Abstract

Secondary natural products (NPs) are a rich source for drug discovery. However, the low abundance of NPs makes their extraction from nature inefficient, while chemical synthesis is challenging and unsustainable. Saccharomyces cerevisiae and Pichia pastoris are excellent manufacturing systems for the production of NPs. This Perspective discusses a comprehensive platform for sustainable production of NPs in the two yeasts through system-associated optimization at four levels: genetics, temporal controllers, productivity screening, and scalability. Additionally, it is pointed out critical metabolic building blocks in NP bioengineering can be identified through connecting multilevel data of the optimized system using deep learning.

Subject terms: Metabolic engineering, Synthetic biology, Applied microbiology, Natural product synthesis

Yeasts, Saccharomyces cerevisiae and Pichia pastoris, are promising chassis for the production of nature products (NPs). Here, the author discusses establishing a comprehensive platform for sustainable production of NPs via system-associated optimization at genetics, temporal controllers, productivity screening, and scalability levels.

Introduction

More than 50% of small-molecule therapeutic agents in current clinical usage are natural products (NPs)1. Importantly, NPs have been sources of new drugs over the past four decades2, and are used as prototypes to discover new drugs because of their massive scaffold diversity and structural complexity3. Plants are excellent producers of NPs with diverse biological activities4,5. Currently, the principal source of most NP-derived pharmaceuticals remains direct extraction from plants3. However, the lack of continuous availability of sufficient amounts of natural sources and variations in yields have limited NP extraction5. Considering the pressures of food security and population ageing6, alternative approaches are urgently needed to enable environmentally friendly production of NP drugs.

Thanks to the rapid progress of synthetic biology, the microbial synthesis of more complex NPs has been possible. A prime example is the successful construction of a yeast microbial cell factory for strictosidine and its downstream vinblastine, positioning yeast as a scalable system to produce more than 3000 reported NPs7. However, only a few natural compounds produced by microbes have reached commercial scale8,9. Opportunely, the increasing sizes of multi-omics datasets and the acceleration of technologies supporting structural analysis and enzyme characterization, the time to discovery of enzymatic steps for synthesis of complex NPs in plants has decreased10. To capitalize on this opportunity, it’s urgent to establish a standardized chemical engineering approach. Here, I discuss yeast as a microbial cell factory for production of complex plant NPs with pharmaceutical importance, such as alkaloids11 and flavonoids12.

Yeast for the heterologous production of NPs

Multi-purpose yeasts, including Saccharomyces cerevisiae and Pichia pastoris (syn. Komagataella phaffii), are the best characterized and the most widely used microorganisms in the fermentation industry13. They can potentially resolve issues associated with low heterologous NP product yield observed in other expression hosts, such as E. coli and mammalian systems14. Yeast is able to synthesize the required precursors of diverse plant NPs including alkaloids, an imperative group of NPs containing at least one nitrogen atom15. Yeast expresses endoplasmic reticulum (ER)–localized cytochrome P450 monooxygenases (P450s, also called CYPs), membrane-anchored cytochrome P450 reductases (CPRs), scaffold Pictet-Spenglerases, and berberine-bridge enzymes, which are essential enzymes for producing NPs16,17. Yeast, like higher eukaryotic organisms, is equipped with subcellular organelles, such as mitochondria, that have been employed to shield the heterologous enzymes18. Compared to mitochondria, peroxisomes are more appropriate organelles for the compartmentalization of engineered NP pathways. Peroxisomes are detoxifying organelles with greater ability than other organelles to tolerate and sequester toxic molecules such as NPs19. Moreover, they are near the ER, thus facilitating efficient cytochrome P450-mediated oxidation of the intermediates required to produce NPs such as monoterpene alkaloids20.

The S. cerevisiae is typically used as a host for manufacturing complex NPs7,21. Recently, the non-conventional methylotrophic yeast P. pastoris has emerged as an attractive host for NP production22. P. pastoris has the advantages of methanol utilization, compatibility with higher density cell growth and large-scale fermentation. Furthermore, it shows a higher expression level of heterologous protein than S. cerevisiae. For example, recombinant proteins expressed under the control of the yeast alcohol oxidase 1 (AOX1) promoter can contribute more than 30% of the total proteins in P. pastoris23. A recent study has shown that a cytochrome P450 enzyme, which catalyzes the conversion of scoulerine (a product downstream of reticuline) to cheilanthifoline, exhibits a higher conversion rate in P. pastoris cells (70%) than S. cerevisiae cells (20%)24. Interestingly, when P. pastoris is grown on methanol, its peroxisomes substantially multiply25, which can be deployed to increase the production of heterologous enzymes.

The genes coding for NPs are typically randomly distributed through the genome in the native host26. To enable yeast cells to produce a chemical-of-interest (Fig. 1), each individual gene encoding one enzyme of the biosynthetic pathway or biosynthesis gene clusters needs to be expressed from the individual promoter and terminator27. Recently several advanced tools such as inducible synthetic transcription factors (synTFs) and promoters28,29, terminators30, and genome editing tools31 have been developed to facilitate regulation of heterologous protein expression in S. cerevisiae. Fortunately, these tools have been found to be functional in tuning heterologous protein expression levels in P. pastoris, for which a limited number of tools and methods are available for metabolic engineering. Considering the dual application of engineering tools and methods in both chassis’ organisms, P. pastoris has attracted attention as an ideal platform for metabolic engineering of plant NPs.

Fig. 1. Schematic overview of the principle of heterologous chemical production in yeast.

The DNA sequences of genes and regulatory elements, promoters, and terminators (to, respectively, start and terminate the transcription of the individual genes) are engineered into the DNA located inside the nucleus in the cell. Followed by translation using the host translational machinery, the expressed enzymes convert the yeast precursor to the intermediate chemicals and, subsequently, the chemical of interest. The schematic shows a chemical biosynthetic pathway consisting of genes ‘Gene1’, ‘Gene2’, and ‘Genen’, requiring three promoters ‘P1’, ‘P2’, and ‘Pn’, and three terminators ‘T1’, ‘T2”, ‘Tn’). Enz enzyme, P promoter, T terminator.

Steps to establish yeast as a sustainable platform for NP production

To increase the opportunities for carbon-neutral or carbon-negative manufacturing, the core metabolism of yeast needs to shift from its dependence on sugars to one-carbon compounds. To this end, the yeast NP production platform can be potentially equipped with two optimizable inputs: (i) one-carbon (C1) resources, e.g., carbon dioxide (CO2); and (ii) an optogenetic inducer (Fig. 2, Step1). The fixed C1 can provide yeast the required carbon sources for NP production. Then, light can activate the transcription of synthetic regulators that control the expression of the NP biosynthetic pathway genes in engineered yeast (Fig. 2, Step 2). To adjust the regulation of intermediate metabolites, many diverse synthetic transcriptional units for each individual gene, consisting of synTFs and pathway genes, should be created through combinatorial optimization methods. Next, the library of synthetic transcriptional units is engineered into the genome of host cells. Compartmentalization of the precursor biosynthetic pathways in yeast organelles allows for increased production of the required substrate and its efficient channeling to downstream enzymes for NP biosynthesis32. Screening the generated cell library with biosensors allows for high-throughput quantification of NP production in yeast cells. The fermentation conditions and light induction system must be optimized in the automated bioreactors to increase the output of the entire system (Fig. 2, Step 3). The high-throughput computational sequencing analysis of the top members of the yeast combinatorial library that are labeled with barcodes is used to feed the deep learning (DL). The obtained dataset drives biosynthetic pathways navigation for increased production of diverse natural small molecules in heterologous hosts (Fig. 2, Step 4). The following sections review current and emerging technologies to conceptually advance the individual steps of the roadmap and align them to illustrate the platform described in Fig. 2.

Fig. 2. Schematic overview of the platform for sustainable production of NPs in yeast.

To sustainably produce the highly required pharmaceutical NPs in an environmentally friendly manner, a four-step platform is designed. Step 1, input optimization (orange box): For carbon-negative manufacturing (i), a photosynthetic microorganism or engineered yeast fixes CO2.The fixed carbon can provide yeast with the required sources for production NP precursors. A light-inducible system is used to dynamically control NP metabolite production in yeast (ii). Step 2, system optimization (blue box): The library of light-inducible synthetic regulators is assembled upstream of genes of enzyme isoforms by using combinatorial assembly approaches (i). Protein engineering strategies are applied to design enzyme derivatives with enhanced activity. Next, yeast cells with rewired endogenous metabolites for the enhanced production of the required precursor in peroxisomes (blue box, ii) are chromosomally engineered with the pathway library (iii). The presence of the NP-responsive biosensor in the yeast cell enables rapid detection of NP production (iv). Step 3, output optimization (green box): Cells with a high level of fluorescence output are subjected to automated process optimization, and the top producers are sorted with FACS flow cytometry. Step 4, DL dataset development (red box): The library variants are subjected to single-cell droplet-based transcriptomics and NGS analyses to feed the DL dataset. The multilayer metadata obtained from dynamic optogenetic stimulation, the productivity of library members and growth fitness in real-time, and the genetic identity of low-to-top producers are used to fit model parameters and extract models to predict optimal conditions for heterologous production of other NPs. To simplify the figure, only three cells, Cell 1, Cell2, and Cell n, from the combinatorial library were shown. CO2 carbon dioxide, DL deep learning, FACS fluorescence-activated cell sorting, NGS next-generation sequencing, NP natural product.

