were measured alternately using a light-scattering photometer (TSI Model 8587 A). Both the flame photometers and the light-scattering photometer measured mass-based concentrations of the NaCl and corn oil aerosols. A LabVIEW program collected the data and provided the TIL for each exercise and for the entire test regimen for the two aerosols.

TIL calculation

TIL for each exercise and for the entire test regimen was measured. Corn oil aerosol deposition in the airways was assumed to be negligible and no correction factor was applied. The percentage of TIL for corn oilaerosol during testing of each subject was calculated using the following formula:

| (1) |

where

C1 is the concentration of corn oil in the test chamber

C2 is the concentration of corn oil in the respiratory interface

NaCl aerosol is highly hygroscopic, and TIL was calculated considering aerosol deposition in the airways of test subjects during testing. A correction factor for a continuous sampling method used in the study is calculated using the sample drawn from the inhalation portion (50%) and exhalation portion (50%) of breathing which is measured by the flame photometer. The correction factor also assumes that 80% of NaCl aerosol is absorbed by the airways. Based on the above considerations, the measured concentration was multiplied by 1.6 to get the inhaled concentration as shown previously (Rengasamy et al. 2018).

The percentage of TIL was calculated as follows:

| (2) |

where

C1 is the concentration of NaCl in the test chamber

C2 is the concentration of NaCl inside the respiratory device

S is the sample flow rate (L/min)

D is the drying airflow rate (L/min)

Data analysis

All TIL values were common logarithmically transformed to calculate the geometric mean (GM) TIL and geometric standard deviation (GSD) of TIL by respirator model and test aerosol (corn oil or NaCl). For each respirator model, an analysis of variance (ANOVA) using the PROC GLM procedure (general linear model in SAS software: V9.3 SAS Institute, Inc., Cary, NC) was performed on the dependent variable of log-transformed TIL to test the effects variable of test aerosol type (NaCl and corn oil) at the significance level (p-value) of 0.05.

Results and discussion

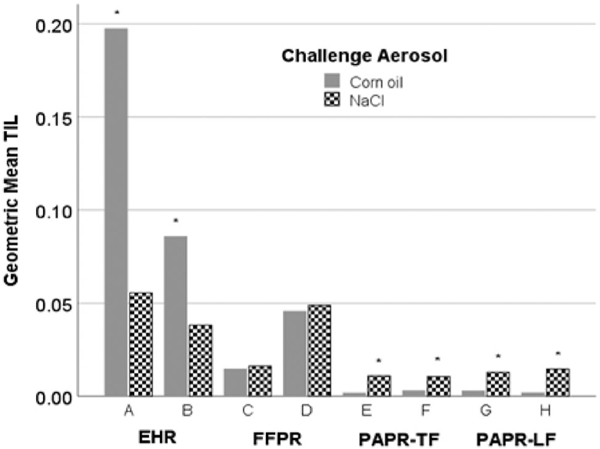

Figure 1 shows GM TIL results for eight models from four respirator types tested by 16 subjects. TIL values decreased for respirators in the order from EHR, full-facepiece respirator to PAPR models. The two EHR models with P100 filters showed significantly (p < 0.05) larger TIL values for corn oil aerosol than for NaCl aerosol (Table 3). The results are consistent with the higher TIL values obtained for corn oil aerosol for lower protection level respirators including FFP1, N95, P100 filtering facepiece respirators and EHR models with N95 filters (Table 4) in our previous study (Rengasamy et al. 2018). The higher TIL obtained for corn oil aerosol was associated with the charge status of the aerosol (Rengasamy et al. 2018). NaCl aerosol was highly charged (~ +70 fA) and was easily captured by the electrostatic filter media of filtering facepieces, and EHRs equipped with N95 filters possibly by coulombic attraction. This resulted in relatively lower TIL values. Corn oil aerosol, however, at near neutral charge (~ +0.5 fA) was believed to pass through the filter media more freely resulting in larger TIL than NaCl aerosol (Rengasamy et al. 2018). Coulombic attraction of particles by electrostatic filter media is well documented (Hinds 1999). The EHR models tested in the present study were equipped with P100 cartridges or filters which are mechanical filters unlike the electrostatic N95 filters on the same EHR models tested previously (Rengasamy et al. 2018). EHRs with P100 cartridges or filters also showed larger TIL for corn oil aerosol than for NaCl aerosol (Table 3). Charged particles are also attracted to a neutral fiber at close range by image forces (Hinds 1999). The charged NaCl particle creates an induced dipole in the fiber surface and is attracted and captured, whereas corn oil aerosol with a net neutral charge is not attracted to the filter media and passes through with airflow. The net result was a larger TIL for corn oil aerosol than for NaCl aerosol.

