Abstract

Nano-emulsions are receiving great attention in various industries, especially in the food sector. Peculiar properties of nano-sized droplets and high surface area are most suited for the development and delivery of functional ingredients. Nano-emulsions systems are suitable for encapsulation, protection, improving bioavailability, and target release of sensitive functional compounds. Nano-emulsions have promising potential for the delivery of nutraceuticals, probiotics, flavors, and colors. Nano-emulsions with active ingredients (antimicrobials) have a key part in ensuring food safety, nutrition, and quality of food. Nanoemulsions can also be used for biodegradable coating, packaging, antimicrobial coating, and quality and shelf life enhancement of different foods. The current review includes an overview of nanotechnology nano-emulsions, materials, techniques for formulation & production of nano-emulsions for food and nutrition. Furthermore, the analytical approaches used for the characterization of nano-emulsions and finally, the applications and limitations of nano-emulsions in the food industry are discussed in detail.

Supplementary Information

The online version contains supplementary material available at 10.1007/s13197-022-05387-3.

Keywords: Nanotechnology, Nano-emulsions, Active ingredients, Encapsulation, Bioactive compounds, Coating, Shelf life, Packaging

Introduction

Nanoemulsions have revolutionized the world of functional food development by providing new perspectives on nutrient encapsulation (Kumar et al. 2018). Food products have healthpromotion or preventive properties in addition to their nutritional content. Research studies suggested that the health-promoting potential of food items is attributable to the synergy or interactions of bioactive molecules and other key nutrients found in food products (Alshahrani et al. 2022). Moreover, due to low bioavailability long-term stability, these bioactive compounds may not be enough to retain their effects. As a result, nanotechnology in food applications has attracted a lot of attention in recent periods. One of the most innovative techniques for functional ingredients delivery in food products is nanoemulsions. The bioavailability of incorporated bioactive components are improved by nanoemulsion-based delivery technologies, which also enhance food stability (Tripathi et al. 2021; Salem et al. 2019). Nanoemulsions in foods are progressively improved digestibility, encapsulation efficiency, and bioavailability (McClements et al. 2011). Nanoemulsions are more effective as compared to other techniques. Stabilizers such as emulsifiers, maturation retarders, weighing agents, and texture regulators may enhance the kinetic durability of nanoemulsions. Plasticizers applied on different food products may include tiny particles of surfactants (Tweens and Spans), amphiphilic carbohydrates (resin Arabic and improved starch), phospholipids (soybean, eggs, and dairy lecithin’s), and amphiphilic polypeptides (casein or whey protein extract) (Wilson et al. 2021; Gupta et al. 2016). The emulsions are categorized as macroemulsions, microemulsions, and nanoemulsions depending on the dimension and constancy of their droplets. The emulsions having a coarser texture are referred to as macro-emulsions or ordinary emulsions. Emulsions are thermally metastable and have a granular size range of > 200 nm. Emulsions deteriorated over time due to a variety of destabilizing processes (Ahmed & Ramalingam, 2022). Traditional emulsions are visually turbid because the droplet diameter is proportional to the wavelength of sunlight, scattering the incident light and making it appear opaque (Saifullah et al. 2016). The selection of surfactants in nanoemulsions is crucial since emulsifiers must quickly occupy many new sites that are formed. Monoglycerides and other comparatively tiny surfactants such as sugarcane esters, proteins, and altered starches are macromolecular emulsifiers, are commonly utilized in food emulsions. To improve antibacterial activity by enhancing essential oil (EO) bioavailability in the aqueous solution, 25 EOs must be linked or mixed with surfactants. Tween 80 offers a good blend of hydrophilic or lipophilic properties. Tween 80 is a non-ionic emulsion stabilizer that works through stearic stabilization (Amaral et al. 2015). Green tea leaf contains epigallocatechin gallate, a hydrophilic flavanol. Inside the intestine, this flavanol is vulnerable to oxidation. Emulsion methods can be utilized to boost bioavailability and stability. Encapsulation not only improves Epigallocatechin gallate (EGCG) bioavailability throughout the body but also improves bioactivity within the emulsion matrix (Ru et al. 2010). Dynamic light dispersion, zeta potential, thermal stability tests, pH, refractive index, and the thickness could all be used to describe a nano-emulsion based delivery method. The size distribution profile of components in nanoemulsions is determined by dynamic light dispersion, as well as the zeta potential shows emulsion persistence (Ma et al. 2016). To determine particle size and nanoparticle dispersion, imaging methods such as transmissions electron-microscope, scanning-electron microscope, and atomic force microscope are utilized. Nanotechnology is a novel technique that has the ability to alter the food sector forever (Silva et al. 2012). Nanotechnology is the study, development, and regulation of objects with sizes of 1–100 nm. Functional chemicals and active substances, such as antioxidants and nutraceuticals, can be encapsulated using nanoemulsions. Emulsions are also beneficial for releasing taste ingredients in foodstuffs in a controlled manner (Aswathanarayan et al. 2019). Foods such as meats, dairy items, fresh produce, fresh cuts, confectionaries, can be coated with nano-emulsion-based eatable nano-coatings comprising of flavor and coloring additives, anti-oxidants, enzymes, antimicrobial compounds, and anti-browning agents to extend their life span. Nano-emulsion coverings can also decrease humidity and gas exchange, as well as food oxidation and water loss (Galus et al. 2015). The utilization of nanoemulsions within the food industry provides commercial, technological, and scientific benefits (Quintanilla-Carvajal et al. 2010; Nguyen et al. 2016). The focus of this study is on new advancements in the formulation, characterization, and utilization of nanoemulsions in the food sector for more sustained food manufacturing including packaging.

Emulsions

Emulsions are suspensions comprised of two immiscible liquid stages that are mixed with the help of mechanical shears and surfactants. Because the component size of this traditional emulsion expands with duration, separation eventually happens due to gravitational force, making these emulsions thermally unstable (kale et al. 2017). The concept of emulsification is based on surface tensions theory, emulsifiers decrease the surface tensions between the two non-miscible fluids, lowering the repellent force between the two fluids thus decreasing the adhesion between components of the same fluid. The theory of the oriented wedge implies that the emulsifying agents generate monomolecular coatings that are bent around the droplets of the emulsion's internal phase. A few emulsifying agents, position themselves in the fluid molecule in a way that reflects their solubility in that particular liquid.

Single emulsions

It is water in oil emulsions and oil in water emulsions. A single-step technique is used to make it. In this case, a single surfactant is utilized in conjunction with immiscible fluids that act as a surface emulsifying coating between these double layers. Water droplets are distributed in-water-in-oil emulsion, whereas oil particles are distributed in a water solution with the other (Naseema et al. 2020).

Double emulsions

Such emulsions are (water–oil-water) or (oil–water-oil). It is formed in 2 steps, with one hydrophobic surfactants were employed to stabilize the surface and another hydrophilic surfactant utilized to stabilize the oil globule interfaces. The oil/water emulsion is disseminated in the oil phase of o/w/o emulsions. High shear procedures are utilized to develop the primary oil in water, whereas low shear techniques are used to preserve the interior droplets from rupturing (Garti and Aserin 2018).

