Abstract

Stevia (Stevia rebaudiana) has been employee for developing food products as a substitute for sucrose, low caloric, and natural sweetener. Different studies have evaluated the effect of this ingredient on the physicochemical, nutritional and technological properties of products; their application in dairy products affects some sensory characteristics such as taste; in the case of bread, cookies, and cakes modify the properties of the dough, altering attributes of the manufactured product, including color, texture, and flavor; also the use of stevia reduces gelling and affects the optical properties of the final product; and in beverages cases, the total substitution of sugar has led to bitter and unpleasant flavor. This review presents stevia general information and its employees in dairy, bakery, beverages, and jelly products.

Keywords: Stevia (Stevia rebaudiana), Steviol glycosides, Food application, Technological functionality

Introduction

Sweeteners are substances with a very intense sweet taste used in small amounts to replace the sweetness of a much larger amount of sucrose. Currently, on the market, some caloric sweeteners are available, such as aspartame, saccharin, acesulfame-k, sucralose, neotame, cyclamate, alitame, thaumatin, moneline, and pentadine. These substances are considered by the United States Food and Drug Administration (FDA) and the European Food Safety Authority (EFSA) as food additives or ingredients, classified as natural and synthetic sweeteners (Wan et al. 2021). There is a great controversy, different studies show that some artificial sweeteners are harmful to health, and that is the point where natural sweeteners add value in terms of health by reducing calories and using ingredients obtained from natural sources and not by chemical synthesis (Ribeiro et al. 2020). However, the number of non-caloric natural sweeteners is small, and, among those currently known, stevia (Stevia rebaudiana) is the sweetener that has raised the greatest scientific interest in recent years.

Stevia (Stevia rebaudiana) is a small perennial shrub that belongs to the Asteraceae family, native to northern Paraguay and areas adjacent to Brazil, discovered in 1887 by the scientist Moisés Santiago Bertoni. The Guaraní Indian tribe has used their leaves since pre-Columbian times to sweeten food. In 1955, the Japanese began to cultivate stevia crops, initially in Paraguay, and around 1970, in southern Japan, thus promoting the development of genetic improvements to the content of stevioside in leaves. One of the main reasons this spread to southern Japan was that artificial sweeteners were heavily regulated and even banned. Today, it is grown in various Asian countries such as Japan, China, Korea, Thailand, Indonesia, the Philippines, and Latin America, mainly in Paraguay, Brazil, Argentina, Colombia, and Peru. It should be mentioned that China is the largest producer of stevia globally and exports approximately 80% of its production, and Japan is the country with the largest number of factories that process and extract stevioside (Hossain et al. 2017; Ahmad et al. 2020).

Several studies have shown that stevia has health benefits that include antidiabetic, antiobesity, antitumor, antihypertensive, antimicrobial, anticaries, and antioxidant. In addition, they have reported that steviol glycosides from stevia leaves are not teratogenic, carcinogenic, or mutagenic, and they do not cause subacute or acute toxicity (Ahmad et al. 2020). Stevia leaves are becoming an important source of highly potent sweeteners for the growing market for natural foods. Therefore, stevia (Stevia rebaudiana) is used in many countries as a substitute for sugar in foods, beverages, and medicines, and well-known commercial products have been formulated from its derivatives (Putnik et al. 2020).

However, stevioside is bitter or stringent when it is steamed (Hernández et al., 2022); for this reason, it is important to evaluate the proportion of stevia employees for product development. The purpose of this review is to present a complete and updated description of the general characteristics of stevia (Stevia rebaudiana), the effect of its incorporation into various food matrices as a substitute for common sugar, sucrose, and other possible uses of it in the industry as natural emulsifiers or as an effective solubilizing agent.

Characteristics of stevia (Stevia rebaudiana)

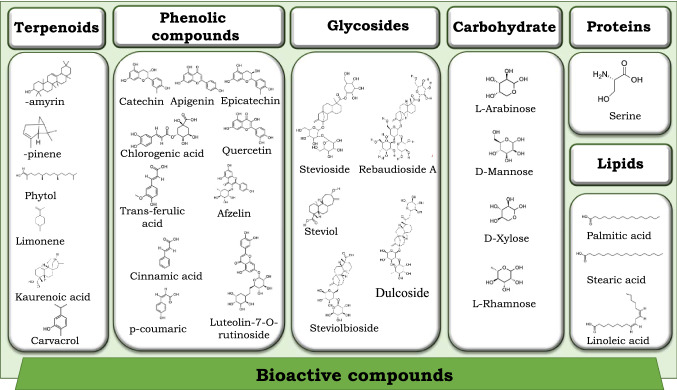

Stevia (Stevia rebaudiana), also known as a honey leaf, a caramel leaf, or a sweet leaf (Ahmad et al. 2020), is currently the only species in the Asteraceae family with sweetening properties due to the active compounds present in its leaves, the so-called steviol glycosides; also, stevia (Stevia rebaudiana) present terpenoids, phenolic compounds, carbohydrate, and some proteins (Fig. 1).

Fig. 1.