Input optimization

Yeast tends to offer modest emissions savings over conventional agricultural processes in the production of pharmaceutical chemicals, including less consumption of water, nutrients, energy, and land, lower costs, faster and more stable production cycles, and higher quality products33. However, the cost and land resources required to produce sugar feedstocks make manufacturing pharmaceutical products in yeast not entirely environmentally friendly. In addition, with rising concerns regarding global climate change, a transition to clean energy sources (e.g., light and hydrogen) to achieve net zero emissions of natural gases will be necessary34. In the next three subsections, I discuss strategies for carbon-negative manufacturing through enabling yeast to metabolize CO2 or pairing yeast with autotrophic microorganisms, as well as approaches to using light to activate NP production.

Carbon-negative manufacturing in yeast

To switch to carbon-negative manufacturing, a recent study has suggested a promising metabolic engineering approach by harnessing autotrophic acetogens that uses the Wood-Ljungdahl pathway35. However, applying acetogenic bacteria or other natural C1-utilizers for industrial-scale production is hindered by the limited availability of genetic manipulation tools, slow growth, and/or a narrow product spectrum36. Hence, chemical engineering strategies enabling S. cerevisiae and P. pastoris to utilize CO2, as a carbon source, rather than sugar, are increasingly being considered.

Methylotrophic P. pastoris can obtain all the carbon and energy needed for growth and metabolism from reduced C1-molecule methanol37. However, it leads to release of CO2 that cannot be used by P. pastoris37. By adding eight heterologous genes and deleting three native genes, Gassler et al. have engineered the peroxisomal methanol-assimilation pathway of P. pastoris into a CO2-fixation pathway resembling the Calvin–Benson–Bassham cycle (hereafter denoted the Calvin cycle)38. The Calvin cycle is then targeted to either the cytosol or peroxisome. Next, the team have replaced the formaldehyde-assimilating dihydroxyacetone synthase enzyme of P. pastoris with the bacterial ribulose 1,5-bisphosphate carboxylase/oxygenase (RuBisCO) enzyme. After introducing phosphoribulose kinase from spinach, the generated yeast strain directly assimilated CO2 instead of methanol, and converted it to organic acids39. Portions of the Calvin cycle have been introduced into the yeast S. cerevisiae40. To enhance CO2-fixation efficiency via the Calvin cycle in yeast, several optimization routes, for example, expressing RuBisCo derived from various origins have been evaluated41. Li et al. have increased the production of adenosine triphosphate (ATP), and relieved the nicotinamide adenine dinucleotide phosphate (NADPH) imbalance involved in the CO2-fixation Calvin cycle42. A highly active RuBisCo from the endosymbiont of the deep-sea tubeworm Riftia pachyptila43 may offer a unique application avenue for creating an efficient artificial photosynthetic pathway. Ultimately, yeast requires conversion of the Calvin cycle’s final product, glycerate 3-phosphate (G3P), to precursors for NP manufacturing (Fig. 3a). Kildegaard et al. have optimized the conversion of G3P to acetyl-CoA, required precursor for production monoterpene indole alkaloids (MIAs), by overexpressing native enzymes and heterologous acetyl-CoA synthase44. Combining the above engineering efforts may enable establishment of a yeast strain that can efficiently assimilate CO2 into acetyl-CoA-derived NPs via the Calvin cycle. As an alternative to natural CO2 fixation, crotonyl-coenzyme A (CoA)/ethylmalonyl-CoA/hydroxybutyryl-CoA (CETCH) has been established for the in vitro fixation of CO245. The CETCH cycle, based on crotonyl-CoA carboxylases, allows converting CO2 into glyoxylate at a higher carbon fixation rate than the Calvin cycle. CETCH has been successfully coupled to (i) encapsulated photosynthetic membranes for light-powered CO2 fixation to glyoxylate46, and (ii) the β-hydroxyaspartate cycle, a glyoxylate assimilation cycle from marine bacteria, to convert CO2 to acetyl-CoA in vitro47. Although light-responsive CETCH cycle has not yet been implemented in vivo, it may offer a way to couple CO2 assimilation pathways with NP-producing pathways in yeast (Fig. 3b). CETCH cycle requires two ATPs and three NADPH cofactors to convert two CO2 molecules into organic compounds45.

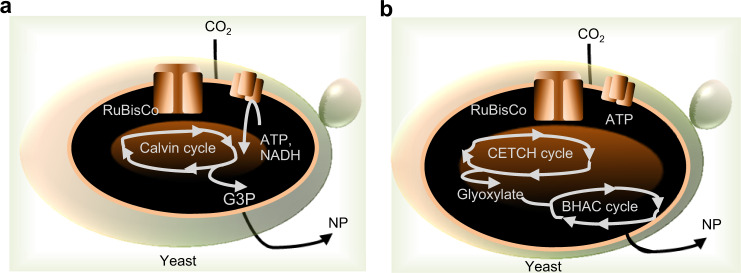

Fig. 3. Synthetic routes for carbon-negative manufacturing to produce NP in yeast.

a The yeast is engineered for the Calvin cycle to convert CO2 to G3P, RuBisCo expression, and enhanced production of ATP and NADPH. b The yeast is engineered for the synthetic CETCH cycle to produce glyoxylate from CO2, the β-hydroxyaspartate cycle to convert glyoxylate to NP, RuBisCo expression, and enhanced production of ATP and NADPH. ATP, adenosine triphosphate, BHAC β-hydroxyaspartate cycle, CETCH crotonyl-coenzyme A (CoA)/ethylmalonyl-CoA/hydroxybutyryl-CoA, CO2 carbon dioxide, G3P glyceraldehyde-3-phosphate, NADPH nicotinamide adenine dinucleotide phosphate, NP natural product.

CETCH and other routes relying on C1-assimilation require an energy source to convert thermodynamically stable CO2. The relatively low-price methanol has been considered a promising energy source for CO2 assimilation. To produce the required energy for CO2 fixation, methanol is initially oxidized in the peroxisome of P. pastoris to hydrogen peroxide (H2O2), which may lead to oxidative damage to cells, and the toxic formaldehyde48. To minimize oxidative damage, balanced expression of the peroxisomal H2O2-generating oxidases and catalases through combinatorial optimization is an interesting subject for investigation. To decrease the production level of formaldehyde, Gassler et al. have deleted the AOX1 in P. pastoris (formaldehyde can still be synthesized by AOX2)38. In fact, a small fraction of the formaldehyde is required to generate energy (and glyceraldehyde-3-phosphate carbon sugar)38. Therefore, the balanced expression of formaldehyde synthesizing and consuming enzymes may enhance energy production in P. pastoris using methanol. To improve the performance of P. pastoris rewired for CO2 assimilation and methanol-based energy system, Gassler et al. have enhanced growth of the autotrophic P. pastoris by reverse engineering and adaptive laboratory evolution38,49. However, to deploy C1’s potential for producing complex NPs in yeast, it should be stressed that a long way has to be taken concerning an efficient energy-producing route establishment in yeast. One promising path to circumvent the problem is the electromicrobial conversion of C1 sources into NPs using “green hydrogen” energy carriers50. Theoretically, in a custom-designed bioreactor, yeast cells engineered to express hydrogen-oxidizing enzymes can consume hydrogen produced by solar electricity to drive CO2 fixation. Cheng et al. have established a bacterial mixotrophical CO2 assimilation system utilizing hydrogen, generated by hydrolysis of sodium borohydride, as an energy source51. This is an important step toward utilizing green hydrogen to support carbon-negative manufacturing in yeast. However, low solubility, poor mass transfer rate, and process safety issues of hydrogen in microbial cultures are the conceivable obstacles. Hopefully, these can possibly be addressed via a systematic design of chemical-biological interface52.

Artificial communities

In engineering the C1-fixation pathway to produce NPs in yeast, we must consider that yeast needs to be engineered to express many heterologous enzymes (in addition to C1-fixation enzymes), that may cause a metabolic burden on the yeast cell. Division of labor between cells can alleviate the metabolic burden. However, a few artificial cell-cell communication systems in yeast have been developed53. Alternatively, the use of autotrophic microorganisms and yeast in synthetic microbial consortia (SMC) divides labor between cells. Recent progress in SMC designing strategies allows the production of value-added chemicals in an environmentally friendly manner. In an established SMC through co-culture of bacteria Clostridium acetobutylicum and C. ljungdahlii, CO2 has been fixed and converted to C2-C4 alcohols54. In another example, a consortium for a cooperative relationship between alginate-utilizing Vibrio sp. dhg and 3-hydroxypropionic acid (3-HP)-producing Escherichia coli strains has been established, allowing the direct conversion of alginate to 3-HP55. For carbon-negative processing, pairwise SMC can be defined between C1-consuming autotrophic bacteria and yeast56. However, establishing such artificial communities fails in most cases, as one organism dominates in nutrient competition in co-cultivation condition57. Molitor et al. have established a two-stage bioprocessing system between acetogenic bacteria C. ljungdahlii and S. cerevisiae58. First, in a bioreactor with a pure culture of C. ljungdahlii, CO2 with oxygen and nitrogen supplies (sourced by wastewater) has been converted to acetate. Next, in the other bioreactor with a pure culture of yeast, the acetate has been converted to animal feeding protein58. In another two-stage system, CO2 (mixed with reducing agents carbon monoxide or hydrogen) has been converted into acetic acid using acetogen Moorella thermoacetica in the first-stage anaerobic bioreactor59. Subsequently, acetic acid has been utilized for lipid production by engineered oleaginous yeast Yarrowia lipolytica in the second-stage aerobic bioreactor59. Although establishing a two-stage bioprocessing system can overcome the drawbacks of co-culture schemes, the start-up of two connected bioreactors still generates high capital costs.

