Abstract

Globally, the Peruvian squid (Dosidicus gigas) has the highest productivity among squid species. However, due to its high-water content and astringent taste, it has limited fresh food value. This study used Peruvian squid meat as the primary material to prepare thin slices of dried squid meat paper mixed with pork. Here, different proportions (20, 40, 60, 80, and 100%, while 0% as the control group) of squid surimi have used to mix with pork for the meat paper preparation and the changes in physicochemical properties, microstructure, and sensory evaluation were analyzed. The results showed that the total volatile basic nitrogen (TVB-N) contents increased with the storage period, where 20% squid surimi substitution had the lowest TVB-N content. The 20% squid surimi substitution group had the highest expansion rate, the lowest peroxide value (PV), and moisture content. The food-borne microorganisms (E. coli, coliforms, and Salmonella spp.) were within the legal limits or negative. Hardness and crispiness, 20–40% squid surimi substitution were closely similar to the control group. This study has provided an effective investigation of the possibility of expanding the utilization of Peruvian squid resources by combining appropriate squid surimi with minced pork for high-quality thin slices of dried meat paper.

Keywords: Peruvian squid, Thin slices of dried meat, Crispiness, Squid surimi

Introduction

Fresh pork acts as a source of high-quality protein, vitamins, minerals, and trace minerals. But the high moisture content limits its use, especially for prolonged storage (Wang; et al. 2022). Meats comprise several entities such as muscle, connective and fatty tissues which are complex, anisotropic, and composite materials (Lepetit; Culioli 1994). (Wang; et al., 2022). Meat jerky is a snack typically made from whole dried meat slices in a cured (high salt content) form to reduce water activity (WA) and control microbial growth to prolong shelf life (Carolina González-González; et al., 2021; Han; et al., 2021; Kim; et al., 2021a; Kučerová; Marek; Banout, 2018). Traditionally, most consumers prefer a tough, chewy, and mouthfeel texture for meat jerky. Overly challenging textures caused by prolonged drying were not preferred (Kim; et al., 2021a; Konieczny; Stangierski; Kijowski, 2007). Hence, giving the jerky a suitable shelf life while maintaining its WA to preserve its tenderness is a serious issue to be solved in the industry (Han; et al., 2021). The traditional dried pork slice (pork jerky), famous for Chinese families, plays a vital role in the Asian snack market (Hung; et al., 2021). It has been considered the most traditional Chinese product, one of the top 10 must-buy souvenirs in Taiwan. As food processing technology continues to develop, a new type of product, thin slices of dried pork (also known as dried meat scraps), has been designed for its paper-thin, crispy and salty taste. It was obtained by squeezing and blending stringy pork into minced meat and then shaping it into thin slices for roasting and the mouthfeel was more delicate than pork jerky.

As a bulk-caught product, squid has been favored by consumers worldwide for fresh and processed products and occupies a significant position in the international market (Aubourg; et al., 2022). Now, Peruvian squid (Dosidicus gigas, commonly named jumbo squid, giant gun squid) has been an important material in the last decade. Even though its tubes were large and thick fleshy enough with encouragingly high yield potential, the taste was poor (bitter), low elasticity of the gel, and insufficient water holding capacity (Carolina González-González; et al., 2021; Gómez-Guillén; Martínez-Alvarez; Montero, 2003; Jun-hui; et al., 2020). Therefore, it lacks fresh or dried edibility and has been commonly used to process aquatic snacks (Jun-hui; et al., 2020). As the traditional processed products of squid were too monotonous, predominantly frozen and seasoned dry products. Additionally, the volatility of pork prices in the marketplace has been an uncontrollable risk and challenge to enterprises incomes in recent years. Thus, it has been considered necessary the possibility of partial substitution of pork. So far, there has been no work on developing similar products with squid and pork mixtures to prepare traditional meat jerky. Hence, this study aimed to investigate the physicochemical and thermal properties of the interactions to prepare the thin slices of dried meat paper mixed with squid and pork.

Materials and methods

Materials

The frozen giant squid (Dosidicus gigas) fillet (skin-off), imported from Peru, was provided by Jen-Fu Foods Co. (Kaohsiung, Taiwan). It was washed with cold water (2 °C), then hand-cut into 2 cm3 squares, and stored at -20 °C until use. Pork (ground pork, ratio of pork fat to lean meat at 1:9) purchased from local supermarkets and stored at −20 °C until use. The reagents used in this study were all analytical grades purchased from Sigma-Aldrich® (Merck KGaA, Darmstadt, Germany).

Squid surimi preparation

The method was performed with modification according to Priyadarshini et al. (Priyadarshini; et al., 2017). The above squid cubes were thawed and minced using a meat grinder with a 3 mm screen (MG510 Vacuum Genie, Kenwood, Hampshire, UK). Next, ice water was added to the minced squid at a ratio of 4:1 and blended for 5 min with a mixing and kneading machine (KitchenAid, KSM150PSER, Ohio, United States), then left to stand for 5 min. The operation was carried out at room temperature below 18 °C during the process, while the temperature of minced squid-water mixture was kept below 10 °C. The minced squid was obtained by filtration through 4 layers of gauze, then repeated twice the same washing procedure as above, with the only difference that a cold 0.3% (w/v) sodium chloride solution was used for the third time instead of ice water, aimed at promoting the dehydration of the minced squid. Next, excess water was removed from the minced squid with a pressure of 10 kg/cm2 for 15 min. Finally, 4% (w/w) sucrose, 4% (w/w) sorbitol, and 0.3% (w/w) sodium tripolyphosphate (wet weight of squid meat) were added and blended in the mixing and kneading machine for 5 min, and the squid surimi was obtained.

