Abstract

Microwave-vacuum drying performance and energy consumption of Camellia oleifera seeds were studied in this paper. The effects of microwave power, vacuum pressure and loading quantity were evaluated and discussed. Orthogonal experiments were also conducted to optimize the drying process. A new drying model based on the weibull distribution model was developed. Results showed that the microwave-vacuum drying process was dominated by internal water diffusion and surface water evaporation. As the microwave power and vacuum pressure increased and the loading quantity decreased, the drying time and energy consumption both decreased. However, too low or too high microwave power would increase the energy consumption. The optimal microwave-vacuum drying conditions were found to be a loading quantity of 150 g, a microwave power of 350 W and a vacuum pressure of 0.09 MPa. The developed drying model and the calculated scale and shape parameter were all consistent with experimental results.

Keywords: Drying performance, Energy consumption, Camelliaoleifera seeds, Microwave-vacuum drying, Drying model

Introduction

Camellia oleifera is one of the most important woody oil tree species in the world. It originates from China and there are 642 counties in 15 provinces planting C. oleifera trees there, driving nearly 2 million poor people out of poverty (Zhu et al., 2020b). The camellia oil extracted from C. oleifera seeds has a high nutritional value and is listed as a healthy edible oil to be promoted by the Food and Agriculture Organization of the United Nations (Hu et al., 2019; Lee et al., 2014; Wang et al., 2017). The drying of C. oleifera seeds has an important influence on their storage as well as the yield and quality of camellia oil. If not handled properly, it will cause very serious consequences, such as producing aflatoxin or causing a high postpartum loss rate. Fresh C. oleifera seeds have high moisture content and are prone to mildew in the warm and humid environment (Zhu et al., 2020a). Moldy C. oleifera seeds are at risk of producing aflatoxins, and the extracted camellia oil can cause cancer after consumption. Besides, the harvest time of C. oleifera fruit is on November and the weather is usually cloudy and rainy, thus the traditional sun drying method cannot be conducted, resulting in an annual postpartum loss rate of more than 10%, which has brought huge economic losses to farmers. Therefore, a high efficient drying method is needed for the processing of C. oleifera seeds.

At present, the widely adopted drying method for C. oleifera seeds is hot air drying (Huang et al., 2020; Wang et al., 2021a). It is low in cost and easy to operate (Chen and Pan, 2021; Wang et al., 2021b), and the quality of camellia oil is ideal. However, the drying time is too long, for instance, the required drying time at 60 °C is about 16 h. Besides, Wang et al. (2018) found that although the drying rate of C. oleifera seeds increased by increasing hot air temperature, too high drying temperature would lead to the ripening of C. oleifera seeds. With the continuous increasing of C. oleifera planting and C. oleifera seeds processing, hot air drying is more and more difficult to meet the short-term drying requirements of large quantities of C. oleifera seeds. Thus, a new drying method is needed.

Microwave drying is a drying method that the direction of heat conduction is the same as the moisture diffusion, thus the drying is fast and efficient (Dehghannya et al., 2018; Hou et al., 2021). Huang et al. (2021) investigated the microwave intermittent drying characteristics of C. oleifera seeds and found that the drying time was more than 4 times shorter than that under hot air drying, and the energy consumption was reduced by hundreds of times. However, it is easy to cause the scorching of C. oleifera seeds and accordingly affect the quality of camellia oil. Vacuum drying is a drying method in which materials are appropriately heated to reach the boiling point under negative pressure. Due to the reduced pressure, low temperature drying is allowed and effective drying can also be achieved. Ye et al. (2019) found that the vacuum drying was the best choice in the drying of clematis as it not only retained the original color and appearance but also achieved a desirable aroma.

Combined microwave and vacuum drying can accelerate the drying rate even at a relatively low temperature, which is very suitable for C. oleifera seeds. Microwave-vacuum drying has been used in various food products, such as beef (Ren and Sun, 2022), potato chips (Gomide et al., 2022) and Tremella fuciformis (Xu et al., 2022) etc. However, no studies have been conducted on the microwave-vacuum drying of C. oleifera seeds. Therefore, this paper aims to evaluate the potential of microwave-vacuum drying for C. oleifera seeds. The effects of microwave power, vacuum pressure and loading quantity on the drying characteristics and energy consumption were investigated and discussed. Orthogonal experiments were also conducted to optimize the microwave-vacuum drying process. Besides, the weibull distribution model was adopted to develop a new model to describe and predict the drying process.

