Abstract

The investigation of the structure and physicochemical properties of starch extracted from a new variety of purple rice was the aim of this study. Starch extracted from a new variety of purple rice named Tianzi No. 1 (PRS) is different in structure and physicochemical properties compared with waxy rice starch (WRS), japonica rice starch (JRS), and indica rice starch (IRS). PRS granules were diversified in shape, and the birefringence of starch particles were clearly observed. Fourier-transform infrared (FT-IR) spectroscopy exhibited the degree of double helix and low short-range order structure of PRS differed from IRS, JRS and WRS. X-ray diffraction analysis shows that PRS presented a typical A-type XRD pattern and possessed lower crystallinity. Based on rheological experiment results, PRS had the highest apparent viscosity, storage modulus (G′) and loss modulus (G″). According to textural experiments, PRS gels had higher textural paraments before and after retrogradation.

Supplementary Information

The online version contains supplementary material available at 10.1007/s10068-022-01205-w.

Keywords: Starch, Purple rice, Physicochemical property, Crystallinity, Structure

Introduction

Purple rice is a kind of pigmented rice, which widely cultivated in China, Japan and Southeast Asia (Shen et al., 2017). The demand for purple rice has increased rapidly in the past years because of the unique color, characteristic flavor, and health benefits (Chen et al., 2016a; Min et al., 2009; Wongwichai et al., 2019). Especially that purple rice had important biological activities, including antioxidant (Min et al., 2009), anti-inflammatory (Sun et al., 2015), hepatoprotective (Hou et al., 2013), anti-cancer (Daiponmak et al., 2014), antiglycation (Chen et al., 2016b; Hlaing et al., 2019), and et al. However, most purple rice varieties had poor plant types, few grains per panicle, weak disease resistance, and low yield, so that they are not suitable for production and application. Recently, a new variety of purple rice, named Tianzi No. 1 has attracted increasing attention. This variety of purple rice was cultivated by hybridizing from traditional purple rice variety and indica rice, and it has been widespread in Guangdong Province.

As a versatile biomaterial, starch influence the physical and cooking properties of rice and is an important food product, which used in a wide range of foods (e.g., bakery products, meat products, snack foods, soft drinks) and non-food applications (e.g., pharmaceuticals, medical, agrochemicals, adhesives) (Amagliani et al., 2016). The structure and physicochemical properties of starch largely defined its versatility in industrial applications. Starch is a polymeric mixture of amylose and amylopectin. And the ratio of amylose and amylopectin varies depending on the botanical origin of the starch. The existing research in the literature have been on purple rice grain itself, e.g. the impacts of starch structure and anthocyanin content on the digestibility of rice (Ratseewo et al., 2019), the physicochemical properties, starch hydrolysis, predicted glycemic index of purple rice flour (Thiranusornkij et al., 2019). However, there is a lack of research on the physicochemical properties of this starch derived from the new variety of purple rice, so systematic research is urgently needed.

The objective of this study was to isolate starch from purple rice and study the morphology, thermal, rheological, textural, and other physicochemical properties and compared with three traditional Chinese rice varieties including indica, japonica and waxy rice. These results of the present work would provide useful information and insights for developing new starch resource and expanding industrial applications of PRS.

Materials and methods

Materials

The purple rice named Tianzi No. 1, a new variety of colored rice varieties, was donated by Xinxing County Weifeng Agricultural Science and Technology Co. Ltd (Yunfu, Guangdong, China). Waxy rice and Japonica rice was purchased in COFCO Haiyou (Beijing) Co., Ltd. (Beijing, China). Indica rice was purchased from Shengbao United Grain Co., Ltd. (Shenzhen, China). All the chemicals used in the experiments were of analytical grade.

Starch isolation

Starch was isolated by using the previously described alkaline steeping method (Chen et al., 2019) with slight modifications. Briefly, rice grain was respectively crushed into powder (0.150 mm diameter) using a multifunctional crusher. The rice flour and 0.3% (w/v) NaOH solution were mixed in a ratio of 1:5 and stirred at ambient temperature for 24 h. The mixture then needs to be centrifuged (H1850R, Xiangyi Centrifuge Instrument Co., Ltd., Changsha, Hunan, China) at 5000 rpm for 10 min. Retain the sediment and repeat the above operation. After that, the starch residue was washed and centrifuged with distilled water at 5000 rpm for 10 min. Repeated the above procedure several times until the starch solution is neutral, after which the sediment was collected and dried at 50 °C for 48 h. Finally, the extracted starch was crushed and sieved through 100 mesh sieves. And finally crush the extracted starch and sieve with a 100-mesh sieve for later use. The ash content, moisture, protein, and fat in rice starch were determined by the AOAC method. Apparent amylose content (%)was determined using the colorimetric method (da Silva et al., 2020). The apparent amylose content of purple rice starch, indica rice starch, japonica rice starch, and waxy rice starch is 26.38%, 22.90%, 18.41%, and 1.05%, respectively. And the results of ash content, moisture, protein, and fat in rice starch were presented in Supplementary Material.

Preparation of starch pastes

The rice starch (5 g, dry basis) and distilled water (100ml) were mixed in the hermetical flask. And then, take the flask in boiling water and stirred continuously for 30 min to form starch pastes (5%, w/w).

Morphological properties

The micrographs of rice starches were taken in deionized water with a polarization microscope (Axioskop 40 Pol/40 A Pol, Zeiss, Oberkochen, Germany) equipped with a 35 mm SLA camera. The magnification was set at 400.