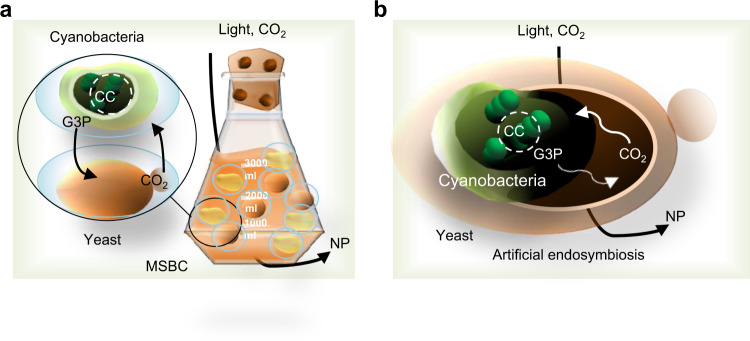

Alternatively, living materials combining a material scaffold with a porous structure may address the imbalanced co-culture composition issue by enabling the spatial organization of SMC species in co-cultures as that in nature (where spatial organization enables multiple species to coexist)60. Recently a methacrylate HEMA-EDMA porous microplate living material has been designed to maximize neighboring well interactions61. This culturing system enables exchange of small molecules, but not cells, between wells61. With this porous microplate, a spatially segregated co-culture of autotrophic bacteria and yeast can potentially be established. However, extensive follow-up work must be performed on the co-culture of autotrophic bacteria and yeast61. Another technique called microbial swarmbot consortia (MSBC) has been created by encapsulating subpopulations in polymeric microcapsules62. The cross-linked structure of microcapsules spatially segregates the microbial cells but permits the small-size molecules and proteins to pass. In an MSBC for sustainable production of small NP drugs, photosynthetic Synechococcus elongatus can capture and convert inorganic CO2 to the carbon-based organic compound G3P in the presence of blue light (Fig. 4a). In fact, blue light activates expression of chlorophyll and the key Calvin cycle enzymes. The produced G3P is then taken up by yeast to provide energy and carbon sources44. To overcome the futile CO2 cycling, which is due to reassimilation of CO2 by RuBisCo63, the synthetic pathway of malonyl-CoA–oxaloacetate–glyoxylate (employing the efficient phosphoenolpyruvate carboxylase to capture CO2)64 can be engineered into S. elongatus (the autotrophic partner of SMC). Alternatively, through artificial endosymbiosis (Fig. 4b), various mutants of model photosynthetic S. elongatus as endosymbionts have been engineered within yeast cells65. In principle, the engineered cyanobacteria perform bioenergetic functions to support the growth of yeast cells under optimal photosynthetic growth conditions to produce NPs.

Fig. 4. Artificial microbial communities to promote circular acetyl-CoA production in yeast.

a An MSBC is created in polymeric microcapsules by encapsulation of subpopulations of cyanobacteria and yeast. Phototrophic cyanobacteria capture the CO2 in the presence of light. The produced G3P is converted to the required carbon for production of metabolites, including NPs, in yeast. CO2 produced by the yeast is reused by the autotrophic partner. b Artificial endosymbiosis. Phototrophic cyanobacteria endosymbionts within yeast cells, in which the cyanobacteria perform bioenergetic functions to provide an energy source for the yeast cells to grow and produce chemicals. CC Calvin cycle, CO2 carbon dioxide, G3P glyceraldehyde-3-phosphate, MSBC microbial swarmbot consortia, NP natural product.

Solar-powered controller

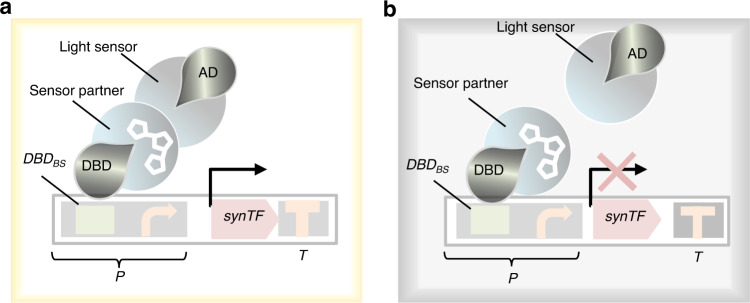

For sustainable and reliable NP production, heterologous enzymes must be expressed after the biomass accumulation phase66. To date, exogenous chemical inducers (e.g., L-rhamnose, IPTG, and arabinose) have been used to control gene expression67. However, the application of chemical inducers is limited owing to hypersensitivity and toxic effects68. Therefore, the development of cost-effective inducers that enable modulation of protein expression levels in a fast-acting and robust manner would support stable biomanufacturing of pharmaceutical drugs69. In the context of the proposed platform, an optogenetic system is required to regulate the expression of synTFs. A customizable synthetic DNA-binding domain (DBD), such as a transcription activator-like effector70, to target the upstream promoter of synTF and a yeast activation domain (AD) to activate transcription are, respectively, linked with the light-using domain and its interacting partner domain (Fig. 5). The DBD binds the promoter of synTF regardless of the light condition. However, dimerization of light partner domains, allowing for activation of synTF, is light-induced (Fig. 5a). The synTF targets a synthetic promoter controlling the expression of a gene of interest. In the absence of light, the interaction of the light sensor and its partner is abolished, thus resulting in the disassociation of DBD and AD (Fig. 5b). Since blue light is required for C1-negative manufacturing, a system based on the red light-sensitive dimerization of the photoreceptor PhyB and its interacting partner, PIF3, may hold the promise71. Benzinger and Khammash have developed a stochastic ordinary differential equation-based gene expression model to predict the output of blue light-mediated gene expression72. Moreover, they have demonstrated how pulsatile blue light signaling allows graded expression of multiple genes at fixed expression ratios, regardless of differences in promoter dose-response features72. Using the same principle, pulsatile red light-induced temporal control can be established to optimize gene expression of NP biosynthetic pathways.

Fig. 5. Light-dependent expression system.

a Light triggers the dimerization of the light-sensing domain and its partner, thus leading to the joining of DBD and AD to form a functional synthetic activator. Next, the synthetic activator targets its BS within a promoter, thus resulting in the expression of a synTF. b In the absence of light, the synthetic activator is not formed, and thus the downstream synTF is not expressed. AD activation domain, BS binding site, DBD DNA binding domain, P synthetic promoter, synTF synthetic transcription factor, T yeast terminator.

System optimization

Evolution has been optimizing the expression level and the function of the enzymes to improve the structure of NPs for definite biological functions, such as cellular defence mechanisms and communication with other organisms5. To generate yeast cells with non-natural features, careful attention must be paid to balance the expression level of the required enzymes and to speed up their catalytic efficiency73. In addition, capturing cell resources for heterologous pathway gene expression may interfere with critical cellular processes and result in energetic inefficiency in the cell74. As a consequence, the enzyme activity and yield of the desired product are negatively influenced74. To overcome these challenges, approaches for rewiring cellular networks and synthetic evolution in the context of microbial production of NPs are needed.

Rewiring cellular network

A considerable hindrance in microbial bioprocess scale-up for NP production is that the accumulation of NPs within intracellular membranes decreases cell growth (and consequently the yield of the desired NP)75. Another issue arises from the lower catalytic efficiency of plant NP enzymatic reactions in microbial cells compared to that in plants73. A strategy to overcome the aforementioned challenges involves targeting membranes of cellular organelles such as mitochondria, peroxisomes, and vacuoles for compartmentalization and the storage of synthesized NP. In addition, placing the heterologous enzymes inside the cellular compartment enables enzymes such as monoterpene synthases (which have lower catalytic efficiency than the enzymes involved in the cytosolic ergosterol pathway) to access their substrates18. Increasing the ER size to cope with P450 protein folding and accumulation has yielded a concentration of 31.01 mg/L for parthenolide, a precursor for the anti-glioblastoma drug ACT00176. In another study, to maximize the peroxisome membrane storage capacity of S. cerevisiae, the number and size of peroxisomes have been increased through the expression of peroxisome biogenesis-associated peroxins77. The peroxisomal compartmentalization of acetyl-CoA, coupled with increased expression of sesquiterpenoid synthase and redirected precursor supply from the mitochondria to the cytosol, has increased production of terpene (+)-valencene 549-fold (1.2 g/L)74. Dusseaux et al. have introduced the mevalonate pathway into the peroxisomes of S. cerevisiae32, which results in 125-fold greater plant terpene limonene production compared to that achieved in cytosolic production. Srinivasan and Smolke have reported an engineered yeast for increased production of hyoscyamine and scopolamine through chemical engineering of cytosol, mitochondrion, peroxisome, ER membrane, and vacuole21. The expression of four plant transporters, engineering cofactor regeneration mechanisms, and optimized growth conditions have resulted in an increase in de novo tropane hyoscyamine production of more than 100-fold (480 μg/L)78. Overall, depending on the complexity of the NPs79,80, different modifications should apply to the yeast strain to enhance precursor level, provide energy supply, and deliver an adequate level of NAD(P)H.

Synthetic evolution

The balance of metabolism in yeast cells has been optimized by natural evolution, wherein natural selection for desired traits creates iterative rounds of genetic diversity-selection cycles over time81. To achieve the optimal level of NP production in yeast, besides rewiring the native global regulatory networks, the optimal expression level of heterologous enzymes must be evaluated. Therefore, many genetic diversities must be created and tested, in so-called synthetic evolution inspired by nature, which is a time-consuming task82. Here, I focus on combinatorial optimization methods to simultaneously assemble millions of variants, followed by high-throughput screening of optimal variants, to enable rapid synthetic evolution.