Preparation of different ratios of squid surimi and ground pork

There were 6 groups used in this study; the first group with 100% ground pork was the control group. The remaining 5 groups were added to 20, 40, 60, 80, and 100% squid surimi as a substitution to ground pork. The squid surimi and ground pork were blended with salt in the above ratio for 10 min (every 2 min with 15 s pause to avoid a temperature rise of the sample due to friction), followed by seasoning ingredients such as almond kernels, soy sauce, sugar, and tapioca starch. Each meat group (with squid and pork) was spread out on baking paper and flattened with a stick to a thickness of < 0.01 cm. Then baked in a preheated oven at 160 °C for 20 min. The thin slices of dried mix with squid and pork were cooled and packed in LDPE bags at room temperature (26 °C) and kept in a desiccator for each group until used.

Analysis of total volatile bases nitrogen (TVB-N)

The method described by Chaijan; et al. (2022) has been used with suitable modifications to detect TVB-N in samples. The sample was weighed to 2 g, added 8 mL of 7% trichloroacetic acid (TCA) was, homogenized, and then centrifuged at 8000 × g for 10 min (at 4 °C). Then, 1 mL supernatant was added to the outer ring of Conway's unit, and 1 mL of 10% boric acid absorbent (containing methyl red and bromocresol green as mixed indicators) was added to the inner ring. Next, 1% saturated potassium carbonate solution was added to the outer ring, which was incubated for 90 min at 37 °C. The boric acid absorbent was titrated with 0.02N HCl to change from green to peach. In the control group, 1 mL of 7% TCA was used to replace the sample solution, with the TVB-N content expressed as mg/100 g.

Analysis of thickness and expansion rate (%)

The thickness and expansion rate (%) were measured and calculated according to the method described by Biao; et al. (2019) with minor modifications. In brief, the thickness of each sample was measured randomly at 5 random points using a thickness gauge with an accuracy of ± 0.05 mm. The expansion rate (%) was calculated with the following equation, > 100% was considered expansion; < 100% as shrinkage.

Determination of moisture content and water activity

The method described by the Association of Official Agricultural Chemists (AOAC) (AOAC 2019) has been used to determine the moisture and water activity in the samples.

Analysis of Peroxide value (PV)

The peroxide value has determined according to the method described in the AOAC (2019).

Microbial population assessment by rapid microbiological tests

The rapid microbiological test operation protocol has been performed according to Petrifilm™ (3 M Co., St. Paul, USA). The models were 6405 (E. coli), 6412 (Coliforms), and 6539 (Salmonella spp.). Each bacterial sample was homogenized with a sterile homogenizer, followed by 1 mL of each homogenized sample was injected. The petrifilms were kept at 37.5 ± 1 °C incubator for 48 ± 2 h, and number of colonies were counted.

Determination of hardness and crispness

The method described by Hou et al. (Hou; et al., 2022) has been used to determine the hardness and friability of the samples with appropriate modifications. The samples were replicated 5 times for each group with a sample length and width of 10 × 3 cm. The texture analyzer (Brookfield CT3-1000, Middleboro, USA) was used to determine the maximum force value in the first downward pressure range as hardness. The smaller peak before hardness was shown as crispness. The conditions were set as follows, with a TA-43 probe, all test speeds were 1.0 mm/s, and the load was 5.0 g.

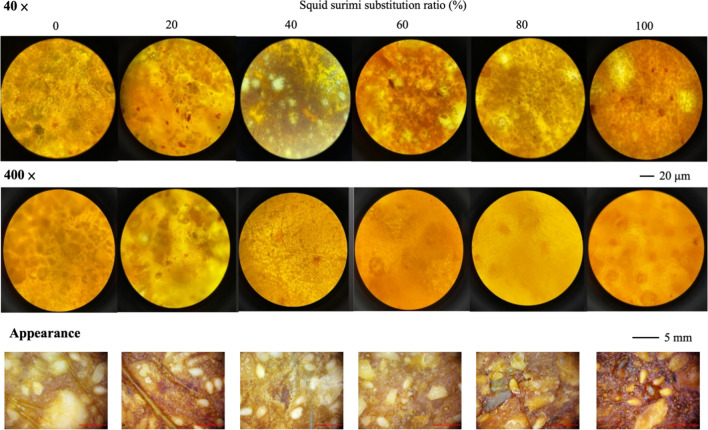

Microstructure of the finished product

The method was performed with modification according to Hou et al. (Ho; et al., 2021). The microstructures of all samples (size 10 × 3 cm2) were observed with an inverted microscope (40 and 400 ×) while photographic records were taken. The difference in the appearance of the samples before and after roasting was recorded by photography using a 20-megapixel digital camera (Cyber-Shot DSC-W810, Sony Co., Tokyo, Japan) in an environment where the light source was natural daylight at 6,500 K.

Sensory evaluation

The sensory evaluation method was carried out with slight modification, as described by Ho et al. (Ho; et al., 2021). In brief, the sensory evaluation of the thin slices of dried meat paper mixed with squid and pork was assessed by 20 experienced panelists. All samples were evaluated for appearance, aroma, taste, texture, and overall acceptability. The evaluation method was performed with a 9-point hedonic scale assessment, where a higher score means a better indicator, in which 1 means weak (unlike), 5 means average (like), and 9 means high (remarkably like) acceptability. For each sample, rinse the mouth with drinking water 3 times before proceeding to the following sample. The room temperature should be kept at 25 ± 2 °C. During the evaluation period, keep the room quiet and avoid noise.

