Abstract

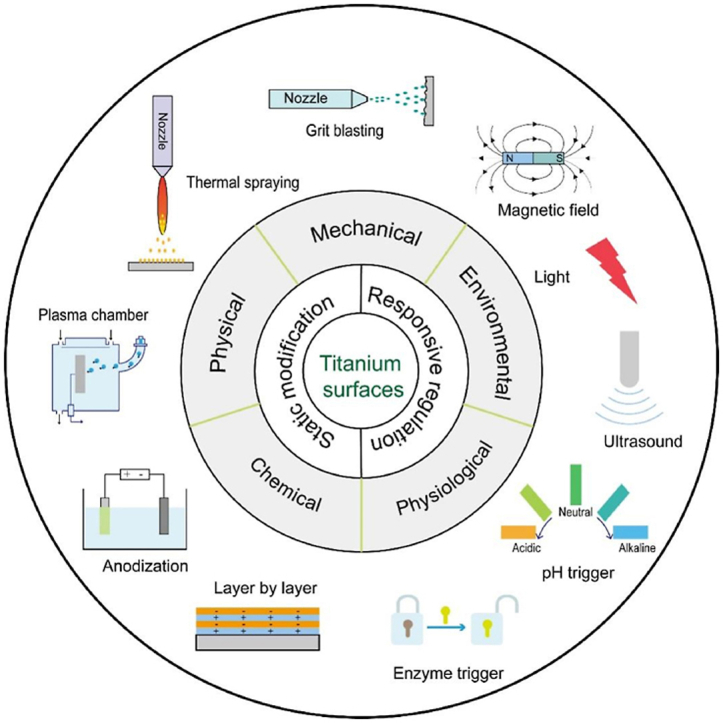

Titanium (Ti) and its alloys have been widely used as orthopedic implants, because of their favorable mechanical properties, corrosion resistance and biocompatibility. Despite their significant success in various clinical applications, the probability of failure, degradation and revision is undesirably high, especially for the patients with low bone density, insufficient quantity of bone or osteoporosis, which renders the studies on surface modification of Ti still active to further improve clinical results. It is discerned that surface physicochemical properties directly influence and even control the dynamic interaction that subsequently determines the success or rejection of orthopedic implants. Therefore, it is crucial to endow bulk materials with specific surface properties of high bioactivity that can be performed by surface modification to realize the osseointegration. This article first reviews surface characteristics of Ti materials and various conventional surface modification techniques involving mechanical, physical and chemical treatments based on the formation mechanism of the modified coatings. Such conventional methods are able to improve bioactivity of Ti implants, but the surfaces with static state cannot respond to the dynamic biological cascades from the living cells and tissues. Hence, beyond traditional static design, dynamic responsive avenues are then emerging. The dynamic stimuli sources for surface functionalization can originate from environmental triggers or physiological triggers. In short, this review surveys recent developments in the surface engineering of Ti materials, with a specific emphasis on advances in static to dynamic functionality, which provides perspectives for improving bioactivity and biocompatibility of Ti implants.

Keywords: Titanium materials, Orthopedic implants, Bioactivity, Static modification, Dynamic responsive regulation

Graphical abstract

Highlights

-

•

Surface modification avenues of Ti materials as orthopedic replacements are critically reviewed.

-

•

Fundamental methods based on mechanical, physical and chemical principles are particularly presented.

-

•

Advances in dynamic responsive regulations containing environmental and psychological triggers are thoroughly scrutinized.

1. Introduction

Biomaterials commonly refers to materials that have been engineered to direct the course of any diagnostic or therapeutic procedure by regulation of interactions with components of living systems [1]. Biomaterials can be well classified into various types according to multiple principles. For instance, according to the material sources, biomaterials include synthetic, nature-derived and semi-synthetic or hybrid materials, where synthetic biomaterials show a big market share [2]. Further, synthetic biomaterials can be divided into the following types: metals, ceramics, polymers and composites [2]. Amongst all these, metal-based materials are widely used as orthopedic replacements because of the superior tolerance, stability and load-bearing properties, whose application as dental, spinal, hip and knee implants is extremely high. It is reported that more than 70% of implant devices—even including about 95% of orthopedic devices—are still comprised of metals [3]. The orthopedic implants and devices already shared the biggest amount in the global implants market in 2015, and the size continued to rapidly grow because of the increased number of the injured, aging and overweight groups, which is estimated to reach $116 billion by 2022 [4]. There is tremendous growth in the demand for long-lasting implants, as the example collected from the total joint replacements surgery. It is reported that primary total hip arthroplasty (THA) and primary total knee arthroplasty (TKA) in the United States will increase by 71% (up to 0.635 million procedures) and 85% (up to 1.26 million procedures) in 2030 according to basis of 2000-to-2014 data, respectively [5]. Besides the replacement surgeries have increased, the revision surgeries have also greatly increased, which induce great pain for the patient. The main reasons for the revision surgeries are related to several factors, such as debris generation and metal ions release caused by wear or corrosion, mismatch in modulus between bone and implants, low fatigue strength and lack of biocompatibility [6]. In addition, the increased life expectancy is another factor that requires a longer useable lifetime of implants. Hence, orthopedic replacements especially for load-bearing applications tend to require appropriate mechanical properties, high corrosion and wear resistance, excellent osseointegration to extend useable lifetime and avoid revision surgeries.

Presently, 316L stainless steel, cobalt-chromium alloys and Ti and its alloys still constitute the main materials for orthopedic applications. Amongst these, Ti and its alloys are the first choice for the majority of implants, because of the high fatigue strength, high corrosion resistance, low modulus and density, and favorable biocompatibility. The mechanical properties and corrosion resistance of Ti-based materials combine to provide implants with high damage tolerance; the low modulus reduces bone resorption; the biocompatibility benefits bone integration. Since 1950s, Ti and its alloys have been widely used in orthopedic applications. Besides the well-known use as hip and knee prostheses, Ti-based materials are also applied as trauma plates, dental implants and bone screws. It is reported that more than 1000 tonnes of Ti-based materials are implanted in human body worldwide every year, and its amount is expected to increase gradually [7]. Although it is a type of traditional biomaterials, the advances in surface engineering may allow for the further development of Ti-based materials as bioactive implants. This paper first provides an overview of physicochemical properties and biocompatibility of Ti-based materials, and then presents various surface modification methods from both conventional and dynamic responsive aspects.

1.1. Physicochemical and mechanical properties

Ti and its alloys are encapsulated by an oxide layer of 3–10 nm on the surface, which typically contains three different oxide layers, with TiO (inner layer), Ti2O3 (intermediate layer) and TiO2 (outer layer) [8]. The superior chemical inertness, corrosion resistance and even biocompatibility of Ti and its alloys are mostly related to the chemical stability and structure of such a native oxide layer, because the repassivation can occur immediately in 30 ms even the oxide layer is destroyed [9]. The suboxides, including TiO and Ti2O3, are easily turned into TiO2 when Ti is immersed into an oxidizing medium, and the native layered structure composed of TiO (inner layer), Ti2O3 (intermediate layer) and TiO2 (outer layer) is reestablished. The oxidation process obviously increases the amount of TiO2 even the underlying suboxides cannot be detected, but the layered organization is not changed.

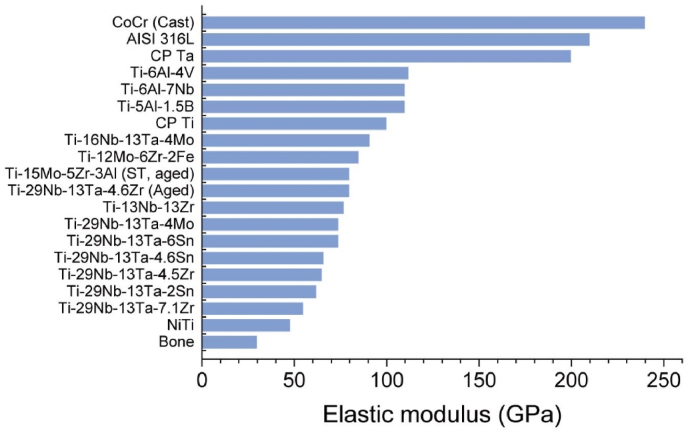

The mechanical properties greatly determine the type of materials selected for a specific application in the living organism. In case of orthopedic implants, the tolerance to repeated cyclic loads and strains in the long term is of prime importance. The materials used as ideal bone replacements are expected to show a modulus equivalent to that of bone. The mismatch in modulus between bone and implants usually leads to bone resorption and subsequent implant loosening. The modulus of natural bone generally ranges from 4 to 30 GPa based on the bone types and the measurement direction [10]. The current implants with much higher modulus than bone prevent appropriate stress being transferred to surrounding bone, and thus cause the death of bone cells and bone resorption, which is also known as ‘‘stress shielding effect” [10]. Amongst all the metals, Ti and its alloys are the preference for orthopedic implants, because their elastic moduli ranging from 48 to 112 GPa are much lower compared with 316L stainless steel of 210 GPa and cobalt-chromium alloys of 240 GPa, as shown in Fig. 1 [10]. The more similar modulus to bone would significantly reduce loosening of implants and prolong the lifetime to avoid revision surgery. In addition, all metal-based implants undergo various corrosion reactions once after implantation because the body environment involves salt solution (e.g., Na+, K+, Cl− and PO43−) and proteins [11,12], including pitting corrosion, crevice corrosion, fatigue corrosion and fretting corrosion [10,11]. As to the long-term usage, the corrosion resistance of Ti implants also influences its lifetime in human body. For instance, the wear ions and particles from Ti-based joints have disseminated to the liver and spleen via blood circulation, with induced inflammatory responses [13,14]. Therefore, it is noteworthy to improve the thickness and stability of passive oxide layers by various means to prevent the release of metal ions and particles, which would reduce the inflammation and osteolysis.

Fig. 1.

Elastic moduli of biomedical metals and bone [10]. Reprinted with permission from Ref. [10].

1.2. Biocompatibility and clinical challenges

1.2.1. Biocompatibility

Biocompatibility as the most important characteristic of biomaterials generally applies to the ability of a material to fulfill its desired function with an appropriate host response [15]. For orthopedic implants, biocompatibility is mostly related to biotolerability, which indicates the ability of a material to reside in the living body for long periods of time with relatively low degrees of inflammatory response [16]. Compared with stainless steel and Co-Cr alloys, Ti and its alloys display superior biocompatibility, which is mostly determined by the surface properties. Ti and its alloys form a stable passive oxide layer (mainly TiO2) on its surface and the immediate repassivation would happen even if the passive layer is destroyed, to protect the underlying metal from corrosion [17]. As a result, the physicochemical characteristics of surface oxide layer, such as crystallinity, impurity segregation and stoichiometry of oxide, markedly influence the biocompatibility and stability. Upon implantation, a cascade of biological reactions would occur between Ti surface and bone tissue. The first step is that proteins from body fluids would rapidly adsorb on Ti surfaces to minimize the interface free energy, whose inner hydrophobic regions and hydrophilic domains are exposed to the surface and aqueous medium, respectively [18]. The initially adsorbed proteins may aggregate with or be replaced by proteins approaching later, forming a hydrated layer of various composition and conformation. Such a hydrated surface would trigger the attachment of different types of cells (e.g., macrophases, bone marrow cells and osteoblasts) and subsequent tissue responses that include foreign body reaction and fibrous capsule formation around the implants [19]. Fibrous capsules generally are formed on large impervious implant surfaces, including breast prostheses and bulk bionert materials. Hence, it is clear that a critical factor modulating the appropriate tissue response is the characteristics of implant surface, where the first body contact occurs [20].

Ti and its alloys present well tolerated, but they are bioinert because the passive oxide layer shows unreactive on both the cellular and tissular levels. The smooth Ti surface lacks osseointegration with bones, with an intervening fibrous or connective layer between them that tends to induce implantation failure and caused great pain to the patients [21]. In orthopedic surgery, the higher the level of osseointegration, the better mechanical stability and the longer useable lifetime are exhibited. To achieve this, specific biomolecular adsorption and osteogenesis-related cell regulation are of great importance, whereas fibroblast adhesion and micromotions at the early stage should be avoided. It is commonly noted that the initial interface developed between the Ti surface and the attached tissue rules the ultimate success or failure of implants. The formation of required interface is influenced both by the nature of implant surfaces and the response of living body, between which the former is regulated in a much controllable way. Hence, in order to improve the interface interaction, surface modification is the most efficient way to modulate the biocompatibility.

