Abstract

Face masks have proven to be a useful protection from airborne viruses and bacteria, especially in the recent years pandemic outbreak when they effectively lowered the risk of infection from Coronavirus disease (COVID-19) or Omicron variants, being recognized as one of the main protective measures adopted by the World Health Organization (WHO). The need for improving the filtering efficiency performance to prevent penetration of fine particulate matter (PM), which can be potential bacteria or virus carriers, has led the research into developing new methods and techniques for face mask fabrication. In this perspective, Electrospinning has shown to be the most efficient technique to get either synthetic or natural polymers-based fibers with size down to the nanoscale providing remarkable performance in terms of both particle filtration and breathability. The aim of this Review is to give further insight into the implementation of electrospun nanofibers for the realization of the next generation of face masks, with functionalized membranes via addiction of active material to the polymer solutions that can give optimal features about antibacterial, antiviral, self-sterilization, and electrical energy storage capabilities. Furthermore, the recent advances regarding the use of renewable materials and green solvent strategies to improve the sustainability of electrospun membranes and to fabricate eco-friendly filters are here discussed, especially in view of the large-scale nanofiber production where traditional membrane manufacturing may result in a high environmental and health risk.

Graphical abstract

1. Introduction

In recent years, the common commercial microfibers have been replaced with nanofibers in manufacturing personal protective equipment (PPE), such as face mask/respirators, which are specifically designed to protect the wearer from inhaling harmful airborne particles, including infectious agents, such as coronavirus, SARS, and bacteria spores. The 2019 coronavirus (SARS-CoV-2) pandemic has forced a widespread use of face coverings as a mandatory step for reducing spreading and infection by the virus, in fact the face masks turned out to be an essential barrier for preventing the transmission of infected aerosols among its user and the surrounding people [1], [2], [3]. Especially at the start of the pandemic outbreak face masks played a fundamental role, since information about the transmission mechanism of the virus was not yet clear and only isolation/ quarantine appeared to be the most significant strategy for infection control [4].

The size of the Corona virus has been observed to range from 60 to 140 nm [5]. The transmission of the virus can occur for close-distance contacts in the form of aerosols or droplets [6], because of its ability to coalesce with solid or liquid pollution particles present in the atmosphere, which makes it extremely infectious [7,8]. Therefore, the aerosol carrier of the virus (diameter < 5 −10 μm) can be transmitted from an infected person to a healthy one by means of respiratory droplets either for breath, coughs, or sneezes [9,10]. The short-range airborne route results to be the primary way to spread either pathogens or respiratory infection [11,12] such that wearing face masks is the most effective solution to prevent the transmission of this disease [13].

Despite the vaccination campaign against COVID continues to progress [14], the importance of wearing a face mask or a respirator in outdoor/indoor places is recommended as an effective measure for the infection control [15], [16], [17]. This led the research community to find more appropriate technologies and advanced materials to design novel high-efficiency mask, with extreme attention to particle filtration, cleaning treatments, adequate breathability, fluid penetration resistance, light weight, and user comfort, along with large-scale production and low costs. In this scenario, electrospun fibers showed their uniqueness and potential as active membranes, due to their reduced pore size as well as their extremely high surface-to-volume ratio [18]. The high performance in filtration is owed to the reduced pore size, which goes from sub-micron to several micrometers, involving a more effective capture mechanism for the small airborne particles below 300 nm, as well as to the high ratio of surface area/volume, which significantly increases the possibility of pollutant deposition on the surface of the fiber, thus reducing the air pressure drop and increasing the air breathability of the mask [19]. Although the melt blown (MB) is a low-cost process commonly used to produce nonwoven filter media [20], [21], [22], [23], the electrospinning (ES) technique has proved to produce nanofibers with better filtration performance in removing submicron particles/contaminants. Compared to the MB microfibers, whose fibers size are generally difficult to control and the diameters range from 1 to 10 μm, the electrospun fibers diameter can be ten or a hundred times smaller, thus providing a higher surface area as well as a lower inter-fiber pore size [24], [25], [26]. Several Reviews reported about the potentiality in using electrospun membranes for new generation face mask/respirators production [27], [28], [29], [30]. An increasing number of papers was found by using the keyword “Electrospinning filter face mask “in the Scopus database (Fig. 1 ).

Fig. 1.

Number of annual publications on Electrospun filters for face mask applications. The data have been collected in a search carried out on the “Scopus” database on 2023–04–06 by using the keyword “Electrospinning filter face mask“.

Besides the high filtering efficiency benefits, the functionalization of electrospun nanofibers through the addition of several compounds, such as metallic and not metallic nanomaterials, vesicles, and cellulose nanocrystals, allows designing advanced nanofibers with outstanding properties, including antibacterial, antiviral, and self-sterilization. Such customizability makes the electrospun nanofibers the ideal material for tackling the current issues from bacterial contamination on PPE surfaces to the reusability of both disposable single use facemask and respirator's filters. Also, modified ES set-ups combined with modern textile techniques turned out to be an innovative way to manufacture nanofiber bio-textiles with suitable mechanical and bioactive properties which effectively support cell tissue regeneration in clinical use [30,31]. Electrospun nanofibers composed by natural and biodegradable polymers can be easily degraded in environment or absorbed by the body, thus preventing the negative long-term degradation effects due to high consume of plastic, ensuring a safer approach to the realization of scaffold and drug delivery system for biomedical application [32], [33], [34], [35]. Although a great number of research in the electrospinning field has been carried out at laboratory scale, alternative techniques have been developed so far to expand the production of electrospun nanofibers on large industrial scale [36]. To date, many companies and start-ups operating in small and large textile manufacturing have been utilizing ES technology to fabricate face masks and protective controls with better performances on personal protection from particulate matter (PM) and airborne hazard. The leading ES research is focusing on the optimization of more sustainable filters to minimize the impact of disposable face masks on the environment, but the large volume of hazardous solvent still used in traditional membrane manufacturing involves a serious environmental issue. With this regard, particular attention has been given to more environmental-friendly ES processes to drastically reduce or completely give up toxic organic solvents, which are strictly used to solubilize polymer in conventional spinning solution.

This Review aims to give a general overview about the recent developments in ES techniques and its further application to produce electrospun nanofiber-based face mask. Firstly, a brief introduction about the fundamental principles behind the filtering mechanism, classification, and the standards for testing the face mask is provided. Then, is presented a description on conventional and alternative ES technologies, evaluating the possible developments for industrial scale-up. After that, are reviewed in detail the innovative scalable strategies present in literature for the processing of electrospun based face masks, highlighting the effects induced by the surface morphology, fibers geometry, and materials properties on the particle filtration, breathability, antibacterial, and antiviral performance. A brief introduction about the recent progress in the manufacturing of bio-textiles by using electrospun nanofiber yarns is also given in this Review. Finally, we discuss about the industrial implementation of ES for nanofiber manufacturing, giving to the reader further insight into the well-defined nanofiber market.

2. Face mask's structure and filtration mechanism

2.1. Surgical mask and respirator standards

Face masks have the important role to protect the wearer from the biological contaminants that can be present in the form of droplet or aerosols in the atmosphere, since respiratory infection may be transmitted due to either talking or coughing droplets from an infected person. The method of infection has been observed to depend on the droplet size [4,37]. Large droplets with diameter ranging between 2.5 and 10 μm can deposit due to gravity either in the nasal, oropharyngeal, laryngeal, or tracheal regions of the respiratory system, whereas the smaller ones ranging between 0.25 and 1 μm can evaporate midair involving airborne transmission eventually depositing in the respiratory tract. In addition, intense coughs and sneezes have been observed to propel larger droplets over 20 feet that can remain airborne for hours [38]. Therefore, face masks are expected to prevent the penetration of contaminant present in the surroundings such as particulate and dust, which can be potential bacteria or virus carriers. Among the various classifications, both the surgical masks and the face piece respirators have been taken in consideration as effective devises in preventing viral infection by airborne contamination.

