Abstract

In this study, a method has been developed to reduce the negative effects of superabsorbent polymers on concrete mechanical properties. The method involves concrete mixing and curing, with the concrete mixture being designed using a decision tree algorithm. Instead of the standard water curing approach, air curing conditions were used during the curing process. In addition, heat treatment was applied to reduce any possible negative effects of the polymers on the concrete's mechanical properties and to enhance their performance. The details of all these stages are presented in this method. Various experimental studies were conducted to demonstrate the validity of this method, which proved to be effective in reducing the negative effects of superabsorbent polymers on concrete mechanical properties.

-

•

The method can be used to eliminate the negative effects of superabsorbent polymers.

-

•

The proposed method yielded promising results, demonstrating that the expected level of compressive strength, modulus of elasticity and toughness in concrete can be achieved in 5-10 days instead of 28 days

-

•

The widespread use of superabsorbent polymers in the concrete industry and reinforced concrete systems can be attributed to their many benefits.

Keywords: Concrete with super absorbent polymer, Curing conditions, Heat treatment, Stress-strain relationship, Modulus of elasticity, Toughness

Method name: Mechanical improvement method of super absorbent polymer-modified concrete

Graphical abstract

Specifications table

| Subject area: | Engineering |

| More specific subject area: | Civil Engineering, Construction Material |

| Name of your method: | Mechanical improvement method of super absorbent polymer-modified concrete |

| Name and reference of original method: | Mechtcherine, V., Wyrzykowski, M., Schröfl, C., Snoeck, D., Lura, P., de Belie, N., Mignon, A., van Vlierberghe, S., Klemm, A. J., Almeida, F. C. R., Tenório Filho, J. R., Boshoff, W. P., Reinhardt, H.-W., & Igarashi, S.-I. (2021). Application of super absorbent polymers (SAP) in concrete construction—update of RILEM state-of-the-art report. Materials and Structures, 54(2), 80. https://doi.org/10.1617/s11527–021–01668-z |

| Resource availability: | N/A |

Method details

Material details of test specimens

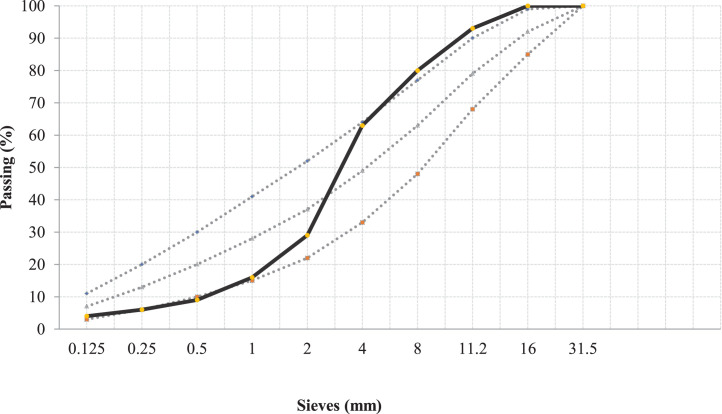

In the concrete mixture of the cube samples used in experimental studies, limestone-based gravel was used as the coarse aggregate and silica-based river sand and limestone-based crushed sand were used as the fine aggregate (Table 1). A concrete mixture aggregate was obtained using these aggregates in different proportions (Fig. 1). CEM I 42.5R type cement was used as a binder in all concrete mixtures (Table 2).

Table 1.

Physical and mechanical properties of aggregates.

| Component of concrete | Origin | Size (mm) | Density (g/cm3) | Water absorption (%) | Los Angles abrasion value |

|---|---|---|---|---|---|

| River sand | Silicious | 0–4 | 2.62 | 1.21 | – |

| Crush sand | Calcareous | 0–4 | 2.62 | 1.14 | – |

| Coarse aggregate | Calcareous | 4–16 | 2.58 | 0.77 | LA30 |

Fig. 1.

Gradation curve of concrete mixtures.

Table 2.

Chemical properties of cement.

| CEM I 42.5R | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| SiO2 (%) | Al2O3 (%) | Fe2O3 (%) | CaO (%) | MgO (%) | SO3 (%) | K2O (%) | Na2O (%) | Loss of Ignition (%) | Blain (cm2/g) | Density (g/cm3) |

| 19.19 | 5.25 | 3.21 | 61.52 | 2.79 | 2.70 | 0.82 | 0.35 | 3.37 | 3871 | 3.09 |

Potable water was used as concrete mixture water. The water/cement ratio was selected as constant and 0.47 in all mixtures according to the literature studies [1]. Superabsorbent polymers (spherical shaped, acrylic-based, anionic SAP hydrogels, average particle size 100 µm) were provided by a commercial company in the chemical sector (Fig. 3). The super absorbent polymer used in concrete mixtures had a water absorption capacity of 60–100 times its own weight (1/10–1/150 g/ml) [2]. In addition, polycarboxylic ether-based superplasticizer additives were used to regulate the workability of concrete mixtures and to ensure homogeneous workability.

Fig. 3.

Mixing steps of super absorbent polymer-modified fresh concrete.