Fourier transform infrared (FTIR) analysis

FTIR spectra of starches were recorded and analyzed with an FTIR spectrophotometer (Vertex 70, Bruke Corporation, Germany) in the range of 400–4000 cm−1, at a resolution of 2 cm−1 using the potassium bromide (KBr) pellets technique. The background spectrum was recorded on air and subtracted from the sample spectrum. All FTIR spectra were processed by OMNIC 8.0 software. The FTIR curves were deconvoluted at the range of 800–1200 cm−1 (k factor 2.0, half-width 25), and the ratio 1047/1022 cm−1 (R1047/1022) were calculated (Ratseewo et al., 2019).

X-ray diffraction (XRD) and relative crystallinity

The crystal morphology of rice starch samples was identified by an X-ray diffractometer (Ulitma IV, Rigaku Corporation, Japan) operating at 40 kV and 40 mA under Cu Kα radiation. The diffraction angle (2θ) scanning range was 4° to 50°, and the scanning speed was 2°/min. The relative crystallinity (Rc) was estimated by MDI Jade 6.0 software according to the previously described method (Chen et al., 2021). Rc was calculated by the following Eq. (1):

| 1 |

where Rc is the integrated areas of all crystalline peaks, and Ra is the integrated areas of the amorphous halo.

Thermal properties

The differential scanning calorimetry (DSC 400, Perkin Elmer, Inc., Waltham, Massachusetts, USA) was used to analyze the thermal properties of starch samples, which were equipped with data software (Chen et al., 2019). Starch samples (3 mg, dry basis) were added into a plastic centrifuge tube and mixed with 9 µL of distilled water. After sealed and equilibrated overnight at 25 °C, the pan was scanned to 120 °C at 20 °C with a constant heating rate of 10 °C /min. Place an empty pan beside it as a reference. The gelatinization onset temperature (To), peak temperature (Tp), conclusion temperature (Tc), and gelatinization enthalpy (ΔH) were calculated and analyzed from the DSC heating curve (Huang et al., 2022).

Rheological properties

The rheometer (MARS 40/60, Thermo Fisher, USA), which was equipped with a Peltier plate temperature system and a parallel plate geometry (35 mm diameter,1 mm gap), was used to analyze the rheological properties of starch pastes (5%, w/w). Silicone oil was applied to cover around the border of the plate to prevent the evaporation of water throughout the test (Liu and Budtova, 2013). All rheological properties were measured at 25 °C. All samples were equilibrated for 3 min before measurement.

The steady-state viscosities of rice paste samples (5%, w/w) were recorded in a shear rate range from 0.1 to 500 s−1at 25 °C. Shear stress and viscosity values were recorded as functions of shear rate. For the sake of describing the steady shear rheological properties of samples, the data were modeled and analyzed by the power-law equation [Eqs. (2) and (3)]:

| 2 |

| 3 |

where is shear stress (Pa), is the shear rate (s-1), K is the consistency coefficient (Pa sn), n is the flow behavior index, and is apparent viscosity (Pa s).

Dynamic rheological variations consisting of storage modulus (G′), loss modulus (G″), and loss factor (tan δ = G′′/ G′) were measured for starch pastes samples (5%, w/w). The gap size, strain and temperature were set at 1 mm, 1% and 25 °C, respectively, for all determinations. The G′, G′ and tan δ in the frequency range of 0.1 ~ 20 rad/s were obtained by angular frequency scanning test.

Freeze-thaw stability

The freeze-thaw stability of starch pastes was evaluated according to the method of Hedayati et al. (2016) with some modifications. After gelatinizing and cooling, the rice starch paste (about 25 g) was transferred to 50 mL centrifuge tubes and frozen at − 18 °C for 18 h, followed by thawing at 30 °C for 6 h. The freeze-thawed samples were centrifuged at 5000 rpm for 20 min after repeating the freeze-thaw cycles five times. The percentage of syneresis (%) was calculated by Eq. (4):

| 4 |

Textural analysis

A texture analyzer was employed by useing the back extrusion test to perform the textural of rice starch pastes with or without retrogradation (Tao et al., 2021). Approximately 50 g fresh starch pastes were transferred into a cylindrical container (50 mm internal diameter), and the extrusion probe (45 mm diameter) was used to perform back extrusion with a distance of 8.0 mm and a trigger force of 5 g. The speed of the pre-test, test and post-test were set at 2 mm s−1, 2 mm s−1 and 10.0 mm s−1, respectively.

Similarly, the texture properties of starch paste samples which kept at 4 °C for 3 and 7 days were determined in accordance with the test methods above.

Statistical analysis

All data were obtained in triplicate experimental tests, and the results were expressed as the mean ± standard deviation. The significant differences (p < 0.05) between data were determine by Duncan test.