Bioactive compounds identified in stevia (Stevia rebaudiana)

The number of different glycosides that have been identified is over 30: stevioside, steviol, steviolbioside, rebaudioside A, B, C, D, E, F, and dulcoside (Putnik et al. 2020), the most important being stevioside and rebaudioside A. Stevioside is present in leaves in greater quantities, approximately 4–13% of the total weight of the leaf, and is 150–300 times sweeter than sucrose, but has a more bitter and licorice taste than rebaudioside A and is the least soluble in water (Kalicka et al. 2017). The variety of stevia available on the market are mixtures; thus, they contain differences in their content of steviol glycosides, and their sweetness potency is directly proportional to the concentration of each of them (Ribeiro et al. 2020). In addition to sweet glycosides, stevia is also a good source of vitamins such as vitamin C, riboflavin, or folic acid, minerals including calcium, phosphorus, sodium, potassium, iron, and magnesium, essential amino acids, fatty acids, fiber, and other bioactive compounds beneficial for health (Hossain et al. 2017; Ahmad et al. 2020), such as terpenoids (i.e., carvacrol, limonene, α-pinene), flavonoids (i.e., catechin, apigenin, epicatechin, chlorogenic acid, quercetin), polyphenols (i.e., trans-3-O-caffeoylquinic acid, p-coumaric, gallic acid, protocatechuic acid, trans-ferulic acid) chlorophylls, carotenoids, tannins, monosaccharides (i.e., arabinose, mannose, xylose, rhamnose), fatty acid (i.e., linoleic, stearic and palmitic acid) and so on (Fig. 1). These compounds are found in the plant's leaves in variable percentages, depending on the species, the growing conditions, the agronomic techniques implemented, and even the different extraction methods used to obtain the different fractions (essential oils, aqueous or ethanolic extracts), and the solvents used in them (Góngora Salazar et al. 2018; Ahmad et al. 2020), as can be observed in Table 1.

Table 1.

Type of fraction, extraction methodology and chemical composition of stevia as an ingredient in food products

| Type of fraction | Extraction methodology | Chemical composition | References |

|---|---|---|---|

| Essential oil | Steam distillation | Silanediol, Cyclopentasiloxane, Cyclohexasiloxane, Estra-1,3,5(10)-trien-17-ones | Siddique et al. (2016) |

| Essential oil | Hydro-distillation | carvacrol, caryophyllene oxide, spathulenol, α-pinene, ibuprofen, isopinocarveol, caryophylle, pinene, limonene | Muanda et al. (2011) |

| Fatty acids | Solid–liquid extraction | Palmitic acid, stearic acid, linoleic acid, palmitic acid, 6-octadecenoic acid | Siddique et al. (2016) |

| Comercial stevia | Steviol; Stevioside, Rebaudioside, Rebaudiosides, Dulcoside, Steviolbioside, Rubusoside, Glucose, Rhamnose, Xylose | Gardana and Simonetti (2018) | |

| Aqueous extracts | Solid–liquid extraction | gallic acid, protocatechuic acid, catechin, chlorogenic acid, epicatechin, p-coumaric acid, rutin, quercetin dihydrate, cinnamic acid, quercetin, apigenin, Caffeic acid, quercetin glucosyl | Muanda et al. (2011) |

| Aqueous extract | Solid–liquid extraction | Mannose, glucose, arabinose, rhamnose, glucuronic acid, and galacturonic acid | Li et al. (2021) |

| Aqueos extract | Solid–liquid extraction | Chlorogenic acid, caffeic acid, rutin, trans-ferulic acid | Lemus-Mondaca et al. (2018) |

| Aquous extract | Pressurized hot water extraction | Condensed tannins, Chlorophyll A, Chlorophyll B, Carotenoids, Stevioside, Rebaudioside A | Bursać Kovačević et al. (2018) |

| Methanol–water-extracts | Solid–liquid extraction | gallic acid, protocatechuic acid, catechin, chlorogenic acid, epicatechin, p-coumaric acid, rutin, quercetin dihydrate, cinnamic acid, quercetin, apigenin | Muanda et al. (2011) |

| Methanolic extract | Solid–liquid extraction | stevioside, rebaudioside, steviobioside A, B, C, D, E and F, and dulcoside | Ghanta et al. (2007) |

| Ethanolic extract | Ultrasound-assisted extraction | cis-3-O-caffeoyl quinic acid, trans-3-O-caffeoyl quinic acid, trans-4-O-caffeoyl quinic acid, hexosylpentosyl | Pacifico et al. (2019) |

| 2-(p-hydroxyphenyl)ethanol, trans-5-O-caffeoyl quinic acid, 5-O-caffeoylshikimic acid, kaempferol dihexoside deoxyhexoside | |||

| Ethanolic extract | Solid–liquid extraction | Serine, quinic acid, 3-caffeoylquinic acid (3-CQA), citric acid, Roseoside, Hydroxybenzoic acid, Caffeoylquinic acid, Caffeic acid, Rutin, Quercetin-O-glucoside, Kaempferol-3-O-rutinoside/Luteolin-7-O-rutinoside, Quercitrin, Rebaudioside E, Rebaudioside D, Afzelin, Rebaudioside A, Steviolbioside/Rubusoside, Rebaudioside F, Rebaudioside C, Kaurenoic acid mannosyl glucoside, Stevioside/Rebaudioside B, Steviolbioside/rubusoside | Ciulu et al. (2017) |

| Aqueous/acetone extract | Maceration | Agatholic acid, 1-heptatriacotanol, duvatrienediol, dihydroxanthin, β-amyrin, lupenone, phytol, palmitic acid, and linoleic acid | Zaidan et al. (2019) |

Application of stevia as an ingredient in food products

The most notable function of sucrose in food is to provide its unique sweet flavor, but also contributes to texture and color profiles, affecting the freezing point acting as a bulking agent or preservative (di Monaco et al. 2018). Therefore, different properties must be considered when replacing sucrose, which can cause many defects related to its quality, that is, the Maillard reaction and its presence in the formation of gel in jams and jelly (di Monaco et al. 2018). Reformulation of a product through partial or total sugar substitution is the most studied strategy in most food categories. However, a gradual reduction in sugar content without influencing different aspects of the quality of the final product and its sensory perception is a challenge that food manufacturers must face (Luo et al. 2019). Stevia has been applied in different food products as a natural sweetener (Table 2), that is, incorporated into carbonated beverages (Saniah et al. 2012), chocolates (Vásquez et al. 2017), confectionery (Sukeaw Samakradhamrongthai and Jannu 2021), and others. However, the food matrices in which the most recent research is being carried out are complex because of their partial or total substitution of sucrose by stevia.