Mixture details and fresh concrete mixing procedure

Detailed information on the mixture component ratios for superabsorbent polymer added concrete is limited and varies across the literature. For this reason, a decision tree (Fig. 2) prepared for natural aggregate concrete was created in order to achieve a standard in the mixture. A decision tree consisting of 1641 concrete data obtained from the literature was used to calculate the mixture of concrete samples used in experimental studies [3]. The decision tree algorithms classify the concrete samples based on their strength. Sojibi et al. [4] stated that this classification can be made in the form of low strength (0–19 MPa), normal strength (20–39 MPa), medium strength (40–69 MPa), high strength (70–119 MPa) and ultra-high strength (120–1000 MPa). The decision tree analysis in Fig. 2, has nodes with three ratios: high and ultra-high (yellow), low and normal (red), and medium (green). Each node is labeled with the name of the largest ratio and is colored according to its corresponding category.

Fig. 2.

Decision tree algorithm results.

According to the results obtained from the decision tree, it was found that the water and cement content values were the most effective parameters to obtain a medium strength grade concrete with the highest probability. In the study, these parameters were determined as 170 kg/m3 of water and 360 kg/m3 of cement, respectively. Section 2.1 provides the material properties of the concrete experimental samples, while Section 2.2 specifies the mixing ratios. Table 3 lists the required material parameters (cement dosage, water content, aggregate content, SAP ratio and super plasticizer ratio) per 1 m3 of concrete. Fig. 3 illustrates the procedure followed in the production of concrete samples. First, fine and coarse aggregates were mixed, and then cement was added to the dry mixture. Next, water with a super plasticizer was added to the dry mixture and after obtaining a sufficient consistency of concrete (S2 slump class), 0.3% superabsorbent polymer was added to the wet mixture. By adding super absorbent polymers to the wet mixture, the workability of the mixture was kept at an optimum level. However, it was observed that super absorbent polymers reduced the workability of the concrete. As a result, this required the use of super plasticizer at higher rates in superabsorbent polymer added in concrete.

Table 3.

Mixture details of specimens.

| Mixture notation | SAP(0)−28d | SAP(1)−28d | SAP(0)−3d | SAP(1)−3d | SAP(0)−5d | SAP(1)−5d | SAP(0)−10d | SAP(1)−10d | |

|---|---|---|---|---|---|---|---|---|---|

| Components of concrete | Cement, kg/m3 | 360 | |||||||

| Water, kg/m3 | 170 | ||||||||

| River Sand, kg/m3 | 458.9 | ||||||||

| Crushed sand, kg/m3 | 462.7 | ||||||||

| Coarse aggregate, kg/m3 | 907.5 | ||||||||

| Chemical admixture,% | 0.85 | 1.10 | 0.90 | 1.10 | 0.87 | 1.15 | 0.85 | 1.10 | |

| Super absorbent polymer,% | – | 0.3 | – | 0.3 | – | 0.3 | – | 0.3 | |

Curing conditions

The experimental samples have been classified according to with/without superabsorbent polymer additives, the compressive strength test day and curing conditions (Table 4).

Table 4.

Test specimens without heat treatment.

| Test specimen | SAP,% | Curing condition | Test day |

|---|---|---|---|

| SAP(0)−28d | 0 | Water | 28th |

| SAP(1)−28d | 0.3 | Water | 28th |

| SAP(0)−3d | 0 | Air | 3rd |

| SAP(1)−3d | 0.3 | Air | 3rd |

| SAP(0)−5d | 0 | Air | 5th |

| SAP(1)−5d | 0.3 | Air | 5th |

| SAP(0)−10d | 0 | Air | 10th |

| SAP(1)−10d | 0.3 | Air | 10th |

To eliminate the negative effects of superabsorbent polymers and attain the desired concrete strength and mechanical properties in a shorter time via air curing, 24-hour heat treatment at 50 °C was applied to some of the experimental samples in the study. The decision to use a temperature of 50 °C was influenced by both literature studies [5] and the fact that this temperature is achievable in building applications. Table 5 provides a breakdown of the classification of experimental samples that underwent heat treatment. The curing and heat treatment of the experimental samples shown in Table 5 were carried out in stages in accordance with Figs. 4(a), (b) and (c). The classification of the experimental samples based on 3, 5 and 10 days, made it possible to evaluate the potential of superabsorbent polymer added and heat-treated concrete to reach the expected mechanical performance of concrete before the standard 28-day period.

Table 5.

Curing details and heat process of test specimens.

| Test specimen | Heat process | SAP,% | Curing condition | Test day |

|---|---|---|---|---|

| SAP(1)−3d-h0 | – | 0.3 | Air | 3rd |

| SAP(1)−3d-h1 | 50 °C for 24 h | 0.3 | Air | 3rd |

| SAP(0)−3d-h1 | 50 °C for 24 h | 0 | Air | 3rd |

| SAP(0)−3d-h0 | – | 0 | Air | 3rd |

| SAP(1)−5d-h0 | – | 0.3 | Air | 5th |

| SAP(1)−5d-h1 | 50 °C for 24 h | 0.3 | Air | 5th |

| SAP(0)−5d-h1 | 50 °C for 24 h | 0 | Air | 5th |

| SAP(0)−5d-h0 | – | 0 | Air | 5th |

| SAP(1)−10d-h0 | – | 0.3 | Air | 10th |

| SAP(1)−10d-h1 | 50 °C for 24 h | 0.3 | Air | 10th |

| SAP(0)−10d-h1 | 50 °C for 24 h | 0 | Air | 10th |

| SAP(0)−10d-h0 | – | 0 | Air | 10th |

Fig. 4.

