Abstract

The purpose of the paper is to identify factors associated with operational factor (OF), geo-environmental factor (GEF), and managerial factor (MF) from the literature. After identification, the study intended to assess the impact of geo-environmental factors and managerial factors on operational factors of the mining industry. The study also tests the indirect effect of managerial factors between GEF and OF in the Indian environment. The geographical boundary of the study was 06 large mines of Odisha, Jharkhand, and Chhattisgarh of India. Three hundred and twenty nine number of purposive samples were collected via email and filtered and processed through the SPSS package. To find out the complex role and inter-relationship of GEF and MF on OF, the study adopted the structural equation modelling technique. The finding reflects that MF plays a partial mediation among GEF and OF. This phenomenon is completely novel in its field when it comes to the geo-environmental and management difficulties confronting mining operations. This research can aid managers in identifying key geological and environmental concerns in mining operations, as well as providing data for regulatory compliance. Overall, this study's findings can help management create policies and manage the environmental concerns of the mining sector. The study's findings provide important directions for future Indian mining research.

Keywords: Geo-environment, Managerial decisions, Operation management, Mining industry, Structural equation modelling

Introduction

Mining is the process of extracting useful ores/materials from the earth. These ores/minerals are converted to metals or alloys as demanded by society in various forms. Whether it is construction or utilities required for human consumption, all come from mines (Rankin, 2011). The demand is increasing day by day as the population is growing at a faster rate. Recycling will provide a tiny portion of demand and is not a complete solution. The demand for metals and minerals is too big. Mining has become a key to almost every facet of our lives. Mining is also a major source of employment and contributes significantly to the economy (Bora, 2023). The international mining market was projected to grow at a composite annual growth rate (CAGR) of 12.4% from $1641.67 billion in 2020 to $1845.55 billion in 2021 and may touch $2427.85 billion in 2025 at 7% CAGR (Research and Market, 2021). Mining is among the few industries that emerged in extraordinary financial & operational shape from the worst economic crisis due to the COVID-19 pandemic (PwC, 2021).

The consequences of mining on the environment might take place in regions, districts, and the globe via indirect and direct mining operations. Environmental impacts of mining might arise on the account of mine destruction techniques such as erosion of mine dumps, sinkholes, and the contamination of surface water, groundwater and soil through the chemicals emitted from mining operations and the elimination of organisms globally (Agboola et al., 2020; Sonter et al., 2018). Natural resources are getting depleted rapidly. For sustained development, assessment and management are very important for all resource-based economies (Ponomarenko et al., 2021). Resource depletion can be combated with productivity enhancement. The mining industry has been successful in raising productivity in the last 150 years. But there have been many slowdowns the industry is facing since 2000. There are concerns underlying addressing the factors or aspects which have kept productivity sustained over the years (Humphreys, 2020). Like any other manufacturing industry, the mining industry is also utilizing productive and sophisticated resources to keep the prospering trend by decreasing operational costs and increasing productivity. Monitoring and controlling each system to maintain a productivity graph in a safe environment with higher efficiency (Kumar & Kumar, 2015). Any comprehensive approach to a mining plan ought to have geostatistical uncertainty (Lagos et al., 2020). Ecosystem damage and resource scarcity are pressurizing the mining industry to enhance the circularity of its operations. Cause-effect groupings and their inter-relationship are being analysed to establish key challenges (Gedam et al., 2021). Geo-environmental hazards of mine waste that sprouted from mining processes, and the growing social awareness of handling those waste, have led to an expanded relevance of the study globally. However, there is no advanced research on the factors affecting mining operations. In modern research, the major areas ecological, geological, environmental, political and managerial factors are significant areas of attention of management for smooth mining operations (Egorova et al., 2018).

Recent literature focuses on the different emerging issues of the mining industry, i.e. environmental aspects, operational structure, and IT investment plans all have a role (Ravichandran & Liu, 2011). Studies have been carried out on ‘the mining area's geo-environmental impact assessment and information system’ (Zhang et al., 2015), ‘Mining Non-Fuel Minerals: Environmental Implications’ (Calvo et al., 2017), ‘Mining heat transfer treatment challenges and prospects in China's present mining industry and multifactor risk assessment in coal mines’ (Qiao, 2021). There is a lack of research on mining operations and that the study's narrow focus restricted it from addressing the influence of geo-environmental and managerial factors on the operational performances of the mines. It is the research gap that is intended to be addressed by the authors through research objectives.

The purpose of this research is,

-

i.

To identify the role of geo-environmental and managerial factors in the operational performance of the mining industry

-

ii.

To know if managerial factors play a mediating role between geo-environmental factors and operational factors and

-

iii.

To reveal the connections between them.

Lööw et al. (2019) have devised the notion of Mining 4.0 in-line with Industry 4.0. This is aimed at fashioning an advanced mining environment in future keeping miners’ perceptions in observation and how the work atmosphere will navigate within the industry. Many directions of research are also mentioned clearly by Mishra and Mohanty (2020). There is a lack of research on mining operations and that the study's narrow focus restricted it from addressing the influence of geo-environmental and managerial factors on the operational performances of the mines. Describing the mechanism of the multifactor contribution to the operation of the coal mine is a novel contribution to the field of mining research. The study discovered that managerial factors play a partial mediation effect on the relationship between geo-environmental and operational factors. Furthermore, it is critical to accurately assess the degree of flexibility of mining operations by assessing the interplay of many coupling factors (Choudhury et al., 2021).

Moving forward, the remaining portion of the study consists of the following sections: a literature review (Sect. 2), theoretical context and hypothesis development (Sect. 3), data collection, analysis, and interpretation (Sect. 4), results and discussion (Sect. 5), and finally, conclusions and recommendations (Sect. 6).

Literature review

The Mining Industry has many factors to look after, like, Operational factors, Geological & Environmental, Marketing & Management, Human Resources, Finance & Commercial, Resources & Utility, Corporate Affairs, CSR etc. (Mishra & Mohanty, 2020). In this study, we have taken up 3-major factors (Geology and Environmental Factors, Managerial Factors and Operational Factors) and the theories associated with that literature. To proceed with our purpose, we searched and collected 83 nos. of related articles of reputation and authenticity, screened them to categorize them suitably and finally 38 nos. articles, covering from 2004 to 2023, were chosen to find out sub-factors related to factors geology and environmental factors (GEF), managerial factors (MF) and operational factors (OF) prevalent in the mining industry. The details of the findings are represented systematically and in the concise form below:

Geo-environmental factor [GEF]

Geo-environmental features include multiple information on the 'geological and geochemical setting of mineral deposits, mining and mineral processing techniques as they relate to the development of mine waste and the environmental behaviour of mineral deposits in the wider context'. Researches in the areas of mineral raw material extraction (exploration), extraction (exploitation), and treatment (treatment), as well as the geo-environment, to preserve and rehabilitate the environment, as well as promoting social well-being, are now priority areas of mining industry (Jones et al., 2017; Mandal & Pal, 2022). The followings are the factors which contributed to operational excellence in mining:

Operational cost of bench

The optimization of mining operations is achieved by considering the whole system rather than concentrating on a single sub-system. The cost optimization approach can be applied by analysing the relationship among drilling, blasting, loading, hauling and crushing. Again, parameters such as burden, spacing, sub-drill, and explosive charges as the blast design parameters are based on the mean fragmentation size of the rock. Total mining cost can be reduced as the bench cost is reduced by 16.8% by an optimization process using an evolutionary algorithm and sensitive analysis (Ozdemir & Kumral, 2019).

Ore deposit and formation

Ore deposits and formations are pure of geological nature. There are many types of ore deposits, but the attributes of concern of all deposits are, slope stability, borehole stability, haulage ramp, and quantity & quality of resource deposits.

Slope stability: Rock slope instabilities are hazardous and can cause financial losses, damage to property, fatality & injury to workmen and maintenance costs. To study the slope stability of mines, a series of studies are carried out to identify the criteria required to be considered (Khakestar et al., 2016). Slope stability is also associated with the dumping of overburden and waste rock. The bearing capacity of the substrate is analysed and calculated. Based on suitable software, the capacity of dumps is determined and expansions are taken up accordingly. This slope stability of dumps has a direct link with transportation costs and work efficiency (Pan et al, 2021).

Borehole stability: A narrow shaft is bored into the mineral-bearing ground vertically or inclined to create a borehole. The instability of boreholes is a challenge to the mining industry. Sheared, deformed, stone-jammed and fractured boreholes are the common failures. Blasting is largely affected by unstable boreholes and so also production (Liu et al., 2017).

Haulage ramp: Ramp width and ramp gradient are two important aspects of open-pit haulage systems. Improvement can be achieved with the application of different simulation techniques. Inefficiency is observed in commonly used lockout-style systems of haulage systems (Haviland & Marshall, 2015).