Results and discussions

Polarized light microscopy analysis

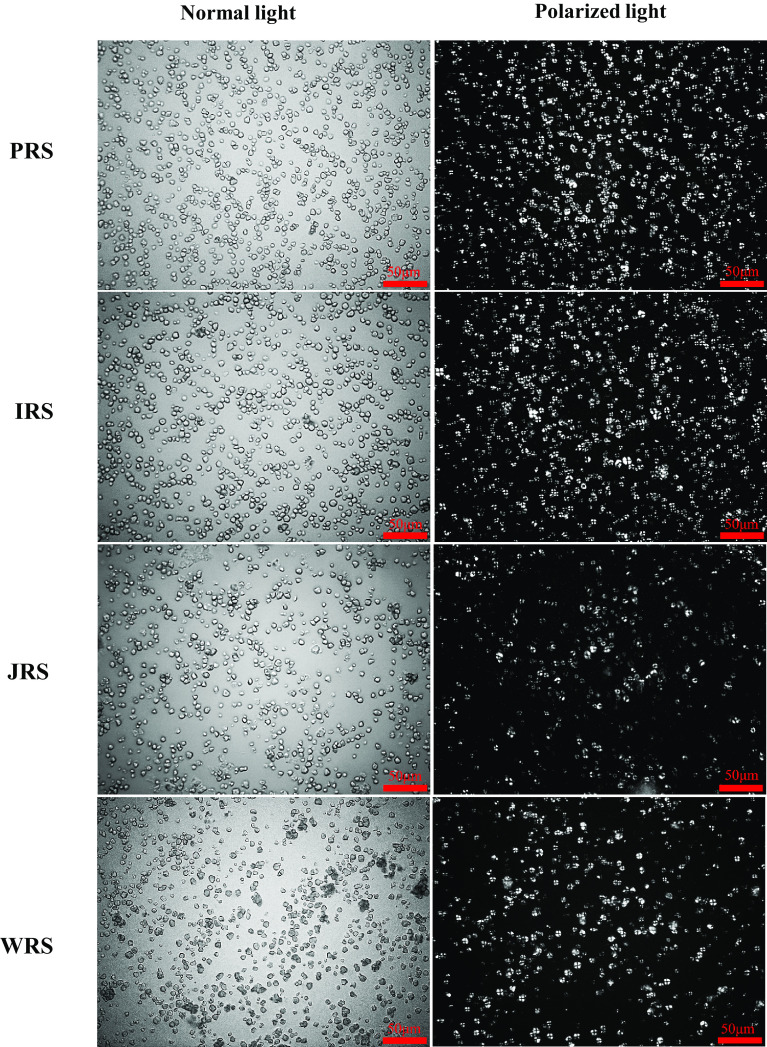

The physicochemical properties of starch are related to the size and shapes of starch granules. Therefore, the study of the morphology of starch granules is essential for a proper understanding of the properties of PRS. Figure 1 exhibited the light microscopic images of four rice starch in water under normal and polarized lights. Under normal light, PRS were observed to be in small and uneven-sized particles with circular, oval, or polyhedral shapes. Under polarized light, the Maltese crosses of four rice starch particles were clearly seen, suggesting the birefringence of native starch crystalline. Besides, the cross intersection was the origin of starch granule growth, which called hilum (Xiao et al., 2020). However, the position, shape and obvious degree of the Maltese crosses were different due to the starch source.

Fig. 1.

Light microscopic images of four rice starches in water under normal and polarized lights. The scal bar size is 50 μm

Fourier transform infrared (FTIR) analysis

To explore the difference between the short-range ordered structure of purple rice starch and other starches, the original and deconvoluted spectra (800 ~ 1200 cm−1) of four rice starches were shown in Fig. 2A–C. Figure 2A showed the broad band at 3297 cm−1and the sharp band at 2929 cm−1 were attributed to the intermolecular –OH stretching vibration, and –CH asymmetric stretching, respectively. There was an intense band at 1639 cm −1, which is attributed to the deformation vibration of the hydroxyl group in water (Guo et al., 2014). A weak band at 1336 cm−1 was ascribed to the twisting shake of –CH2. The peaks at 1149 cm−1 and 1074 cm−1 contributed to C–O stretching of C–O–H in starch (Wang et al., 2021). The peak at 1012 cm−1 was associated with the vibration of C–O–H deformation (Wang et al., 2021; Yang et al., 2021). As shown in the deconvoluted FTIR spectra (Fig. 2B), the similar FTIR spectrum of the PRS sample with the other three rice starches indicates that there are no significant differences in the functional group among them. Moreover, the same absorption peaks of rice starch samples also probably mean they have similar basic chemical structures. These results are consistent with previous reports on starch in other rice varieties (Falade et al., 2014; Gani et al., 2017).

Fig. 2.

The FTIR spectra (A–C) and X-ray diffraction patterns (D–E) of four rice starches. (A): whole FT-IR spectra. (B): deconvoluted FT-IR spectra. (C): the ratio of 1045 to 1022 cm−1 and 1022 to 995 cm−1. (D): the XRD diffractograms. (E): the degrees of crystallinity

The ratio of 1045 to 1022 cm−1 could be an index to evaluate the ordered degree of starch granule, while the content of amorphous structure in starch could be estimated by the ratio of 1022 to 995 cm−1(Ren et al., 2021). Research has shown that the greater amount of the amylopectin content in rice starch may contribute to a higher ordered double helix and crystalline flake stacking area in the starch granules (Jeong et al., 2021). PRS had slightly lower 1045/1022 cm−1 than that of IRS and JRS, but significantly lower than that of WRS (Fig. 2B), which may be ascribed to the fact that the four rice starches have different internal ordering of amylose/amylopectin and relative crystallinity. Among the four rice starches, PRS has the highest amylose content (26.38%), while WRS has the lowest amylose content (1.05%), which means that PRS has less amylopectin double helix structure and a lower ordered degree than WRS.