A surgical or medical mask is used as medical device for health care workers (HCWs) to avoid that patient in hospitals become infected from possible expiratory droplets. These devices are generally used for surgical operations, since they are fluid resistant providing a useful physical barrier from larger droplets and body fluids, despite their loosely fit on the wearer face. The common surgical masks are made of three nonwoven layers, all of which are generally composed of polypropylene (PP) thermoplastic polymer [18,27,[39], [40], [41]] (Fig. 2 a). The cover and shell layer are fabricated with spunbond fabric to provide high tensile strength and good breathability in the mask, respectively. These layers show fibers diameter ranging between 15 and 40 μm, and do not provide any contribute to the overall filtration system. On the other hand, the inner layer is fabricated by means of MB process, which allow to obtain submicron fibers with diameter size ranging between 0.5 and 10 μm. This latter layer sandwiched between spunbond fabrics performs as the filtering system. As their relatively large diameter is insufficient to efficiently filter small airborne particles, electrostatic treatment is performed on the filter to improve the filtration efficiency. However, the static electricity quickly depletes due to long use of the mask with a consequent reduction of the filtration properties, so that they can be used for one time only. The grade of protection from bacteria is obtained by means of Bacterial filtration efficiency test (BFE). This test allows to obtain a measurement of the device's resistance to the penetration of Staphylococcus aureus (S. aureus) aerosols, which is shot with a flow rate equal to 28.3 L/min through the mask by using particle size of 3.0 μm [41]. As the degree of efficiency is reported in percent, higher percent values correspond to better filtration performances from the face mask. According to the European standard (EN 14,683:2019), a surgical mask is classified either as type I, if it presents at least a value of 95% BFE, or as type II, if it provides better filtration performances (BFE ≥ 98%) (see Table 1 ). Furthermore, a third class, namely IIR, includes a splash resistance test to penetration of synthetic blood. About the ASTM F2100–19 standard used in United States, the classification of the surgical masks is almost the same as the EN 14,683:2019, with the exception of a more relevant test required, concerning particle filtration efficiency (PFE) of the submicron particles, with mean diameter of 0.1 μm [42,43].

Fig. 2.

Structure of a surgical mask (a) and filtering half mask (b). (c) Schematic image of different pathogens and air pollutants for a size comparison.

Table 1.

European and USA standards required for surgical mask and facepiece respirators.

| Surgical mask | USA ASTM F2100–19 Standard |

EN 14,683:2019 Standard |

||||

|---|---|---|---|---|---|---|

| Level 1 | Level 2 | Level 3 | Type I | Type II | Type IIR | |

| BFE (%) | ≥95 | ≥98 | ≥95 | ≥98 | ||

| PFE (%) | ≥95 | ≥98 | Not required | |||

| Fluid resistance | >80 mmHg |

>120 mmHg | >160 mmHg | Not required | >120 mmHg | |

| Differential pressure drop | < 5.0 mmH2O/cm2 | < 6.0 mmH2O/cm2 | < 40 Pa/ cm2 | < 40 Pa/ cm2 | < 60 Pa/ cm2 | |

| Facepiece respirator | NIOSH 42 CFR Part 84–2019 standard | EN 149:2001+A1 2009 | ||||

| N95 | N99 | N100 | FFP1 | FFP2 | FFP3 | |

| BFE (%) | ≥95 | ≥99 | ≥99.97 | ≥80 | ≥94 | ≥99 |

| PFE (%) | ≥95 | ≥99 | ≥99.97 | ≥80 | ≥94 | ≥99 |

| Inhalation differential pressure | 343 Pa at 85 l/min | 210 Pa at 95 l/min | 240 Pa at 95 l/min | 300 Pa at 95 l/min | ||

| Exhalation differential pressure | 245 Pa at 85 l/min | 300 Pa at 160 l/min | ||||

EN (European Norm); ASTM (American Society for Testing and Materials; NIOSH (The National Institute for Occupational Safety and Health); CFR (Code of Federal Regulations); BFE (Bacterial Filtration Efficacy); PFE (Particle Filtration Efficiency).

Like surgical masks, a facepiece respirator is composed of polymer-based multiple layers (Fig. 2 b). The outer layers are composed of non-woven fabric with grams per square meters (gsm) ranging between 20 and 50 to create a barrier against moisture. Besides, a higher dense layer of around 250 gsm is employed to provide more stiffness and thickness to the face mask, whereas a more internal layer made via MB process acts as filter. Compared to the surgical masks, the facepiece respirators are tighter and more adherent to the face, in order to avoid inhalation of both droplets (particle size > 0.5 μm) and smaller particles, such as dust, and aerosols (particles size < 0.5 μm), and to provide a real protection from both potential viruses and bacteria [18] (Fig. 2 c). With regards to the EN 149:2001, these respirators are classified as filtering half masks (i.e., Filtering Face Pieces (FFP)) and are divided in three different types, namely FFP1, FFP2, and FFP3, depending on the filtration efficiency values, for both PFE and BFE, equal to 80%, 94%, and 99%, respectively [44], [45], [46] (Table 1). In addition to the filtration performance, the National Institute for Occupational Safety and Health (NIOSH), in the USA, also adopts a classification by letter, namely N-, R-, and P-, to indicate the lack of resistance in oil, somewhat oil resistant, and strongly resistant, respectively. According to this standard, three distinct filtration efficiencies degrees are adopted for the respirators, such as 95%, 99%, and 99.97%, and for each series of letters three facial pieces are classified, for instance N95, R95, and P95 for 95% filtration performance, etc. [4,18].

In high-risk situations both the Centers for Disease Control and Prevention (CDC) and the World Health Organization (WHO) currently recommend to health workers the use of protective sources of respirators with performances of 95% or higher, such as FFP2 and N95 [47,48]. The rigorous standards adopted in Europe and USA have made that these respirators provide higher protection than loose surgical masks, so to prevent users to be infected from either large droplets, originated in air for short periods during cough, sneeze, and talking, or from fine airborne particles which remained in air for long time and have been transported for longer distances. However, there are some clinical researches that have brought to conflicting results. For instance, some studies have evidenced a better effectiveness of N95 respirators in reducing viral infections compared to surgical masks [49,50], while other works reported no significant difference between N95 respirators and medical masks in terms of viral preventing from respiratory infections, including that of influenza [51,52]. Even though concrete evidence about the efficacy in protecting health workers against viral SARS-COV-2 of respirators compared to surgical mask is not totally reliable yet, the utilization of respirators for high-risk setting pandemic is strongly recommended [41,53,54].

2.2. Filtration mechanism of face masks

The filtration effectiveness of a face mask is an estimate of the ability of the inner layer in trapping undesired airborne particles, which could introduce harmful microorganisms or viruses through inhalation of air. The capture mechanism of fibrous media strictly depends on the particle size and can be divided in the following way (Fig. 3 a): direct interception, diffusion, electrostatic deposition, gravitational forces and inertial deposition [18,27,39,55,56]. The interception mechanism generally involves the capture of particles with diameter size lower than 1 μm. When the particle carried by air streamlines is moving in the proximity of the fiber surface, so that their radius is less than the fiber-particle distance, it is affected by Van der Waals attraction forces thus remaining stuck on the mat. Diffusion is another effective method to capture smaller particles, usually those with diameter far below 1 μm. The random collision with other particles from Brownian motion near the fiber brings the aerosol particle to deviate from their original streamline thus impacting with high probability to the fiber surface. Besides, charged fibers can effectively trap submicron particles of opposite charge via electrostatic attraction.

Fig. 3.

(a) A schematic image of the principal capture mechanisms for fibers. Below, a simplified diagram which displays the particles size range where Electrostatic, Diffusion, Interception, and Inertial impact mechanism are more efficient; an example of electrostatic deposition is represented in the schematic picture from the electrostatic attraction occurring between a negative charge fiber (minus sign) and a charged aerosol particle (blue sign). (b) Graphic representation of the main filtering efficiency curves for a single fiber as function of the particle size; adapted with permission from [57].

The effect of the electrostatic charges is that of improving the overall particles filtration efficiency without affecting the morphology of the fiber and either the interception or the diffusion mechanical capture. Corona discharge and triboelectrification methods are commonly used to apply electrical charge on electrically active polymer materials [58,59]. Finally, larger particles ranging from 1 to 10 μm are expected to be easily captured from gravity and inertia mechanisms. Indeed, bigger particles moving along the stream can be deposited on the fiber surface due to the gravity. On the other hand, the inertial deposition results to be a more effective method to capture either aerosols or dust particles larger in size than 1 μm. Particles moving at high velocity near a fiber can come out from the main streamlines and impact on the fiber surface due to the inertia, hence the higher is the particles velocity the better is the capture efficiency. The mechanical efficiency of the commercial face masks in the submicron particle range is mainly due to the interception and diffusion mechanisms, whereas the contribution of inertial impact and gravity are practically negligible. The lowest filtration particle measured is defined as the most penetrating particle size (MPPS) and corresponds to the least efficiency value ensured by the standards adopted (Table 1). The MPPS differs from one filter system to another and is found in the point of intersection between the diffusion and interception curves, which generally falls in the range between 0.1 and 0.3 μm [26,56] (Fig. 3 b). To improve the overall mechanical efficiency against fine particles for the most commonly produced face masks, industries typically rely on the electrostatic charge effect. The performance obtained for charged fibers in face mask are better than those observed in uncharged one [60]. While the mechanical filtration of large droplets in face masks come mainly from the micro-pore size of the fibers, which in a MB-based filter is about ∼20 μm, the filtration of aerosols is due to the electrostatic attraction of smaller particles at the fibers surface. The polymer materials forming these mask devices are generally electrostatic microfiber media, such as PP, that can be electrostatically charged by means of corona discharge. To charge them a high voltage is applied between the two electrodes and the electret filter, thus allowing the ionization of the air to induce a positive or negative charge on the fiber surface [58,60]. Even though this treatment involves a better performance in respirators/ face mask, the effect of either air humidity or liquid contact on charge decay no longer ensure a proper coverage against small particles. It has been stated that longer exposition to air humidity leads to a reduction of the charge on the fibers, thus resulting in a decrease in the filtration performance [56]. Moreover, ethanol and autoclave sterilization treatment remove electrical charges from the polymer filter media thus affecting the performance of the face mask not guaranteeing a proper protection if reused [61]. If on the one hand respirators are expected to provide a greater filtration performance compared to surgical masks due to the effective seal on the face, lower air leakage, and multi-layer structure, on the other hand the lowering of the electret fiber charge can bring to a significant decrease in the overall collection efficiency and make both the class types useless to face coronavirus disease.