Materials and methods

Sample preparation and experimental procedure

The camellia olerifera seeds (Xianglin No. 1 Camellia oleifera) used in this study were harvested on November in Xuefengshan Oil Tea Base grown in the Wangcheng District, CSUFT, China. A RWBZ-08S microwave-vacuum drying oven was used in this experiment. The overall dimensions of the microwave-vacuum drying oven are 900 mm in length, 560 mm in width and 700 mm in height. Microwave energy is produced by a 2450 MHz magnetron with a maximum power output of 800 W. The power of the vacuum pump is 1.5 kW and a maximum vacuum pressure of 0.095 MPa can be achieved.

Fresh C. oleifera seeds with no mildew and uniform size were used for drying. A quantity of 150, 200 and 250 g of C. oleifera seeds with an average initial moisture content on dry basis of 1.3 g/g were weighed and spread in a thin layer on a pan and then dried in the microwave-vacuum drying oven. The pan was rotated to ensure the uniformity of drying. The microwave power was set as 250, 300 and 350 W and the vacuum pressure was 0.03, 0.06 and 0.09 MPa determined by the pre-experiments. The energy consumption during the drying process was measured by an electricity meter. The mass of C. oleifera seeds was recorded every 5 min by taking out the sample and immediately putting on an electronic balance until the moisture content on dry basis was less than 0.09 g/g. Cui et al. (2004) also investigated the microwave-vacuum drying of carrots and measured the weight every 3 min by interrupting the vacuum condition and taking out the sample for measurement. They found that such interruption had negligible influence on the weight loss compared to continuous drying.

Design of the experiments

The single-factor experiments were firstly carried out as follows:

The effects of different microwave powers (250 W, 300 W, 350 W) were studied under the conditions of a loading quantity of 200 g and a vacuum pressure of 0.09 MPa.

The effects of different vacuum pressures (0.03 MPa, 0.06 MPa, 0.09 MPa) were studied under the conditions of a loading quantity of 200 g and a microwave power of 350 W.

The effects of different loading quantities (150 g, 200 g and 250 g) were studied under the conditions of a microwave power of 350 W and a vacuum pressure of 0.09 MPa.

Then, orthogonal experiments were conducted to optimize the microwave-vacuum drying based on the single-factor experiments. Microwave power, vacuum pressure and loading quantity were taken as the variables, and drying time and energy consumption were the responses. The design matrix consisted of 9 trials, which was shown in Table 1.

Table 1.

Results of orthogonal experiments

| Exp | Microwave power(A)/W | Vacuum pressure (B)/MPa | Loading quantity(C)/g | Drying time/min | Energy consumption/KWh |

|---|---|---|---|---|---|

| 1 | 250(1) | 0.03(1) | 150(1) | 145 | 3.088 |

| 2 | 300(2) | 0.06(2) | 150(1) | 65 | 3.801 |

| 3 | 350(3) | 0.09(3) | 150(1) | 35 | 1.628 |

| 4 | 350(3) | 0.06(2) | 200(2) | 65 | 3.575 |

| 5 | 300(2) | 0.03(1) | 200(2) | 130 | 7.233 |

| 6 | 250(1) | 0.09(3) | 200(2) | 75 | 3.088 |

| 7 | 250(1) | 0.06(2) | 250(3) | 140 | 6.307 |

| 8 | 300(2) | 0.09(3) | 250(3) | 70 | 2.801 |

| 9 | 350(3) | 0.03(1) | 250(3) | 120 | 6.307 |

| Ii | 360 | 395 | 245 | ||

| IIi | 265 | 270 | 270 | ||

| IIIi | 220 | 180 | 330 | ||

| Ij | 12.483 | 16.628 | 8.517 | ||

| IIj | 13.835 | 13.683 | 13.896 | ||

| IIIj | 11.510 | 7.517 | 15.415 | ||

| Ri | 140 | 215 | 85 | ||

| Rj | 2.325 | 9.111 | 6.898 |

Data reduction

The drying rate, DR, was caculated as follows:

| 1 |

where Mt is the instantanous moisture content on dry basis and Δt is the time interval.

The moisture ratio, MR, was calculated as:

| 2 |

where M0 is the initial moisture content and Me is the equilibrium dry base moisture content. Me is relatively small, thus it is ignored here.

Drying mathematical model was developed to describe and predict the loss of moisture during microwave-vacuum drying process by fitting the experimental data. Fick’s second law of diffusion as shown in Eq. (3) is widely accepted to describe the moisture change of materials, however, it can be only used in the decelerated drying period (Uribe et al., 2014). Corzo et al. (2008) adopted the Weibull distribution model to predict the moisture change of coroba slices under air drying. They found that Weibull distribution model could accurately predict the experimental value of moisture content. Thus, the Weibull distribution model as shown in Eq. (8) was used here.

| 3 |

Equation (3) can be solved as follows (Crank, 1979):

| 4 |

Considering only the first term in the equation, it can be simplified as follows:

| 5 |

where MR is the moisture ratio caculated by Eq. (2); Deff is the effective moisture diffusion coefficient; t is the drying time; L is the half of thickness, which is found to be 2 mm.