1.2.2. Clinical challenges

Orthopedic implants have demonstrated great successful application in vivo, but most artificial implants show a life expectancy of 10–15 years [22]. For instance, Ti dental implants present a success rate of greater than 90%, whereas a cumulative complication rate of about 33.6% after 5 years has been observed according to both mechanical and biological complications [23]. The reasons for implant failure mainly result from aseptic loosening and infection [24]. Aseptic loosening is caused by various reasons, such as micromotion between the implant and the surrounding bone during loading, production of wear particles from implants, stress shielding from mechanical mismatching between implant and bone, and insufficient osseointegration of the interface between the implant and the bone [24,25]. The occurrence of micromotion during a postoperative stage may jeopardize the long-term stability that hampers healing process and results in callus/fibrous tissue formation, while it also endangers the stable osseointegrated implants that may induce fibrocartilage or fibrous tissue encapsulation in some areas [25]. Wear particles can induce macrophage to secrete cytokines (TNF-α, IL-1 and IL-6 etc.) that activate osteoclasts, and thus initiate bone resorption and inflammation [26]. Stress shielding mainly caused by the elastic mismatching can transfer inappropriate stress from the implant to surrounding bone, and generally lead to less bone mineralization adjacent to the implant [10]. Insufficient integration between the implant and the bone may result from the poor design of the functional interface and poor patient health besides the above factors. For instance, age-related diseases or disorders for the aging patients, including osteoporosis, diabetes and rheumatoid arthritis, complicate bone's capacity for self-healing and compromise the healing outcomes [27]. In short, aseptic loosening generally is the consequence of a combination of several factors once established.

Implant infection is another substantial cause of morbidity in clinic. It is reported that the values of infection rate for hip and knee arthroplasty are 0.4–2.4% and 1–2%, respectively, whereas the value is 2.4–8.9% for ankle arthroplasty because of the delayed wound healing [28]. The infection risk becomes much higher in revision cases. For instance, the values can reach up to 12% and 22% for revision hip and knee arthroplasty, respectively [28]. These statistics suggest that implant-related infections are a type of “chronic diseases” as a detrimental role in human health field. The contamination sources are various, including incomplete disinfection of surgical instruments, contamination from patient's soft tissues and poor hygiene after surgery etc [29]. Among all the pathogenic species, S. aureus and S. epidermidis are key pathogens to cause orthopedic prosthetic infections that account for 31–52% [30]. The adhesion of microbial cells to implant surfaces can accumulate to form biofilm that consists of a three-dimensional extracellular matrix and enmeshed organized microbial communities [31]. The formed biofilm benefits microbial adhesion and growth, and even protects them from antibacterial cleaning and host immune responses. Therefore, biofilm with multi-drug resistance characteristics makes implant infection as one of the most challenging problems to orthopedic doctors. How to endow implants with antibacterial property with the aims of preventing or treating bacterial colonization and biofilm formation, has attracted great considerations in biomedical field.

Aseptic loosening and implant infection seem to be mutually exclusive, however, the two problems about osseointegration and infection prevention are closely correlative. As suggested by Gristina et al., the phrase of “race for the surface” has been well introduced to describe the contest between host cells and bacteria to adhere, replicate and colonize the device surface [32]. If the host cells adhere and occupy the implant surface first, an interface integration will be established while a defensive barrier will also be obtained against bacterial adhesion and colonization. The rapid integration of biomaterials with host tissues is key for successful implantation, and the prompt osseointegration is crucial for inhibiting bacterial attachment as well [33]. Hence, strong osseointegration is the fundamental step to realize successful implant applications, and furthermore, there is an increasing need for multifunctional strategies to resolve the issues of osseointegration, implant infection and long-term mechanical and biological stability [22]. It is noteworthy that the balance between the different factors is challenging. Because some surface characteristics that benefit host cell adhesion and growth are also favorable to microbial cells and in turn, some surfaces with antibacterial property may hamper host cell activities [34]. Surface modification is the most effective strategy to achieve the above goals. In some cases, an optimal surface is able to bond directly with bone tissue [35]. Surface modification can alter one or more than one properties, including surface chemistry, wettability and topography, which greatly affect the implant performance both in vitro and in vivo [36]. For instance, implant surfaces with nanometer and micrometer scale features can achieve profound effects on bone integration [36]. The appropriate surface modification not only endows the implant with specific functions satisfying the requirements of osseointegration, but also preserves the superior characteristics of the underlying bulks, such as proper mechanical properties and corrosion resistance. In addition, the manufacturing process may introduce local contamination and defects, which may be stressed and plastically deformed. Such surfaces are unsuitable for the biomedical application, thus requiring for proper surface modification. In the following sections, various methods for improving bioactivity and biocompatibility of Ti implants are discussed in detail. Basically, the conventional modification strategies with static properties are grouped into three categories: mechanical, physical, and chemical methods. An overview about the conventional surface modification methods is listed as Table 1. In addition, because the cell and tissue require different signal cascades on demand at different time periods, dynamic responsive surfaces with stimuli regulation are discussed as well, with the signal originating from environmental triggers (e.g., light, X-ray, electrical field, piezoelectricity, ultrasound and magnetic/electromagnetic field) and physiological triggers (e.g., pH and enzyme).

Table 1.

An overview of conventional surface modification methods for Ti and its alloys.

| Techniques | Advantages | Limitations |

|---|---|---|

| Grit blasting | Low-cost and simple operation | Blasting particle residues, hard to form nanoscale topography |

| Plasma spraying | Large-scale production, appropriate bioactivity | Low crystallinity, high tensile residual stress, hard to control composition and structure of the coatings |

| HVOF spraying | Large-scale production, appropriate bioactivity | Moderate crystallinity, moderate tensile residual stress, hard to control composition and structure of the coatings |

| Cold spraying | Improved bioactivity, suitable for oxygen- and heat-sensitive compounds. | Hard to form nanoscale topography, moderate adhesion of coatings to Ti substrates |

| PIII&D | Easy composition control, high bonding strength | Hard to form microscale topography, expensive machinery |

| Acid etching | Low-cost and easy operation | Hard to form nanoscale topography, poor uniformity |

| Alkali-heat treatment | Low-cost and easy operation, uniform distribution | Time consuming, easy loss of sodium ions under the moisture |

| Anodization | Uniform nanoscale topography with defined pore diameters | Hard to form microscale topography, moderate bonding strength |

| Micro-arc oxidation | High strength, micro-hardness and wear resistance | Hard to form nanoscale and suitable topography |

| Electrodeposition | Low-cost and easy operation, controllable thickness with broad range | Moderate bonding strength, limited coating diversity |

| Electrophoretic deposition | High deposition rate, controllable thickness with broad range | Uniformity limited by size of particles, hard to form nanoscale topography |

| Chemical covalent immobilization of biomolecules | Precise immobilization of various biomolecules | Complex operation in some cases, special storage conditions |

| Layer-by-layer assembly | Simple operation, controllable layered structures | Difficult-to-scale preparation, low bonding to substrates, special storage conditions |

2. Surface modification

2.1. Mechanical methods

Mechanical methods generally refer to treating, shaping or removal of the surface by use of physical forces performed via the action of another solid material. Such methods are to remove surface contamination and/or obtain specific surface topographies, which usually include machining, grinding, polishing, and grit blasting [17,37]. Amongst them, grit blasting is the most common approach used to form roughed topographies on Ti surfaces to improve the bioactivity. Hence, grit blasting is discussed in detail.

2.1.1. Grit blasting

Grit blasting that is also known as sandblasting is considered as the application of abrasive particles, like hard ceramic materials, against smooth surfaces by high pressure and compressed air [38]. The surface roughness and topography generated by such a crash depend on the shape and size of the grit particles, and the air pressure used. The grit particles should be chemically stable, biocompatible and should not hinder the osseointegration of Ti implants [39]. Generally, the particles, including Al2O3, TiO2, SiC and hydroxyapatite (HA), are normally used for the blasting [17,36].

Some studies have used particles of different sizes to treat the surfaces, and the influence of surface roughness on the bone attachment was investigated. For instance, Wennerberg et al. have added four different values of roughness to the implant surfaces by using TiO2 (25 μm) and Al2O3 (25, 75, and 250 μm) as the abrasive particles, with the Sa values ranging from 0.6 to 2.1 μm [[40], [41], [42]]. The strongest bone integration according to removal torque and bone-to-implant contact tests was detected for a blasted surface with a Sa value of 1.5 μm in rabbit bone after a follow-up time of 1 year, suggesting the moderate roughness benefitted implant bioactivity. Similar results were observed by Ronold et al. that the tensile strength in vivo of Ti implants showed a positive correlation with the increasing roughness produced by TiO2 blasting, but the further increase in roughness was to decrease the effect [43]. The above results both provide the notion that a moderate roughed surface favors bone response. Blasting tends to introduce the contamination and alter the surface composition because of particle residues. For example, some previous studies have indicated that the presence of Al3+ inhibited the expression of the osteoblastic phenotype in vitro [[44], [45], [46]], and exerted an adverse effect on tissue reactions in vivo [[47], [48], [49]]. Therefore, to reduce the toxicity, some bioactive materials of bioceramics such as HA and biphasic calcium phosphate (BCP) have been used to blast the surfaces [50,51]. Grit blasting is more commonly combined with other methods to modify Ti surfaces, such as acid etching and anodization.

2.2. Physical methods

Physical methods generally refer to the layers directly formed on Ti surfaces almost without the occurrence of chemical reactions. In this case, the formation of layers are mainly driven by thermal, kinetic and electrical energy. Conventional physical methods include thermal spraying and plasma immersion ion implantation (PIII) and deposition (PIII&D).

2.2.1. Thermal spraying

Thermal spraying refers to a coating process that feedstock materials are loaded into a heating zone, accelerated and propelled from the torch towards the substrate in molten or semi-molten state by the high-temperature and high-velocity gas stream [52,53]. The feedstock includes metallic and nonmetallic materials in the form of powders, suspensions, rods, wires or liquids [53]. Thermal spraying technologies for medical coatings contain plasma spraying, high-velocity oxygen fuel (HVOF) spraying and cold spraying [53,54].

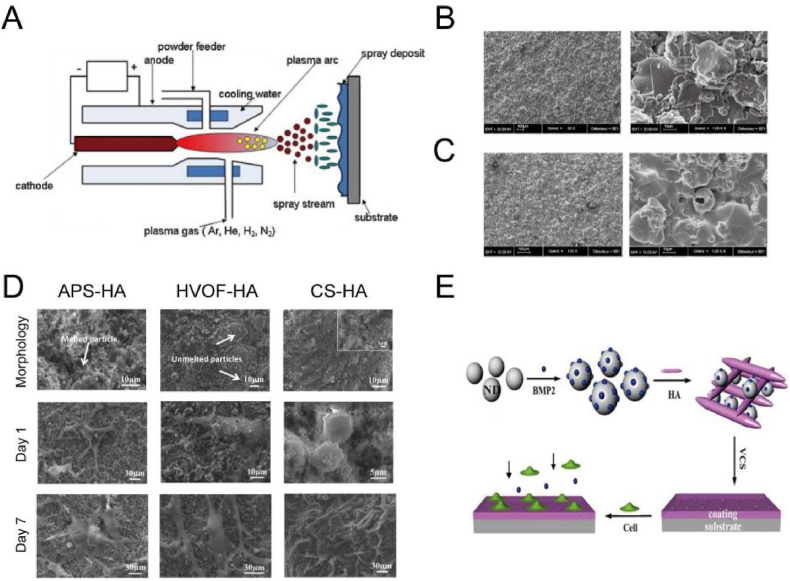

2.2.1.1. Plasma spraying

Plasma spraying has been introduced to treat the material surface for several decades [55,56]. This method utilizes plasma beam at a high temperature ranging from 6000 °C to 15,000 °C, to melt the supplied particles [54]. The melted powders then impinge onto the Ti substrates with a particle velocity ranging from 20 to 500 m/s where they are condensed and fused together with the kinetic energy turned into thermal and deformation energy [57], as shown in Fig. 2A [58]. The formed coating produced by plasma spraying tends to show a thickness varying from several micrometers to millimeters [59]. In general, to improve the bonding strength of the coating, the substrate surfaces are degreased and roughened in prior to plasma spraying. Plasma spraying contains atmospheric plasma spraying (APS), vacuum plasma spraying (VPS) and controlled atmospheric plasma spraying (CAPS) [56].

Fig. 2.

(A) Schematic diagram of a non-transferred arc plasma setup [58]. Reprinted with permission from Ref. [58]. (B) SEM images of a titanium plasma-sprayed (TPS) surface (Courtesy of Cam Implants BV, The Netherlands) [39].

(C) SEM images of a plasma-sprayed hydroxyapatite (HA) coating surface (Courtesy of Cam Implants BV, The Netherlands) [39]. Reprinted with permission from Ref. [39].

(D) SEM images of surface morphology of APS, HVOF and CS HA coatings before and after cell culture for 1 and 7 days [86]. Reprinted with permission from Ref. [86]. (E) Schematic diagram of HA/nano-diamond/BMP-2 coating via vacuum CS [87]. Reprinted with permission from Ref. [87].

Since 1970s, a titanium plasma-spraying (TPS) technique was developed to treat titanium implants [60]. The titanium plasma by injecting the powder into a plasma torch was projected onto the implant surface where it formed a condensed coating of 30–50 μm thickness. The value of TPS-treated surface roughness can reach as high as 7 μm with extremely rough and irregular appearance, which is due to the existence of large areas of sheets, globular outcroppings, frequent fissures, deep pits and cracks [61,62], as shown in Fig. 2B [39]. In a clinical research, TPS-coated dental implants displayed a success rate of 86.7% of after the 5-year follow-up study, showing an acceptable success result [63]. However, some works have revealed the controversy on the binding strength and on granule release from TPS coatings into the host tissue, owing to the mechanical friction between the implant surface and the host bone. The detachment of metallic wear particles or the dissolution of metal ions arousing concern is because they may potentially induce local and systemic carcinogenic effects [64,65]. In order to reduce the dissolution and release of titanium particles, some post processing of the TPS surface is explored, including the introduction of another protective coatings. For instance, an additional coating of fluorohydroxyapatite (FHA) on the TPS surface can effectively reduce the detachment of titanium particles in the bone medullary spaces around the implants after implantation in the femoral and tibial diaphysis of mongrel sheep for 12 weeks [66].