Combinatorial optimization library

Strong promoters of yeast genes are repetitively implemented for metabolic engineering purposes in S. cerevisiae, and P. pastoris, which may create a metabolic burden on the cell (thus negatively affecting growth)66. The absent or very low transcription levels of the main biosynthetic genes for complex metabolites plays an essential role in the failure to detect compound production in native or heterologous hosts15. These issues are more severe and challenging for the long biosynthetic pathways of NPs, particularly alkaloids, which are highly toxic metabolites for the host cell19. Fast-growing collections of synTFs for S. cerevisiae67 and P. pastoris28 provide a sophisticated solution to this problem, because they enable orthogonal, tunable, and inducible expression of the target gene(s) at desired processing time. The synTFs are well suited to the platform discussed herein, especially for controlling heterologous gene expression with a light inducer27,83. Using combinatorial optimization strategies, a library of synTFs can be assembled upstream of the individual genes of a biosynthetic pathway to create synthetic transcriptional units69. Combinatorially assembled units in artificial operons are integrated into the multilocus of the yeast genome for stable metabolite production. For example, nine synTFs have been assembled with four genes (to convert farnesyl pyrophosphate (FPP) to aromatic β-ionone) in only seven combinatorial cloning reactions 27. The resulting 36 synthetic transcriptional unit modules have been used to generate a genomically engineered yeast library, in which various cells produce different levels of β-ionone.

In alkaloid biosynthetic pathways, master builder P450s play key roles in generating the structural variety underlying the functional diversity of produced NPs84. Modifying substrate recognition sites of a P450 responsible for the first putative oxygenation step of the forskolin pathway has been found to increase its catalytic activity up to 6-fold in plants85. Davies et al. have reported optimized expression ratio between P450s G8H and its redox partner increases the production of the insect-repellent nepetalactone86. It has been shown that combined synthetic biology and protein engineering allows to identify a suitable cytochrome P450 to decorate the terpene scaffolds leading to produce 28 different noncanonical terpenes87. Concerning several ambiguities about obtaining catalytically active heterologous enzymes (naturally occurring in plants), yeast must be engineered with multiple gene isoforms to identify the optimal enzyme variant. Including different isoforms of various enzymes in the context of combinatorial optimization strategies enables automated optimization at the levels of transcription and translation, thus opening new routes to enhance NP production in yeast cell factories. As a starting point, Zhang et al. have optimized the production of nepetalactol in S. cerevisiae using screening a combinatorial library of four isoforms for iridoid synthases and cyclases7.

Generalized strategies for biosensor development

Detecting enzymes that can improve yield is a crucial challenge in the microbial production of chemicals69. The problem is more pronounced when therapeutic NPs, the end product of long-biosynthetic pathways, are participants in combinatorial optimization techniques88. Moreover, stable scale-up of manufacturing processes faces a bottleneck due to reliance on low-throughput analytical methods for assessing strain performance89. The identification of genetically encoded transcription factor (TF) biosensors may provide alternatives to natural selection through fast screening of top-performing cells. Thus genetically encoded biosensors may potentially become part of a general platform for sustainable production of NPs. d’Oelsnitz et al. have developed a generalized approach to identify TF biosensors to detect plant NPs that are based on the TetR-family of multidrug-resistant TFs from Salmonella typhimurium, RamR, and its derivatives89. RamR derivative biosensor libraries containing more than 105 members have been filtered into several high-performing variants in less than one week, and used to detect several benzylisoquinoline alkaloids (BIAs)89. TF-derived biosensors were subsequently used to translate the BIAs production level into a fluorescence signal. In addition, the TetR-family regulator CamR from Pseudomonas putida has been established to detect the monoterpene NPs90. These data altogether highlight the generalized abilities of the approach to detect various alkaloid-based NPs. This strategy can also be used to screen the intermediate metabolites produced by various isoforms of, for example, P450s and their partners within a combinatorial library to identify the most efficient enzyme isoforms. Another general method to generate biosensors for user-defined molecules has been developed by Beltran et al.91. They have used the plant abscisic acid receptor PYR1, with a malleable ligand-binding pocket, to evolve 21 sensors for a range of small molecules, including structurally diverse natural and synthetic cannabinoids91. Using the systematic evolution of ligands by exponential enrichment (SELEX) strategy, we are potentially able to screen a library of synthetic riboswitches for one with high binding affinity to a NP of interest69. Jang et al. have reported RNA aptamers for naringenin using SELEX92. In this study, the high-affinity naringenin-responsive riboswitches have been identified through applying in vivo selection route to the library by supplementing naringenin at different concentrations during enrichments. With the established NP biosensors, yeast cells producing high levels of NP within the combinatorial library can be detected and sorted with a flow cytometer for further optimization at bioreactor scale.

Output optimization

Bioprocess engineering aims to address the poor productivity of biomanufacturing systems arising from the manual handling of samples, dynamically changing growth environments, external sources of noise, and a lack of control over the conditions experienced by cells before and during growth93. Cybergenetics involves advanced bioprocess engineering approaches that combine engineering and biology, and support the control of engineered metabolic pathways through computer interfaces and feedback controlling biological processes in real time. In this context, Chi.Bio94 and eVOLVER95 are two optogenetic-ready, open-source bioreactors that have been developed and made commercially available. The possibility of continuous cell culturing in automated bioreactors enables optimizing growth conditions for the top NP producers of the combinatorial library. ReacSight, a complementary strategy to enhance bioreactor arrays for automated measurements, provides a flexible instrument control architecture96. The combined platform of ReacSight and Chi.Bio has been used to demonstrate the real-time optogenetic control of gene expression and to achieve dynamic control of the composition of a two-strain consortium96. Similar strategies can be applied to evaluate the target metabolite production in yeast using the light-inducible synTFs and to establish optimal microbial consortia between yeasts and bacteria for carbon-negative manufacturing. In addition, the NP production output of the system can be quantified by real-time measuring the biosensor-derived fluorescent output using flow cytometry linked to an automated bioreactor. Finally, the protocol extracted from the in situ optimization of NP-producing yeast cells in bulk culture would enable unprecedented strategies for bioreactor operation.

Dive into deep-learning data

Previous sections have discussed a platform to simplify the complex tasks of maximizing the synthesis of different NPs in microbial cells. To develop rational engineering strategies for producing rare NPs in the microbial cell, understanding the sophisticated feedback regulations controlled by the intermediate compounds is essential97. The multilayer optimization platform discussed herein may potentially generate a large dataset for developing DL algorithms with direct applications in biomanufacturing. Next-generation sequencing (NGS) approaches have revolutionized the identification of DNA diversity98. NGS can unlock new ways to tackle the DNA diversity in not only top producers but also subpopulations of low- to non-producer cells within the (combinatorial) library. Nevertheless, it alone is not appropriate for identifying the combination of DNA sequence of synTFs and genes encoding enzymatic isoforms within a combinatorial library of yeast population. The high similarity of DNA sequences encoding various synTFs (identical activation domains, minimal promoters, and terminators are typically used to generate synTFs) makes it challenging to infer the relative combination of DNAs of synTF and enzymes during assembly analysis of a (sub) population69. The droplet-based single-cell RNA sequencing allows flag-tagging of individual cells within the population99. The detailed description of droplet-based single-cell RNA sequencing to evaluate a yeast NP-producing library is illustrated in Box 1. However, a drawback to single-cell RNA sequencing is the missing values or dropouts that often occur, mainly because of the low amount of starting material (and consequently failed amplification of the original RNAs)100. Nanopore sequencing produces reads as long as 10 kb, thus resolving the sequencing issue for the repetitive region of synTFs used to modulate the production of NPs. Analytic tools that consider the characteristics of long-read data are mandatory101, but the development of such novel tools might take time. Large-scale single-cell genomics and transcriptomic datasets can be potentially generated using RNA sequencing for both undesirable and desirable populations. Together with induction, production, and bioprocessing optimization data, these data can feed DL algorithms to fit mathematical models, including model predictive control algorithms102,103. Consequently, upon tight control of the experimental conditions and properly processing the generated data, the behavior of the biological system (e.g., dynamics of the gene expression) can be quantitatively described, and its functionality can be enhanced. Ultimately, the mechanisms that trigger loading problems are pinpointed and emergence of non-producer mutants is prevented in scaled-up fermentation.

How DL algorithms may specifically contribute to extracting maximum information from an extensive combinatorial library of NP-producing variants warrants an in-depth review. To call synthetic biologists and bioinformaticians to action in this regard, promising DL programs that are applicable to substantially improving NP production are suggested here. First, Enformer can learn to predict promoter-enhancer interactions directly from the DNA sequence104, thus allowing the design of more robust synTFs for bioengineering heterologous pathways. Second, an array of machine learning methods and amino acid property descriptors are applicable to protein redesign problems, essential tasks in NP biomanufacturing105. Third, the PRISM 4 platform can predict chemical structure106. Through combinatorial optimization of NP pathway engineering in yeast, new derivatives of NPs might be produced for new drug discovery. However, the isolation of novel NP molecules is hindered by the challenge of connecting sequence information to the chemical structures of the molecules. PRISM 4 enables the development of machine-learning methods to predict the likely biological activity of new encoded molecules. In addition to new DL algorithms, powerful computational hardware would be essential to improve the quality and reproducibility of small molecule studies. An important subject that must be addressed is the lack of accessibility of such data and their maintenance. More than 120 natural product databases and collections have been published since 2000107. However, many of them are not automated facilities and do not provide open access to researchers. Generating the dataset based on the FAIR data principle (Findable, Accessible, Interoperable, and Reusable)108, followed by uploading the dataset to third-party facilities such as CloudLabs (https://cloudlabs.us/) or biofoundries (https://agilebiofoundry.org/, http://syncti.org/synthetic-biology-foundry/), can accelerate the design-build-test-learn cycle of NP metabolic engineering in microbial cell factories109.