Figure 1.

Total inward leakage (TIL) for elastomeric half-mask (EHR), full-facepiece (FFPR), powered air-purifying respirators-tight-fitting (PAPR-TF), and PAPR-loose-fitting (PAPR-LF) respirators for corn oil and NaCl aerosol. EHR models A – MSA Comfo Classic and B – North 7700; FFPR models C – 3 M 7800 and D – MSA Advantage 3000; PAPR-TF models E – Bullard EVA and and F – MSA Advantage 4000; PAPR-LF models G – 3 M Air-Mate and H – Bullard EVA. *Significantly (p ≤ 0.05) larger than NaCl aerosol for EHR, and significantly (p ≤ 0.05) larger than corn oil aerosol for tight-fitting and loose-fitting PAPRs.

Table 3.

Protection class (PC) and protection level (PL) for elastomeric half-facepiece (EHR), full-facepiece, and powered air-purifying (PAPR) respirators using the Second Highest TIL Method ISO.

| Respirator | Model | Aerosol | GM Fit Factor | GM TIL (%) | GSD | Second Highest TIL (%) | PC | PL |

|---|---|---|---|---|---|---|---|---|

| EHR | A | NaCl | 1507 | 0.056 | 5.57 | 0.614 | 3 | 30 |

| Corn oil | 0.197* | 4.03 | 1.048 | 2 | 10 | |||

| B | NaCl | 1667 | 0.038 | 6.48 | 0.799 | 3 | 30 | |

| Corn oil | 0.086* | 9.19 | 1.852 | 2 | 10 | |||

| Full-facepiece | C | NaCl | 4670 | 0.049 | 2.22 | 0.128 | 3 | 30 |

| Corn oil | 0.046 | 1.84 | 0.089 | 4 | 250 | |||

| D | NaCl | 7753 | 0.016 | 1.84 | 0.054 | 4 | 250 | |

| Corn oil | 0.015 | 3.20 | 0.064 | 4 | 250 | |||

| PAPR | E | NaCl | 7731 | 0.010** | 1.57 | 0.021 | 4 | 250 |

| Tight-fitting | Corn oil | 0.003 | 3.31 | 0.003 | 5 | 2000 | ||

| F | NaCl | 3799 | 0.011 ** | 1.52 | 0.019 | 4 | 250 | |

| Corn oil | 0.002 | 1.53 | 0.019 | 4 | 250 | |||

| PAPR | G | NaCl | N/A | 0.013** | 1.83 | 0.026 | 4 | 250 |

| Loose-fitting | Corn oil | 0.003 | 2.83 | 0.022 | 4 | 250 | ||

| H | NaCl | N/A | 0.015** | 2.27 | 0.026 | 4 | 250 | |

| Corn oil | 0.002 | 1.47 | 0.003 | 5 | 2000 |

ISO ISO/CD (2018) recommended method.

Significantly larger for corn oil aerosol than for NaCl aerosol.

Significantly larger for NaCl aerosol than for corn oil aerosol.

Table 4.