Resource depletion: Metals are essential for humanity, so also the ores. Several indicators are there to assess the depletion of mineral resources (Rötzer & Schmidt, 2018). Depletion of mineral resources has severe consequences on society, economics and environmental costs associated with extracting them (Northey et al., 2018).

Seismic risk management

The magnitude of seismic events in deep mining occurs when mining deeper horizons. Developed mining countries are tackling this issue successfully, and injuries and fatalities are rare (Potvin et al., 2019). Real-time monitoring can assist prevention of such failures and post-failures incidents. Mitigation of such risks can be met by evacuating workmen and machinery areas from possible threat areas (Mishra et al., 2017).

Climate change-risk

Climate change and the associated increase in air temperatures are compounding work-related stress. Exposure to higher-temperature mining workers is at risk of heat-related illness, injury and even death. Inadequate awareness will increase heat stress risks which require proper techniques to manage (Nunfam et al., 2019). The climate change-risk has both positive and negative impacts on mining. Waterlogging and flooding can impede mining operations, whereas drought has a positive impact as mining activities are better in dry rather than wet (Khan et al., 2022; Sun et al., 2020).

Environmental protection and sustainable development

Mining provides raw materials for most of the basic amenities of human needs from agriculture to energy. It also acts as one of the most disturbing parts of the environment and is linked to large inequality in society. Future society will have bigger needs such as water, food, and energy, and the ores & minerals have to be ensured for them. Current economic growth is directly linked to the blind exhaust of resources. The ethical duty is intergenerational solidarity. Resources have to be conserved for future generations (Carvalho, 2017). This is also a major challenge faced by the sensible mining industry ensuring operation with minimal environmental impact in protected areas (Agyemang et al., 2021; Marnika et al., 2015).

Environmental risks (regulations)

Unregulated mining has the potential to severely damage the environment. It can damage soil, air, and water. Governments enforce regulations on companies to use advanced technology to meet environment-related protections. Environment licenses and social licenses are made compulsory to start and operate mines (Chen et al., 2023).

Environmental sustainability and energy management

One of the greatest challenges thrown by the mineral industry is the integration of economic activity with the environment, society and governance. This solution lies in sustainable development. Investment in environmental protection while doing business will reduce threats for future generations. Mining companies have to adopt sustainable development to ensure longevity in long-term business. The industry has adopted many such measures in the past. The industry can improve by considering the Paris Agreement adhering to climatic change. The approach may invite diversification of funds, but in the long term, it will prove beneficial to those companies who have invested in them (Jabareen, 2008; Tost et al., 2018).

Managerial factor [MF]

Quality of decision

Natural resources have the potential to transform the prospects of economic development. But these minerals can only generate prosperity if proper technique is employed to use the resources effectively and generate revenue from it for long-term benefit. The roadmap of such an ambitious goal requires effective management, consistent support and proper decision models. Again, the integration of environmental and social aspects invites tactical operational decisions, which are challenging. Decision models devoted to project optimization, mining operations and closure elements considering social and environmental issues to be formulated (Pimentel et al., 2016).

Management of supply chains

Supply chains of mineral resources for capacity planning remain a difficult managerial problem for mining companies. Cost-effective expansion of infrastructure to satisfy a higher projected demand is always challenging. The struggle associated with the problem is due to the complex nature of supply chains which involves production in mines; transportation from mines site to loading point; transporting via rail or road to sea terminal/customer destination; sea terminal to other terminal/customer destination, etc. Stockpiles or rail rakes have predetermined consignment plans. Any change or enhancement in demand necessitates multi-million cost involvement for capacity expansion, the addition of infrastructure and making all required provisions (Fung et al., 2015).

Managing change

The importance lies in the scale of change the industry is going to face or presently facing. High skill is required to manage these changes. The adaptability quotient reflects the ability to evolve and regenerate people. Changes are imminent, and they will happen slower or faster. Mining companies often neglect to change, considering it as an afterthought process. Some majorities of mining companies do not invest enough or properly to meet the challenges of change. They are not aware that change management is not just training and communication. The tenacity and persistence to change the mindsets and ultimately, behaviour is truly underestimated (Leonida, 2021).

Water and power management

Mining has to contribute to sustainable water management outcomes. Often the companies release water-related data. Withdrawals and discharges vary considerably between operations. The reporting schemes have to be encouraged to improve comprehensiveness and consistency. It has value for investors, regulators, the industry itself and the community around the industries. Water risks can be evaluated with proper data in hand. Water management outcomes and potential contributions, if available, can transform sustainable development goals (Northey et al., 2019; Fayiga et al., 2018).

Operational factor [OF]

Machine productivity

The two major areas on which machine productivity is dependent are transportation and equipment optimization.

Transportation: Shovels and trucks are the majority of loading and haulage systems used in open-pit mining involving huge investments. The associated transporting cost is around 50 to 60% of the total operational cost of mining (Upadhyay & Askari-Nasab, 2019). Fleet management systems seek optimal decision-making in handling minerals. This is performed in two steps: real-time truck dispatching and path-production optimization. Researchers like to study minimizing shovel idle times, truck wait times and minimal deviations from the path of optimized production, etc. The fleet requirement can be reduced by 30% of size if proper modular Mining DISPATCH systems are employed (Afrapoli et al., 2019).

Equipment optimization: Any change in technological advancement requires the adoption of mining methodology until the best approach arrives. New mining layouts are possible with an engineering approach. Advanced and tested technological combinations should be implemented for the optimality of equipment, optimality of layouts and processes and their optimal implementation (Pickering, 2004).

Production scheduling optimization

Production scheduling is crucial to the mining industry. Profits are hugely dependent on optimal and efficient production schedules. Consistent productions are only possible if production schedules are well planned and properly executed. Stockpiling and blending of minerals become smooth in an optimized production schedule. Quality and quantity can be met to meet the customers' demands. Operational efficiency is highly dependent on efficient production schedules (Kumar & Chatterjee, 2017).

Production scheduling: The production scheduling process has a significant role in the efficiency and subsequent profitability of mining operations (Sotoudeh et al., 2020). Mining has inherent geological variability for which conventional approaches to optimize mine design and production scheduling are though estimated but are not practicable. There is an uncertainty in the pattern of grade deposit and conditional simulation techniques can be employed to address this quantitatively. Production schedules are meant to maximize total net present value, reducing unsatisfied demand for processed ore. Production scheduling optimization processes are taken up using multiple-simulated-orebody-models and stochastic integer programming models for the integration of deposit variability and pattern of grade uncertainty (Ramazan & Dimitrakopoulos, 2018).

Resource allocation: Resource allocation is a key issue in mining for its business process management. The geography and geology of each mine are different from each other. Situations are different in each mine, and hence, standard resource allocation rules are not applicable (Huang et al., 2011). Internet of Things or more advanced, the Tactile Internet can be used to communicate from one geographical location to another in real-time control and navigation (Aazam et al., 2019).

Production sequencing: Mining planning has three directions of concerns, viz. block sequencing, cut-off grade fixing and production rate determination. Optimization models are prepared to maximize net present value with due consideration of capacity constraints and access capability (Kumral, 2012). Mine production scheduling is a sequence of extraction within a predetermined production plan. The schedules are the operational guides to meet the desired objective under prevailing constraints and operating conditions. In the first step, the physical sequence of extraction of minerals is optimized and in the second step, mining equipment fleet, availability and hauling time are optimized.

Ore recovery

It is generally defined as the percentage of mineable reserve extracted during the mining process.

In India, 15–20% of mined ore remains unutilized and discarded as slime. The industry is looking forward to technologies to transform the discarded minerals to make mining more environmentally sustainable. Low-grade minerals require beneficiation to be used as normal raw minerals (Singh et al., 2015).

Early rejection of low-value mineral: Average-grade ore bodies have significantly decreased in the last few decades, and waste removal has increased many folds. The energy expenditure is compounding with higher waste removal, decreasing overall productivity. Low-grade minerals can be rejected and dumped suitably for re-use later on, and effective grade extraction can be availed to the present requirement (Carrasco et al, 2016).

Machine reliability

The reliability of machines is dependent on their availability. Again, availability is dependent on the maintenance programme of mining machinery.

Reliability cantered maintenance programmes: Equipment and machinery are assets of the mining industry, and their efficiency depends on higher availability and low failure. Reliability-centred maintenance reduces failure rate and increases availability. Cost-effective strategies based on reliable maintenance are required to maximize profit and productivity in a competitive environment. Machine breakdowns can disrupt production, resulting in noticeable loss and hurting equipment lifespan (Jafarpisheh et al., 2021).

MMS (maintenance management systems): 15–40% of the total production cost is the cost of preventive maintenance in the mining industry (Savsar, 2014). With the advancement of the industrial revolution, the maintenance function of mining machinery is gaining importance in the mining field. Maintenance management systems are being computerized. The system supporting maintenance function is termed a computerized maintenance management system (CMMS). The CMMS is a tool aimed at formulating a strategy of maintenance by combining different functions and related information to reflect indications related to maintenance instructions (Stefaniak et al., 2017).