2.3. Breathability test

In addition to filtration efficiency, the overall layers constituting either a surgical mask or a facepiece respirator must be both comfortable and breathable for the users. Indeed, the fabric fibers used to make a mask have to provide an effective barrier against airborne particles, but they also must ensure the person to breath properly [39,58,[62], [63], [64]]. The pressure drop is the most commonly used parameter to quantify a mask breathability, being an index of the air flow resistance of the filter for a specific material surface, which makes it a suitable indicator to assess the filter performance. Pressure drop is obtained at specific flow rates by measuring the difference in pressure between the two outer layers of a face mask [63]. Lower values of pressure drop involve better breathability for the face device, thus making breathing more comfortable for the wearers. The difference in pressure between the upstream and downstream measured on the two outer layers side is proportional to the volumetric air per unit area, also known as face velocity, that crosses through the face mask. The presence of multiple layers as well as the occurrence of inhomogeneity in the air flux in the fabric fiber can affect in many ways the pressure difference measurement for a given tested area. Therefore, a comparison between pressure drop measurements obtained in different experiments with different values of tested face velocity is not advised [63]. The measure of the pressure drop is usually reported in units of Pascal for surface area (Pa/cm2) and varies depending on the standard adopted by the different countries. About surgical masks for instance, the flow rate values, which is generally expressed in liters per minutes (Lpm), used for the test performed both in USA and Europe, according to ASTM F2299 or F2101 and EN 14,683:2019 standards respectively, is fixed to 8 L/min over a tested mask surface of 4.9 cm2, but the maximum pressure drop specified for these tests varies from 40/40/60 Pa/cm2, for type I, II, and IIR in Europe, to 50/60/60 Pa/cm2 for barrier levels equal to 1, 2, and 3 in USA [63,64]. The high number of layers that structure a face piece respirator provide a better resistance to flow stream compared to surgical masks but results also in a large pressure drop which makes breathing more difficult for the user (Table 1). Because of the shortage as well as the intense workload and patient flow during the pandemic outbreak, face masks were allowed to be worn for an extended period longer than that recommended. Nevertheless, a prolonged use can involve a serious of discomfort due to an increase of the facial temperature, both during exhalation and inhalation [65]. Recent studies investigated the possible factors involved in the discomfort increase and in the protection drop due to long-term usage of common face mask by testing particle filtration, breathability, and humidity. Experimentally it has been observed that high breathing resistance and low moisture permeability make a respirator more discomfortable than a surgical mask, especially after many hours of use [66]. Additionally, an increase in temperature and humidity due to moist air expired and inspired in repeated breathing cycles have been observed to promote the growth of bacteria on the face mask, thus putting the most vulnerable people at risk of infection [66,67]. Also, evident drop in humid air filtration efficiency after prolonged wearing of common face mask, with also further proliferation of fungi and bacteria colonies, have been recently reported [68]. A research stated that the use of surgical masks of high quality, like the Type IIR, can be extended to 8 h, and then beyond the recommended time of 4 h, but only under restricting conditions and for that specific brand and standard [69]. These studies highlights that a prolonged use of commercial face mask over the usual recommendation can then involve a considerable discomfort for the combined effect of high humidity and temperature rise on the face but can also expose the user to other potential health risks.

3. Introduction to electrospinning

3.1. Electrospinning as alternative method for the fabrication of face mask filters

The layers forming a commercial face mask are mainly produced by means of Melt-blowing (MB) and Spunbond (SB) methods. Both the techniques are based on the extrusion process of melted polymers in a continuous fluid jet through a spin- hole, which size generally range between 250 and 1000 μm [58]. However, the two methods involve a different process during the collection of the nonwoven fibers. While in the SB process the fluid moving across a quench chamber is cooled by flow air, thus leading to a stretch of the fibers diameter in the range 10–35 μm, in the MB process the polymer fluid is further heated by high-speed hot air thus involving the formation of finer fibers with diameter size ranging between 1 and 10 μm. Since the hot filament spontaneously bond in MB process, no further processing is provided on the nonwoven fiber. Conversely, to improve the bonding in air cooled non-woven fibers, additional treatments, such as thermal, mechanical, or chemical, are carried out in SB method [58]. Because of the smaller diameter size and poor mechanical strength, the MB fibers are usually sandwiched between the SB fabric ones providing filtration performance in commercial face mask. Despite PP is the most popular polymer employed in filters formation, many other viscous thermoplastic polymers, such as polyethylene, polystyrene, polyesters, or polyamides, can be melt blowing [21].

The electrospinning is another flexible technique to fabricate polymer nonwoven fibers and has been attracting great attention from the scientific research community and from industries due to its application in air filter systems [70]. The physical phenomena of the ES dates to the 16th century when William Gilbert for the first time observed the formation of a cone shaped droplet as a consequence of the exposure to the electrostatic field [71]. The behavior of the formation of aerosols of charged liquid have been investigated also by Rayleigh, who obtained an estimate of the maximum charge that a liquid droplet can carry before the liquid jets are ejected from the surface [72]. In addition, Zeleny has conceived a mathematical model to explain the physics of this process [73]. The first patented ES set-up was that of Cooley in1900 [74], which involved the use of many electrodes bringing fiber deposition on a continuously rotating drum similar to that conventionally employed nowadays, but only between the 1930s and the1940s Formhals implemented an alternative set-up, which paved the way to the modern electrospinning techniques [75], [76], [77]. The basic set-up for conventional ES consists of four major components, which include a syringe for containing the electrospun solution, a spinneret which usually consist of a metallic needle with a blunt tip, a high-voltage power supply which can be either direct current (DC) or alternating current (AC), and a conductive grounded collector [78]. During the ES process the syringe pump is used to push a polymer solution at a constant and controllable rate. To obtain the ES solution, the polymer compound is being dissolved by means of a proper organic solvent. When high voltage is supplied between the needle tip and the ground collector, opposite charges will separate within the liquid, due to the electrostatic repulsion among them, thus involving an increase of density charge on the surface of the droplets.

The surface tension will promote the formation of a spherical shape to minimize the electrostatic pressure induced by the external electrical field, which will tend to deform the shape of the droplets. From the syringe a charged jet will flow out initially in a straight line towards the grounded collector following the direction of the applied electric field (Fig. 4 a). As this latter reaches a critical voltage, the surface tension will be exceeded by the electrostatic pressure and an instability of the liquid solution occurs with further deformation of the droplets from spherical to cone shape (i.e., Taylor cone formation) [79] . While the jet extends towards the grounded collector, it undergoes a whipping motion due to the bending instability. While the external perturbation field accelerates the charged jet to move forward the collector, the effect due to the electrostatic repulsion among the opposite charges on the surface of the jet will generate upward and outward forces thus forcing the jet to bend during the motion. Meanwhile, the trajectory is subjected to form a series of loops, resulting in the formation of a coil with several turns. As the distance from the tip increases, the diameter of the charged jet tends to decrease and to continuously stretch. With further elongation the jet solidifies, as a consequence either of the solvent evaporation or the cooling of the melt, forming thin fibers. Finally, the collection of the jet as solid and stable fibers involves the dissipation of the charges through the ground collector. Modifications of the basic set up have been adopted over the years to enhance the fabrication of more complex nanofibers. An example of advancement in standard needle‐based ES methods is given by the introduction of a coaxial spinneret, which allows the fluids from different polymer solutions to be ejected in a coaxial jet thus forming a core−sheath electrospun nanofiber with controlled size [80] (Fig. 4 e). Another example is the triaxial ES method, in which triaxial needles are used to fabricate nanofibers that are structured in three layers [81] (Fig. 4 c). Similar to coaxial, the side-by-side ES technique allows to produce a hierarchical Janus fibers composed of two different sides starting from different polymer solutions [82] (Fig. 4 b).

Fig. 4.

ES process: (a) Formation of Taylor cone and further stretch of polymer jet under bending instability, adapted with permission from [83]. (b) Side-by-side ES set-up, adapted with permission from [84]. (c) Triaxial ES setup and (d) fiber structure: SEM image of fiber; TEM image of fiber; laser confocal image of fiber. (e) Coaxial ES and SEM image of aligned TiO2; adapted with permission from [85].