Total inward leakage (TIL) for filtering facepiece respirators (FFRs) elastomeric half-facepiece respirators (EHR) with N95 and P100 filters.

| GM TIL (%) | GMD | GM TIL (%) | GMD | ||||

|---|---|---|---|---|---|---|---|

| Respirator | Manufacturer | Model | Filter efficiency (%) | NaCl aerosol | Corn oil aerosol | ||

| FFP1 FFR | 3M* | 8710E | 99.34 | 0.89 | 2.14 | 4.03 | 1.71 |

| Blackrock* | TY0919 | 91.75 | 18.5 | 2.62 | 21.63 | 1.62 | |

| N95 FFR | Sperion* | 1870 | 99.97 | 12.84 | 2.26 | 14.2 | 2.24 |

| 3M* | N1105 | 99.48 | 0.82 | 4.05 | 2.95 | 2.7 | |

| P100 FFR | Sperion* | P1130 | 99.98 | 0.48 | 15.89 | 1.19 | 4.48 |

| 3M* | 8293 | 99.99 | 0.44 | 8.47 | 0.76 | 24.5 | |

| EHR | North* | 7700 | 99.63 | 0.19 | 2.83 | 1.09 | 1.97 |

| (N95) | MSA* | Comfo Classic | 99.73 | 0.33 | 4.49 | 0.73 | 3.01 |

| EHR (P100) | Northa | 7700 | >99.75 | 0.09 | 9.2 | 0.2 | 4 |

| MSAa | Comfo Classic | >99.75 | 0.04 | 6.5 | 0.06 | 5.6 | |

Respirators tested in a previous study (Rengasamy et al. 2018).

Filter efficiency not determined in this study.

Shaded row indicates relatively higher efficiency model of the respirator type.

Interestingly, higher protection level respirators including full-facepiece respirators and PAPRs, both tight-fitting and loose-fitting models, showed larger TIL for NaCl aerosol than for corn oil aerosol. In the case of full-facepiece respirators, TIL for NaCl aerosol was larger than for corn oil aerosol but not statistically significant. In general, TIL values were smaller than those for EHR models indicating that filter penetration as well as faceseal leakage are at minimum levels for full-facepiece respirators and PAPRs. However, both tight-fitting and loose-fitting PAPR models showed significantly (p < 0.05) larger TIL for NaCl aerosol than for corn oil aerosol. The results raise a question on the mechanism of larger TIL for NaCl aerosol. There are two possibilities that can produce larger TIL for NaCl aerosol inside the facepiece of PAPRs: an increase in NaCl aerosol penetration or a decrease in corn oil aerosol penetration through filter media. The high efficiency (HE) filters of PAPRs capture NaCl aerosol by mechanical forces and the penetration is expected to be <0.03% which is unlikely to increase the TIL for NaCl aerosol relative to corn oil aerosol. In addition, the relatively higher TIL for NaCl aerosol cannot be explained by particle charge which may decrease TIL (Rengasamy et al. 2018). Aerosol size distribution is another factor that may influence penetration. The smaller-sized NaCl aerosol (~80 nm count median diameter) may not have contributed to the larger TIL than corn oil aerosol had (~190 nm count median diameter) because the same NaCl aerosol did not show higher TIL for lower protection level respirators, such as N95 and P100 filtering facepiece respirators (Rengasamy et al. 2018). This indicates that mechanisms other than net charge of aerosols are responsible for the relatively higher TIL for NaCl aerosol.

The higher TIL for NaCl aerosol can partly be explained by the characteristics of respirators as well as aerosols. Tennal et al. suggested that oily liquid aerosol droplets spread over charged fiber surfaces, reduce the electrostatic filtration, resulting in increased penetration as a function of loading (Tennal et al. 1991). But recently developed advanced electret filter media behaved similar to fiberglass mechanical filters and showed no change in penetration by oily aerosols (Barrett and Rousseau 1998). A PAPR is designed to withdraw aerosols through an oil resistant HE filter, supplying purified air to a facepiece at positive pressure. The process of withdrawing liquid corn oil aerosol at high flow rates (i.e., 115 L/min for tight-fitting PAPRs and 170 L/min for loose-fitting PAPRs) may spread or coalesce the oil particles on HE filters and may impede aerosol penetration to yield a smaller TIL than NaCl aerosol. Solid NaCl particles, on the other hand, are likely to penetrate through the filter media without much hinderance resulting in a relatively larger TIL than corn oil aerosol inside the facepiece. The higher flow rate or velocity may increase solid NaCl aerosol penetration through the filter and increase TIL. An increase in velocity is known to increase particle penetration through respirators (Huang et al. 2013). Higher protection-level respirators (full-facepiece respirator and PAPR) showed relatively larger TIL for NaCl aerosol (Table 3) than lower protection-level respirators (FFP1, N95, and P100 FFRs, Table 4) (Rengasamy et al. 2018) indicating that TIL testing should consider respirator types as well as properties of test agents. Based on these results, generalization of TIL for respirator types may not be appropriate when using different aerosols.