Some bioinert ceramic powders, such as Al2O3, ZrO2 and TiO2, have been widely used for the spraying because of favorable mechanical properties [67]. Although the wear resistance and corrosion resistance of Al2O3 and ZrO2 are excellent, such coatings cannot directly bind to human bone tissues due to the bionert nature. Hence, bioactive HA is mostly chosen as a coating on metallic bulks to improve the osseointegration, because it constitutes the main inorganic component of bones. Plasma-sprayed HA coatings have been widely used in dental and orthopedic prostheses (e.g., hip and knee implants), whose typical morphology is as shown in Fig. 2C [39]. A lot of short-term and long-term investigations have been conducted on clinical behaviors of HA coatings [[68], [69], [70], [71]]. For example, studies on the 15-years minimum follow-up of HA-coated fermoral componets (Ti alloy implant) by Capello et al. [70] and Epinette et al. [71], revealed (1) a high survival rate (over 99.20%), (2) a fast and painless bone ingrowth, and (3) superior bone tissue modelling and remodeling quality. However, the concerns on the durability, bonding strength and degradability of the HA coatings are still under discussion.

The structure, composition, crystallinity and bonding strength of HA coating strongly rely on the quality of HA powder and processing parameters of plasma spraying. The morphology, crystal structure and phase composition of plasma-sprayed HA coatings obviously differ from those of the original starting powders. This result arises because the plasma spraying process contains melting of particles that leads to thermal decomposition and phase changes of the individual particles. HA particles subjected to the high temperature within a plasma jet always undergo dehydroxylation and decomposition. Table 2 lists the main reactions that take place at the elevated temperature [72,73], and Table 3 gives out the reactions occurring as HA is heated from room temperature up to 1730 °C [73]. It is difficult to detect the accurate temperatures for those reactions because they arise over a wide temperature range that is influenced by factors related to the spraying environment and the HA composition. One major concern is about the effect of the crystallinity of HA on bioactivity. The existence of amorphous and metastable compounds in prepared HA coatings has both advantages and disadvantages. The advantage is that it accelerates fixation of the implant and promotes bone remodeling and attachment, because of its higher solubility than that of crystalline HA. The disadvantages is that the excessive dissolution would affect the long-term reliability and biocompatibility of the implants. From the viewpoint of long-term stability, a high crystallinity of HA coating is required. It is generally accepted that the minimum crystallinity of the HA coating for biomedical applications is 62% as described in the Food and Drug Administration (FDA) guidelines as well as in the International Organization for Standardization (ISO) standards [74]. Hence, to improve the crystallinity, some post processing has also been developed, such as furnace heating [75], and hydrothermal treatment [76]. In addition, another concern is about the influence of bonding strength and thickness of the HA coating on stability. The bonding strength between the HA coating and substrates is relatively poor which ranges from 5 to 35 MPa, because of the high residual stress gaining from the mismatch of coefficient of the thermal expansion between HA (13.3 × 10−6 K−1) and titanium ((8.4–8.8) × 10−6 K−1) [17]. In order to improve the bonding strength, some ceramic nanoparticles (e.g., ZrO2 [77], TiO2 [78] and CaSiO3 [79]), were introduced to augment the HA properties. Such coatings exhibited enhanced cohesion as the existence of the particle reinforcement and the reduced residual stress state from the functional gradient coatings. The thickness of the HA coating also influences the resorption and mechanical properties. Although the value varies, a thickness ranging from 50 to 75 μm is commonly applied for orthopaedic implants by such technique [17]. Plasma spraying of HA is the only FDA-approved technique to coat implants in clinic, however, some disadvantages still exist, including thermal decomposition during spraying, the inability to modulate pore sizes and porosity as well as the difficulty to prepare coatings with less than 20 μm thickness [72]. Hence, the careful engineering of HA coatings via regulating plasma-spraying parameters is still under exploration to improve mechanical, microstructural and biological behaviors.

Table 2.

Thermal decomposition of HA. V represents a vacancy and x < 1 [72].

| Ca10(PO4)6(OH)2 → Ca10(PO4)6(OH)2-2xOxVx + xH2O | (1) |

| Hydroxyapatite → Oxyhydroxyapatite (OHA) | |

| Ca10(PO4)6(OH)2-2xOxVx → Ca10(PO4)6OxVx + (1-x)H2O | (2) |

| Oxyhydroxyapatite → Oxyapatite (OA) | |

| Ca10(PO4)6OxVx → 2Ca3(PO4)2 + Ca4O(PO4)2 | (3) |

| Oxyapatite → Tricalcium phosphate (TCP) + Tetracalcium phosphate (TTCP) | |

| Ca3(PO4)2 → 3CaO + P2O5 | (4a) |

| Tricalcium phosphate → Calcium oxide + Phosphorus pentoxide | |

| Ca4O(PO4)2 → 4CaO + P2O5 | (4b) |

| Tetracalcium phosphate → Calcium oxide + Phosphorus pentoxide |

Table 3.

Thermal effects of HA [73].

| Temperature (°C) | Reactions |

|---|---|

| 25–200 | Evaporation of absorbed water |

| 200–600 | Evaporation of lattice water |

| 600–800 | Decarbonation |

| 800–900 | Dehydroxylation of HA to form partially or completely dehydroxylated oxyhydroxyapatite |

| 1050–1400 | HA decomposes into β-TCP and TTCP |

| <1120 | β-TCP is stable |

| 1120–1470 | β-TCP is turned into α-TCP |

| 1550 | Melting temperature of HA |

| 1630 | Melting temperature of TTCP and leaving behand CaO |

| 1730 | Melting of TCP |

2.2.1.2. High-velocity oxygen fuel spraying

High-velocity oxygen fuel (HVOF) spraying ignites a mixed flow of oxygen and fuel gases inside a combustion chamber, producing a supersonic gas jet with a temperature up to 3000 °C and particle velocities up to 1000 m/s [53]. The high particle velocity at a moderate temperature makes coatings with low porosity, high bonding strength and high abrasive resistance, because of the short dwell time of particles during the spraying. Similar to plasma spraying, HA is still the predominant materials for coating Ti implants via HVOF technique. Luma et al. observed that the HVOF-HA coating on Ti6Al4V presented high crystallinity (84%), low porosity (1.4%), high bonding strength (24 MPa) and low degradation, because the HA particles flowing through the HVOF flame did not undergo phase transformations, whose average surface temperature was only 1826 ± 346 °C [80]. The high crystallinity, low degradation and dense coating benefit the long-term stability of Ti implants. A recent study conducted by Ghadami et al. revealed that HA coating prepared by HVOF method showed an enhanced crystallinity, hardness and elastic modulus than that of APS method [81]. However, the in vivo rabbit study presented no significant differences between the two methods even though the HVOF coating showed a slight higher values of pull-out force and bone-implant contact (BIC). Hence, it still needs more studies in the future to optimize the HVOF coatings. In addition, some ceramic-reinforced HA coatings, such as TiO2/HA composite coating [82], can be facially prepared by this technique, which improves the mechanical properties but without compromising the bioactivity of HA composites.

2.2.1.3. Cold spraying

Cold spraying (CS) is a kinetic-spray and solid-state deposition process where particles are accelerated by a pre-heated gas with a low temperature (25–1100 °C) and propelled towards a substrate with supersonic velocities (300–1200 m/s) [83]. Cold spraying is suitable for depositing oxygen-sensitive metals, heat-sensitive organic compounds, because the temperature is generally lower than the thermal decomposition or melting point of the feedstock. Feedstock particles including metals, ceramics, composites and organic compounds have been successfully deposited on Ti surfaces, providing the coatings with various functionalities. Metallic particles, such as Ti [84] and Ta [85], that show exceptional corrosion resistance and non-toxic track record have been coated on Ti6Al4V implants to improve the chemical stability in physiological solution, in vitro biomineralization and osteoblast activities. However, metallic particles appear bioinert, and thus, bioactive HA and its composites attract great attention. For instance, Vilardell et al. prepared HA coatings on Ti6Al4V surfaces via APS, HVOF and cold spraying, respectively (Fig. 2D) [86]. It is found that the HA coatings with higher crystallinity by HVOF and CS methods presented higher proliferation and differentiation of human osteoblastic cells than that of lower crystallinity by APS method. Beyond conventional metal and ceramic particles, it is suitable to prepare HA composite coatings containing temperature-sensitive drugs and biomolecules, such as growth factors [87] and antibiotics [88], because feedstock particles can be sprayed at room temperature. For instance, Li et al. prepared the composite coating consisting of nano-diamond, BMP-2 and HA via vacuum cold spraying (Fig. 2E), [87]. The presence of nano-diamond and BMP-2 significantly improved the attachment and proliferation of human osteoblast cells compared with the pure HA coating. In short, cold spraying is one of the newest thermal techniques and more researches on the process are yet to be carried out.

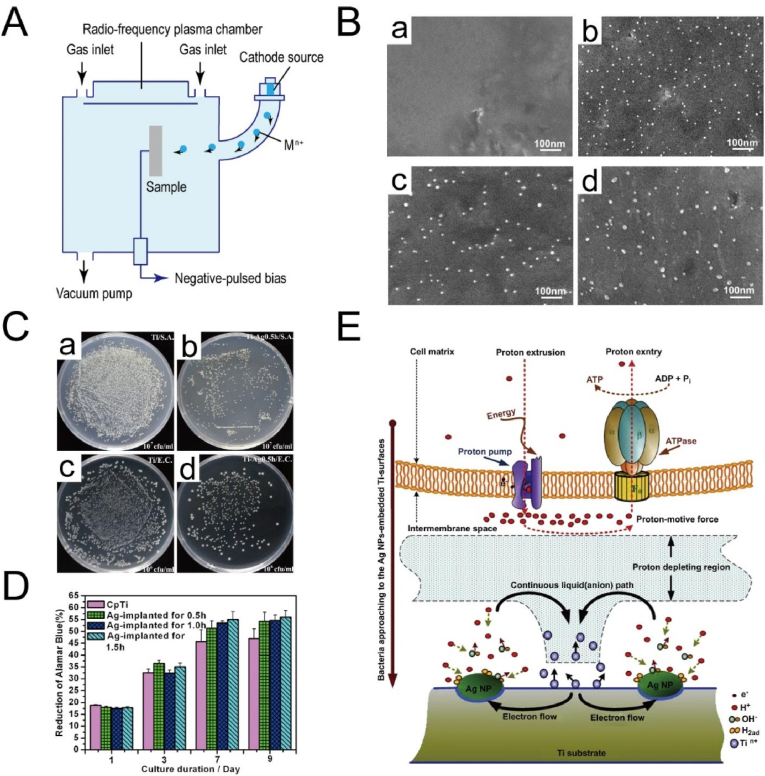

2.2.2. Plasma immersion ion implantation and deposition (PIII&D)

Plasma immersion ion implantation and deposition (PIII&D) is a flexible technique that can perform multiple processes, including simultaneous and consecutive implantation, deposition and etching, because of its combining advantages of other conventional plasma and ion beam methods [89,90]. A PIII&D system contains a vacuum chamber with a workpiece stage, a high-voltage pulse modulator and a plasma source (Fig. 3A) [89]. During the processing, a workpiece is placed in plasma at a high bias voltage, repelling electrons away from the workpiece and driving the positive ions toward it, thus a plasma sheath formed around the workpiece [91]. Then ions bombard the sample surfaces provided that the dimensions of plasma sheath are small compared with the feature sizes of workpiece. The plasma sheath has a critical impact, because it determines the implantation operation and foresees the process parameters and results, such as implantation current and dose as well as impurities profile [89]. Many elements have been implanted into the titanium surface, including non-metallic element (e.g., N and O) and metallic elements (e.g., Ca, Ag and Zn) [92].

Fig. 3.

(A) Schematic diagram of ion implantation and deposition setup [89]. Reprinted with permission from Ref. [89] with minor modification.

(B) SEM images of surface morphology of Ti surfaces after Ag-PIII: (a) Cp Ti, (b) 0.5 h-Ag-PIII, (c) 1.0 h-Ag-PIII, and (d) 1.5 h-Ag-PIII [98].

(C) Re-cultivated bacterial colonies on agar:S. aureus colonies are previous dissociated from (a) Cp Ti and (b) 0.5 h-Ag-PIII. The E. colicolonies are previous dissociated from (c) Cp Ti and (d) 0.5 h-Ag-PIII [98].

(D) The alamarBlue™ assay for MG63 cells on the various surfaces [98].

(E) Schematic diagram for the possible toxicity mechanism of the Ag NPs embedded surfaces [98]. Reprinted with permission from Ref. [98].