(a) Curing steps of SAP(0/1)−28d, (b) Curing steps of SAP(0/1)−3/5/10d-h0 and (c) Curing steps of SAP(0/1)−3/5/10d-h1.

Before being subjected to the pressure test, both concrete samples with and without SAP additives were water cured for 28 days, and subjected to the procedures shown in Fig. 4a. Here, the concrete was left to harden in the mold through air curing for one day, and then water curing was applied for 28 days. Three of the SAP-added and non-water-cured concrete samples (Fig. 4b) were left in the mold for one day, air-cured for one day and tested on the third day. Three of the samples were air cured for four days and tested on the fifth day. Three of them were air cured for nine days and tested on the tenth day. All of the other heat-treated samples shown in Fig. 4c were heat treated for one day after they were removed from the mold. Three of these samples were tested after heat treatment, another three were air cured for three days after heat treatment, and the remaining samples were tested after eight days of air curing.

Method validation

The experimental studies conducted in this article involved compressive strength tests on concrete cube samples using a concrete press with a capacity of 1500-tons. In addition, deformation measurement was performed using a digital compressometre that can take sensitive measurements. The loading speed of the concrete press was set to 13.5 kN/s. The TS EN 12,390–3 standard was taken into account in the compressive strength test [6]. The experiments were carried out on 2nd, 4th, 9th and 27th days, after the demolding of 3, 5, 10 and 28-day samples with different curing conditions. As a result of the experiments, stress-strain curves were obtained from the load-deformation curves. The stress-strain curve functions obtained for all combinations of experimental samples given in Table 4 and Table 5 have been produced. The obtained stress-strain curve functions with a high correlation coefficient were determined for each experimental sample (R2>0,95). For example, the stress-strain curve and function for SAP(1)−5d-h1 are shown in Fig. 5, and their values are shown in Table 6. According to Eurocode, the stress-strain curve can be defined by a second-degree polynomial [7], and the modulus of elasticity and toughness comparison of the concrete can be calculated from the stress-strain curves. In addition, the strain values corresponding to the maximum stress values were determined from the experimental data (Table 7).

Fig. 5.

Stress-strain curve and function for SAP(1)−5d-h1.

Table 6.

Stress-strain curve data.

| Test specimens |

y = A x2 + B x |

||

|---|---|---|---|

| A | B | R2 | |

| SAP(0)−28d | −5.00E+06 | 3.15E+04 | 0.9615 |

| SAP(1)−28d | −3.00E+06 | 2.51E+04 | 0.9504 |

| SAP(1)−3d-h0 | −4.00E+06 | 2.35E+04 | 0.9762 |

| SAP(1)−3d-h1 | −6.00E+06 | 2.96E+04 | 0.9894 |

| SAP(0)−3d-h1 | −3.00E+06 | 2.02E+04 | 0.9826 |

| SAP(0)−3d-h0 | −1.00E+06 | 1.48E+04 | 0.9824 |

| SAP(1)−5d-h0 | −3.00E+06 | 2.18E+04 | 0.9781 |

| SAP(1)−5d-h1 | −1.00E+06 | 1.73E+04 | 0.9800 |

| SAP(0)−5d-h1 | −3.00E+06 | 2.31E+04 | 0.9823 |

| SAP(0)−5d-h0 | −3.00E+06 | 2.42E+04 | 0.9846 |

| SAP(1)−10d-h0 | −3.00E+06 | 2.09E+04 | 0.9906 |

| SAP(1)−10d-h1 | −3.00E+06 | 2.50E+04 | 0.9921 |

| SAP(0)−10d-h1 | −3.00E+06 | 2.64E+04 | 0.9822 |

| SAP(0)−10d-h0 | −2.00E+06 | 1.86E+04 | 0.9946 |

Table 7.

Comparing stress-strain relationship based on peak stress value.

| Test specimens | Peak stress value (MPa) | Strain value for peak stress |

|---|---|---|

| SAP(0)−28d | 42.77 | 0.0027 |

| SAP(1)−28d | 49.14 | 0.0055 |

| SAP(1)−3d-h0 | 41.86 | 0.0027 |

| SAP(1)−3d-h1 | 40.04 | 0.0026 |

| SAP(0)−3d-h1 | 38.22 | 0.0033 |

| SAP(0)−3d-h0 | 34.58 | 0.0062 |

| SAP(1)−5d-h0 | 48.23 | 0.0036 |

| SAP(1)−5d-h1 | 49.14 | 0.0050 |

| SAP(0)−5d-h1 | 45.50 | 0.0040 |

| SAP(0)−5d-h0 | 40.04 | 0.0040 |

| SAP(1)−10d-h0 | 41.86 | 0.0040 |

| SAP(1)−10d-h1 | 50.96 | 0.0039 |

| SAP(0)−10d-h1 | 46.41 | 0.0026 |

| SAP(0)−10d-h0 | 39.13 | 0.0037 |

Comparison of the results of 28-Day water-cured concrete with/without SAP

In reinforced concrete calculations, theoretical analyses are usually carried out using an ultimate strain value of concrete as 0.003. In this context, the comparison of the experimental concrete stress-strain curves given in Table 4 was performed in two different ways, taking into account the x-axis strain value up to 0.003 and the maximum strain value of the experimental data in the graphs. Fig. 6(a) and (b) show a comparison of stress-strain curves of concrete cured in water for 28 days with and without SAP. The target values for the modulus of initial elasticity and compressive strength were 35 000 MPa [8] and 40 MPa, respectively, for the reference test specimens (SAP(0)−28d), which were cured in water for 28 days (Table 4).

