Abstract

Scanning electrochemical probe microscopy (SEPM) techniques can disclose the local electrochemical reactivity of interfaces in single-entity and sub-entity studies. Operando SEPM measurements consist of using a SEPM tip to investigate the performance of electrocatalysts, while the reactivity of the interface is simultaneously modulated. This powerful combination can correlate electrochemical activity with changes in surface properties, e.g., topography and structure, as well as provide insight into reaction mechanisms. The focus of this review is to reveal the recent progress in local SEPM measurements of the catalytic activity of a surface toward the reduction and evolution of O2 and H2 and electrochemical conversion of CO2. The capabilities of SEPMs are showcased, and the possibility of coupling other techniques to SEPMs is presented. Emphasis is given to scanning electrochemical microscopy (SECM), scanning ion conductance microscopy (SICM), electrochemical scanning tunneling microscopy (EC-STM), and scanning electrochemical cell microscopy (SECCM).

1. Introduction

Today, electrocatalysis plays a key role in achieving defossilization in minimizing carbon emission and hence in supporting the ambitious goals necessary to fight climate change. The electrochemical conversion of abundant small molecules like H2O, N2, O2, and CO2 into chemical feedstocks or energy carriers using renewable electricity is considered a promising approach to the global supply of sustainable energy.1−6 Consequently, the development of (electro)catalysts that can maximize the rates of reaction and minimize the overpotentials of these conversions is crucial for the large-scale industrialization of this green technology.7,8 To enable a rational design of electrocatalysts, an in-depth understanding of the complex chemical occurrences at the electrochemical interface during a reaction (e.g., adsorption and desorption, charge and electron transfer, solvation and desolvation, and electrostatic interactions) is of high importance and the basis for engineering and optimizing electrocatalytic systems.2,7,9−11

A holistic study of the interfacial processes demands measuring kinetic and thermodynamic parameters.12 One strategy to enhance the selectivity and to investigate the interfacial electrode–electrolyte composition is to couple methods for real-time analysis, enabling so-called operando measurements. The goal of most operando measurements is to gain in-depth insight into the mechanism of a reaction. To this end, working under operando conditions has been proposed as a method that bridges experimental gaps in measurement conditions between instrumental requirements and realistic electrocatalytic reactions.13 This approach combines techniques for simultaneously recording independent signals, where one technique is employed as an actuator for altering the interface properties (e.g., structure, morphology, activity, mechanism), while a second technique acts as a spectator to monitor the resulting changes.14 General aspects of operando measurements are illustrated in Scheme 1. As such, changes in chemical or structural compositions are typically monitored using spectroscopic methods while controlling the reactivity of the surface with e.g., electrochemical methods. Most applied operando characterization methods including transmission electron microscopy (TEM), X-ray absorption spectroscopy (XAS), X-ray photoelectron spectroscopy (XPS), X-ray diffraction (XRD), Raman spectroscopy, infrared (IR) spectroscopy, mass spectroscopy, online inductively coupled plasma mass spectrometry (ICP-MS), among others, have been developed to study electrocatalysts under realistic reaction conditions.15−17 However, each approach shows its advantages and limitations. For instance, operando XAS is sensitive to the local coordination structure and oxidation state of elements in the catalysts, but it is a bulk technique failing to reflect detailed information on reactions occurring at the catalyst surface.18 While operando XRD has been well-developed, it is often challenging to detect amorphous structures at the surface of a reconstructed OER electrocatalyst.19 Considering the advantages and disadvantages, local investigation of exclusively the catalytically active interface is one important key to obtain a complete picture of the reaction. In this regard, scanning electrochemical probe microscopy (SEPM) has been largely explored in electrocatalysis to shed light on the mechanism of a catalytic reaction and on the activity of the catalyst.13,18,20 Besides the advantage of its inherent high lateral resolution, the use of micro-nanoelectrochemistry in SEPM studies of electrocatalytic activity circumvents the limiting mass transport condition of conventional/traditional techniques due to the hemispherical diffusion conditions.10,21−23

Scheme 1. Diagram Exemplifying a General Operando Measurement Which Involves a Spectator and an Actuator Method Performed Simultaneously, with the Spectator Response Depending on the Actuator Modulation in Real-Time.

Although “operando” is not a typical wording used in the majority of SEPM investigations, the combination of measurements to invoke kinetics changes on a surface while monitoring the subsequent effect is a common aspect in many in situ SEPM analyses. Hence, to clarify this, we here refer to operando SEPM for SEPM experiments when simultaneously: (i) an actuator measurement is applied to tailor changes at the investigated surface, and (ii) the SEPM tip is employed as a spectator to monitor local changes at the investigated surface by measuring processes directly or indirectly related to the surface reaction. In the general case of operando SEPM, two electrochemical reactions are controlled independently and simultaneously, where the reaction of interest is invoked at the sample surface and the SEPM response depends in real-time on the modulation of the response at the sample surface. In contrast with macroscopic techniques, the use of operando SEPM can help to disclose the interfacial dynamics that influence electrode kinetics and reaction mechanisms. Moreover, the correlation of intrinsic electrochemical reactivity with the physical and chemical properties of an electrocatalyst is possible by SEPM mapping or coupling with other techniques.

The literature is replete with review papers on applications of SEPM for imaging electrochemical processes at interfaces locally.24−26 Hence, the focus of this review is on the advances made thus far using SEPM techniques in the field of electrocatalysis however exclusively concerning operando measurements, i.e., the simultaneous readout of an actuator process and a spectator process usually at the tip of the SEPM method. The discussed SEPM methods comprise scanning electrochemical microscopy (SECM), scanning ion conductance microscopy (SICM), scanning electrochemical cell microscopy (SECCM), and electrochemical scanning tunneling microscopy (EC-STM).

The review is organized in two sections considering the preknowledge of potentially interested readers. In the first section, each SEPM method is presented with respect to principles and modes of operation as well as potential applicability. This is complemented by a description of the prerequisites for operando SEPM measurement conditions with examples to enable the reader to appreciate the potential and current limitations of each technique. Moreover, the diversity of the applicability of the different SEPM techniques is covered to provide an overview of the limitations of each technique for the evaluation of interfacial processes. The second section focuses on the progress in operando SEPM for electrocatalysis. Measurements as applied to monitor electrocatalytic processes such as the oxygen reduction reaction (ORR), the hydrogen evolution reaction (HER), the oxygen evolution reaction (OER), and the CO2 reduction reaction (CO2RR) are comprehensively discussed.

2. Backstage: Principles and Applicability of Operando SEPM

SEPM represents a family of techniques that use an electrochemical tip or probe to investigate the local properties of an interface.27 The tip interacts with the surface under investigation and physical quantities such as current or potential are determined. SEPM has been employed for electrochemical studies in corrosion,28−31 single-cells,32−41 batteries,42−48 bioelectrocatalysis,49−51 and electrocatalysis.52,53 Generally, the working principle of all SEPM techniques hinges on the precise positioning of a localized probe (the SEPM tip) to interact with a surface under interrogation, allowing one to image and manipulate the surface with submicron, nanometer and/or atomic scale precision.54−56 To this end, the SEPM tip plays a central role in SEPM measurements because its properties (size and shape) define the resolution and applicability of the particular SEPM technique.54 Note, millimeter resolution and nonscanning techniques such as the scanning vibrating electrode technique (SVET)57−59 and single nanoparticle electrochemical impact (SNEI) measurements,60−63 which, although powerful tools used to investigate corrosion and electron-transfer processes, are not included in this review.

SEPM tips can be divided into solid and pipette-based probes. For instance, tips used for EC-STM measurements consist of a very-sharp metal or an alloy that allows resolutions down to the atomic level.64−67 Likewise, SECM tips are solid-based and predominantly made of platinum, gold, and carbon-based disk-shaped electrodes allowing resolutions in the micrometer to nanometer range. Surface-modified micro/nanoelectrodes are also employed in SECM to increase selectivity during amperometric or potentiometric measurements.26,54,68−72 Electrolyte-filled pipettes are employed in SICM and SECCM in which case the resolution (which reaches the nanometer range) depends on the aperture of the pipette.73,74 In coupled SEPM techniques (e.g., SECM-SICM), solid- and pipette-based probes are merged into a single tip.75 Besides the SEPM tip, the positioning unit which enables precise control of tip movement in the x-, y-, and z-directions relative to the investigated surface is of high importance.54,68,76 The positioned tip monitors signals whose magnitude corresponds to the tip-to-surface distance, which need to be compared with a reference value, known as the set point or feedback signal. For image generation the set point needs to be established, and as the tip scans the surface of interest, a feedback loop compares the measured signals (i.e., faradaic or capacitive signals for SECM and SECCM, ion current for SICM, and tunneling current for EC-STM) with the set point.54,68,73−77

The main goal is to demonstrate the general principles and the limitations associated with the use of operando SEPM. Table 1 and Scheme 2 resume the general aspects and cell configurations of each SEPM technique discussed in this review. The intention is to present a snapshot of the general principles and to give the reader an overview of the capability of each SEPM technique for performing in situ measurements as well as the possibility of simultaneously coupling independent techniques to achieve operando conditions. The applicability of operando SEPM is exemplified also with studies not addressing specifically electrocatalysis to give the reader a general overview of principle operando capabilities, while examples of operando SEPM electrocatalysis are covered in the next section.

