Abstract

Yogurt, produced by the lactic fermentation of milk base, is an important dairy product worldwide. One of the essential sensory properties of yogurt is the texture, and some textural defects such as weak gel firmness and syneresis likely occur in various types of yogurts, affecting consumer acceptance. In this regard, various strategies such as enrichment of milk-based with different additives and ingredients such as protein-based components (skimmed milk powder (SMP), whey protein-based powders (WP), casein-based powders (CP), and suitable stabilizers, as well as modification of processing conditions (homogenization, fermentation, and cooling), can be applied in order to reduce syneresis. The most effective proteins and stabilizers in syneresis reduction are CP and gelatin, respectively. Furthermore, yogurt's water holding capacity and syneresis can be affected by the type of starter cultures, the protolithic activity, production of extracellular polysaccharides, and inoculation rate. Moreover, optimizing the heat treatment process (85 °C/30 min and 95 °C/5 min), homogenization (single or dual-stage), incubation temperature (around 40 °C), and two-step cooling process can decrease yogurt syneresis. This review is aimed to investigate the effect of fortification of the milk base with various additives and optimization of process conditions on improving texture and preventing syneresis in yogurt.

Keywords: Syneresis, Whey separation, Yogurt, Water holding capacity, Starter culture, Stabilizer

Introduction

Yogurt, a fermented milk product provided by thermophilic lactic acid bacteria, mainly Streptococcus thermophilus and Lactobacillus delbrueckii ssp. Bulgaricus is preferably consumed due to its approved health beneficial impacts (Dönmez et al., 2017). It is a nutrient-dense food supply beneficial to humans who suffer from lactose intolerance, constipation/diarrheal diseases, hypertension, diabetes, cardiovascular diseases, and cancer. Three major types of yogurt are available at the market, known as drinking, set, and stirred ones, similar in manufacturing practices (Karam et al., 2013). The main steps in yogurt production include: milk clarification and its separation into the cream and skim milk, homogenization, pasteurization, inoculation of starter culture, and incubation at 43 °C for 4–6 h and finally, rapid cooling when the pH reaches 4.0–4.7. The formation of lactic acid during the fermentation process provides a gel matrix via aggregation of casein micelles strands when pH reaches around 4.6 (Dönmez et al., 2017). Set and stirred yogurts are different according to the filling stage performed before and after incubation. Drinking yogurt is provided by stirred yogurt dilution from runny to viscose liquid (Arab et al., 2019a).

Yogurt structure as a firm gel is provided by disulfide cross-link between denatured whey proteins and k-casein and casein micelle aggregation at its isoelectric pH with interlocked whey via hydrogen bond (Karam et al., 2013). A yogurt set, usually fermented "in the pack," is firmer in structure than others. No mechanical agitation like shearing has been experienced and is not expected to be slimy in texture (Wang et al., 2019). The rheological characteristic of yogurt as a bridge between microscopic and macroscopic characteristics is critically important in determining its quality, shelf life, and consumer acceptability, especially in set ones. It is influenced by milk composition, total solid content, thermal processing condition, type and ratio of inoculated microorganisms, fermentation process (time and temperature), and storage time (Wang et al., 2019).

Syneresis or whey separation is a crucial technological defect in fermented milk-based gels that provides liquid on the gel surface and consequently undesired sensory mouthfeel characteristics, which is not appealing to the consumer (El Bouchikhi et al., 2019). Alongside the less consumer acceptability of whey separated yogurt due to its undesirable textural and flavor characteristics, its nutritional value may also be decreased, mainly attributed to the loss of water-soluble nutrients. An indirect correlation has been observed between yogurts' viscoelastic network (gel strength) and the syneresis ratio. Less syneresis is observed in the gel matrix than gel-like ones (Bitaraf et al., 2018). Yogurt would be less susceptible to syneresis during storage if its water holding capacity is enhanced (Sánchez et al., 2020).

Regarding the importance of yogurt as a healthy dessert and the critical role of its desired textural properties in consumer acceptance, in this study, the importance of syneresis as a textural defect in yogurt and the effect of various ingredients as well as processing conditions on improving texture and retarding syneresis in yogurts are discussed.

Mechanisms of syneresis creation in yogurt

Yogurt is considered a semisolid fermented milk (generally cow's milk) product with a three-dimensional network that can entrap a large liquid phase quantity. The cross-link formation of protein, polysaccharides, and fat provides the network, affecting the final product's total solid content and flavor, texture, and structure (Kim et al., 2020). Proteins are considered the main constituent of yogurts' structure. The total protein quantity of cow's milk is 3.48%, with caseins (αs1, αs2, β and κ components) and whey proteins at 80% and 20%, respectively. Yogurt structure results from casein's physical interaction with each other and with whey proteins through hydrophobic and disulfide bonds. Due to acidification (decrease of pH to isoelectric point) and enzymatic reaction during fermentation, caseins tend to form a gel to entrap whey via hydrogen bonds (Zhao et al., 2016).

Its global vision is important to guarantee yogurt's consumer acceptance during the distribution chain, market, and eventual consumption. The approximate shelf life of yogurt has been estimated to be around 16–21 days under refrigeration temperature (4–6 °C) storage (Alakali et al., 2009). The primary physical defects that have been observed in yogurt after processing and/or keeping for a particular time are viscosity fluctuation and syneresis.