Fig. 6.

(a) Stress-strain graph up to 0.003 strain value and (b) Stress strain relationship of concrete (maximum experimental strain value).

In the experimental results, it was found that the initial modulus of elasticity of the SAP(0)−28d concrete sample was 36 400 MPa and the compressive strength was 43.3 MPa. In the comparative graph (Fig. 8(a)), where the strain value 0.003 is taken into account, it is seen that the modulus of elasticity of SAP-modified concrete is lower than to reference (SAP(0)−28d) under the same curing conditions, but the peak compressive strength of SAP-modified concrete is higher (Table 8). Superabsorbent polymers absorb water and become saturated when they are exposed to water for 28 days. After a while, these polymers release the absorbed water into the concrete mixture over time. The superabsorbent polymers that become saturated with water do not offer the same resistance as aggregates in concrete, resulting in a lower modulus of elasticity of SAP-modified concrete that is cured in water for 28 days compared to the reference sample. However, the degree of hydration of cement in concrete is higher with superabsorbent polymers. While the concrete is cured by water from the outside, it is cured from the inside with the given water in concrete mixture by the SAP. For this reason, higher compressive strength is achieved. In the comparison made, taking into account the maximum compressive stress value, it was found that the toughness value of SAP-modified concrete was much higher compared to the reference concrete (SAP(0)−28d). It has been interpreted that the contribution of SAP is effective in achieving this condition because the cement in the concrete mixture with SAP additives has a higher degree of hydration.

Fig. 8.

(a) Stress-strain graph up to 0.003 strain value and(b) Stress strain relationship of concretes (maximum experimental strain value).

Table 8.

Comparison of modulus of elasticity and compressive strength (28 days water curing).

| Test specimen | Young modulus (Secant) (MPa) | Compressive strength (MPa) |

|---|---|---|

| SAP(0)−28d (Reference) | 24 700 | 42.77 |

| SAP(1)−28d | 22 244 (-%9.9) | 46.41 (+%8.5) |

Comparison of results of 3–5–10-Day air-cured concrete with/without SAP

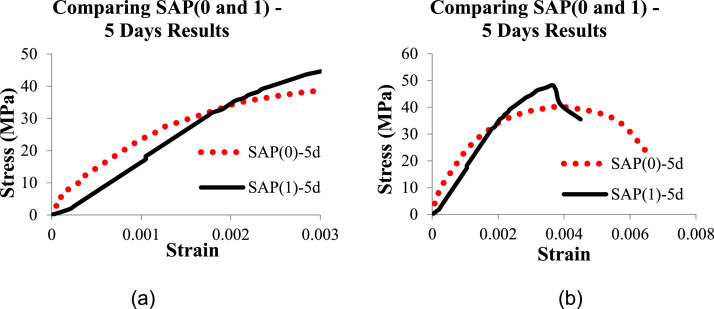

In the scope of the article, the 3–5–10-day with/without SAP added, and air cured concrete stress-strain curves were compared and evaluated. In the comparative graph (Fig. 7(a)), where the strain value 0.003 is considered, it is seen that both the modulus of elasticity and the compressive strength of SAP-modified concrete is higher than SAP free concrete (SAP(0)−3d). However, in the comparison made, considering the maximum stress value (Fig. 7(b)), it was found that the toughness level of SAP-modified concrete is very low compared to SAP free concrete. The reason for this has been interpreted as the fact that the superabsorbent polymers have absorbed enough water for hydration in the concrete mixture, which has not yet been fully desorbed.

Fig. 7.

(a) Stress-strain graph up to 0.003 strain value and (b) Stress strain relationship of concrete (maximum experimental strain value).

In the comparative graph (Fig. 8(a)), where the strain value 0.003 is taken into account, it is seen that both the modulus of elasticity and the compressive strength of SAP-modified concrete is closer to SAP free concrete (SAP(0)−5d). However, in the comparison made in Fig. 8(b), taking into account the maximum stress value, it was found that the toughness level of SAP-modified concrete is increased compared to 3-day results. This has been interpreted as the fact that according to the 3-day results, a little more water required for hydration is desorbed into the concrete mixture by SAP.

In the comparative graph (Fig. 9(a)), where the strain value 0.003 is taken into account, it is seen that both the modulus of elasticity and the compressive strength of SAP-modified concrete is higher than SAP free concrete (SAP(0)−10d). However, in the comparison made using the maximum stress value (Fig. 9(b)), it was found that the toughness level of SAP-modified concrete is very close to SAP free concrete. Therefore, it was determined that air cured SAP-modified concrete gave better results in 10 days compared to 3–5 days (Table 9).

Fig. 9.

(a) Stress-strain graph up to 0.003 strain value and (b) Stress strain relationship of concretes (maximum experimental strain value).

Table 9.