As well as for MB membranes, the overall electrospun membranes generally provide low mechanical properties and therefore auxiliary outer layers are provided for face mask applications to make them more resistant. Although several processing parameters, such as air velocity, melt flow index, processing temperature, and orifice size can be tuned to obtain smaller MB based fibers [21,26], the MB fibers developed so far on laboratory scale as filter media for face mask application are characterized by fiber diameter of about the submicron size [23,[86], [87], [88]]. Unlike the MB process, the fibers obtained with ES method can reach diameter size down to 100 nm and a broad range of polymer materials have been successfully electrospun into nanofibers so far [26,89]. A decrease of the fiber diameter to the nanoscale has been observed to contribute in increasing the capture of fine aerosols particles (< 0.5 μm) [62,90,91]. Since the diameter of electrospun nanofiber can be comparable with the free path of air molecules at ambient condition, a slip flow regime occurs around the single nanofiber [26,70,92]. In this regime the fiber's drag force friction is substantially reduced, therefore a low momentum exchange between the fine particles and the fiber surface occurs, resulting in a low pressure drop [93]. Besides, the air streamlines behave in a straight-line fashion getting closer to the nanofiber thus resulting in a higher filtration efficiency due to interception mechanisms [70]. On the other hand, many drawbacks in conventional ES are due to the use of volatile organic solvents, which represents almost the 80% of the solution used for polymer solubility. Some of them are toxic and a small part of them may remain in the nanofiber fabric, without evaporating completely during the process [26] . Instead, many different MB set-up are solvent-free and can also achieve high production rates, thus providing low cost and eco-friendly manufacturing of nonwoven fabric compared to ES [21]. Although ES is a relatively new and promising method for the manufacturing of nanofiber-based filter in application for face masks, new technologies and strategies should be developed to reduce the high cost of hazardous solvent and promote a safer production of nanofiber on large scale.

3.2. Electrospinning design for high production

Because of the long fiber deposition time occurring in conventional ES using a single needle (capacity of ∼ 0.01- 0.1 g/h), several techniques such as multi-needles, needleless, free solvent or melt, and centrifugal ES have been developed to improve the production rate of nanofiber membranes [94,95]. The idea behind the multi-needle is based on conventional ES, but with the utilization of a nozzles array that allow the outflow of several polymer solution simultaneously (Fig. 5 a).

Fig. 5.

(a) Multi-needles ES set up; adapted with permission from [96]. (b) Needleless ES using spiral coil spinneret; adapted with permission from [94]. (c) Centrifugal ES set-up; adapted with permission from [97]. (d) Umbrella like spinneret and schematic diagram of melt polymer differential ES; (e) formation of multiple melt polymer jet; (f) definition of interjet distance; adapted with permission from [98].

Although better production rates have been observed by increasing the number of nozzles in several ES spinnerets, drawbacks due to either the needle clogging or electric field interference between the close needles arranged on the array may affect the nanofiber productivity [99]. Unlike the multi-needle method, the needleless ES overcomes the shortcoming of clogging, because of the absence of needles use [83] (Fig. 5 b). The spinneret in this case generally consists of a rotating cylinder with large surface area that is partially immersed into the spinning polymeric solution. As a result of the rotation, a continuous production of thin polymer layer occurs on the spinneret surface with the further formation of steady conical spikes. The application of high voltage to the spinning solution intensifies the perturbations, thus leading to the formation of Taylor cones, from which polymer jets are further stretched out to finally results in fibers. In comparison with multi-needle method the needleless ES can produce the highest quality fibers and can have higher rates of production by exploiting different spinneret shapes in the set-up, such as cylinder, ball, disk, coil, and beaded chain [100,101]. Centrifugal ES has proven to be also a promising method to produce ultrathin fiber with large volume and high efficiency compared to other techniques [97,102]. This technique combines centrifugal and electrical forces to manufacture fiber from micrometers to nanofibers scale (Fig. 5 c). Because of both rotating spinneret and applied electric field, the stretching effect on the polymer jet expelled from the nozzle rim is higher than that observed in conventional ES. The combination of centrifugal, viscous, electrical, and gravity forces leads to a greater elongation of the polymer jet with lower bending instability, thus resulting in a better orientation in the formation of fibers [97]. As it can be observed in Table 2 , several synthetic polymer membranes, including Polyacrylonitrile (PAN), Polyvinylpyrrolidone (PVP), and Polyvinylidene fluoride (PVDF), have been electrospun so far by means of needless and centrifugal techniques, providing high-rate productivity compared to the conventional ones.

Table 2.

A comparison between scale up electrospinning methods to fiber manufacturing.

| Electrospinning Technique | Method | Polymer1 | Solvent2 | Productivity | Electrospun fiber size | Application | Refs. |

|---|---|---|---|---|---|---|---|

| Needleless |

Anular spinneret | PAN | DMF |

∼4.5 g/h | ∼133- 351 nm | Air filtration | [100] |

| Needle roller electrospinner | PVA | DI | ∼12.8 g /h | ∼190 nm | – | [103] | |

| Anular spinneret | PVP PCL Silk fibroin PANI /PAA PAN PVDF/PEG |

DMF/Ethanol/DI TFA Trifluororethylene DMF DMF DMF/DI |

∼4.8 g/h | < 2 μm | – | [104] | |

| Yarn spinneret | PAN | DMF | ∼1.17 g /h | ∼100–117 nm | – | [105] | |

| Threaded rod spinneret | PEO | DI and ethanol | ∼5–6 g/h | ∼100–500 nm | – | [106] | |

| Linear flume spinneret | PAN | DMF | ∼4.8 g/h | ∼108–210 nm | – | [107] | |

| Mushroom-spinneret. | PAN | DMF | 13.7 g/h | ∼100–200 nm | – | [108] | |

| Bullet spinneret | PVA | Water | ∼1.08–4.55 g/h | ∼123–546 nm | – | [109] | |

| Multi-needle | – | TPU | – | ∼50 g/h | ∼145 nm | Air filtration for PM2.5 | [110] |

| High speed (HSES) |

Rotational spinneret | SBE-β-CD | VOR and water | ∼240 g/h | ∼0.5 – 2 μm | – | [111] |

| Rotational spinneret | PVA |

DI |

∼3.6–6 g/h | ∼271–477 nm |

Biopharmaceutical | [112] | |

| Air-blowing assisted Coaxial | – | PVP | DMF | ∼3.6 g/h | ∼1–16 μm | – | [113] |

| Centrifugal |

Single subdisk | PS PVP |

Chloroform Ethanol |

∼25 g/h | ∼263–8372 nm | Mask filter | [114] |

| – | PVP TPU |

Ethanol DMF |

∼50 g/h | ∼2.8–8.9 μm ∼1.8 – 5.4 μm |

Biomaterial and biomedical | [115] | |

| – | PEO PLA |

Water Chloroform |

∼38.3 g/h ∼12.8 g/h |

∼180 nm ∼525 nm |

– | [97] | |

| Melt Differential Centrifugal (MDCE) | Centrifugal differential disk | PP | (Solvent-free) | ∼124.3 g/h | ∼790 nm | – | [116] |

| Melt Differential (PMDES) | Umbrella-like spinneret | PP/PLA |

(Solvent-free) | ∼0.3–0.6 kg/h | ∼300 nm | Biomedical and tissue engineering | [98] |

| Melt | 600-nozzle spinneret | PLA | (Solvent-free) | ∼0.9–5.1 kg/h | ∼1 μm | – | [117] |

Polymers abbrevations: PAN (Polyacrylonitrile); PVA (Polyvinyl acid); PVP (Polyvinylpyrrolidone); PCL (Polycaprolactone); PANI (Polyaniline); PAA (polyacrylic acid); PVDF (Polyvinylidene fluoride); PEG (polyethylene glycol); PEO (polyethylene oxide); TPU (Thermoplastic polyurethane); SBE-β-CD (Sulfobutylether-β-cyclodextrin); PS (polystyrene); PLA (polylactic acid); PP (Polypropylene). 2Solvents abbreviations: DMF (N, N-Dimethylformamide); DI (De-ionized water); TFA (trifluoroacetic acid); VOR (Voriconazole).