Syneresis is considered the expulsion of interlocked whey (serum) from the continuous yogurt network (Lee and Lucey, 2010). The milk transformation from a Newtonian fluid to a semisolid/solid product occurs through the milk gelation, and the formed protein network can maintain serum in pores. Gel rigidity and its water holding capacity are considered factors in determining yogurt's stability against syneresis (Gilbert et al., 2020). However, syneresis is mainly found in set yogurt; the stirred are also prone to it, mainly regarding the lack of gel rigidity. Syneresis has been motivated by the contrast of two main groups of reason as (1) influensive factors on water holding capacity in gel networks, including physical (network density, formation, and stability) and chemical factors (factors that cause chemical inactivation of water), (2) factors facilitate the removal of water from gel networks including intra network stresses (network rearrangement, fast cooling, and acidification) and extra network stresses (shaking and cutting the gel) (Mortazavian and Sohrabvandi, 2004).

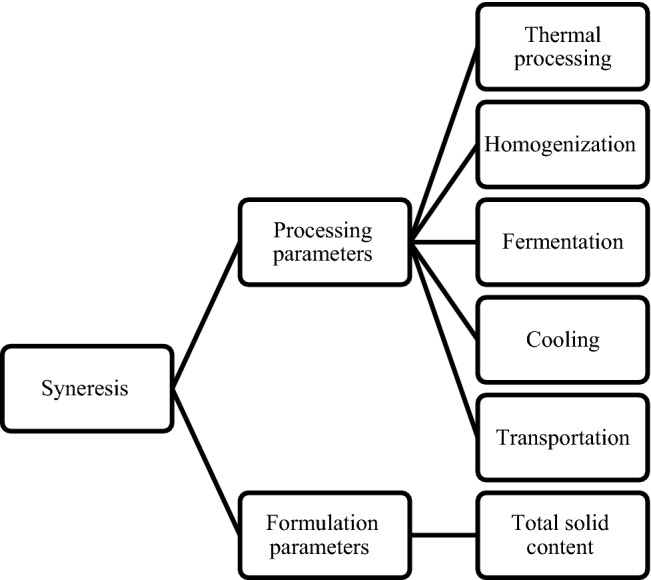

The serum separation in yogurt is supposed to be induced via poor formulation, with low total solid content, inadequate thermal and homogenization practice, inappropriate inoculated species, incubation time/temperatures, and deficiencies experienced during marketing transportation (Bierzuńska et al., 2019). Syneresis is a gel network rearrangement through enhancement in the particle–particle junction that is influenced by formulation and processing parameters, as depicted in Fig. 1.

Fig. 1.

Main influensive factors on yogurt syneresis

Effective factors on syneresis

Although various dairy raw materials were utilized in formulating yogurt, the approximately same method was used by all manufacturers to produce yogurt. Modification in producing methods and ingredients plays an essential role in improving yogurt quality, notably better texture and lower syneresis. In this section, the effect of processing conditions and added additives on yogurt quality has been reviewed.

Additives

Yogurt is considered a three-dimensional network that can entrap an effective liquid phase content. The microstructure consists of a protein matrix with fat globules embedded in it. Other ingredients called stabilizers are also used in yogurt production for better structure. They increase the yogurt mix's total solids to decline syneresis by around 14% (w/w). Types and amounts of proteins, stabilizers, and fat influence yogurt gel stability (Clark et al., 2019). Various types of mentioned compounds are applied in the dairy industry. The important and common types are discussed in the following sections.

Protein

The most critical components in yogurt formation are proteins. Protein interactions (type and levels) and raising the ratio of protein to total solids are two essential factors that significantly affect gel elasticity, leading to less rupture and better texture properties. Enhancement of protein levels promotes gel firmness and reduces syneresis. Various ingredients are used to increase the protein content, including skimmed milk powder (SMP), whey protein-based, and casein-based ingredients that showed different effects on water holding capacity and other yogurt properties. Caseins, undenatured and denatured whey proteins, can immobilize around 2.82, 0.32, and 2.34 g water per g protein, respectively (Snoeren et al., 1982).

SMP, traditionally used for yogurt production, improved the textural quality and decreased the syneresis levels. It was reported that SMP addition resulted in a good quality yogurt with increased yogurt viscosity and gel strength compared to unfortified yogurt (Karam et al., 2013). Although SMP addition to yogurt mix resulted in a firmer body, it was demonstrated that a large amount of SMP led to a great powdery mouthfeel and remarkable fermented flavor (Karam et al., 2013; Tamime and Robinson 2007). The excess lactose from SMP can develop extreme acidity during product storage (Karam et al., 2013). Due to the appearance of powdery taste in the yogurt due to the higher addition of milk powder, other dried dairy ingredients divided into two groups (whey protein-based and casein-based ingredients) have been utilized to increase dry ingredients yogurt-mix composition.

Whey protein concentrates (WPC), isolate (WPI) or hydrolysate (WPH), denatured whey protein, whey protein fraction, and non-protein nitrogen products are some of the different types of whey powder (WP) (Kelly, 2019). Due to WP's nutritional and functional properties have increased attention to fortifying yogurt with these proteins (Wherry et al., 2019). It was claimed that WP and yogurt's milk base at the range of 0.6 to 4% w/w resulted in syneresis reduction (Mahomud et al., 2017). However, due to an undesirable whey flavor and sometimes a grainy texture in high WP levels, its content yogurt mix was limited to 1–2% (Lee and Lucey, 2010). The addition of WPC to the milk base of yogurt sounds to be a more common practice than the WPI addition. WPC contains 34–88% protein produced by ultrafiltration, and drying of whey, and it has been indicated that the whey processing conditions can influence the functional properties of WPC, such as solubility, foaming, heat gelation, and emulsion capacity (Karam et al., 2013; Kumar et al., 2018). It was said that both heat treatment and acidity of the whey during the production of WPC induct negative effect on the water-holding capacity of the yogurt, resulting in the more particulate and heterogeneous texture of the final product (Kelly, 2019). Various studies have investigated the effect of WPC addition instead of SMP on yogurt's physical and textural properties, and contradictory results were observed. Some studies showed increased yogurts' firmness and viscosity when SMP was replaced with WPC (Sodini et al., 2005).