Statistical analysis

All values in this study have been expressed as mean ± standard deviation (SD) and used the One-way ANOVA statistically analyze all data. Correlation coefficients were analyzed by IBM SPSS Statistics (version 20, IBM SPSS Institute Inc., Armonk, New York, USA), with a p-value less than 0.05 that was considered statistically significant. All analyses in this study were performed in triplicates.

Results and discussion

The change of TVB-N content during the storage

In squid, as the freshness decreases, the pH value in the muscle increases. As a result, the skin's pigment starts accumulating, which causes the body surface to appear brownish. Thus, the freshness of squid was judged by the body surface color frequently in the market. The TVB-N contents were an important quality indicator of aquatic product spoilage, attributed to lipid oxidation and bacterial decomposition of nitrogenous compounds and metabolically produced ammonia (Dong; et al., 2013; Lu; et al., 2022). This study showed that the increase in TVB-N contents showed a positive correlation with the ratio of squid meat addition, where the 100% squid meat group was always at the highest TVB-N level compared to the other groups during the stored period yet still within the regulatory limits (Table 1). It was reported that TVB-N content changed with another possible cause attributable to autolysis in fish, where proteases degrade muscle proteins into amino acids and ammonia, carbon dioxide, amines, fatty acids, etc. The autolytic products provide advantageous conditions for bacterial growth (Aubourg; et al., 2022; Niu; et al., 2022).

Table 1.

Variations in the physicochemical properties of thin slices of dried mix with squid and pork

| Detection items | Units | Squid surimi substitution ratio (%) | ||||||

|---|---|---|---|---|---|---|---|---|

| 0 | 20 | 40 | 60 | 80 | 100 | |||

| T-VBN | 0 | 0.66 ± 0.27a | 1.50 ± 0.13ab | 2.32 ± 0.57bc | 2.45 ± 0.44c | 2.77 ± 0.38c | 3.21 ± 0.27c | |

| 7 | mg/100 g | 2.59 ± 0.18e | 1.87 ± 0.37d | 2.90 ± 0.26ef | 2.95 ± 0.26ef | 3.13 ± 0.28ef | 3.26 ± 0.04f | |

| 14 | 2.66 ± 0.60 g | 2.33 ± 0.34 g | 2.97 ± 0.29 g | 3.02 ± 0.17 g | 3.96 ± 0.12 h | 4.47 ± 0.13 h | ||

| Thickness | Before Roasting | mm | 0.68 ± 0.18c | 0.34 ± 0.05a | 0.42 ± 0.18ab | 0.56 ± 0.07bc | 0.53 ± 0.05abc | 0.55 ± 0.22abc |

| After Roasting | 1.54 ± 0.34ab | 1.71 ± 0.07b | 1.58 ± 0.31ab | 1.83 ± 0.05b | 1.47 ± 0.19a | 1.36 ± 0.12a | ||

| Expansion rate | % | 222.99 ± 43.50a | 487.63 ± 46.58c | 486.00 ± 70.00c | 330.48 ± 30.70b | 344.60 ± 83.90b | 313.09 ± 91.10b | |

| moisture content | % | 0.12 ± 0.42a | 0.80 ± 0.42a | 2.16 ± 0.14b | 3.07 ± 0.64c | 4.62 ± 0.64d | 5.69 ± 0.21e | |

| water activity (WA) | 0.3902e | 0.3141c | 0.2393a | 0.292b | 0.4073f | 0.3765d | ||

| Peroxide value (PV) | meq/Kg oil | 3.33 ± 0.21a | 4.06 ± 0.28b | 4.5 ± 0.48c | 5.01 ± 0.3d | 7.19 ± 0.19f | 6.66 ± 0.14e | |

| Escherichia coli | log CFU/g | N.D | N.D | N.D | N.D | N.D | N.D | |

| coliforms | N.D | N.D | N.D | N.D | N.D | N.D | ||

| Salmonella spp. | Negative | Negative | Negative | Negative | Negative | Negative | ||

| Hardness | N | 69.50 ± 049b | 59.50 ± 2.55a | 86.00 ± 0.21c | 108.00 ± 3.04d | 134.00 ± 0.85e | 183.00 ± 1.55f | |

| Crispness | mJ | 0.53 ± 0.0,1a | 0.55 ± 0.01a | 0.80 ± 0.01c | 0.63 ± 0.03b | 1.16 ± 0.02e | 1.50 ± 0.01f | |

Data were means ± SD

Values with different letters are significantly different in the same row (p < 0.05)

N.D. means no detection

Moreover, it has been reported that some bacteria that can degrade proteins lead to spoilage, producing volatile nitrogen compounds (Aubourg; et al., 2022). The same phenomenon was found in this study, where the TVB-N content in the control group of 100% minced pork increased from 0.66 mg/100 g to 2.66 mg/100 g during storage. Therefore, food-borne pathogen detections were organized in this study to clarify the growth of microorganisms. The squid meat gel formed of squid protein formation is relatively weak. This challenge was caused by the high protein hydrolytic activity of endogenous squid enzymes, which rapidly degrade myosin (Aubourg; et al., 2022; Nyaisaba; et al., 2019). In a previous study, the squid has been shown to contain highly active proteolytic enzymes that tend to lead to elevated TVB-N. However, the processed squid in this study required high-temperature roasting, which significantly reduced the water content and inhibited the effect of proteolytic enzymes, which resulted in TVB-N levels within the regulatory limits (Aubourg; et al., 2022).