However, the use of large amounts of harmful solvents, such as DMF, can require a high cost in recycling, thus limiting the large-scale production of these synthetic membranes. Safer bio-sources, deep eutectic, and ionic liquids solvents have been recently proposed as low toxic solution to allow a proper spinnability and processability for these synthetic polymers, but further investigations should be done to extend their use to pilot scale manufacturing [118,119]. On the other hand, the formulation of alternative solvents, including water and ethanol, with biopolymer materials, such as Polyvinyl acid (PVA), polylactic acid (PLA), and polyethylene oxide (PEO), have been used in both these ES techniques, showing high productivity rate [97,103,106,109,114,115] (Table 2). These polymers are nowadays widely implemented in health industry application, including personal protective-clothing, tissue engineering and drug delivery, due to their biocompatibility and biodegradable characteristics [[120], [121], [122]]. Unlike these solvent based methods, the melt ES is an eco-friendly and solvent free process [95,123]. Given the absence of solvents to solubilize the polymer in the spinning solution, the viscosity of the polymer melt is higher than that usually obtained for standard solution ES with single needle. Therefore, a strong electric field, three or five times higher than that used in conventional ES, is applied to the melt polymer to guarantee the fiber formation. Among the different types of melt ES set-ups designed so far, the needleless melt differential ES proved to be a promising method to start mass production of fiber. Like needleless ES, the needleless melt differential process avoids the use of capillarity needle and make use of very high voltage to produce multiple jets from free melt polymer surface. The set-up is provided with five principal components, including both a melt inlet and distributor, umbellate nozzle spinneret, high voltage power supply, and a receiver plate (Fig. 5 d). Firstly, the melt polymer is being channeled by means of a micro inlet toward a melt distributor to be then transformed from a cylindrical flow into a more uniform ring-like shape one. The further distribution of the flow to umbellate nozzle spinneret allows the formation of a uniform melt thin layer on the circumferential surface. The application of a critical high voltage power involves the formation of polymer multiple jets around the circular edge of the umbellate nozzle and their further ejection in the form of fibers to the receiver plate. An increase in the output of the melt polymer fibers is possible by reducing the distance between the multiple jets (interjet distance) forming around the rim of the nozzle, and thus expanding the number of Taylor cones produced (Fig. 5 e, f). Shorter interjet distance can be obtained by applying high electric fields during the spinning process as well as by lowering the value of the polymer melt viscosity by varying the nozzle temperature [117,124,125]. Despite the high-rate production, the resulting fibers are still large, exceeding 1 μm in size than those fabricated by means of solution ES methods. To address the drawbacks due to the large diameter limitation, nontoxic additives have been blended with polymer to produce submicron fiber [98,126]. Scale up production line for melt ES providing polymers electrospun membrane sheet of width around 1.6 m with 1–10 m/min speed production have been reported in literature [98]. The productivity efficiency of synthetic PP and biodegradable PLA electrospun membranes were comparable with those reported for standard MB lines, which provided high throughput rate around ∼1 kg/h [21]. Also, a scalable set-up for melt Centrifugal ES has been designed with the inclusion of nozzle spinneret to generate multiple jets from the rim disk and enhance the throughput rate of nanofibers [116] (Table 2). A list of international companies that supply several ES equipment based on needleless and centrifugal technologies for industrial production of nanofibers, has been reviewed in other works [127,128]. The advantage of melt ES processes, including the Needleless and Centrifugal ones, is due to a reduction in cost of solvent recovery that brings to a more sustainable manufacturing process of polymer membranes. However, the high processing temperatures ensure that only thermoplastic polymer showing high decomposition temperature can be processed [95]. On the other hand, less toxic solvent-based ES methods can be a solution to high productivity of biopolymer membranes, due to their low impact on environmental waste, life cycle and health assessment [119]. Further assessment on environmental cost and impact for many alternative green solvents is necessary to reduce the risk caused by using hazardous solvents and to allow a more sustainable manufacturing process for large scale polymer membranes.

3.3. Electrospinning parameters and filtration efficiency

ES technique has shown to be a low expensive approach to design nanofiber with controlled size. Many processing ES parameters, including applied voltage, distance between the two electrodes, nozzle tip (needle) diameters, and flow rate, as well as polymer concentration in the solution, can be properly tuned to control structural morphology and orientation distribution of the fibers [[129], [130], [131], [132], [133]]. Among these parameters, the polymer concentration strongly affects the fibers diameter. It was observed that lower viscosity in the ES solution involves the formation of finer fibers in the electrospun membrane [[134], [135], [136], [137]]. A reduction of the fiber size in the range of nanofiber is required to obtain high filtration efficiency against submicron particles [[138], [139], [140]]. Indeed, the probability of fine aerosols to impact the ultrafine fibers increase due to the high surface area, whereas small interstitial sites between the fibers improves the ability of the membranes to remove particles bigger than the pores size because of the sieving effect [141]. Also, an increase of the basis weight for a given surface or thickness obtained with a longer deposition time during the ES process has proven to be a good strategy to improve filtration efficiency of the filters [[142], [143], [144]]. However, the use of thicker layers as well as that of small fibers can negatively affect the air permeability of the fabric resulting in an increase of the pressure drop with consequences on the breathability. Therefore, the overall performance of the filter can be estimated by means of the calculation of the quality factor (QF), which takes into account both the pressure drop (ΔP) and the filtering efficiency towards particles (η) [141]:

| (1) |

Better filter performance can be obtained for high QF values, which means to keep low pressure drop and high particles filtering efficiency. One strategy to obtain effective filtration is that to fabricate electrospun fibers with high interconnectivity or porosity. An enhanced porosity can involve a proper airstream across the electrospun membrane with a significant reduction in the pressure drop, without affecting the ability of capture of the nanofibers against submicron particles [62,141].

4. The use of electrospun nanofibers in surgical mask and respirator applications

4.1. Improvement of the face mask's performance by using nanofibers

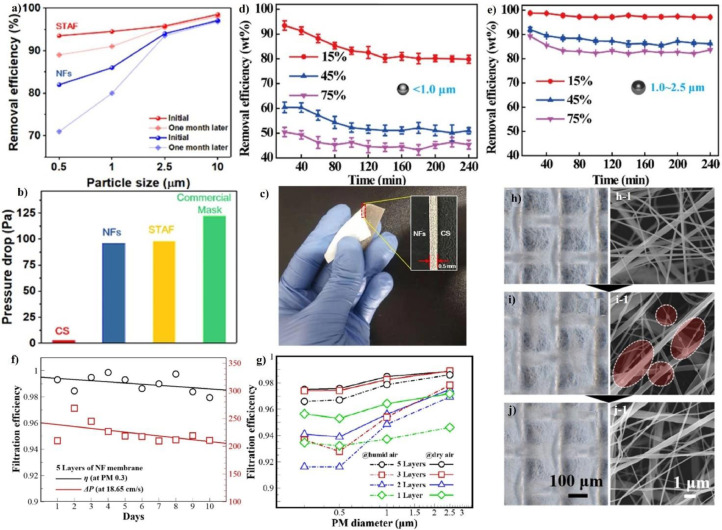

In recent years many synthetic and thermoplastic polymers such as PVDF, PAN, PP, Polyimide (PI), and polystyrene (PS), have been electrospun in fibers to improve the prevention of infection from expiration of airborne contaminants [4,18,27]. A reduction of the fiber diameter as well as of the interstitial space between the fibers has been observed to lead to a significant improvement in mechanical adsorption of fine particles in several polymer based electrospun membranes [[145], [146], [147], [148]]. Ultrathin PVDF-g-POEM electrospun fibers exhibited higher performance in capturing NaCl particle (≤ 0.3 um) compared to PVDF nanofibers with larger diameter (Fig. 6 a) [146].

Fig. 6.

(a) Comparison between the filtration efficiency measured for PVDF and amphiphilic PVDF-g-POEM double comb copolymer for different pressure drop values; adapted with permission from [146]. (b) Filtration efficiency values measured for PAN electrospun fibers as function of different average diameter; adapted with permission from [148]. (c) Filtration efficiency measured for PAN10%−1%Ag (1.50 g/m2), Respirator Face Mask and Three-Ply surgical as function of aerosol particle size; adapted with permission from [147]. Diameter statistics of (d) PAN, (e) PAN/ (Graphene oxide) GO, and (f) PAN/GO/PI-6 nanofibers; SEM images of (d-1) PAN, (e-1) PAN/GO, and (f-1) PAN/GO/PI-6; SEM images and illustration of (d-2) PAN, (e-2) PAN/GO, and (f-2) PAN/GO/PI-6 nanofibers after PM2.5 adsorption; (g) pore size distribution measured for PAN, PAN/GO, and PAN/GO/PI electrospun membranes; adapted with permission from [149]. (h) Filtration efficiency and pressure drop measured for multilayer PE/PA with different PA electrospun membrane thickness; SEM images obtained for (i) PE meltblown nonwoven membrane and (j) PA electrospun one after filtering the PM; (k) water vapor transmission rate test measured for the PE/PA and two different commercial face masks, namely com-1 and com-2; adapted with permission from [150].