In contrast, the replacement resulted in an inconsistent loss (Lesme et al., 2020). It has been reported that WP addition to milk before heat treatment and fermentation resulted in a denser protein network in which small pores and a well cross-linking between caseins and whey proteins are created (Lesme et al., 2020). It seems that WP's composition and functionality, the amount of WP addition, the intensity of milk heat treatment, and starters used for the fermentation can be effective in the appearance of inconsistent results.

Casein-based ingredients are also utilized to increase dry ingredients of the yogurt-mix composition. Casein-based powders (CP) manufactured from skimmed milk have several types (e.g., acid or rennet casein, sodium, potassium or calcium caseinate, and casein hydrolysate). These powders enhance the hydrophilic properties by increasing protein content, resulting in lower yogurt syneresis levels due to improved viscosity. It has been indicated that the best levels of casein are around 1–2% w/w. The addition of a higher amount of casein led to uncontrolled thickening (Amalfitano et al., 2019). Various studies have reported that the addition of sodium-caseinates to milk led to higher viscosity, firmness and more robust networks and less syneresis in comparison to the yogurt enriched with different types of milk protein ingredients (Karam et al., 2013).

One of the most critical parameters in yogurt syneresis is CP to WP ratios. Nearly all studies reported that the levels of syneresis decreased as CP/WP reduced (Zhao et al., 2016; Laiho et al., 2017). Reduction of CP/WP increased the density of protein matrix and compactness of yogurt microstructure, leading to a high level of immobilized free water in the yogurt gel. Some recent studies about adding protein-based powders and CP/WP ratio on yogurt syneresis are summarized in Table 1.

Table 1.

Effects of protein-based powders on yogurt syneresis

| Sample | Independent variables | Levels | Results | References |

|---|---|---|---|---|

| Non-fat cup set-style | Neutralized acid whey protein concentrate (NAWPC), sweet whey protein concentrate (SWPC), or skim milk concentrate (SMC) | 7.75% (AWPC), 88.0% (SMC), 8.30% (SWPC) | Higher pH in NAWPC yogurt changed gel structure formation and water holding capacity. The yogurt showed higher syneresis | Wherry et al., (2019) |

| Low-fat set yogurt | Polymerized whey protein (PWP) | 1.4% | The WHC of yogurts with the addition of PWP was significantly higher than full-fat yogurt | Fang et al., (2019) |

| Fat-free stirred yogurts | Casein/whey protein (C/W) | 80:20 (Control) to 50:50 | Decreasing C/W (increased W content) results in a stronger protein network due to increasing crosslinking levels. Sample with 50:50 ratio showed higher syneresis | Laiho et al., (2017) |

| Low-fat yogurt | Casein/whey protein (C/W) | 4:1, 3:1, 2:1, and 1:1 | When C: W ratio decreased, yogurt coagulum showed higher G´ and greater yield stress. The fermentation period was shortened, and the microstructure became more compact with smaller pores | Zhao et al., (2016) |

| Low fat set type yogurt | W/C | 0.22–0.7% | Yogurt syneresis was positively affected by FC, W/C ratio, and TG | Pakseresht et al., (2017) |

| Fat content (FC) | 0.5–1.5% | |||

| Microbial transglutaminase (TG) | 0.0–1.0 U/g | |||

| Non-fat stirred yogurts | C/WP | 1:1, 1:2 and 1:3 | Samples with lower C/W were firmer and stiffer than those with higher C/W. It also had a more elastic gel at 4.5 | Chua et al., (2017) |

Fat

Milk typically contains 2.5–3% fat. The fat content in yogurt varies depending on the final product, high in full-fat yogurt and less in low-fat yogurt (Clark et al., 2019). Some studies reported that fat reduction from yogurt milk harmed the final gel's textural properties (Aryana and Olson 2017). However, it has been declared by Laiho et al., 2017 that skim yogurts had greater firmness and higher viscosities than whole fat yogurts. Adding fat replacers can modify the texture of low-fat yogurts (Laiho et al., 2017).

Milk is usually homogenized to decrease fat globules diameter at pressures ranging between 15 and 20 MPa and temperature at around 65–70 °C, through a single stage or 10–20 and 5 MPa two-stage homogenizer (Chandan and O’Rell 2013). Under high pressure, the fat globule's size is decreased, and the fat surface is partially covered with proteins leading to more hydrophilic properties. So, smaller fat globules were incorporated into the gel by cross-linking with proteins and resulted in a product with lower syneresis, favorable firmness, and mouthfeel. The other method is ultra-high pressure homogenization performed at the pressure of 200 or 300 MPa leading to higher firmness and water holding capacity. After heat treatment, the homogenization process makes the casein micelles covered with denatured whey protein incorporated in the fat membrane, resulting in higher firmness in final products. It should be noticed that unhomogenized large fat globules may interrupt the yogurt gel network and increase syneresis.