Interestingly, the three groups with 20, 40, and 60% squid meat had the lowest TVB-N contents during the whole storage period, with significant differences compared to the other groups (p < 0.05). In contrast, 80 and 100% groups were significantly higher than the other groups. Thus, both groups were unsuitable for consideration in the preparation of thin slices of dried meat paper mixed with squid and pork. The increased TVB-N over the storage period indicates a deterioration in the quality of meat products (Kim; et al., 2021a). Hence, this study found that partial substitution of squid meat for minced pork can retard the increase in TVB-N content.

Changes in thickness and expansion rate (%)

The results of the thickness variation and expansion rate of the thin slices of dried meat paper mixed with squid and pork before and after roasting in this study showed (Table 1) that the 20 and 60% squid meat groups had the most increase in thickness, 1.71 and 1.83 mm respectively, which were significantly different from all other groups (p < 0.05). However, 40, 80, and 100% were not far from the thickness of the control group (0%). In terms of expansion rate, all groups showed the effect of expansion. The expansion rates were the highest in the 20 and 40% groups, which was 2.19 folds more elevated than the control group, with a significant difference (p < 0.05).

Moisture content and water activity

Water activity (WA) indicates the number of free water molecules in foods available to growth of microorganisms (Kim; et al., 2021b). Therefore, WA will affect the colonization and metabolic activity of microorganisms in foods. Thus, it can serve as an important factor to inhibit the growth of food-borne microorganisms thus extending the shelf life of foods (Achata; et al., 2021; Carolina González-González; et al., 2021; Kim; et al., 2021a). Traditional methods frequently preserve meat products with dryness; according to the parameters, it can be classified as medium moisture meat (IMM); WA ranges from 0.60 to 0.90 (Kim; et al., 2021a). WA concept has been widely used in food preservation, based on which several processes were adapted, or new products designed (van den Berg 1991).

The results indicate that the moisture content of the thin slices of dried meat paper mixed with squid and pork and the ratio of squid meat substitution were correlated (Table 1). It is worth mentioning that the 20% squid meat group was the lowest (8.00%) moisture content and had a significant difference compared to other groups (p < 0.05). Furthermore, the water content in the control group (1.20%) was lower than that of the 20% squid meat group, with no significant difference. In contrast, an opposite result was observed for WA, with 0.39 and 0.31 for the control and 20% squid meat groups, respectively, with a significant difference (p < 0.05). Notably, 40–100% of squid meat groups had a dose-dependent relationship and significant differences among all groups (p < 0.05). However, there is no linear relationship between moisture content and WA; both indices change synchronously (Bolin 1980).

Peroxide value (PV)

A well-known fact of lipid oxidation causes off-flavors and potentially toxic products that adversely affect the flavor, color, and texture of foods (Priyadarshini; et al., 2021). The PV in food was determined by measuring the peroxide oxygen, which is the primary product of lipid oxidation, which occurred from the attack of oxygen on the double bonds in lipids. Therefore, the measurement of PV in foods illustrates the degree of oxidation of lipids (Mottram 1998). The oxidation of lipids in aquatic products has been partially attributed to Pseudomonas species. It is a psychotropic bacterium that produces lipases and phospholipases, which increase the content of free fatty acids, which readily oxidize to form unstable lipid hydroperoxides (Lu; et al., 2022).

This study found that the PV content was correlated with squid surimi replacement (0–80%), while the PV content of 100% squid meat replacement was lower than 80% (Table 1). Nevertheless, there were significant differences in all groups. It was assumed that the uneven distribution of squid surimi in the samples caused such results. Moreover, the proportion of squid surimi substituted for minced pork was 20–40% (4.06 and 4.50 meq/Kg oil), and the PV value was lower than 60–100% (5.01, 7.19, and 6.66 meq/Kg oil), which was relatively close to that of the 0% group (3.33 meq/Kg oil). Therefore, the better squid surimi addition ratios regarding PV values were 20 and 40%. As previously reported, the PV detection results of this study would be considered low-content within aquatic products. Yet, the peroxide compounds were unstable and susceptible to decomposition and produced low-molecular-weight molecules. Thus, the PV values were, in fact, not a helpful measurement tool in determining food quality (Aubourg; et al., 2022).

The growth of food-borne microorganisms

It is widely known that the growth of microorganisms was affected by water activity, additives, pH values, oxygen, and temperature (Borch; Kant-Muermans; Blixt, 1996). However, the protein-rich content of meat products provides an excellent environment for the growth of food-borne bacteria. Thus, the shelf life of meat products depends closely on the growth of microorganisms (Holley; McKellar, 1996). The foods are dried, the moisture necessary for the growth of microorganisms will be reduced, and their growth will be inhibited. Moreover, moisture is one of the significant contents of meat jerky that affects its texture (Lee; Kang, 2003; Vega-Gálvez; et al., 2011). Meat jerky is a type of intermediate moisture food (IMF) with a moisture content of approximately 20–40% and 0.6–0.9 of WA (Kim; et al., 2021b). It was a popular traditional processed product owing to its long shelf life and serving convenience (Kim; et al., 2022). Most IMF meat products have been stabilized without refrigeration, and its stability has maintained by low WA (Kim; et al., 2021a). In this study, the thin slices of dried meat paper mixed with squid and pork were found to have WA range of 0.292 to 0.40 for the final products (Table 1). The thin slices of dried meat paper mixed with squid and pork showed no microbial growth. After microbiological detection, they were within regulatory limits or negative for all groups, either E. coli, coliform, or Salmonella spp. (Table 1). However, the results of the present study were in agreement with the findings of previous studies also (Torres; et al., 1994).