Materials utilized in the production of nano-emulsions

Solvents

Several of the procedures recorded above are solvent-dependent, and these solvents are essential for the generation of nanoemulsions. The most commonly utilized solvents, a few of them are not foodstuff level or commonly considered as nontoxic, if are not generally recognized by customers, this being a problem which requires to be addressed. Solvents such as n-hexane and others can thus be substituted with alternatives such as sunflower oil, MCTs, and so on.

Surfactants

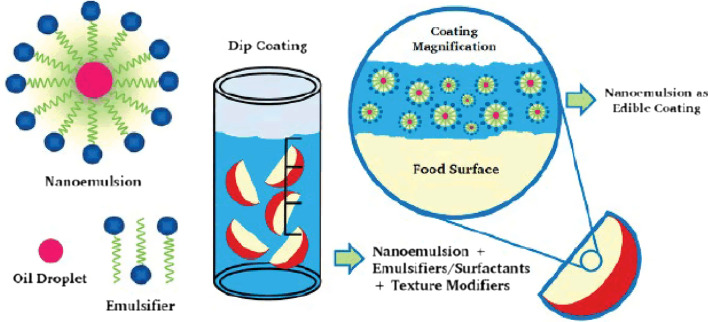

Numerous physical parameters can influence or disrupt the constancy of emulsion particles, as well as their properties as beneficial component carriers. As a result, emulsion stabilization is critical to deliver superior kinetic and thermal stability, more effective encapsulation of functional chemicals, and improved bioavailability compared to typical emulsions (Grigoriev and Miller 2009). Stabilizer absorption at the surface with both particles and the dispersion medium, which reduces surface tension, is the most popular approach to stabilize emulsions. Utilization of composite coating (nano-emulsion + surfactants) by dipping method as shown in Fig. 1.

Fig. 1.

Edible coating and nanoemulsion.

Source: Zambrano-Zaragoza et al. (2018)

Various methods are also employed in the food industry where surfactants are added to increase the quality of food products. Ionic surfactants can give emulsion droplets an electrical charge, while non-ionic surfactants can create a steric barrier by directing immense molecule groups toward dispersion solutions. Surfactants have a wide range of applications in the food sector but due to their harmful impact on human health industry is looking towards bioactive compounds.

Functional compounds

Because of growing interest in the use of bioactive compounds for preserving the quality and safety of the product food sector focus on their utilization, due to their acquired health and environmental advantages. Nowadays plants and animal-based bioactive compounds are typically used in emulsion-based coatings like fatty acids (e.g., omega three fatty acids), xanthophyll (e.g., beta carotenes), anti-oxidants (e.g., alpha-tocopherol), that must be needed in the diet regularly. Essential oils (EO) from plants such as oregano, thyme, and orange, as well as their constituents have potent antibacterial action against food-borne infections. However, because of their hydrophobicity, their applicability in the food matrix is limited. Essential oil nanoemulsion formulations can be used in foods as food preservatives as well as in food packaging to address this issue. (Acevedo-Fani et al. 2015). Nanoemulsions potentially encapsulate bioactive components which not only enhance the product quality but also enhance the flavoring, antimicrobials, antioxidants, and medicinal properties (McClements et al. 2009).

Novel nano-emulsion preparation techniques

Nano-emulsion is a non-equilibrium process that requires an external or internal energy supply to form appropriately. Nanoemulsions could be made in a range of ways, each of which could be classed as high and low energy (Salem et al. 2019). The nano-emulsion manufacturing methods used have an important impact on atom size and, as a consequence, on the emulsion system’s stability procedures via operating circumstances and composition. Nanoemulsions are typically prepared with lower surfactant contents (5–10%) than micro-emulsions (20 percent and greater) (Sarheed et al. 2020). This part gives a quick summary of the most frequently utilized both high and low-energy nano-emulsion generation techniques (Table 1).

Table 1.

Solvents utilized in the manufacturing of nanoemulsions, as well as their functional ingredients and classification

| Solvents | Foods containing it are permitted | Maximum values that can be used (ppm) | Compounds with functional properties | References |

|---|---|---|---|---|

| n-Hexane | Yes | 50 | Beta-carotene | Ee et al. (2008) |

| Ethyl acetate | Yes | 50 | – | Lee et al. (2010) |

| Acetone | Yes | 50 | β-carotene | Yin et al. (2009) |

| MCT | Yes | – | β-carotene | Wulff-Pérez et al. (2009) |

| Milk fat that is high in stearin | Yes | – | α-tocopherol | Relkin et al. (2008) |

| Corn oil | Yes | – | – | Lee et al. (2010) |

| Ethanol | Yes | – | β-carotene | Pan et al., 2007 |

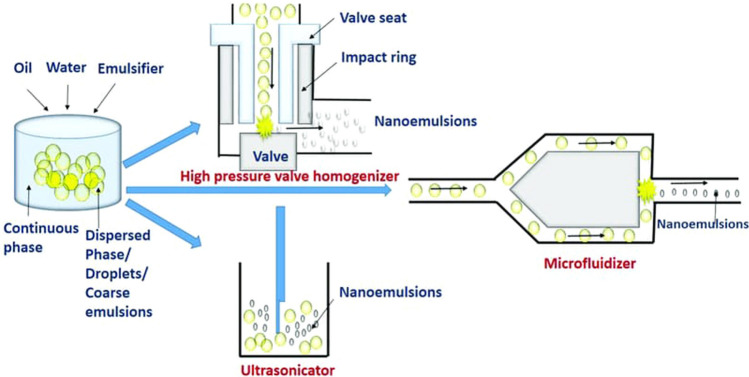

High energy methods

Mechanical equipment like high-pressure valves homogenizers, micro fluidizers, and ultrasonicators are used in high-energy procedures. These instruments are used to generate a strong disruptive force to disperse phase nanoemulsions into small droplets (Table 2).

Table 2.