Table 1. General Aspects of Scanning Electrochemical Probe Microscopy (More Details Are Discussed in Each SEPM Technique Section).

| SEPM (resolution) | set point for the feedback position | main application | main limitation | operation modes and hybrid techniques |

|---|---|---|---|---|

| SECM54,78 (sub-μm) | The set point is typically achieved at the distance range where the diffusion layer (faradaic process) or electrical double layer of the tip is disturbed physically or chemically by the investigated surface. The range of the set point distance is wide, and the tip current depends on electrochemical processes and the difference in surface topography. | SECM is applied for the investigation of local electron-transfer processes at interfaces (liquid/solid, liquid/gas, liquid/liquid). It is the most adaptable SEPM technique covered in this review. Because the sample can be independently polarized, investigation with good chemical specificity is achievable. | Imaging is typically done at a constant distance. However, the distance between the tip and the sample can vary with changes in the sample topography. The user should use a hybrid SECM technique to decouple the topographic effect from electroactivity. The complexity associated with the fabrication of smaller tips limits the resolution achievable in SECM measurements. Besides that, SECM tips of few nm was already reported (>3 nm).79,80 Hybrid techniques should be coupled to deconvolute the topographic contribution on the tip response. | The option to use a large variability of different SECM tips such as modified electrodes surfaces, potentiometric tips, or ion-selective electrodes makes SECM a versatile tool. |

| Modes: feedback (FB), tip collector/substrate generator (TC-SG) and substrate collector/tip generator (SC-TG), redox competition (RC), AC-SECM (or local EIS), direct mode, and surface interrogation (SI). | ||||

| Hybrid techniques: SECM/SICM, SECM/Raman, SECM/SPR, SECM/FTIR, SECM/AFM, SECM/EQCM, SECM/SVET, SPECM. | ||||

| SICM73 (few nm) | The set point is defined by a distance at which the ion current is disturbed by the underlying surface. The ion current is caused by the movement of ions through the pipette aperture. | SICM is used to acquire topographical images of soft surfaces such as biological samples. In contrast to STM, the tip never touches the sample surface. | SICM has low chemical specificity, which can be rectified by coupling the SICM to other SEPM techniques like SECM (SECM-SICM) or by using ion current rectification (ICR). | Modes: DC and AC (oscillating) modes, and ICR. |

| Hybrid techniques: SICM/SECM, SICM/AFM, SICM/potentiometric sensor. | ||||

| EC-STM76,81 (sub-nm, atomic resolution) | The tunneling current is used as set point, and the feedback signal is reached when the sharp tip is positioned at some atomic distances to the sample surface. A potential is applied between the tip and sample surface to generate the tunneling current. | EC-STM is the technique with the highest resolution (atomic resolution) and is used to simultaneously probe the electrochemical activity and topography of surfaces. | The main limitations are the inability to follow rough surfaces, prolonged scanning times, and the restriction to cover large areas. | Modes: constant current and constant height. |

| Hybrid techniques: EC-STM/SECM, EC-STM/DEMS | ||||

| SECCM74,82 (few nm) | SECCM pipette confines the electrochemical cell size to the contact of the hanging droplet with the surface. The set point is reached when the meniscus of the droplet touches the surface. Typically, a potential is applied between the surface and the QRCE inserted inside the pipette. | SECCM is used to record both topographical and electrochemical activity, at the same time. It exhibits high lateral resolution and yields high-throughput information. | Its is hard to control the integrity of the droplet at the SECCM tip. Additionally, because the set point is defined when the droplet touches the surface, and experimentation begins when the surface is polarized, coupling with other techniques is limited. | Modes: SECCM is a direct method to probe the surface because the desired electrochemical reaction occurs at the sample surface. Single- or double-barrel pipettes are used to interrogate the surface. |

| Hybrid techniques: SECCM/optical methods. |

Scheme 2. Typical Electrochemical Cell Configuration for the Operation of SEPM Techniques.

WE, working electrode; RE, reference electrode; CE, counter electrode; QRCE, quasi reference-counter electrode; colored curved arrows indicate an electron-transfer reaction recorded at the WE 1 (orange arrows) and WE 2 (red arrows). (a) Four-electrode SECM cell, where a disk-shaped micro/nanoelectrode is the SECM tip (WE 2). An electron-transfer reaction at the tip generates the SECM tip current, which is modulated by the underlying surface (WE 1). (b) SICM two-electrode configuration, in which one QRCE is inserted inside the filled nanopipette (SICM tip), while the other QRCE is immersed in the sample solution. A potential is applied between the QRCEs, and the SICM tip current is related to the ion flux through the aperture of the capillary. (c) A sharp EC-STM tip is employed as working electrode (WE 2) in a four-electrode cell configuration. The tunneling current is the set point for the EC-STM, due to the electron-transfer tunneling between the surface (WE 1) and the tip. (d) In the case of SECCM, the electron-transfer reaction occurs directly on the investigated surface (WE 1). A single-barrel or double-barrel pipette is filled with the electrolyte, and a QRCE is inserted in each channel. The SECCM tip droplet confines the electrochemical cell. In the double-barrel configuration, a potential is applied between the two QRCEs to achieve the set point, while the sample potential is applied between the sample and the QRCEs.

2.1. Scanning Electrochemical Microscopy

SECM was first reported in 198954,78 and has since become a robust and largely explored SEPM technique for electrochemical investigations. The SECM technique uses a micro/nanoelectrode as a probe, typically a metallic disk-shaped electrode encased in an insulating body. Scheme 2a shows a SECM electrochemical cell in which WE1 and WE2 are controlled independently. The principle of SECM is to register the electrochemical conversion of free-diffusing species under diffusion-limited conditions, such that the current recorded at the tip during the lateral and vertical interrogation of the interfacial region is invariable with time. The SECM tip current results either from a faradaic process or a non-faradaic process that occurs at the tip surface and is dependent on the distance between the tip and the sample.54 Thus, one of the limitations of SECM is that when the tip scans laterally (x- and y-directions) over the surface at a constant height without variations in the z-position of the tip, the recorded current contains contributions from the sample topography. Deconvolution of these two contributions is the primary motivation for coupling SECM with other techniques to independently adjust the working distance and obtain a constant distance mapping condition. The tip–sample interaction condition occurs when the polarized microelectrode is positioned very close to the sample surface such that the diffusion layer of the tip is modulated by the presence of the sample. The sample, on the one hand, acts as a physical barrier to the diffusion of species to the tip. Furthermore, the sample can locally perturb the composition/flux of species reaching the tip by consuming or releasing material. Under this condition, the sample surface can be unbiased or polarized (WE2) simultaneously with the tip, ensuring that the operando condition is intrinsically achieved as the tip and surface are modulated independently. The analytical aspects of SECM,83 its versatility for nanoscale studies,84 applications in heterogeneous electron transfer,23,26 and biological processes have been reviewed.85,86 The operation of SECM modes depends on the electrochemical processes occurring at the tip and the sample surface. In the ensuing sections, the main SECM modes and hybrid techniques are described. We also highlight the conditions that qualify a particular mode as an operando measurement, where the SECM tip acts as a spectator while the WE1 is employed as an actuator (Scheme 1).

2.1.1. Feedback SECM Mode

The feedback mode (FB) is the most commonly used operational mode of SECM, where due to the feedback effect, the sample does not necessarily require polarization to enable the local biased tip-to-sample electron-transfer kinetics.68,87 The tip current depends on faradaic processes involving electroactive species like freely diffusing reversible redox couples (redox mediators) in the electrolyte. In the bulk solution, when a disk-shaped microelectrode is polarized at a potential, at which the mass transport is limited by diffusion of the species, then the current follows the equation for hemispherical diffusion:54

| 1 |

where ibulk is the measured current at the tip at positions far from the sample surface, n is the number of transferred electrons involved in the electrochemical reaction, F is the Faraday constant (s·A·mol–1), D is the diffusion coefficient of the electroactive species (m2·s–1), C is the concentration of the electroactive species in the bulk (mol·m–3), and r is the radius of the electroactive surface of probe/tip/microelectrode (m).

When the SECM tip is moved toward the sample surface, the species generated at the tip during the electrochemical process diffuse to the surface of the sample. Once the species of the reversible redox couple are confined within a thin layer, a small overpotential is generated, sufficiently high to facilitate electrochemical reactions at the surface of a conductive sample. This phenomenon is called positive feedback, as countless cycles occur between the tip and the conductive surface, leading to a higher SECM tip current in comparison to the value measured at far working distance.54,78 The extension of the feedback effect depends on the kinetics of the electrochemical conversion on the conductive surface and can be calculated.68,88,89 When the substrate is an insulator or the tip reaction yields a non-electroactive species, the SECM tip current decreases as it approaches the substrate, because the diffusion of the electroactive species is hindered by the insulating walls of the SECM tip and the sample surface. This effect is known as hindered diffusion or negative feedback and is entirely dependent on the size of the microelectrode.54,90 The negative feedback is used to map topographical features, while the positive feedback mode is used to assess the electron-transfer ability of the sample surface.54

As the FB mode does not necessarily require that the sample is polarized, an external or additional method/technique must be incorporated simultaneously to conduct operando measurements. As an example, operando FB mode was used to follow the growth of the insulating character of the solid-electrolyte interphase on battery materials.91 The SECM tip was positioned at a working distance using the feedback effect on an anatase TiO2 paste, and the oxidation of ferrocene was performed at the tip while the potential at the battery surface was scanned to invoke the formation of the solid-electrolyte interphase. The potential at which the electrochemical processes on the TiO2 paste occurred to generate the insulating film, were monitored by the drastic changes of the feedback current at the tip.91