The estimated moisture diffusion coefficient was calculated as:

| 6 |

where r is the equivalent radius of C. oleifera seeds, which is found to be 6.83 mm.

The relationship between Deff and Dcal is:

| 7 |

where Rg is the geometric parameter related to the shape of material, which is 18.6 for spherical materials, 9.5 for cylindrical materials and 13.1 for flat materials (Bai et al., 2013).

The Weibull distribution model is:

| 8 |

where α is the scale parameter, which is approximately equal to the time required for 63% of the water in the material to evaporate; β is the shape parameter, which is related to the drying rate and water migration mechanism during the drying process.

The parameter in weibull distribution model can be obtained by nonlinear regression, and the goodness of fit between experimental data and predicted values was evaluated by the determination coefficient R2, reduced chi-square value χ2, and root mean square variance RMSE. The larger the value of R2 and the smaller the values of χ2 and RMSE, the better the model fitting. R2, χ2, and RMSE can be calculated by the following formulas:

| 9 |

| 10 |

| 11 |

where MRexp,i is the ith experimental MR value; MRpre,i is the ith predicted MR value; MRaver is the average MR value; N is the number of observations; n is the number of constants in the model.

Determination of peroxide value and acid value

The dried C. oleifera seeds were pressed and oiled, and the peroxide value (POV) and acid value (AV) of camellia oil were determined according to the National Standard of China of GB5009.227-2016 and GB5009.229-2016, respectively.

Statistical analysis

All the experiments were investigated for three times and the average values were used. The results were statistically analyzed by mutli-way ANOVA by SPSS software.

Results and discussion

Effects of microwave power

Figure 1a and b show the effects of microwave power on the drying characteristics of C. oleifera seeds under a loading quantity of 200 g and a vacuum pressure of 0.09 MPa. During the pre-experiments, it was found that the C. oleifera seeds burst quickly when the microwave power was greater than 350 W and the drying time was relatively long when the power was less than 250 W. However, the drying time and quality of camellia oil under microwave powers of 250–350 W were ideal, for instance, the POV value was 0.17 g/100 g and the AV value was 1.67 mg/g at 350 W. These values are within the range of first-grade camellia oil specified in the National Standard of China GBT11765-2018, in which the POV value should be less than 0.25 g/100 g and the AV value should be less than 2 mg/g. Thus, the power of 250–350 W was selected here.

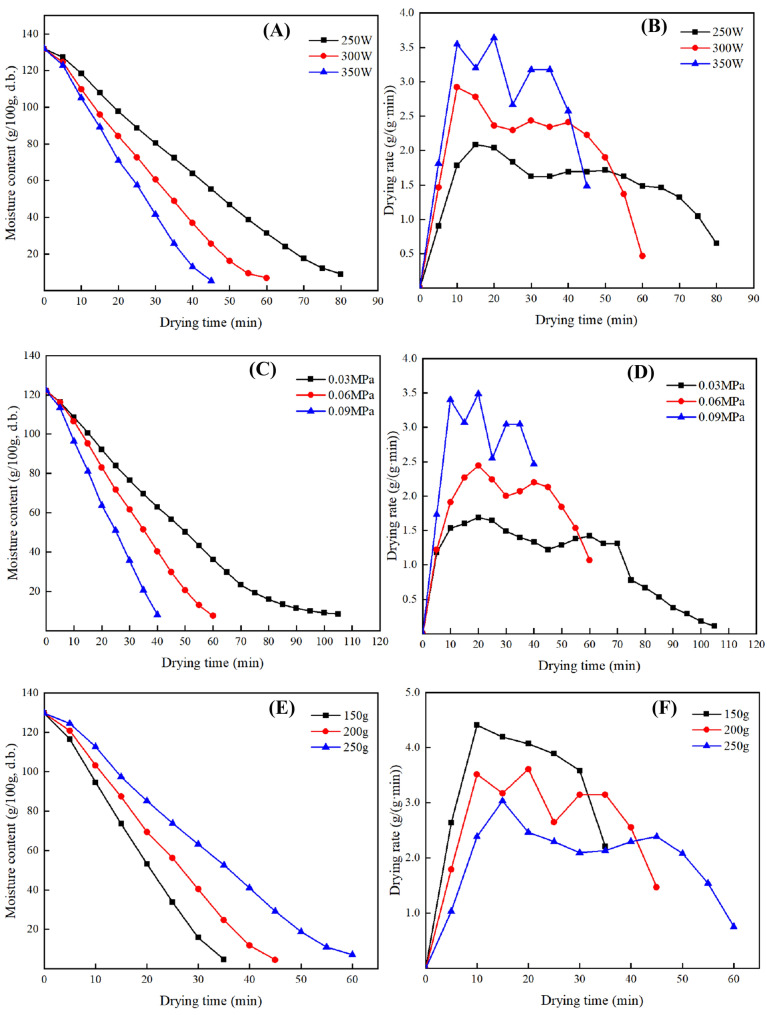

Fig. 1.