Major stabilizers (surfactants) used in food industry

| Stabilizing agent | Compound | Concentration | References |

|---|---|---|---|

| Emulsifier (Non-ionic surfactant) | Lecithin (Phospholipid) and Tween 80 | Tween 80 at 2 wt% with the aqueous phase and lecithin at 1 wt% with the oil phase | Tan et al. (2016) |

| Lecithin and Tween 80 | 0.3 molar ratio of lecithin to tween 80 | Kumar et al. (2017) | |

| Tween 20 and Span 80 | 1 wt% Tween 20 and aqueous phases | Alexandre et al. (2016a, b) | |

| Tween 80 and Span 80 | Tween 80 has a 1.25 percent aqueous phase while Span 80 has a 3.75 percent oil phase | Dammak et al. (2017) | |

| Emulsifier (Anionic) | Sodium dodecyl sulfate | with an aqueous phase of 2.5 wt% | Qian et al. (2011) |

| Emulsifier (Amphiphilic) | Whey protein isolate | With a 4 wt% aqueous phase | Hebishy et al. (2015) |

| Plasticizer | Glycerol | 0.3 glycerol/biopolymer ratio while blending Nano-emulsion and biopolymer | Alexandre et al. (2016a, b) |

| Ripening retardant | Sodium chloride | W/O/W inner emulsion mixed with aqueous phase at 0.5 weight percent | Schuch et al. (2014) |

| Texture modifier | Sodium alginate | Addition at 1% before coarse emulsion creation using an Ultra-Turrax homogenizer at 11,000 revolution per minute for two minutes at ambient temperature | Artiga-Artiga et al. (2017) |

High-pressure homogenizers

A progressive dislodgment pump, pressure release valve, and homogenization and interface tanks are utilized in the (HPVH) process. The sucking stroke of the pump draws the coarse emulsion into the homogenization tank. A simple perforated plate, collision plane, and radial diffuser assembly can be used as the homogenization tank. The rough emulsion is pressed out via a minute aperture of micrometric diameter by a homogenizer valve under the pressure of up to 300 MPa created in the chamber during the distribution phase (Maali et al. 2013). Emulsification happens in two stages during high-pressure homogenization. In the homogenization chamber, disruption of the dispersed phase leads to the creation of minute droplets with enhanced surface area. The inclusion of emulsifier particles and their imbibition on the newly created interfaces leads the droplets in the interaction container to stabilize in the second stage. The formation of a greater number of small droplets arises from repeated disruptions and stabilization (Liu et al. 2019). Nano-emulsions of carvacrol, mandarin, bergamot, and lemon were made using a high-pressure homogenization process. To create nanoemulsions of 133 to 200 nm, basic emulsions of vital oils were treated to 5 sequences of high-pressure homogenization at 200 Mega Pascal. Carvacrol nano-emulsions were found to have substantial growth prohibiting action versus E. coli O157:H7 and Salmonella typhimurium (Shariffa et al. 2017). To create a bioactive film, carvacrol nano-emulsion was mixed with improved chitosan. Green beans kept at 4 °C had a storage life of approximately 13 days after using them. High-pressure homogenization (400 to 800 bar) was used to create oil–water nano-emulsions of jackfruit paste isolate abundant in carotenoids. The nano-emulsion was stabilized by the sucrose monostearate emulsifier, and its antioxidant action was more stable after storage at 4 °C. At 800 bar, nanoemulsions of great stability were created (Ruiz-Montañez et al. 2017). Nano-emulsion preserved the antioxidant ability of a jackfruit pulp extract. Due to the short retention duration (3 to 40 ms), recent investigations have demonstrated that no thermal deterioration occurs in valves (Håkansson et al. 2019).

Ultrasonication

This is one of the most effective small-scale processes for producing nanoemulsions. Because the waves have a strong influence on the molecules nearby, this cannot be performed on a big scale. The excitation of molecules caused by sound waves is the mechanism behind it. Two mechanisms have been postulated. The first is that the generation of the sonic wave which aids in the distribution of oil in the water phase (Kentish et al. 2008). An ultrasonic container with an ultrasonic probe makes up the apparatus. The ultrasonic probe, disruptive forces, together with cavities, agitation, and surface waves, transform rough emulsions within the ultrasonic tank into fine nanoemulsions (Nakabayashi et al. 2011). Nanoemulsions generated from flax seeds oil and the nonionic stabilizers (Tween 40) were found to have a droplet radius of less than 70 nm when prepared using high-intensity ultrasonication. Nanoemulsions with a particle radius of 20 nm have also been created using high-intensity ultrasound. Grade emulsifiers like sunflower oil, Tween 80, and Span 80 were used to make them. Nanoemulsions having a droplet width of 29.3 nm were created by increasing the ultrasonication period and decreasing the surfactant content (Ghosh et al. 2013).

Micro-fluidization

This strategy is more effective than the others. Nanoemulsions are generated by using this technique because of high shear strains within the micro-fluidizer. The Y-type fluidizer is the most prevalent. There are numerous patented varieties as well. The coarse emulsion jets were permitted to strike with one another at elevated pressure (about 40,000 psi/ 270 Mpa) in this method (Ganesan et al. 2018). The raw emulsion jets collide and merge in the Y type. The trim pressure produced was related to the jets’ pressure as well as velocity. It was found that the pressure influenced the particle diameter; the higher the pressure, the smaller will be the drop size (Serdaroğlu et al. 2015). Sample velocities approached 400 m/sec, and channel diameters ranged from 50 to 300 µm. Shear rates of up to 10,000,000/sec are possible. Scientists have shown that by utilizing a micro fluidizer, Nano-emulsions of silicon oil as tiny as 50 nm may be generated and stabilized utilizing SDS as the detergents. (Acevedo-Fani et al. 2015) Micro-fluidization was used to create a nano-emulsion of ginger crucial oil. Ginger crucial oil nano-emulsion was used to activate edible coatings fortified with montmorillonite. Nanoemulsions were added to montmorillonite coatings, which increased their properties and antioxidant properties. The addition of montmorillonite with nano-emulsion to gelatin-based coatings boosted their thickness while lowering their water solubility, moisture level, and surface hydrophobicity (Alexandre et al. 2016a, b). Whey protein extract and quillaja saponin were much more successful from gum arabic but also soy lecithin for producing nanoemulsions of fine particles by using this method. Smaller particles were created with a tiny amount of emulsifier (Bai et al. 2016). Increased droplets size as a consequence of coalescence because of prolonged emulsification time, but the application of high pressure raises nanoemulsions' temperature are two drawbacks of micro-fluidization techniques. However, as compared to other homogenization processes, the micro-fluidization method's effectiveness of droplet disruption is high, resulting in the creation of small droplets of homogeneous size.

High-speed devices

When collating to other high-energy approaches, rotor/stator devices (like Ultra-Turrax) do not give appropriate droplets size dispersion. The effectiveness of such equipment was calculated to be 0.1 percent, with 99.9 percent of energy delivered being lost as a source of heat during the homogenization activity, resulting in the majority of the energy supplied being wasted as heat, creating heat (Tadros et al. 2004).

Low energy methods

Low-energy techniques depend upon the chemical action of the constituents to provide energy to nanoemulsions. By carefully mixing the ingredients, nanoemulsions develop automatically at the oil–water phase surface. Phase inversion temperature (PIT), phase inversion composition (PIC), as well as solvent dispersion technique are low-energy technologies used in nano-emulsion synthesis. These methods generate very little energy and so protect heat-labile substances from degrading (Anton and Vandamme 2009).