2.1.2. Generation–Collection SECM Modes: Substrate Generation–Tip Collection and Tip Generation/Substrate Collection Modes

The generation–collection (G-C)87,92,93 mode of SECM is carried out in a four-electrode electrochemical cell or with two separate electrochemical cells. The principle of the G-C mode relies on the generation of an electroactive species at a biased substrate (or tip), which diffuses and gets detected or collected electrochemically by a simultaneously polarized tip (or substrate). Thus, the G-C mode is, in principle, considered operando, even though the SECM community rarely used this term. During the substrate generation–tip collection (SG-TC) mode experiments, the SECM tip is polarized at a defined potential to collect substrate-generated species while the potential at the substrate is scanned.93

The SG-TC mode was explored extensively to map the local electron transfer at electrode surfaces.94,95 Interfacial processes during the OER on irradiated semiconductor materials for photoelectrochemical cell applications have been studied via the SG-TC mode to screen n-type W-doped BiVO4, and to determine the effective heterogeneous electron-transfer constant of semiconductor materials.96,97 Moreover, the SECM tip can also be employed as a local generator in the TG-SC mode, and most of the species generated at the small tip are collected by the polarized sample surface. Under this condition, the collection efficiency is about 1, which is a difficult value to be reached with conventional rotating ring-disk electrodes.98−102 The SG-TC-SECM mode has also been used to monitor the activity of biological samples like cells and enzymes,103,104 although the increased complexity associated with modulating the activity of the biological samples makes it difficult to meet the operando condition.

2.1.3. Redox Competition SECM Mode

Although previously reported in the context of numerical simulation at a heptode SECM tip,105 the feasibility of the RC-SECM mode was first employed experimentally to locally visualize the catalytic activity of surface-confined noble metal catalysts toward the ORR.106 In the RC mode both the SECM tip and the substrate compete for the same electroactive species present in the electrolyte.106−109 The RC mode, like the two G-C modes, is an “intrinsic” operando measurement because two independent signals are employed to modulate the reaction on the substrate and the SECM tip simultaneously. The RC mode was used to study corrosion processes,110,111 enzyme activity,112−114 ORR activity of catalysts,115−117 and to evaluate the rates of respiration in cells and biological entities.36−38,118−120 In a particular study, local oxygen consumption rates calculated by SECM measurements via the RC mode showed that the reproductive organ of C. elegans was responsible for the observed oxygen consumption, indicating the high energy demand of reproduction for adult worms.37 A similar approach was used to follow oxygen consumption due to mitochondrial activity.38 Specific mitochondria inhibitors were added to the electrolyte containing the cells and the measured SECM tip current showed a variation in the oxygen consumption rate by the cells.

2.1.4. AC-SECM or Local Electrochemical Impedance Spectroscopy (LEIS)

In the AC-SECM mode, a sine potential wave (AC) is applied to the SECM tip enabling the acquisition of localized electrochemical impedance spectra as a function of spatial position.121−125 The tip response in the AC-SECM mode also depends on the working distance between the electrode and the sample surface. During AC-SECM, when the tip is brought closer to an insulating surface, the electric field lines are blocked by the tip leading to a significant increase in the measured impedance. Conversely, when the tip is moved toward a conducting surface, the field lines can pass through the conducting sample to the counter electrode thereby reducing the measured impedance. The observed effect depends on the properties of the conducting surface and the resistance of the solution. In the case of low salt concentration, the pathway of lowest resistance for charge transfer is through the conducting surface, especially at high frequencies. Consequently, the measured impedance at the tip decreases as a function of the working distance. In any case, adequate fitting to equivalent circuits is necessary to extract quantitative and physically meaningful information. An advantage of the AC-SECM is that, unlike the FB mode, no redox mediator is required to map the topography of the sample.123,126 Hence, AC-SECM measurements can be used to decouple topographical effects during kinetic evaluations of surfaces.

2.1.5. Surface Interrogation SECM Mode and Direct Mode of SECM

The surface interrogation (SI) mode was first described in 2008 to quantify surface-adsorbed species at the substrate electrode.127 The technique involves first the generation of a surface intermediate on the substrate by biasing the substrate, followed by a switch of the substrate to open circuit potential and finally the polarization of the tip to generate a redox pair which then reacts with the surface-adsorbed species.128−130 The SECM tip follows a positive feedback effect due to the diverse redox cycles occurring between the tip-generated species and the adsorbed species. The SI-SECM mode can quantify an interfacial modification when the redox cycle is complete or when the depletion of adsorbed species on the sample surface occurs.131 The SI-SECM mode was applied to quantify adsorbed CO,132,133 hydroxyl radicals during water oxidation,134,135 and other molecules.136−138

The direct mode of SECM is used to pattern surfaces and also acquire topographic images.139−142 In this mode, the SECM tip works as a counter electrode while the substrate is employed as the working electrode. The reaction taking place at the tip locally modifies the sample surface, making the direct mode an ideal strategy for constructing microstructures on films or surfaces.143−145 To the best of our knowledge, no operando studies with SI and direct SECM modes have been reported.

2.1.6. SECM Hybrid Techniques

SECM is a dynamic technique and coupling it to other techniques allows the acquisition of a plethora of information in a single experiment. Complementary SECM techniques can be applied to correlate an additional property (structural or chemical information) to the electrochemical property. Contrary to the use of several techniques in sequence to analyze the interface, we focused here on the coupling of a technique with SECM to perform operando measurements. As explained before, SECM is normally coupled with other independent methods to deconvolute the topographic contribution of the SECM tip response during mapping. AFM, SICM, and shear force positioning have been coupled with SECM to overcome this bottleneck.75,146−166 Such approaches have been essential in the study of biological materials.167−169 Strategies to deconvolute SECM tip topographic contribution from the electrochemical activity are still hot topics under discussion.170,171 Although the clear advantage of coupling methods to deconvolute the topographic contribution, the independent additional method is mostly performed in a sequence of measurements with the SECM and not simultaneously, therefore the measurement is not intrinsically an operando method. The coupling of SECM with potentiometric sensors and double-barrel electrodes, SECM tips have been employed to control the tip positioning while mapping local information with the tip. Local information such as pH, magnesium ions, potassium ions or metal ions concentrations has been mapped using this approach.172−174 Recently, a multibarrel SECM tip containing a pH sensor and a Mg2+ ion-selective electrode was employed to map the spontaneous corrosion process at the interface of a magnesium alloy.175

A combination of SECM and quartz crystal microbalance (EQCM) was proposed as an operando approach to correlate the changes in mass with the local electrochemical activity.176−179 Copper ions were monitored using the SECM tip positioned in the vicinity of an aluminum alloy interface, while a cyclic voltammogram was performed at the substrate and the EQCM results were correlated to the corrosion rate.180 A similar strategy was adopted to monitor the evolution of iron pitting corrosion.181,182

SECM was also coupled to Raman spectroscopy to analyze the changes in chemical properties while modulating electrochemical processes on the surface.183−186 The operando SECM-Raman analysis was recently applied to interrogate a self-assembled monolayer with high structural-pH sensitivity.185 The local pH was modulated by the HER on the SECM tip and the Raman analysis registered changes of the protonated state of a modified self-assembled monolayer on the surface. Additionally, SECM was combined with optical techniques, such as surface plasmon resonance (SPR)187−189 and infrared,190,191 fluorescence, and chemiluminescence spectroscopies192−195 to study molecular changes on surfaces, electrodeposition processes, or film thickness changes.

Strategies to modify the tip functionality were also used to derive information with an enhancement in selectivity. In scanning photoelectrochemical microscopy (SPECM) a focalized light source is coupled to locally illuminate the SECM analysis.196−201 For instance, photocurrents of an irradiated BiVO4/FTO semiconductor surface were monitored while the SECM tip measured the local photoelectrocatalytic activity through the oxygen evolved from the semiconductor surface.196

The above discussions show how SECM/hybrid techniques can be employed to correlate interfacial processes to local electroactivity.