Influence of different factors on moisture content and drying rate. (A) Effects of microwave power on moisture content; (B) effects of microwave power on drying rate; (C) effects of vacuum pressure on moisture content; (D) effects of vacuum pressure on drying rate; (E) effects of loading quantity on moisture content; (F) effects of loading quantity on drying rate

From Fig. 1a, it can be seen that the moisture content of C. oleifera seeds decreased with the extension of drying time and microwave power. The required drying time under 250 W, 300 W and 350 W was 80 min, 60 min and 45 min, respectively. The drying time was reduced by 43.8% at 350 W compared to that at 250 W. This was because the higher the microwave power, the more intense the molecular motion inside the material. The inner temperature increased fast and the heat transfer driving force was great under relatively high microwave power. Therefore, the moisture migration accelerated and the drying time reduced. Sun et al. (2019) investigated the microwave-vacuum drying of ginger and also found that the higher the microwave power, the shorter the total drying time and the faster the drying rate, which was consistent with the study in this paper.

Figure 1b shows the drying rate variations under different microwave powers. As can be seen, the microwave-vacuum drying curve can be divided into accelerated drying period (in which the drying rate increases fast), constant drying period (in which the drying rate almost keeps stable) and decelerated drying period (in which the drying rate drops fast). In the accelerated drying period, the moisture content of C. oleifera seeds was relatively high and most of them was free water. At this period, the loss of moisture was relatively easy and fast, thus the drying rate was fast. With the extension of drying time, the moisture content gradually decreased, and the moisture loss was basically equal to the moisture absorption by microwave energy. Thus, the drying rate was relatively stable. When the moisture content reduced to a low value, the remaining bound water with a low freedom was difficult to migrate outward and the microwave energy absorption by C. oleifera seeds also reduced. Therefore, the drying rate dropped.

The energy consumption under 250 W, 300 W and 350 W was found to be 2.738 kWh, 2.152 kWh and 1.697 kWh, respectively. It can be seen that the value decreased with increasing microwave power due to the reduced drying time. However, too low or too high microwave power would increase the energy consumption. According to the pre-experiments, the drying time under 200 and 400 W was 120 and 65 min and the corresponding energy consumption was 4.025 kWh and 2.338 kWh, respectively. The energy consumption at 200 W was 47% and 137% higher than that at 250 W and 350 W, respectively. The energy consumption at 400 W was also higher than that at 300 and 350 W, except for 250 W. This was because too high power would burst the C. oleifera seeds and cause the hardening of C. oleifera seed shell, the moisture migration towards outside was thus hindered. As a result, the drying time was not sufficiently reduced, and the energy consumption appeared to be relatively high at 400 W.

Effects of vacuum pressure

Figure 1c and d show the effects of vacuum pressure on the drying characteristics of C. oleifera seeds under a loading quantity of 200 g and a microwave power of 350 W. As can be seen from Fig. 1c, vacuum pressure had a great influence on the loss of moisture (p < 0.05). The required drying time under 0.03 MPa, 0.06 MPa and 0.09 MPa was 105 min, 60 min and 40 min, respectively, i.e., the drying time was reduced by 61.9% at 0.09 MPa compared to that at 0.03 MPa. This was because the higher the vacuum pressure, the greater the pressure gradient inside and outside the C. oleifera seeds. The large pressure difference formed a high driving force to accelerate the moisture migration and hence shorten the drying time. Besides, a high vacuum pressure led to a low boiling point of water, thus the evaporation of water also became fast. Tian et al. (2015) investigated the microwave-vacuum drying of kiwifruit slices and also found that the vacuum pressure had a significant effect on the drying characteristics of kiwifruit slices. The drying time under the maximum vacuum pressure (95 kPa) was only 36.84% of that under the minimum vacuum pressure (75 kPa). The drying rate curve as shown in Fig. 1d was also divided into accelerated drying period, constant drying period and decelerated drying period. The maximum drying rate was 1.69, 2.44 and 3.49 g/(g∙min) at 0.03 MPa, 0.06 MPa and 0.09 MPa, respectively. As the vacuum pressure increased, the drying rate increased as illustrated above.

The energy consumption under 0.03 MPa, 0.06 MPa and 0.09 MPa was found to be 5.169 kWh, 3.027 kWh and 1.509 kWh, respectively. According to the pre-experiments, the drying time under 0.05 and 0.07 MPa was 65 and 55 min, which was very close to that at 0.06 MPa, and the corresponding energy consumption was 3.563 kWh and 2.702 kWh, respectively. It can be seen that the energy consumption decreased with increasing vacuum pressure due to the reduced drying time. As the drying time reduced significantly at 0.09 MPa, the energy consumption was much lower than that at other vacuum pressures.