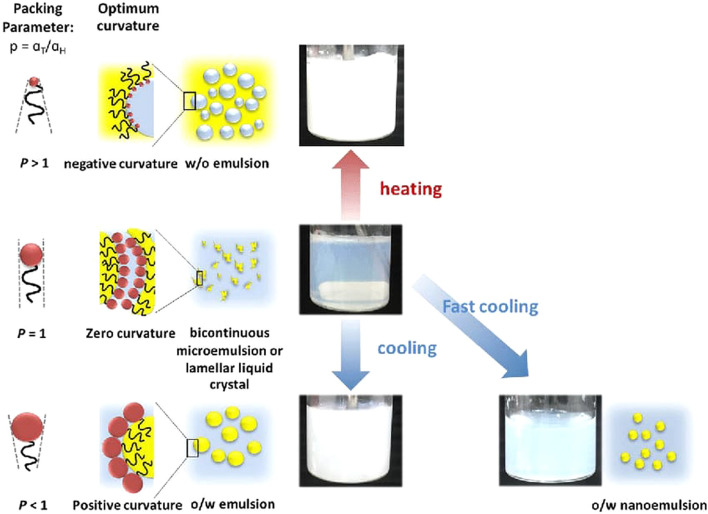

Phase inversion temperature

Chemical energy generated from phase changes occurring during emulsification is used to achieve fine dispersion in this approach. By altering the concentration at persistent temperature or altering the temperature at a fixed concentration, adequate phase changes can be achieved. The (PIT) approach is established on temperature-dependent variations in the dissolving ability of polyoxyethylene-type surfactants (Izquierdo et al. 2002). The dehydration of the polymer chain enables these surfactants to become more lipophilic as the temperature rises. The surfactants monolayer, on the other hand, has a significant positive spontaneous curve at low temperatures, generating an oil-swollen micellar solution stage. Particle sizes in the sub-micrometer category are often manufactured with high energy input. Ultrasound devices or high shear agitation are used to accomplish this (Morales et al. 2003). If an anionic surfactant is utilized, the impulsive curvature of droplets could be altered by varying the system's temperature, e.g., raising the temperature like oil-in-water emulsion preserved it at low-temperature to establish a water-in-oil emulsion (accomplished by the addition of water). Transitional phase inversion is the term used for this. The system overcomes a zone of zero involuntary curvature and negligible surface tension during cooling the hot emulsion, assisting in the creation of finely distributed oil particles. This is referred to as phase inversion. The pre-emulsion is heated at its (hydrophilic-lipophilic) temperature and later cooled to ambient temperature in the first stage. The cooling rate affects the emulsion’s clarity and stability. This can be accomplished by using more surfactants than is necessary. As a result, the technique is prohibitively expensive and thus unsuitable for industrial use (Santana et al. 2013). Different methods used for nanoemulsion preparation were described in Fig. 2.

Fig. 2.

Different methods used for nanoemulsion preparation.

Source: Aswathanarayan and Vittal (2019)

Phase inversion composition

The hydrophilic and lipophilic behavior of the emulsifier is modified by altering the ingredient concentration in this approach. The electric charges of the surfactant alter when salt is added to a nano-emulsion of oil in water having an ionic emulsifier, and the solution becomes a water-in-oil emulsion process. Similarly, a large water emulsion could be changed to oil in water by dilution with the use of water (Liew et al. 2010). This method is inexpensive, does not need the application of organic solvents, and therefore is thermodynamically stable. Nanoemulsions that are safe to eat supplemented by acetate of vitamin E with a standard particle size of 40 nano-meter were prepared using the phase inversion compositions technique. This process proved more efficient than micro-fluidization in creating nanoemulsions with high surfactants concentration (Shakeel et al. 2009). Mechanism of phase inversion are shown in Fig. 3

Fig. 3.

Flow diagram of phase inversion temperature (PIT) technique for prepartion of nano-emulsion

Source: Jintapattanakit (2018)

Spontaneous emulsification

Low-energy nano-emulsion formation is achieved through spontaneous emulsification. This approach is created at ambient temperature and does not necessitate the use of any additional equipment. Bit by bit, at a constant temperature, pour water into the oil and surfactant solution, stirring moderately to generate nanoemulsions on O/W. The phase alteration region, surfactant content and structure, surface and huge stickiness, and surface tension all influence the spontaneous of the emulsification mechanism. The lack of oil phase and the existence of a solvent are the method's limitations (Subasi et al. 2017). Vitamin E acetate nanoemulsions with droplet size less than 50 nm and low poly-disparity values were created using the spontaneous emulsification technique. Furthermore, the technique of spontaneous emulsification has been utilized to create vitamin D nanoemulsions. Applying a co-surfactant during the formation enhanced the thermal lifetime of the nano-emulsions (Guttoff et al. 2015). Fish oil nanoemulsions, which are high in omega-3 fatty acids, were made by spontaneous emulsification. It was possible to make translucent nanoemulsions with structural constancy of about 37 °C and oxidative durability at 55 °C for fourteen days (Walker et al. 2015). The influence of low- and high-energy techniques on nanodispersions physicochemical qualities has been studied.

Solvent displacement

The generation of nanoemulsions is aided by the fast dispersion of an organic solvent that is water-miscible containing a lipophilic functional chemical into the aquatic layer. This quick diffusion allows for one-step manufacturing of nano-emulsion with a good yield of encapsulation at lesser energy input. Finally, the organic liquid under vacuum vaporized from the nano-dispersion. Therefore, this method can only be used with water-miscible solvents (Yin et al. 2009).

Emulsion inversion point

This process involves altering the system's makeup while maintaining a steady temperature. The particles are generated through a gradual use of water as a diluent as well as oil to generate kinetically persistent nanoemulsions. The transfer from W/O into O/W or vise-versa in EIP techniques requires a disastrous phase inversion instead of a PIC or PIT technique (Thakur et al. 2008). When the properties of a surfactant are modified by modifying one of the form factors, like temperature, pH, or ionic activity, a transitional-phase inversion develops.

Methods of characterization

Nanodelivery systems are used for recognition, identification, including characterization, are critical for evaluating the advantages as well as the possible hazard of these methods (Luykx et al. 2008). The analytical approaches that could be utilized for the physical depiction of nanoemulsions (e.g., zeta potential, nuclear magnetic resonance, x-ray diffraction, FTIR, DSC) are discussed in this article.

Dynamic light scattering

DLS also referred to as photon correspondence spectroscopy or virtual elastic light dispersion is a method utilized for determining the diameter distributions profile of microscopic droplets in solution or polymers in suspension in a short amount of time. DLS monitors Brownian motion as well as employs the Stokes–Einstein formula to relate it to particle diameter. DLS enables the particle size to be calculated by illuminating them by a laser and evaluating the intensity variations in the dispersed light (Silva et al. 2011).

Zeta potential

Electro-kinetic capacity in dispersion processes is referred to as zeta potential in science. The zeta potential is defined as the potential distinction between the distribution medium and static layer of fluid connected to the scattered particles in colloidal chemistry research. The random amount of 30 mili volt (positive and negative) could be used to distinguish low-charged materials from extremely charged ones (Preetz et al. 2010). A strong zeta potential provides stability to molecules and particles of sufficient size, i.e., the solution or distribution will oppose accumulation. At low potential, attraction overcomes repulsion, causing the dispersion to split and flocculate. Colloids having a significant zeta potential (negative or positive) are electrically stable, whereas those having a lower zeta potential agglomerate or flocculate. In a summary, zeta potentials suggest instability, whereas those greater than ± 30 mV show stability (Araújo et al. 2010).