Table 2.

Application of stevia as an ingredient in different food products

| Food products | Application | Major findings | Referencess |

|---|---|---|---|

| Yogurts | Substitute of sucrose | The addition of sucrose did not affect the consistency of the yogurt | Kalicka et al. (2017) |

| Carbonated drinks | Substitute of sucrose | The employee of stevia as a sweetener reduces the amount of calories and carbohydrate in carbohydrate beverages | Saniah et al. (2012) |

| Ice cream | Substitute of sucrose | Stevia did not change the sensorial properties of ice cream | Ozdemir et al. (2015) |

| Yogurts | Low caloric sweetener | Stevia did not affect the physicochemical and microbiological properties of yogurt | Reyes and Ludeña (2015) |

| Jams | Substitute of sucrose | Stevia did not change the texture of low-caloric jams | Márquez et al. (2016) |

| Tea beverage | Develop a low-calorie product | A functional radish tea beverage with overall acceptance, taste, and sweetness scores | Kim et al. (2016) |

| Sponge cake slices | Substitute of sucrose | Replacing sucrose with low-calorie sugar substitutes based on Stevia glycosides may have variable humectant properties and bulking agents, which may shorten the potential shelf-life of intermediate moisture bakery products | Rodríguez et al. (2016) |

| Fruit Juice beverage | Natural sweeteners | A development of fruit juice-stevia beverage with great content in bioactive compounds and sweeting properties with minimal color changes | Carbonell-Capella et al. (2017) |

| Bakery products | Natural Sweetener | Development a bread alternative with functional properties | Jaimes Tarazona et al. (2018) |

| Berry juices | Natural Sweetener | The addition of stevia increases the antioxidant properties of berry juice | Bender et al. (2018) |

| Protein beverage | Natural Sweeteners | The development of naturally sweetened protein beverages with reduced calories and desirable sensory properties highlights the importance of label claims for consumers in general, but for a segment of label-conscious consumers | Parker et al. (2018) |

| Chocolate ice cream | Low-caloric sweetener/natural sweetener | The use of stevia contributes to the manufacture and development of low-calorie chocolate ice cream with functional properties, with a reduction or total absence of sucrose, highlighting the impact of labeling these products on consumer perception | Peres et al. (2018) |

| Carbonated soft drink | Natural Sweeteners | This study provides a methodology to optimize non-caloric sweetener mixtures for preparing carbonated soft drinks with the lowest possible caloric content while maintaining the tastiness, high sweetness and low bitterness, of full-caloric ones, containing the bulk sweetener tagatose and the high-intensity sweetener stevia | Acevedo et al. (2018) |

| Coconut jelly | Natural sweeteners | Coconut jelly prepared with steviol glycoside as a sweetener might be an optional food product for healthy people or patients with non-communicable diseases such as diabetes mellitus | Chupeerach et al. (2018) |

| Pumpkin jams | Low caloric sweetener | Develop a low-calorie peach ready-to-serve beverage that is a promising nutraceutical drink for the management of obesity, diabetes, and its associated complications | Alsuhaibani and Al-Kuraieef (2018) |

| Jelly candy | Natural sweetener | Develop healthier jelly candies enriched with extracts | Uchiyama et al. (2018) |

| Carbonated beverage | Low caloric sweetener | Regular soda and low-calorie soda containing different commercial sweeteners appear to influence the surface morphology of primary tooth enamel | Korte et al. (2019) |

| Ice cream | Natural sweetener | Develop ice cream with adaptogenic functional properties | Bavyko and Bondarchuk (2019) |

| Jam | Low-caloric sweetener/natural sweetener | The development of low-caloric jam when storage intervals influence physicochemical and sensory characteristics | Sutwal et al. (2019) |

| Dessert | Natural Sweeteners | Stevia and sucralose were good substitutes for sucrose in formulating lactose-free frozen desserts, but not in vegan versions (with rice and soy protein) | de Medeiros et al. (2019) |

| Ice cream | Natural Sweeteners | The development of stevia in ice cream helps to produce products with good viscosity characteristics and antioxidant activity | Mayangsari et al. (2019) |

| Jelly candy | Natural Sweetener | Develop healthier jelly candies enriched with antioxidant extracts | Cedeño-Pinos et al. (2020) |

| Biscuits | Low caloric sweetener | The replacement of sugar by stevia up to 50% in biscuits is acceptable without appreciable changes in physicochemical and sensory properties | Rana et al. (2020) |

| Strawberry jam | Substitute of sucrose | Partial substitution of sucrose by fructose or stevia did not impair jam sensory properties and consumers’ acceptance, an alternative for developing a product for diabetics | Jribi et al. (2020) |

| Sweetened beverage | Natural Sweetener | Develop a beverage with hydration properties | García-Arroyo et al. (2020) |

| Milk gels | Substitute of sucrose | Fermented milk with stevia sweetener and naturally colored red beetroot may be an alternative to therapeutic dairy products that have positive synergistic interactions providing rich probiotic bacteria to deliver | Ozdemir and Ozcan (2020) |

| Apricot nectar | Substitute sucrose/low caloric sweetener | Nectars produced with stevia resulted in a significantly reduced caloric value from 86 kcal (nectar with 10% sucrose) to 49 kcal (nectars with stevia), maintaining that they are sweet and licorice aroma | Reale et al. (2020) |

| Ice cream | Low caloric sweetener | A low-calorie chocolate ice cream sweetened with stevia promotes relevant differences in lactose-free ice cream to traditional ice cream, increasing the duration and dominance of bitter taste, as and pasting, and decreasing consumer acceptance | Medeiros et al. (2020) |

| Jelly- drink | Low caloric sweetener | Development of antidiabetic product | Jariyah and Sarofa (2021) |

| Ice cream | Substitute of sucrose | Stevia extract substitutions were highly effective in the technological properties of ice cream in terms of overflow, first dripping time, melting rate, pH, and viscosity | Gençdağ et al. (2021) |

| Chocolate flauvored milk | Natural Sweeteners | The combination of sugar and stevia as sweeteners resulted in a sweetness synergy and the bitte | Mahato et al. (2021) |

| Functional beverage | Substitute of sucrose | The sample sweetened with stevia showed higher levels of sweetness, bitterness, and longer duration of the sweet stimulus in the time intensity test | Lima et al. (2021) |