2.2. Scanning Ion Conductance Microscopy (SICM)

SICM was introduced by Hansma and colleagues in 1989, as a high-resolution and noncontact imaging SEPM technique for the investigation of samples.73 The technique uses an electrolyte-filled nanopipette as a scanning probe and relies on the flow of ionic current between an electrode inside the nanopipette and a second electrode immersed in the bulk solution or electrochemical cell to create a surface-sensitive feedback signal. Topographical information on the sample is obtained by scanning the nanopipette or probe over the interface in the x- and y-directions. Fluctuations in the flow of ionic current are used to monitor the position of the tip relative to the substrate surface.73

During operation, a DC or an AC potential is applied between two wires: one wire, typically Ag/AgCl, is inserted into the SICM pipette and the other wire is immersed into the electrolyte of the electrochemical cell outside of the nanopipette channel. Scheme 2b illustrates the SICM tip and the two wires as QRCE, with the blue arrow representing the ions movement and no electron-transfer reaction occurring at the pipette aperture. The resulting current is caused by the movement of ions through the SICM tip aperture, which serves as a resistor to the ionic flux.202 Once the pipette is moved toward a surface, the ion flux is physically blocked when the aperture is some nanometers close to the substrate. At this point, the monitored ion current decreases due to the increased resistance and this variation defines the set point for controlling the SICM tip position.203,204 SICM topographic maps are obtained by correcting the tip height (z-direction) to reach the set point. In contrast to SECM microelectrodes, the simple SICM pipette fabrication allows the preparation of nanometer-sized tips. For this reason, SICM is a high-resolution technique, capable of measuring the topography of nonconductive surfaces,205 and mapping activities of soft samples such as cells,205−210 in contrast to AFM.211

2.2.1. SICM Modes of Operation

In addition to the DC or AC modulation of the ion flux into the SICM tip strategies are employed to allow imaging beyond highly resolved topographic maps. The capability to map the topography of highly ordered porous silicon functionalized with lipid membranes was shown using noncontact DC-SICM including the manipulation of the soft membranes.212 Due to drifts encountered using the DC-SICM current response, the positioning stability can be increased by employing AC-SICM. During AC modulation, the set point is reached when a small variation of the tip response is detected. Typically the AC modulation is imposed using an AC potential signal or a physical tip vibration in the vertical direction.203,213,214 The variation in AC is coupled to topographic acquisition while the variation of the DC ion current is related to the charge transfer property of the surface. As an example, vibrations in the vertical direction were used to record topographic images of pores on polymeric membranes while the DC ion current was correlated to the transport of KCl through the pores.215 Instrumental advances have made it possible to carry out electrochemical impedance experiments to image the local capacitance and topography of a gold nanoparticle.216 Advances in DC-SICM and pulse-mode SICM have been proposed as routes to improve the SICM mapping and applied to monitor volume changes in cells.217,218 In parallel, modified nanopipettes were developed to record the ion current rectification (ICR).219−223 With this approach, the SICM sensitivity is increased due to specific ion interaction with the modified aperture.219−223 The correlation of changes in the ion current of functionalized nanopipette pores to the presence of ions was demonstrated by measuring variations in ICR due to a KCl concentration gradient224 and at different pH conditions.225 Moreover, a modified lipid bilayer SICM pore was reported and used to map the diffusion of β-cyclodextrin through a glass micropore.226 Furthermore, the possibility to set up an SICM experiment in a configuration similar to the patch-clamp technique paves the way for SICM to be largely explored in the biophysical analysis of cells.227−231 Recently, SICM tips were inserted into a macrophage cell, and intracellular events such as nanoparticles and vesicle collisions were monitored.232

Although the high capability of SICM to record topography with high resolution is widely explored, the correlation of electrochemical activity to surface properties is complex using SICM alone. A strategy adopted to overcome this is to conduct the measurement in a low ionic strength electrolyte, allowing the double layer of the SICM tip to interact with the charged substrate.220,233 This way, the SICM tip response can then be correlated to surface reactivity.

The use of surface charge mapping was demonstrated on living cells,234−238 films,239,240 and electrode surfaces.241−243 Recently, operando SICM was employed to simultaneously map the surface charge, reactivity and topography of a carbon fiber microelectrode surface.242 In this operando SICM case, the SICM tip is employed as the spectator while the surface activity is modulated by an electrochemical method (Scheme 1). Moreover, Unwin’s group showed that electroosmotic flow controls the flux of uncharged molecules within the SICM tip, in contrast to the flux of charged molecules, which is easily controlled through the migration effect. The role of a biased underlying surface on the ion current was also interrogated and the mass transport and flow rate of species were quantified using simulation tools. This work showed that besides voltage, pipette wall charge, and working distance, the ion flux through the SICM tip also depends on the substrate surface charge.242 Besides the richness on the information on charge mapping, the exploration of using operando SICM during modulation of the surface was not extended to any electrocatalysis study.

2.2.2. SICM Hybrid Techniques

As pointed out before, SICM is a great tool to provide stable and great control of the tip positioning. Due to this unique functionality, SICM was coupled with other techniques like SECM, as this compensates for the lack of selectivity of the SICM measurements, and also serves as a strategy to deconvolute the topographic contributions from the SECM tip response.75,157,244 As discussed in the SECM section 2.1, to adjust the tip height by means of the SICM response and acquisition of the electrochemical information by SECM response is commonly performed sequentially (not operando).

The same hybrid strategy was used by coupling a potentiometric sensor to the SICM tip,245,246 and in a typical example, a dual function tip was used to record the local pH value and the topography: one channel of the double-barrel electrode was modified with a potentiometric iridium oxide sensor to record the pH map, while the SICM tip channel corrected the working distance over a calcite microcrystal.247

SICM hybrid techniques were also employed to image living cells by coupling SICM to near-field optical microscopy248 and confocal microscopy.249−254 The confocal microscopy SICM approach was used to target fluorescing molecules and to correlate changes in the topography of cells. A hybrid confocal microscopy SICM was applied to monitor the topographical changes due to a virus-like particle assembly on a cellular membrane.255 A protein that induces the formation of a virus-like particle was labeled with fluorescent molecules. The topographic changes were correlated to the virus-like particle growth mechanism, as well as the release event. The obtained results were an important step in the elucidation of the replication mechanism of the virus.

2.3. Electrochemical Scanning Tunneling Microscopy (EC-STM)

Scanning tunneling microscopy (STM) was proposed by Binnig and Rohrer at the beginning of 1980 as a technique for imaging the topography of samples with atomic resolution.76 For that, a sharp metallic tip is slightly polarized against the underlying conductive sample, and when the distance between the very end of the STM tip and the surface reaches a distance in the atomic range, electrons can flow due to the tunneling effect.256,257 The electron flow initiates a tunneling current which is adopted as the set point to control the working distance. The STM technique can image surfaces with atomic resolution because of the very sensitive interaction between atoms of the STM tip and the sample surface.258 Advances in STM have enabled measurements in aqueous solution, making it possible to monitor structural changes due to surface polarization.81,259 This condition is called electrochemical STM (EC-STM or ESTM) and it was proposed to monitor redox processes on surfaces by adding a high-impedance reference electrode in a four-electrode cell configuration (2 WE, 1 CE, 1 RE) and illustrated in Scheme 2c.260−263 In this configuration, the potential can be applied independently at the conductive surface and the STM tip, in a similar manner as in the G-C mode of the SECM. One limitation of the EC-STM is the difficulty to deconvolute the tunneling current from the faradaic process at the tip. A strategy frequently used to offset this challenge is to partially coat the body of the EC-STM probe (but not the tip) with an insulating layer, such as nail varnish or Apiezon wax,154,264 to reduce the area exposed to the electrolyte. The insulating layer is illustrated as a black cover on the EC-STM tip in the Scheme 2c). As faradaic and double-layer charge–discharge currents depend on the surface area, this approach is adopted to minimize such currents with respect to the tunneling current.265,266 Another strategy is to keep the tip at the same position while the potential on the surface is scanned. The scanning tunneling spectroscopy (STS) is a deviation of EC-STM, where the applied potentials on the sample are interpreted as energy levels and scanned to obtain an electronic spectrogram. This strategy was widely utilized to study electron-transfer reactions on Au substrates, where the enhancement of the tunneling current was correlated to the reactivity of the surface.267−271

2.3.1. EC-STM Modes of Operation

The typical operation of EC-STM is based on approaching the STM tip toward the surface until a tunneling current is detected and used as the set point. The main feature of STM is to acquire the morphology of the investigated surface with atomic resolution.272 The STM map is built by adjusting the STM position in the vertical direction (z-axis) to reach the same set point value. In contrast, the STM image can also be recorded by keeping the vertical distance (z-axis) constant and recording the tunneling current at each x–y-position. This strategy reduces the image acquisition time, however, the surface morphology should not be rough. Most of the EC-STM measurements are done by using the constant tunneling current mode, which is a powerful tool for investigating electrochemical processes like adsorption,273−275 passivation,276−278 and corrosion279 of surfaces. One of the limitations of EC-STM is the slow scanning process, which makes it difficult to couple measurements simultaneously for operando studies. For this reason, in situ analysis is often used to evaluate morphological changes on surfaces, such as to investigate protein/enzyme covered surfaces,280−284 metallic crystalline interfaces,272,285 electrocatalysts,286−288 and battery materials.289,290 EC-STM was employed to study the topographical changes on highly oriented pyrolytic graphite (HOPG), that was polarized to invoke intercalation of Li ions.289,290 The results indicated that the exfoliation process took place at the HOPG edges instead of at the basal planes. Recently, Wan and Wang used the approach of sequentially polarizing the surface and intermittently acquiring EC-STM images to study the mechanisms of CO2RR and ORR on an adlayer of a cobalt-phthalocyanine catalyst on a gold surface.291,292 In parallel, Itaya’s group used EC-STM to investigate the correlation between the morphology and applied potentials in the formation of regularly patterned adlayers of Zn(II)phthalocyanine and a zinc metalloporphyrin on the crystalline surfaces of Au(111) or Au(100).293 It was shown that the assembly of fullerene molecules was dependent on the packing arrangement of the adlayer, which is also influenced by the crystallographic orientation of Au. Another interesting study used in situ EC-STM to follow the changes in the HOPG morphology during the solid-electrolyte interphase (SEI) formation.294 The topographical changes during electrolyte reduction and film deposition were monitored, as well as the intercalation processes of Li ions and solvent molecules into the resulting surface. Moreover, the operando conditions employed allowed for the concurrent acquisition of STM images and potential programs on the HOPG surface. The overlay of the STM image with the potential scans showed a clear potential dependence of the surface processes, such as material deposition and surface morphological changes. After sequentially scanning the potential of the surface, a potential limit was found where the changes in surface processes became irreversible, which was attributed to the reduction process of the electrolyte anion.