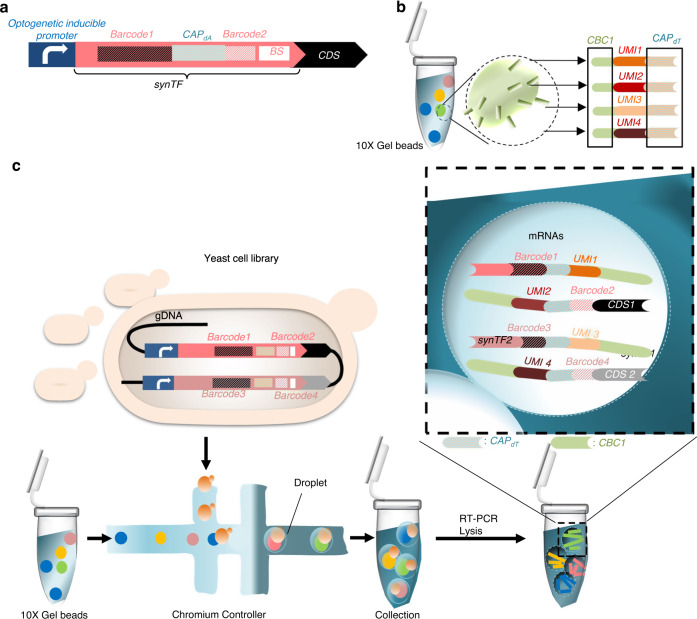

Box 1 Schematic of gDNA capture during RNA-seq of a combinatorial library.

Within the combinatorial libraries, each synthetic DNA cassette encoding synTF, and pathway genes in a single cell can conceivably be labeled with unique barcodes. a, “Barcode 1” is added to the terminator region of the synTF-encoding sequence, whereas a fragment containing artificially added “CAPdT” and “Barcode 2” is inserted upstream of the synTF binding site. The 10x Genomics gel beads consist of a pool of primer sequences that are used to separately index each cell’s transcriptome. The presence of CAPdT in all primer sequences enables RT of the cellular mRNAs within a library. All primers on a single gel bead contain identical CBC sequences to identify all transcriptomes of a single cell. Each primer has a unique UMI to tag each individual cDNA fragment. b, The Chromium Controller from 10x Genomics enables generation of tens of thousands of labeled single-cell partitions in emulsion droplets within minutes. Each droplet contains an identifying barcoded gel bead. c, In each droplet, the gel beads and cells are dissolved. All fragments from the same cell share a standard 10x barcode. In the given example, “Barcode 1” and “Barcode 2” enable identifying the combination of synTF 1 and CDS 1; “Barcode 3” and “Barcode 4” enable identifying the combination of synTF2 and CDS 2. UMIs 1, 2, 3, and 4 enable molecular counting of the captured mRNA molecules synTF 1, CDS 1, synTF 2, and CDS 2, respectively. After reverse transcription, the oil is removed, and all tagged cDNA reads are pooled to be sequenced (alongside whole single-cell transcriptomics) with NGS. The turnkey bioinformatics tools map sequencing reads back by using the identifying barcodes. Abbreviations: CAPdT, capture poly dT; CBC, cell barcode capture; cDNA, coding DNA; CDS, coding DNA sequences; gDNA, genomic DNA; NGS, next-generation sequencing; RT, reverse transcription; synTF, synthetic transcription factor; UMI, unique molecular identifier.

Concluding remarks

We will face the consequences of the largest population explosion in human history in this century110, leading to demand for increasing cropland that competes with the need for land to produce plant-made pharmaceuticals. In a step toward sustainable manufacturing, a desirable strategy is to switch to low-carbon or carbon-neutral manufacturing. Some progresses have been made in converting C1 to value-added chemicals at the industrial scale by acetogens. For example, a recent study has suggested a promising approach for carbon-negative manufacturing of isopropanol chemicals at a large scale by harnessing autotrophic acetogens through metabolic engineering111. However, the conversion of C1 gases to complex NPs of plant, like MIAs, BIAs, by engineering acetogens has still been hindered mainly by the limited availability of genetic manipulation tools, compared to a variety of advanced tools available for yeast36. The slow growth and low productivity under autotrophic conditions are other barriers preventing the commercialization of acetogens on the industrial scale112.

To face possible difficulties to achieve sustainable NP production, a generalized microbial biomanufacturing platform using a wide range of state-of-the-art tools and techniques, as discussed herein, is necessary. To practically use the tools and methods in various laboratories, we must consider the requirement for standardization efforts113. Encouraging chemical engineering laboratories to apply similar principles in designing their toolboxes and methods, for example, according to the BioBrick design rules, and delivering the parts to the BioBrick repository may be a large part of the solution114. To rapidly iterate and improve the NP production protocol, the discussed platform (Fig. 2) was equipped with lab-scale bioreactors for in situ optimization of the output of NP-producing yeast in bulk culture. The generated optimized bioprocessing protocols significantly leverage developing large-scale production strategies. In scale-up bioreactors, the applicability of optogenetic induction systems and the possibility of the mixed microbial co-culture are two specific features for consideration. Open infrastructures such as UNLOCK bioreactor platform115 may offer promising avenues toward scale-up production of the NPs using CO2 and optogenetic inducer. The flexible arrangement of different types of bioreactors of UNLOCK platform allows for high-throughput cultivation of mixed cultures in MSBC and further optimization of the upstream and downstream bioprocessing protocols. Notably, safely storing the multilayer metadata produced according to the FAIR guiding principles108 is of particular relevance for simultaneously ingesting, exploring, and analyzing using DL approaches.

Before transitioning NP production technology to the commercial production level, an essential consideration is developing effective regulatory compliance, besides establishing the scale-up protocol. One of the highest commercial potentials is to focus on carbon-negative biomanufacturing strategies, as they may offer promising global warming solutions while concurrently providing further economic benefits from cheap C1 feedstocks by producing high-value NPs116. Recent progresses, like establishing anaerobic biofoundries, leads to the fast growth of this path117. Nevertheless, analytic studies on the quality, stability, and safety of C1-derived NPs, and the potential effect of by-products on the efficiency of processing during fermentation118 should be seriously considered. Furthermore, to develop cost-effective, large-scale biomanufacturing, deliberating on the process cost and technical and economic performances of the entire supply chain is necessary. For example, 30–50% of the manufacturing costs of supplies are typically allocated to downstream processing118. In addition, to successfully establish the discussed platform, communication issues between the disciplines must be addressed. Therefore, organizing annual interdisciplinary conferences focusing on sustainable NP production and workshops teaching various aspects of the involved disciplines are of critical importance. Providing more funding opportunities to support interdisciplinary projects can be an impetus for collaboration between different disciplines. For example, the willingness of biopharmaceutical companies to potentially commercialize C1-derived products opens new doors to defray some of the research costs to continue the investigation on improving the potential of the C1 technology. As a breakthrough step toward facilitating the funding of interdisciplinary fields, ‘Executive Order 14081’ on advancing biotechnology and biomanufacturing was recently approved in the USA, which aims to encourage federal investment in biotechnology and biomanufacturing. Hopefully, more countries will also take into consideration to further support research on developing the interdisciplinary field of sustainable biomanufacturing of small-molecule drugs.

Several tools and approaches to establish the discussed platform, e.g., synTFs, combinatorial optimization techniques, light inducers, bioprocessing optimization strategies, and single-cell sequencing technologies, can be implemented individually to optimize production of NP drugs in yeast. They can also be adapted to other bioengineering projects to facilitate the production of high nutritional value proteins, enzymes, and vitamins. Overall, the proposed biomanufacturing platform’s roadmap provides a unique niche for academia-industry collaboration.

Acknowledgements

The author thanks the Max Planck Society for its financial support (to Marc Erhardt, Max Planck Fellow, Max Planck Unit for the Science of Pathogens), and Emmanuelle Charpentier and Marc Erhardt for their insightful discussions.

Author contributions

G.N. conceived and wrote the article.

Peer review

Peer review information

Nature Communications thanks Pablo Carbonell, Oliver Kayser and Michael Köpke for their contribution to the peer review of this work.

Competing interests

The author declares no competing interests.