Dairy products

To remain competitive on the market by offering clean label products and complying with the new nutritional label requirements, the yogurt industry has redoubled its efforts to develop new technological approaches that allow the reduction of sugar content without affecting properties such as taste, texture, and shelf life, influencing the final acceptance by the consumer (Wan et al. 2021). Despite the healthy components of yogurt, it should be noted that traditional formulations of this product still use sucrose, and the most prominent strategies to reduce its content in yogurt are ultrafiltration, lactose hydrolysis, reduction of sucrose, or substitution by sweeteners, such as stevia in this case (Ribeiro et al. 2020).

Stevia has been a low-calorie sweetener in yogurt and ice cream development, i.e., Reyes and Ludeña (2015) made a low-calorie yogurt using sucralose and stevia as sweeteners. It was observed that the use of stevia in this type of food matrix does not significantly affect the physicochemical and microbiological properties of the product; they verified that the incorporation of steviol glycosides into a probiotic yogurt does not affect the growth of probiotic microorganisms in the culture, also maintaining a functional level after 28 days of storage. The descriptive sensory test established that sucralose significantly improved sweetness compared to the product sweetened with stevia, yogurt added with sucralose being the best treatment.

Additionally, stevia has been employed as a substitute for sucrose in dairy products: Kaur and Goswami (2020) used different proportions of sugar and stevia in their formulations. They found an alternative in the preparation of Rasgulla, a typical Indian dessert prepared with cottage cheese and syrup, especially for those who like to take care of their health. However, Rodriguez Furlán and Campderrós (2017) suggest that sugar can be replaced by a combination of stevia and sucralose in the same proportions to obtain a product with the same level of sensory acceptability without added sugars. In the case of Ozdemir and Ozcan (2020), they achieved a total replacement of sugar by steviol glycosides, in obtaining a dairy product (fermented milk), due to a significant increase in bacterial growth that they attribute to the possible prebiotic effect of stevia and the bioactive compounds present in it. Flavored milk is also a booming dairy product on the market. While most of the available ice cream and cream literature focuses on fat reduction, there is also the challenge of developing low-sugar products.

Furthermore, in 2020, people began to talk about the use of stevia mixtures as a way to overcome the limitations of each stevia separately and at the same time improve the flavor profile of the final product; this was the case of Ribeiro et al. (2020), who compared the formulations of different stevia mixtures, in other words, different concentrations of steviol glycosides with the so-called standard samples sweetened with sucrose and sucralose, where they concluded that the application of this type of stevia mixtures is a potential substitute for sucrose and sucralose in natural yogurt, since their sensory profile was very similar, presenting a dominant sweet flavor and the absence of an undesirable residual flavor.

A general analysis of the findings in this type of food matrix reveals that stevia, which is non-fermentable, does not affect the yogurt fermentation process and shows a perception of taste or a temporal profile dependent on the concentration of steviol glycosides. Those with an aftertaste can be enhanced with synergistic sweetener mixtures or even the use of flavorings, as is the case with fruit yogurts. On the other hand, ice cream and cream with bulking agents or texturizers help to maintain the quality of the final product. Intermediate levels or partial substitution of sucrose provide greater sensory acceptance without bad taste, and no significant effects have been observed on the rheology, texture, or consistency of different dairy products with added sweeteners (Wan et al. 2021).

Nectar and juice type drinks

For a long time, the beverage industry has turned around reducing sugar in response to increased consumer awareness of their health (Mielby et al. 2016), indeed there is a wide range of carbonated beverages on the market that meet this condition, which does not imply that it is a surpassed issue, since today one of its greatest challenges focuses on natural drinks such as nectar and juices. Fruit nectar must be free of foreign matter and flavors; its color must be homogeneous; its smell is generally characteristic of the respective fruit, and the sugar content must be at least 10°Brix. However, this does not apply to products sweetened by total or partial substitute; that sugar, that non-caloric sweeteners are used, this percentage will be lower, and this is reflected in the level of acceptance of the product (Escorcia et al. 2019).

In the case of the employee of stevia as a low caloric sweetener, Zaquinaula (2017) developed a cocona nectar evaluating the effect of the concentration of stevia and sucrose on physicochemical and sensory characteristics. However, no notable changes were obtained on the sensory characteristics of the different treatments; the Brix degrees (6.7°Brix) differed significantly. Regarding the sensory profiles of these product products, various studies have shown that nectars and juices containing stevia as a non-caloric sweetener have a high prevalence of bitterness and unpleasant taste. Furthermore, the current demand for antioxidant-rich beverages is expanding simultaneously as that of making products sweetened with natural ingredients; then, Bender et al. (2018) used stevia as a natural sweetener, taking into account their phenolic compounds; developing high-quality berry juices with antioxidants.

Baked or bakery products

Baked products are one of the most popular foods with a high added sugar content. Theoretically, complete elimination of sucrose from baked products is impossible without negatively affecting some aspects of the quality of the final product (Ahmad et al. 2020) since, in addition to providing sweetness, sucrose has other important functions, such as in the structure of the dough, texture, and volume of the product, hygroscopicity.