It is possible that respirator fit can change during the exercise regime and introduce differences in TIL for the two aerosols. All subjects tested the four types of respirators in both the corn oil aerosol and NaCl aerosol chambers in random order. Eight subjects tested a respirator in the NaCl aerosol chamber and then, without adjusting or removing the respirator, the subjects continued testing in the corn oil aerosol chamber. The other eight subjects tested the respirators in the corn oil aerosol chamber first and then in the NaCl chamber. Results showed relatively lower TIL values for PAPRs and full-facepiece respirators than EHRs, regardless of the order of testing atmosphere. Moreover, the TIL values for all PAPRs and full-facepiece respirators were higher for NaCl than for corn oil aerosol. These results indicate that face fitting may not have contributed to the discrepancy observed with the TIL values for the two aerosols.

Table 3 shows the TIL values obtained for the four respirator types as well as the PC and PL. The TIL results have implications to the ISO 16900–1 and ISO 17420–1 standards. ISO 17420–1 recommended the use of the “second highest TIL” from the data for 16 subjects to obtain PC and PL (ISO 2013). Results showed that the two aerosols failed to show similar PCs or PLs for five out of eight models because of the difference in the characteristics of the two test agents. Both EHR models showed relatively lower PL with corn oil aerosol whereas one full-facepiece respirator model and all four PAPR models showed relatively lower PL with NaCl aerosol. For comparison of the PL (for different PCs) with the OSHA assigned APF, smaller PLs representing conservative values were used. The smaller PL 10 (PL 10 = PC2) for corn oil aerosol for the two EHR models agreed with the APF values (10) for half mask respirators. In the case of full-facepiece respirators, NaCl aerosol showed smaller (PL 30 = PC3) for one model and larger (PL250 = PC4) for another model compared to the APF value of 50 for full-facepiece respirators. Both tight-fitting and loose-fitting PAPR models showed a conservative PL value (PL 250 = PC4) which is lower than the APF of 1000 for these respirators. The self-contained breathing apparatus (SCBA) is the next higher protection-level respirator which may give 10 times larger PL (PL~2500 = PC5). This may suggest that ISO should consider fewer than six PCs for respirator classification. Further studies are needed to confirm the findings in the present study and to understand what other higher protection-level respirators would show larger PL values than SCBA.