Differential scanning calorimeter

The distinction in the quantity of heat needed to raise the sample's temperature and references are evaluated as a role of temperature in DSC which is a thermos analytical method. During the experimentation process, the samples and references are kept approximately at the same temperature. The temperatures program for a DSC study is usually set up so that the specimen holder temperature rises gradually as time passes. Above the temperature range be scanned, the references samples would have a well-defined heat potential (Venturini et al. 2011).

Fourier transform infrared

FTIR spectroscopy is dependent on infrared rays crossing through a material, most of which is absorbed but some of which is transmitted. The generated spectrum depicts the molecule absorption and propagation resulting in a molecule fingerprint. Each specimen fingerprint has its own set of absorption peaks, which correlate to the incidence of oscillations among the bonds of the molecule's atoms. Since each molecule is made up of a particular set of atoms, no two substances have an identical infrared spectrum. As a result, infrared spectroscopy may be used positively to identify various materials. Furthermore, the magnitude of the peaks in the spectrum indicates the amount of material contained in the sample. The ability to detect the number of components in a combination, the characteristic or stability of a sample, and thus the short time needed for analysis all are the key benefits of FTIR (Araújo et al. 2011). The crystallization mechanism of thalidomide in nanoemulsions was analyzed using FTIR examination of the crystals; when contained within a nano-emulsion, these crystals were observed to be in a distinct polymorphic state than before nano-emulsion generation.

X-ray diffraction

XRD methods are a group of non-analytical methods for revealing details about the molecule's crystallographic structure, chemical content, and physical characteristics. The scattering intensity of X-ray beams striking material is measured as a consequence of incident and dispersed angles, polarization, and wavelengths or energies in XRD. The scattering pattern of crystalline substances is used to identify them using XRD. Despite this, it covers a wide range of applications; Characterization of single-phase substances, particle structure identification, sample attribution, and structural analysis, confirmation of amorphous substances in slightly crystalline mixtures, crystallite diameter identification from high point expansion, crystallite shape recognition from peak symmetry assessment, and analysis of thermal enlargement in crystal structures utilizing a situ heating phase apparatus (Mulik et al. 2010). Curcumin's scattering pattern differs greatly from that of nanoparticles of solid lipids coated with curcumin, according to the study.

Nuclear magnetic resonance

NMR is an advanced and sophisticated analytical method that may be used to examine molecules in liquid or solid form and can be used for both quantitative and structural research. It is extremely effective at collecting structural data on molecular fragments. It can be used in conjunction with optical spectroscopy and mass-spectrometry to obtain accurate data regarding the structural formula, stereochemistry, and preferred configuration of molecules; it could also be used to recognize the substance under investigation. The utilization of NMR to the characterization of nanoemulsions has been utilized. The composition of the liquid lipids within the mixture of nanoparticles of solid lipids was described using 1H NMR following successfully incorporated medium-chain triglycerides oil in a mixture of a glyceryl behenate (solid long-chain glyceride).

Application of nano-emulsion in food

Vitamins are incorporated and efficiently delivered in the bloodstream through the digestive system. Nanoparticles are used in the preparation of foods and beverages without compromising their properties or flavor. Nanoemulsions have also been utilized to improve the consistency and texture of ice cream (Zeng et al. 2019). The process of spontaneous emulsification was used to create nanoemulsions of the insecticide Norcantharidin, which is effective versus Plutella xylostella. Twenty percent butanol, 20% cremophor EL, and 80% triacetin were used in the nanoemulsions with norcantharidin encapsulated nanoemulsions. When compared to the norcantharidin acetone solution separately, this emulsion had a stronger insecticidal effect, suggesting that it could be useful in agriculture.. Nanoemulsions are an effective way to improve food digestion and the availability of bioactive compounds. The amount of food taken into the blood by the gastrointestinal system is referred to as food digestibility. Nanoemulsions are an effective way to increase the digestion of foods and natural extracts. Beta-carotene is a red–orange antioxidant found in carrots and other colorful vegetables. Beta-carotene is a terpene (isoprenoids) that is biosynthesized from geranylgeranyl pyrophosphate and belongs to the carotenes family (Qian et al. 2012).

Conclusion

Nanoemulsions are the novelist systems for improving hydrophobic chemical dissolving, bioavailability, and performance. The system is very effective for the incorporation of lipophilic functional compounds in food matrices. The results of the various studies indicated that nanoemulsions based approaches are effective in protection and delivery of various bioactive compounds. Nanoemulsions based approaches effectively improve the functional aspects along with quality and safety. There are various techniques to develop and characterize the nanoemulsions. Due to its outstanding qualities like high surface area, translucent appearance, durable stability, and tunable rheology, nanoemulsions have earned too much consideration and appeal over in different sectors of industrial importance. High-energy methods such as HPVH, micro fluidizers, and ultrasonic homogenization, as well as low-energy methods such as spontaneous emulsification, phase inversion composition, phase inversion temperature, and emulsion inversion point, are the most extensively utilized methods for the synthesis of nanoemulsions. Furthermore, there is dire need to study biological and toxicological effect of nano particles after their digestion to ensure the safety of the consumers.

Supplementary Information

Below is the link to the electronic supplementary material.

Acknowledgements

Authors are thankful Government College University for providing literature collection facilities

Author Contributions

FI, FS, MA, proposed this idea and drafted initial manuscript. MH, AI, MAK helped in preparing figures and tables and oveall qulity of the manuscript.

Funding

The authors declare that no funds, grants, or other support were received during the preparation of this manuscript.

Data availability

Even though adequate data has been given in the form of tables and figures, however, all authors declare that if more data required then the data will be provided on request basis.

Declarations

Conflict of interest

Authors declare that they have no conflict of interest.

Ethical approval

This article does not contain any studies with human participants or animals performed by any of the authors.

Consent to participate

Corresponding and all the co-authors are willing to participate in this manuscript.

Consent for publication

All authors are willing for publication of this manuscript.