Comparison of modulus of elasticity and compressive strength (10 days air curing).

| Test specimen | Young modulus (Secant) (MPa) | Compressive strength (MPa) |

|---|---|---|

| SAP(0)−10d-h0 | 14 368 | 36.4 |

| SAP(1)−10d-h0 | 18 200 (+%26.6) | 39.13 (+%7.5) |

Comparison results of 1 day heat treatment ± 1 day / 4 days / 9 days air-cured concrete without sap additives

In order to eliminate the negative effects of superabsorbent polymers and to reach expected strength and mechanical properties of concrete in a shorter time via air curing, 24-hour heat treatment at 50 °C was applied to some of the experimental samples in this article. Firstly, to determine the most effective air curing day after heat treatment, stress-strain curves were compared for SAP free concrete samples (Fig. 10(a), (b) and (c)).

Fig. 10.

(a) Stress-strain relationship of concrete after 3 days, (b) Stress-strain relationship after 5 days, (c) Stress-strain relationship after 10 days.

As a result of the comparison conducted to see the effect of heat treatment on SAP free concrete samples, it was concluded that the combination of heat treatment at 50 °C for one day and air curing for four days of SAP free concrete is higher in terms of compressive strength and toughness. However, a decrease in the modulus of elasticity was observed after four days of air curing (Table 10). On the other hand, an increase in both the modulus of elasticity and strength was observed in concrete as a result of nine days of air curing after heat treatment (Table 11).

Table 10.

Comparison of modulus of elasticity and compressive strength (4 days air curing).

| Test specimen | Young modulus (Secant) (MPa) | Compressive strength (MPa) |

|---|---|---|

| SAP(0)−5d-h0 | 25 480 | 39.13 |

| SAP(0)−5d-h1 | 20 341 (-%20.2) | 44.59 (+%13.9) |

Table 11.

Comparison of modulus of elasticity and compressive strength (9 days air curing).

| Test specimen | Young modulus (Secant) (MPa) | Compressive strength (MPa) |

|---|---|---|

| SAP(0)−10d-h0 | 14 368 | 36.40 |

| SAP(0)−10d-h1 | 22 750 (+%58.3) | 45.5 (+%25.0) |

Comparison results of 1 day heat treatment ± 1 day / 4 days / 9 days air-cured concrete with/without sap additives

In this study, the effects of super-absorbent polymers and heat treatment processes on stress-strain curves was analyzed, and the effects of super absorbent polymer and heat treatment were compared separately (Fig. 11(a), (b) and (c)). The comparison of SAP added concrete with 1-day 50 °C heat treated concrete with those of SAP free-without heat treated concrete stress-strain curves, revealed highly effective results in terms of the modulus of elasticity, compressive strength and toughness. According to the graphs, the most positive results in terms of the modulus of elasticity, compressive strength and toughness were obtained in SAP added in concrete that were heat treated for one day and air cured for nine days (Fig. 11(c) and Table 12).

Fig. 11.

(a) Stress-strain relationship of concrete after 3 days, (b) Stress-strain relationship after 5 days, (c) Stress-strain relationship after 10 days.

Table 12.

Comparison of modulus of elasticity and compressive strength (9 days air curing).

| Test specimen | Young modulus (Secant) (MPa) | Compressive strength (MPa) |

|---|---|---|

| SAP(0)−10d-h0 | 14 368 | 36.4 |

| SAP(1)−10d-h1 | 20 800 (+%44.7) | 49.14 (+%35.3) |

Which cure is more effective in with/without SAP-modified concrete: water curing? air curing? heat treatment ± air curing?

A detailed study was conducted in this article to determine the number of days required for concrete to gain its expected strength with minimum curing and heat treatment for structural engineering applications that use superabsorbent polymer added concrete. Stress-strain curves of the 28-day water-cured, and SAP added/SAP free concrete, and heat-treated SAP-modified concrete that underwent 4–9 days of air curing were compared. Fig. 12 shows that heat-treated (4 days air cured) concrete with SAP additive has higher toughness and compressive strength values and a lower modulus of elasticity compared to 28-day water cured concrete. When comparing the stress-strain curves of SAP added heat treated (9-day) air cured concrete and SAP-free water-cured (28 days) concrete, the modulus of elasticity is approximately the same, but the compressive strength and toughness of SAP added heat-treated concrete are considerably higher. Therefore, it has been observed that applying only air curing for 9 days, heat treatment and SAP additives can achieve the expected modulus of elasticity, strength, and toughness compared to a concrete that is 28 days water-cured without SAP additives and heat treatment. Although expected strength and toughness can be achieved in SAP added heat-treated concrete in 5 days, it was determined that the elasticity module is lower than the expected elasticity module, as shown in Table 13.

Fig. 12.

Comparing SAP(0–1)-h(0–1) 5 and 10 Days to 28 Days Results.

Table 13.