TIL is a function of filter penetration and faceseal leakage (Coffey et al. 1999; Han and Lee 2005; Grinshpun et al. 2009; Rengasamy and Eimer 2011, 2012, Rengasamy et al. 2014a, 2018; Reponen et al. 2011; Zhuang et al. 2003). The higher the efficiency of the respirator type, the lower the TIL value. FFP1, N95, P100 and EHR with N95 filters and EHR with P100 filters are certified for percentage efficiencies of 80, 95, 99.97, 95, and 99.97, respectively. Our previous (Rengasamy et al. 2018) study and this study’s results showed that TIL value decreased with increasing filter efficiency of respirator types. Further evidence is that between the two models tested for each respirator type, the higher efficiency model showed lower TIL values. This is noticeable in the case of FFP1 and N95 FFRs rather than in the higher-level respirator types. The inverse relationship between filter efficiency and TIL also can be seen for the two EHR models with N95 and P100 filters. The TIL values for P100 and N95 filter materials were 0.04 and 0.06 for NaCl aerosol and 0.09 and 0.19 for corn oil aerosol (Table 4). TIL for the same two EHR models equipped with N95 filters were 0.21 and 0.13 for NaCl aerosol and 0.73 and 1.09 for corn oil aerosol (ISO 2017) which is several-fold larger than for P100 filters. The relatively higher efficiency (>99.75%) P100 filters of EHR models showed lower TIL compared to the N95 filters (<95%). The results obtained in the study corroborate the inverse relationship between TIL and filter efficiency reported previously (Han and Lee 2005; Rengasamy and Eimer 2011, 2012, Rengasamy et al. 2014a, 2014b, 2018; Steinle et al. 2018). The results in the study in conjunction with our previous work (Rengasamy et al. 2018) showed a decreasing trend in TIL with increasing filter efficiency from FFP1 (≥80%), to N95 (≥95%), to P100 (≥99.75%), to EHR with P100 filters (≥99.75%), and to full-facepiece respirators (≥99.97%) respirator types showing an inverse relationship between filter efficiency and TIL. Although the efficiencies of P100 filters of EHR and full-facepiece respirators are similar, the full-facepiece respirators are likely to fit well to provide minimum faceseal leakage and allow lesser aerosol penetration, yielding relatively lower TIL values. However, the lower TIL values for PAPRs may be from mechanisms other than efficiency as described above in this study.

Faceseal leakage is another important component of respiratory protection as described previously (Coffey et al. 1999; Grinshpun et al. 2009; Reponen et al. 2011; Zhuang et al. 2003). In our studies, faceseal leakage was measured as fit factors before measuring TIL. Fit factors were ~1,600, ~6,200, and ~5,800 for EHRs, full-facepiece respirators, and tight-fitting PAPRs, which yielded GM TIL values of ~0.1%, ~0.03%, and ~0.006%, respectively, showing an inverse relationship with TIL. The increase in fit factors from EHRs, to full-facepiece respirators, and then to tight-fitting PAPRs with a decrease in TIL may indicate a decrease in faceseal leakage. Overall, the results indicated that TIL is from both filter penetration and faceseal leakage. Neither the fluorometric method nor the light-scattering photometric method can distinguish between particle penetration through filter media and through faceseal leakage pathways.

Recommendations

The findings of this study are limited to two models of each respirator type. Nevertheless, the results present some new understanding on respiratory protection. The results from this study showed different TIL values for two different test aerosols. This is important because selection of an aerosol that yields relatively larger TIL values allows conservative estimates of respiratory protection level to be obtained in real workplaces. Standards organizations can apply this information in developing or revising standards. An example is that ISO standard 16900–1 (ISO 2014) assumes similar TIL values for different test aerosols as well as for aerosols and gaseous agents which can be revised using the findings from this study. For NIOSH certification, corn oil aerosol is used for TIL measurement of HE filters of PAPRs and Chemical Biological Radiological and Nuclear (CBRN) respirators. HE filters tested in this study showed lower TIL with corn oil aerosol than NaCl aerosol, indicating an overestimation of protection. Both faceseal leakage and filter penetration contribute to TIL indicating that respirators passing a fit test with an aerosol that gives relatively smaller fit factors may be needed to obtain conservative levels of respiratory protection. This study also shows that TIL is dependent on filter efficiency suggesting that relatively higher efficiency models with good fitting characteristics would provide better protection in workplaces.

Conclusions

TIL values for EHR models were larger for corn oil aerosol than for NaCl aerosol. The full-facepiece respirator models showed marginally larger TIL values for NaCl aerosol than for corn oil aerosol. Interestingly, NaCl aerosol produced significantly (p < 0.05) larger TIL than for corn oil aerosol for loose-fitting as well as tight-fitting PAPR models. This may be partly because the process of withdrawing liquid corn oil aerosol through HE filter media might cause the aerosol to spread out and stick, and impede aerosol penetration through filter media, whereas solid NaCl aerosol readily passes through the filter media at the higher flow rates used for PAPR models. This indicates the trend in TIL for two aerosols may be different between respirator types. The difference in TIL values for the two aerosols produced different PCs and PLs for some respirator models. TIL obtained for EHRs with P100 filters were smaller than the values obtained for the same EHRs with N95 filters showing an inverse relationship with filter efficiency. Similarly, an inverse relationship was obtained between TIL and fit factor for respirator models showing the influence of respirator fit. Results from the study showed two aerosols with different characteristics may not produce similar TIL values for any given respiratory device. The relative trends in TIL for the two aerosols differ between respirator types indicating that generalization of TIL cannot be applied to respirator types when using different test agents.