Footnotes

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

References

- 1.Patridge E, Gareiss P, Kinch MS, Hoyer D. An analysis of FDA-approved drugs: natural products and their derivatives. Drug Discov. Today. 2016;21:204–207. doi: 10.1016/j.drudis.2015.01.009. [DOI] [PubMed] [Google Scholar]

- 2.Newman DJ, Cragg GM. Natural Products as sources of new drugs over the nearly four decades from 01/1981 to 09/2019. J. Nat. Prod. 2020;83:770–803. doi: 10.1021/acs.jnatprod.9b01285. [DOI] [PubMed] [Google Scholar]

- 3.Atanasov AG, Zotchev SB, Dirsch VM, Supuran CT. Natural products in drug discovery: advances and opportunities. Nat. Rev. Drug Discov. 2021;20:200–216. doi: 10.1038/s41573-020-00114-z. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 4.Pollier J, Moses T, Goossens A. Combinatorial biosynthesis in plants: a (p)review on its potential and future exploitation. Nat. Prod. Rep. 2011;28:1897–1916. doi: 10.1039/c1np00049g. [DOI] [PubMed] [Google Scholar]

- 5.Chong KW, et al. Biosynthetic Enantiodivergence in the Eburnane Alkaloids from Kopsia. J. Nat. Prod. 2017;80:3014–3024. doi: 10.1021/acs.jnatprod.7b00621. [DOI] [PubMed] [Google Scholar]

- 6.Mobasheri A, et al. Recent advances in understanding the phenotypes of osteoarthritis. F1000Res. 2019;8:2091. doi: 10.12688/f1000research.20575.1. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 7.Zhang J, et al. A microbial supply chain for production of the anti-cancer drug vinblastine. Nature. 2022;609:341–347. doi: 10.1038/s41586-022-05157-3. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 8.Meadows AL, et al. Rewriting yeast central carbon metabolism for industrial isoprenoid production. Nature. 2016;537:694–697. doi: 10.1038/nature19769. [DOI] [PubMed] [Google Scholar]

- 9.Zhang C, Zou R, Chen X, Stephanopoulos G, Too HP. Experimental design-aided systematic pathway optimization of glucose uptake and deoxyxylulose phosphate pathway for improved amorphadiene production. Appl. Microbiol. Biotechnol. 2015;99:3825–3837. doi: 10.1007/s00253-015-6463-y. [DOI] [PubMed] [Google Scholar]

- 10.Winter JM, Behnken S, Hertweck C. Genomics-inspired discovery of natural products. Curr. Opin. Chem. Biol. 2011;15:22–31. doi: 10.1016/j.cbpa.2010.10.020. [DOI] [PubMed] [Google Scholar]

- 11.Daley SK, Cordell GA. Alkaloids in contemporary drug discovery to meet global disease needs. Molecules. 2021;26:3800. doi: 10.3390/molecules26133800. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 12.Tanaka Y, Sasaki N, Ohmiya A. Biosynthesis of plant pigments: anthocyanins, betalains and carotenoids. Plant J. 2008;54:733–749. doi: 10.1111/j.1365-313X.2008.03447.x. [DOI] [PubMed] [Google Scholar]

- 13.Kastberg LLB, Ard R, Jensen MK, Workman CT. Burden imposed by heterologous protein production in two major industrial yeast cell factories: identifying sources and mitigation strategies. Front. Fungal biol. 2022;3:827704. doi: 10.3389/ffunb.2022.827704. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 14.Mattanovich D, Sauer M, Gasser B. Yeast biotechnology: teaching the old dog new tricks. Micro. Cell Fact. 2014;13:34. doi: 10.1186/1475-2859-13-34. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 15.Brown S, Clastre M, Courdavault V, O’Connor SE. De novo production of the plant-derived alkaloid strictosidine in yeast. Proc. Natl Acad. Sci. USA. 2015;112:e3205–e3210. doi: 10.1073/pnas.1423555112. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 16.Roddan R, Ward JM, Keep NH, Hailes HC. Pictet-Spenglerases in alkaloid biosynthesis: future applications in biocatalysis. Curr. Opin. Chem. Biol. 2020;55:69–76. doi: 10.1016/j.cbpa.2019.12.003. [DOI] [PubMed] [Google Scholar]

- 17.Galanie S, Smolke CD. Optimization of yeast-based production of medicinal protoberberine alkaloids. Micro. Cell Fact. 2015;14:144. doi: 10.1186/s12934-015-0332-3. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 18.Yee DA, et al. Engineered mitochondrial production of monoterpenes in Saccharomyces cerevisiae. Metab. Eng. 2019;55:76–84. doi: 10.1016/j.ymben.2019.06.004. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 19.Beaudoin GA, Facchini PJ. Benzylisoquinoline alkaloid biosynthesis in opium poppy. Planta. 2014;240:19–32. doi: 10.1007/s00425-014-2056-8. [DOI] [PubMed] [Google Scholar]

- 20.Knoblach B, et al. An ER-peroxisome tether exerts peroxisome population control in yeast. EMBO J. 2013;32:2439–2453. doi: 10.1038/emboj.2013.170. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 21.Srinivasan P, Smolke CD. Biosynthesis of medicinal tropane alkaloids in yeast. Nature. 2020;585:614–619. doi: 10.1038/s41586-020-2650-9. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 22.Bernauer L, Radkohl A, Lehmayer LGK, Emmerstorfer-Augustin A. Komagataella phaffii as emerging model organism in fundamental research. Front. Microbiol. 2020;11:607028. doi: 10.3389/fmicb.2020.607028. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 23.Gao J, et al. Biosynthesis of catharanthine in engineered Pichia pastoris. Nat. Synth. 2023;2:231–242. [Google Scholar]

- 24.Urui M, et al. Establishment of a co-culture system using Escherichia coli and Pichia pastoris (Komagataella phaffii) for valuable alkaloid production. Micro. Cell Fact. 2021;20:200. doi: 10.1186/s12934-021-01687-z. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 25.Yurimoto H, Oku M, Sakai Y. Yeast methylotrophy: metabolism, gene regulation and peroxisome homeostasis. Int. J. Microbiol. 2011;2011:101298. doi: 10.1155/2011/101298. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 26.Winter JM, Tang Y. Synthetic biological approaches to natural product biosynthesis. Curr. Opin. Biotechnol. 2012;23:736–743. doi: 10.1016/j.copbio.2011.12.016. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 27.Naseri G, Behrend J, Rieper L, Mueller-Roeber B. COMPASS for rapid combinatorial optimization of biochemical pathways based on artificial transcription factors. Nat. Commun. 2019;10:2615. doi: 10.1038/s41467-019-10224-x. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 28.Naseri G, Prause K, Hamdo HH, Arenz C. Artificial transcription factors for tuneable gene expression in Pichia pastoris. Front. Bioeng. Biotechnol. 2021;9:676900. doi: 10.3389/fbioe.2021.676900. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 29.Sanford A, Kiriakov S, Khalil AS. A toolkit for precise, multigene control in Saccharomyces cerevisiae. ACS Synth. Biol. 2022;11:3912–3920. doi: 10.1021/acssynbio.2c00423. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 30.Ito Y, et al. Exchange of endogenous and heterogeneous yeast terminators in Pichia pastoris to tune mRNA stability and gene expression. Nucleic Acids Res. 2020;48:13000–13012. doi: 10.1093/nar/gkaa1066. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 31.Gao J, Jiang L, Lian J. Development of synthetic biology tools to engineer Pichia pastoris as a chassis for the production of natural products. Synth. Syst. Biotechnol. 2021;6:110–119. doi: 10.1016/j.synbio.2021.04.005. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 32.Dusseaux S, Wajn WT, Liu Y, Ignea C, Kampranis SC. Transforming yeast peroxisomes into microfactories for the efficient production of high-value isoprenoids. Proc. Natl Acad. Sci. USA. 2020;117:e31789–e31799. doi: 10.1073/pnas.2013968117. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 33.Freestone TS, Zhao H. Combinatorial pathway engineering for optimized production of the anti-malarial FR900098. Biotechnol. Bioeng. 2016;113:384–392. doi: 10.1002/bit.25719. [DOI] [PubMed] [Google Scholar]

- 34.Woodley JM. Towards the sustainable production of bulk-chemicals using biotechnology. Nat. Biotechnol. 2020;59:59–64. doi: 10.1016/j.nbt.2020.07.002. [DOI] [PubMed] [Google Scholar]

- 35.Fast AG, Papoutsakis ET. Stoichiometric and energetic analyses of non-photosynthetic CO2-fixation pathways to support synthetic biology strategies for production of fuels and chemicals. Curr. Opin. Chem. Eng. 2012;1:380–395. doi: 10.1016/j.coche.2012.07.005. [DOI] [Google Scholar]

- 36.Bennett RK, Steinberg LM, Chen W, Papoutsakis ET. Engineering the bioconversion of methane and methanol to fuels and chemicals in native and synthetic methylotrophs. Curr. Opin. Biotechnol. 2018;50:81–93. doi: 10.1016/j.copbio.2017.11.010. [DOI] [PubMed] [Google Scholar]

- 37.Couderc R, Baratti J. Immobilized yeast cells with methanol oxidase activity: preparation and enzymatic properties. Biotechnol. Bioeng. 1980;22:1155–1173. doi: 10.1002/bit.260220605. [DOI] [PubMed] [Google Scholar]

- 38.Gassler T, et al. The industrial yeast Pichia pastoris is converted from a heterotroph into an autotroph capable of growth on CO2. Nat. Biotechnol. 2020;38:210–216. doi: 10.1038/s41587-019-0363-0. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 39.Baumschabl M, et al. Conversion of CO2 into organic acids by engineered autotrophic yeast. Proc. Natl Acad. Sci. USA. 2022;119:e2211827119. doi: 10.1073/pnas.2211827119. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 40.Papapetridis I, et al. Optimizing anaerobic growth rate and fermentation kinetics in Saccharomyces cerevisiae strains expressing Calvin-cycle enzymes for improved ethanol yield. Biotechnol. Biofuels. 2018;11:17. doi: 10.1186/s13068-017-1001-z. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 41.Gong F, Cai Z, Li Y. Synthetic biology for CO2 fixation. Sci. China Life Sci. 2016;59:1106–1114. doi: 10.1007/s11427-016-0304-2. [DOI] [PubMed] [Google Scholar]