Comparison of modulus of elasticity and compressive strength (28 days water-cured and 4–9 days air-cured).

| Test specimen | Young modulus (Secant) (MPa) | Compressive strength (MPa) |

|---|---|---|

| SAP(0)−28d (Reference) | 24 700 | 43.30 |

| SAP(1)−10d-h1 | 20 800 (-%15.7) | 49.14 (+%13.4) |

| SAP(1)−5d-h1 | 14 560 (-%69.6) | 41.86 (-%3.3) |

| SAP(0)−10d-h1 | 22 750 (-%7.9) | 45.50 (+%5.0) |

| SAP(1)−10d-h0 | 18 200 (-%26.3) | 39.13 (-%9.6) |

28 days of water-curing and sap effect

The stress-strain curves of SAP added and free samples that underwent 28-day water curing were compared in this experimental study. The comparison revealed that the modulus of elasticity of SAP-modified concrete was −9.9% lower compared to SAP free concrete under the same curing conditions, while the peak compressive strength of SAP-modified concrete was +8.5% higher. The superabsorbent polymers were found to reduce the modulus of elasticity in concrete after 28 days of water curing but increased the strength. This phenomenon is attributed to the desorption of water from the superabsorbent polymers into the concrete mixture, which leads to the formation of lower rigidity and strength components than the aggregate in the concrete. The observed increase in strength was attributed to the fact that superabsorbent polymers create continuity in cement hydration by desorbing water with SAP, which leads to more effective cement hydration at every point in the internal structure of concrete over time.

3–5–10 days of air curing and sap effect

After evaluating the research results, the performance of superabsorbent polymers in air curing conditions was examined. The stress-strain curves of SAP-modified concrete that underwent air-curing for 3–5–10 days were compared. The comparison showed that while superabsorbent polymers had positive effects on the strength and modulus of elasticity after 3 days of air curing, they had negative effects in the toughness parameter. After 5 days of air curing, there was an improvement in these negative effects in terms of toughness, but the desired level of energy consumption capacity was not achieved. Satisfactory results were obtained in terms of modulus of elasticity, strength and toughness after 10 days of air curing. Under the effect of air curing for 10 days, it was determined that SAP additives increased the modulus of elasticity of concrete by +26.6% and the compressive strength by +7.5%. This is because superabsorbent polymers can desorb the necessary water for the strength of concrete in at least 5–10 days. Therefore, it is necessary to wait at least 5–10 days to obtain good performance from superabsorbent polymers under air curing conditions. The increase in the modulus of elasticity was evaluated as superabsorbent polymers enhancing the mechanical performance by strengthening the concrete mortar phase and improving the quality of the aggregate mortar phase transition zone.

1–4–9 Days of air curing ± heat treatment effect

At the third stage of evaluating the study results, the effects of heat treatment application (1–4–9 days of air curing after 1-day 50 °C heat treatment) was investigated to achieve the required mechanical properties of superabsorbent concrete in less than 10 days. In the first comparison, the stress-strain results of heat-treated concrete without SAP additives were examined, revealing that 1-day heat treatment + 1 day air curing did not have a positive effect on the energy consumption capacity of concrete. However, positive results were obtained in terms of energy absorption capacity when applying 1 day heat treatment and 4 days air curing. Nonetheless, this caused a 20.2% decrease in the modulus of elasticity. In contrast, samples kept in 9 days of air curing after 1 day of heat treatment showed an increase of 58.3% in the modulus of elasticity and 25.0% in compressive strength. Consequently, it was concluded that at least 9 days of air curing are necessary for sufficient hydration after 1 day of heat treatment.

1–4–9 days of air curing ± heat treatment ± sap effect

At the fourth stage of evaluating the study results, the stress-strain curves of both heat treatment + air cured (1–4–9 days air curing after 1 day heat treatment) and the effects of superabsorbent polymers were compared. The comparison revealed that the combination of SAP and heat treatment did not yield positive results within 3 days, in terms of energy consumption capacity. Although there was an improvement in toughness after 5 days, of the elasticity modulus was negatively affected. However, after 10 days, there was a significant increase of 44.7% in the modulus of elasticity and 35.3% in compressive strength. Nonetheless, the increase in modulus of elasticity was less than the increase (58.3%) observed in heat treatment application. This is because superabsorbent polymers are considered to form less rigid structures in concrete than aggregates. However, when superabsorbent polymers were combined with heat treatment, there was a greater increase (10.3%) in compressive strength. This indicates the positive effect of superabsorbent polymers on the hydration grade of cement in concrete. Without heat treatment, the increase in the modulus of elasticity would have remained at +26.6% and the increase in compressive strength would have remained at +7.5%. With heat treatment, there was an additional 21.1% increase in the modulus of elasticity and a 27.8% increase in compressive strength in the superabsorbent polymer added concrete.

Comparison of air curing ± heat treatment ±SAP and 28 days of water curing reference results

Finally, the study evaluated the difference in mechanical behavior between superabsorbent polymer + heat-treated and air cured concrete and SAP free 28-day water cured concrete. The comparison involved using stress-strain curves for 28 days of water-cured SAP free concrete and 4–9 days air cured + 1 day heat treated SAP-modified concrete. The study also determined the rate at which the application of heat treatment for SAP free concrete alters the modulus of elasticity and compressive strength parameters compared to 28 days water-cured reference concrete.

In the comparison, it was found that although the compressive strength of heat-treated SAP added concrete air-cured for 4 days was only 3.3% lower than the reference concrete, the modulus of elasticity was 69.6% lower. Therefore, it was concluded that 4 days of air curing is insufficient after heat treatment. In the results of the concrete that was air-cured for 9 days after the heat treatment, the compressive strength increased by 13.4% and the modulus of elasticity decreased by only 15.7%. This result supports the conclusion that at least 9 days of air curing is required to achieve sufficient strength and elasticity modulus in heat treated concrete with superabsorbent polymer additives. However, when comparing the results of concrete without SAP additives and only heat treated 9 days air cured concrete in Table 13, an increase in strength of 5.0% and a decrease in the modulus of elasticity is 7.9% were observed.