When the small fibers and the mean free path of air become comparable, a slip flow regime occurs for the nanofibers, resulting in a low pressure drop for the electrospun membranes as well. Moreover, from an analysis of the filtration test performed on PAN nanofibers prepared at different fiber size, a significant drop in both particle capture of PM2.5 (particle size < 2.5 μm) and pressure drop has been observed and attributed to the presence of large diameter fiber and wide pore size in the electrospun membranes (Fig. 6 b) [148]. Additionally, small pore size in electrospun membranes improved the capture of particles of greater dimension because of the sieving effect. The measures of minimum efficiency values obtained from particle filtration curves performed on several PAN nanofibers have proven to be comparable with the average pore size, thus indicating that particles slightly smaller in size were the most penetrating in the filters [147]. Nevertheless, because of the small inter-fiber space, the least efficiency measured for PAN electrospun membranes were shifted to a lower particle size range, providing a better interception of submicron particles compared to those observed for commercial filters used in face masks (Fig. 6 c). Also, Dai et al. reported that a decrease in pore size leads to a better capture of aerosols particles [149]. From an analysis of the Scanning Electron Microscopy (SEM) images performed on the PAN, PAN/ Graphene oxide (GO), and PAN/GO/PI membranes they noted that within the same adsorption time the amount of PM2.5 particles, present with the shape of beads, were more uniformly adsorbed on the nanofibers composed of PAN/GO/PI and in greater amount than those found on PAN (Fig. 6 d–f). The best interaction occurred between nanofibers and submicron particles has been attributed to the uniform inter-fiber space distribution observed at 0.5 μm, which was lower in size and narrower compared to those observed for other PAN and PAN/GO electrospun membranes (Fig. 6 g). In Table 3 a summary of the performances obtained from recent electrospun membranes-based face masks is provided for a comparison.

Table 3.

Performance of electrospun filter for face mask application.

| Tested aerosols particles | 1Electrospun fiber composition | PFE | BFE | Pressure drop | Quality Factor (QF) | Electrospun fiber size (Pore size) |

Refs. |

|---|---|---|---|---|---|---|---|

| (%) | (%) | (Pa) | (Pa−1) | ||||

| NaCl | Nylon-6 onto PE MB nonwovens (Face velocity 5.33 cm s−1) |

>99 | – | <100 | ∼0.0486 | ∼126 nm (6 μm) | [150] |

| PMMA-EVOH onto spunbonded PP |

∼99 | – | ∼44 | – | ∼319 nm | [151] | |

| PVA (Needleless electrospinning) |

∼99 | – | ∼78 | ∼0.0593 | ∼273 nm | [152] | |

| PAN/PVDF-PDMAEMA | <96 | – | ∼78 | ∼0.398 | ∼190/525 nm | [153] | |

| PVDF-Si NPs2 | 99% | – | ∼392 | ∼0.02 | ∼1 μm | [145] | |

| PVDF/TTVB3 | ∼99 | – | ∼350 | – | ∼479 nm | [154] | |

| PVDF-g-POEM (Face velocity 5.3 cm s−1) |

>93% | – | – | ∼0.06 | ∼77 nm | [146] | |

| (ABC)-type terpolymer (Face velocity 5.3 cm s−1) |

∼99 | – | ∼177 | ∼0.025 | ∼400 nm | [155] | |

| PLA | ∼95 | – | – | ∼0.014 | ∼630 nm | [156] | |

| PLA | ∼99 | – | ∼104 | ∼0.094 | ∼37.4 nm (0.73 μm) | [157] | |

| PA6/PVP/CS | ∼99 | – | ∼54 | ∼0.118 | ∼130 nm | [158] | |

| CA-TiO2 | ∼99 | – | ∼31 | – | ∼278 nm | [159] | |

| PP/PLA-Ag NPs (Face velocity 10.67 cm s−1) |

∼99 | – | ∼105 | ∼0.048 | ∼820 nm (5 μm) | [160] | |

| PS/Ag NPS | >97 | – | <147 | – | ∼ 3 μm- | [161] | |

| PAN/Ag NPs | ∼99 | – | ∼65 | ∼0.15 | ∼320 nm (0.3–0.9 μm) | [147] | |

| PAN/Ag NPs/Bontioides/g-C3N4 (Face velocity 0.29 m s−1) |

∼99 | – | ∼65 | ∼0.097 | ∼727 nm | [162] | |

| PVA/PEO/CNF/N-TiO2 | ∼98 | – | – | – | ∼0.79 μm | [163] | |

| Recycled PET | >98 | – | ∼36 | – | ∼1.2 μm | [164] | |

| Recycled EPS (Face velocity 5.3 cm s−1) (Needleless Electrospinning) |

∼99 | – | ∼48 | ∼0.099 | ∼1.04 μm | [165] | |

| PVA/AG NPS (Face velocity 5.5 cm s−1) |

97.7 | ∼59 | ∼0.09 | ∼434 nm | [166] | ||

| PVA/WS-CS4 (Needleless electrospinning) |

∼97 | – | ∼57 | ∼0.0825 | ∼217 nm (12–22 nm) | [167] | |

| PVA/SBE-βCD (Face velocity 5.3 cm s−1) |

∼99 | – | ∼57 | ∼0.82 | ∼2.26 μm | [168] | |

| PAMAM/PAN/TEO (Needleless Electrospinning) |

∼98 | – | ∼388 | – | 440 nm | [169] | |

| Murine hepatitis virus A59 (MHV-A59) used in NaCl | PVDF-RB5 | ∼99 | – | ∼40 | – | ∼200 nm (1.5–2.0 μm) | [170] |

Polystyrene latex

|

PLA and Manuka oil | >99 ∼99 ∼99 ∼99 |

∼99 | <58 | – | ∼168 nm | [171] |

| – | PS/PVDF | ∼99 |

– | ∼72 | – | – | [172] |

| – | PLA & phytochemical-based herbal-extracts (Needleless Electrospinning) |

– | ∼97 | ∼35 | ∼0.097 | ∼8 μm (20 μm) | [173] |

| – | PVB-Thymol | ∼83 | ∼99 | ∼46 | – | ∼375 nm | [174] |

| – | Nylon 6 (Needleless Electrospinning) |

– | ∼97 | – | – | 110–400 nm (0.6 μm) | [175] |

| Dioctyl sebacate (DEHS) | CA/TPU-LiCl | ∼99 | – | ∼52 | ∼0.12 | ∼280 nm (0.9 μm) | [176] |

| PVA-TA |

∼99 | – | ∼35 | ∼0.15 | ∼430 nm | [177] | |

| PVA-LS | ∼99 | – | ∼24 | ∼0.212 | ∼439 nm | [178] | |

| PM0.3 | PAN | >97 | – | ∼ 50–500 | – | ∼430 nm (0.5–1.2 μm) | [179] |

| PAN/ZnO NPs | ∼98.8 | – | ∼48 | ∼0.092 | < 420 nm | [180] | |

| CA/AC/TiO2 (Face velocity 0.8 m s−1) |

∼82 | – | ∼63 | ∼0.0271 | – | [181] | |

| PAN/FPVDP@CNTs6 (Face velocity 5.33 m s−1) |

∼99 | – | ∼49 | ∼0.1984 | ∼113 nm (1.5 μm) | [182] | |

| Gelatin/β–Cyclodextrin (Face velocity 6 cm s−1) |

>95 | – | ∼148 | ∼0.029 | ∼130–247 nm (1–1.4 μm) | [183] | |

| SP/PS | >95 | – | <343 | – | – | [184] | |

| Zein on cellulose paper towel | 99% | – | 109 | – | 0.6–2.4 μm (0.2–0.3 μm) | [185] | |

| PM1.0 | PLA | ∼98 | – | ∼29 | – | ∼274 nm (2.5 μm) | [186] |

| PLA-PA11 | ∼89 | – | ∼6.5 | – | ∼76 nm | [187] | |

| PAN/silane/ZnO NPs | ∼99 | – | ∼44 | ∼0.137 | 1 < μm (19 nm) | [188] | |

| PM2.5 | PAN/PI/GO7 | ∼99 | – | ∼92 | ∼0.0576 | ∼244 nm (0.5 μm) | [149] |

| Recycled PET (Face velocity 4.8 cm s−1) |

∼100 | – | ∼212 | – | ∼1.27–3.25 μm | [189] | |

| PAN/CTAB8 | >99 | – | ∼11 | ∼0.469 | ∼150–200 nm (2–4 μm) | [148] | |

| PASS/Ag/ZnO | ∼99 | – | ∼42 | ∼0.07 | ∼330 nm (2 μm) | [190] |

Electrospun fibers abbreviations: PE (Polyethylene); PMMA (poly(methyl methacrylate)); EVOH (ethylene vinyl alcohol); PVA (Polyvinyl acid); PAN (Polyacrylonitrile); PVDF (Polyvinylidene fluoride); PDMAEMA (poly [2-(N,N-dimethyl amino) ethyl methacrylate]); g-POEM (graft-poly(oxyethylene methacrylate); (ABC)-type terpolymer (Poly(styrene-co-2-(dimethylamino)ethyl methacrylate-co-acrylonitrile))); PLA (polylactic acid); PA6 (polyamide 6); PVP (Polyvinylpyrrolidone); CS (Chitosan); CA (cellulose acetate); PP (Polypropylene); PEO (polyethylene oxide); CNF (cellulose nanofibers); PET (polyethylene terephthalate); Polyarylene sulfide sulfone (PASS); EPS (expanded polystyrene); SBE-β-CD (Sulfobutylether-β-cyclodextrin); PAMAM (polyamidoamine dendritic polymers); TEO (tea tree essential oil); PS (polystyrene); PVB (polyvinyl butyral); CA (cellulose acetate); TPU (Thermoplastic polyurethane); TA (Tannic acid); LS (lignosulfonate); AC (activated charcoal); FPVDP (fluorinated polyvinylpyrrolidone); SP (Spiropyran); PS (polystyrene); PA11 (Polyamide-11); PI (Polymide).