These studies demonstrated the capability of the EC-STM to correlate morphological changes to the electrochemical activity of interrogated surfaces.

2.3.2. EC-STM Hybrid Techniques

One of the limitations of EC-STM is the convolution of the tunneling current with the faradaic processes occurring at the EC-STM tip. Consequently, EC-STM has been coupled with SECM to overcome this bottleneck.295 In this case, a single tip is employed with a dual function of acting as an EC-STM tip to image the surface morphology and as an SECM tip to register the local electroactivity of the surface. After the positioning step, the tip is retracted to a working distance where there is no tunneling effect but is still in the range of the SECM set point. The applicability of SECM/EC-STM to image the topography and reactivity was demonstrated on a self-assembled monolayer (SAM) on gold by the feedback effect.295 Soriaga’s group employed a hybrid EC-STM/DEMS technique to follow changes on a polycrystalline Cu surface in basic medium and under an applied potential to promote CO reduction.296 The products of the reduction reaction were detected by differential electrochemical mass spectrometry (DEMS). The hybrid EC-STM/DEMS analysis was used to correlate the observed low activity of ethanol generation to the ordering process of the Cu(100) lattice over Cu(110), in comparison to the Cu(110) on the polycrystalline surface.296

2.4. Scanning Electrochemical Cell Microscopy

Scanning electrochemical cell microscopy (SECCM), sometimes also called scanning micropipette contact method (SMCM), is a pipette-based tip technique capable of imaging surfaces with a lateral resolution in the nanometer ranges. As a result, SECCM has become a powerful tool for investigating electrochemical properties in single entity/sub-entity studies.297−299 The principle of the technique is to confine the electrochemical cell in a droplet (protruding from the end of the nanopipette aperture), which is brought in contact with the interrogated surface. In contrast to SECM, SICM, and EC-STM, SECCM operates in air or an immiscible solution. Hence, the sample is not entirely immersed in the electrolyte before the local measurement is made. The colored background in Scheme 2a–c represents the electrolyte, indicating the absence of an electrolyte covering the sample in the case of SECCM (Scheme 2d). The electrochemical processes in SECCM take place exclusively on the probed surface providing direct electrochemical activity imaging. The SECCM tip is typically a single-barrel micro- or nanopipette containing the electrolyte and a quasi-reference counter electrode (QRCE). During measurements, a potential is applied between the QRCE and the conductor/semiconductor surface under interrogation. The set point is reached with the flow of a non-faradaic current caused by the contact of the hanging droplet to the surface (note: the pipette tip never touches the surface). Like in the SICM, an AC-modulated current caused by tip vibration is implemented in SECCM measurement for tip positioning. In this configuration, a double-barrel pipette (theta capillary) is used as SECCM tip with QRCEs inserted in each channel (see Scheme 2d). A potential is applied between the QRCEs, and the modulated ion current is then used as a set point. Before the contact between the hanging droplet and the surface is achieved, the modulated ion current is constant, and once there is contact, the ion current changes in its magnitude and oscillates with the same frequency as the tip vibration due to the droplet deformation. The magnitude of the resulting AC current is used to control the tip-to-surface distance. In the case that the interrogated surface is a semiconductor/conductor, an additional (floating) potential can be applied between the QRCEs and the sample. By adjusting this potential, the electrochemical processes occurring at the sample surface, which is wetted by the droplet, can be measured. Details of SECCM instrumentation have been reviewed.74,299,300 Scanning is performed either in a constant distance mode by adjusting the magnitude of the ion current signal with the SECCM tip position, or in a hopping scanning mode where the tip is withdrawn far from the surface and reapproached at each x–y-position. The latter is essential for single-barrel SECCM configurations because it prevents tip crash on rough surfaces.301

The general limitations of all SPEMs such as long scanning time and noise level in single-entity studies are also present in SECCM. The use of smaller SECCM tips leads to a reduction in the noise level because such tips wet smaller electrochemical areas, which increase the signal-to-noise ratio. This approach was explored to record the electron-transfer reaction on nanoparticles82,302,303 and events of single nanoparticle electrochemical impacts (SNEI).304,305 A strategy of coupling optical microscopy to SECCM to follow events during electrochemical measurements was proposed by Hill et al.306,307 for reducing the typical extended scanning time. The optical image was employed to visualize Au nanorods on a transparent electrode surface, i.e., indium tin oxide (ITO). By using a LABVIEW program, the electrochemical measurements were performed just where a particle was visualized. The strategy reduced the scanning time and improved the sample throughput compared to the typical scanning-tip approach.306

Developments in SECCM are still in progress, and the power of the technique is enhanced when local electrochemical data in tandem with data treatment and simulations are used to calculate intrinsic properties. In addition, some technical and instrumental improvements are still under discussion. For example, recently strategies were shown to measure electrochemical impedance spectra,308 acquire high-speed images,309 and use amplified signals to achieve high temporal resolution.310 Moreover, effects of experimental parameters such as the impact of the ohmic drop on the applied potential311 or the possibility of contamination from the Ag-QRCE312 were described.

2.4.1. SECCM Operation Modes and Applicability

During SECCM measurement, the tip performs a direct electrochemical interrogation of electron or charge transfer reactions on the sample surface in a single electrochemical cell configuration (see Scheme 2d). This is in contrast to SECM, SICM, and EC-STM, where the SEPM tip works generally as a spectator to probe the surface properties. The intrinsic operation of SECCM complicates the possibility of combining it with other techniques to perform operando measurements (Scheme 1). Although SECCM, hitherto, has not been coupled with other electrochemical method for operando measurements, the use of optical probes to modulate surface activity was suggested as actuator method. In this approach, the sample surface is irradiated to induce changes in surface activity while the SECCM tip acts as a spectator. The operando optical/SECCM approach was explored for studying the photoelectrochemical activity of semiconductors. Differences in the photoelectrochemical activity of TiO2 and transition metal dichalcogenides such as MoS2 were evaluated by performing measurements in dark and light conditions in the presence of a redox mediator.313−315 The lack of operando SECCM is most likely due to the high complexity of the experimental design of coupling techniques.

It is worth noting that its applicability has been extensively demonstrated to directly probe electrochemical processes on surfaces at high resolution.316 The electrochemical activity was probed using reversible redox species (e.g., hexaammineruthenium(III), ferrocenium, ferrocene trimethylammonium) to establish the structure–activity relationship in single entity studies.317 SECCM was extensively used to acquire high spatial resolution maps to elucidate differences in electrochemical activity between phases and grain boundaries of many polycrystalline materials such as platinum,318,319 palladium,320 gold,321−323 copper,28 or boron-doped diamond324−327 surfaces. SECCM in tandem with simulations was used to spatially map electron-transfer kinetics parameters, like the Tafel slope and the heterogeneous electron-transfer rate constant.328−330 The sensitivity of the SECCM for local activity measurement was demonstrated and used to differentiate the surface activities of glassy carbon331 and graphite.332−335 Two-dimensional materials, such as graphene,336−339 MoS2,340,341 and other transition metal dichalcogenides341,342 were also investigated by SECCM. The studies demonstrated the presence of heterogeneous activity at different sites such as defects, edges, and basal planes. The results further showed that the local activity depends on the number of layers of the 2D material. These findings reveal the capability of SECCM to disclose the role of surface conditions on the activity of materials.

Moreover, SECCM is a powerful technique for monitoring the activity of electrocatalysts, allowing the correlation of topography/structure with electrocatalytic activity. The high-throughput characterization potential of SECCM helps to study the intrinsic activity and the kinetic of electron-transfer processes. Catalyst materials for the HER that have been interrogated include transition metal dichalcogenides,323,331,341−345 bimetallic materials such as FeNi,346 Au,323,347,348 Pt,303,349−354 Zn,355 ITO, doped graphene,339,356 boron-doped diamond,326 and low-carbon steel.357 SECCM has also been used to study the ORR,28,82,323,326,358−361 the OER,309,362−364 and the CO2RR.321,322,365,366

In addition to decreasing the probed area, SECCM tip droplets can also be employed as a tool to modify surfaces with high spatial precision. Such strategies have been used for local deposition,367,368 etching,369,370 as well as to fabricate thin film metal oxides371,372 and polymers.373−375 The small area confined by the SECCM tip droplet is an important feature that allows high mass transport rates of materials coming from the pipette aperture to the interrogated surface. For this reason, SECCM is used to study slow kinetic processes, such as charge transfer on lithium-ion battery materials.302,376−382 Adaptations of the experimental conditions of SECCM are in progress to enable further studies for lithium-ion batteries materials. Recently, SECCM studies were carried out in an argon-filled glovebox,383 and using aprotic electrolytes.384 Moreover, SECCM was also employed to monitor corrosion processes by recording polarization curves and revealing the susceptibility of crystallographic phases to the corrosion of polycrystalline low-carbon steel.355,385−389

3. Operando SEPM Applications in Electrocatalysis

In this section, we discuss the application of operando SEPMs during electrocatalysis (ORR, OER, HER, CO2RR, and other important reactions). In selecting the papers that have been reviewed, particular attention was given to those in which operando conditions, as delineated in the introductory and earlier sections of this paper, are met. These studies comprise an actuator measurement or potential, which is applied to stimulate changes at the investigated surface or substrate, while a simultaneously biased SEPM tip is employed as a spectator to detect or monitor local changes on the investigated surface.