Drill and blast efficiency

The mining industry is adopting optimization processes. Advanced technologies based on efficient blasting equipment and explosives make the operation more cost-effective. Drilling & blasting is the most essential part of the mining industry that plays a crucial role in downstream stages. Attributes such as rock density, bit life of the drill, uniaxial compressive strength and associated operational costs are taken into consideration while optimizing results (Abbaspour et al., 2018).

The details of findings from literature review are mentioned in Table 1.

Table 1.

Summary of literature review.

Source: Author's findings from different literatures

| Sl. No | Factor | Sub-factors | Authors (Year) |

|---|---|---|---|

| 1 |

Geo-environmental factors [GEF] |

Operational cost of bench | Ozdemir and Kumral (2019) |

| Slope stability | Khakestar et al., (2016); Pan et al., (2021) | ||

| Borehole stability | Liu and et al., (2017) | ||

| Haulage ramp | Haviland and Marshall (2015) | ||

| Resource depletion | Rötzer and Schmidt (2018); Northey et al., (2018) | ||

| Seismic risk management | Mishra et al., (2017); Potvin et al., (2019) | ||

| Climate change-risk | Nunfam et al., (2019); Sun et al., (2020); Khan et al., (2022) | ||

| Environmental protection & sustainable development | Carvalho (2017); Marnika et al., (2015); Agyemang et al. (2021) | ||

| Environmental risks (regulations) | Chen et al. (2023) | ||

| Environmental sustainability and energy management | Tost et al., (2018); Jabareen (2008) | ||

| 2 |

Managerial factors [MF] |

Quality of decision | Pimentel et al., (2016) |

| Management of supply chains | Fung et al., (2015) | ||

| Managing change | Leonida (2021) | ||

| Water & power management | Northey et al., (2019); Fayiga et al. (2018) | ||

| 3 |

Operational factors [OF] |

Machine productivity | |

| Transportation |

Upadhyay & Askari-Nasab (2019); Afrapoli et al., (2019) |

||

| Equipment optimization | Pickering (2004) | ||

| Production scheduling optimization | Kumar and Chatterjee (2017) | ||

| Production scheduling |

Sotoudeh et al., (2020); Ramazan and Dimitrakopoulos (2018) |

||

| Resource allocation | Huang et al., (2011); Aazam et al., (2019) | ||

| Production sequencing | Kumral (2012) | ||

| Ore recovery | Singh et al. (2015) | ||

| Rejection of low value mineral at the earliest | Carrasco et al., (2016) | ||

| Machine reliability | |||

| Reliability cantered maintenance | Jafarpisheh et al., (2021) | ||

| MMS (maintenance management systems) | Savsar (2014); Stefaniak et al. (2017) | ||

| Drill & blast efficiency | Abbaspour et al., (2018) |

Theoretical background and hypothesis development

The mining business comes under operations & production management. Modern operations management consists of four theories: business process redesign (BPR), six sigma, lean manufacturing, and reconfigurable manufacturing systems.

Business process management (BPM) is an organizational discipline wherein a company analyses all its processes individually as well as in total to identify the process deficiencies that need improvement for an effective and efficient organization (Hammer, 2015).

Six sigma is a statistical tool used to benchmark a business process or elements of business processes. The deviations of the mean are identified, and the limits of consumers are checked whether it is within the satisfaction limit or not. The practitioners use statistics, financial analysis, and project management aspects to improve the functions of the business.

Lean & agile manufacturing is a production process aimed at maximizing productivity while working on minimizing waste within a manufacturing operation. The overall benefits are observed: lead time improves, operation costs reduce, and product quality improves (Feld, 2000).

Sustainable operations management (SOM) strategies are concerned with procedures, processes, practices and systems within which the preservation of social and environmental aspects is taken into consideration. This is essential for the long-term success and survival of industries (Pimentel et al., 2016).

There are many sub-activities within the mining operation. If we consider the whole operation as a business process, the sub-activities or elements of the mining operation are following different trends. The mining operation, as a whole, can be linked with the theory of BPM, but the sub-activities or elements may follow a similar theory or are different. While analysing the elements in consultation with mining field experts and operation management experts, we recommend Table 2 linking the elements of concern in this paper with related theories of operation management.

Table 2.

Linked theories of operation and production management with concerned mining activities.

Source: Author

| Factors | Sub-factors | Linked theories | ||

|---|---|---|---|---|

| Geo-environmental factors [GEF] | 1 | Operational cost of bench | Six sigma | Business process management (BPM) |

| i. Slope stability | Multi-criteria decision making | |||

| ii. Borehole stability | Natural phenomena and hence, not applicable | |||

| iii Haulage ramp | Business process management | |||

| 2 | Resource depletion | Lean & agile manufacturing | ||

| 3 | Seismic risk management | Sustainable operations management | ||

| 4 | Climate change-risk | Sustainable operations management | ||

| 5 | Environmental protection & sustainable development | Sustainable operations management | ||

| 6 | Environmental risks (regulations) | Sustainable operations management | ||

| 7 | Environmental sustainability and energy management | Sustainable operations management; lean & agile manufacturing | ||

| Managerial Factors [MF] | 8 | Quality of decision | Business process management | |

| 9 | Management of supply chains | Business process management | ||

| 10 | Managing change | Business process management | ||

| 11 | Water & power management | Lean & agile manufacturing | ||

| Operational Factors [OF] | 12 | Machine productivity | Six sigma, lean & agile manufacturing | |

| i Transportation | Lean & agile manufacturing | |||

| ii Equipment optimization | Business process management | |||

| 13 | Production scheduling optimization | Lean & agile manufacturing six sigma | ||

| Production scheduling | Lean & agile manufacturing | |||

| i Resource allocation | Lean & agile manufacturing | |||

| ii Production sequencing | Lean & agile manufacturing | |||

| 14 | Ore recovery | Lean & agile manufacturing | ||

| 15 | Machine reliability | Sustainable operations management | ||

| i Reliability cantered maintenance | Lean & agile manufacturing | |||

| ii MMS (maintenance management systems) | Lean & agile manufacturing | |||

| 16 | Drill & blast efficiency | Six sigma, lean & agile manufacturing | ||

Hypotheses formulation

Geo-environmental factor and operational performance

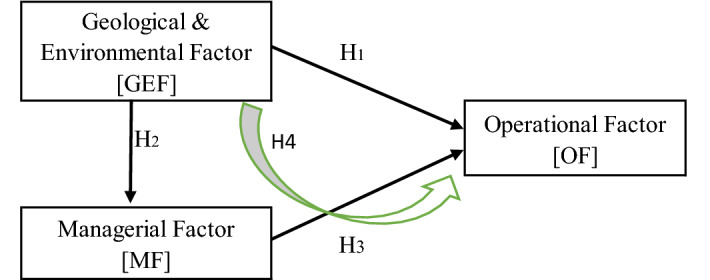

Mining is critical to the creation of commodities, services, and infrastructure; it improves the standard of living in society. However, the potential dangers of waste and radioactivity created by mining, dumping, and tailing have prompted society to seek solutions that would appropriately handle mining waste from mine dumps, tailings, and abandoned mines. Mine waste reusing in the mining industry might provide cost-effective benefits by balancing specifications and reducing waste volumes to be controlled (Agboola et al., 2020). One of the most important aspects of any successful company plan is proper care and consideration for the environment. Given the increased focus on environmental concerns in the mining industry, it is even more vital today (Chiaro, 1997; Zhang et al., 2015). Geo-environmental consequences, such as geological disasters, environmental pollution, and resource depletion, have been linked to mining activity. Environmental impact assessment (EIA) is widely regarded as a useful tool for integrating environmental protection and the use of natural resources into planning, mining operation and programme execution. Ensuring that mining activities have a positive impact on the environment while protecting natural resources is essential for long-term mining viability along with operation (Huang et al., 2011; Tayebi-Khorami et al., 2019). From the above literature study, no study is found establishing any relationship between these three factors. But we can consider that the geological and environment factor determines the outcome of the mining business (Carlson, 2019). It indicates operational factor is dependent on geology and environment factors. This study proposed the hypothesis mentioned below:

H1

Geo-environmental factor (GEF) has direct influence on operational factor (OF).

Geo-environmental factor and managerial factor

In the mining industry, environmental concerns are one of the major concerns in the competitive world. Operational managers should include geo-environmental factors in the decision-making process. An organization's immediate surroundings have a significant influence on its performance since it is continually in touch with its environment. In a coal mines production system, the dynamic and nonlinear features of the system are impacted by difficult geological conditions, undeveloped technology and insufficient miner skills, and weak safety management (Ravichandran & Liu, 2011). Geological, environmental is a direct relation to managerial decisions and factors (Calvo et al., 2017). To address all the adversaries and challenges of both geology & environment, management has to take proactive and remedial steps to tackle them. By looking at the above justification complexity, study proposed the hypothesis:

H2

Geo-environmental factor has direct influence on managerial factor (MF).