NPs (Nanoparticles).

TTVB (organic photosensitizer).

WS (water soluble).

RB (Rose Bengal).

CNTs (Carbon nanotubes).

GO (Graphene oxide).

CTAB (Cetyltrimethylammonium bromide-Br−).

As it can be seen in Table 3, the measurements performed so far on several natural and synthetic polymer-based electrospun filters demonstrate that in addition to small fiber size also the area of the pores results to be lower compared to those reported for commercial face mask [[191], [192], [193]]. These results therefore indicate that the optimization of both fibers and inter-fiber space in electrospun membranes can be beneficial to achieve proper nanofibers filters with high filtration effectiveness to remove submicron particles. The application of electrospun fibers as filter to improve performance in commercial face mask has been also investigated. The inclusion of PS/PVDF nanofiber membranes inside a N95 respirator has been observed to provide higher filtration performance compared to the standard one, showing also low pressure drop at ∼ 72 Pa, well below the maximum limit imposed by the NIOSH standard (Table 1) [172]. On the other hand, the application of electrospun PAN/ based microporous carbon nanofibers (MCNFs) in face masks proved a significant reduction in facial temperature recording during exhalation and inhalation test, thus making them more comfortable during the breathing compared to a common mask [194]. Combining electrospun fibers and melt blowing fabric with different pore and fiber morphology in masks turned out to be an excellent way to fabricate new face masks with excellent filtration performance and more comfortable wearability. From a comparison between the filtration curve measured for the pristine MB based polyethylene (PE) membranes and those obtained for multilayer designed at different thickness of electrospun Nylon-6 (PA) fibers, it is shown that the addition of ultrathin PA significantly improved the capture of fine particles in the multilayer PE/PA [150] (Fig. 6 h). This analysis was in accordance with what was observed in the SEM images performed on PA and PE membranes, where an evident capture of low particle size prevalently occurred in the PA membranes due to the smaller fiber and micro-pore size (Fig. 6 i, j). A similar result has been reported in the work carried out by Yuanqiang Xu et al. where a higher capture of fine particles with size below 0.5 μm was attributed to the addition of electrospun nanofiber with smaller inter-fiber space on MB-based PE membrane, which was made instead of larger pores [160]. Furthermore, experimental evidence based on water vapor transmission rate (WVT) revealed that multilayer membranes based on electrospun and MB fabric provided higher values of WVT compared to that observed in commercial face masks, thus proving a better passage of moisture air during exhalation, and therefore a less human discomfort in wearing the mask [150,160] (Fig. 6 k). Also, the measures obtained from the air permeability test, which is related to the pressure drop of the fabric and is defined as the rate of the air passing through the membrane under a certain pressure, were found to be comparable and in accordance with the standard required for commercial face masks, thus ensuring a proper breathability in the multilayer fabric [150]. These results indicate that a combination of micro and nanofibers in a multilayer membrane can involve a better breathability over commercial face mask, while providing an effectiveness capture of PM. It is worth noting that electrospun of thin polymeric nanofibers on thicker MB membranes allow to address the drawback due to the poor mechanical properties. Furthermore, the addition of nanofiber with sub-micron pores structures in MB based face mask can face the issues of discharge dissipation in a high humidity exposure for used charged fibers and ensure a more stable filtration performance, without the need of further electrostatic treatment for the membranes.

4.2. Eco-sustainable polymer materials for nanofiber masks

The polymers employed for membrane manufacturing are non-degradable and even worse their production as well as their disposal is not sustainable environment-wise, in most cases [195]. The outbreak of pandemic has revealed these environmental issues, given the large amount of plastic pollution due to the improper disposal of discarded masks [[196], [197], [198]]. It was estimated that just the 1% of the total disposed masks, which is around 10 million of mask for month, corresponds to a plastic weight ranging between 30 – 40 tons dumped in the environment [199]. The plastic fibers composing the inner and outer layers of waste masks, such as PP and PE, can be broken down in smaller parts, also defined as microplastics (MPs), and remain in the environment for a very long time [200]. Besides, these MPs can further decompose due to a series of potential aging process, including physical abrasion, ultraviolet (UV) radiation, and chemical oxidation, and so release toxic additives as well as provide attachment points for microorganism with negative consequences for ecosystem and human health [201]. The enhancement of the ecotoxicity of the MPs released in open sea, which is provoked by the continuous accumulation of plastic coming from disposable masks at the landfills, is rising up nowadays a global concern [202,203]. Therefore, the urgent need to implement more sustainable development has become a relevant issue to address in the increasing demand of face masks [156]. To reduce the environmental impact due to the massive use of disposable masks, some researchers explored the fabrication of high efficiency filter material by employing recycled polyethylene terephthalate (PET) [164] (Fig. 7 a).

Fig. 7.

(a) Schematic diagram of a face mask obtained by bottle recycled PET; adapted with the permission from [164]. (b) Example of nonwoven base with multiple EPS fiber layers for air filter; and (c) SEM image of the membrane cross-section, indicating the three different fiber sizes; adapted with the permission from [165]. (d) Filtration performance measure for the three-layer face mask based on PLA electrospun membranes at different relative humidity and the (e) long-term filtration stability test carried out, under 90% humidity; (f) weight loss measure for the for the three-layer face mask based on PLA electrospun membranes after being buried in outdoor soil; (g) images taken to the three-layer face mask based on PLA electrospun membranes showing the soil burial degradation within the 150 days; adapted with permission from [157]. (h) SEM image showing the bacteria growth on PLA surface after 20 days of treatment in cow-dung, jaggery and water containing biodegradation slurry; adapted with permission from [173]. Biodegradability tests performed on the CA electrospun based membranes by employing esterase and cellulase enzymes: (i) Polypropylene fibrous membrane used as control, given its non-susceptibility to degrade under enzymes conditions; (j) CA nanofibers tissue; (k) CA nanofibers tissue processed with tetrabutylammonium bromide (TBAB); and (l) CA nanofibers tissue processed with High-foaming HoneySurf (HS); adapted with permission from [204].

Investigation on ES of recycled PET filter have been carried out with satisfactory results on PM removal efficiency and low pressure drop [189]. The latest works have shown how filters based on PET waste nanofiber can be achieved by optimization of the ES parameters and can additionally be redissolved and reprocessed, without losing their performance in filtration [164]. The use of recycled expanded polystyrene (EPS) for the manufacturing of multilayer electrospun filter mask with different fibers size provided promising performances for both submicron particles filtration (∼ 99.4%) and optimal pressure drop, ranging between 48 and 58 Pa [165] (Fig. 7 b, c). Therefore, the feasibility in using recycled materials such as PET and EPS for the fabrication of face mask could be considered to implement a circular economy and a significantly lowering in the environmental impact in terms of resources consumption and environmental pollution for future policies [205,206]. Also, the utilization of renewable and biodegradable thermoplastic polymers, such as PLA and polyvinyl butyral (PVB), has shown to be a sustainable alternative to produce effective filters comparable to many commercial face mask [156,157,173,174,207]. Wang et al. designed a biodegradable face mask entirely formed of PLA polymer [157]. The assembly of nanofibers layers with different diameter size, provided a multi-scale structure in the membrane with high porosity and small pore size, which was able to maintain high filtration performance against PM0.3 also after a prolonged exposure in high humidity environment (Fig. 7 d, e). Besides, from a study on the weight loss in degradation (WL), they observed that the PLA-based face mask was completely decomposed from microorganism present in soil after being buried in for 150 days (Fig. 7 f, g). A similar result in biodegradation performance has been reported also by Patil et al. [173]. The SEM images performed on the 3-ply cotton-PLA-cotton layered face mask after 20 days of pretreatment with a slurry consisting of fresh cow-dung microflora, revealed an extensive growth of bacteria colonies on the PLA nanofiber surface, thus suggesting an effective biodegradation process occurring on the membrane (Fig. 7 h). The filtration performance of green PLA face masks result to be comparable with that obtained for multilayer membranes of MB and synthetic electrospun nanofibers seen above [150,160] (Table 3). On the other hand, the biodegradable PLA-based face mask can be easily decomposed trough biological process in a reasonable time, thus resulting in less pollution for the environment. In addition to synthetic and biodegradable polymers, the cellulose nanofibers have been receiving attention as emerging raw materials because of their abundant availability and for their properties, such as biodegradability, renewability, high mechanical strength, porosity, etc. [[208], [209], [210]]. Recent works have focused on the ES of polymers and cellulose blends for the development of filter materials, reporting promising performances for face mask/ respirators [158,211,212]. Additionally, the cellulose acetate (CA) has shown to be an eco-friendly alternative to petroleum-based non-biodegradable polymers for the fabrication of electrospun nanofiber filters [159,181,213]. Wang et al. investigated the application of CA by means of ES technique to design new biodegradable filter for face mask [176]. The electrospun membrane based on CA, thermoplastic polyurethanes (TPU), and lithium cloride (CA/TPU-LiCl) showed high filtration efficiency (99.8%) against dioctyl sebacate (DEHS) aerosol micro particles with low pressure drop (∼ 52 Pa). To test the reusability, a standard disinfection method involving alcohol has been performed on the biodegradable CA/TPU-LiCl membrane. The disinfection test revealed a high resistance of the electrospun filter to alcohol soaking, such that after ten repeated cycles both the filtration performance and the pressure drop remained quite stable around 98.2% and 34 Pa, respectively. The degradation of CA can occur in the soil surface as well as by means of microorganism and enzymes treatments, but the rate is strictly dependent on the environmental conditions in which the natural polymer is subjected [214]. A recent study carried out by Samadian et al., demonstrated that the inclusion of berberine in a CA/gelatin based electrospun nanofibers enhanced the degradation rate of the membrane, which resulted in a high weight loss around ∼ 80% after only 14 days of exposition in PBS solution [215]. Also, Oldal et al. observed that CA electrospun nanofibers membrane can be easily degraded by means of natural enzymes, such as cellulase and esterase [204]. Compared to pristine CA nanofibers, a faster response in the degradation process has been observed for CA membranes pretreated in solution with green surfactant (Fig. 7 i–l). The use of tetrabutylammonium bromide (TBAB) and High-foaming Honey Surf (HS) made the access to the polymer chain of CA-based membrane easier for both enzymes, thus improving the biodegradation process in the observed elapsed time of 16 h. These results indicate that electrospun membranes based on natural polymers, such as PLA and CA, can be a valid solution to fabricate more sustainable and high-performance face mask, to relieve the high consumption of petroleum-derived plastics polymers, which is used in the manufacturing of disposable commercial face mask, and to prevent possible effect on environmental hazard in the long run.