Overall, SECM is the most explored SEPM technique for operando investigation of local electrocatalytic activity and interfacial electron-transfer processes during the ORR, OER, HER, and CO2RR. This extended utility stems from the versatility of SECM due to its unique ability to characterize a wide variety of samples for various applications, adapt with other SEPMs (to improve and augment the information available for SECM only) and employ amperometric, potentiometric, as well as multifunctional probes during investigations. Furthermore, compared to the other SEPMs, which require coupling to other techniques to perform operando studies, the intrinsic operational modes of the SECM (SG-TC, TG-SC, and RC) are by default operando measurements.

3.1. Investigation of ORR Activity at the Sample Surface

The electrochemical reduction of molecular oxygen (ORR) has been extensively investigated because of its central role in fuel cells, metal-air batteries, sealed storage batteries, corrosion, and industrial electrocatalytic processes.390,391 Generally, depending on the cathode material, electrode potential, and electrolyte composition,392 it is believed (though debatable) that ORR proceeds in either of two pathways:391,392 a highly efficient four-electron pathway in one step to generate H2O or OH– or a sluggish peroxide-intermediate-based two-electron pathway in two steps to form H2O2. ORR reaction pathways have been extensively reviewed.393−398 The ORR follows either a direct four-electron pathway, or a two-electron-transfer pathway with hydrogen peroxide as intermediate.391,392

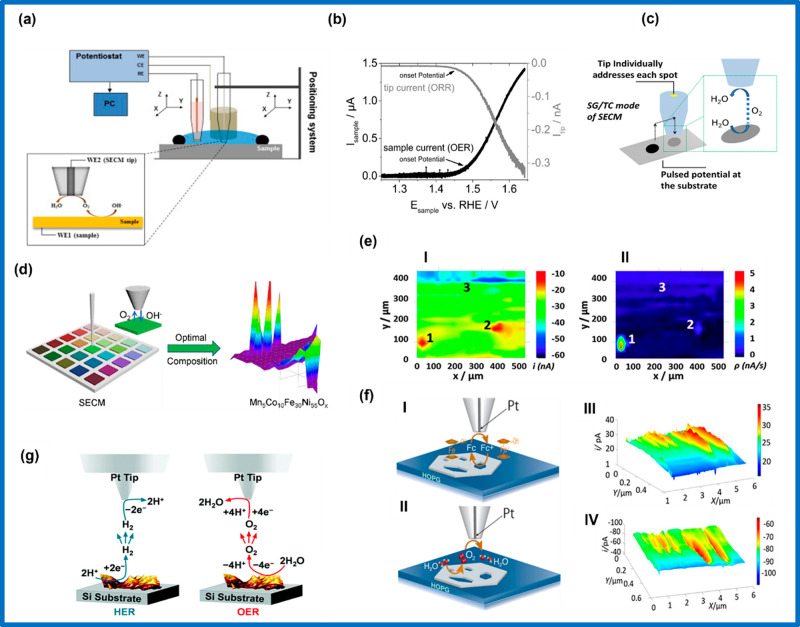

ORR investigations are typically performed using Pt-based electrocatalysts because Pt can reduce both O2 and H2O2 to H2O, and more importantly, it avoids the formation of H2O2 and/or other aggressive oxygenated species.399 The high cost, scarcity, and easy poisoning associated with Pt-based materials discourage their use as ORR electrocatalysts on a large scale.399 Addressing these challenges has triggered an intensive search for active electrocatalysts that are less expensive, earth-abundant, poisoning-tolerant, and can achieve ORR overpotentials in the range of that of Pt-based materials.400 Some advances made in this direction include the alloying of Pt with less expensive metals, use of non-platinum metal combinations, transition metal oxides, chalcogenides, inorganic and organometallic complexes, and enzyme electrodes for ORR.400 Despite these research leaps, the detailed mechanism of the ORR process, even on Pt, remains elusive.400 Besides the difficulty encountered in O2 activation, and O–O bond cleavage, which results in the observed sluggish kinetics,401 the pronounced irreversibility of the cathodic reaction, the different possible reaction pathways and the possible generation of a wide spectrum of oxygenated intermediates, are considered as factors that make the detailed study of ORR mechanism an arduous task. Furthermore, the dependence of the reaction rate on the state of the electrode surface, coupled with the lack of a rational approach to the design of new electrocatalysts that can strictly follow the direct four-electron reduction pathway makes studying ORR even more difficult.99,400 As an alternative to traditional macroscopic RDE and RRDE measurements, operando SEPMs, particularly SECM, have been employed to study the ORR (Scheme 3). Maps of chemical reactivity and topographic images were obtained.99 Furthermore, the coupling of SECM with other analytical methods was proposed already by Hillier and Bard in 2003 as an effective approach for studying the ORR and screening of electrocatalysts.99 The general principle for probing the ORR with operando SEPM involves biasing the substrate of interest to invoke the ORR while a simultaneously polarized SEPM tip is used to locally monitor the substrate-generated species, such as H2O2, HO2–, or OH– (SG-TC, TG-SC, and EC-STM in Scheme 3) or compete (RC-SECM on the Scheme 3) with the substrate for O2 in the gap between them. Kinetic parameters, such as the heterogeneous electron-transfer rate, can then be extracted by fitting the experimental tip approach curves to developed quantitative theories for the different operational modes in the case of SECM techniques.23,68,93 In the ensuing paragraphs, the advances made thus far in ORR investigations with SEPMs are recounted, highlighting the operando conditions and the uniqueness of SEPMs as qualitative and/or quantitative electroanalytical characterization tools during ORR electrocatalysis.

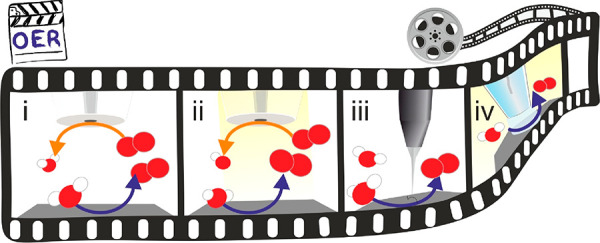

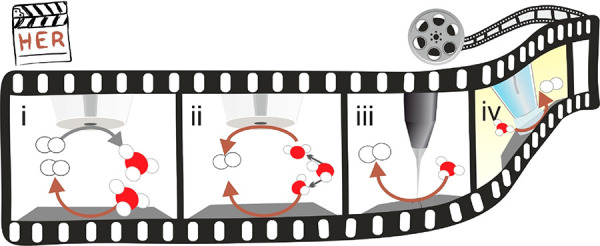

Scheme 3. Schematic Drawing Representing the Main Operando SEPM Configurations for ORR Interrogation.

The SEPM tip acts as the spectator while a modulation occurs on the electrocatalyst’s activity by an actuator method. The SEPM tip can be polarized to (i) reduce oxygen (orange arrows) in RC-SECM; (ii) reduce (green arrow) H2O2, an ORR product when n = 2, in SG-TC-SECM; (iii) oxidize H2O2 in TG-SC-SECM; (iv) map with high-resolution SEPM, EC-STM.