- 42.Li YJ, et al. Engineered yeast with a CO2-fixation pathway to improve the bio-ethanol production from xylose-mixed sugars. Sci. Rep. 2017;7:43875. doi: 10.1038/srep43875. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 43.Yang F, Zhang J, Cai Z, Zhou J, Li Y. Exploring the oxygenase function of Form II RuBisCo for production of glycolate from CO2. AMB Express. 2021;11:65. doi: 10.1186/s13568-021-01224-6. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 44.Kildegaard KR, et al. Engineering and systems-level analysis of Saccharomyces cerevisiae for production of 3-hydroxypropionic acid via malonyl-CoA reductase-dependent pathway. Micro. Cell Fact. 2016;15:53. doi: 10.1186/s12934-016-0451-5. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 45.Schwander T, Schada von Borzyskowski L, Burgener S, Cortina NS, Erb TJ. A synthetic pathway for the fixation of carbon dioxide in vitro. Science. 2016;354:900–904. doi: 10.1126/science.aah5237. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 46.Miller TE, et al. Light-powered CO2 fixation in a chloroplast mimic with natural and synthetic parts. Science. 2020;368:649–654. doi: 10.1126/science.aaz6802. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 47.Sundaram S, et al. A modular in vitro platform for the production of terpenes and polyketides from CO2. Angew. Chem. Int. Ed. Engl. 2021;60:16420–16425. doi: 10.1002/anie.202102333. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 48.Cai P, et al. Methanol biotransformation toward high-level production of fatty acid derivatives by engineering the industrial yeast Pichia pastoris. Proc. Natl Acad. Sci. USA. 2022;119:e2201711119. doi: 10.1073/pnas.2201711119. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 49.Gassler T, Baumschabl M, Sallaberger J, Egermeier M, Mattanovich D. Adaptive laboratory evolution and reverse engineering enhances autotrophic growth in Pichia pastoris. Met. Eng. 2022;69:112–121. doi: 10.1016/j.ymben.2021.11.007. [DOI] [PubMed] [Google Scholar]

- 50.Shlosberg Y, Schuster G, Adir N. Harnessing photosynthesis to produce electricity using cyanobacteria, green algae, seaweeds and plants. Front. Plant Sci. 2022;13:955843. doi: 10.3389/fpls.2022.955843. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 51.Cheng YC, et al. Conversion of Escherichia coli into mixotrophic CO2 assimilation with malate and hydrogen based on recombinant expression of 2-oxoglutarate:ferredoxin oxidoreductase using adaptive laboratory evolution. Microorganisms. 2023;11:253. doi: 10.3390/microorganisms11020253. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 52.Zhang P, et al. Chem-bio interface design for rapid conversion of CO2 to bioplastics in an integrated system. Chem. 2022;8:3363–3381. doi: 10.1016/j.chempr.2022.09.005. [DOI] [Google Scholar]

- 53.Khakhar A, Bolten NJ, Nemhauser J, Klavins E. Cell-cell communication in yeast using auxin biosynthesis and auxin responsive CRISPR transcription factors. ACS Synth. Biol. 2016;5:279–286. doi: 10.1021/acssynbio.5b00064. [DOI] [PubMed] [Google Scholar]

- 54.Charubin K, Papoutsakis ET. Direct cell-to-cell exchange of matter in a synthetic Clostridium syntrophy enables CO2 fixation, superior metabolite yields, and an expanded metabolic space. Metab. Eng. 2019;52:9–19. doi: 10.1016/j.ymben.2018.10.006. [DOI] [PubMed] [Google Scholar]

- 55.Kang CW, et al. Circuit-guided population acclimation of a synthetic microbial consortium for improved biochemical production. Nat. Commun. 2022;13:6506. doi: 10.1038/s41467-022-34190-z. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 56.Sudheer S, Bai RG, Usmani Z, Sharma M. Insights on engineered microbes in sustainable agriculture: biotechnological developments and future prospects. Curr. Genomics. 2020;21:321–333. doi: 10.2174/1389202921999200603165934. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 57.Johns NI, Blazejewski T, Gomes AL, Wang HH. Principles for designing synthetic microbial communities. Curr. Opin. Microbiol. 2016;31:146–153. doi: 10.1016/j.mib.2016.03.010. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 58.Molitor B, Mishra A, Angenent LT. Power-to-protein: converting renewable electric power and carbon dioxide into single cell protein with a two-stage bioprocess. Energy Environ. Sci. 2019;12:3515–3521. doi: 10.1039/C9EE02381J. [DOI] [Google Scholar]

- 59.Hu P, et al. Integrated bioprocess for conversion of gaseous substrates to liquids. Proc. Natl Acad. Sci. USA. 2016;113:e3773–e3778. doi: 10.1073/pnas.1516867113. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 60.Nguyen PQ, et al. Wearable materials with embedded synthetic biology sensors for biomolecule detection. Nat. Biotechol. 2021;39:1366–1374. doi: 10.1038/s41587-021-00950-3. [DOI] [PubMed] [Google Scholar]

- 61.Vaiana CA, et al. Characterizing chemical signaling between engineered “microbial sentinels” in porous microplates. Mol. Syst. Biol. 2022;18:e10785. doi: 10.15252/msb.202110785. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 62.Wang L, et al. Engineering consortia by polymeric microbial swarmbots. Nat. Commun. 2022;13:3879. doi: 10.1038/s41467-022-31467-1. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 63.Bar-Even A, Noor E, Lewis NE, Milo R. Design and analysis of synthetic carbon fixation pathways. Proc. Natl Acad. Sci. USA. 2010;107:e8889–e8894. doi: 10.1073/pnas.0907176107. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 64.Durall C, Lindberg P, Yu J, Lindblad P. Increased ethylene production by overexpressing phosphoenolpyruvate carboxylase in the cyanobacterium Synechocystis PCC 6803. Biotechnol. Biofuels. 2020;13:16. doi: 10.1186/s13068-020-1653-y. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 65.Cournoyer JE, et al. Engineering artificial photosynthetic life-forms through endosymbiosis. Nat. Commun. 2022;13:2254. doi: 10.1038/s41467-022-29961-7. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 66.Borodina I, Nielsen J. Advances in metabolic engineering of yeast Saccharomyces cerevisiae for production of chemicals. Biotechnol. J. 2014;9:609–620. doi: 10.1002/biot.201300445. [DOI] [PubMed] [Google Scholar]

- 67.Naseri G, et al. Plant-derived transcription factors for orthologous regulation of gene expression in the yeast Saccharomyces cerevisiae. ACS Synth. Biol. 2017;6:1742–1756. doi: 10.1021/acssynbio.7b00094. [DOI] [PubMed] [Google Scholar]

- 68.Dvorak P, et al. Exacerbation of substrate toxicity by IPTG in Escherichia coli BL21(DE3) carrying a synthetic metabolic pathway. Micro. Cell Fact. 2015;14:201. doi: 10.1186/s12934-015-0393-3. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 69.Naseri G, Koffas MAG. Application of combinatorial optimization strategies in synthetic biology. Nat. Commun. 2020;11:2446. doi: 10.1038/s41467-020-16175-y. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 70.Machens F, Balazadeh S, Mueller-Roeber B, Messerschmidt K. Synthetic promoters and transcription factors for heterologous protein expression in Saccharomyces cerevisiae. Front. Bioeng. Biotechnol. 2017;5:63. doi: 10.3389/fbioe.2017.00063. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 71.Hochrein L, Machens F, Messerschmidt K, Mueller-Roeber B. PhiReX: a programmable and red light-regulated protein expression switch for yeast. Nucleic Acids Res. 2017;45:9193–9205. doi: 10.1093/nar/gkx610. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 72.Benzinger D, Khammash M. Pulsatile inputs achieve tunable attenuation of gene expression variability and graded multi-gene regulation. Nat. Commun. 2018;9:3521. doi: 10.1038/s41467-018-05882-2. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 73.Montano Lopez J, Duran L, Avalos JL. Physiological limitations and opportunities in microbial metabolic engineering. Nat. Rev. Microbiol. 2022;20:35–48. doi: 10.1038/s41579-021-00600-0. [DOI] [PubMed] [Google Scholar]

- 74.Cao C, et al. Global metabolic rewiring of yeast enables overproduction of sesquiterpene (+)-valencene. J. Agric Food Chem. 2022;70:7180–7187. doi: 10.1021/acs.jafc.2c01394. [DOI] [PubMed] [Google Scholar]

- 75.Huang M, Bao J, Hallstrom BM, Petranovic D, Nielsen J. Efficient protein production by yeast requires global tuning of metabolism. Nat. Commun. 2017;8:1131. doi: 10.1038/s41467-017-00999-2. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 76.Shi Y, et al. Production of plant sesquiterpene lactone parthenolide in the yeast cell factory. ACS Synth. Biol. 2022;11:2473–2483. doi: 10.1021/acssynbio.2c00132. [DOI] [PubMed] [Google Scholar]

- 77.Choi KR, Ahn Y-J, Lee SY. Bacterial conversion of CO2 to organic compounds. J. CO2 Util. 2022;58:101929. doi: 10.1016/j.jcou.2022.101929. [DOI] [Google Scholar]