Sucrose is hygroscopic and competes with gluten to retain water, so it can delay the formation of gluten webs, resulting in a tender texture and slowing the gelatinization of starch, giving the baked product a more porous structure better expansion in volume. Crystallization is another important property that explicitly affects the texture and appearance of cookies and biscuits due to their low water content. Sucrose tends to crystallize when the water content is low, resulting in a crunchy texture and a cracked surface, a desirable feature in many cookies (Luo et al., 2019). Regarding color and aroma properties, sucrose also plays an important role due to its participation in the Maillard reaction and caramelization, providing a pleasant brown bark color and a unique aroma of this product (Ahmad et al. 2020). Therefore, eliminating or replacing sucrose in sweetened baked goods requires prior studies that explore the minimum level of sugar and/or optimal sugar substitutes that must be added to maintain basic functionality (Luo et al. 2019).

Bread is one of the most consumed bakery products in the world and its technology, despite being one of the oldest, has evolved with the application of new ingredients, equipment, and processes (Vigneshwari and Manonmani 2020).

Stevia, as a substitute for sucrose in bakery products, improves the sensorial and nutritional properties of products. Vigneshwari and Manonmani (2020) mention that the total substitution of sucrose with a mixture of stevia and mannitol reduces the speed of fermentation of the dough and the specific volume of bread and improves the nutritional value of bread by reducing the glycemic index and decreasing the energy value of bread. Recently, Góngora Salazar et al. (2018) prepared oatmeal cookies replacing sucrose with aqueous stevia extract in different percentages, evaluated sensory properties such as appearance, taste, smell, and texture, and demonstrated that cookies prepared by replacing 25 and 50% sucrose with stevia extract were the most accepted by judges, presenting a good smell, ideal texture, sweetness, and crunchiness, unlike cookies with 75 and 100%, which showed the lowest level of acceptance. Furthermore, a greater amount of water activity was detected, and with it the possibility of greater development of molds and yeasts, unlike those partially sweetened with stevia, which would be more stable.

Jellified products

The jams and jellies industry has reached important technical levels, and research continues to improve the final product in all aspects, both organoleptic, health, and technological. They are daily consumption products for a large part of the population, so one of the main objectives is to reduce the sugar content (approximately 60% of its formulation). In addition to providing a sweet taste, sugar contributes to the increase in total soluble solids. The interaction with water and hydrocolloids influences the texture transition (gelation), affecting properties such as color, texture, and stability of jam and jelly (di Monaco et al. 2018).

For example, Sutwal et al. (2019) state that the appearance of undesirable attributes such as the appearance and texture of the low-calorie jam is a constant problem with high-intensity sweeteners if a total sugar substitution is done. Thus, to counteract the texture problems that commonly occur due to pectins and the absence of sucrose in the formulations, Márquez et al. (2016) developed a blackberry jam made with sucralose, stevia, and agar-agar as gelling. Against this, no significant differences were found in the texture of the treatments, and it was established that agar-agar could be used as a gelling agent in low-calorie jams, presenting a firmness like a pectin. Therefore, during its preparation, many authors propose adjustments in the formulation, either through the partial substitution of sucrose or the use of alternative ingredients such as hydrocolloids and acid regulators, which allow the gelled product to be much more similar to the original.

Conclusion

Stevia is an important source of high-potency, low-calorie sweeteners and an appropriate nutritional alternative to replace sucrose in food products. Their main compound found in the plant is steviol glycoside, and it is stable at different pH values, non-fermentative, heat resistant, has high solubility (hot or cold water), and stable in aqueous solution.

Stevia could be employed as a total or partial substitute of sucrose, in combination with additives such as bulking agents, gelling agents, stabilizers, flavorings, and flavorings, improving counteract changes in the textural and sensory properties of the final product. Using appropriate combinations of steviol glycosides allows the control of the appearance of unpleasant flavors that affect the quality of the final product, improving the flavor profile of stevia through some structural changes to the steviol glycoside molecules. The trend towards a “clean label” in which easily identifiable components with non-artificial character are used has made the modern consumer give more importance to foods that can promote their well-being and help reduce the risk of disease. Consequently, stevia could be used as a natural sweetener; also, present antioxidant and technological properties such as emulsifier, texturizing agent, and coloring agent, be a good ingredient for developing functional products.

Acknowledgements

This work is part of a research program “Programa nacional de ciencia, tecnología e innovación en ciencias agropecuarias; Project 368-2019 code 110780864755” sponsored by the Administrative Department of Science, Technology, and Innovation (CTeI)—Minciencias (Colombia). The authors are grateful for their financial support.

Authors' contributions

Conceptualization, IPSS, SEQ and LAG-Z; methodology, IPSS, SEQ and LAG-Z; formal analysis, IPSS and LAG-Z; investigation, IPSS resources, SEQ and LAG-Z; writing—original draft preparation, IPSS, SEQ and LAG-Z; writing—review and editing, SEQ and LAG-Z; supervision, LAG-Z; project administration, LAG-Z; funding acquisition, SEQ and LAG-Z. All authors have read and agreed to the published version of the manuscript.

Funding

Project 368-2019 code 110780864755”.

Declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Footnotes

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

References

- Acevedo W, Capitaine C, Rodríguez R, et al. Selecting optimal mixtures of natural sweeteners for carbonated soft drinks through multi-objective decision modeling and sensory validation. J Sens Stud. 2018;33:e12466. doi: 10.1111/JOSS.12466. [DOI] [Google Scholar]

- Ahmad J, Khan I, Blundell R, et al. Stevia rebaudiana Bertoni.: an updated review of its health benefits, industrial applications, and safety. Trends Food Sci Technol. 2020;100:177–189. doi: 10.1016/J.TIFS.2020.04.030. [DOI] [Google Scholar]

- Alsuhaibani AMA, Al-Kuraieef AN. Effect of low-calorie pumpkin jams fortified with soybean on diabetic rats: study of chemical and sensory properties. J Food Qual. 2018 doi: 10.1155/2018/9408715. [DOI] [Google Scholar]

- Bavyko O, Bondarchuk M (2019) Ice-cream with functional properties means commercial networks assortment extension and population feeding improving. undefined

- Bender C, Killermann KV, Rehmann D, Weidlich HH. Effect of Stevia rebaudiana Bert. Addition on the Antioxidant of Red Raspberry (Rubus idaeus L.) Juices. Beverages. 2018;4:52. doi: 10.3390/BEVERAGES4030052. [DOI] [Google Scholar]

- Bursać Kovačević D, Barba FJ, Granato D, et al. Pressurized hot water extraction (PHWE) for the green recovery of bioactive compounds and steviol glycosides from Stevia rebaudiana Bertoni leaves. Food Chem. 2018;254:150–157. doi: 10.1016/J.FOODCHEM.2018.01.192. [DOI] [PubMed] [Google Scholar]

- Carbonell-Capella JM, Buniowska M, Cortes C, et al. Influence of pulsed electric field processing on the quality of fruit juice beverages sweetened with Stevia rebaudiana. Food Bioprod Process. 2017;101:214–222. doi: 10.1016/J.FBP.2016.11.012. [DOI] [Google Scholar]

- Cedeño-Pinos C, Martínez-Tomé M, Murcia MA, et al. Assessment of rosemary (Rosmarinus officinalis L.) extract as antioxidant in jelly candies made with fructan fibres and stevia. Antioxidants. 2020;9:1–16. doi: 10.3390/ANTIOX9121289. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Chupeerach C, Yothakulsiri C, Chamchan R, et al. The effect of coconut jelly with stevia as a natural sweetener on blood glucose, insulin and C-peptide responses in twelve healthy subjects. Recent Pat Food Nutr Agric. 2018;9:127–133. doi: 10.2174/2212798410666180717163852. [DOI] [PubMed] [Google Scholar]

- Ciulu M, Quirantes-Piné R, Spano N, et al. Evaluation of new extraction approaches to obtain phenolic compound-rich extracts from Stevia rebaudiana Bertoni leaves. Ind Crops Prod. 2017;108:106–112. doi: 10.1016/J.INDCROP.2017.06.024. [DOI] [Google Scholar]

- de Medeiros AC, Filho E, Bolini H. Impact of natural and artificial sweeteners compounds in the sensory profile and preference drivers applied to traditional, lactose-free, and vegan frozen desserts of chocolate flavor. J Food Sci. 2019;84:2973–2982. doi: 10.1111/1750-3841.14806. [DOI] [PubMed] [Google Scholar]

- di Monaco R, Miele NA, Cabisidan EK, Cavella S. Strategies to reduce sugars in food. Curr Opin Food Sci. 2018;19:92–97. doi: 10.1016/J.COFS.2018.03.008. [DOI] [Google Scholar]

- Escorcia YMC, Villadiego DB, Vásquez MJC, et al (2019) Caracterización fisicoquímica de un néctar obtenido a partir del yacón (Smallanthus Sonchifolius), pera (Pyrus Communis) y stevia (Stevia Rebaudiana). Rev Colomb Investig Agroind 6:81–94. 10.23850/24220582.1863

- García-Arroyo FE, Tapia E, Muñoz-Jiménez I, et al. Fluid intake restriction concomitant to sweetened beverages hydration induce kidney damage. Oxid Med Cell Longev. 2020 doi: 10.1155/2020/8850266. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Gardana C, Simonetti P. Determination of steviol glycosides in commercial extracts of Stevia rebaudiana and sweeteners by ultra-high performance liquid chromatography Orbitrap mass spectrometry. J Chromatogr A. 2018;1578:8–14. doi: 10.1016/J.CHROMA.2018.09.057. [DOI] [PubMed] [Google Scholar]

- Gençdağ E, Görgüç A, Aylan F, et al. Techno-functional effect of stevia extract substitution on dry fig–fortified ice cream. J Food Process Preserv. 2021;45:e15578. doi: 10.1111/JFPP.15578. [DOI] [Google Scholar]

- Ghanta S, Banerjee A, Poddar A, Chattopadhyay S. Oxidative DNA damage preventive activity and antioxidanantioxidant of Stevia rebaudiana (Bertoni) Bertoni, a natural sweetener. J Agric Food Chem. 2007;55:10962–10967. doi: 10.1021/JF071892Q. [DOI] [PubMed] [Google Scholar]

- Góngora Salazar VA, Vázquez Encalada S, Corona Cruz A, Segura Campos MR. Stevia rebaudiana: a sweetener and potential bioactive ingredient in the development of functional cookies. J Funct Foods. 2018;44:183–190. doi: 10.1016/J.JFF.2018.03.007. [DOI] [Google Scholar]

- Hernández KV, Moreno-Romero J, Hernández de la Torre M, et al. Effect of light intensity on steviol glycosides production in leaves of Stevia rebaudiana plants. Phytochemistry. 2022;194:113027. doi: 10.1016/J.PHYTOCHEM.2021.113027. [DOI] [PubMed] [Google Scholar]

- Hossain MF, Islam MT, Islam MA, Akhtar S. Cultivation and uses of stevia (Stevia rebaudiana Bertoni): a review. Afr J Food Agric Nutr Dev. 2017;17:12745–12757. doi: 10.4314/ajfand.v17i4. [DOI] [Google Scholar]

- Jaimes Tarazona LK, Atencia Berbesi CM, Campo Vera Y, et al. A functional bread designed with rye flour and stevia sweetener: a sensory and microbiological annalysis. Arch Venez Farmacol Ter. 2018;37(2):2018. [Google Scholar]