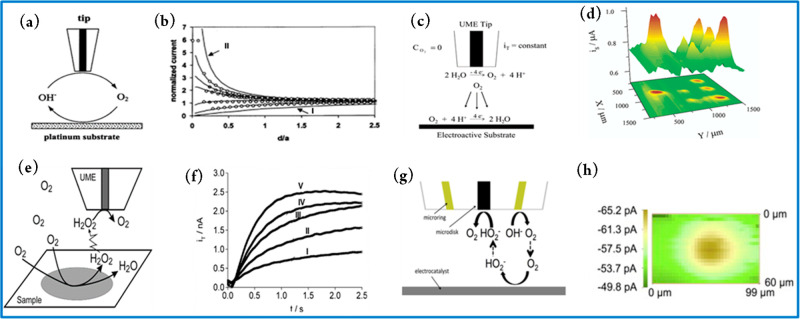

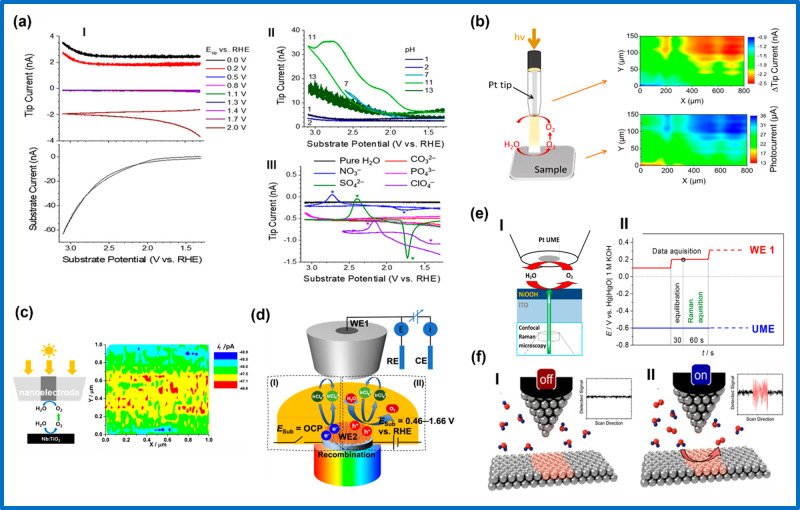

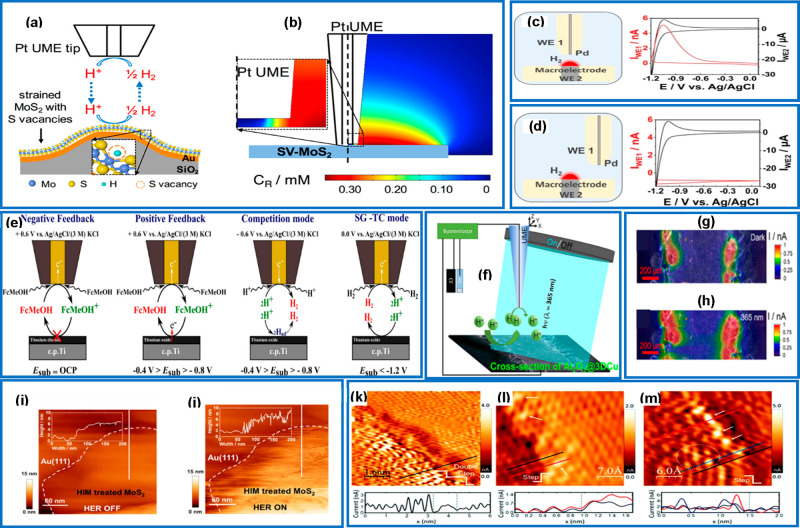

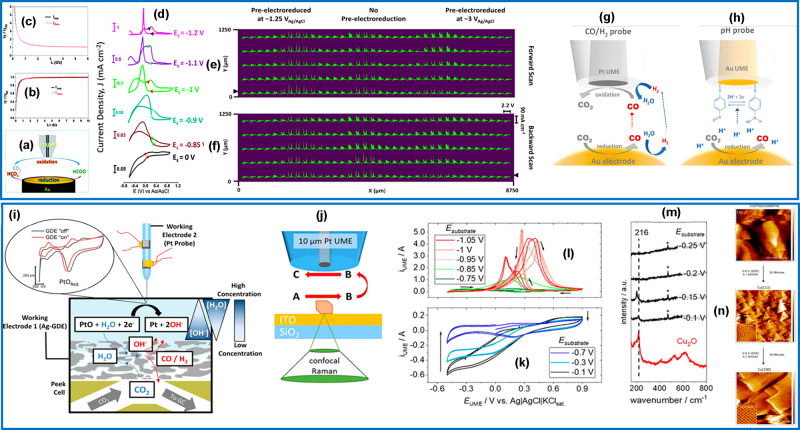

One of the pioneering studies of ORR with the SECM was performed by Liu and Bard402 under operando conditions using the FB operational mode (Figure 1a) to estimate the rate constant of the ORR on a Pt electrode in alkaline solution. A Au UME was employed as SECM tip which was polarized to 1.2 V vs Hg/HgSO4 (i.e., at the diffusion limiting potential for OH– oxidation). The polarized tip was then moved toward the surface of the Pt substrate which was simultaneously held at different potentials to obtain the SECM approach curves (Figure 1b). The Tafel slope and rate constant agreed with previously reported values derived from RDE and other electrochemical techniques. However, the operation of this technique was limited to a short pH range (9–12), where OH– oxidation at the tip could be used. As such, the study of ORR in acid or neutral media is impossible with the FB mode because the feedback diffusion of the tip reactant (H2O) does not induce modulations in the tip current.93,396 Perhaps this observation explains why the FB mode was less explored in operando ORR SECM studies. The Bard group in 2003 proposed the TG-SC mode (Figure 1c) as an alternative to the FB mode to analyze and compare the electrocatalytic activity of an array of finely dispersed catalyst spots of Pt, Ru, and Au for the ORR in acidic medium (0.5 M H2SO4).99 In this mode, the substrate (Pt, Ru, and Au catalyst spots) was polarized to a potential (<1.23 V vs Hg/HgSO4) to facilitate the reduction of O2 to H2O while an oxidation current (between 10 and 220 nA) was applied to the Pt SECM tip to oxidize H2O to O2 and ensure a constant flow and diffusion of tip-generated O2 to the substrate. Figure 1d represents an ORR image obtained in the TG-SC mode of an array of Pt and Ru spots on glassy carbon (GC). The main advantage of the TG-SC mode is that it assumes no feedback contribution and hence allows for the study of reactions inaccessible to the FB mode. Additionally, working in the TG-SC mode allows for studies in solutions with varying concentrations as opposed to the stringent conditions needed in the FB mode to reach diffusion control at the UME tip. As an added advantage, TG-SC is ideal for the rapid screening of large arrays of multicomponent electrocatalysts.99,400 The TG-SC mode was later used to study and screen the electrocatalytic activity of binary and ternary combinations of Pd, Au, Ag, and Co (or Cu) deposited on GC as substrates for the ORR in acidic medium using Pt as SECM tip.400 A drawback of the TG-SC mode lies in the inability to precisely quantify the products/intermediates formed during the ORR.100,399 The detection and quantification of H2O2, for instance, is very important because its formation has been associated with undesirable processes like membrane degradations, corrosion of metals, polymer fittings, and carbon materials, as well as a reduction in the efficiencies of fuel cells.399 Hence there is a need for methods that can directly investigate the formation of H2O2. In 2008, Shen et al.399 proposed and used a transient SG-TC mode to detect H2O2 produced during the ORR at Au, Pt, and PdCo alloy-modified GC electrodes in acidic medium using a Pt-UME as amperometric H2O2 sensor. Figure 1e shows the principle of the transient SG-TC mode: the substrate is first stepped from a potential where no faradaic processes happen, to a value within the limiting-current region of the ORR, while the tip is kept at a fixed potential of 1.1 V vs Ag/AgCl (Figure 1f) to detect and oxidize H2O2.399 Sánchez-Sánchez and co-workers demonstrated a new approach to quantify reaction intermediates based on the SG-TC mode but using smaller substrates (≤200 μm diameter) to induce stationary-state reaction conditions.403 As a demonstration, they employed the technique to quantify H2O2 during ORR at a Hg on Au substrate (100 μm) electrode in acidic media using Pt or Au as SECM tips. The use of smaller substrate electrodes (100 μm diameter) allowed a relatively high collection efficiency at the SECM tip, making it possible to detect and quantify the substrate generated H2O2 as well as to estimate the number of transferred electrons (n) during the ORR. The value of n was in the range of 2.12 to 2.19, and thus the two-electron pathway was clearly revealed as the predominant reaction pathway.404 Bard and co-workers employed SG-TC-SECM in a fundamental study of the ORR mechanism at a Pt SECM tip in alkaline media. Operando SG-TC-SECM was capable to estimate n = 2 when the ORR occurred at NaOH concentration <2 M, and n = 1 in the case of concentrations >6 M with formation of O2•–.405 Related ORR studies with the SG-TC mode were reported for different electrocatalysts including Hg, Au, Ag, Cu, Pt, Pd, Pd80Co20, Au60Cu40,403 Pt and Pd nano/microstructures embedded in multilayer polyelectrolyte films,406 different Fe porphyrins on GC,407 nanoporous Au and flat Au substrates,408 and cobalt metalloids (CoxB and CoxP) in a nitrogen-doped carbon matrix.409 Johnson and Walsh suggested a novel “tip generation–substrate collection–tip collection” (TG-SC-TC) sequence for screening the activity of ORR catalysts while detecting H2O2 simultaneously with the aid of a microring-disk SECM tip (Figure 1g).100 As a proof of concept, the technique was employed to measure the activity of a Au electrocatalyst toward the ORR in alkaline media, while simultaneously monitoring the formation of H2O2. Oxygen is generated at the microring of the SECM tip at a constant current, the O2 generated at the microring diffuses to the substrate (which is polarized at −0.5 V vs Ag/AgCl) to reduce oxygen to HO2–. The substrate-generated HO2– then diffuses to the microdisk (which is biased at a sufficiently anodic potential of 0.2 V vs Ag/AgCl) and HO2– gets oxidized to O2. Figure 1h is an SECM image recorded when the substrate was polarized at −0.50 V vs Ag/AgCl. The advantage of this method lies in the fact that no potential programming of tip or substrate is needed. Furthermore, taking continuous SECM tip scans of the substrate generates maps that correlate to activity and reaction mechanism.

Figure 1.

(a) Feedback mode SECM used in the study of O2 reduction in alkaline solution. (b) SECM approach curves: solid lines “a” and “b” are theoretical approach curves at conducting and insulating substrates, respectively. Circular symbols are experimental approach curves, and solid lines are theoretical curves at a Pt substrate with its potential held at, from top to bottom, −0.9, −0.8, −0.7, −0.6, and −0.5 V vs Hg/HgSO4. Reproduced from ref (402). Copyright 2002 American Chemical Society. (c) Scheme of the modified TG-SC mode for the study of the ORR in acidic medium. (d) ORR images obtained by the TG-SC mode of an array of Pt (left spot and right row) and Ru (middle row) spots supported on glassy carbon. Reproduced from ref (99). Copyright 2003 American Chemical Society. (e) Schematic illustration of the SECM operation in the pulsed SG-TC mode. (f) UME transient currents at ET = 1.1 V for the collection of H2O2 produced during ORR at a Au electrode. The potential of the Au substrate was stepped from +0.4 V to (I) +0.1, (II) +0.05, (III) 0, (IV) −0.05, and (V) −0.1 V. Reproduced from ref (399). Copyright 2008 American Chemical Society. (g) ‘‘Tip generation–substrate collection–tip collection’’ mode SECM using a microring-disk SECM tip for simultaneous ORR electrocatalyst screening and HO2– detection. (h) SECM image recorded at the microring-disk SECM tip (held at 0.2 V to oxidize HO2–) while scanned over the Au substrate polarized at −0.5 V vs Ag/AgCl. Reproduced with permission from ref (100). Copyright 2012 Elsevier Ltd.