Crystallinity

Figure 2D–E showed the XRD diffractograms and the degrees of crystallinity (Rc, %) of four rice starch samples. All the granules of starch samples contained amorphous, crystalline, and semi-crystalline regions. Like most normal cereal starches, the four rice starches represented a typical A-type XRD pattern of diffraction and mainly exhibited peak values at 15, 17, 18 and 23°(Bhat and Riar, 2019), retaining more compact packing of double helices in their starch granules. However, the relative crystallinity (Rc, %) ranged from 24.02 ± 0.59% to 31.20 ± 0.35%, in the order of WRS > JRS > IRS > PRS. Relative crystallinity is an index to describe the ratio of the crystalline peak area to the total area, and it is associated with the differences in the amylose and amylopectin ratio of starch (da Silva et al., 2020). The relative crystallinity seemed to decrease with the increase in amylose content, which indicated that PRS had the highest amylose content among the four samples.

Thermal properties

Table 1 showed the gelatinization temperatures of the samples. According to the data in Table 1, it was found that there was a difference in the values of ΔH, To, Tp, and Tc of four rice starches, thereby the different degrees of crystallinity in starch granules were revealed. The PRS had the highest gelatinization temperatures (To, Tp, and Tc), whereas the WRS showed the lowest. The To, Tp, and Tc of PRS were 62.39 ± 0.61 °C, 70.23 ± 0.92 °C, and 77.71 ± 0.60 °C, respectively. Generally, the gelatinization temperatures of starch were affected by amylose content, due to the restricted hydration of the amorphous regions of amylose. Table 1 revealed that the gelatinization temperatures of PRS and IRS were significantly higher than JRS and WRS, which attributable to the different amylose content. The To, Tp, and Tc of PRS were 63.72 ± 0.32 °C, 68.74 ± 0.02 °C, and 75.49 ± 0.61 °C, respectively. Generally, the gelatinization temperatures of starch were affected by amylose content, due to the restricted hydration of the amorphous regions of amylose (Jeong et al., 2021). However, the amylose content of PRS is slightly higher than IRS, which is inconsistent with previous research (Tangsrianugul et al., 2019), possibly because the amylopectin chain length distribution was different between PRS and IRS. The gelatinization temperatures of rice starches were related not only to the amylose content but also to the chain length distributions of amylopectin (Takahashi and Fujita, 2017). During heating, starch absorbed water and swelled. Amylose tended to increase the rigidity and compactness of starch granules, inhibiting the expansion of starch granules. Hence, the higher gelatinization temperatures of PRS may be due to more amylose and less amylopectin.

Table 1.

The gelatinization characteristics of four rice starches from DSC thermograms

| Starch type | To (°C) | Tp (°C) | Tc (°C) | ΔH (J/g) |

|---|---|---|---|---|

| PRS | 63.72 ± 0.32b | 68.74 ± 0.02b | 75.49 ± 0.61c | 8.47 ± 0.07c |

| IRS | 76.06 ± 0.84a | 81.89 ± 0.06a | 87.71 ± 0.12a | 12.03 ± 0.69b |

| JRS | 59.75 ± 0.07c | 68.19 ± 0.21c | 79.57 ± 0.12b | 13.85 ± 0.25a |

| WRS | 59.63 ± 0.22c | 66.02 ± 0.42d | 79.18 ± 0.39b | 14.19 ± 0.12a |

Mean ± standard deviation values in the same column for each solution followed by different superscripts are significantly different (p ≤ 0.05)

As an indicator to assess the loss of molecular order, ΔH provides an overall measurement of the crystallinity of starch granules, reflecting the thermal energy associated with the melting of crystallites by breaking both inter- and intra-helical hydrogen bonds (Li and Gong, 2020). As shown in Table 1, the ΔH decreases with increasing the amylose content in the four rice starches, and PRS with higher amylose content had the lowest ΔH (8.47 ± 0.07 J/g) among all kinds of rice starch. The differences in enthalpy of the four kinds of samples may be attribute to the differences in the internal granule structure of amylopectin between varieties. According to the FT-IR results, PRS had the lowest ordered degree, which means the molecular compactness of PRS particles is lower than that of other rice starch samples. Thus, PRS requires less energy to decompose intermolecular bonds in the starch granules, which is consistent with the results of Tangsrianugul et al. (2019).