Non-metallic elements generally induce polar functional groups and change the physicochemical properties but without altering surface topography [92]. The implantation of N and O is able to improve the corrosion resistance, wear resistance and cell activities. Huang et al. used N-PIII treatment to add a TiN film (<1 μm in thickness) to improve the surface hardness and corrosion resistance of Ti6Al4V [93]. Together with the modified mechanical strength, the N-PIII-treated surface enhanced the adhesion, proliferation and mineralization of human bone marrow mesenchymal stem cells (hMSCs) but prevent the adhesion of Streptococcus salivarius. Similarly, two oxygen ions with low and high doses were implanted into the Ti surface to form compact oxide layers that higher oxygen ions dose obtained higher thickness and amount of rutile phase [94]. The high oxygen-treated surface enhanced differentiation of hMSCs and in vivo osseointegration. Additionally, the O-PIII-treated surface with a rutile phase can also enhance blood-clotting and platelet activation but reduce the adhesion of Streptococcus mutans [95]. Beyond N and O, non-metallic species including H2O have been used to modify the hydroxyl groups on Ti surfaces to improve the adhesion, spreading and growth of human osteoblastic OPC-1 cells [96].

Metallic elements are generally implanted to the Ti surface to improve the osteogenesis and antibacterial activity [92]. Ca is generally ion-implanted to favor osteogenic response [97], while Ag and Zn are sources to reduce bacterial infection [[98], [99], [100]]. For instance, Cao et al. prepared Ti surface embedded with Ag nanoparticles (Ag NPs) by one-step silver plasma immersion ion implantation (Ag-PIII) (Fig. 3B–E) [98]. When placed in a physiological solution, a Ti-Ag micro-galvanic couple would appear, where α-Ti matrix and Ag NPs served as the anode and cathode, respectively. The cathodic reactions would generate a proton-depleted region between bacterial membrane and Ag-embedded Ti substrate, which may destroy the proton electrochemical gradient across the intermembrane space, interfere with the synthesis of adenosine triphosphate (ATP) and ultimately lead to bacteria death. However, the promoted proliferation of MG-63 cells may be due to the difference in structure and size between bacteria and osteoblast-like cells. MG-63 cells have a much more complex endomembrane system compared with bacteria, making it unaffected but with enhanced energy-dependent proliferation. In addition to single metallic element, two types of elements can be co-implanted into Ti surfaces. Jin et al. modified Ti surfaces with Zn and Ag co-implantation by PIII&D [101]. The Zn/Ag co-implanted Ti surface not only significantly induced the proliferation, differentiation of rat bone mesenchymal stem cells (rBMSCs) and effectively killing bacteria in vitro, but also exhibited strong osteogenic activity and antibacterial ability in vivo. The excellent performance was related with the synergistic effects from the long-range and short-range interactions of the released Zn2+ and Ag NPs, respectively. Similarly, Ag and Ca were co-implanted into Ti surface to produce bifunctional galvanics, which synergistically hindered bacterial activity and enhanced osteoblastic differentiation [102]. Besides the treatment of smooth Ti surfaces after polishing, PIII&D can treat roughed Ti surfaces after other modification, including acid etching [103], anodization [104], plasma spraying [105] and acid etching/sandblasting [106].

2.3. Chemical methods

Chemical modification is mainly based on the occurrence of chemical reaction at the interface between Ti substrate and the immersed medium. Such kind of modification generally involves acid etching, alkali-heat treatment, electrochemical methods and biochemical methods.

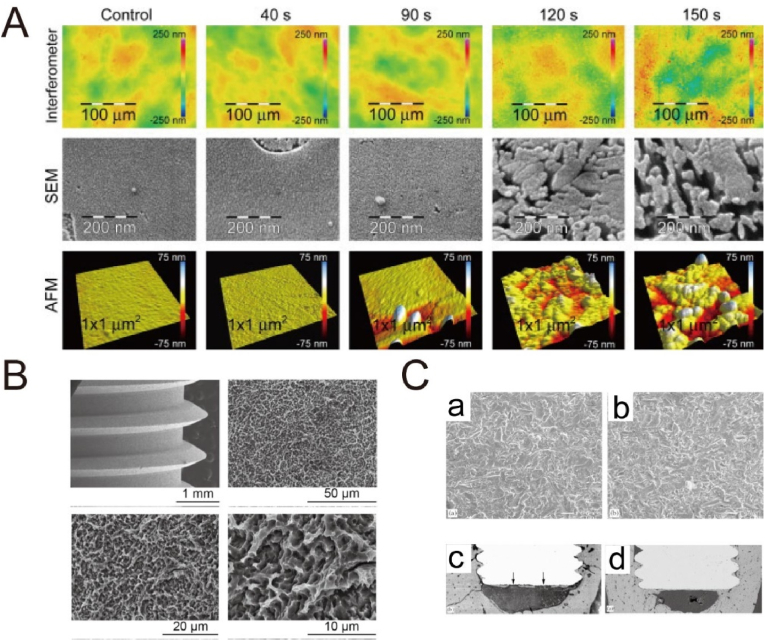

2.3.1. Acid etching

Acid treatment is commonly used to remove surface oxide and contamination to clean and uniform surface finishes. Some strong corrosive acids, such as H2SO4, HCl, HNO3 and HF, are adopted to roughen the Ti surface with a micro-scale feature, because H+ ions attack TiO2 and Ti with the production of soluble Ti compounds and hydrogen. However, the adsorption of hydrogen generally forms titanium hydride, which may lead to hydrogen embrittlement [107,108]. Table 4 lists typical reactions of Ti substrates subjected to H2SO4 etching [109]. The micro-scale feature relies on acid concentration, solution temperature and etching time. The micropits created by acid etching varying from submicron to several microns tend to favor cell activities (red blood cells and osteoblasts) and bone integration [17,36,110]. Many studies have revealed the positive effect of the acid etching on bone regeneration. For instance, Lamolle et al. cultured MC3T3-E1 cells on the Ti surface that was treated with weak HF (0.2 vol%) solution, and observed the lower cytotoxicity level and better cell attachment compared with smooth control surface, as shown in Fig. 4A [111]. The reason may be due to the fact that the micro- and nano-level topography and the surface composition that included low hydrocarbon content and presence of fluoride, hydride and oxide, produced a favorable microenvironment together for cell growth with enhanced biocompatibility.

Table 4.

Ti substrates subjected to concentrated H2SO4 etching [109].

| TiO2 + H2SO4 → Ti(SO4)2 + 2H2O | (1) |

| Ti + 2H2SO4 → Ti(SO4)2 + 2H2 | (2) |

| Ti + H2 → TiH2 | (3) |

Fig. 4.

(A) Blue light interferometer, SEM and AFM images of the modified Ti disks in 0.2 vol% HF [111]. Reprinted with permission from Ref. [111]. (B) SEM images of the untreated SLA implants at different magnifications [115]. Reprinted with permission from Ref. [115]. (C) SEM images of (a) TiO2 grit-blasted Ti surface and (b) fluoride ion-modified TiO2 grit-blasted Ti surface. Histological assessment of bone-to-implant contact of (c) TiO2 grit-blasted implant surface and (d) fluoride ion-modified TiO2 grit-blasted implant surface [112]. Reprinted with permission from Ref. [112].

More commonly, acid etching is performed after a sandblasting step to remove blasting residues and to refine the surface morphology and roughness. Many studies have indicated that the combined treatment of sandblasting and acid etching (SLA) on Ti surfaces significantly improved osseointegration [[112], [113], [114], [115]]. A typical morphology after SLA treatment is shown in Fig. 4B [115], with irregular micropits in a few microns. For instance, the TiO2 grit-blasted surface after HF modification significantly promoted osteoblastic differentiation and interfacial bone formation, when compared with the TiO2 grit-blasted surface (Fig. 4C) [112]. Therefore, acid etching provides an efficient way to improve the bioactivity of sand-blasted Ti surfaces. In a clinic study, a 10-year follow-up study of SLA dental implants has suggested the survival and success rate of 511 implants was 98.8% and 97.0%, respectively, and the prevalence of peri-implantitis was low with 1.8% [116].

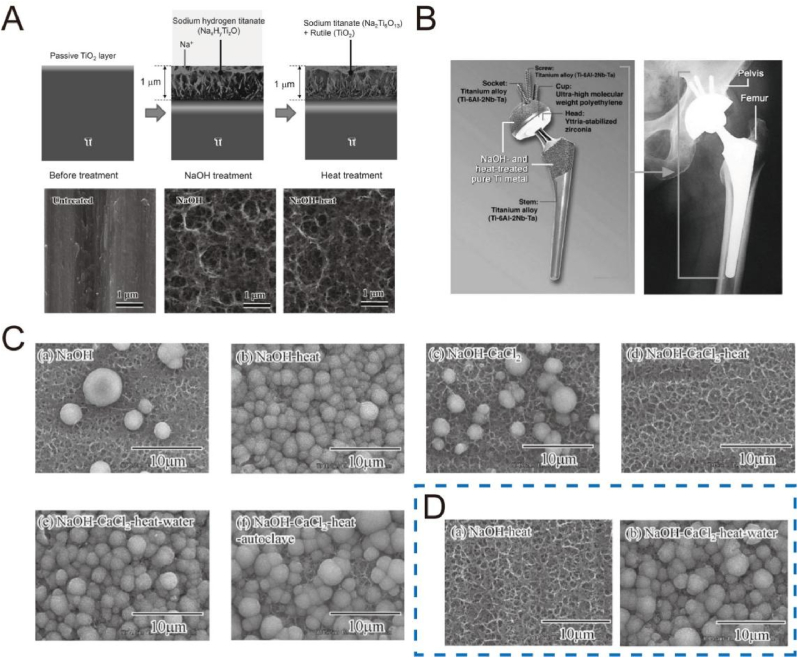

2.3.2. Alkali-heat treatment

Since 1990s, alkali-heat treatment is used to modify Ti surface by immersing the substrate in 5–10 M NaOH or KOH solution at 60 °C for 24 h and subsequently heating treatment at 600 °C for 1 h [[117], [118], [119]]. The typical process of alkali-heat treatment is shown in Fig. 5A [120]. In the first step, the Ti substrate can react with the NaOH to form an alkalinic titanate hydrogel layer and the corresponding reactions are described in Table 5 [117]. After heat treatment, the hydrogel layer undergoes dehydration and densification to form a stable amorphous or crystalline sodium titanate layer, whose scratch resistance is increased from 5 to 50 mN [120,121]. Heat treatment significantly impoves the bioactivity of Ti substrates in vivo after alkali treatment [122,123]. The reason may be due to the unstable reactive and mechanically weak layer of the alkali-treated surface, while subsequent heat treatment reinforced the stability of the sodium titanate layer [122].

Fig. 5.

(A) Structural change of the surface of Ti metal after NaOH and heat treatments [120]. Reprinted with permission from Ref. [120].

(B) A total hip joint system of Ti-6Al-2Nb-Ta alloys after NaOH and heat treatments (left), and its clinical application (right) [118]. Reprinted with permission from Ref. [118].

(C) SEM images of various Ti surfaces after immersion in SBF for 1 day [124].

(D) SEM images of the Ti surfaces soaked in SBF for 1 day after storage at 95% relative humidity for 1 week with NaOH-heat and NaOH-CaCl2-heat-water treatments [124]. Reprinted with permission from Ref. [124].

Table 5.

Ti substrates subjected to alkali treatment [117].

| TiO2 + OH− → HTiO3− | (1) |

| Ti + 3OH− → Ti(OH)3+ + 4e- | (2) |

| Ti(OH)3+ + e− → TiO2·H2O + 0.5H2 | (3) |

| Ti(OH)3+ + OH− → Ti(OH)4 | (4) |

| TiO2•nH2O + OH− ↔ HTiO3−•nH2O | (5) |

The sodium titanate layer undergoes ion exchange with H3O+ ions upon immersion in SBF to form a titania gel layer rich in Ti-OH groups, thus inducing apatite nucleation and deposition via alternative adsorption of positively charged calcium ions and negatively charged phosphate ions [118]. However, the apatite-forming ability of Ti surface with alkali-heat treatment tends to decrease when stored in a humid environment over a long time period, because the Na + ions can exchange with the H3O+ in the moisture. Hence, in some cases, the Na + ion is replaced by Ca2+ ion to strength the apatite-forming ability. Kizuki et al. immersed the alkali-treated Ti surface in a CaCl2 solution for replacing Na+ with Ca2+ to form calcium hydrogen titanate [124]. After heat treatment, the calcium hydrogen titanate was transformed into calcium titanate. Because of the tight structure, the release of Ca2+ from calcium titanate was slow and made it hardly to induce apatite formation in SBF. To enhance the mobility of Ca2+ ions, the calcium titanate layer was further subjected to hot-water treatment, and thus its apatite-forming ability was obviously restored (Fig. 5C), and strongly maintained even in the humid environment (Fig. 5D). Furthermore, Ti alloys after this treatment led to their direct bonding with bone without an intervening fibrous layer after implantation in rabbit tibia for 26 weeks [125,126]. Tian et al. also noted that the NaOH-CaCl2-heat-water-treated surface showed a similar bone-bonding ability to the alkali-heated surface at 2 and 3 weeks after implantation in rabbit tibias, but it presented a greater bonding ability at 4 weeks [127]. Therefore, such a method enriches the originally-developed alkali-heat treatment to improve the bioactivity of Ti implants. Alternatively, other bioactive ions, such as Ag+ [128] and Sr2+ [129], can be incorporated into the calcium-deficient calcium titanate layer by introducing them either into the CaCl2 solution or into the hot water of the last step, and thus a multifunctional surface with bifunctional ions can be achieved to improve osteogenetic and antibacterial activity [128,129].