Therefore, although the SAP additives decreased the modulus of elasticity of the concrete, it caused a greater increase in strength (8.4% → 3.64 MPa) compared to heat treatment. However, after 9 days of air curing without the application of heat treatment, the SAP additives caused a 26.3% decrease in the modulus of elasticity and a 9.6% decrease in the compressive strength. This result revealed that heat treatment is necessary if sufficient strength and modulus of elasticity within a short time is desired from superabsorbent polymer added in concrete. According to the aggregate type used in a current valid standard (Eurocode 2), it is stated that the decrease in the modulus of elasticity is within acceptable limits of up to 30% [9]. Therefore, the decrease in the modulus of elasticity in the concrete that has been air-cured for 9 days after the heat treatment is a sufficient value for reaching the expected modulus of elasticity in the concrete.

All experimental results carried out within the scope of this article were interpreted comparatively with numerical data. As a result, it was determined that very good values can be obtained in terms of concrete strength and elasticity modulus compared to concrete that has been water cured for 28 days (reference) by adding super-absorbent polymer additives to the concrete mixture and applying a heat treatment of 50 °C for 24 h to this concrete, followed by 9 days of air curing. Heat treatment applications are effective in eliminating the negative effects of superabsorbent polymers on the mechanical properties of concrete. As a result of the experimental studies, an approach has been developed for the structural engineering applications where the use of superabsorbent polymer additives in concrete is considered, with minimum air curing and heat treatment application, to gain the expected strength/elastic modulus/toughness of the concrete in 10 days. In this context, the behavior of structural load-bearing system elements made of super-absorbent concrete will be examined experimentally and theoretically in further studies.

Background information

The use of polymer-based additives to improve the physical, mechanical and durability properties of concrete has become widespread. One of these additives is superabsorbent polymers. Superabsorbent polymers (SAP) are a hydrogel material with very good rates of water absorption (100–400 g/g) and desorption [1,10]. In the literature, studies are conducted on the effects of SAP additives on the strength and durability properties of concrete. In these studies, the positive effects of SAP contribution as well as the negative effects are emphasized [11]. For example, it is stated in the literature that SAP additives can increase and decrease the strength of concrete according to whether the water/cement ratio is greater than or less than 0.45 [1]. In order to examine the effect of this limit value specified in the literature, the water/cement ratio was determined as approximately 0.45 of the concrete mixture prepared in our study.

The durability of concrete is very important in the field of building materials and the construction industry. In the literature, the effects of SAP additives on the durability properties of concrete (freeze-thaw, fire, shrinkage, etc.) are being investigated [12]. However, despite these detailed studies, there are still problems with the application of SAP-modified concrete in the building construction sector, which require further study. In addition, there is no standard for the design of SAP-modified concrete and the use of the concrete [13]. However, in addition to the research articles in the literature, there is a RILEM research report in which SAP-modified concrete is examined in detail and the researchers are often cited [13,14]. In addition to the effects of superabsorbent polymers on the durability of concrete, the effects of superabsorbent polymers on the mechanical properties of concrete are also being investigated. For example, the effects of SAP admixture on the physical and mechanical properties of concrete have been studied by Zheng et al. In their experimental studies, Zheng et al. studied the parameters of compressive, bending, tensile strength and modulus of elasticity of superabsorbent polymer added in concrete [15]. In the study, it has been stated that there is a relationship between the SAP ratio and the mechanical properties of concrete. In addition, it has been observed that the modulus of elasticity and compressive strength values of SAP-modified concrete generally decreased depending on the SAP particle sizes. However, this article emphasizes that the water/cement ratio should be selected at values of 0.30 and 0.37. Zheng et al. have stated that additional experimental studies and data are needed for optimal use of SAP [15]. Proceeding from this point, within the scope of our article, experimental studies have been carried out in terms of optimal design, curing, production, and use of SAP-modified concrete and its effects on the mechanical properties of concrete.

In order to reduce the negative effects of superabsorbent polymer in concrete, heat treatment was applied to concrete. The main purpose of our study is to determine the most effective availability of SAP-modified concrete properties (i.e., compressive strength, modulus of elasticity, energy consumption capacity, optimum curing) of structural load-bearing system members (column, beam, flat and shear wall). The experimental samples have been classified according to with/without superabsorbent polymer additives, the compressive strength test day and curing conditions. Water curing and air curing were applied to the concrete. Air curing in general has been described negatively in the literature for concrete. These negative results occur in air curing because of the evaporation of water, which is necessary for hydration in the concrete [16]. However, to determine whether these negative results apply to SAP-modified concrete, the application of air curing was preferred within the scope of this article because air curing is a very practical approach for concrete to reach the expected strength and modulus of elasticity level. To eliminate the negative effects of superabsorbent polymers and to reach expected strength and mechanical properties of concrete in a shorter time via air curing, 24-hour heat treatment of 50 °C was applied to some of the experimental samples in this article. In the literature, it is stated that the application of temperatures above 60 °C is not effective in accelerating the hydration rate of cement and therefore, the effective temperature range should only be up to 60 °C [5],which is why heat treatment at 50 °C was selected. Axial compressive strength test was applied to 150 mm cube concrete test samples. In the compressive strength tests, strain measurements of concretes were made with a digital compressometre. As a result of each experiment, stress-strain curves of the samples were obtained. These curves were compared to each other while considering the parameters of compressive strength, modulus of elasticity and relative energy consumption capacities. In the comparison of the modulus of elasticity, the secant elasticity modulus was also taken into account [17].