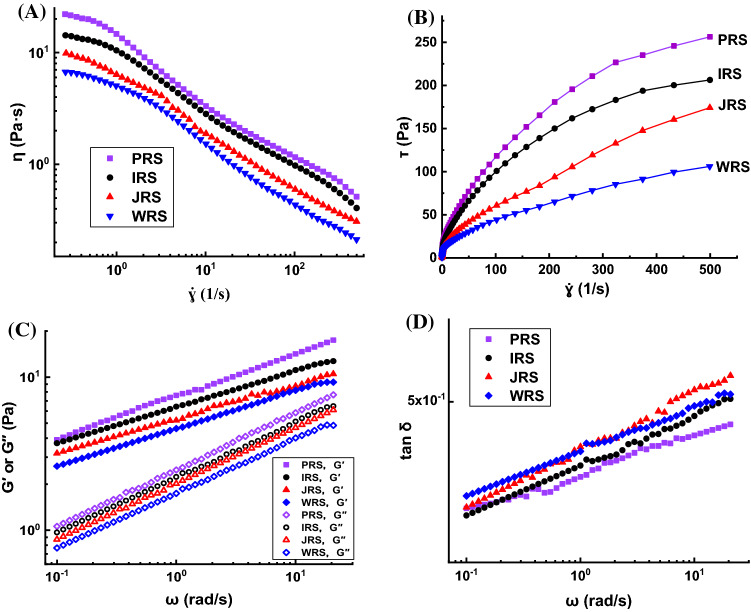

Steady shear rheological properties

The steady shear rheological properties of four different rice starch paste samples were summarized in Fig. 3A–B and Table 2. It can be seen from Fig. 3A–B that the apparent viscosity of all starch samples decreased with the increase of shear rate (Fig. 3A, B), illustrate that all samples showed shear thinning fluid behavior (Wang et al., 2021). In same shear rate, PRS showed higher apparent viscosity, and WRS was opposite, indicating that PRS was with a poorer shear thinning behavior. Generally, the ratio of amylose and amylopectin influenced the apparent viscosity of starches (Lawal et al., 2011). Higher amylose content may be contributed to form more tangles among amylose chains into three-dimensional structure, whereas amylopectin cannot form effective tangles due to more branches (Wang et al., 2021). Correspondingly, the shear stress of all starch samples gradually increased with the increasing of the shear rate, and PRS exhibits significantly greater shear stress than other starches (Fig. 3B).

Fig. 3.

The steady shear rheological properties (A–B), dynamic frequency sweep (C–D) of four rice starch pastes (5%, w/w) at 25 °C

Table 2.

The power law parameters for four rice starch pastes (5%, w/w)

| Starch type | K (Pa sn) | n | R2 |

|---|---|---|---|

| PRS | 13.714 ± 0.586a | 0.449 ± 0.007d | 0.990 |

| IRS | 9.945 ± 0.079b | 0.510 ± 0.007c | 0.988 |

| JRS | 6.246 ± 0.219c | 0.562 ± 0.011b | 0.996 |

| WRS | 4.424 ± 0.127d | 0.595 ± 0.002a | 0.973 |

Mean ± standard deviation values in the same column for each solution followed by different superscripts are significantly different (p ≤ 0.05)

The steady shear rheological curves were fitted by the power-law equation (R2 > 0.97) and the calculated parameters (K and n) were presented in Table 2. The flow behavior indexes (n) of four rice starch samples were less than 1.0, revealing all test samples were non-Newtonian fluids. Amylose chains twined and bound reciprocally through hydrogen bond to form a better starch gel structure, contributing a greater viscosity. In the current study, the K value of PRS was higher than other three kinds of rice starch, suggesting the positive relationship between K value and amylose content.

Dynamic rheological properties

The dynamic rheological results were visualized in Fig. 3C–D. The storage modulus (G′) and loss modulus (G″ )of all samples increase linearly with the increase of angular frequency range (ω). Additionally, G″ values of all samples were lower than the corresponding G′ values, and there was no crossover between the G′ and G″ throughout the tested frequency ranges, reflecting that all rice starch samples showed higher elastic behavior and performed a typical weak gel rheologically (Tangsrianugul et al., 2019). Over the entire frequency range, tan δ increased with the increasing frequency, and the tan δ of four rice starch gels were much smaller than unity, indicating that four rice starch pastes displayed elastic or solid-like behavior (Tangsrianugul et al., 2019). Among all rice varieties, PRS has higher G ′ and G″ and lower tan δ values, and the amylose content of PRS is the highest. Correspondingly, PRS gels were regarded as more structured and more elastic. These results here were consistent with the previous research on some other rice starch (Lu et al., 2009; Tangsrianugul et al., 2019).