Footnotes

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

References

- Acevedo-Fani A, Salvia-Trujillo L, Rojas-Graü MA, Martín-Belloso O. Edible films from essential-oil-loaded nanoemulsions: physicochemical characterization and antimicrobial properties. Food Hydrocoll. 2015;47:168–177. doi: 10.1016/j.foodhyd.2015.01.032. [DOI] [Google Scholar]

- Ahmed J, Ramalingam K. Handbook of research on nanoemulsion applications in agriculture, food, health, and biomedical sciences. USA: IGI Global; 2022. The essential properties of nanoemulsions: Basics of nanoemulsion; pp. 1–23. [Google Scholar]

- Alexandre EMC, Lourenço RV, Bittante AMQB, Moraes ICF, do Amaral Sobral PJ. Gelatin-based films reinforced with montmorillonite and activated with nanoemulsion of ginger essential oil for food packaging applications. Food Packag Shelf Life. 2016;10:87–96. doi: 10.1016/j.fpsl.2016.10.004. [DOI] [Google Scholar]

- Alexandre EMC, Lourenço RV, Bittante AMQB, Moraes ICF, Sobral PJA. Gelatine based films reinforced with montmorillonite and activated with nanoemulsion of ginger essential oil for food packaging applications. Food Pack Shelf Life. 2016;10:87–96. doi: 10.1016/j.fpsl.2016.10.004. [DOI] [Google Scholar]

- Alshahrani SM (2022) A judicious review on the applications of chemotherapeutic loaded nanoemulsions in cancer management. J Drug Deliv Sci Technol 103085

- Amaral DMF, Bhargava K. Essential oil nanoemulsions and food applications. Adv Food Technol Nutr Sci Open J. 2015;1(4):84–87. doi: 10.17140/AFTNSOJ-1-115. [DOI] [Google Scholar]

- Anton N, Vandamme TF. The universality of low-energy nano-emulsification. Int J Pharm. 2009;377(1–2):142–147. doi: 10.1016/j.ijpharm.2009.05.014. [DOI] [PubMed] [Google Scholar]

- Araújo FA, Kelmann RG, Araújo BV, Finatto RB, Teixeira HF, Koester LS. Development and characterization of parenteral nanoemulsions containing thalidomide. Eur J Pharm Sci. 2011;42(3):238–245. doi: 10.1016/j.ejps.2010.11.014. [DOI] [PubMed] [Google Scholar]

- Artiga-Artigas M, Acevedo-Fani A, Martín-Belloso O. Effect of sodium alginate incorporation procedure on the physicochemical properties of nanoemulsions. Food Hydrocoll. 2017;70:191–200. doi: 10.1016/j.foodhyd.2017.04.006. [DOI] [Google Scholar]

- Aswathanarayan JB, Vittal RR. Nanoemulsions and their potential applications in food industry. Front Sustain Food Syst. 2019;3:95. doi: 10.3389/fsufs.2019.00095. [DOI] [Google Scholar]

- Bai L, Huan S, Gu J, McClements DJ. Fabrication of oil-in-water nanoemulsions by dual-channel microfluidization using natural emulsifiers: Saponins, phospholipids, proteins, and polysaccharides. Food Hydrocoll. 2016;61:703–711. doi: 10.1016/j.foodhyd.2016.06.035. [DOI] [Google Scholar]

- Casadei MA, Cerreto F, Cesa S, Giannuzzo M, Feeney M, Marianecci C, Paolicelli P. Solid lipid nanoparticles incorporated in dextran hydrogels: a new drug delivery system for oral formulations. Int J Pharm. 2006;325(1–2):140–146. doi: 10.1016/j.ijpharm.2006.06.012. [DOI] [PubMed] [Google Scholar]

- Dammak I, de Carvalho RA, Trindade CSF, Lourenço RV, do Amaral Sobral PJ. Properties of active gelatin films incorporated with rutin-loaded nanoemulsions. Int J Biol Macromol. 2017;98:39–49. doi: 10.1016/j.ijbiomac.2017.01.094. [DOI] [PubMed] [Google Scholar]

- Ee SL, Duan X, Liew J, Nguyen QD. Droplet size and stability of nano-emulsions produced by the temperature phase inversion method. Chem Eng J. 2008;140(1–3):626–631. doi: 10.1016/j.cej.2007.12.016. [DOI] [Google Scholar]

- Galus S, Kadzińska J. Food applications of emulsion-based edible films and coatings. Trends Food Sci Technol. 2015;45(2):273–283. doi: 10.1016/j.tifs.2015.07.011. [DOI] [Google Scholar]

- Ganesan P, Karthivashan G, Park SY, Kim J, Choi DK. Microfluidization trends in the development of nanodelivery systems and applications in chronic disease treatments. Int J Nanomed. 2018;13:6109. doi: 10.2147/IJN.S178077. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Garti N, Aserin A. Micelles, microemulsions, and monolayers. 2018. Double emulsions stabilized by macromolecular surfactants; pp. 333–362. [Google Scholar]

- Ghosh V, Mukherjee A, Chandrasekaran N. Ultrasonic emulsification of food-grade nanoemulsion formulation and evaluation of its bactericidal activity. Ultrason Sonochem. 2013;20:338–344. doi: 10.1016/j.ultsonch.2012.08.010. [DOI] [PubMed] [Google Scholar]

- Grigoriev DO, Miller R. Mono-and multilayer covered drops as carriers. Curr Opin Colloid Interface Sci. 2009;14(1):48–59. doi: 10.1016/j.cocis.2008.03.003. [DOI] [Google Scholar]

- Gupta A, Eral HB, Hatton TA, Doyle PS. Nanoemulsions: formation, properties and applications. Soft Matter. 2016;12(11):2826–2841. doi: 10.1039/C5SM02958A. [DOI] [PubMed] [Google Scholar]

- Guttoff M, Saberi AH, McClements DJ. Formation of vitamin D nanoemulsion-based delivery systems by spontaneous emulsification: factors affecting particle size and stability. Food Chem. 2015;171:117–122. doi: 10.1016/j.foodchem.2014.08.087. [DOI] [PubMed] [Google Scholar]

- Håkansson A. Can high-pressure homogenization cause thermal degradation to nutrients? J Food Eng. 2019;240:133–144. doi: 10.1016/j.jfoodeng.2018.07.024. [DOI] [Google Scholar]

- Hebishy E, Buffa M, Guamis B, Blasco-Moreno A, Trujillo AJ. Physical and oxidative stability of whey protein oil-in-water emulsions produced by conventional and ultra-high-pressure homogenization: Effects of pressure and protein concentration on emulsion characteristics. Innov Food Sci Emerg Technol. 2015;32:79–90. doi: 10.1016/j.ifset.2015.09.013. [DOI] [Google Scholar]

- Izquierdo P, Esquena J, Tadros TF, Dederen C, Garcia MJ, Azemar N, Solans C. Formation and stability of nano-emulsions prepared using the phase inversion temperaturemethod. Langmuir. 2002;18(1):26–30. doi: 10.1021/la010808c. [DOI] [Google Scholar]

- Jintapattanakit A. Preparation of nanoemulsions by phase inversion temperature (PIT) method. Pharm Sci Asia. 2018;45(1):1–12. doi: 10.29090/psa.2018.01.001. [DOI] [Google Scholar]

- Kale SN, Deore SL. Emulsion micro emulsion and nano emulsion: a review. Syst Rev Pharm. 2017;8(1):39. doi: 10.5530/srp.2017.1.8. [DOI] [Google Scholar]

- Kentish S, Wooster TJ, Ashokkumar M, Balachandran S, Mawson R, Simons L. The use of ultrasonics for nanoemulsion preparation. Innov Food Sci Emerg Technol. 2008;9(2):170–175. doi: 10.1016/j.ifset.2007.07.005. [DOI] [Google Scholar]