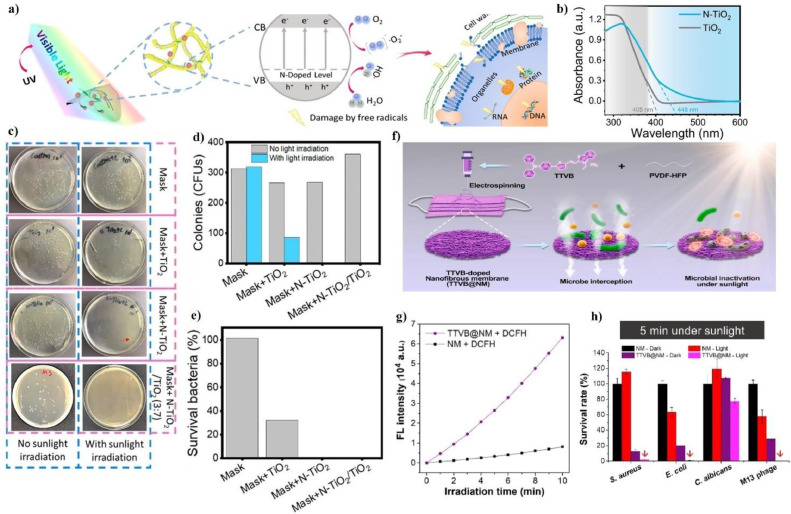

4.3. Nanoparticles surface modification for better antibacterial and antiviral electrospun face masks

Face masks provide a useful physical resistance to the transmission of aerosol carriers of either viruses or bacteria, but a high risk of contamination occurs on the fabric for long time usage. Considering therefore the current COVID-19 pandemic, the importance of providing stable self-cleanable filters with strong antibacterial and antiviral activity has led to the development of nanoparticles (NPs) embedded electrospun nanofibers, in the past few years. The ES of hybrid materials has shown to be a straightforward and innovative approach to process and stabilize NPs either onto or into the electrospun nanofibers membranes. The antimicrobial effectiveness of metal NPs, such as Au and Ag, as well as metal oxide NPs, such as, TiO2, CuO, ZnO, and MgO, have been studied with several human pathogens bacteria such as Escherichia coli (E. coli) and S. aureus [[216], [217], [218], [219], [220]]. Most of these inorganic NPs exhibit bactericidal properties either through photocatalytic activity, where reactive oxygens species (ROS) are induced by visible or UV light to affect the cell viability by hindering principal mechanisms of protein and enzymes, or by electrostatic interaction with the bacteria cell wall, where NPs bind electrostatically the cell membranes causing their alteration in both potential and depolarization thus involving respiratory disfunction and eventually the cell death [221]. Several studies reported about the efficacy of ZnO as antimicrobial coating for surfaces exposed to possible contamination of either bacteria or SARS-COV-2 [[222], [223], [224], [225]]. It is well known that both Zn and ZnO are of particular interest as supportive treatment in therapy of COVID‑19 infection [[226], [227], [228], [229], [230]]. The fabrication of several based polymers electrospun embedded with low-cost ZnO NPs have been investigated and proposed for protective clothing application. Nanofibers made of Polyvinyl pyrrolidone (PVP) and PVA with the addition of ZnO NPs showed antimicrobial activity against S. aureus, E. coli, Klebsiella pneumonia and Streptococcus aeruginosa tested bacterial strains [231]. The incorporation of ZnO NPs at 10 wt.% in the poly- L- lactic acid (PLLA, or polylactide) electrospun membrane was observed to improve the mechanical properties as well as the bacteriostatic action against S. aureus [232]. A noticeably enhancement of the mechanical strength occurs also for PVDF nanofiber loaded with 5 wt.% of ZnO NPs, since an elongation-at-break equal to (30 ± 2)% was observed compared to the pristine PVDF nanofibers, which owns (24 ± 0.5)% [233]. Cytotoxicity test proved the nontoxicity for 5% ZnO—NPs@ PVDF nanofibers. Besides, for these NPs loading the hybrid PVDF nanofiber exhibits a high antiviral activity against human adenoviruses type-5 (ADV5) in both the adsorption and virucidal mechanisms; therefore, the fabric has shown to easily prevent both the entry and the replication of the virus in the cells. An activity increase against colistin resistant bacteria, such as K. pneumoniae strain 10, has been observed for thermoplastic polyurethane (TPU) nanofibers with 4% ZnO [234]. Moreover, it has been shown that a higher presence of ZnO on the nanofibers membrane involves a lower ability of the SARS-CoV-2 spike protein to engage with the human cell receptor (ACE2). Therefore, the concentration of the metal oxide in the TPU nanofibers resulted to be crucial to inactivate the virus. Abdul Salam et al. [235] have investigated both the antibacterial and antiviral properties of hybrid PAN nanofibers with 5 wt.% ZnO as function of the HeiQ Viroblock (VB) concentration. They observed that the higher the amount of VB in the PAN/ZnO electrospun the higher is the antibacterial efficiency of the hybrid membrane against both S. aureus and Pseudomonas aeruginosa, with efficiency values equal to 92.59% and 88.64% respectively. Besides, the PAN/ZnO sample loaded with the maximum concentration of VB (5%) showed a significant antiviral activity against avian influenza virus compared to the pristine PAN sample. The antiviral mechanism behind the VB technology has been attributed to the combined action of the vesicle component and the inside silver ions. Indeed, the cosmetic grade liposomes forming the vesicle are expected to weaken the envelope membrane of the influenza thus allowing the silver ions to directly attack the inner core to destroy the virus (Fig. 8 a).

Fig. 8.

(a) Schematic picture of antiviral activity of VB-loaded PAN/ZnO electrospun nanofibers; TEM analysis of VB-loaded ZnO/PAN electrospun nanofibers: (b) pristine PAN nanofibers; (c) ZnO/PAN nanofibers; (d) 2.5% VB-loaded ZnO/PAN electrospun nanofibers; (e) 5% VB-loaded ZnO/PAN nanofibers; adapted with permission from [235]. (f) Schematic diagram modification process for of ZnO NPs by means of the reaction with silane coupling agent MPTMS; (g) comparison between the QF measured for PAN nanofibers obtained at 9 wt% (PZ9) and 12 wt% (PZ12) for different silane/ZnO NPs mass ratio; adapted with permission from [188]. (h) TEM images obtained for PASS/ZnO/sulfide electrospun membrane showing both agglomerated (left) and more uniform NPs (right) distribution on the fiber surface; adapted with permission from [190]. (i) Filtration curves measured for PS electrospun membranes fabricated at different Ag concentrations and tested at different aerosol particle size; adapted with permission from [161].