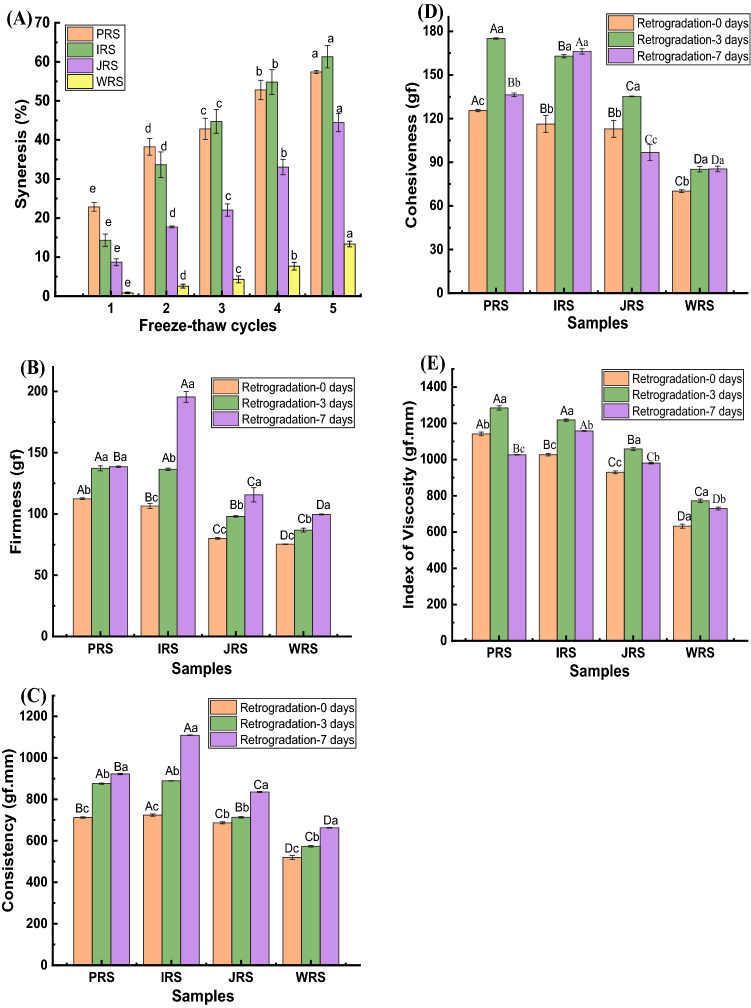

Freeze-thaw stability

The freeze-thaw stability of four rice starch pastes (5%, w/w) was presented in Fig. 4A. It has been reported that lower syneresis rate indicated better freeze-thaw stability. Through the comparison of four samples, it is found that PRS showed higher syneresis, indicating its poorer freeze-thaw stability. Through five freeze-thaw cycles, the syneresis of PRS gel was 60.79 ± 0.94%, while IRS, JRS and WRS gels were 67.04 ± 1.45%, 44.45 ± 2.32% and 13.35 ± 0.73%, respectively. Normally, the freeze-thaw stability was relative to starch sources, modification conditions, freeze-thaw conditions, additives, and et al. (Srichuwong et al., 2012). To sum up, the freeze-thaw stability of PRS gel was poor, which means PRS gel deteriorated easily during the repeat freeze-thaw cycle, indicating that PRS did not be suitable for application in frozen food and need to improve its stability by additives additions or further modifications.

Fig. 4.

The freeze-thaw stability (A) and textural parameters (B–E) of four rice starch pastes (5%, w/w)

Textural properties

The transformations in textural paraments of four rice starch pastes (5%, w/w) before or after retrogradation were summarized in Fig. 4B–E. For fresh starch pastes, the texture parameters of the four rice starch pastes were significantly different, with a decreasing order: PRS > IRS > JRS > WRS. The textural paraments tended to increase with the amylose content, since linear amylose molecules cross-linked through hydrogen bond during gelatinization to form a tough gel structure. The existence of amylopectin seemed to prevent the starch molecular rearrangement, and therefore, PRS performed highest textural values.

After retrogradation at 4 °C for 3 days and 7 days, the firmness and consistency of PRS both increased with the increase of retrogradation time. Throughout the starch retrogradation process, amylose and amylopectin in starch paste were recrystallized as a result of moisture migration, thereby changing the textural properties (Donmez et al., 2021). Along with the extension of retrogradation time, the cohesiveness, and the viscosity index of PRS first increased and then decreased, and both paraments showed high values compared to other samples.

In conclusion, the starch of Tianzi No. 1 purple rice (PRS) varied significantly from Chinese traditional rice cultivar starches [waxy rice starch (WRS), japonica rice starch (JRS), and indica rice starch (IRS)] in the fine structure, color, pasting, rheological, textural, and other physicochemical properties. As visualized by polarized light microscopy, the PRS presented diversiform morphologies, and the birefringence of starch particles were clearly seen. PRS presented a typical A-type XRD pattern and possessed lower crystallinity of 24.02 ± 0.59%. Based upon the FTIR spectroscopy results, PRS exhibited similar FTIR spectra with IRS, JRS and WRS, but the degree of double helix and lower short-range order structure varied. Furthermore, PRS had the highest apparent viscosity, storage modulus (G′) and loss modulus (G″) in rheological experiments. The PRS gels were characterized by the higher textural paraments than those of IRS, JRS and WRS, which help to extend the application range. However, PRS with higher amylose content showed higher syneresis and lower freeze-thaw stability. In conclusion, purple rice could be seen as a potential new starch, which could be utilized as a viable functional food ingredient widely used in food industries. These new findings here provided useful information and insights into developing new starch resources and a theoretical basis for the processing of purple rice.

Supplementary Information

Below is the link to the electronic supplementary material.

Acknowledgements

This research was supported by Guangdong Simiao Rice Characteristic industrial clusters (Grant Yue Nong Han [2022] No. 840), Sail Plan for Talents Development (Grant No. 2017YT05H077) and the Postdoctoral Science Foundation of China (Grant No. 2017M612679).

Declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Footnotes

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Xiaoqi Tao and Qiqi Su have contributed equally to this work.

Contributor Information

Xiaoqi Tao, Email: txq_1995@163.com.

Qiqi Su, Email: jysqq666@163.com.

Hai Wu, Email: 1364112768@qq.com.

Lei Zhan, Email: leizhan@stu.scau.edu.cn.

Wei Huang, Email: weih007@scau.edu.cn.

Jingshao Zheng, Email: Zl2809909498@163.com.

Qingling Zhong, Email: zhongkylie@163.com.

Pei Chen, Email: peichen@scau.edu.cn.

References

- Amagliani L, O’Regan J, Kelly AL, O’Mahony JA. Chemistry, structure, functionality and applications of rice starch. Journal of Cereal Science. 2016;70:291–300. doi: 10.1016/j.jcs.2016.06.014. [DOI] [Google Scholar]

- Bhat FM, Riar CS. Effect of chemical composition, granule structure and crystalline form of pigmented rice starches on their functional characteristics. Food Chemistry. 2019;297:124984. doi: 10.1016/j.foodchem.2019.124984. [DOI] [PubMed] [Google Scholar]