Effects of loading quantity

Figure 1e and f show the effects of loading quantity on the drying characteristics of C. oleifera seeds under a microwave power of 350 W and a vacuum pressure of 0.09 MPa. It can be seen from Fig. 1e that the moisture content decreased as the loading quantity decreased. The required drying time under 150 g, 200 g and 250 g was 35 min, 45 min and 60 min, respectively, i.e., the drying time was increased by 71.4% at 250 g compared to that at 150 g. The less the loading quantity was, the more microwave energy was absorbed by each C. oleifera seed, and the faster the moisture inside C. oleifera seeds was evaporated, thus the shorter the drying time was required. As expected, the drying rate curve under differetent loading quantities also consisted of three periods. Reducing the loading quantity of samples can effectively increase the drying rate, for instance, the maximum drying rate was increased from 3.03 g/(g∙min) at 250 g to 4.41 g/(g∙min) at 150 g. The extreme difference value of drying time under different vacuum pressures, microwave powers and loading quantities as shown in Table 1 was found to be 215, 140 and 85, respectively, indicating that the effect of loading quantity on drying time and drying rate was smaller than that of microwave power and vacuum pressure. The energy consumption under 150 g, 200 g and 250 g was found to be 1.252 kWh, 1.697 kWh and 2.124 kWh, respectively. It can be seen that the energy consumption increased with increasing loading quantity due to the extended drying time. However, the differences under various loading quantities were small (p > 0.05).

Optimization of microwave-vacuum drying process

Orthogonal experiments were designed by SPSS software and the results of experiments were shown in Table 1 (Ding et al., 2010; Wu et al., 2012). Ii, IIi and IIIi is the sum of drying time at level 1, level 2 and level 3, respectively. Ij, IIj and IIIj is the sum of energy consumption at level 1, level 2 and level 3, respectively. R is the extreme difference, where Ri is the extreme difference of {Ii, IIi, IIIi} and Rj is the extreme difference of {Ij, IIj, IIIj}.

It can be seen from Table 1 that the Ri value under different vacuum pressures was the highest, followed by the value under different microwave powers. Therefore, the influence degree of various factors on drying time was: vacuum pressure > microwave power > loading quantity. The optimum drying condition corresponding to the shortest drying time was A3B3C1. The Rj value under different vacuum pressures was also the highest, followed by the value under different microwave powers. Therefore, the influence degree of various factors on energy consumption was: vacuum pressure > microwave power > loading quantity. The optimum drying conditions corresponding to the lowest energy consumption was also A3B3C1. Thus, the optimal microwave-vacuum drying conditions for C. oleifera seeds under the experimental conditions here were: a loading quantity of 150 g, a microwave power of 350 W and a vacuum pressure of 0.09 MPa.

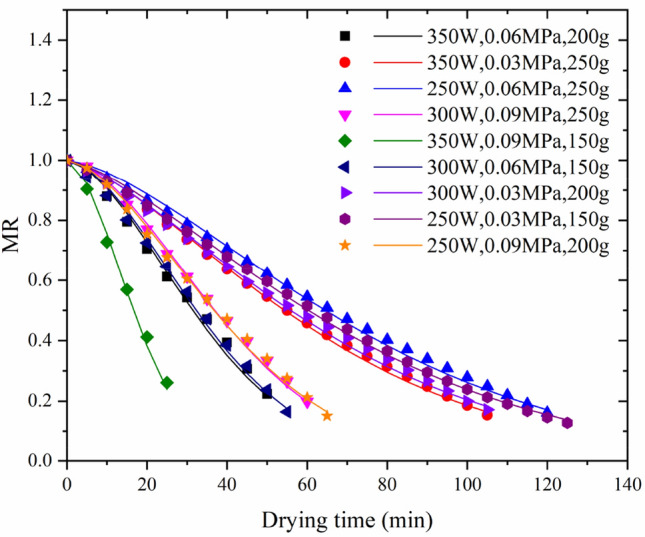

Model fitting

The obtained experimental data was fitted to weibull distribution model, and the results were shown in Table 2. It can be seen that the RMSE value varies from 0.0119 to 0.0299 and the χ2 value varies from 0.0001 to 0.0007, which is relatively small. The R2 value varies from 0.9910 to 0.9983, which is larger than 0.99, indicating that the fitting degree of weibull distribution model is good.

Table 2.