Hardness and crispiness

Hardness is one of the crucial properties of jerky products, which determines the consumer's acceptance (Han; et al., 2021). Shear value refers to the energy required to simulate the product's bite by the apparatus's teeth. In terms of physical properties, shear value, hardness value, and polyunsaturated fatty acid content were correlated. When the product has higher polyunsaturated fatty acids, it may have a higher shear value. If there are more saturated fatty acids, the shear value will be lower but will get better tenderness, flavor, and overall acceptability in sensory evaluation (Hovenier; Kanis; Verhoeven, 1993). However, there is a close relationship between muscle fibers and tenderness of the meat, as the finer the fibers, the lower the shear value, while the meat would be easier to bite off (Picard; Gagaoua, 2020).

Moreover, apart from the integrity of myofibrillar protein and the muscle connective tissue strength in the meat, the moisture content was the key factor related to the hardness of the uneven texture (Hughes; et al., 2014). It has been reported that water content significantly affects the juiciness and tenderness of beef jerky. However, jerky with high water content will probably have a higher WA, which may compromise shelf life (Han; et al., 2021).

The hardness and crispiness were found to increase with the increasing ratio of squid meat substitution, with significant differences in each group (p < 0.05) (Table 1). The 20% group (59.50 N) had the smallest hardness value, which means it was softer and nearest to the control group (69.50 N). Crispiness (mJ) was also similar in the 20% squid surimi substitution group (0.55 mJ) with an equal value to the control group (0.53 mJ) and significantly different from other groups with various ratios (p < 0.05). It has been reported that muscle myofibrillar proteins were hydrolyzed with bromelain and papain, which have been shown to cause disruption of muscle fiber structure and reduced shear forces, thus promoting soft and tender squid meat (Jun-hui; et al., 2020). Overall, the 20–40% squid surimi substitution rate had suitable hardness and crispness, which might be a candidate for continuous investigations accompanied by proteolytic enzymes.

Microstructure

The drying process involves simultaneous heat and mass transfers, and different drying methods cause various changes in the foods' compositional, physicochemical, and structural properties. The hot air-dried method was widely used for ease of use and economic advantages (Kim; et al., 2021a; Vega-Gálvez; et al., 2011). Thermal transients and humidity variability change the muscle protein conformational stability and degradation within the cellular structure by generating tensile and compressive stresses, which leads to microstructure changes, such as porosity formation (BAI; SUN, 2011; Laopoolkit; Suwannaporn, 2011; Wang; et al., 2013). Vega-Gálvez et al. (Vega-Gálvez; et al., 2011) showed that squid from Peru that had been air dried at 50 °C and 90 °C have significantly degenerated myogenic fibers and myofibrils. The microstructure (Fig. 1, 40 ×) of the thin slices of dried mix with squid and pork products in 0 and 20–100% groups showed a difference. After roasting, 0% group could still clearly see the fibrous tissue of pork, while the 20–100% groups all showed the light white area of squid surimi. The microstructures in Fig. 1 (400 ×) clearly showed the internal structure of each group. As the substitution rate of squid surimi increased, a uniform continuous sheet appeared. Moreover, the network with a compact structure and continuous matrix, moreover, which has similar results compared with the study of Nyaisaba et al. (Nyaisaba; et al., 2019).

Fig. 1.

The microstructures of thin slices of dried mix with squid and pork under the microscope (40, 400 X, and photos of appearance)

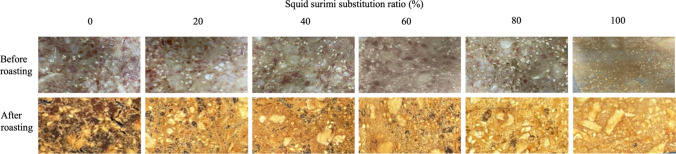

The difference in an appearance before and after roasting

The molecular structure of starch has been loose, and during the heating process of meat-based products, the starch expanded due to water absorption. Some of the unabsorbed swollen starch appeared as particles, which caused light refraction, thereby reducing the whiteness of the products (Tabilo-Munizaga; Barbosa-Cánovas, 2005).

This cloudy white paste occurs caused by the presence of minor fatty acids in the molecular structure of the starch. Regarding the appearance color, the 0% group showed a reddish color before roasting. Post-slaughter number and status of myoglobin, oxymyoglobin and metmyoglobin influenced the color of the meat, where the accumulation of myoglobin was the reaction to the oxidation of myoglobin and oxymyoglobin (Shi; et al., 2021). As the amounts of squid meat substitution increased, the color distribution appeared slightly whiter, and it was due to the light white color of squid surimi. In contrast, the 100% group had a bright white color (Fig. 2).

Fig. 2.

Appearance photographs of thin slices of dried mix with squid and pork before and after roasting

The roasting heat caused a browning reaction of myoglobin, which decreased red coloration (Du; et al., 2021). In addition, heated (at 40–60 °C) induced denaturation of myofibrillar proteins directly influences the structural characteristics of myofibrillar proteins, which the coagulation and contraction of myofibrillar denaturation increase the amount of fibronectin and its resistance to shear forces (Becker; et al., 2016; Shi; et al., 2021; Wang; et al., 2022). The phenomenon gives the meat products hardness and toughness, which include the color of the product's appearance. During the roasting process, the hot air inside the oven caused the rapid evaporation of moisture inside each group to the generation of pressure, which led to the expansion of the sample volume, while the vaporization of surface moisture caused the shrinkage behavior of the surfaces with the mixture of squid surimi and minced pork. The thin slices of dried meat paper with squid and pork products produce a puffy effect and a crispy mouthfeel due to these opposite trends of expansion and contraction.