- Chen M-H, McClung AM, Bergman CJ. Bran data of total flavonoid and total phenolic contents, oxygen radical absorbance capacity, and profiles of proanthocyanidins and whole grain physical traits of 32 red and purple rice varieties. Data in brief. 2016;8:6–13. doi: 10.1016/j.dib.2016.05.001. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Chen YF, Shibu MA, Fan MJ, Chen MC, Viswanadha VP, Lin YL, Lai CH, Lin KH, Ho TJ, Kuo WW, Huang CY. Purple rice anthocyanin extract protects cardiac function in STZ-induced diabetes rat hearts by inhibiting cardiac hypertrophy and fibrosis. The Journal of Nutritional Biochemistry. 2016;31:98–105. doi: 10.1016/j.jnutbio.2015.12.020. [DOI] [PubMed] [Google Scholar]

- Chen F, Xie F, Liu P, Chen P. Structure, thermal stability and suspension rheological properties of alcohol–alkali-treated waxy rice starch. International Journal of Biological Macromolecules. 2019;134:397–404. doi: 10.1016/j.ijbiomac.2019.05.009. [DOI] [PubMed] [Google Scholar]

- Chen P, Zhang Y, Qiao Q, Tao X, Liu P, Xie F. Comparison of the structure and properties of hydroxypropylated acid-hydrolysed maize starches with different amylose/amylopectin contents. Food Hydrocolloids. 2021;110:106134. doi: 10.1016/j.foodhyd.2020.106134. [DOI] [Google Scholar]

- da Silva LR, Piler de Carvalho CW, Velasco JI, Fakhouri FM. Extraction and characterization of starches from pigmented rice. International Journal of Biological Macromolecules. 2020;156:485–493. doi: 10.1016/j.ijbiomac.2020.04.034. [DOI] [PubMed] [Google Scholar]

- Daiponmak W, Senakun C, Siriamornpun S. Antiglycation capacity and antioxidant activities of different pigmented Thai rice. International Journal of Food Science & Technology. 2014;49:1805–1810. doi: 10.1111/ijfs.12487. [DOI] [Google Scholar]

- Donmez D, Pinho L, Patel B, Desam P, Campanella OH. Characterization of starch–water interactions and their effects on two key functional properties: starch gelatinization and retrogradation. Current Opinion in Food Science. 2021;39:103–109. doi: 10.1016/j.cofs.2020.12.018. [DOI] [Google Scholar]

- Falade KO, Semon M, Fadairo OS, Oladunjoye AO, Orou KK. Functional and physico-chemical properties of flours and starches of African rice cultivars. Food Hydrocolloids. 2014;39:41–50. doi: 10.1016/j.foodhyd.2013.11.002. [DOI] [Google Scholar]

- Gani A, Ashwar BA, Akhter G, Shah A, Wani IA, Masoodi FA. Physico-chemical, structural, pasting and thermal properties of starches of fourteen Himalayan rice cultivars. International Journal of Biological Macromolecules. 2017;95:1101–1107. doi: 10.1016/j.ijbiomac.2016.10.100. [DOI] [PubMed] [Google Scholar]

- Guo J, Liu L, Lian X, Li L, Wu H. The properties of different cultivars of Jinhai sweet potato starches in China. International Journal of Biological Macromolecules. 2014;67:1–6. doi: 10.1016/j.ijbiomac.2014.03.002. [DOI] [PubMed] [Google Scholar]

- Hedayati S, Shahidi F, Koocheki A, Farahnaky A, Majzoobi M. Functional properties of granular cold-water swelling maize starch: effect of sucrose and glucose. International Journal of Food Science & Technology. 2016;51:2416–2423. doi: 10.1111/ijfs.13222. [DOI] [Google Scholar]

- Hlaing EE, Rungcharoenarrichit S, Lailerd N, Roytrakul S, Piamrojanaphat P. Purple rice bran improves hepatic insulin signaling via activation of akt and stabilization of igf in diabetic rats. pp. 297-312. In: Dietary Interventions in Liver Disease. Watson RR, Preedy VR (eds). Academic Press (2019)

- Hou F, Zhang R, Zhang M, Su D, Wei Z, Deng Y, Zhang Y, Chi J, Tang X. Hepatoprotective and antioxidant activity of anthocyanins in black rice bran on carbon tetrachloride-induced liver injury in mice. Journal of Functional Foods. 2013;5:1705–1713. doi: 10.1016/j.jff.2013.07.015. [DOI] [Google Scholar]

- Huang Y, Zhan L, Du B, Li P, Lin Q, Zheng J, Chen P. Effects of Inca peanut seed albumin fraction on rheological, thermal and microstructural properties of native corn starch. International Journal of Biological Macromolecules. 2022;194:626–631. doi: 10.1016/j.ijbiomac.2021.11.106. [DOI] [PubMed] [Google Scholar]

- Jeong D, Lee JH, Chung HJ. Effect of molecular structure on phase transition behavior of rice starch with different amylose contents. Carbohydrate Polymers. 2021;259:117712. doi: 10.1016/j.carbpol.2021.117712. [DOI] [PubMed] [Google Scholar]

- Lawal OS, Lapasin R, Bellich B, Olayiwola TO, Cesàro A, Yoshimura M, Nishinari K. Rheology and functional properties of starches isolated from five improved rice varieties from West Africa. Food Hydrocolloids. 2011;25:1785–1792. doi: 10.1016/j.foodhyd.2011.04.010. [DOI] [Google Scholar]

- Li C, Gong B. Insights into chain-length distributions of amylopectin and amylose molecules on the gelatinization property of rice starches. International Journal of Biological Macromolecules. 2020;155:721–729. doi: 10.1016/j.ijbiomac.2020.04.006. [DOI] [PubMed] [Google Scholar]