Model fitting results

| Drying condition | α | β | R2 | RMSE | |||

|---|---|---|---|---|---|---|---|

| Microwave power/W | Vacuum pressure/MPa | Loading quantity/g | |||||

| 250 | 0.03 | 150 | 77.7691 | 1.4400 | 0.9983 | 0.0119 | 0.0002 |

| 300 | 0.06 | 150 | 39.8950 | 1.7336 | 0.9936 | 0.0247 | 0.0007 |

| 350 | 0.09 | 150 | 20.4298 | 1.7816 | 0.9943 | 0.0253 | 0.0009 |

| 350 | 0.06 | 200 | 38.9516 | 1.7116 | 0.9910 | 0.0299 | 0.0001 |

| 300 | 0.03 | 200 | 72.2643 | 1.4302 | 0.9962 | 0.0180 | 0.0003 |

| 250 | 0.09 | 200 | 45.6844 | 1.6794 | 0.9942 | 0.0235 | 0.0006 |

| 250 | 0.06 | 250 | 82.3405 | 1.5081 | 0.9951 | 0.0204 | 0.0004 |

| 300 | 0.09 | 250 | 45.5013 | 1.7487 | 0.9955 | 0.0204 | 0.0005 |

| 350 | 0.03 | 250 | 69.8874 | 1.4564 | 0.9966 | 0.0170 | 0.0003 |

The shape parameter and scale parameter varied with microwave power P, vacuum pressure Pv and loading quantity m. The smaller the scale parameter α, the shorter the drying time consumed during the drying process. The smallest α value was at a loading quantity of 150 g, a vacuum pressure of 0.09 MPa and a microwave power of 350 W, which was consistent with the experimental result. The shape parameters β is large than 1. According to the study in (Uribe et al., 2011), when β value was between 0.3 and 1, the drying process was mainly controlled by internal moisture diffusion; when β > 1, the drying process was dominated by internal water diffusion and surface water evaporation and the drying curve would show an upward trend in the early stage. The β value here varies from 1.4302 to 1.7816, which is also consistent with the drying characteristics shown in Fig. 1a, c and e.

Taking α and β as dependent variables, and P, Pv and m as independent variables, new relationships were developed as follows:

| 12 |

| 13 |

where a, b, c and d are the coefficients to be solved in the model. The 1stopt5.0 software was used to obtain these coefficients and the results were shown in Table 3 and as follows:

| 14 |

| 15 |

Table 3.

Model parameter results

| Model | Parameters | Value | Sig | |

|---|---|---|---|---|

| 193.30347 | 0.078 | 0.96047 | ||

| − 76.17904 | 0.002 | |||

| − 32.36417 | 0.000 | |||

| 38.10633 | 0.007 | |||

| 1.38058 | 0.116 | 0.94281 | ||

| 0.32524 | 0.030 | |||

| 0.27153 | 0.000 | |||

| − 0.15781 | 0.077 |

From Table 3, one can see that the R2 value of Eqs. (14) and (15) is 0.96047 and 0.94281, respectively, indicating that the fitting degree of the model is high. The models are siginificant as the p values are less than 0.05. The effects of microwave-vacuum parameters on α and β values are all significant, except for the effect of loading quantity on β value. Substituting Eqs. (14) and (15) into Weibull distribution model, then a new relationship of MR was obtained:

| 16 |

According to the developed Weibull distribution model, the predicted values of MR were compared with the experimental values, as shown in Fig. 2. It was found that the deviation between experimental and predicted values was less than 10%, thus the developed model can be used to predict the moisture loss of C. oleifera seeds under microwave-vacuum drying.

Fig. 2.

Comparison between experimental (symbol) and predicted (line) values under microwave-vacuum drying

Moisture diffusion coefficient

The calculated results of moisture diffusion coefficient were shown in Table 4. It can be seen that the moisture diffusion coefficient increased with increasing microwave power and vacuum pressure and decreasing loading quantity. Rg value varies from 10.7794 to 18.2449, showing that the shape of C. oleifera seeds is between spherical material and flat material, which is also consistent with the actual shape of C. oleifera seeds.

Table 4.

Calculated results

| Drying condition | Deff | Dcal | Rg | ||

|---|---|---|---|---|---|

| Microwave power/W | Vacuum pressure/MPa | Loading quantity/g | |||

| 250 | 0.03 | 150 | 5.4849E−10 | 1.0007E−08 | 18.2449 |

| 300 | 0.06 | 150 | 1.3942E−09 | 1.9507E−08 | 13.9919 |

| 350 | 0.09 | 150 | 3.3585E−09 | 3.8093E−08 | 11.3425 |

| 350 | 0.06 | 200 | 1.8535E−09 | 1.9980E−08 | 10.7794 |

| 300 | 0.03 | 200 | 6.3224E−10 | 1.0769E−08 | 17.0336 |

| 250 | 0.09 | 200 | 1.2375E−09 | 1.7035E−08 | 13.7661 |

| 250 | 0.06 | 250 | 5.9982E−10 | 9.4515E−09 | 15.7572 |

| 300 | 0.09 | 250 | 1.1888E−09 | 1.7104E−08 | 14.3870 |

| 350 | 0.03 | 250 | 6.8358E−10 | 1.1136E−08 | 16.2902 |

Acknowledgements

This work has been supported by the Changsha Municipal Natural Science Foundation (kq2014151; kq2014153; kq2007033), the Nature Science Foundation of Hunan (2022JJ40860; 2021JJ41081) and Hunan Provincial Key Research and Development Program (2021NK2023).