- 78.Srinivasan P, Smolke CD. Engineering cellular metabolite transport for biosynthesis of computationally predicted tropane alkaloid derivatives in yeast. Proc. Natl Acad. Sci. USA. 2021;118:e2104460118. doi: 10.1073/pnas.2104460118. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 79.Liu J, Zhang W, Du G, Chen J, Zhou J. Overproduction of geraniol by enhanced precursor supply in Saccharomyces cerevisiae. J. Biotechnol. 2013;168:446–451. doi: 10.1016/j.jbiotec.2013.10.017. [DOI] [PubMed] [Google Scholar]

- 80.Scalcinati G, et al. Combined metabolic engineering of precursor and co-factor supply to increase alpha-santalene production by Saccharomyces cerevisiae. Micro. Cell Fact. 2012;11:117. doi: 10.1186/1475-2859-11-117. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 81.Campbell R, Robert JS. The structure of evolution by natural selection. Biol. Philos. 2005;20:673–696. doi: 10.1007/s10539-004-2439-5. [DOI] [Google Scholar]

- 82.Simon AJ, d’Oelsnitz S, Ellington AD. Synthetic evolution. Nat. Biotechol. 2019;37:730–743. doi: 10.1038/s41587-019-0157-4. [DOI] [PubMed] [Google Scholar]

- 83.Hérisson J, et al. The automated Galaxy-SynBioCAD pipeline for synthetic biology design and engineering. Nat. Commun. 2022;13:5082. doi: 10.1038/s41467-022-32661-x. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 84.Zanger UM, Schwab M. Cytochrome P450 enzymes in drug metabolism: regulation of gene expression, enzyme activities, and impact of genetic variation. Pharm. Ther. 2013;138:103–141. doi: 10.1016/j.pharmthera.2012.12.007. [DOI] [PubMed] [Google Scholar]

- 85.Forman V, Bjerg-Jensen N, Dyekjaer JD, Moller BL, Pateraki I. Engineering of CYP76AH15 can improve activity and specificity towards forskolin biosynthesis in yeast. Micro. Cell Fact. 2018;17:181. doi: 10.1186/s12934-018-1027-3. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 86.Davies ME, Tsyplenkov D, Martin VJJ. Engineering yeast for de-novo synthesis of the insect repellent - nepetalactone. ACS Synth. Biol. 2021;10:2896–2903. doi: 10.1021/acssynbio.1c00420. [DOI] [PubMed] [Google Scholar]

- 87.Ignea C, et al. Expanding the terpene biosynthetic code with non-canonical 16 carbon atom building blocks. Nat. Commun. 2022;13:5188. doi: 10.1038/s41467-022-32921-w. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 88.Hossain GS, Saini M, Miyake R, Ling H, Chang MW. Genetic biosensor design for natural product biosynthesis in microorganisms. Trends Biotechnol. 2020;38:797–810. doi: 10.1016/j.tibtech.2020.03.013. [DOI] [PubMed] [Google Scholar]

- 89.d’Oelsnitz S, et al. Using fungible biosensors to evolve improved alkaloid biosyntheses. Nat. Chem. Biol. 2022;18:981–989. doi: 10.1038/s41589-022-01072-w. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 90.d’Oelsnitz S, Nguyen V, Alper HS, Ellington AD. Evolving a generalist biosensor for bicyclic monoterpenes. ACS Synth. Biol. 2022;11:265–272. doi: 10.1021/acssynbio.1c00402. [DOI] [PubMed] [Google Scholar]

- 91.Beltran J, et al. Rapid biosensor development using plant hormone receptors as reprogrammable scaffolds. Nat. Biotechnol. 2022;40:1855–1861. doi: 10.1038/s41587-022-01364-5. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 92.Jang S, et al. Development of artificial riboswitches for monitoring of naringenin in vivo. ACS Synth. Biol. 2017;6:2077–2085. doi: 10.1021/acssynbio.7b00128. [DOI] [PubMed] [Google Scholar]

- 93.Castillo-Hair SM, et al. FlowCal: a user-friendly, open source software tool for automatically converting flow cytometry data from arbitrary to calibrated units. ACS Synth. Biol. 2016;5:774–780. doi: 10.1021/acssynbio.5b00284. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 94.Steel H, Habgood R, Kelly CL, Papachristodoulou A. In situ characterisation and manipulation of biological systems with Chi.Bio. PLoS Biol. 2020;18:e3000794. doi: 10.1371/journal.pbio.3000794. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 95.Wong BG, Mancuso CP, Kiriakov S, Bashor CJ, Khalil AS. Precise, automated control of conditions for high-throughput growth of yeast and bacteria with eVOLVER. Nat. Biotechnol. 2018;36:614–623. doi: 10.1038/nbt.4151. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 96.Bertaux F, et al. Enhancing bioreactor arrays for automated measurements and reactive control with ReacSight. Nat. Commun. 2022;13:3363. doi: 10.1038/s41467-022-31033-9. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 97.Zhou Q, Ning S, Luo Y. Coordinated regulation for nature products discovery and overproduction in Streptomyces. Synth. Syst. Biotechnol. 2020;5:49–58. doi: 10.1016/j.synbio.2020.04.002. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 98.Bratovic M, et al. Bridge helix arginines play a critical role in Cas9 sensitivity to mismatches. Nat. Chem. Biol. 2020;16:587–595. doi: 10.1038/s41589-020-0490-4. [DOI] [PubMed] [Google Scholar]

- 99.Jariani A, et al. A new protocol for single-cell RNA-seq reveals stochastic gene expression during lag phase in budding yeast. eLife. 2020;9:e55320. doi: 10.7554/eLife.55320. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 100.Chen G, Ning B, Shi T. Single-cell RNA-seq technologies and related computational data analysis. Front. Genet. 2019;10:317. doi: 10.3389/fgene.2019.00317. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 101.Amarasinghe SL, et al. Opportunities and challenges in long-read sequencing data analysis. Genome Biol. 2020;21:30. doi: 10.1186/s13059-020-1935-5. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 102.Kumar SS, Indiran T, Itty GV, Shettigar JP, Paul TV. Development of a nonlinear model predictive control-based nonlinear three-mode controller for a nonlinear system. ACS Omega. 2022;7:42418–42437. doi: 10.1021/acsomega.2c05542. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 103.O’Connor OM, Alnahhas RN, Lugagne JB, Dunlop MJ. DeLTA 2.0: a deep learning pipeline for quantifying single-cell spatial and temporal dynamics. PLoS Comput. Biol. 2022;18:e1009797. doi: 10.1371/journal.pcbi.1009797. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 104.Avsec Z, et al. Effective gene expression prediction from sequence by integrating long-range interactions. Nat. Methods. 2021;18:1196–1203. doi: 10.1038/s41592-021-01252-x. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 105.Xu Y, et al. Deep dive into machine learning models for protein engineering. J. Chem. Inf. Model. 2020;60:2773–2790. doi: 10.1021/acs.jcim.0c00073. [DOI] [PubMed] [Google Scholar]

- 106.Skinnider MA, et al. Comprehensive prediction of secondary metabolite structure and biological activity from microbial genome sequences. Nat. Commun. 2020;11:6058. doi: 10.1038/s41467-020-19986-1. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 107.Sorokina M, Steinbeck C. Review on natural products databases: where to find data in 2020. J. Cheminform. 2020;12:20. doi: 10.1186/s13321-020-00424-9. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 108.Wilkinson MD, et al. The FAIR guiding principles for scientific data management and stewardship. Sci. Data. 2016;3:160018. doi: 10.1038/sdata.2016.18. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 109.Hillson N, et al. Building a global alliance of biofoundries. Nat. Commun. 2019;10:2040. doi: 10.1038/s41467-019-10079-2. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 110.FAO | United Nations organization. World Summit on Food Security. Wikipedia, (2009).

- 111.Liew FE, et al. Carbon-negative production of acetone and isopropanol by gas fermentation at industrial pilot scale. Nat. Biotechnol. 2022;40:335–344. doi: 10.1038/s41587-021-01195-w. [DOI] [PubMed] [Google Scholar]

- 112.Lee H, Bae J, Jin S, Kang S, Cho BK. Engineering acetogenic bacteria for efficient one-carbon utilization. Front. Microbiol. 2022;13:865168. doi: 10.3389/fmicb.2022.865168. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 113.Malci K, et al. Standardization of Synthetic biology tools and assembly methods for Saccharomyces cerevisiae and emerging yeast species. ACS Synth. Biol. 2022;11:2527–2547. doi: 10.1021/acssynbio.1c00442. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 114.Dixon TA, Freemont PS, Johnson RA, Pretorius IS. A global forum on synthetic biology: the need for international engagement. Nat. Commun. 2022;13:3516. doi: 10.1038/s41467-022-31265-9. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 115.UNLOCK. Wageningen University & Research. https://m-unlock.nl/ (2022).

- 116.Teixeira LV, Moutinho LF, Romão-Dumaresq AS. Gas fermentation of C1 feedstocks: commercialization status and future prospects. Biofuels Bioprod. Biorefin. 2018;12:1103–1117. doi: 10.1002/bbb.1912. [DOI] [Google Scholar]

- 117.Kopke M, Simpson SD. Pollution to products: recycling of ‘above ground’ carbon by gas fermentation. Curr. Opin. Biotechnol. 2020;65:180–189. doi: 10.1016/j.copbio.2020.02.017. [DOI] [PubMed] [Google Scholar]

- 118.Takors R, et al. Using gas mixtures of CO, CO2 and H2 as microbial substrates: the do’s and don’ts of successful technology transfer from laboratory to production scale. Micro. Biotechnol. 2018;11:606–625. doi: 10.1111/1751-7915.13270. [DOI] [PMC free article] [PubMed] [Google Scholar]