- Liu W, Budtova T. Dissolution of unmodified waxy starch in ionic liquid and solution rheological properties. Carbohydrate Polymers. 2013;93:199–206. doi: 10.1016/j.carbpol.2012.01.090. [DOI] [PubMed] [Google Scholar]

- Lu Z-H, Sasaki T, Li Y-Y, Yoshihashi T, Li L-T, Kohyama K. Effect of amylose content and rice type on dynamic viscoelasticity of a composite rice starch gel. Food Hydrocolloids. 2009;23:1712–1719. doi: 10.1016/j.foodhyd.2009.01.009. [DOI] [Google Scholar]

- Min B, Chen MH, Green BW. Antioxidant activities of purple rice bran extract and its effect on the quality of low-NaCl, phosphate-free patties made from channel catfish (Ictalurus punctatus) belly flap meat. Journal of Food Science. 2009;74:C268-77. doi: 10.1111/j.1750-3841.2009.01108.x. [DOI] [PubMed] [Google Scholar]

- Ratseewo J, Warren FJ, Siriamornpun S. The influence of starch structure and anthocyanin content on the digestibility of Thai pigmented rice. Food Chemistry. 2019;298:124949. doi: 10.1016/j.foodchem.2019.06.016. [DOI] [PubMed] [Google Scholar]

- Ren Y, Wei Q, Lin L, Shi L, Cui Z, Li Y, Huang C, Wei C. Physicochemical properties of a new starch from ramie (Boehmeria nivea) root. International Journal of Biological Macromolecules. 2021;174:392–401. doi: 10.1016/j.ijbiomac.2021.01.205. [DOI] [PubMed] [Google Scholar]

- Shen Y, Song X, Chen Y, Li L, Sun J, Huang C, Ou S, Zhang H. Effects of sorghum, purple rice and rhubarb rice on lipids status and antioxidant capacity in mice fed a high-fat diet. Journal of Functional Foods. 2017;39:103–111. doi: 10.1016/j.jff.2017.10.017. [DOI] [Google Scholar]

- Srichuwong S, Isono N, Jiang H, Mishima T, Hisamatsu M. Freeze–thaw stability of starches from different botanical sources: Correlation with structural features. Carbohydrate Polymers. 2012;87:1275–1279. doi: 10.1016/j.carbpol.2011.09.004. [DOI] [Google Scholar]

- Sun D, Huang S, Cai S, Cao J, Han P. Digestion property and synergistic effect on biological activity of purple rice (Oryza sativa L.) anthocyanins subjected to a simulated gastrointestinal digestion in vitro. Food Research International. 2015;78:114–123. doi: 10.1016/j.foodres.2015.10.029. [DOI] [PubMed] [Google Scholar]

- Takahashi T, Fujita N. Thermal and rheological characteristics of mutant rice starches with widespread variation of amylose content and amylopectin structure. Food Hydrocolloids. 2017;62:83–93. doi: 10.1016/j.foodhyd.2016.06.022. [DOI] [Google Scholar]

- Tangsrianugul N, Wongsagonsup R, Suphantharika M. Physicochemical and rheological properties of flour and starch from Thai pigmented rice cultivars. International Journal of Biological Macromolecules. 2019;137:666–675. doi: 10.1016/j.ijbiomac.2019.06.196. [DOI] [PubMed] [Google Scholar]

- Tao X, Zhang Y, Chen F, Huang Y, Chen P. Effects of sucrose on pasting, thermal, rheological and textural properties of native and alcohol-alkali-treated waxy rice starch. International Journal of Biological Macromolecules. 2021;166:108–116. doi: 10.1016/j.ijbiomac.2020.10.102. [DOI] [PubMed] [Google Scholar]

- Thiranusornkij L, Thamnarathip P, Chandrachai A, Kuakpetoon D, Adisakwattana S. Comparative studies on physicochemical properties, starch hydrolysis, predicted glycemic index of Hom Mali rice and Riceberry rice flour and their applications in bread. Food Chemistry. 2019;283:224–231. doi: 10.1016/j.foodchem.2019.01.048. [DOI] [PubMed] [Google Scholar]

- Wang J, Liu T, Bian X, Hua Z, Chen G, Wu X. Structural characterization and physicochemical properties of starch from four aquatic vegetable varieties in China. International Journal of Biological Macromolecules. 2021;172:542–549. doi: 10.1016/j.ijbiomac.2021.01.078. [DOI] [PubMed] [Google Scholar]

- Wongwichai T, Teeyakasem P, Pruksakorn D, Kongtawelert P, Pothacharoen P. Anthocyanins and metabolites from purple rice inhibit IL-1beta-induced matrix metalloproteinases expression in human articular chondrocytes through the NF-kappaB and ERK/MAPK pathway. Biomed Pharmacother. 2019;112:108610. doi: 10.1016/j.biopha.2019.108610. [DOI] [PubMed] [Google Scholar]

- Xiao H, Wang S, Xu W, Yin Y, Xu D, Zhang L, Liu G-Q, Luo F, Sun S, Lin Q, Xu B. The study on starch granules by using darkfield and polarized light microscopy. Journal of Food Composition and Analysis. 2020;92:103576. doi: 10.1016/j.jfca.2020.103576. [DOI] [Google Scholar]

- Yang Z, Hao H, Wu Y, Liu Y, Ouyang J. Influence of moisture and amylose on the physicochemical properties of rice starch during heat treatment. International Journal of Biological Macromolecules. 2021;168:656–662. doi: 10.1016/j.ijbiomac.2020.11.122. [DOI] [PubMed] [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.