Stabilizers

Stabilizers, especially hydrocolloids, are widely used in various food products to improve textural properties and shelf life (Khanniri et al., 2019; Khorshidian et al., 2018). Their long and branched molecules made them prone to bind with water, reduce water flow in the matrix space, and potentially decrease syneresis in yogurt (Saha and Bhattacharya 2010; Yemenicioğlu et al., 2020; Khanniri et al., 2017). Furthermore, the interaction of hydrocolloids with milk constituents enhances their hydration. Therefore, a network of linkages between the milk constituents that retards the free movement of water is formed. Additionally, it was indicated that hydrocolloids' addition at an optimized level improves the yogurt characteristics like texture, viscosity, appearance, and mouthfeel (Pavlou et al., 2020). Starch, pectin, alginate, xanthan, carrageenan, derivatives of methylcellulose (such as carboxymethyl cellulose (CMC), gum arabic, tragacanth, karaya, locust bean gum (LBG), or guar and gelatin are common hydrocolloids in the food industry.

Hydrocolloids used in yogurt can be categorized as anionic and neutral. The interaction of anionic hydrocolloids (κ-carrageenan and pectin, CMC) with the positively charged functional groups on the surface of casein micelles provides a more robust casein network. The interaction also affects the ion equilibrium and sooner precipitation of caseins compared to yogurt without hydrocolloids. In contrast, neutral hydrocolloids (xanthan, guar, and LBG) increased the continuous phase viscosity. The addition of hydrocolloids to yogurt is considered a practical method to enhance viscosity and decrease syneresis. In this part application of the most important stabilizers utilized in yogurt is reviewed. It has been indicated that gelatin is one of the most prominent hydrocolloids in controlling syneresis in yogurt (Yousefi and Jafari 2019). Yogurt formulated with gelatin shows better rheological and textural properties and lower syneresis in a way that it has been reduced to zero in some cases.

Starch is a type of carbohydrate consisting of a large number of glucose units joined by glycosidic bonds. The viscosity enhancement induced by starch granules swelling can reduce syneresis. Also, they could improve the mouthfeel properties of low-fat yogurts. It is a cost-effective hydrocolloid known as one of the thickening agents used in yogurt production (Saleh et al., 2020). For many years, maize starches have been used as a thickening agent and fat replacer in yogurts. Recently, other botanical sources such as kudzu starch, tapioca starch, water yam starch, and potato starch have also been used, potentially effective in syneresis reduction (Altemimi, 2018). However, it was stated that gelatin is more effective in syneresis reduction in yogurt than starch.

Xanthan gum is a polysaccharide secreted by the bacterium Xanthomonas campestris, used as a food additive, commonly as a fat replacer, food thickening, and stabilizer (Gyawali et al., 2016). It has unique properties such as solubility in hot or cold water and an acidic media, high thermal stability, little shift in viscosity by changing temperature, high viscosity at low shear, and low viscosity at high shear (Saha and Bhattacharya, 2010). Xanthan gum hydrates immediately after dispersion and prevents syneresis defect by providing water-binding (Gyawali and Ibrahim, 2016). Studies revealed that xanthan addition at a concentration of 0.005–0.01% decreased syneresis rate through its shelf life.

Carrageenan is a sulfated polysaccharide that extracts from red edible seaweeds. It synergizes with other gums and is commonly used as a gelling, thickening, and stabilizing agent. Carrageenan has a variable ratio of sulfate groups in various positions and is classified into three main groups: kappa, iota, and lambda. Due to variation in carrageenan, various rheological properties could be achieved (Fontes-Candia et al., 2020). Carrageenan could influence food's textural properties by increasing viscosity and its unique water-holding ability (Li et al., 2020). Despite the prevalence of using carrageenan in ice cream or ice milk (Gyawali and Ibrahim, 2016), it could also potentially be used to decrease yogurt syneresis. As an anionic hydrocolloid, carrageenan can interact with positive charges on proteins' surfaces and provide a robust protein network. It has been stated that carrageenan, which resulted in earlier milk gelation at low concentration (≤0.05%), can entirely prevent gelation at higher concentration (0.2%) (Clark et al., 2019). Generally, carrageenan's thickening and stabilizing properties could be one of the desired additives in yogurt production. Cations are limiting factors to carrageenan and casein interaction (Tang et al., 2019). It is recommended to use a proper combination of carrageenan and galactomannan, such as guar and locust bean gum.

Inulin consists of β-(2, 1)-linked fructosyl units with a terminal glucosyl unit. It is used as a highly soluble dietary fiber reducing blood cholesterol, lipid levels, and increasing calcium absorption. As prebiotic agent can also stimulate probiotic bacteria's growth and regulate intestinal flora in the colon (Ahmed and Rashid 2019; Yousefi et al., 2018). The degree of polymerization (DP) influenced inulin's functional properties. Entrapment of water by hydroxyl groups of inulin makes it potentially able to form a stable gel with high water holding capacity. Gel formation by inulin is independent of the presence of the casein network. In other words, gel creature has been induced by water entrapment of network provided by inulin interaction. Inulin could increase viscosity enhancement, texture improvement, and syneresis reduction in low-fat yogurt (Żbikowska et al., 2020). Long-chain inulin is more effective in decreasing syneresis, modifying the texture, enhancing creaminess, and improving mouthfeel than a shorter chain because of better binding ability (Gomez‐Betancur et al., 2020). Some recent researches about the effects of stabilizers on yogurt structure and syneresis are summarized in Table 2.

Table 2.