Sensory evaluation

Sensory evaluation involves the application of scientific and observational methods to measure understanding of the consumers' perception or preference of the product and its characteristics. The application in enterprises can include new product development, product (process or package) improvement, a market survey of consumers, storage stability and quality assurance, etc. From the evaluation results, the control group (0%) scored the highest in appearance, while the 20% squid surimi substitution group scored the highest in aroma, taste, and texture. In contrast, the 100% substitution group showed the highest scores in overall acceptability (Table 2), with significant differences (p < 0.05).

Table 2.

The sensory evaluation results of thin slices of dried mix with squid and pork

| Acceptability | Squid surimi substitution ratio (%) | |||||

|---|---|---|---|---|---|---|

| 0 | 20 | 40 | 60 | 80 | 100 | |

| Appearance | 7.90 ± 0.78a | 7.40 ± 1.42a | 7.05 ± 1.27b | 6.40 ± 1.50b | 6.40 ± 1.29a | 7.61 ± 0.93a |

| Aroma | 7.05 ± 1.70a | 7.20 ± 1.54a | 6.50 ± 1.79b | 6.25 ± 1.61b | 6.78 ± 1.08b | 7.04 ± 1.71a |

| Taste | 6.95 ± 1.54a | 7.40 ± 1.93a | 6.45 ± 1.67b | 6.05 ± 1.70b | 6.95 ± 0.97b | 7.19 ± 1.33a |

| Texture | 7.55 ± 1.05a | 8.00 ± 1.03a | 6.70 ± 1.87b | 5.60 ± 2.41c | 6.15 ± 1.89c | 7.52 ± 1.36b |

| Overall | 7.10 ± 1.17b | 7.15 ± 1.46a | 6.40 ± 1.56b | 5.90 ± 1.55c | 5.84 ± 1.26c | 7.47 ± 0.87a |

Data were means ± SD

Values with different letters are significantly different in the same row (p < 0.05)

Conclusion

In this study, it was found that substitution of 20% squid surimi with pork meat for the preparation of meat paper, the physical properties and the sensory evaluation scores were improved. The results showed that the 20% squid meat substitution group has lowest total volatile basic nitrogen (TVB-N), the highest expansion rate, the lowest peroxide value (PV), and moisture content. The food-borne microorganisms (E. coli, coliforms, and Salmonella spp.) were within the legal limit of food application. Hardness and crispiness of squid surimi substitution were closely similar to the control group. In depth study including shelf-life assessment and cost analysis compared to the meat product has to be performed. This study has showed the possibility of expanding the utilization of Peruvian squid resources by combining squid surimi with minced pork for high-quality meat paper.

Acknowledgements

The authors would like to acknowledge all the individuals who volunteered for this study.

Abbreviations

- WA

Water activity

- TVB-N

Total volatile bases nitrogen

- PV

Peroxide value

- IMF

Intermediate moisture food

Authors' contribution

P.-H.H, C.-Y.H. and S.H.H wrote the manuscript. Y.-T. Q carried out the experiment, analyzed and interpreted the data. C.-Y.H., C.-C.H., and P.-H.H designed the conception of this study. C.-W.H, K.-C.C and J.-Y.C helped interpret the data and participate in writing the manuscript. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Ministry of Science and Technology, the Republic of China (Grant no. 110–2320-B-992 -001-MY3, 111–2622-E-992 -002 – and 111–2221-E-328 -001 -MY3).

Declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have influenced the work reported in this paper.

Ethics approval

Not applicable.

Consent for publication

Consent for publication (appropriate statements regarding publishing an individual’s data or image)-Not applicable.

Consent to participate

Consent to participate (include appropriate consent statements)-Not applicable.

Availability of data and material (data transparency)

All data generated or analysed during this study included in this published article (and its supplementary information files) are available with the corresponding author and will be shared upon reasonable request.

Code availability

Not applicable.

Ethical approval

The authors have reviewed the final version of the manuscript and approved it for publication To the best of our knowledge and belief, this manuscript has not been published in whole or in part nor is it being considered for publication elsewhere.

Footnotes

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Ping-Hsiu Huang and Chih-Yao Hou these authors contributed equally to this work.

Contributor Information

Ping-Hsiu Huang, Email: hugh0530@gmail.com.

Chih-Yao Hou, Email: chihyaohou@gmail.com.

Chang-Wei Hsieh, Email: welson@nchu.edu.tw.

Kuan-Chen Cheng, Email: kccheng@ntu.edu.tw.

Jhih-Ying Ciou, Email: jyciou2010@gmail.com.

Yi-Ting Qiu, Email: F111176103@nkust.edu.tw.

Sulfath Hakkim Hazeena, Email: sh.hazeena14@gmail.com.

References

- Achata, E. M.; Esquerre, C.; Ojha, K. S.; et al. (2021): Development of NIR-HSI and chemometrics process analytical technology for drying of beef jerky. Innovative Food Science & Emerging Technologies 69, 102611. 10.1016/j.ifset.2021.102611.

- AOAC (2019): Official Methods of Analysis, 21st Edition (Oxford University Press).