Managerial factor and operational factor

The organizational and managerial factors influence the various phases of a firm's international development process. Managerial issues are substantially impacted businesses that have a better commitment to total quality management, which in turn also contributed to firms' operational performance. Environmental and management issues were significant factors in the development of a company's distribution channels (Walden-Schreiner et al., 2017). When it comes to iron ore mining firms, they are confronted with the challenge of production and distribution planning. Every mining industry is looking at a reduction of the overall cost of the iron ore extract throughout the entire processing and marketing system, which is part of managerial issues. Managerial elements influence the implementation and utilization of overall efficiency in a company's operations. When it comes to mining operations and, ultimately, the quality necessary to maintain the business safe and lucrative, the managerial factor must perform its function prudently and impeccably, as described above (Mishra & Mohanty, 2020). It concluded by proposing the following hypothesis:

H3

Managerial factor has direct influence on operational factor.

Mediation effect of managerial factor in between geo-environmental factor and operational factor

Changing living circumstances on mining allotment lands and surrounding territories, as well as a rapid deterioration in the quality of the environment, have been linked to the mining industry (Koščová et al., 2018). This remark indicates that the importance of both geo-environmental concerns and managerial concerns are top priorities for the mining sector, as well as its operational activities (Liu et al., 2019; Mishra & Mohanty, 2020; Sonter et al., 2018). To achieve sustainable growth, mining companies must take action at all levels, including those concerning environmental, economic, managerial, operational and social ramifications (Chattopadhyay & Chattopadhyay, 2012). Environmental and geological, managerial concerns are becoming more pressing for the mining sector at the same time as society's and stakeholders' expectations are rising. In recent times, from a management perspective, strategic approaches to environmental challenges in the mining sector in foreign nations are discussed (Ruokonen, 2021). In line with the above literature, it was evident that managerial concerns have a link with both geo-environmental as well as operation prospects of the mining industry. Because of this, the major focus of the research was on understanding the reasons for and methods used by the Indian mining sector to cope with geo-environmental and managerial concerns on operational prospects. It will be tested with the proposed hypothesis mentioned below:

H4

Indirect effect of managerial factors in between geo-environment factor and operational factors.

The proposed model for our study can be as mentioned in Fig. 1.

Fig. 1.

Proposed model

Data source, methodology used and analysis

Data source

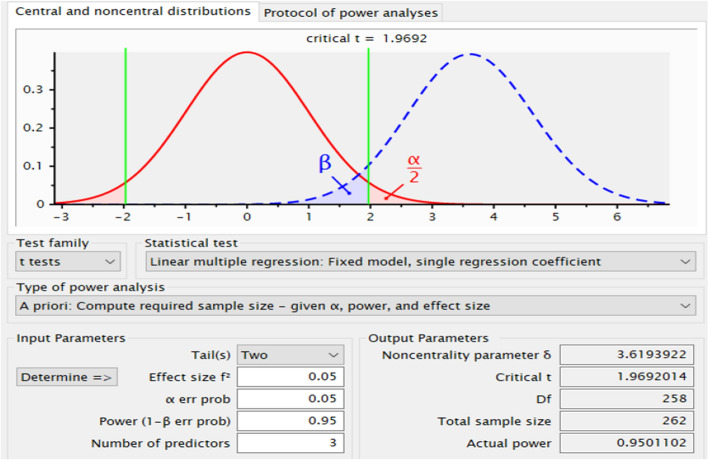

Sample and size: Convenience sampling has been used in this study. 329 nos. executives with 10 or more years of experience in the mining industry have been considered as samples. G*power statistic is used to determine the sample size.

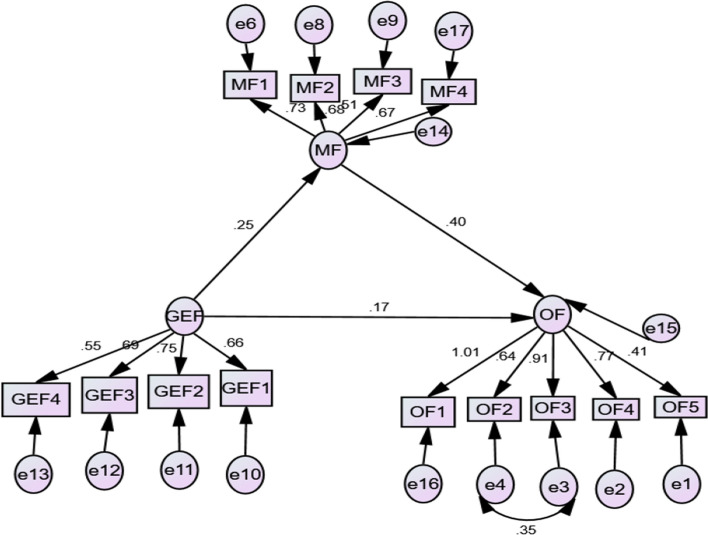

Data analysis technique: For the measurement of the model, confirmed factor analysis (CFA) and for structural model structural equation modelling (SEM) has been used to find out the relationships and dependence on factors. The measurement model describes the links between a set of observable variables and the latent constructs that underpin them. Latent constructs are variables that are unobservable but can be inferred from seen variables. The measuring model contributes to the validity and reliability of the measures used to assess latent components. The structural model describes the connections between the latent constructs. It shows theorized causal linkages between latent constructs and aids in the testing of theories or hypotheses about how these constructs are related to one another. The structural model specifies the direction and strength of the interactions between the latent constructs and can be used to test several hypotheses to determine which model best fits the observed data.

Geographical boundary: The study has been carried out in Indian Surface Mines consisting of three states, viz. Odisha, Jharkhand, and Chhattisgarh. The industries were covered by large-scale mining projects.

Methodology used

In the present study, structural equation modelling (SEM) techniques are being used to study complex relationships as well as to know the study impact of managerial factors and geo-environmental factors on mining operational performances (Maiti et al., 2004; Probst et al., 2020). An earlier study on the issue demonstrated that the approach used to explore the intricate interplay between diverse elements that have an impact on mining operations was well founded (Paul, 2013; Pedram et al., 2020).

There are 16 items under three constructs considered from various established studies to take up the research. The 7 items of the geo-environmental construct are the operational cost of the mining bench (Ozdemir & Kumral, 2019), resource depletion (Northey et al., 2018; Rötzer & Schmidt, 2018), seismic risk management (Mishra et al., 2017; Potvin et al., 2019), climate change-risk (Nunfam et al., 2019; Sun et al., 2020; Khan et al., 2022), environmental protection & sustainable development (Agyemang et al., 2021; Carvalho, 2017; Marnika et al., 2015), environmental risks (Chen et al., 2023), and environmental sustainability & energy management (Jabareen, 2008; Tost et al., 2018). The 4 items considered for the managerial construct are quality of decision (Pimentel et al., 2016), management of supply chains (Fung et al., 2015), managing change (Leonida, 2021), and water & power management (Northey et al., 2019; Fayiga et al., 2018). The five items under operational construct are machine productivity (Upadhyay & Askari-Nasab, 2019; Afrapoli et al., 2019; Pickering, 2004), production scheduling optimization (Sotoudeh et al., 2020; Ramazan & Dimitrakopoulos, 2018; Huang et al., 2011; Aazam et al., 2019; Kumral, 2012), ore recovery (Singh et al., 2015; Carrasco et al., 2016), machine reliability (Jafarpisheh et al., 2021; Savsar, 2014; Stefaniak et al., 2017), and drill & blast efficiency (Abbaspour et al., 2018).

In this investigation, the authors employ structural equation modelling (SEM) to understand the intricate connections of relationships between study variables (Hair et al., 2010). In mining industry operations studies, structural equation modelling (SEM) can be used to dissect the interconnected web of variables that determines how well mines operation performs from a geographical and managerial perspective (Hou et al., 2018; Zhang et al., 2016). One of the major problems mining operations can cause for the environment and the people who live in their surroundings is crucial (Mishra et al., 2022). To determine the most influential aspects of geo-environmental, and managerial factors on operational factors, SEM can be used to model interactions between them. Additionally, SEM can be used to evaluate current practices in environmental management and pinpoint places where enhancements are needed.

Data analysis

Sample size determination (G*power): In addition, the G*power statistic is used to determine the sample size. The formula G*power was used to determine the sample size (Faul et al., 2009; Shiva et al., 2020). The sample size for this study was 329 participants, which is considered to be a satisfactory number and an appropriate sample size for this study. Figure 2 shows the result as 2.