In a quest to further improve the lateral resolution of the SECM the feasibility of a transient RC mode, which was mentioned in an earlier heptode SECM tip simulation study,410 was introduced. In the RC mode, local catalytic information at the substrate is transduced through a current measured at the tip while simultaneously avoiding the need to apply potential pulses to the substrate. The technique was applied to qualitatively monitor the lateral activity of Pt-spots on a GC support during the ORR using a Pt-UME as SECM tip. During the study, both tip and substrate were biased to a reductive potential (e.g., −0.60 V vs Ag/AgCl/3 M KCl) to compete for O2 in the gap between them. Since the diffusion of bulk O2 to the gap between the tip and substrate is hindered during measurement, a predefined potential pulse (1.4 V vs Ag/AgCl/3 M KCl) is applied to the tip to avoid complete depletion of O2. The activity of catalyst spots with different Pt loadings within a single spot was successfully visualized. The inability to extract quantitative kinetic conclusions was reported as an inherent limitation of the RC mode that needed to be addressed to enable the detection of H2O2. Furthermore, it was suggested that by combining the RC-mode with the shearforce-based constant distance mode of SECM, the chronoamperometric features of the RC mode can provide a detailed insight into the catalytic activity at tip-to-substrate distances below 100 nm.106 Regardless of the noted drawbacks, the transient RC mode was successfully used to visualize the local ORR catalytic activity of Pt–Ag nanoparticles with different Ag content,411 patterned carbon nanotubes decorated with Pt nanoparticles,412 undoped and nitrogen-doped CNTs,413 metal nanoclusters (Pt, Au, Ru, and Rh and their co-deposits), CoS2,414 and lanthanide-based oxides (La0.6M0.4Ni0.6Cu0.4O3, M = Ag, Ba, Ce).415

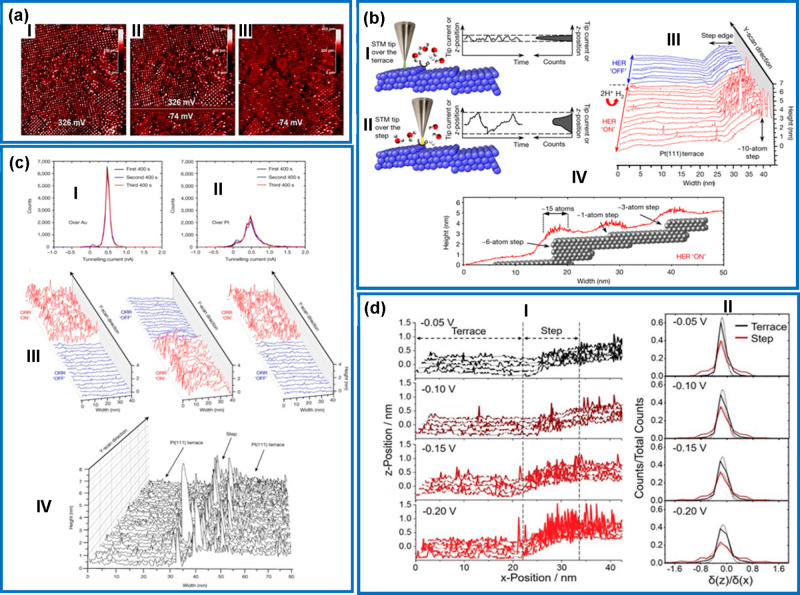

In 2007, Eckhard and Schuhmann suggested a sequential dual imaging mode of SECM making it possible not only to monitor local activity but also to determine the selectivity of electrocatalysts concurrently. The principle as depicted in Figure 2a involves combining three different SECM modes (TG-SC, SG-TC, and RC) and applying a sequential pulse program. Thus, two images are obtained in parallel; one gives information about the activity of the catalyst while the other monitors H2O2 (if any) produced during the ORR (see Figure 2b,c). The local activity and selectivity of Pt and Au spots for ORR were visualized using a Pt-UME as SECM tip. The RC mode enabled effective visualization of the local activity of substrates and the SG-TC mode allowed H2O2 detection and a better understanding of the branching between the two-electron and four-electron pathway of ORR at a given potential.115 The same technique was employed to visualize the catalytic activity and selectivity of different electropolymerized metalloporphyrins,416 tetratolyl porphyrins (with Mn, Fe, and Co as central metal ions),108 to screen Pd–Pt and Pd–Au co-deposits for H2O2 reduction,417 bifunctional catalysts based on cobalt and nickel oxides embedded in nitrogen-doped carbon (CoxOy/NC, NixOy/NC), bifunctional catalyst materials (mixed Ni0.9Co0.1Fe2O4 oxide) in alkaline media,418 multiwalled carbon nanotubes (MWCNTs), cobalt protoporphyrin (CoP) and their composite (MWCNTs/CoP) in neutral solution419 during ORR.

Figure 2.

(a) Schematic representations of different detection modes in SECM. (I) Tip generation–sample collection (TG-SC) mode. The scanning microtip oxidizes water to produce O2. The O2 reduction current at the sample is the analytical signal. (II) Sample generation–tip collection (SG-TC) mode. The sample is polarized to reduce O2. The tip oxidizes H2O2 which may be formed as a byproduct at the sample. The analytical signal is the peroxide oxidation current detected at the tip. (III) Redox competition mode (RC-SECM). The O2 reduction current is detected at the tip. Depletion of this current is correlated to a locally diminished oxygen concentration caused by a competing O2-reducing catalyst site of the sample, 3D false color representations of the obtained SECM images when the substrate was polarized at −400 V. (b) Reduction current at the tip due to competition for oxygen. Darker shaded blue areas correspond to a diminished current flow due to competition for the available O2 with active sites of the substrate. (c) Oxidation current of H2O2 at the tip concurrently registered. Reproduced with permission from ref (115). Copyright 2007 Elsevier Ltd. (d) Tip generation–redox competition–SECM images for O2 reduction on FeN4/rGO modified microelectrode. Color contrasts correspond to the measured cathodic tip current. Reproduced with permission from ref (420). Copyright 2016 Springer Nature. (e) Monitoring local ion activity changes in the water and hydroxide diffusion layer of an operating GDE and in dependence of its ORR rate is realized by voltammetric detection of the PtO reduction peak at a positioned Pt microelectrode. Reproduced with permission from ref (422). Copyright 2018 John Wiley & Sons, Ltd. (f) AFM/SECM mapping on Pt NPs performed using a Au-c-Pt tip: (I) topography, (II) oxygen reduction currents, and (III) peroxide oxidation currents recorded in N2-saturated on HOPG. Reproduced with permission from ref (423). Copyright 2019 John Wiley & Sons, Ltd.

Silva and colleagues, employed a TG-RC mode to map the activity of iron(III) tetra(N-methyl-4-pyridyl)porphyrin/reduced graphene oxide composite (FeN4/rGO) toward the ORR using a Pt-UME as SECM tip.420 The tip was first polarized at 1.25 V vs Ag/AgCl to generate O2 in the substrate–tip gap followed by an immediate polarization of both tip and substrate at sufficiently cathodic potentials to consume the O2 generated. Figure 2d shows the SECM image obtained for the ORR when the substrate was polarized at −0.50 V vs Ag/AgCl.420 Schulte and co-workers used the RC mode combined with shearforce-based constant distance positioning (4D-SF/SECM) to examine the topography and activity of gas diffusion electrodes toward the ORR.421 Botz and colleagues developed a method to monitor the activity of other redox species in parallel with the ORR (Figure 2(e)) which they implemented to visualize the changes in the local activities of OH– ions and H2O on the surface of an oxygen-depolarized cathode during the ORR in high alkaline medium.422 The substrate was polarized to induce the ORR consuming O2 and H2O and producing OH– while recording CV scans at a Pt-UME SECM tip for the detection of the OH– and H2O activities. The reduction of PtO on the surface of the tip was used to quantify local OH– and H2O activities which is a relevant information for the properties of high-current-density GDEs.422

Besides the use of shear force-based systems,421,424 SECM was hyphenated with other probe techniques to minimize the effect of sample topography on the measured tip current during ORR measurements. O’Connell et al. coupled SECM and SICM (SECM-SICM) to study localized H2O2 generation at individual Au nanoparticles (AuNPs) within ensemble electrodes during the ORR.425 They fabricated a theta (double-barrel) pipette which they used as the imaging probe and employed the SG-TC-SECM mode to detect H2O2 during the ORR at individual AuNPs. The potential of the substrate was varied to induce ORR while the SECM tip was biased at +1 V vs RHE to oxidize H2O2. The SICM hoping mode was employed to yield topographical information about the substrate.425 AFM-SECM operating in the noncontact mode was used to simultaneously map topography, oxygen reduction and detect peroxide intermediates on a bare highly oriented pyrolytic graphite (HOPG) surface and isolated Pt particles during ORR, using a Au-coated SiO2/Pt tip.423 During AFM-SECM image acquisition (Figure 2(f)) the substrate was polarized at 0.7 V vs SHE (for the ORR) and tip at 0.98 V vs SHE (for H2O2 oxidation), and it was concluded that the ORR on isolated Pt particles proceeds selectively via the two-electron pathway.423