Effects of stabilizers on yogurt structures and syneresis

| Sample | Stabilizers | Levels | Results | References |

|---|---|---|---|---|

| Skim set yogurt | Gelatin, xanthan gum, carrageenan and modified starch | (0.5–1.5%), (0.005–0.015%), (0.01–0.08%) and (0.5–1.5%), respectively | Both xanthan gum and carrageenan significantly increased the syneresis. Modified starch improved thickness without significant changes in the product texture. Gelatin was the best hydrocolloid due to its ability to reduce syneresis | Nguyen et al., (2017) |

| Non-fat Set Yogurt | Potato, sweet potato, corn, chickpea, and Turkish beans starch | 1.0 g | Wheying-off was significantly reduced, regardless of starch type | Saleh et al., (2020) |

| Low- fat set yogurt | Resistant cassava and corn Starch | 0, 0.1, 0.5 and 1% of cassava starch and 0.6% Corn starch as control | During cold storage, yogurt treated with 1% resistant cassava starch had the highest viscosity and the least syneresis (22.5%) | Mwizerwa et al., (2017) |

| Full fat set yogurt containing coffee-cascara extract | Inulin | 0, 3, 7, and 13% | The addition of inulin increased the firmness and consistency of yogurt. Inulin at a 13% level significantly decreased syneresis compared to the control and the sample containing 3% inulin | Iriondo-DeHond et al., (2020) |

| Full fat set yogurt | Potato starch | 0.25%, 0.5%, 0.75% and 1% | Potato starch at levels 0.75 and 1% resulted in less syneresis and acceptable sensory characteristics with little change in the total acidity | Altemimi, (2018) |

| Low-fat stirred yogurt | Tilapia skin gelatin (TSG) | 0.4, 1.0, and 2.5% | TSG enhanced the firmness of the gel with an increase in concentration. The addition of 0.4% TSG completely prevented whey separation | Pang et al., (2017) |

Processing conditions

Heat treatment

The intensive thermal processing used in yogurt production aims to change milk components, especially whey proteins, and destroy unwanted microorganisms for better starter bacteria growth. Through thermal processing (appropriate time–temperature), the enhanced denaturation of whey protein and its association with casein micelles increase the water holding capacity by decreasing the hydrophobicity (Nagaoka, 2019). The best conditions are 85 °C/30 min and 95 °C/5 min. Generally, heat treatment positively influences syneresis. However, severely heat-treated milk led to faster formation of yogurt gel with a weaker structure, which is more susceptible to syneresis like unheated or inadequately heat-treated milk (Shaker et al., 2000). Syneresis ratio was higher in yogurt produced with raw milk than pasteurized and UHT milk (Célia et al., 2017). Also, heat treatment lower than 85 °C resulted in yogurt being more susceptible to syneresis than adequate heating (Zamberlin and Samarzija 2017).

Homogenization

Homogenization is a process that results in fracturing fat globules into smaller and better-dispersed particles, which leads to the formation of smoother and creamier end products. Homogenization in commercial yogurt produces a more uniform product, which is less susceptible to whey off. In a homogenizer, milk is forced through the tiny orifice at high pressure, and fat globules are broken up due to shearing forces (Chandan and O’Rell, 2013). In the manufacture of yogurt with minimum stabilization (MSNF 11–13%), a high-pressure double stage homogenization, approximately 23–28 MPa/ 6 MPa (2000–2500/500 psi), or single-stage, 23–28 MPa (2000–2500 psi), is used in order to improve consistency and prevent whey separation. Yogurt with higher total solids content and/or stabilizers can be homogenized at lower pressures, approximately 6–17 MPa (500–1500 psi) (Chandan and O’Rell 2006). Homogenization and stirring process in the production of set sheep yogurt resulted in no additional syneresis after 28 days of storage. Also, decreasing the natural creaming during the initial hours of fermentation as the result of altering the milk structure was observed (Tribst et al., 2020). Using other technologies such as high-intensity ultrasound (HIU) combined with homogenization has been reported to be more efficient in decreasing the syneresis induced by the decrease in the size of fat globules and viscosity/ water holding capacity enhancement (Akdeniz and Akalin 2019).

Fermentation

Fermentation parameters, including time, temperature, and starter cultures, significantly affect syneresis. A temperature around 42–45 °C was commonly applied in the fermentation process (Arab et al., 2019b). At high incubation temperatures, the gel's number or strength of hydrophobic interactions increased (Roefs and Vliet 1990). However, incomplete solubilization of colloidal calcium phosphate (CCP) induced by gel formation at higher pH leads to more rearrangements in the gel matrix. Consequently, increasing syneresis occurs during the storage time (Lucey and Singh 1997). At lower gelation temperature, more strong cross-links of caseins and denatured whey proteins result in less rearrangement and syneresis. About 62% reduction in syneresis has been demonstrated by reducing the incubation temperature from 45.7 to 40 °C (Lee and Lucey 2004).

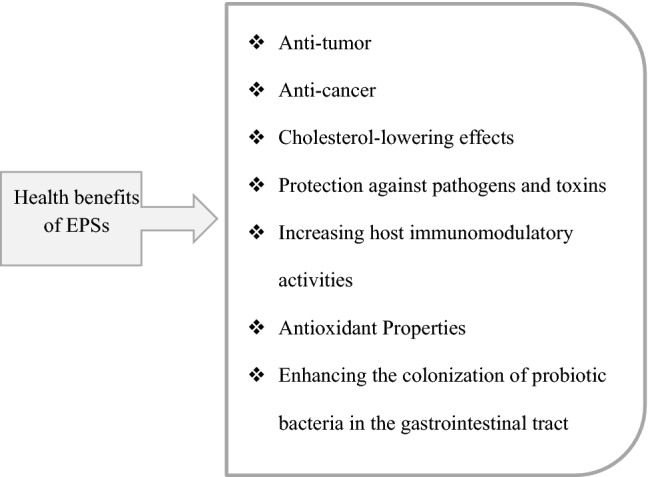

The syneresis ratio is also determined by the types of starter cultures, inoculation rates, and the starter bacteria's metabolic activity. However, Lactobacillus delbrueckii ssp. bulgaricus and Streptococcus salivarius subsp. thermophiles are the traditional starter bacteria in yogurt formation; some other strains have also been approved (Alimentarius, 2011). Syneresis increased in yogurts obtained by high proteolytic activity cultures during storage. Several studies have mentioned that exopolysaccharides (EPS) producing cultures could be considered a new approach to modifying fermented milk (Ghasempour et al., 2019). EPSs are natural bio-thickening agents, and their functionality depends on the monosaccharide composition, charges, structure (length and frequency of branching), and interaction of the EPS with milk constituents. EPSs can be divided into two groups: homopolysaccharides and heteropolysaccharides. Several health benefits have been attributed to EPs, as presented in Fig. 2.