- Jariyah EMN, Sarofa U. Characteristics and anti-diabetics activity of jelly drink okra mucus (Abelmoschus Escullentus L.) J Phys Conf Ser. 2021;1899:012023. doi: 10.1088/1742-6596/1899/1/012023. [DOI] [Google Scholar]

- Jribi S, Ouhaibi M, Boukhris H, et al. Formulations of low-sugar strawberry jams: quality characterization and acute post-pandrial glycaemic response. J Food Meas Charact. 2020;15:1578–1587. doi: 10.1007/S11694-020-00747-Z. [DOI] [Google Scholar]

- Kalicka D, Znamirowska A, Buniowska M, et al. Polish journal of natural sciences effect of stevia addition on selected properties of yoghurt during refrigerated storage. Pol J Natur Sc. 2017;32:2017. [Google Scholar]

- Kaur G, Goswami TK. Effect of stevia level on chemical, microbiological, and sensory properties of dairy dessert (rasgulla) at different storage periods and temperatures. J Food Process Preserv. 2020;44:e14293. doi: 10.1111/JFPP.14293. [DOI] [Google Scholar]

- Kim S, Kim M, Song Y-B, et al. Development of low calorie roasted radish tea beverage with anti-oxidaantioxidant. Food Sci Biotechnol. 2016;25:113. doi: 10.1007/S10068-016-0107-6. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Korte A, Angelopoulou MV, Maroulakos G (2019) Assessing the effect of low calorie soda beverages on primary tooth enamel: an in vitro study. J Clin Pediatr Dent 43:190–195. 10.17796/1053-4625-43.3.8 [DOI] [PubMed]

- Lemus-Mondaca R, Vega-Gálvez A, Rojas P, et al. Antioxidant, antimicrobial and anti-inflammatory potential of Stevia rebaudiana leaves: effect of different drying methods. J Appl Res Med Aromat Plants. 2018;11:37–46. doi: 10.1016/J.JARMAP.2018.10.003. [DOI] [Google Scholar]

- Li Z, An L, Zhang S, et al. Structural elucidation and immunomodulatory evaluation of a polysaccharide from Stevia rebaudiana leaves. Food Chem. 2021;364:130310. doi: 10.1016/J.FOODCHEM.2021.130310. [DOI] [PubMed] [Google Scholar]

- Lima RS, de Medeiros AC, Bolini HMA. Sucrose replacement: a sensory profile and time-intensity analysis of a tamarind functional beverage with artificial and natural non-nutritive sweeteners. J Sci Food Agric. 2021;101:593–602. doi: 10.1002/JSFA.10671. [DOI] [PubMed] [Google Scholar]

- Luo X, Arcot J, Gill T, et al. A review of food reformulation of baked products to reduce added sugar intake. Trends Food Sci Technol. 2019;86:412–425. doi: 10.1016/J.TIFS.2019.02.051. [DOI] [Google Scholar]

- Mahato DK, Keast R, Liem DG, et al. Optimisation of natural sweeteners for sugar reduction in chocolate flavoured milk and their impact on sensory attributes. Int Dairy J. 2021;115:104922. doi: 10.1016/J.IDAIRYJ.2020.104922. [DOI] [Google Scholar]

- Márquez CJ, Caballero BL, Vanegas Berrouet K. Efecto de edulcorantes no calóricos sobre el desarrollo de mermelada de mora (Rubus glaucus Benth) Temas Agrarios. 2016;21(2):32–39. doi: 10.21897/rta.v21i2.899. [DOI] [Google Scholar]

- Mayangsari AS, Wahyuni LS, Purwadi, Evanuarini H (2019) Characteristic ice cream using stevia (Stevia rebaudiana) leaf powder as natural sweetener. Curr Res Nutr Food Sci 7:600–606. 10.12944/CRNFSJ.7.2.29

- Medeiros AC de, Filho ERT, Bolini HMA (2020) Temporal profile of low calorie lactose-free ice cream chocolate flavor: temporal dominance sensation and multiple time–intensity analysis. J Food Sci Technol 58:3164–3173. 10.1007/S13197-020-04819-2 [DOI] [PMC free article] [PubMed]

- Mielby LH, Andersen BV, Jensen S, et al. Changes in sensory characteristics and their relation with consumers’ liking, wanting and sensory satisfaction: using dietary fibre and lime flavour in Stevia rebaudiana sweetened fruit beverages. Food Res Int. 2016;82:14–21. doi: 10.1016/J.FOODRES.2016.01.010. [DOI] [Google Scholar]

- Muanda FN, Soulimani R, Diop B, Dicko A. Study on chemical composition and biological activities of essential oil and extracts from Stevia rebaudiana Bertoni leaves. LWT Food Sci Technol. 2011;44:1865–1872. doi: 10.1016/J.LWT.2010.12.002. [DOI] [Google Scholar]

- Ozdemir C, Arslaner A, Ozdemir S, Allahyari M. The production of ice cream using stevia as a sweetener. J Food Sci Technol. 2015;52:7545–7548. doi: 10.1007/S13197-015-1784-5. [DOI] [Google Scholar]

- Ozdemir T, Ozcan T. Effect of steviol glycosides as sugar substitute on the probiotic fermentation in milk gels enriched with red beetroot (Beta vulgaris L.) bioactive compounds. LWT. 2020;134:109851. doi: 10.1016/J.LWT.2020.109851. [DOI] [Google Scholar]

- Pacifico S, Piccolella S, Nocera P, et al. New insights into phenol and polyphenol composition of Stevia rebaudiana leaves. J Pharm Biomed Anal. 2019;163:45–57. doi: 10.1016/j.jpba.2018.09.046. [DOI] [PubMed] [Google Scholar]