Acknowledgments

The authors acknowledge NIOSH colleagues including, Dana Rottach, Bingbing Wu, and Kevin Strickland for their useful suggestions and critical review of the manuscript.

Funding

This study is supported by National Institute for Occupational Safety and Health (Award-Id CAN#93902JS).

Footnotes

IRB approval

The NIOSH Human Subjects Institutional Review Board approved this study (Protocol# HSRB14-NPPTL-02) and all subjects gave written consent to participate.

Disclaimer

Mention of any company or product does not constitute endorsement by the National Institute for Occupational Safety and Health, Centers for Disease Control and Prevention. The findings and conclusions in this report/presentation have not been formally disseminated by the National Institute for Occupational Safety and Health, Centers for Disease Control and Prevention and should not be construed to represent any agency determination or policy.

References

- Barrett LW, Rousseau AD. 1998. Aerosol loading performance of electret filter media. Am Indus Hyg Assoc J. 59(8):532–539. doi: 10.1080/15428119891010703 [DOI] [Google Scholar]

- Coffey CC, Campbell DL, Zhuang Z. 1999. Simulated workplace performance of N95 respirators. Am Indus Hyg Assoc J. 60(5):618–624. doi: 10.1080/00028899908984481 [DOI] [PubMed] [Google Scholar]

- Eninger RM, Honda T, Reponen T, McKay R, Grinshpun SA. 2008. What does respirator certification tell us about filtration of ultrafine particles? J Occup Environ Hyg. 5(5):286–295. doi: 10.1080/15459620801960153 [DOI] [PMC free article] [PubMed] [Google Scholar]

- Frost S, Mogridge R, Roff M. 2014. Fit of filtering facepiece class 3 (FFP3) respirators part 1: a comparison of fit test methods. J Int Soc Respir Prot. 31(1):57–72. [Google Scholar]

- Grinshpun SA, Haruta H, Eninger RM, Reponen T, McKay RT, Lee S-A. 2009. Performance of an N95 filtering facepiece particulate respirator and a surgical mask during human breathing: two pathways for particle penetration. J Occup Environ Hyg. 6(10):593–603. doi: 10.1080/15459620903120086 [DOI] [PMC free article] [PubMed] [Google Scholar]

- Han DH, Lee J. 2005. Evaluation of particulate filtering respirators using inward leakage (IL) or total inward leakage (TIL) testing–Korean experience. Ann Occup Hyg. 49: 569–574. [DOI] [PubMed] [Google Scholar]

- Hinds WC. 1999. Properties, behavior, and measurement of airborne particles. New York: Wiley-Interscience Publication, John Wiley & Sons, Inc. [Google Scholar]

- Huang SH, Chen CW, Kuo YM, Lai CY, McKay R, Chen CCb. 2013. Factors affecting filter penetration and quality factor of particulate respirators. Aerosol Air Qual Res. 13(1):162–171. doi: 10.4209/aaqr.2012.07.0179 [DOI] [Google Scholar]

- International Organization for Standardization (ISO). 2013. ISO Standard 17420–1. Respiratory protective devices – performance requirements – part 1. general. [Google Scholar]

- International Organization for Standardization (ISO). 2014. ISO Standard 16900–1:2014. Respiratory protective devices – methods of test and test equipment – part 1: determination of inward leakage. [Google Scholar]

- International Organization for Standardization (ISO). 2016. ISO/TS 16975–1:2016. Respiratory protective decices – selection, use and maintenance - part 1: establishing and implementing a respiratory protective device programme. [Google Scholar]

- International Organization for Standardization (ISO). 2017. ISO 16975–3:2017. Respiratory protective devices – selection, use and maintenance – part 3: fit-testing procedures. [Google Scholar]

- International Organization for Standardization (ISO). 2021. ISO Standard 17420–1(en):2021. Respiratory protective devices - performance requirements - part 1: general. [Google Scholar]

- Occupational Safety and Health Administration (OSHA). 2006. Assigned protection factors: final rule. 29 CFR Parts 1910, 1915, 1926 71: 50121–50192. http://www.osha.gov/pls/oshaweb/owadisp.show_document?p_table=FEDERAL_REGISTER&p_id=18846.