Fig. 2.

Health benefits of exopolysaccharides(EPSs)

Some starter bacteria can produce heteropolysaccharides at their optimal growth temperature, usually uncharged and exist in two forms: capsular and ropy. Ropy EPSs are attached to bacterial cell surfaces while the capsular forms are excreted in the environment. Both forms of EPSs show high water-binding ability. However, yogurt gels obtained by the ropy strains show a more homogenous structure with randomly distributed small cavities than non-ropy strains (Duboc and Mollet 2001). Starter cultures that produce EPSs with a greater chain length result in more viscous products with lower syneresis. Effects of EPS producing starter cultures and a commercial starter culture (S. thermophiles and Bifidobacterium animalis subsp. lactis) in probiotic goats' milk set yogurt were investigated. It was observed that the level of whey separation was reduced in yogurts with EPS producing starters due to the modification of yogurt microstructure by EPS producing cultures and the higher water-binding capacity of EPS (Madhubasani et al., 2020).

On the other hand, it was reported that yogurts produced with EPS producing starter cultures had lower firmness than samples without EPS producing starter cultures, especially at 9% (w/w) total solid compared to 12% (w/w) (Amatayakul et al., 2006). This phenomenon could be explained by differences in the protein aggregation mechanisms and gel structure. Due to the incompatibility of EPSs with milk protein, they are separated from milk proteins and fill the gel pores that reduce firmness and syneresis (Hassan et al., 2003).

Inoculation rate and metabolite activity of starter bacteria are other parameters that can effectively treat syneresis. Metabolite activities are dependent on inoculation temperature, which has been decreased at lower temperatures.

Cooling process

When the final product reaches a favorable pH (~4.6), a cooling step must be performed to decrease or eliminate starter bacteria's activities to prevent higher acidity and rearrangements in gel structure during storage periods (Yildiz, 2010). Starters activity has been reported to be decreased at temperature < 10 °C, usually 5 °C. For this goal, two methods can be performed: Yogurt directly reached to temperature under 10 °C, in one step cooling, or reached 15 or 20 °C at first then reached to temperature under 10 °C, in two-step cooling (Tamime and Robinson 1999). It was clear that two-step cooling led to a final product with lower syneresis and a better texture (Mortazavian and Sohrabvandi, 2004). Syneresis in yogurt cooled with plate heat exchanger was lower than tubular heat exchanger (Guénard-Lampron et al., 2019).

Conclusion

This article considered the effects of formulation and processing steps on yogurt syneresis. The addition of protein-based powders and stabilizers could decrease yogurt syneresis. Casein-based powders and gelatin are the most effective protein and stabilizers in syneresis reduction, respectively. Unheated and severely heat-treated milk results in higher syneresis products than optimum heat treatment (at 85 °C/30 min and 95 °C/5 min). The homogenization process at a higher pressure and after heat treatment is useful in decreasing syneresis. Fermentation conditions, including a higher inoculation rate and lower incubation temperature, effectively reduce syneresis in the final products. Also, EPSs producing starter cultures with low proteolytic activity can effectively increase water holding capacity. Furthermore, the two-step cooling process is more effective in yogurt production with lower syneresis. It is suggested that the effect of different methods of milk standardization, such as vacuum evaporation (VE) and membrane filtration, on the yogurt syneresis is investigated in future studies. Furthermore, it is recommended to study the combined effects of EPS producing cultures and different types and content of stabilizers for the next research.

Acknowledgements

Support for this study provided by Shahid Sadoughi University of medical sciences is gratefully acknowledged.

Abbreviations

- SMP

Skimmed milk powder

- WP

Whey powder

- WPC

Whey protein concentrates

- WPI

Whey protein isolate

- WPH

Whey protein hydrolysate

- CMC

Carboxymethyl cellulose

- LBG

Locust bean gum

- EPS

Exopolysaccharides

Author contribution

MA and NM designed the study. MY, VQ and NM collected the data. EK and MA wrote the initial draft. MY, MA and VQ revised the initial draft and finally all the autohrs approved the final version of manuscript for the submission.

Funding

Not Applicable.

Declaration

Conflict of interest

The authors declare that there is no conflict of interest.

Footnotes

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Contributor Information

Vahid Ghasemzadeh-Mohammadi, Email: v.gh-mo@umsha.ac.ir.

Neda Mollakhalili-Meybodi, Email: neda_mabodi@yahoo.com.

References

- Ahmed W, Rashid S. Functional and therapeutic potential of inulin: a comprehensive review. Crit Rev Food Sci Nutr. 2019;59:1–13. doi: 10.1080/10408398.2017.1355775. [DOI] [PubMed] [Google Scholar]

- Akdeniz V, Akalın AS. New approach for yoghurt and ice cream production: High-intensity ultrasound. Trends Food Sci Technol. 2019;86:392–398. doi: 10.1016/j.tifs.2019.02.046. [DOI] [Google Scholar]

- Alakali JS, Unwiyi I, Ejiga O. Effect of milk blends and temperature on the quality of thermized yoghurt. Elec J Environ Agricult Food Chem. 2009;8:676–684. [Google Scholar]

- Alimentarius FWC (2011) Milk and milk products. Codex Standard for Fermented Milk 6–616.