Measurement model (CFA): This study uses CFA to assess measurement model reliability and validity. Statistical error checking and Cronbach's alpha analysis play a vital role in establishing the trustworthiness and validity of a study's findings. Many types of checks were performed on the data in this study before any processing took place. These checks included looking for outliers, missing data, and other irregularities in the data set. The study also checked with common method bias tests for assessing the degree of overlap or similarity between items used to measure different constructs in a survey or questionnaire (MacKenzie & Podsakoff, 2012). Cronbach's alpha analysis can be employed as a measure of internal consistency and reliability of the measurement scale. All the scores of Cronbach's alphas for the constructs are, i.e. geo-environmental factor is 0.738, the managerial factor is 0.719, and the operational factor is 0.874 (Table 3). All three constructed Cronbach alpha scores are above the threshold limit of 0.70 (Santos, 1999; Taber, 2018). There is no issue of internal consistency. On the basis of low factor loading below 0. 50 and minimum threshold score of Cronbach's alphas of 0.70, three items under the geo-environmental construct are dropped in the final structural model analysis (Santos, 1999; Taber, 2018), i.e. resource depletion, seismic risk management, and climate change-risk.

Fig. 2.

G* Power sample size determination (Refs.: Faul et al, 2009; Shiva et al, 2020).

Source: Authors’ calculation

Table 3.

Quality criterion for model assessment (reliability and validity).

Source: Compiled by Author

| Constructs | Items | Loading/weights | Cronbach's Alpha | CR | AVE | MSV |

|---|---|---|---|---|---|---|

| Geo-environmental factor [GEF] | GEF2 | 0.83 | 0.738 | 0.756 | 0.600 | 0.071 |

| GEF1 | 0.757 | |||||

| GEF3 | 0.712 | |||||

| GEF4 | 0.692 | |||||

|

Managerial factor [MF] |

MF1 | 0.794 | 0.719 | 0.748 | 0.508 | 0.194 |

| MF2 | 0.714 | |||||

| MF3 | 0.695 | |||||

| MF4 | 0.699 | |||||

|

Operational factor [OF] |

OF2 | 0.95 | 0.874 | 0.875 | 0.603 | 0.194 |

| OF1 | 0.932 | |||||

| OF3 | 0.897 | |||||

| OF4 | 0.809 | |||||

| OF2 | 0.737 | |||||

| OF5 | 0.635 |

The measurement model refers to convergent and discriminant validity for all three constructs/factors (Fig. 2). Confirmation of factor properties based on composite reliability, convergence validity, and discriminant validity are required for all three constructs (O'Leary-Kelly & Vokurka, 1998). For each construct, the convergent validity is examined using three criteria. After that, researchers used CR to verify that it was greater than the predetermined threshold limit of 0.70. The calculated CR value ranged from 0.748 to 0.875 in reference (Table 3). As you can see, this has a high degree of dependability and internal consistency (Gaskin, 2020; Hair et al., 2010), then after the constructs are checked through (average variance explained) AVE’s threshold limit of 0.50 (AVE > 0.5) (Fornell & Larcker, 1981; O'Leary-Kelly & Vokurka, 1998), in comparison with this calculated AVE values are ranging from 0.508 to 0.603, and certified as per the AVE criteria, refer to Table 3. Lastly, all CR values must be greater than the values of the AVE value (CR > AVE). There was a greater difference between the CR values of the three constructs and the AVE values of the three constructs in this study. The study's convergent validity has been established after it meets the above-mentioned three requirements (Fig. 3).

Fig. 3.

Measurement model (CFA)

Following the achievement of convergent validity, all elements must now meet the requirements for discriminant validity (Table 3). AVE's value must be greater than MSV to meet discriminant validity criteria (AVE > MSV). The study confirms that all four construct MSV values are lower than the AVE value for all three constructs (Table 3). Comparing the AVEs of different measurements with shared variances between measurements can then assess another criterion of discriminant validity (Fornell & Larcker, 1981). The validity of the discriminant was demonstrated by comparing the similarity of inter-items. A larger diagonal under the AVEs of the construct was found than the correlation between the construct's components' correlations. As a result, the discriminant validity test could be confirmed. All three constructs under root values of AVEs are GEF = 0.775, MF = 0.713, and OF = 0.776 is greater than the correlation values between items in the three constructs (refer to Table 4).

-

(c)

Structural model assessment: After confirmation through the measurement model, the next step is to proceed towards the present robustness of the model through structural equation modelling (SEM). In the context of mining operations and operation management, SEM can be used to investigate the relationships between factors such as safety culture, operational performance, and environmental impact as referred to by earlier studies (Kursunoglu & Onder, 2019; Muduli et al., 2020). Comparing the theoretical model to the observed data and making adjustments to better fit is the iterative process that is the assessment of a structural model. To this end, it is necessary to construct a model that faithfully reproduces the underlying inter-relationships among the variables to reliably forecast future outcomes or guide present-day research in mining operations.

Table 4.

Discriminant validity assessment.

Source: Compiled by Author

| OF | MF | GEF | |

|---|---|---|---|

| OF | 0.776 | ||

| MF | 0.441*** | 0.713 | |

| GEF | 0.266*** | 0.247** | 0.775 |

In a model fit of structural model (Fig. 4), the study frequently uses relative Chi-square (CMIN/DF: Chi-square/degree of freedom), the goodness of fit indicators such as CFI, IFI, NFI, TLI, and badness of fit indicator is RMSEA. The threshold limit of indicators is CMIN/DF—< 3 (less than 3) indicated as a reasonable model fit (Byrne, 2016; Hu & Bentler, 1999). Whereas CFI, IFI, NFI, and TLI > 0.9 (greater than 0.90) indicate good levels of fit between data and model (Bentler, 1988; Chou & Bentler, 1995; Mueller & Hancock, 2008) and badness of fit indicators RMSEA threshold values of less than 0.01, 0.05, and 0.08 indicate excellent, good, and mediocre fit, respectively, more than 0.1 (> 0.10) indicate poorly specified model. All the above criteria must be checked in the structural model assessment (Garg & Kothari, 2019; Hair et al., 2010; Saunders et al., 2019). As per the above threshold limits of CMIN/DF—2.632, which is under the limit of reasonable model fit. Accordingly, CFI- 0.948, NFI- 0.920, and TLI- 0.934 all are acceptable threshold limits of (> 0.9) (greater than 0.90) (Hair et al., 2010; Saunders et al., 2019) which indicate good levels of model fit. The root-mean-square error of approximations (RMSEA) was 0.092, which indicates excellent model fit (Garg & Kothari, 2019; Hair et al., 2010; Saunders et al., 2019) (refer to Table 5).

Fig. 4.

Structural model (SEM)

Table 5.

Model goodness of fit.

Source: Compiled by Author

| Criteria | X2/CMIN/DF | CFI | RMSEA | NFI | TLI |

|---|---|---|---|---|---|

| Qualifying criteria | < 3.0 (Less than 3) | ≥ 0.9 | ≤ 0.05 | ≥ 0.9 | ≥ 0.9 |

| Structural modal values | 2.632 | 0.95 | 0.092 | 0.90 | 0.93 |

Result and discussion

The findings indicate that the GEF has a statistically significant and positive effect on OF, with a standardized beta value of 0.168 and a p-value of 0.009, which indicates that H1 is supported. Again, the effects of GEF on MF are positive and statistically significant, with a standardized beta value of b = 0.247 and a p-value of 0.001. As a result, H2 is also accepted. In this study, MF was found to be the second most important predictor of OF. The results of the analysis revealed that the MF has a positive and significant impact on OF, with a standardized beta value of b = 0.399 and a p-value of 0.001. As a result, H3 has also been confirmed (refer to Table 6).

Table 6.

Hypothesis path table. Source (s): Compiled by Author

| Hypothesis | Relationship | Estimates | t-Value | p-Value | Decisions |

|---|---|---|---|---|---|

| H1 | GEF → OF | 0.168 | 2.597 | 0.009 | Supported |

| H2 | GEF → MF | 0.247 | 3.319 | 0.001 | Supported |

| H3 | MF → OF | 0.399 | 4.879 | 0.001 | Supported |

| H4 | GEF → MF → OF | 0.099 | 3.266 | 0.001 | Supported |

The study confirms GEF has an impact on OF, GEF on MF, and MF on OF. The study also confirms GEF has an impact on both MF and OF in cascade. We have discussed the matter with field experts. Geological and environmental factors are natural phenomena and while operating a mine, these factors and their concerns have to be attended to. Hence, these factors decide what course of action management takes to address them. Human factors can alter the geology and environmental factors but not immediately. It is a very slow process.

Similarly, GEF decides which course of action is to be taken by managerial factors to address its concerns. The mining benches can be formed considering the geology of deposits, and accordingly, slope stability and haulage ramp will be decided. Borehole stability is completely dependent on geological factors. Resources depletion is a major threat that modern mining is facing. The higher deposits have been exhausted in the past due to various reasons. The scenario in mining-developed states requires managerial decisions and techniques to meet the standard output. Climatic conditions, environmental sustainability issues and energy management aspects have to be addressed by management to keep the mining business going. Similarly, geological and environmental factors can only be met by effective managerial actions and operational activities would be set considering the geological and environmental conditions.