Declarations

Conflict of interest

None of the authors of this study has any financial interest or conflict with industries or parties.

Footnotes

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Contributor Information

Dongyan Zhang, Email: dongyzj0327@163.com.

Dan Huang, Email: T20162326@csuft.edu.cn.

Xiyang Zhang, Email: 1963698503@qq.com.

Hangyi Zhao, Email: 2735923525@qq.com.

Guiliang Gong, Email: guiliang_gong@163.com.

Xiaohong Tang, Email: zhuzhoutxh@163.com.

Lijun Li, Email: junlili1122@163.com.

References

- Bai J, Sun D, Xiao H, Mujumdar A, Gao Z. Novel high-humidity hot air impingement blanching (HHAIB) pretreatment enhances drying kinetics and color attributes of seedless grapes. Innovative Food Science & Emerging Technologies. 2013;20:230–237. doi: 10.1016/j.ifset.2013.08.011. [DOI] [Google Scholar]

- Chen C, Pan Z. Heat and moisture transfer studies on walnuts during hot air drying in a fixed-bed column dryer. Applied Thermal Engineering. 2021;199:117554. doi: 10.1016/j.applthermaleng.2021.117554. [DOI] [Google Scholar]

- Corzo O, Bracho N, Pereira A, Vásquez A. Weibull distribution for modeling air drying of coroba slices. LWT-Food Science and Technology. 2008;41:2023–2028. doi: 10.1016/j.lwt.2008.01.002. [DOI] [Google Scholar]

- Crank J. The mathematics of diffusion. Oxford University Press (1979).

- Cui Z, Xu S, Sun D. Microwave–vacuum drying kinetics of carrot slices. Journal of Food Engineering. 2004;65:157–164. doi: 10.1016/j.jfoodeng.2004.01.008. [DOI] [Google Scholar]

- Dehghannya J, Hosseinlar S-H, Heshmati MK. Multi-stage continuous and intermittent microwave drying of quince fruit coupled with osmotic dehydration and low temperature hot air drying. Innovative Food Science & Emerging Technologies. 2018;45:132–151. doi: 10.1016/j.ifset.2017.10.007. [DOI] [Google Scholar]

- Ding D, Peng G, Xia H, Wan H, He D. Orthogonal array design for extraction optimization of protein from Camellia oleifera seed meal. Food Science. 2010;31:102–105. [Google Scholar]

- Gomide AI, Monteiro RL, Laurindo JB. Impact of the power density on the physical properties, starch structure, and acceptability of oil-free potato chips dehydrated by microwave vacuum drying. LWT-Food Science and Technology. 2022;155:112917. doi: 10.1016/j.lwt.2021.112917. [DOI] [Google Scholar]

- Hou L, Li R, Wang S, Datta AK. Numerical analysis of heat and mass transfers during intermittent microwave drying of Chinese jujube (Zizyphus jujuba Miller) Food and Bioproducts Processing. 2021;129:10–23. doi: 10.1016/j.fbp.2021.06.005. [DOI] [Google Scholar]

- Hu B, Li C, Qin W, Zhang Z, Liu Y, Zhang Q, Liu A, Jia R, Yin Z, Han X, Zhu Y, Luo Q, Liu S, et al. A method for extracting oil from tea (Camelia sinensis) seed by microwave in combination with ultrasonic and evaluation of its quality. Industrial Crops and Products. 2019;131:234–242. doi: 10.1016/j.indcrop.2019.01.068. [DOI] [Google Scholar]

- Huang D, Tao Y, Li W, Sherif S, Tang X. Heat transfer characteristics and kinetics of Camellia oleifera seeds during hot-air drying. Journal of Thermal Science and Engineering Applications. 2020;12:031017. doi: 10.1115/1.4045118. [DOI] [Google Scholar]

- Huang D, Men K, Tang X, Li W, Sherif S. Microwave intermittent drying characteristics of Camellia oleifera seeds. Journal of Food Process Engineering. 2021;44(1):e13608. doi: 10.1111/jfpe.13608. [DOI] [Google Scholar]