- Aubourg SP, Trigo M, González MJ, et al. Evolution of lipid damage and volatile amine content in Patagonian squid (Doryteuthis gahi) by-products during frozen storage. Int J Food Sci Technol. 2022;57(8):5409–5418. doi: 10.1111/ijfs.15873. [DOI] [Google Scholar]

- Bai Y-X, Sun B. STUDY OF ELECTROHYDRODYNAMIC (EHD) DRYING TECHNIQUE FOR SHRIMPS. J Food Process Preserv. 2011;35(6):891–897. doi: 10.1111/j.1745-4549.2011.00542.x. [DOI] [Google Scholar]

- Becker A, Boulaaba A, Pingen S, et al. Low temperature cooking of pork meat — Physicochemical and sensory aspects. Meat Sci. 2016;118:82–88. doi: 10.1016/j.meatsci.2016.03.026. [DOI] [PubMed] [Google Scholar]

- Biao, Y.; Yuxuan, C.; Qi, T.; et al. (2019): Enhanced performance and functionality of active edible films by incorporating tea polyphenols into thin calcium alginate hydrogels. Food Hydrocolloids 97, 105197. 10.1016/j.foodhyd.2019.105197.

- Bolin HR. RELATION OF MOISTURE TO WATER ACITIVITY IN PRUNES AND RAISINS. J Food Sci. 1980;45(5):1190–1192. doi: 10.1111/j.1365-2621.1980.tb06518.x. [DOI] [Google Scholar]

- Borch E, Kant-Muermans M-L, Blixt Y. Bacterial spoilage of meat and cured meat products. Int J Food Microbiol. 1996;33(1):103–120. doi: 10.1016/0168-1605(96)01135-X. [DOI] [PubMed] [Google Scholar]

- Carolina González-González, D.; Elena Lugo-Sánchez, M.; Olivia García-Sifuentes, C.; et al. (2021): Influence of pH, ionic strength and isoascorbic acid on the gel-forming ability of Jumbo squid muscle (Dosidicus gigas). Food Chemistry 337, 127993. 10.1016/j.foodchem.2020.127993. [DOI] [PubMed]

- Chaijan, M.; Chaijan, S.; Panya, A.; et al. (2022): Combined effects of prior plasma-activated water soaking and whey protein isolate-ginger extract coating on the cold storage stability of Asian sea bass (Lates calcarifer) steak. Food Control 135, 108787. 10.1016/j.foodcont.2021.108787.

- Dong L, Zhu J, Li X, et al. Effect of tea polyphenols on the physical and chemical characteristics of dried-seasoned squid (Dosidicus gigas) during storage. Food Control. 2013;31(2):586–592. doi: 10.1016/j.foodcont.2012.10.014. [DOI] [Google Scholar]

- Du, X.; Zhao, M.; Pan, N.; et al. (2021): Tracking aggregation behaviour and gel properties induced by structural alterations in myofibrillar protein in mirror carp (Cyprinus carpio) under the synergistic effects of pH and heating. Food Chemistry 362, 130222. 10.1016/j.foodchem.2021.130222. [DOI] [PubMed]

- Gómez-Guillén MC, Martínez-Alvarez O, Montero P. Functional and Thermal Gelation Properties of Squid Mantle Proteins Affected by Chilled and Frozen Storage. J Food Sci. 2003;68(6):1962–1967. doi: 10.1111/j.1365-2621.2003.tb07002.x. [DOI] [Google Scholar]

- Han, G.; Chen, Q.; Xia, X.; et al. (2021): High hydrostatic pressure combined with moisture regulators improves the tenderness and quality of beef jerky. Meat Science 181, 108617. 10.1016/j.meatsci.2021.108617. [DOI] [PubMed]

- Ho H-Y, Ciou J-Y, Qiu Y-T, et al. Improvement of Foaming Characteristics and Stability of Sterilized Liquid Egg with Egg White Hydrolysate (EWH) Foods. 2021;10(6):1326. doi: 10.3390/foods10061326. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Holley RA, McKellar RC. Influence of unsliced delicatessen meat freshness upon bacterial growth in subsequently prepared vacuum packed slices. Int J Food Microbiol. 1996;29(2):297–309. doi: 10.1016/0168-1605(95)00048-8. [DOI] [PubMed] [Google Scholar]

- Hou C-Y, Lin C-M, Patel AK, et al. Development of novel green methods for preparation of lead-free preserved pidan (duck egg) J Food Sci Technol. 2022 doi: 10.1007/s13197-022-05417-0. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Hovenier R, Kanis E, Verhoeven JAM. Repeatability of taste panel tenderness scores and their relationships to objective pig meat quality traits. J Anim Sci. 1993;71(8):2018–2025. doi: 10.2527/1993.7182018x. [DOI] [PubMed] [Google Scholar]

- Hughes JM, Oiseth SK, Purslow PP, et al. A structural approach to understanding the interactions between colour, water-holding capacity and tenderness. Meat Sci. 2014;98(3):520–532. doi: 10.1016/j.meatsci.2014.05.022. [DOI] [PubMed] [Google Scholar]

- Hung, Y.-T.; Lee, Y.-T.; Inbaraj, B. S.; et al. (2021): Analysis and formation of polycyclic aromatic hydrocarbons and cholesterol oxidation products in thin slices of dried pork during processing. Food Chemistry 353, 129474. 10.1016/j.foodchem.2021.129474. [DOI] [PubMed]

- Jun-hui, X.; Hui-juan, C.; Bin, Z.; et al. (2020): The mechanistic effect of bromelain and papain on tenderization in jumbo squid (Dosidicus gigas) muscle. Food Research International 131, 108991. 10.1016/j.foodres.2020.108991. [DOI] [PubMed]

- Kim, S.-M.; Kim, T.-K.; Cha, J. Y.; et al. (2021a): Novel processing technologies for improving quality and storage stability of jerky: A review. LWT 151, 112179. 10.1016/j.lwt.2021.112179.