Since September 2000, a series of 70 artificial total hip joints with an alkali-heat treatment was carried out in clinical trials [130,131]. A titanium macroporous structure was generated on the surface of a Ti alloy as a proximal site stem, and on the entire surface of a Ti alloy covering a polyethylene cup, and then the joints underwent alkali-heat treatment [130], as shown in Fig. 5B [118]. Although a gap between the host tissue and the socket existed in over 70% cases, it disappeared and closed within one year [131]. During the average 4.8-year follow-up study, 68 hips (97%) were considered as bone ingrowth fixation and only two hips (3%) as stable fibrous ingrowth, indicating the good osteoconduction [131]. As the time prolonged to 10 years, the overall survival rate was 98% of the 67 hips (two patients were lost) [132]. No obvious signs appeared of osteolysis, loosening, or formation of a reactive line.

2.3.3. Electrochemical methods

2.3.3.1. Anodization

Anodization is a traditional method to form compact and protective oxide films on valve metals. In a typical procedure, the Ti serves as an anode and an inert materials as a counter electrode, such as graphite and platinum. In 2001, a well-aligned TiO2 nanotube arrray was prepared on pure Ti sheet by anodization in HF solution [133]. Since then, the preparation and application of TiO2 nanotubes have been extensively studied. The F− ion is needed in nanotubular formation and the mechanism can be explained as follows, as shown in Table 6 [[134], [135]]. Firstly, a compact oxide layer is formed with the reactions shown by Eqs (1-4). Secondly, F− in the electrolyte can react with Ti4+ dissolved at the oxide-electrolyte interface and attack the formed TiO2 to form irregular nanoscale pores with Eqs (5-6). Finally, the competition between oxidation and dissolution reaching steady leads to the formation of a regular nanopore or nanotube layer. The tube geometry, diameter and length of the nanotube array can be varied by regulating the anodization parameters, such as applied voltage, anodization time and electrolyte [134,136].

Table 6.

TiO2 TNTs formation in fluoride-containing electrolyte [134,135].

| 2H2O → O2 + 4H+ + 4e- | (1) |

| Ti → Ti4+ + 4e- | (2) |

| H2O → O2− + 2H+ | (3) |

| Ti4+ + 2O2− → TiO2 | (4) |

| Ti4+ + F− → [TiF6]2- | (5) |

| TiO2 + 6F− + 4H+ → [TiF6]2- + 2H2O | (6) |

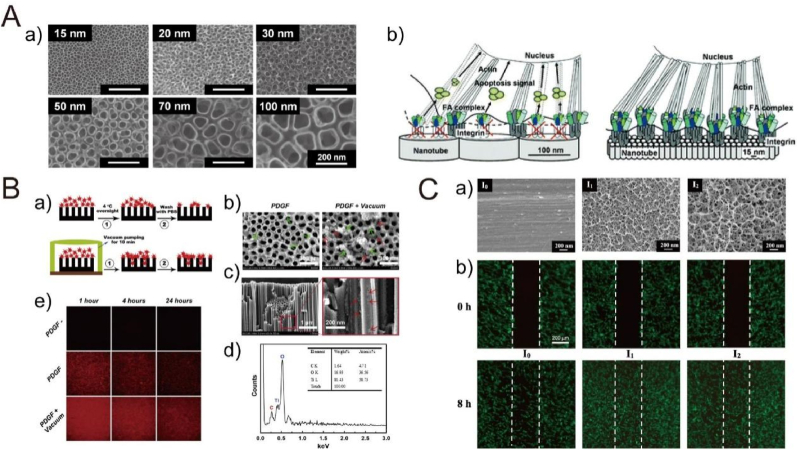

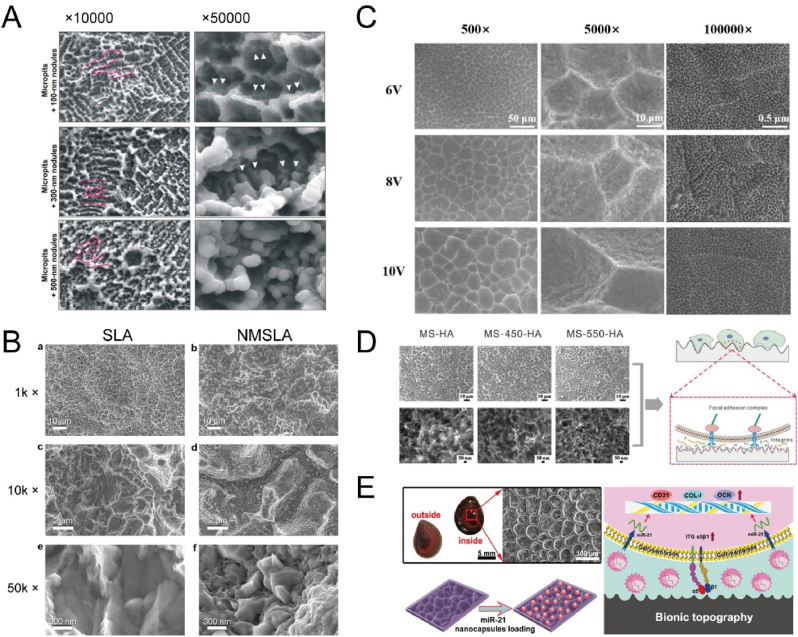

The biomedical application of TiO2 nanotube array has been widely investigated. Park et al. cultured rat mesenchymal stem cells on TiO2 nanotubes with defined diameters between 15 and 100 nm, as shown in Fig. 6A [137]. The best performance in cell adhesion, spreading, growth, and differentiation was obtained on the nanotube array with a diameter of 15 nm, because such a size effectively accelerated integrin assembly into focal contacts and therefore induced actin filament assembly and signaling conduction to the nucleus. However, tube size larger than 50 nm severely impaired cell activity, and the diameter of 100 nm almost completely hindered integrin clustering and focal adhesion formation, resulting in a high degree of anoikis that is the adhesion-dependent type of apoptosis. Oh et al. noted that the small nanotube array (∼30 nm) enhanced the adhesion without noticeable differentiation of human mesenchymal stem cells (hMSCs), but larger nanotube array (70–100 nm) obviously accelerated cytoskeletal stress and differentiation into osteoblast-like cells [138]. The mechanism was related with the fact that small-diameter nanotubes induced protein aggregate adhesion configurations and thus caused adhesion and growth of hMSCs with minimal differentiation, while large-diameter nanotubes made cells elongate and stretch to seek protein aggregates and thus were forced to differentiate into osteoblasts. The inconsistent results are common of the effect of diameters on the osteoblast response [[139], [140], [141], [142]]. The reason for the differences is associated with the processing parameters, surface chemistry, crystal phase of TiO2 as well as cell origins [143]. As to in vivo studies, Ti implants with TiO2 nanotube array positively induced molecular response and osseointegration at the bone-implant interface [[144], [145], [146], [147]]. It is noted that the overexpression of purinergic receptor P2Y6 caused by TiO2 nanotubes can increase osteogenic differentiation of bone marrow mesenchymal stem cells (BMSCs) through activating PKCα-ERK1/2 signal pathway, and thus enhance bone tissue deposition around the implant in vivo [147]. In addition, the crystalline phase of TiO2 nanotubes strongly affects the cell activity. For instance, Yu et al. prepared the anatase and anatase/rutile TiO2 nanotubes by annealing at 450 °C and 550 °C, respectively [148]. They observed the better proliferation and mineralization of MC3T3-E1 cells on anatase and anatase/rutile surfaces than on smooth and amorphous nanotube surfaces, and even the anatae/rutile surface showed slightly better performance compared with the anatase surface. However, in Park et al.'s study, adhesion and proliferation rates of rat bone marrow mesenchymal cells (MSCs) presented somewhat higher adhesion and proliferation rates on amorphous than on anatase nanotubes [149]. Hence, it is still necessary to investigate the influence of crystalline phase on cell behaviors and osseointegration in vivo, thus optimizing the bioactivity of Ti implants.

Fig. 6.

(A) SEM images (a) of TiO2 nanotubes with different diameters created by controlling potentials ranging from 1 to 20 V. (b) Schematic model showing the lateral spacing of focal contact formation on nanotubes of different diameters [137]. Reprinted with permission from Ref. [137]. (B) Immobilization and release of rhPDGF-BB: (a) schematic diagram of vacuum extraction, (b) SEM images of rhPDGF-BB-loaded nanotube surface, (c) cross-sectional SEM image of the protein particles loaded into the nanotubes in the PDGF + Vacuum group, (d) corresponding EDS of the rectangular region, and (e) the decrease trends of PDGF-BB fluorescence intensity on the Ti plates from 1 to 24 h after immersion in PBS [151]. Reprinted with permission from Ref. [151]. (C) SEM images (a) of the Ti surfaces with (I1 and I2) and without (I0) electrochemical anodization treatment. (b) Cell (hBMSCs) motility by the wound healing assay on Ti surfaces with (I1 and I2) and without (I0) anodization treatment [158]. Reprinted with permission from Ref. [158].

Because of the unique tubular structure, TiO2 nanotube array is usually loaded with drug and biomolecules to strength bioactivity. Some model drugs, such as large-molecular proteins (e.g., BMP-2 [150], PDGF-BB [151] and FGF-2 [152]) and common small-molecular antibiotics (e.g., gentamicin [153] and sirolimus [154]), have been loaded into the nanotube array to enhance osteogenic response and antibacterial property. For instance, the nanotube array loaded with PDGF-BB that was released for at least 14 days, promoted adhesion, proliferation as well as differentiation of bone marrow stem cells (BMSCs) in vitro and induced fast new bone formation in vivo, as shown in Fig. 6B [151]. Although the nanotube structure provides a smart platform for the local drug release, unsatisfying results on the release kinetics still occur, including burst release, because the drug is usually immobilized by repeated lyophilization or vacuum extraction. Therefore, a barrier coating with degradation is exploited to improve the release kinetics. Biopolymers, such as poly(lactic-co-glycolic acid) (PLGA), have been applied to coat the TiO2 nanotube after loading BMP-2 [155] or ciprofloxacin [156], respectively, to enhance the release patterns.

Besides in F−-containing solution, anodization can also be conducted in NaOH solution to form nanostructures on Ti surfaces [157,158]. The nanonetwork-structured TiO2 layers, with average lateral pore sizes of 70 ± 30 nm (∼200 nm thickness) and 90 ± 50 nm (∼300 nm thickness), were formed depending on the anodized current [158]. The nanonetwork-structured surfaces favored focal adhesion formation and signaling conduction via integrins and activated FAK and ERK1/2 pathways, and thus obviously improved the motility, spreading, proliferation as well as differentiation of human bone marrow mesenchymal stem cells (hBMSCs) (Fig. 6C) [158].

2.3.3.2. Micro-arc oxidation

The electrode process obeys Faraday's law and Ohm's law at relatively low voltages, however, increased gas evolution, sparks and micro arc discharges would appear when the voltages are beyond the dielectric breakdown limit of the grown oxide [159,160]. This kind of anodization is usually referred to micro-arc oxidation (MAO), anodic spark oxidation or plasma electrolytic oxidation (PEO). In MAO, the voltage usually varies in 150–1000 V and in 0–100 V in the anodic and cathodic half circles, respectively [17]. The local temperature and pressure generated inside the discharge channel can reach up to 103-104 K and 102-103 MPa, respectively, which induces the plasma thermochemical reactions between the substrate and the electrolyte [161]. Interestingly, the porous surface morphology usually shows crater-like with holes at the center, whose size tends to be a few microns [135]. The quality and characteristics of MAO coating are associated with processing parameters, such as applied voltage, electrolyte composition, and anodization time.