- Altemimi AB. Extraction and optimization of potato starch and its application as a stabilizer in yogurt manufacturing. Foods. 2018;7:14. doi: 10.3390/foods7020014. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Amalfitano N, Cipolat-Gotet C, Cecchinato A, Malacarne M, Summer A, Bittante G. Milk protein fractions strongly affect the patterns of coagulation, curd firming, and syneresis. J Dairy Sci. 2019;102:2903–2917. doi: 10.3168/jds.2018-15524. [DOI] [PubMed] [Google Scholar]

- Amatayakul T, Sherkat F, Shah N. Physical characteristics of set yoghurt made with altered casein to whey protein ratios and EPS-producing starter cultures at 9 and 14% total solids. Food Hydrocoll. 2006;20:314–324. doi: 10.1016/j.foodhyd.2005.02.015. [DOI] [Google Scholar]

- Arab M, Razavi SH, Hosseini SM, Nayebzadeh K, Meybodi NM, Khanniri E, Mardi P, Mortazavian AM. Production and characterization of functional flavored milk and flavored fermented milk using microencapsulated canthaxanthin. LWT. 2019;114:108373. doi: 10.1016/j.lwt.2019.108373. [DOI] [Google Scholar]

- Arab M, Sohrabvandi S, Khorshidian N, Mortazavian AM. Combined effects of salt-related variables on qualitative characteristics of probiotic fermented milk. Curr Nutr Food Sci. 2019;15:234–242. doi: 10.2174/1573401314666180123151007. [DOI] [Google Scholar]

- Aryana KJ, Olson DW. A 100-year review: yogurt and other cultured dairy products. J Dairy Sci. 2017;100:9987–10013. doi: 10.3168/jds.2017-12981. [DOI] [PubMed] [Google Scholar]

- Bierzuńska P, Cais-Sokolińska D, Yiğit A. Storage stability of texture and sensory properties of yogurt with the addition of polymerized whey proteins. Foods. 2019;8:548. doi: 10.3390/foods8110548. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Bitaraf MS, Khodaiyan F, Hosseini SS. Rheological properties of probiotic non-fat yogurt containing Lactobacillus reuteri: effects of inulin addition, inoculum level and fermentation temperature. J Food Bioprocess Eng. 2018;1:109–116. [Google Scholar]

- Célia JA, da Silva MAP, de Oliveira KB, Souza DG, de Moura Silva LC, Nicolau ES, Gonçalves JA. Influence of heat treatment on physicochemical and rheological characteristics of natural yogurts. Semin Cienc Agrar. 2017;38:2489–2503. doi: 10.5433/1679-0359.2017v38n4Supl1p2489. [DOI] [Google Scholar]

- Chandan RC, O’Rell KR. Manufacture of various types of yogurt. In: Chandan RC, editor. Manufacturing yogurt and fermented milks. 1. New York: Blackwell; 2006. pp. 211–236. [Google Scholar]

- Chandan RC, O’Rell K. Principles of yogurt processing. In: Chandan RC, Kilara A, editors. Manufacturing yogurt and fermented milks. 2. London: Wiley-Blackwell; 2013. pp. 239–262. [Google Scholar]

- Chua D, Deeth HC, Oh HE, Bansal N. Altering the casein to whey protein ratio to enhance structural characteristics and release of major yoghurt volatile aroma compounds of non-fat stirred yoghurts. Int Dairy J. 2017;74:63–73. doi: 10.1016/j.idairyj.2017.05.002. [DOI] [Google Scholar]

- Clark S, Michael M, Schmidt KA. Rheological properties of yogurt: effects of ingredients, processing and handling. In: Joyner SH, editor. Rheology of semisolid foods. 1. Switzerland: Springer; 2019. pp. 203–229. [Google Scholar]

- Dönmez Ö, Mogol BA, Gökmen V. Syneresis and rheological behaviors of set yogurt containing green tea and green coffee powders. J Dairy Sci. 2017;100:901–907. doi: 10.3168/jds.2016-11262. [DOI] [PubMed] [Google Scholar]

- Duboc P, Mollet B. Applications of exopolysaccharides in the dairy industry. Int Dairy J. 2001;11:759–768. doi: 10.1016/S0958-6946(01)00119-4. [DOI] [Google Scholar]

- El Bouchikhi S, Pagès P, El Alaoui Y, Ibrahimi A, Bensouda Y. Syneresis investigations of lacto-fermented sodium caseinate in a mixed model system. BMC Biotechnol. 2019;19:57. doi: 10.1186/s12896-019-0539-1. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Fang T, Shen X, Hou J, Guo M. Effects of polymerized whey protein prepared directly from cheese whey as fat replacer on physiochemical, texture, microstructure and sensory properties of low-fat set yogurt. LWT. 2019;115:108268. doi: 10.1016/j.lwt.2019.108268. [DOI] [Google Scholar]

- Fontes-Candia C, Ström A, Lopez-Sanchez P, López-Rubio A, Martínez-Sanz M. Rheological and structural characterization of carrageenan emulsion gels. Algal Res. 2020;47:101873. doi: 10.1016/j.algal.2020.101873. [DOI] [Google Scholar]

- Ghasempour Z, Kia EM, Golbandi S, Ehsani A. Effects of mixed starters on quality attributes of probiotic yogurt using statistical design approach. Nutr Food Sci. 2019 doi: 10.1108/NFS-11-2017-0255. [DOI] [Google Scholar]