The operational factors are dependent on managerial factors. It indicates, whatever action is taken by managerial staff, will reflect on operational activities. The operational elements are human-centric. The highest business-impacting activity is transportation followed by other operational elements. Managerial actions determine what course of action has to be taken on the field. Implementation of efficient practices to adopt various new and developed technologies require managerial intervention. Whether it is the process of reliability-centred maintenance, production schedules, or resource allocation, all require human involvement. Operational factors determine the whole mining operation. Management has to fix these elements judiciously to meet the requirements of both managerial and geological & environmental elements. The study indicates this direction.

Conclusion and recommendation

This study exposes many aspects of mining management. The study will compel and encourage the management of the industry to take adequate courses of action to address the implications of each element. The study focuses on only three factors of the Indian mining industry. There are many mineral states in India with varied types of mineral deposits. The geographical boundary of the study is confined to three states of India.

Limitations of the study

The study has inherent limitations in sample size, which could have been higher and the particular geography under which the study was carried out. A higher sample size may or may not offer different results. The study is confined to a certain geography. The results may differ in Africa or South America or the Australian mining environment as the variables may differ in their geography.

Managerial implications

It is a unique initiative to explore different influential elements of mining operations. The current study provides benefits to stakeholders and owners in terms of building trust and belonging among consumers, society, and other stakeholders. This is one of the most important contributions to the unorganized Indian mining industry. It outlines significant obstacles and identifies potential study routes for the future. This study helps managers to identify different prominent issues related to geological, and environmental in mining operations and also provides substantive information for government compliance. Overall, the conclusions of this study assist management in the creation of policy and the management repercussions of resolving the mining industry's environmental challenges.

Social implications

GEF issues have greater potential to affect society as a whole in the long term if neglected consistently. The study will encourage and compel the mining industry to adopt sustainability practices in India's Mining Industry.

Future scope of the study

The study output suggests substantial ideas for further investigation of Indian research in the domain of mining operations. Future research focuses on the efforts aimed at improving environmental performance concerning emerging sectors. The study will also look into how mining industry executives see the strategic importance of geo-environmental concerns and their impact on creating a competitive edge for mining companies.

Author contributions

PCM contributed to the data curation, writing—original draft, visualization, and investigation. RRP was involved in the conceptualization, methodology, and writing—review. AKS assisted in preparing revision, supervision, and validation and editing.

Funding

The authors declare that no funds, grants, or other support was received during the preparation of this manuscript.

Data availability

Data will be shared on the basis of request.

Declarations

Conflict of interest

The authors have no relevant financial or non-financial interests to disclose.

Consent to participate

Not applicable.

Consent to publish

Not applicable.

Ethical approval

Not applicable.

Footnotes

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Contributor Information

Padma Charan Mishra, Email: pcmishra71@gmail.com.

Rashmi Ranjan Panigrahi, Email: rashmipanigrahi090@gmail.com.

Avinash K. Shrivastava, Email: kavinash1987@gmail.com

References

- Aazam M, Harras KA, Zeadally S. Fog computing for 5G tactile industrial Internet of Things: QoE-aware resource allocation model. IEEE Transactions on Industrial Informatics. 2019;15(5):3085–3092. doi: 10.1109/TII.2019.2902574. [DOI] [Google Scholar]

- Abbaspour H, Drebenstedt C, Badroddin M, Maghaminik A. Optimized design of drilling and blasting operations in open pit mines under technical and economic uncertainties by system dynamic modelling. International Journal of Mining Science and Technology. 2018;28(6):839–848. doi: 10.1016/j.ijmst.2018.06.009. [DOI] [Google Scholar]

- Afrapoli AM, Tabesh M, Askari-Nasab H. A multiple objective transportation problem approach to dynamic truck dispatching in surface mines. European Journal of Operational Research. 2019;276(1):331–342. doi: 10.1016/j.ejor.2019.01.008. [DOI] [Google Scholar]

- Agboola O, Babatunde DE, Isaac Fayomi OS, Sadiku ER, Popoola P, Moropeng L, Yahaya A, Mamudu OA. A review on the impact of mining operation: Monitoring, assessment and management. Results in Engineering. 2020;8:100181. doi: 10.1016/j.rineng.2020.100181. [DOI] [Google Scholar]

- Agyemang AO, Yusheng K, Twum AK, Ayamba EC, Kongkuah M, Musah M. Trend and relationship between environmental accounting disclosure and environmental performance for mining companies listed in China. Environment, Development and Sustainability. 2021;23:12192–12216. doi: 10.1007/s10668-020-01164-4. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Bentler PM. Handbook of multivariate experimental psychology. Springer; 1988. Causal modeling via structural equation systems; pp. 317–335. [Google Scholar]

- Bora A. Mining is the future: Three-step process to achieve sustainability in mining. Friesen Press; 2023. [Google Scholar]

- Byrne BM. Structural equation modeling with AMOS: Basic Concepts, Applications, and Programming. Routledge; 2016. [Google Scholar]

- Calvo G, Valero A, Valero A. Assessing maximum production peak and resource availability of non-fuel mineral resources: Analyzing the influence of extractable global resources. Resources, Conservation and Recycling. 2017;125:208–217. doi: 10.1016/j.resconrec.2017.06.009. [DOI] [Google Scholar]

- Carlson R. Understanding geologic uncertainty in mining studies. SEG Discovery. 2019;117:21–29. doi: 10.5382/Geo-and-Mining-03. [DOI] [Google Scholar]

- Carrasco C, Keeney L, Walters SG. Development of a novel methodology to characterise preferential grade by size deportment and its operational significance. Minerals Engineering. 2016;91:100–107. doi: 10.1016/j.mineng.2015.08.013. [DOI] [Google Scholar]

- Carvalho FP. Mining industry and sustainable development: Time for change. Food and Energy Security. 2017;6(2):61–77. doi: 10.1002/fes3.109. [DOI] [Google Scholar]

- Chattopadhyay S, Chattopadhyay D. Encyclopedia of sustainability science and technology. Springer; 2012. Mining mine/mining Industries mine/mining industry and their sustainable management; pp. 6645–6665. [Google Scholar]

- Chen J, Jiskani IM, Lin A, et al. A hybrid decision model and case study for comprehensive evaluation of green mine construction level. Environment, Development and Sustainability. 2023;25:3823–3842. doi: 10.1007/s10668-022-02206-9. [DOI] [Google Scholar]

- Chiaro PS. The industrial green game implications for environmental design and management. National Academies Press; 1997. Environmental strategies in the mining industry: One company’s experience; pp. 165–181. [Google Scholar]

- Chou CP, Bentler PM. Estimates and tests in structural equation modeling. In: Hoyle RH, editor. Structural equation modeling: Concepts, issues, and applications. Sage Publications; 1995. pp. 37–55. [Google Scholar]

- Choudhury A, Lahkar J, Saikia BK, Singh AKA, Chikkaputtaiah C, Boruah HPD. Strategies to address coal mine-created environmental issues and their feasibility study on North-eastern coalfields of Assam, India: A review. Environment, Development and Sustainability. 2021;23(7):9667–9709. doi: 10.1007/s10668-020-01091-4. [DOI] [Google Scholar]

- Egorova N, Zaruba N, Jurzina T, Tumin V. Ecological Management as a factor of Mining Region Development. E3S Web of Conferences. 2018;41:02001. doi: 10.1051/e3sconf/20184102001. [DOI] [Google Scholar]

- Faul F, Erdfelder E, Buchner A, Lang AG. Statistical power analyses using G* Power 3.1: Tests for correlation and regression analyses. Behavior Research Methods. 2009;41(4):1149–1160. doi: 10.3758/BRM.41.4.1149. [DOI] [PubMed] [Google Scholar]

- Fayiga AO, Ipinmoroti MO, Chirenje T. Environmental pollution in Africa. Environment, Development and Sustainability. 2018;20:41–73. doi: 10.1007/s10668-016-9894-4. [DOI] [Google Scholar]

- Feld WM. Lean manufacturing: Tools, techniques, and how to use them. CRC Press; 2000. [Google Scholar]

- Fornell C, Larcker DF. Evaluating structural equation models with unobservable variables and measurement error. Journal of Marketing Research. 1981;18(1):39. doi: 10.2307/3151312. [DOI] [Google Scholar]

- Fung J, Singh G, Zinder Y. Capacity planning in supply chains of mineral resources. Information Sciences. 2015;316:397–418. doi: 10.1016/j.ins.2014.11.015. [DOI] [Google Scholar]

- Garg G, Kothari CR. Research methodology: Methods and techniques. 4. New Age International (P) Limited; 2019. [Google Scholar]