- Kumar DL, Sarkar P. Encapsulation of bioactive compounds using nanoemulsions. Environ Chem Lett. 2018;16(1):59–70. doi: 10.1007/s10311-017-0663-x. [DOI] [Google Scholar]

- Kumar R, Kaur K, Uppal S, Mehta SK. Ultrasound processed nanoemulsion: a comparative approach between resveratrol and resveratrol cyclodextrin inclusion complex to study its binding interactions, antioxidant activity and UV light stability. Ultrason Sonochem. 2017;37:478–489. doi: 10.1016/j.ultsonch.2017.02.004. [DOI] [PubMed] [Google Scholar]

- Lee SJ, McClements DJ. Fabrication of protein-stabilized nanoemulsions using a combined homogenization and amphiphilic solvent dissolution/evaporation approach. Food Hydrocoll. 2010;24(6–7):560–569. doi: 10.1016/j.foodhyd.2010.02.002. [DOI] [Google Scholar]

- Liew JCL, Nguyen QD, Ngothai Y. Effect of sodium chloride on the formation and stability of n-dodecane nanoemulsions by the PIT method. Asia-Pac J Chem Eng. 2010;5(4):570–576. doi: 10.1002/apj.445. [DOI] [Google Scholar]

- Liu J, Bi J, Liu X, Zhang B, Wu X, Wellala CKD, et al. Effects of high pressure homogenization and addition of oil on the carotenoid bioaccessibility of carrot juice. Food Funct. 2019;10:458–468. doi: 10.1039/C8FO01925H. [DOI] [PubMed] [Google Scholar]

- Luykx DM, Peters RJ, van Ruth SM, Bouwmeester H. A review of analytical methods for the identification and characterization of nano delivery systems in food. J Agric Food Chem. 2008;56(18):8231–8247. doi: 10.1021/jf8013926. [DOI] [PubMed] [Google Scholar]

- Ma Q, Davidson PM, Zhong Q. Antimicrobial properties of microemulsions formulated with essential oils, soybean oil, and Tween 80. Int J Food Microbiol. 2016;226:20–25. doi: 10.1016/j.ijfoodmicro.2016.03.011. [DOI] [PubMed] [Google Scholar]

- Maali A, Mosavian MH. Preparation and application of nanoemulsions in the last decade (2000–2010) J Dispersion Sci Technol. 2013;34(1):92–105. doi: 10.1080/01932691.2011.648498. [DOI] [Google Scholar]

- McClements DJ. Edible nanoemulsions: fabrication, properties, and functional performance. Soft Matter. 2011;7(6):2297–2316. doi: 10.1039/C0SM00549E. [DOI] [Google Scholar]

- McClements DJ, Decker EA, Park Y, Weiss J. Structural design principles for delivery of bioactive components in nutraceuticals and functional foods. Crit Rev Food Sci Nutr. 2009;49(6):577–606. doi: 10.1080/10408390902841529. [DOI] [PubMed] [Google Scholar]

- Morales D, Gutiérrez JM, García-Celma MJ, Solans YC. A study of the relation between bicontinuous microemulsions and oil/water nano-emulsion formation. Langmuir. 2003;19(18):7196–7200. doi: 10.1021/la0300737. [DOI] [Google Scholar]

- Mulik RS, Mönkkönen J, Juvonen RO, Mahadik KR, Paradkar AR. Transferrin mediated solid lipid nanoparticles containing curcumin: enhanced in vitro anticancer activity by induction of apoptosis. Int J Pharm. 2010;398(1–2):190–203. doi: 10.1016/j.ijpharm.2010.07.021. [DOI] [PubMed] [Google Scholar]

- Nakabayashi K, Amemiya F, Fuchigami T, Machida K, Takeda S, Tamamitsu K, Atobe M. Highly clear and transparent nanoemulsion preparation under surfactant-free conditions using tandem acoustic emulsification. Chem Commun. 2011;47(20):5765–5767. doi: 10.1039/c1cc10558b. [DOI] [PubMed] [Google Scholar]

- Naseema A, Kovooru L, Behera AK, Kumar KP, Srivastava P (2020) A critical review of synthesis procedures, applications and future potential of nanoemulsions. Adv Colloid Interface Sci 102318 [DOI] [PubMed]

- Nguyen TTL, Anton N, Vandamme TF (2016) Nutraceutical compounds encapsulated by extrusion–spheronization. New Polym Encapsul Nutraceutical Compd 195–230

- Pan X, Yao P, Jiang M. Simultaneous nanoparticle formation and encapsulation driven by hydrophobic interaction of casein-graft-dextran and β-carotene. J Colloid Interface Sci. 2007;315(2):456–463. doi: 10.1016/j.jcis.2007.07.015. [DOI] [PubMed] [Google Scholar]

- Preetz C, Hauser A, Hause G, Kramer A, Mäder K. Application of atomic force microscopy and ultrasonic resonator technology on nanoscale: distinction of nanoemulsions from nanocapsules. Eur J Pharm Sci. 2010;39(1–3):141–151. doi: 10.1016/j.ejps.2009.11.009. [DOI] [PubMed] [Google Scholar]

- Qian C, McClements DJ. Formation of nanoemulsions stabilized by model food-grade emulsifiers using high-pressure homogenization: factors affecting particle size. Food Hydrocoll. 2011;25(5):1000–1008. doi: 10.1016/j.foodhyd.2010.09.017. [DOI] [Google Scholar]

- Qian C, Decker EA, Xiao H, McClements DJ. Physical and chemical stability of β-carotene-enriched nanoemulsions: Influence of pH, ionic strength, temperature, and emulsifier type. Food Chem. 2012;132(3):1221–1229. doi: 10.1016/j.foodchem.2011.11.091. [DOI] [PubMed] [Google Scholar]

- Quintanilla-Carvajal MX, Camacho-Díaz BH, Meraz-Torres LS, Chanona-Pérez JJ, Alamilla-Beltrán L, Jimenéz-Aparicio A, Gutiérrez-López GF. Nanoencapsulation: a new trend in food engineering processing. Food Eng Rev. 2010;2(1):39–50. doi: 10.1007/s12393-009-9012-6. [DOI] [Google Scholar]

- Relkin P, Yung JM, Kalnin D, Ollivon M. Structural behaviour of lipid droplets in protein-stabilized nano-emulsions and stability of α-tocopherol. Food Biophys. 2008;3(2):163–168. doi: 10.1007/s11483-008-9064-9. [DOI] [Google Scholar]

- Ru Q, Yu H, Huang Q. Encapsulation of epigallocatechin-3-gallate (EGCG) using oil-in-water (O/W) submicrometer emulsions stabilized by ι-carrageenan and β-lactoglobulin. J Agric Food Chem. 2010;58(19):10373–10381. doi: 10.1021/jf101798m. [DOI] [PubMed] [Google Scholar]