CRediT author statement

Hasan Dilbas: Methodology, Investigation, Writing-Original draft preparation, Conceptualization, Validity tests. Furkan Birdal: Reviewing and Editing, Methodology, Validation, Supervision, Investigation. Coşkun Parim: Decision tree algorithm software, Reviewing, Editing. Mehmet Şamil Güneş: Mixing design data collection, Data curation, Reviewing, Editing.

Acknowledgments

This research did not receive any specific grant from funding agencies in the public, commercial, or not-for-profit sectors.

Declaration of Competing Interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Contributor Information

Hasan Dilbas, Email: hasandilbas@yyu.edu.tr.

Furkan Birdal, Email: f.birdal@ahievran.edu.tr.

Coşkun Parim, Email: cparim@yildiz.edu.tr.

Mehmet Şamil Güneş, Email: msgunes@yildiz.edu.tr.

Data availability

The data graphs are given in the manuscript.

References

- 1.O.M. Jensen, Use of Superabsorbent Polymers in Concrete, Concrete International. January 2013 (2013) 48–52.

- 2.Tusorb, https://tusorb.com/sivi-emici-absorban.html, (2022).

- 3.Adil M., Ullah R., Noor S., Gohar N. Effect of number of neurons and layers in an artificial neural network for generalized concrete mix design. Neural. Comput. Appl. 2020 doi: 10.1007/s00521-020-05305-8. [DOI] [Google Scholar]

- 4.Sojobi A.O., Aladegboye O.J., Awolusi T.F. Green interlocking paving units. Constr. Build. Mater. 2018;173:600–614. doi: 10.1016/j.conbuildmat.2018.04.061. [DOI] [Google Scholar]

- 5.Pang X., Sun L., Sun F., Zhang G., Guo S., Bu Y. Cement hydration kinetics study in the temperature range from 15°C to 95°C. Cem. Concr. Res. 2021;148 doi: 10.1016/j.cemconres.2021.106552. [DOI] [Google Scholar]

- 6.Turkish Standards Institution; Ankara Turkey: 2010. TS EN 12390-3 Testing Hardened Concrete - Part 3 : Compressive Strength of Test Specimens. [Google Scholar]

- 7.EN, EN 1992-1-1 Design of Concrete Structures – Part 1-1: general Rules for Buildings, Brussels, Belgium, 2004.

- 8.Turkish Standards Institution; Ankara, Yucetepe, Turkey: 2000. TS 500 Requirements for Design and Construction of Reinforced Concrete Structures. [Google Scholar]

- 9.Dilbas H., Çakır Ö., Atiş C.D. Experimental investigation on properties of recycled aggregate concrete with optimized Ball Milling Method. Constr. Build. Mater. 2019;212:716–726. doi: 10.1016/j.conbuildmat.2019.04.007. [DOI] [Google Scholar]

- 10.Wong H.S. Eco-Efficient Repair and Rehabilitation of Concrete Infrastructures. Elsevier; 2018. Concrete With superabsorbent polymer; pp. 467–499. [DOI] [Google Scholar]

- 11.Dang J., Zhao J., Du Z. Effect of superabsorbent polymer on the properties of concrete. Polymers (Basel) 2017;9:672. doi: 10.3390/polym9120672. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 12.Shen D., Li C., Kang J., Liu K., Liu C., Li M. Influence of loading ages on the early age tensile creep of high-strength concrete modified with superabsorbent polymers. J. Mater. Civil Eng. 2022;34 doi: 10.1061/(ASCE)MT.1943-5533.0004207. [DOI] [Google Scholar]

- 13.Mechtcherine V., Wyrzykowski M., Schröfl C., Snoeck D., Lura P., de Belie N., Mignon A., van Vlierberghe S., Klemm A.J., Almeida F.C.R., Tenório Filho J.R., Boshoff W.P., Reinhardt H.-.W., Igarashi S.-.I. Application of super absorbent polymers (SAP) in concrete construction—Update of RILEM state-of-the-art report. Mater. Struct. 2021;54:80. doi: 10.1617/s11527-021-01668-z. [DOI] [Google Scholar]

- 14.Mechtcherine V., Reinhardt H.-W., editors. Application of Super Absorbent Polymers (SAP) in Concrete Construction. Springer; Netherlands, Dordrecht: 2012. [DOI] [Google Scholar]

- 15.Zheng X., Han M., Liu L. Effect of superabsorbent polymer on the mechanical performance and microstructure of concrete. Materials. 2021;14:3232. doi: 10.3390/ma14123232. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 16.Erdoğan T. 2nd Ed. METU Press; Ankara Turkey: 2007. Beton (in Turkish) [Google Scholar]

- 17.Turkish Standards Institute; Ankara: 1981. Test Method for Static Modulus of Elasticity and Poisson's Ratio of Concrete In Compression. [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.

Data Availability Statement

The data graphs are given in the manuscript.