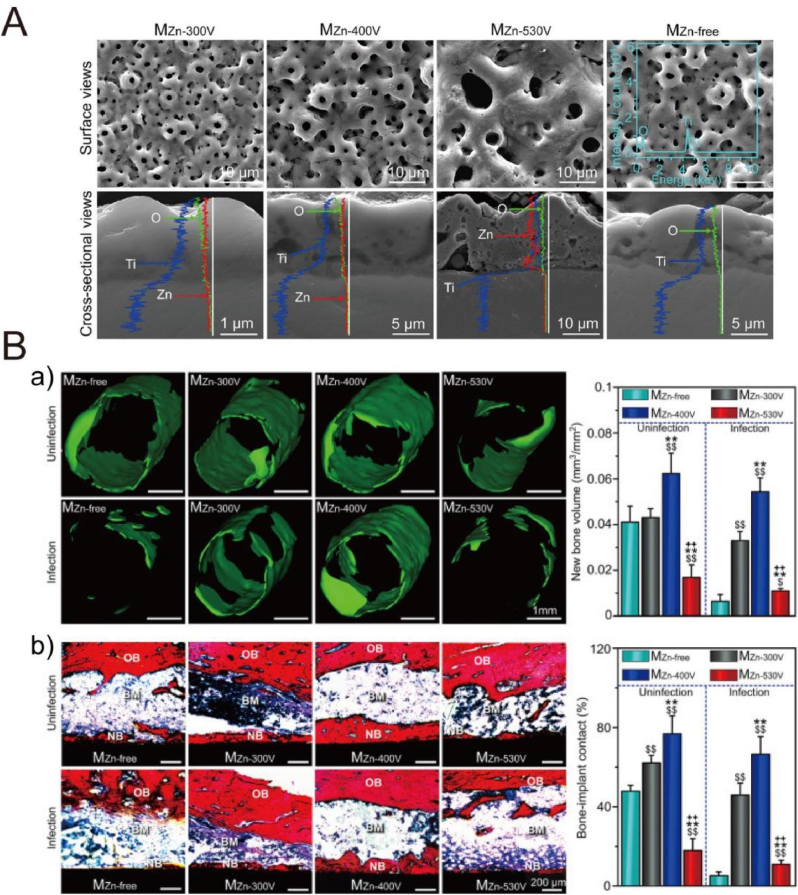

Many studies have focused on the preparation of oxide coatings on Ti surfaces by MAO treatment with improved bioactivity, biocompatibility and antibacterial properties. The electrolyte formulation greatly affects the composition of surface oxide coatings, so some bio-functional elements, such as Ca, P, Mg and S, can be readily incorporated into the oxide layer by introducing their corresponding compounds to the electrolyte [135]. For instance, Fe3+-incorporated TiO2 film significantly enhanced proliferation, osteogenic differentiation and extracellular matrix mineralization of osteoblasts (hFOB1.19) [162]. Ca- and P- incorporated oxide layers showed an improved bone-implant contact and removal torques [163,164]. In order to reduce infection, some antibacterial elements, such as Ag [165], Zn [166], Cu [167] and Mn [168], can be incorporated into the oxide film to hinder bacterial adhesion and biofilm formation. In one case, the TiO2-Ag coatings with different concentrations of Ag NPs (designated as TiO2-0.3Ag and TiO2-3.0Ag) showed an effective antibacterial activity against methicillin-resistant Staphylococcus aureus (MRSA), with percentage killing as high as 98.0 ± 2% for TiO2-0.3Ag and 99.75 ± 0% for TiO2-3.0Ag, respectively [165]. As to cell viability, the TiO2-0.3Ag presented no obvious cytotoxicity to human osteoblastic cells (SV-HFO), but TiO2-3.0Ag significantly inhibited cell adhesion and proliferation, because higher concentration of Ag NPs may disrupt normal cell behaviors. Because Ag as a strong bactericide may induce the cytotoxic risk, some mild bactericides, such as Zn and Cu, may be safer towards mammalian cells. For instance, Ye et al. prepared Zn-doped TiO2 coatings with Zn existing in the form of weaken Zn-O bonds in the outer layer and Zn2TiO4 underneath, respectively, as shown in Fig. 7 [166]. The reactive oxide species (ROS) induced by the Zn2+ ions released from Zn-doped coatings can break the cell walls and plasma membranes, and further strength the intracellular ROS level of S. aureus, resulting in bacteria death. In contrast to the overdose of Zn-doped coating (MZn-530 V), the moderate doses of Zn ions (MZn-300 V and MZn-400 V) did not generate intracellular ROS and reduce viability of osteoblasts, but it inversely enhanced proliferation of osteoblasts and osseointegration in both S. aureus-uninfected and infected rat tibias.

Fig. 7.

(A) SEM images of MZn-300V, MZn-400V and MZn-530V and MZn-free coatings prepared by micro-arc oxidation [166]. (B) Micro-CT (a) and histological analyses (b) of the coated pillars implanted in rat tibias under S. aureus-infected and uninfected conditions at week 4 of surgery. OB: original bone, NB: new bone and BM: bone marrow [166]. Reprinted with permission from Ref. [166].

Ti implants subjected to MAO treatment have been successfully applied in clinic. In a long-term study, 210 implants of TiUnite with a porous anodized surface were implanted in 59 patients [169]. During a 10-year follow-up study, 47 (22.38%) implants were lost because these patients refused to continue the study, and another 5 implants were lost. Based on the final follow-up, the cumulative survival rate of the implants placed in healed and postextractive sites were 98.05% and 96.52%, respectively, suggesting a positive result in terms of bone maintenance and integration.

2.3.3.3. Electrodeposition

Electrochemical deposition can be divided into electrodeposition (ED) and electrophoretic deposition (EPD). ED is an electrochemical reduction process of metallic ions hydrolyzed or metal complexes by cathodic reactions to generate dispersive particles or continuous film on the substrates, whereas EPD uses an electric field to drive the charged organic or inorganic particles in suspended solution towards the oppositely charged electrode to form thin and thick films [135]. Distinctions of such two techniques are displayed in Table 7 [135].

Table 7.

Distinctions of electrodeposition and electrophoretic deposition [135].

| Electrodeposition | Electrophoretic deposition | |

|---|---|---|

| Medium | Solution | Suspension |

| Moving species | Ions or complexes | Particles |

| Electrode reaction | Reduction of metal ions or hydrolyzation by electrogenerated base | None |

| Preferred liquid bath | Mixed solvent (water-organic) | Organic solvent |

| Required conductivity | High | Low |

| Deposition rate | 10−3 - 1 μm/min | 1–103 μm/min |

| Deposition thickness | 10−3 - 10 μm | 1–103 μm |

| Deposition uniformity | On nanometer scale | Limited by size of particles |

ED not only can fabricate various metallic coatings on the electrodes, but also is able to construct organic or inorganic films on the conductive materials by controlling electrochemical condition and electrode interfacial environment. As a powerful modification method, ED is widely used to deposit CaP-based coatings on Ti surfaces to improve the bioactivity under galvanostatic processing. The typical reactions of CaP deposition can be described as follows [[170], [171], [172], [173]], as shown in Table 8. The cathodic polarization produces OH− and H2 (Eqs 1-5), and then the produced OH− makes the local pH around the cathode increase to facilitate reactions (Eqs 6-7) and move the ionization equilibrium forward of H2PO4− and HPO42− (Eqs 8-9), thus generating PO43−. In addition, PO43− can also be produced by reduction of H2PO4− (Eqs 10–11). The accumulated Ca2+, HPO42−, PO43− and OH− ions lead to local supersaturation and subsequent nucleation and growth of CaP based on the applied current density (Eqs 12). The composition, morphology, crystallinity and stability of CaP are associated with the deposition parameters, such as current density, deposition time and temperature, and electrolyte properties (e.g., pH, additives, ion concentrates) [135]. In some cases, low current density produces HA precursors, including CaHPO4·2H2O (DCPD) (Eqs 12a), Ca8H2(PO4)6·5H2O (OCP) (Eqs 12b), and Ca2(PO4)3·nH2O (TCP) (Eqs 12c), high current density facilitates HA (Eqs 12d) formation [170,172].

Table 8.

Typical reactions of preparation of CaP coating by ED [170–173].

| 2H2O + O2 + 4e− → 4OH− | (1) |

| 2H2O + 2e− → H2 + 2OH− | (2) |

| 2H+ + 2e− → H2 | (3) |

| NO32− + H2O + 2e− → NO2− + 2OH− | (4) |

| H2PO4− + H2O + 2e− → H2PO3− + 2OH− | (5) |

| H2PO4− + OH− → HPO42− + H2O | (6) |

| HPO42− + OH− → PO43− + H2O | (7) |

| H2PO4− ↔ HPO42− + H+ | (8) |

| HPO42− ↔ PO43− + H+ | (9) |

| 2H2PO4− + 2e−→ 2HPO43− + H2 | (10) |

| H2PO4− + 2e− → PO43− + H2 | (11) |

| Overall reactions: | ||

| Ca2+ + HPO42− + 2H2O → CaHPO4·2H2O | (DCPD) | (12a) |

| 8Ca2+ + 6HPO42− + 5H2O → Ca8H2(PO4)6·5H2O | (OCP) | (12b) |

| 3Ca2+ + 2PO42− + nH2O → Ca3(PO4) ·nH2O | (TCP) | (12c) |

| 10Ca2+ + 6PO43− + 2OH− → Ca10(PO4)6(OH)2 | (HA) | (12d) |

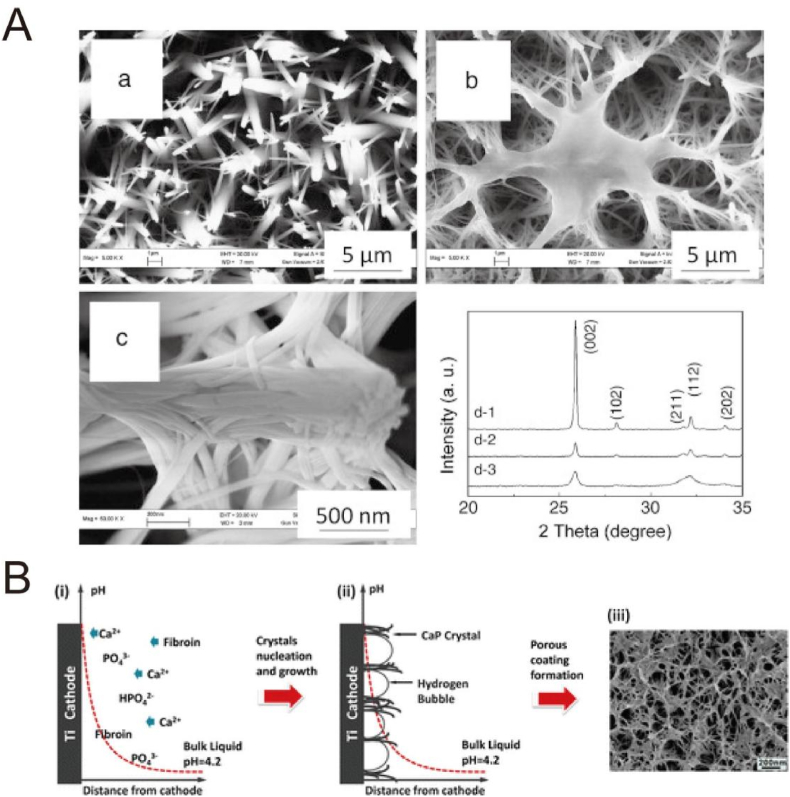

The bioactivity of HA and other CaP-based coatings by ED has been widely investigated. HA-coated Ti surfaces significantly improve osteoblast adhesion, spreading and gene expression of ALP as well as osteocalcin related with differentiation in vitro [[174], [175], [176]]. The in vivo studies have also indicated the superior bone regeneration and apposition [177,178]. Chai et al. modified a three-dimensional porous Ti6Al4V scaffold with HA by perfusion electrodeposition with different current densities (1.54, 5, 10 and 20 mA/cm2) [178]. After in vitro test, they implanted HA-Ti hybrids (5 and 10 mA/cm2) seeded with human periosteum-derived cells on the backs of mice in the cervical region. The absolute volume and the percentage of bone formed on the hybrids produced at 10 mA/cm2 were significantly higher than that of hybrids produced at 5 mA/cm2. It was assumed that the osteoclastic resorption may occur earlier on the hybrids produced at 10 mA/cm2, resulting in a faster initiation of ectopic bone formation. Because various elements exists as ionic substitutions in bone mineral, such as Na+, Mg2+, Sr2+, Zn2+, CO32−, F− and Cl− [179,180], which obviously influence the biological activity of bone mineral, some ion-substituted HA materials are facilely prepared via adding corresponding ions into the electrolytes. Such ion-substituted HA significantly improves coating stability, cell activity, and antibacterial properties. For example, Sr-HA via addition of Sr2+ obviously enhanced cell adhesion, proliferation and differentiation in vitro, and induced superior new bone formation as well as bone-implant contact in vivo [181]. Similarly, Ag+ [182], Cu2+ [183], Cu2+/Zn2+ [184] and Sr2+/Mg2+/Zn2+ [185], are introduced into the HA by single- or co-substitution to promote the osteoblast activity as well as to reduce bacterial infection [[182], [183], [184], [185]]. In addition, some HA-based composite coatings have been obtained on Ti surfaces by ED to better mimic the inorganic/organic hierarchical structure and composition. For instance, after addition of collagen I into the electrolyte, the electrolyte viscosity was increased, which would benefit the stability of the H2 bubbles on the interface as a dynamic porous template [186]. During the nucleation and growth, the collagen might act as a “glue” to chemically bond with HA and hinder the fast growth of HA, and thus produced a gel-crystal hybridized and micro-nano porous coating with fiber-like crystals orderly arranged together, as shown in Fig. 8A. Similarly, by introducing the soluble chemicals, such as chitosan [187], heparin [188] and amino acids [189], the corresponding HA-based composite coatings can be realized via the incorporation during the nucleation and growth, to construct a bioactive platform [[187], [188], [189]].

Fig. 8.