- Ruiz-Montañez G, Ragazzo-Sanchez JA, Picart-Palmade L, Calderón-Santoyo M, Chevalier-Lucia D. Optimization of nanoemulsions processed by high-pressure homogenization to protect a bioactive extract of jackfruit (Artocarpus heterophyllus Lam) Innov Food Sci Emerg Technol. 2017;40:35–41. doi: 10.1016/j.ifset.2016.10.020. [DOI] [Google Scholar]

- Saifullah M, Ahsan A, Shishir MRI. Emulsion. USA: Academic Press; 2016. Production, stability and application of micro-and nanoemulsion in food production and the food processing industry; pp. 405–442. [Google Scholar]

- Salem MA, Ezzat SM. Nanoemulsions in food industry. Some New Aspects Colloid Syst Foods. 2019;2(12):238–267. [Google Scholar]

- Santana RC, Perrechil FA, Cunha RL. High-and low-energy emulsifications for food applications: a focus on process parameters. Food Eng Rev. 2013;5(2):107–122. doi: 10.1007/s12393-013-9065-4. [DOI] [Google Scholar]

- Sarheed O, Shouqair D, Ramesh KVRNS, Khaleel T, Amin M, Boateng J, Drechsler M. Formation of stable nanoemulsions by ultrasound-assisted two-step emulsification process for topical drug delivery: effect of oil phase composition and surfactant concentration and loratadine as ripening inhibitor. Int J Pharm. 2020;576:118952. doi: 10.1016/j.ijpharm.2019.118952. [DOI] [PubMed] [Google Scholar]

- Schuch A, Wrenger J, Schuchmann HP. Production of W/O/W double emulsions. Part II: influence of emulsification device on release of water by coalescence. Colloids Surf, A. 2014;461:344–351. doi: 10.1016/j.colsurfa.2013.11.044. [DOI] [Google Scholar]

- Serdaroğlu M, Öztürk B, Kara A. An overview of food emulsions: description, classification and recent potential applications. Turk J Agric-Food Sci Technol. 2015;3(6):430–438. [Google Scholar]

- Shakeel F, Baboota S, Ahuja A, Ali J, Shafiq S. Celecoxib nanoemulsion for transdermal drug delivery: characterization and in vitro evaluation. J Dispers Sci Technol. 2009;30(6):834–842. doi: 10.1080/01932690802644012. [DOI] [Google Scholar]

- Shariffa YN, Tan TB, Uthumporn U, Abas F, Mirhosseini H, Nehdi IA, et al. Producing a lycopene nanodispersion: formulation development and the effects of high pressure homogenization. Food Res Int. 2017;101:165–172. doi: 10.1016/j.foodres.2017.09.005. [DOI] [PubMed] [Google Scholar]

- Silva HD, Cerqueira MA, Souza BW, Ribeiro C, Avides MC, Quintas MA, Coimbra JS, Carneiro-da-Cunha MG, Vicente AA. Nanoemulsions of β-carotene using a high-energy emulsification–evaporation technique. J Food Eng. 2011;102(2):130–135. doi: 10.1016/j.jfoodeng.2010.08.005. [DOI] [Google Scholar]

- Silva HD, Cerqueira MÂ, Vicente AA. Nanoemulsions for food applications: development and characterization. Food Bioprocess Technol. 2012;5(3):854–867. doi: 10.1007/s11947-011-0683-7. [DOI] [Google Scholar]

- Subasi A, Alickovic E, Kevric J. CMBEBIH 2017. Singapore: Springer; 2017. Diagnosis of chronic kidney disease by using random forest; pp. 589–594. [Google Scholar]

- Tadros TF, Vandamme A, Levecke B, Booten K, Stevens CV. Stabilization of emulsions using polymeric surfactants based on inulin. Adv Colloid Interface Sci. 2004;108:207–226. doi: 10.1016/j.cis.2003.10.024. [DOI] [PubMed] [Google Scholar]

- Tan TB, Yussof NS, Abas F, Mirhosseini H, Nehdi IA, Tan CP. Comparing the formation of lutein nanodispersion prepared by using solvent displacement method and high-pressure valve homogenization: Effects of formulation parameters. J Food Eng. 2016;177:65–71. doi: 10.1016/j.jfoodeng.2015.12.020. [DOI] [Google Scholar]

- Thakur RK, Villette C, Aubry JM, Delaplace G. Dynamic emulsification and catastrophic phase inversion of lecithin-based emulsions. Colloids Surf A. 2008;315(1–3):285–293. doi: 10.1016/j.colsurfa.2007.08.017. [DOI] [Google Scholar]

- Tripathi AD, Sharma R, Agarwal A, Haleem DR. Nanoemulsions based edible coatings with potential food applications. Int J Biobased Plast. 2021;3(1):112–125. doi: 10.1080/24759651.2021.1875615. [DOI] [Google Scholar]

- Venturini CG, Jäger E, Oliveira CP, Bernardi A, Battastini AM, Guterres SS, Pohlmann AR. Formulation of lipid core nanocapsules. Colloids Surf A. 2011;375(1–3):200–208. doi: 10.1016/j.colsurfa.2010.12.011. [DOI] [Google Scholar]

- Walker RM, Decker EA, McClements DJ. Physical and oxidative stability of fish oil nanoemulsions produced by spontaneous emulsification: effect of surfactant concentration and particle size. J Food Eng. 2015;164:10–20. doi: 10.1016/j.jfoodeng.2015.04.028. [DOI] [Google Scholar]

- Wilson RJ, Li Y, Yang G, Zhao CX (2021) Nanoemulsions for drug delivery. Particuology

- Wulff-Pérez M, Torcello-Gómez A, Gálvez-Ruíz MJ, Martín-Rodríguez A. Stability of emulsions for parenteral feeding: preparation and characterization of o/w nanoemulsions with natural oils and Pluronic f68 as surfactant. Food Hydrocoll. 2009;23(4):1096–1102. doi: 10.1016/j.foodhyd.2008.09.017. [DOI] [Google Scholar]

- Yin LJ, Chu BS, Kobayashi I, Nakajima M. Performance of selected emulsifiers and their combinations in the preparation of β-carotene nanodispersions. Food Hydrocoll. 2009;23(6):1617–1622. doi: 10.1016/j.foodhyd.2008.12.005. [DOI] [Google Scholar]

- Zambrano-Zaragoza ML, González-Reza R, Mendoza-Muñoz N, Miranda-Linares V, Bernal-Couoh TF, Mendoza-Elvira S, Quintanar-Guerrero D. Nanosystems in edible coatings: a novel strategy for food preservation. Int J Mol Sci. 2018;19(3):705. doi: 10.3390/ijms19030705. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Zeng L, Liu Y, Pan J, Liu X. Formulation and evaluation of norcanthridin nanoemulsions against the Plutella xylostella (Lepidotera: Plutellidae) BMC Biotechnol. 2019;19(1):1–11. doi: 10.1186/s12896-019-0508-8. [DOI] [PMC free article] [PubMed] [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.

Supplementary Materials

Data Availability Statement

Even though adequate data has been given in the form of tables and figures, however, all authors declare that if more data required then the data will be provided on request basis.