- Lee SY, Jung MY, Yoon SH. Optimization of the refining process of camellia seed oil for edible purposes. Food Science and Biotechnology. 2014;23(1):65–73. doi: 10.1007/s10068-014-0009-4. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Ren Y, Sun DW. Monitoring of moisture contents and rehydration rates of microwave vacuum and hot air dehydrated beef slices and splits using hyperspectral imaging. Food Chemistry. 2022;382:132346. doi: 10.1016/j.foodchem.2022.132346. [DOI] [PubMed] [Google Scholar]

- Sun Y, Zhang M, Bhandari B, Yang P. Intelligent detection of flavor changes in ginger during microwave vacuum drying based on LF-NMR. Food Research International. 2019;119:417–425. doi: 10.1016/j.foodres.2019.02.019. [DOI] [PubMed] [Google Scholar]

- Tian Y, Wu S, Zhao Y, Zhang Q, Huang J, Zheng B. Drying Characteristics and Processing Parameters for Microwave-Vacuum Drying of Kiwifruit (A Ctinidia deliciosa) Slices. Journal of Food Processing and Preservation. 2015;39:2620–2629. doi: 10.1111/jfpp.12512. [DOI] [Google Scholar]

- Uribe E, Lemus-Mondaca R, Vega-Gálvez A, Zamorano M, Quispe-Fuentes I, Pasten A, Di Scala K. Influence of process temperature on drying kinetics, physicochemical properties and antioxidant capacity of the olive-waste cake. Food Chemistry. 2014;147:170–176. doi: 10.1016/j.foodchem.2013.09.121. [DOI] [PubMed] [Google Scholar]

- Uribe E, Vega-Gálvez A, Di Scala K, Oyanadel R, Saavedra Torrico J, Miranda M. Characteristics of convective drying of pepino fruit (Solanum muricatum Ait.): Application of weibull distribution. Food and Bioprocess Technology. 2011;4:1349–1356. doi: 10.1007/s11947-009-0230-y. [DOI] [Google Scholar]

- Wang X, Zeng Q, del Mar Contreras M, Wang L. Profiling and quantification of phenolic compounds in Camellia seed oils: Natural tea polyphenols in vegetable oil. Food Research International. 2017;102:184–194. doi: 10.1016/j.foodres.2017.09.089. [DOI] [PubMed] [Google Scholar]

- Wang F, Ding Y, Chen P, Xie W, Li X, Yang D. Investigation on hot-air drying of Camellia oleifera seeds. Transactions of the Chinese Society for Agricultural Machinery. 2018;49:433–439. [Google Scholar]

- Wang F, Shao W, Yang D. Effect of different drying methods on drying characteristics and quality of Camellia oleifera seeds. Journal of Food Processing and Preservation. 2021;45:e15976. doi: 10.1111/jfpp.15976. [DOI] [Google Scholar]

- Wang P, Liu G, Ao S, Sun D, Yu B, Wu X. Numerical investigation of airflow and heat transfer characteristics and optimal design of the American ginseng drying room. Applied Thermal Engineering. 2021;183:115885. doi: 10.1016/j.applthermaleng.2020.115885. [DOI] [Google Scholar]

- Wu T, Yan J, Liu R, Marcone MF, Aisa HA, Tsao R. Optimization of microwave-assisted extraction of phenolics from potato and its downstream waste using orthogonal array design. Food Chemistry. 2012;133:1292–1298. doi: 10.1016/j.foodchem.2011.08.002. [DOI] [Google Scholar]

- Xu J, Wang D, Lei Y, Cheng L, Zhuang W, Tian Y. Effects of combined ultrasonic and microwave vacuum drying on drying characteristics and physicochemical properties of Tremella fuciformis. Ultrasonics Sonochemistry. 2022;84:105963. doi: 10.1016/j.ultsonch.2022.105963. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Ye S, Wang Z, Shen J, Shao Q, Fang H, Zheng B, Younis A. Sensory qualities, aroma components, and bioactive compounds of Anoectochilus roxburghii (Wall.) Lindl. as affected by different drying methods. Industrial Crops and Products. 2019;134:80–88. doi: 10.1016/j.indcrop.2019.03.063. [DOI] [Google Scholar]

- Zhu G, Liu H, Li W. Change rule of storage quality and optimization of storage condition for Camellia oleifera seeds. Transactions of the Chinese Society of Agricultural Engineering (transactions of the CSAE) 2020;36:301–311. [Google Scholar]

- Zhu G, Liu H, Xie Y, Liao Q, Lin Y, Liu Y, Xiao H, Gao Z, Hu S, et al. Postharvest processing and storage methods for Camellia oleifera seeds. Food Reviews International. 2020;36:319–339. doi: 10.1080/87559129.2019.1649688. [DOI] [Google Scholar]