(A) SEM images (a–c) of the hydroxyapatite coatings: (a) without collagen, and (b, c) with collagen prepared by electrodeposition method. (d) XRD patterns of (1) hydroxyapatite coating, (2) collagen-modified hydroxyapatite coating, and (3) bovine cortical bone [186]. Reprinted with permission from Ref. [186]. (B) Schematic diagram of mechanism in the formation of OCP/SF composite coatings [192]. Reprinted with permission from Ref. [192].

Besides HA-based coatings, some other CaP-based composites have been prepared as well. Some inorganic/organic hierarchical structures based on octacalcium phosphate (OCP) coatings have been obtained by assembling from fiber-like nanocrystals, such as OCP/collagen [190,191], OCP/silk fibroin (SF) [192,193]. For instance, the OCP/SF coating with a bioinspired nano-micro structure was formed because the produced hydrogen bubbles functioned as a template during ED process, as shown in Fig. 8B [192]. The OCP/SF coating improved adhesion, spreading and proliferation of MC3T3-E1 cells and human umbilical cord-derived mesenchymal stem cells (HUMSCs), because of the multiscale structure and proper chemical composition.

2.3.3.4. Electrophoretic deposition

Electrophoretic deposition (EPD) is a typical colloidal processing technique usually used in ceramic production with many advantages, such as short formation time and little restriction of the substrate shape [194]. The charged particles are first dispersed or suspended in a liquid medium, and then moved towards the electrode of opposite charge under an electric field to form a deposited film [195]. A major difference between the EPD and ED is that, the electrolyte of EPD is a suspension of particles in a solvent but the latter is a solution of salts (e.g., ionic species) [196]. The EPD is usually carried out in organic solvents with the advantages of low conductivity, favorable chemical stability of the suspension and absence of the electrolytic reactions, because water tends to cause the electrolysis and evolution of H2 and O2, resulting in formation of incompact coating [197]. Many factors influence the coating properties, such as particle size, dielectric constant of liquid, conductivity of suspension, Zeta potential, deposition time and applied voltage [198].

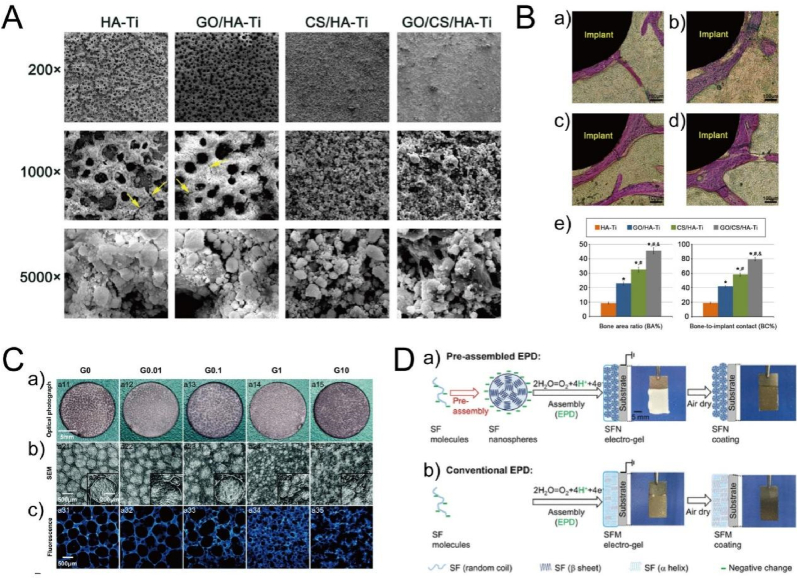

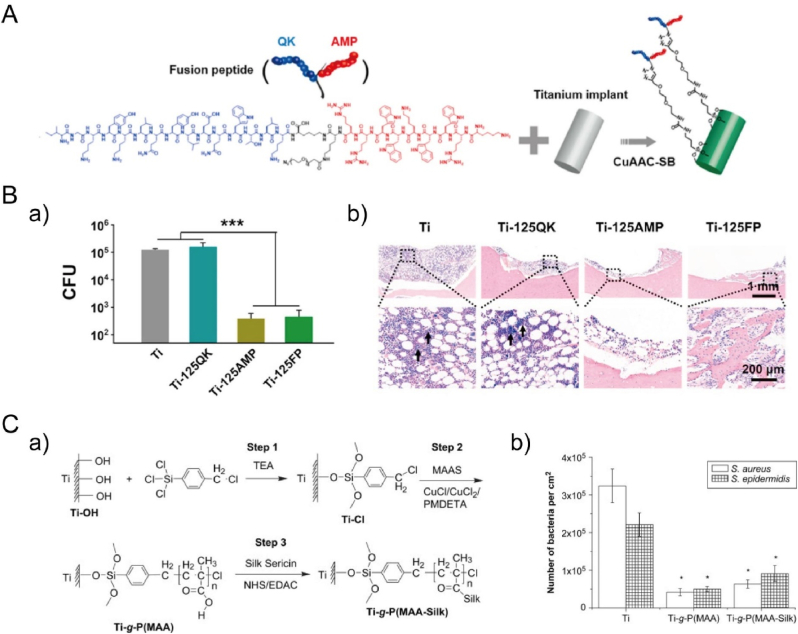

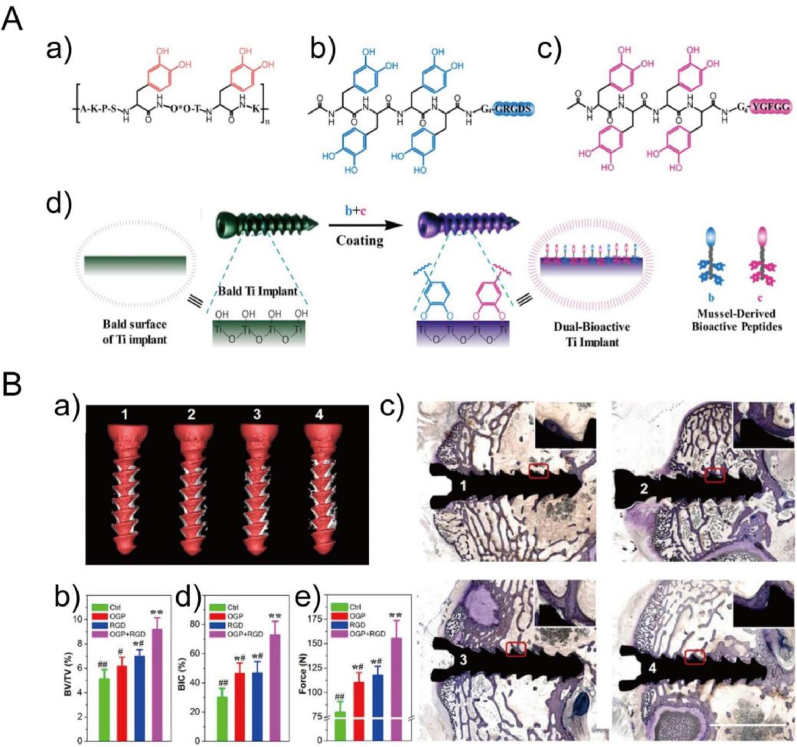

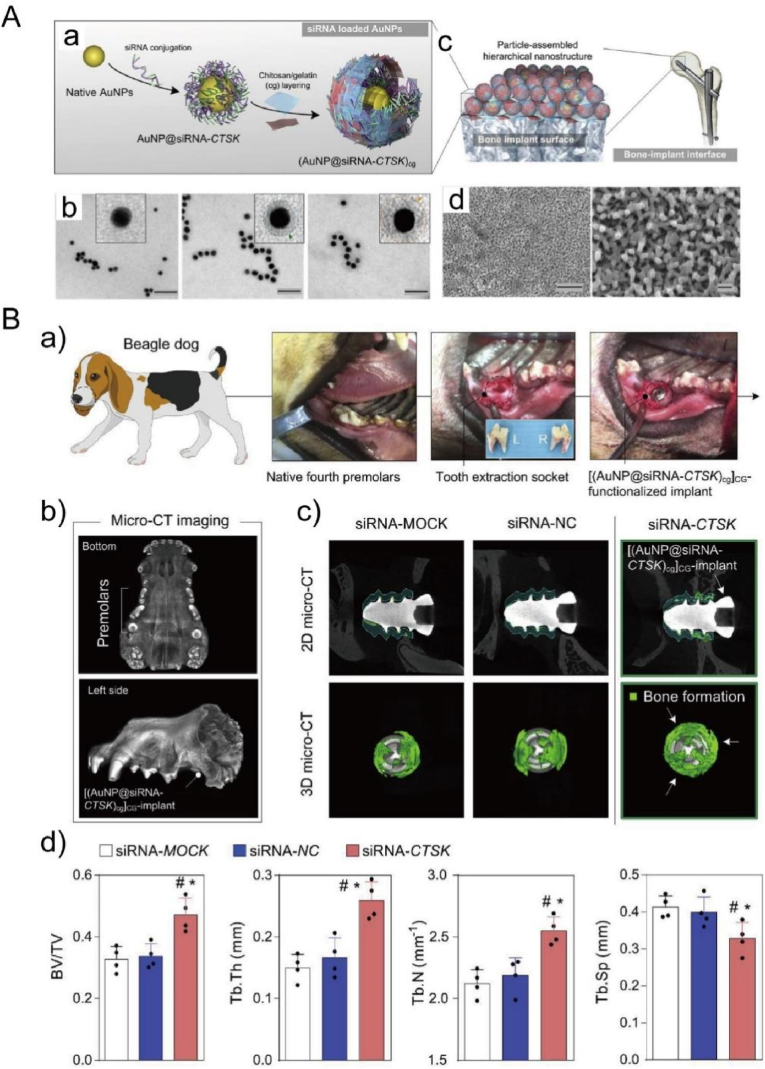

The EPD of HA or HA-based composited coating has been widely developed since 1986 [199]. Compared with other techniques, the advantage of EPD-prepared HA coating shows fine stoichiometry control, high purity of the deposited coating, and wide range of coating thickness varying from 0.1 μm to more than 100 μm [200]. The prepared HA coating obviously promoted cell adhesion, spreading, proliferation, differentiation and cytoskeleton organization [201,202], suggesting favorable cell-substrate interaction. In order to endow the coating with better bioactivity as well as antibacterial activity, some other one or two components (inorganics or organics) were incorporated to form HA-based composite coatings, such as polyetheretherketone/HA [203], graphene oxide/HA [204], chitosan/HA [205], Ag/amorphous calcium phosphate/HA [206], Fe3O4/chitosan/HA [207] and poly-l-lysine/3,4-dihydroxybenzylaldehyde/HA [208]. In one case, Suo et al. modified the Ti surface with a graphene oxide/chitosan/hydroxyapatite (GO/CS/HA) composite coating with a thickness of 10 μm by one-step EPD, as shown in Fig. 9A-B [209]. Such a crack-free GO/CS/HA composite displayed a bonding strength of 27.1 ± 1.2 MPa, much higher than that of HA, GO/HA, CS/HA coatings with a value of 16.8 ± 1.5 MPa, 24.5 ± 1.3 MPa and 17.3 ± 1.7 MPa, respectively. The GO/CS/HA coating significantly enhanced not only the extension, proliferation, ALP activity and mineralization of bone marrow stromal cells (BMSCs), but also the bone area ratio, bone-to-implant ratio and the biomechanical properties after implantation in rat tibia for 12 weeks. In addition, some drugs or proteins are easily incorporated into the coatings by EPD [[210], [211], [212], [213], [214]]. For instance, gentamicin was loaded to the chitosan/HA coating by dissolving it in the electrolyte, and such coating effectively inhibited growth of Staphylococcus aureus and Escherichia coli, without inducing obvious cytotoxicity towards fibroblast cells (L929 and MRC-5) [210].

Fig. 9.

(A) SEM images of HA-Ti, GO/HA-Ti, CS/HA-Ti, and GO/CS/HA-Ti prepared by electrophoretic deposition [209]. (B) Stained histological sections of the proximal tibiae (a: HA-Ti; b: GO/HA-Ti; c: CS/HA-Ti; d: GO/CS/HA-Ti) and the quantitative results (e) after implantation for 12 weeks [209]. Reprinted with permission from Ref. [209]. (C) Topography of chitosan/gelatin coating including (a) optical photographs, (b) SEM images and (c) fluorescence images [217]. Reprinted with permission from Ref. [217]. (D) Assembly mechanism of (a) pre-assembly and (b) conventional assembly of SF EPD coatings [222]. Reprinted with permission from Ref. [222].