- Parker MN, Lopetcharat K, Drake MA. Consumer acceptance of natural sweeteners in protein beverages. J Dairy Sci. 2018;101:8875–8889. doi: 10.3168/JDS.2018-14707. [DOI] [PubMed] [Google Scholar]

- Peres J, Esmerino E, da Silva A, et al. Sensory profile, drivers of liking, and influence of information on the acceptance of low-calorie synbiotic and probiotic chocolate ice cream. J Food Sci. 2018;83:1350–1359. doi: 10.1111/1750-3841.14120. [DOI] [PubMed] [Google Scholar]

- Putnik P, Bezuk I, Barba FJ, et al. Sugar reduction: Stevia rebaudiana Bertoni as a natural sweetener. Agri-Food Ind Strat Healthy Diets Sustain. 2020 doi: 10.1016/B978-0-12-817226-1.00005-9. [DOI] [Google Scholar]

- Rana MS, Das PC, Yeasmin F, Islam MN (2020) Effect of polydextrose and stevia on quality characteristics of low-calorie biscuits. Food Res 4:2011–2019. 10.26656/FR.2017.4(6).223

- Reale A, di Renzo T, Russo A, et al. Production of low-calorie apricot nectar sweetened with stevia: impact on qualitative, sensory, and nutritional profiles. Food Sci Nutr. 2020;8:1837–1847. doi: 10.1002/FSN3.1464. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Reyes J, Ludeña F. Evaluación de las características físico-químicas, microbiológicas y sensoriales de un yogur elaborado con sucralosa y estevia. Rev Politéc. 2015;36:16–16. [Google Scholar]

- Ribeiro MN, Rodrigues DM, Rocha RAR, et al. Optimising a stevia mix by mixture design and napping: a case study with high protein plain yoghurt. Int Dairy J. 2020;110:104802. doi: 10.1016/J.IDAIRYJ.2020.104802. [DOI] [Google Scholar]

- Rodríguez A, Magan N, Medina A. Evaluation of the risk of fungal spoilage when substituting sucrose with commercial purified Stevia glycosides in sweetened bakery products. Int J Food Microbiol. 2016;231:42–47. doi: 10.1016/J.IJFOODMICRO.2016.04.031. [DOI] [PubMed] [Google Scholar]

- Rodriguez Furlán LT, Campderrós ME. The combined effects of Stevia and sucralose as sugar substitute and inulin as fat mimetic on the physicochemical properties of sugar-free reduced-fat dairy dessert. Int J Gastron Food Sci. 2017;10:16–23. doi: 10.1016/J.IJGFS.2017.09.002. [DOI] [Google Scholar]

- Saniah K, Samsiah MS, Sharifah Samsiah M. The application of Stevia as sugar substitute in carbonated drinks using response surface methodology (Penggunaan Stevia sebagai pengganti gula di dalam minuman berkarbonat menggunakan Kaedah Gerak Balas Permukaan) J Trop Agric Food Sci. 2012;40:23–34. [Google Scholar]

- Siddique AB, Mizanur Rahman SM, Hossain MA. Chemical composition of essential oil by different extraction methods and fatty acid analysis of the leaves of Stevia Rebaudiana Bertoni. Arab J Chem. 2016;9:S1185–S1189. doi: 10.1016/J.ARABJC.2012.01.004. [DOI] [Google Scholar]

- Sukeaw Samakradhamrongthai R, Jannu T. Effect of stevia, xylitol, and corn syrup in the development of velvet tamarind (Dialium indum L.) chewy candy. Food Chem. 2021;352:129353. doi: 10.1016/J.FOODCHEM.2021.129353. [DOI] [PubMed] [Google Scholar]

- Sutwal R, Dhankhar J, Kindu P, Mehla R (2019) Development of low calorie jam by replacement of sugar with natural sweetener stevia. Int J Cur Res Rev. 10.31782/IJCRR.2019.11402

- Uchiyama H, Nogami S, Katayama K, et al. Jelly containing composite based on α-glucosyl stevia and polyvinylpyrrolidone: improved dissolution property of curcumin. Eur J Pharm Sci off J Eur Feder Pharm Sci. 2018;117:48–54. doi: 10.1016/J.EJPS.2018.02.011. [DOI] [PubMed] [Google Scholar]

- Vásquez EP, Ibarbo JHH, Roa JDA, et al. Edulcorantes naturales utilizados en la elaboración de chocolates. Biotecnol Sect Agropecu Agroind. 2017;15:142–152. doi: 10.18684/BSAA(15)142-152. [DOI] [Google Scholar]

- Vigneshwari K, Manonmani K. Effect of sugar replacer (Stevia and Maltitol) on quality characteristics of bread. Asian J Dairy Food Res. 2020;39:159–163. doi: 10.18805/AJDFR.DR-1531. [DOI] [Google Scholar]

- Wan Z, Khubber S, Dwivedi M, Misra NN. Strategies for lowering the added sugar in yogurts. Food Chem. 2021;344:128573. doi: 10.1016/J.FOODCHEM.2020.128573. [DOI] [PubMed] [Google Scholar]

- Zaidan UH, Mohamad Zen NI, Amran NA, et al. Biochemical evaluation of phenolic compounds and steviol glycoside from Stevia rebaudiana extracts associated with in vitro antidiabetic potential. Biocatal Agric Biotechnol. 2019;18:101049. doi: 10.1016/J.BCAB.2019.101049. [DOI] [Google Scholar]

- Zaquinaula IRA. Características fisicoquímicas y sensoriales del néctar de cocona (Solanum sessiliflorum Dunal) con extracto de stevia (Stevia rebaudiana Bertoni) Rev Cient Pakamuros. 2017;5:15–15. doi: 10.37787/PAKAMUROS-UNJ.V5I1.46. [DOI] [Google Scholar]