- Gaskin, J. (2020). Confirmatory factor analysis. StatWiki. http://statwiki.kolobkreations.com/index.php?title=Confirmatory_Factor_Analysis

- Gedam VV, Raut RD, de Sousa Jabbour ABL, Agrawal N. Moving the circular economy forward in the mining industry: Challenges to closed-loop in an emerging economy. Resources Policy. 2021;74:102279. doi: 10.1016/j.resourpol.2021.102279. [DOI] [Google Scholar]

- Hair JF, Black WC, Babin BJ, Anderson RE. Multivariate data analysis. 7. Pearson; 2010. [Google Scholar]

- Hammer M. Handbook on Business Process Management 1. Springer; 2015. What is business process management? pp. 3–16. [Google Scholar]

- Haviland D, Marshall J. Fundamental behaviours of production traffic in underground mine haulage ramps. International Journal of Mining Science and Technology. 2015;25(1):7–14. doi: 10.1016/j.ijmst.2014.11.006. [DOI] [Google Scholar]

- Hou X, Liu S, Zhao S, Zhang Y, Wu X, Cheng F, Dong S. Interaction mechanism between floristic quality and environmental factors during ecological restoration in a mine area based on structural equation modeling. Ecological Engineering. 2018;124:23–30. doi: 10.1016/j.ecoleng.2018.09.021. [DOI] [Google Scholar]

- Hu LT, Bentler PM. Cutoff criteria for fit indexes in covariance structure analysis: Conventional criteria versus new alternatives. Structural Equation Modeling: A Multidisciplinary Journal. 1999;6(1):1–55. doi: 10.1080/10705519909540118. [DOI] [Google Scholar]

- Huang Z, Lu X, Duan H. Mining association rules to support resource allocation in business process management. Expert Systems with Applications. 2011;38(8):9483–9490. doi: 10.1016/j.eswa.2011.01.146. [DOI] [Google Scholar]

- Humphreys D. Mining productivity and the fourth industrial revolution. Mineral Economics. 2020;33(1–2):115–125. doi: 10.1007/s13563-019-00172-9. [DOI] [Google Scholar]

- Jabareen Y. A new conceptual framework for sustainable development. Environment, Development and Sustainability. 2008;10:179–192. doi: 10.1007/s10668-006-9058-z. [DOI] [Google Scholar]

- Jafarpisheh R, Karbasian M, Asadpour M. A hybrid reliability-centered maintenance approach for mining transportation machines: A real case in Esfahan. International Journal of Quality & Reliability Management. 2021;38(7):1550–1575. doi: 10.1108/ijqrm-09-2020-0309. [DOI] [Google Scholar]

- Jones III, J. V., Piatak, N. M., & Bedinger, G. M. (2017). Zirconium and hafnium (No. 1802-V). US Geological Survey. 10.3133/pp1802V

- Khakestar MS, Hassani H, Moarefvand P, Madani H. Prediction of the collapsing risk of mining slopes based on geostatistical interpretation of geotechnical parameters. Journal of the Geological Society of India. 2016;87:97–104. doi: 10.1007/s12594-016-0377-x. [DOI] [Google Scholar]

- Khan MK, Trinh HH, Khan IU, Ullah S. Sustainable economic activities, climate change, and carbon risk: An international evidence. Environment, Development and Sustainability. 2022;24(7):9642–9664. doi: 10.1007/s10668-021-01842-x. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Koščová M, Hellmer M, Anyona S, Gvozdkova T. Geo-environmental problems of open pit mining: Classification and solutions. E3S Web of Conferences. 2018;41:01034. doi: 10.1051/e3sconf/20184101034. [DOI] [Google Scholar]

- Kumar A, Chatterjee S. Open-pit coal mine production sequencing incorporating grade blending and stockpiling options: An application from an Indian mine. Engineering Optimization. 2017;49(5):762–776. doi: 10.1080/0305215x.2016.1210312. [DOI] [Google Scholar]

- Kumar D, Kumar D. Management of coking coal resources. Elsevier; 2015. [Google Scholar]

- Kumral M. Production planning of mines: Optimisation of block sequencing and destination. International Journal of Mining, Reclamation and Environment. 2012;26(2):93–103. doi: 10.1080/17480930.2011.644474. [DOI] [Google Scholar]

- Kursunoglu N, Onder M. Application of structural equation modeling to evaluate coal and gas outbursts. Tunnelling and Underground Space Technology. 2019;88:63–72. doi: 10.1016/j.tust.2019.02.017. [DOI] [Google Scholar]

- Lagos T, Armstrong M, Homem-de-Mello T, Lagos G, Sauré D. A framework for adaptive open-pit mining planning under geological uncertainty. Optimization and Engineering. 2020;2020:1–36. doi: 10.1007/s11081-020-09557-0. [DOI] [Google Scholar]

- Leonida, C. (2021). The importance of managing change in mining. The Intelligent Miner. Retrieved from https://theintelligentminer.com/2021/02/26/the-importance-of-managing-change-in-mining/. Accessed on 01 Mar 2021

- Liu Q, Cheng Y, Jin K, Tu Q, Zhao W, Zhang R. Effect of confining pressure unloading on strength reduction of soft coal in borehole stability analysis. Environmental Earth Sciences. 2017;76:1–11. doi: 10.1007/s12665-017-6509-9. [DOI] [Google Scholar]

- Liu, W., Agusdinata, D. B., & Myint, S. W. (2019). Spatiotemporal patterns of lithium mining and environmental degradation in the Atacama Salt Flat, Chile. International Journal of Applied Earth Observation and Geoinformation, 80, 145–156.

- Lööw J, Abrahamsson L, Johansson J. Mining 4.0-The impact of new technology from a work place perspective. Mining, Metallurgy & Exploration. 2019;36:701–707. doi: 10.1007/s42461-019-00104-9. [DOI] [Google Scholar]

- Maiti J, Chatterjee S, Bangdiwala SI. Determinants of work injuries in mines—An application of structural equation modelling. Injury Control and Safety Promotion. 2004;11(1):29–37. doi: 10.1076/icsp.11.1.29.26305. [DOI] [PubMed] [Google Scholar]

- Mandal I, Pal S. Assessing the impact of ecological insecurity on ecosystem service value in stone quarrying and crushing dominated areas. Environment, Development and Sustainability. 2022;24(10):11760–11784. doi: 10.1007/s10668-021-01918-8. [DOI] [Google Scholar]

- Marnika E, Christodoulou E, Xenidis A. Sustainable development indicators for mining sites in protected areas: Tool development, ranking and scoring of potential environmental impacts and assessment of management scenarios. Journal of Cleaner Production. 2015;101:59–70. doi: 10.1016/j.jclepro.2015.03.098. [DOI] [Google Scholar]

- Mishra, R. K., Janiszewski, M., Uotinen, L. K. T., Szydlowska, M., Siren, T., & Rinne, M. (2017). Geotechnical risk management concept for intelligent deep mines. In ISRM European Rock Mechanics Symposium-EUROCK 2017. OnePetro.

- Mishra, P. C., Panigrahi, R. R., & Samantaray, A. (2022). Impact of commercial, financial and corporate affairs on operational excellence of the Indian mining industry. International Journal of Lean Six Sigma, (ahead-of-print).

- Mishra PC, Mohanty MK. A review of factors affecting mining operation. World Journal of Engineering. 2020;17(3):457–472. doi: 10.1108/WJE-03-2019-0082. [DOI] [Google Scholar]

- Muduli KK, Luthra S, Kumar Mangla S, Jabbour CJC, Aich S, de Guimaraes JCF. Environmental management and the “soft side” of organisations: Discovering the most relevant behavioural factors in green supply chains. Business Strategy and the Environment. 2020;29(4):1647–1665. doi: 10.1002/bse.2459. [DOI] [Google Scholar]

- Mueller RO, Hancock GR. Best practices in structural equation modeling. Best practices in quantitative methods. Sage; 2008. pp. 488–508. [Google Scholar]

- Northey SA, Mudd GM, Werner TT. Unresolved complexity in assessments of mineral resource depletion and availability. Natural Resources Research. 2018;27:241–255. doi: 10.1007/s11053-017-9352-5. [DOI] [Google Scholar]

- Northey SA, Mudd GM, Werner TT, Haque N, Yellishetty M. Sustainable water management and improved corporate reporting in mining. Water Resources and Industry. 2019;21:100104. doi: 10.1016/j.wri.2018.100104. [DOI] [Google Scholar]

- Nunfam VF, Oosthuizen J, Adusei-Asante K, Van Etten EJ, Frimpong K. Perceptions of climate change and occupational heat stress risks and adaptation strategies of mining workers in Ghana. Science of the Total Environment. 2019;657:365–378. doi: 10.1016/j.scitotenv.2018.11.480. [DOI] [PubMed] [Google Scholar]