Beyond CaP-based coatings, some polyelectrolyte components have been deposited on Ti surfaces as well. Chitosan/gelatin [215] and chitosan/silk fibroin [216], can form polyelectrolyte complex by electrostatic interaction in acidic aqueous solution. After the pH value around the cathode increased higher than chitosan's pKa with the applied voltage, the amino groups of chitosan were deprotonated, leading to the decreased solubility and subsequent co-deposited coatings of the chitosan/gelatin [215] and chitosan/silk fibroin [216]. Similarly, Zhang et al. observed comparable and positive behaviors of MC3T3-E1 cells on the porous chitosan/gelatin coating with various surface porosity. The best cell response was observed in small pores with integral and continuous structure of G1 group, because of the synergistic effects of the porous structure and component, as shown in Fig. 9C [217]. Furthermore, some inorganic elements, such as Mg [218], Sr [219] and Zn [220], were able to incorporate into the chitosan/gelatin to form organic/inorganic composites, and the promoted cell proliferation and differentiation as well as antibacterial activity were obtained via the ion release. In addition to inorganic elements, drug-loaded nanoparticles can be co-deposited to realize the controlled release of functional molecules [221,222]. For instance, Cheng et al. loaded vancomycin into the silk fibroin (SF) nanospheres via electrostatic and hydrophobic interactions, and then deposited nanospheres on Ti surfaces by oxidation of water near the anode to neutralize the negatively charged SF nanospheres to induce irreversible aggregation and deposition, as shown in Fig. 9D [222]. The drug-loaded coating effectively inhibited S. aureus for at least 21 days, but it did not show cytotoxic to fibroblasts. In short, the EPD process has gained considerable interest for fabrication of functional coatings on Ti surfaces in 2-D and 3-D substrates, because of the simple and easy-to-use properties.

2.3.4. Biochemical methods

2.3.4.1. Chemical covalent immobilization of biomolecules

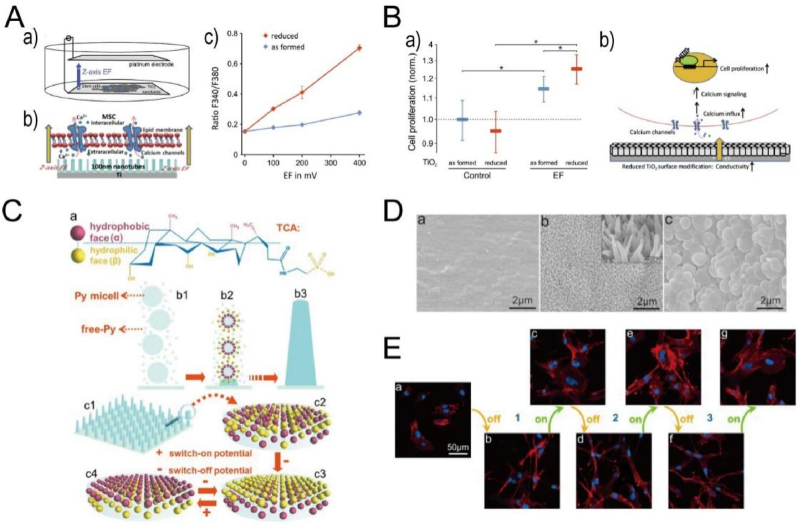

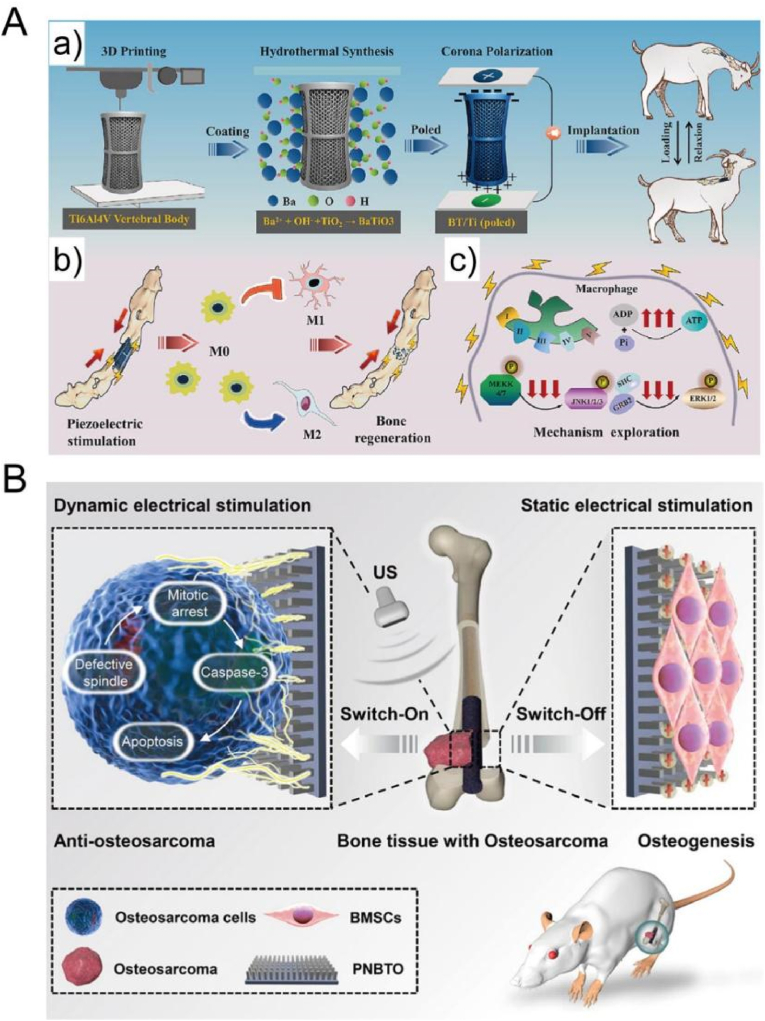

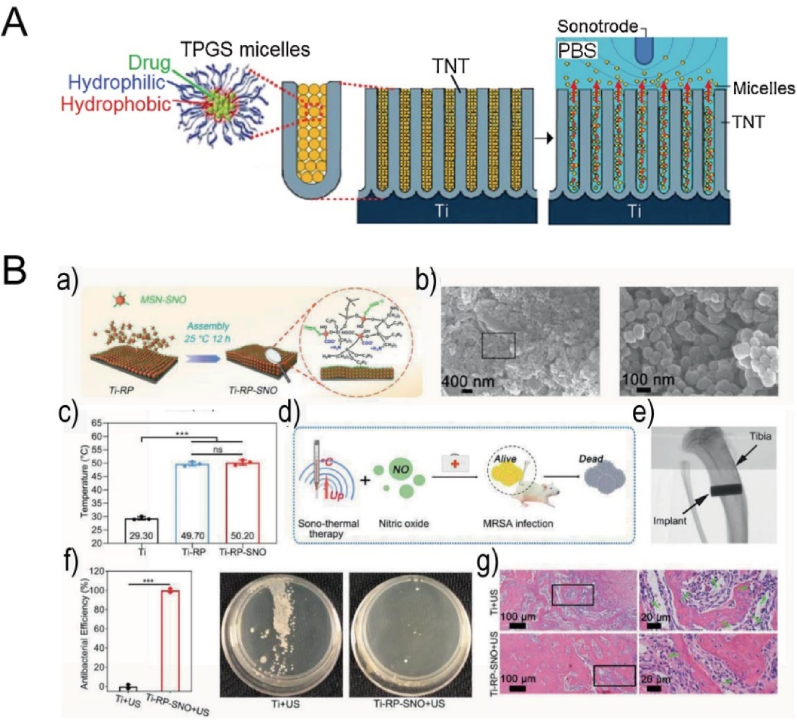

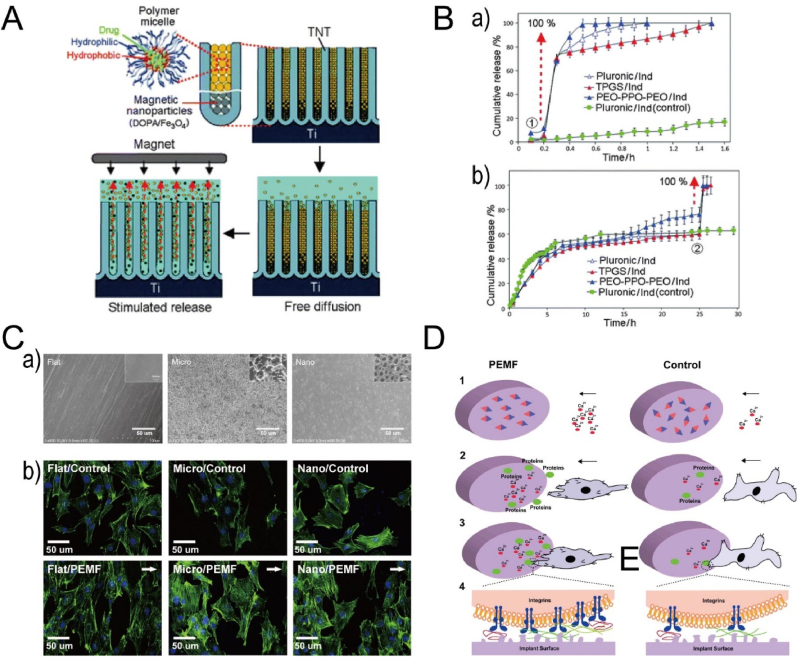

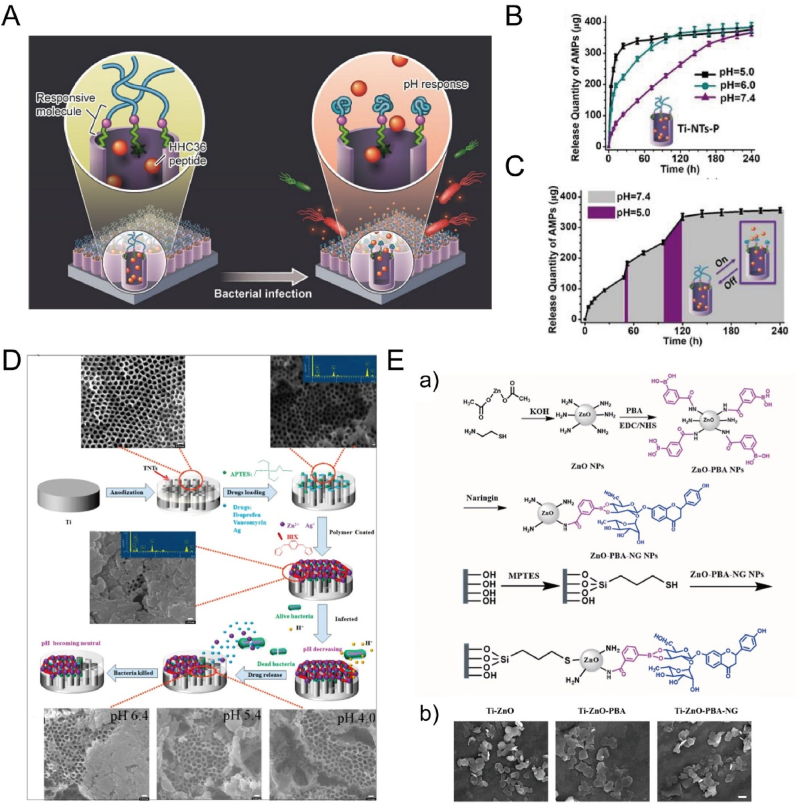

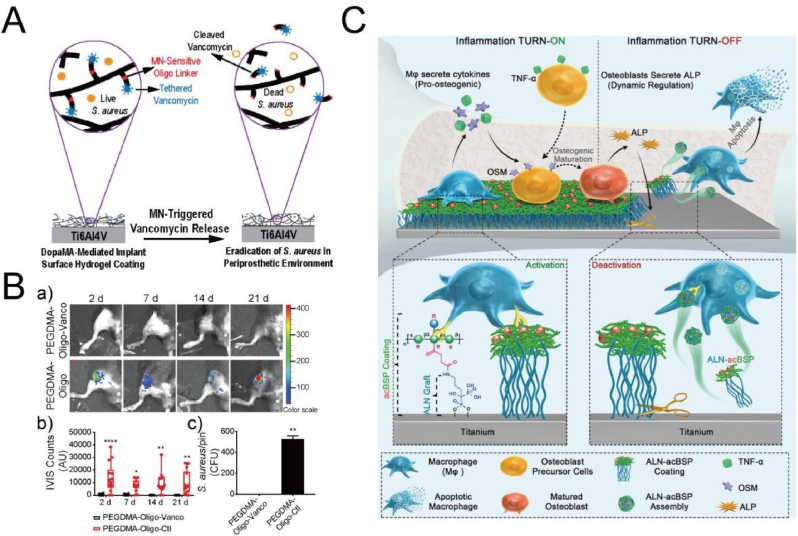

Chemical covalent immobilization of biomolecules usually binds selective biomolecules onto the surfaces by chemical grafting approach to realize specific cell or tissue response [18,36]. In contrast to the non-covalent methods (physical adsorption or entrapment), such a covalent immobilization method has some advantages, such as high specificity, low competitive replacement and the relatively low-loss rates [18]. It has been noted that the amount grafting on the surfaces should exceed the threshold levels to induce cellular activity. The Ti metal does not possess surface functional groups (e.g., -NH2 and -COOH) required for the covalent immobilization of biomolecules by most of the binding strategies, but the passive oxide films on the metals can form surface hydroxyl groups upon immersion in aqueous environments, which provide potential binding sites for covalent attachment of a linker molecule for further bio-functionalization. In general, a pre-treatment step (e.g., acid or alkali immersion and O2 plasma) is needed to enrich the surface hydroxyl groups for the dehydration/condensation reactions to covalently attach the linker molecules, which are either synthetic compounds, including silane and polyethylene glycol, or biologically-derived compounds, including heparin, dopamine and chitosan [18]. By reacting with the linker molecules, biomolecules, such as peptides and proteins, are immobilized on the Ti surface to promote the bioactivity.