- Occupational Safety and Health Adminstration (OSHA). 1998. Code of federal regulation 29 part 1910.134 App A: fit testing procedures (mandatory). [Google Scholar]

- Rengasamy S, Eimer B. 2011. Total inward leakage of nanoparticle penetration through filter facepiece respirators. Ann Occup Hyg. 55:253–263. [DOI] [PubMed] [Google Scholar]

- Rengasamy S, Eimer B. 2012. Nanoparticle penetration through filter media and leakage through faceseal interface of N95 filtering facepiece respirators. Ann Occup Hyg. 56:568–580. [DOI] [PubMed] [Google Scholar]

- Rengasamy S, Eimer B, Szalajda J. 2014a. A quantitative assessment of the total inward leakage of NaCl aerosol representing submicron-size bioaerosol through N95 filtering facepiece respirators and surgical masks. J Occup Environ Hyg. 11(6):388–396. doi: 10.1080/15459624.2013.866715 [DOI] [PMC free article] [PubMed] [Google Scholar]

- Rengasamy S, Walbert G, Newcomb W, Faulkner K, Rengasamy M, Brannen JJ, Szalajda J. 2014b. Total inward leakage measurement of particulates for N95 filtering facepiece respirators - a comparison study. Ann Occup Hyg. 58:206–216. [DOI] [PubMed] [Google Scholar]

- Rengasamy S, Zhuang Z, Niezgoda G, Walbert G, Lawrence R, Boutin B, Hudnall J, Monaghan WP, Bergman M, Miller C, et al. 2018. A comparison of total inward leakage measured using sodium chloride (NaCl) and corn oil aerosol methods for air-purifying respirators. J Occup Environ Hyg. 15(8):616–627. doi: 10.1080/15459624.2018. 1479064 [DOI] [PMC free article] [PubMed] [Google Scholar]

- Reponen T, Lee S-A, Grinshpun SAJE, McKay R.2011. Effect of fit testing on the protection offered by N95 filtering facepiece respirators against fine particles in a laboratory setting. Ann Occup Hyg. 56:568–580. [DOI] [PubMed] [Google Scholar]

- Steinle S, Sleeuwenhoek A, Mueller W, Horwell CJ, Apsley A, Davis A, Cherrie JW, Galea KS. 2018. The effectiveness of respiratory protection worn by communities to protect from volcanic ash inhalation. Part II: total inward leakage tests. Int J Hyg Environ Health. 221(6):977–984. doi: 10.1016/j.ijheh.2018.03.011 [DOI] [PubMed] [Google Scholar]

- Tennal KB, Mazumder MK, Siag A, Reddy RN. 1991. Effect of loading with an oil aerosol on the collection efficiency of an electret filter. Particulate Sci Technol. 9(1–2):19–29. doi: 10.1080/02726359108906574 [DOI] [Google Scholar]

- Zhuang Z, Coffey CC, Jensen PA, Campbell DL, Lawrence RB, Myers WR. 2003. Correlation between quantitative fit factors and workplace protection factors measured in actual workplace environments at a steel foundry. Am Indus Hyg Assoc J. 64(6):730–738. doi: 10.1202/475.1 [DOI] [PubMed] [Google Scholar]

- Zhuang Z, Groce D, Ahlers HW, Iskander W, Landsittel D, Guffey S, Benson S, Viscusi D, Shaffer RE. 2008. Correlation between respirator fit and respirator fit test panel cells by respirator size. J Occup Environ Hyg. 64: 617–628. [DOI] [PubMed] [Google Scholar]