- O'Leary-Kelly SW, Vokurka RJ. The empirical assessment of construct validity. Journal of Operations Management. 1998;16(4):387–405. doi: 10.1016/S0272-6963(98)00020-5. [DOI] [Google Scholar]

- Ozdemir B, Kumral M. A system-wide approach to minimize the operational cost of bench production in open-cast mining operations. International Journal of Coal Science & Technology. 2019;6(1):84–94. doi: 10.1007/s40789-018-0234-1. [DOI] [Google Scholar]

- Pan W, Pan W, Luo J, Fan L, Li S, Erdenebileg U. Slope stability of increasing height and expanding capacity of south dumping site of Hesgoula coal mine: A case study. International Journal of Coal Science & Technology. 2021;8:427–440. doi: 10.1007/s40789-020-00335-y. [DOI] [Google Scholar]

- Paul PS. Investigation of the role of personal factors on work injury in underground mines using structural equation modeling. International Journal of Mining Science and Technology. 2013;23(6):815–819. doi: 10.1016/j.ijmst.2013.10.006. [DOI] [Google Scholar]

- Pedram S, Palmisano S, Skarbez R, Perez P, Farrelly M. Investigating the process of mine rescuers’ safety training with immersive virtual reality: A structural equation modelling approach. Computers & Education. 2020;153:103891. doi: 10.1016/j.compedu.2020.103891. [DOI] [Google Scholar]

- Pickering, R. G. B. (2004). The optimization of mining method and equipment. In The Third Southern African Conference on Base Metals, Platinum Adding Value Conference, Sun City, October, pp. 111–115. Retrieved from http://saimm.org.za/Conferences/Pt2004/111_Pickering.pdf

- Pimentel BS, Gonzalez ES, Barbosa GN. Decision-support models for sustainable mining networks: Fundamentals and challenges. Journal of Cleaner Production. 2016;112:2145–2157. doi: 10.1016/j.jclepro.2015.09.023. [DOI] [Google Scholar]

- Podsakoff PM, MacKenzie SB, Podsakoff NP. Sources of method bias in social science research and recommendations on how to control it. Annual Review of Psychology. 2012;63:539–569. doi: 10.1146/annurev-psych-120710-100452. [DOI] [PubMed] [Google Scholar]

- Ponomarenko T, Nevskaya M, Jonek-Kowalska I. Mineral resource depletion assessment: Alternatives, problems, results. Sustainability. 2021;13(2):862. doi: 10.3390/su13020862. [DOI] [Google Scholar]

- Potvin, Y., Wesseloo, J., Morkel, G., Tierney, S., Woodward, K., & Cuello, D. (2019, June). Seismic risk management practices in metalliferous mines. In Deep Mining 2019: Proceedings of the Ninth International Conference on Deep and High Stress Mining (pp. 123–132). The Southern African Institute of Mining and Metallurgy.

- Probst A, Nitzl C, Kraus F, Förstner R. Cost estimation of an asteroid mining mission using partial least squares structural equation modelling (PLS-SEM) Acta Astronautica. 2020;167:440–454. doi: 10.1016/j.actaastro.2019.07.032. [DOI] [Google Scholar]

- PwC (2021). Mine 2021: Great expectations, seizing tomorrow. Retrieved from https://www.pwc.com/gx/en/industries/energy-utilities-resources/publications/mine.html. Accessed on 07 Sep 2021

- Qiao W. Analysis and measurement of multifactor risk in underground coal mine accidents based on coupling theory. Reliability Engineering & System Safety. 2021;208:107433. doi: 10.1016/j.ress.2021.107433. [DOI] [Google Scholar]

- Ramazan S, Dimitrakopoulos R. Advances in applied strategic mine planning. Springer; 2018. Stochastic optimisation of long-term production scheduling for open pit mines with a new integer programming formulation; pp. 139–153. [Google Scholar]

- Rankin WJ. Minerals, metals and sustainability: Meeting future material needs. CSIRO Publishing; 2011. [Google Scholar]

- Ravichandran T, Liu Y. Environmental factors, managerial processes, and information technology investment strategies. Decision Sciences. 2011;42(3):537–574. doi: 10.1111/j.1540-5915.2011.00323.x. [DOI] [Google Scholar]

- Research and Markets (2021). Global Mining Market Report 2021. Retrieved from https://www.prnewswire.com/news-releases/global-mining-market-report-2021-301241616.html. Accessed on 07/09/2021

- Rötzer N, Schmidt M. Decreasing metal ore grades—Is the fear of resource depletion justified? Resources. 2018;7(4):88. doi: 10.3390/resources7040088. [DOI] [Google Scholar]

- Ruokonen E. Managerial perspectives on strategies for advancing environmental considerations in the mining industry. The Extractive Industries and Society. 2021;8(1):434–441. doi: 10.1016/j.exis.2020.12.002. [DOI] [Google Scholar]

- Santos JRA. Cronbach’s alpha: A tool for assessing the reliability of scales. Journal of Extension. 1999;37(2):1–5. [Google Scholar]

- Saunders, M. N. K., Lewis, P., & Thornhill, A. (2019). Research methods for business students. In Pearson Education Limited: Vol. limi (Issue 10), UK.

- Savsar, M. (2014). Modeling of maintenance operations. In Encyclopedia of business analytics and optimization (pp. 1569–1580). IGI Global.

- Shiva A, Narula S, Shahi SK. What drives retail investors’ investment decisions? Evidence from no mobile phone phobia (Nomophobia) and investor fear of missing out (I-FoMo) Journal of Content, Community and Communication. 2020;10(6):2–20. [Google Scholar]

- Singh GP, Choudhary RP, Vardhan H, Aruna M, Akolkar AB. Iron ore pelletization technology and its environmental impact assessment in eastern region of India—A case study. Procedia Earth and Planetary Science. 2015;11:582–597. doi: 10.1016/j.proeps.2015.06.060. [DOI] [Google Scholar]

- Sonter LJ, Ali SH, Watson JEM. Mining and biodiversity: Key issues and research needs in conservation science. Proceedings of the Royal Society b: Biological Sciences. 2018;285(1892):20181926. doi: 10.1098/rspb.2018.1926. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Sotoudeh F, Nehring M, Kizil M, Knights P, Mousavi A. Production scheduling optimisation for sublevel stoping mines using mathematical programming: A review of literature and future directions. Resources Policy. 2020;68:101809. doi: 10.1016/j.resourpol.2020.101809. [DOI] [Google Scholar]

- Stefaniak P, Wodecki M, Michalak A. Association rules discovery from diagnostic data-application to gearboxes used in mining industry. Vibroengineering Procedia. 2017;13:103–108. doi: 10.21595/vp.2017.19082. [DOI] [Google Scholar]

- Sun Y, Yang Y, Huang N, Zou X. The impacts of climate change risks on financial performance of mining industry: Evidence from listed companies in China. Resources Policy. 2020;69:101828. doi: 10.1016/j.resourpol.2020.101828. [DOI] [Google Scholar]

- Taber KS. The use of Cronbach’s alpha when developing and reporting research instruments in science education. Research in Science Education. 2018;48:1273–1296. doi: 10.1007/s11165-016-9602-2. [DOI] [Google Scholar]

- Tayebi-Khorami M, Edraki M, Corder G, Golev A. Re-thinking mining waste through an integrative approach led by circular economy aspirations. Minerals. 2019;9(5):286. doi: 10.3390/min9050286. [DOI] [Google Scholar]

- Tost M, Hitch M, Chandurkar V, Moser P, Feiel S. The state of environmental sustainability considerations in mining. Journal of Cleaner Production. 2018;182:969–977. doi: 10.1016/j.jclepro.2018.02.051. [DOI] [Google Scholar]

- Upadhyay SP, Askari-Nasab H. Dynamic shovel allocation approach to short-term production planning in open-pit mines. International Journal of Mining, Reclamation and Environment. 2019;33(1):1–20. doi: 10.1080/17480930.2017.1315524. [DOI] [Google Scholar]

- Walden-Schreiner C, Leung Y-F, Kuhn T, Newburger T, Tsai W-L. Environmental and managerial factors associated with pack stock distribution in high elevation meadows: Case study from Yosemite National Park. Journal of Environmental Management. 2017;193:52–63. doi: 10.1016/j.jenvman.2017.01.076. [DOI] [PubMed] [Google Scholar]

- Zhang Y, Lu W, Guo J, Zhao H, Yang Q, Chen M. Geo-environmental impact assessment and management information system for the mining area, Northeast China. Environmental Earth Sciences. 2015;74(10):7173–7185. doi: 10.1007/s12665-015-4695-x. [DOI] [Google Scholar]

- Zhang Z, Zhang S, Zhang F, Yu J, Zhu Y. Validity of sustainability framework for China’s mining cities—A structural equation modelling approach. Applied Economics. 2016;48(48):4585–4605. doi: 10.1080/00036846.2016.1161720. [DOI] [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.

Data Availability Statement

Data will be shared on the basis of request.