- Kim S-M, Kim T-K, Kim H-W, et al. Quality Characteristics of Semi-Dried Restructured Jerky Processed Using Super-Heated Steam. Foods. 2021;10(4):762. doi: 10.3390/foods10040762. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Kim, T.-K.; Yong, H. I.; Cha, J. Y.; et al. (2022): Drying-induced restructured jerky analog developed using a combination of edible insect protein and textured vegetable protein. Food Chemistry 373, 131519. 10.1016/j.foodchem.2021.131519. [DOI] [PubMed]

- Konieczny P, Stangierski J, Kijowski J. Physical and chemical characteristics and acceptability of home style beef jerky. Meat Sci. 2007;76(2):253–257. doi: 10.1016/j.meatsci.2006.11.006. [DOI] [PubMed] [Google Scholar]

- Kučerová I, Marek Š, Banout J. Solar Drying and Sensory Attributes of Eland<i> (Taurotragus oryx)</i> Jerky. J Food Qual. 2018;2018:1067672. doi: 10.1155/2018/1067672. [DOI] [Google Scholar]

- Laopoolkit P, Suwannaporn P. Effect of pretreatments and vacuum drying on instant dried pork process optimization. Meat Sci. 2011;88(3):553–558. doi: 10.1016/j.meatsci.2011.02.011. [DOI] [PubMed] [Google Scholar]

- Lee S-W, Kang C-S. Effects of moisture content and drying temperature on the physicochemical properties of ostrich jerky. Food / Nahrung. 2003;47(5):330–333. doi: 10.1002/food.200390076. [DOI] [PubMed] [Google Scholar]

- Lepetit J, Culioli J. Mechanical properties of meat. Meat Sci. 1994;36(1):203–237. doi: 10.1016/0309-1740(94)90042-6. [DOI] [PubMed] [Google Scholar]

- Lu W-C, Chiu C-S, Hsieh C-W, et al. Calcined Oyster Shell Powder as a Natural Preservative for Maintaining Quality of White Shrimp (Litopenaeus vannamei) Biology. 2022;11(2):334. doi: 10.3390/biology11020334. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Mottram DS. Flavour formation in meat and meat products: a review. Food Chem. 1998;62(4):415–424. doi: 10.1016/S0308-8146(98)00076-4. [DOI] [Google Scholar]

- Niu, F.; Ju, M.; Du, Y.; et al. (2022): Changes in properties of nano protein particles (NPP) of fish muscle stored at 4 °C and its application in food quality assessment. LWT 155, 112968. 10.1016/j.lwt.2021.112968.

- Nyaisaba BM, Miao W, Hatab S, et al. Effects of cold atmospheric plasma on squid proteases and gel properties of protein concentrate from squid (Argentinus ilex) mantle. Food Chem. 2019;291:68–76. doi: 10.1016/j.foodchem.2019.04.012. [DOI] [PubMed] [Google Scholar]

- Picard B, Gagaoua M. Muscle Fiber Properties in Cattle and Their Relationships with Meat Qualities: An Overview. J Agric Food Chem. 2020;68(22):6021–6039. doi: 10.1021/acs.jafc.0c02086. [DOI] [PubMed] [Google Scholar]

- Priyadarshini B, Xavier KAM, Nayak BB, et al. Instrumental quality attributes of single washed surimi gels of tilapia: Effect of different washing media. LWT. 2017;86:385–392. doi: 10.1016/j.lwt.2017.08.022. [DOI] [Google Scholar]

- Priyadarshini, M. B.; Xavier, K. A. M.; Dhanabalan, V.; et al. (2021): Development of ready-to-cook shrimp analogue from surimi: Effect of natural plant extracts on the chemical quality during refrigerated storage. LWT 135, 110239. 10.1016/j.lwt.2020.110239.

- Shi, S.; Zhao, M.; Li, Y.; et al. (2021): Effect of hot air gradient drying on quality and appearance of beef jerky. LWT 150, 111974. 10.1016/j.lwt.2021.111974.

- Tabilo-Munizaga G, Barbosa-Cánovas GV. Pressurized and heat-treated surimi gels as affected by potato starch and egg white: microstructure and water-holding capacity. LWT Food Sci Technol. 2005;38(1):47–57. doi: 10.1016/j.lwt.2004.04.013. [DOI] [Google Scholar]

- Torres EAFS, Shimokomaki M, Franco BDGM, et al. Parameters determining the quality of charqui, an intermediate moisture meat product. Meat Sci. 1994;38(2):229–234. doi: 10.1016/0309-1740(94)90112-0. [DOI] [PubMed] [Google Scholar]

- van den Berg, C. (1991): Food-Water Relations: Progress and Integration, Comments and Thoughts. In Water Relationships in Foods: Advances in the 1980s and Trends for the 1990s, Levine, H.; Slade, L., eds. (Boston, MA, Springer US), pp 21–28. [DOI] [PubMed]

- Vega-Gálvez A, Miranda M, Clavería R, et al. Effect of air temperature on drying kinetics and quality characteristics of osmo-treated jumbo squid (Dosidicus gigas) LWT Food Sci Technol. 2011;44(1):16–23. doi: 10.1016/j.lwt.2010.06.012. [DOI] [Google Scholar]

- Wang, H.; Yang, Z.; Yang, H.; et al. (2022): Comparative study on the rheological properties of myofibrillar proteins from different kinds of meat. LWT 153, 112458. 10.1016/j.lwt.2021.112458.

- Wang Y, Zhang M, Mujumdar AS, et al. Quality Changes of Dehydrated Restructured Fish Product from Silver Carp (Hypophthalmichthys molitrix) as Affected by Drying Methods. Food Bioprocess Technol. 2013;6(7):1664–1680. doi: 10.1007/s11947-012-0812-y. [DOI] [Google Scholar]