- Gilbert A, Rioux L-E, St-Gelais D, Turgeon SL. Characterization of syneresis phenomena in stirred acid milk gel using low frequency nuclear magnetic resonance on hydrogen and image analyses. Food Hydrocoll. 2020;106:105907. doi: 10.1016/j.foodhyd.2020.105907. [DOI] [Google Scholar]

- Gomez-Betancur AM, Carmona-Tamayo R, Martínez-Álvarez OL, Casanova-Yepes H, Torres-Oquendo JD. Effect of fat substitution using long-chain inulin and fortification with microencapsulated calcium in the rheological and sensory properties of yogurt mousse. J Food Process Eng. 2020 doi: 10.1111/jfpe.13433. [DOI] [Google Scholar]

- Guénard-Lampron V, St-Gelais D, Villeneuve S, Turgeon SLJJ (2019) Individual and sequential effects of stirring, smoothing, and cooling on the rheological properties of nonfat yogurts stirred with a technical scale unit. 102: 190–201. Doi:10.3168/jds.2018-14565 [DOI] [PubMed]

- Gyawali R, Ibrahim SA. Effects of hydrocolloids and processing conditions on acid whey production with reference to Greek yogurt. Trends Food Sci Technol. 2016;56:61–76. doi: 10.1016/j.tifs.2016.07.013. [DOI] [Google Scholar]

- Hassan A, Ipsen R, Janzen T, Qvist K. Microstructure and rheology of yogurt made with cultures differing only in their ability to produce exopolysaccharides. J Dairy Sci. 2003;86:1632–1638. doi: 10.3168/jds.S0022-0302(03)73748-5. [DOI] [PubMed] [Google Scholar]

- Iriondo-DeHond M, Iriondo-DeHond A, Herrera T, Fernández-Fernández AM, Sorzano COS, Miguel E, Castillo MDd. Sensory acceptance, appetite control and gastrointestinal tolerance of yogurts containing coffee-cascara extract and inulin. Nutrients. 2020;12:627. doi: 10.3390/nu12030627. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Karam MC, Gaiani C, Hosri C, Burgain J, Scher J. Effect of dairy powders fortification on yogurt textural and sensorial properties: a review. J Dairy Res. 2013;80:400–409. doi: 10.1017/S0022029913000514. [DOI] [PubMed] [Google Scholar]

- Kelly P. Manufacture of whey protein products: concentrates, isolate, whey protein fractions and microparticulated. In: Deeth HC, Bansal N, editors. Whey proteins: from milk to medicine. New York: Academic Press; 2019. pp. 97–122. [Google Scholar]

- Khanniri E, Sohrabvandi S, Arab SM, Shadnoush M, Mortazavian AM. Effects of stabilizer mixture on physical stability of non-fat Doogh, an Iranian traditional drink. Koomesh. 2017;19:144–153. [Google Scholar]

- Khanniri E, Yousefi M, Khorshidian N, Sohrabvandi S, Mortazavian AM. Development of an efficient stabiliser mixture for physical stability of nonfat unfizzy doogh. Int J Dairy Technol. 2019;72:8–14. doi: 10.1111/1471-0307.12554. [DOI] [Google Scholar]

- Khorshidian N, Yousefi M, Shadnoush M, Mortazavian AM. An overview of β-glucan functionality in dairy products. Curr Nutr Food Sci. 2018;14:280–292. doi: 10.2174/1573401313666170609092748. [DOI] [Google Scholar]

- Kim SY, Hyeonbin O, Lee P, Kim Y-S. The quality characteristics, antioxidant activity, and sensory evaluation of reduced-fat yogurt and nonfat yogurt supplemented with basil seed gum as a fat substitute. J Dairy Sci. 2020;103:1324–1336. doi: 10.3168/jds.2019-17117. [DOI] [PubMed] [Google Scholar]

- Kumar R, Chauhan SK, Shinde G, Subramanian V, Nadanasabapathi S. Whey proteins: a potential ingredient for food industry—a review. J Dairy Foods Home Sci. 2018;37:283–290. [Google Scholar]

- Laiho S, Williams RP, Poelman A, Appelqvist I, Logan A. Effect of whey protein phase volume on the tribology, rheology and sensory properties of fat-free stirred yoghurts. Food Hydrocoll. 2017;67:166–177. doi: 10.1016/j.foodhyd.2017.01.017. [DOI] [Google Scholar]

- Lee WJ, Lucey JA. Structure and physical properties of yogurt gels: effect of inoculation rate and incubation temperature. J Dairy Sci. 2004;87:3153–3164. doi: 10.3168/jds.S0022-0302(04)73450-5. [DOI] [PubMed] [Google Scholar]

- Lee W, Lucey J. Formation and physical properties of yogurt. Asian-Aust J Anim Sci. 2010;23:1127–1136. doi: 10.5713/ajas.2010.r.05. [DOI] [Google Scholar]

- Lesme H, Rannou C, Famelart M-H, Bouhallab S, Prost C. Yogurts enriched with milk proteins: Texture properties, aroma release and sensory perception. Trends Food Sci Technol. 2020;98:140–149. doi: 10.1016/j.tifs.2020.02.006. [DOI] [Google Scholar]

- Li J, Xu L, Su Y, Chang C, Yang Y, Gu L. Flocculation behavior and gel properties of egg yolk/κ-carrageenan composite aqueous and emulsion systems: effect of NaCl. Food Res Int. 2020;132:108990. doi: 10.1016/j.foodres.2020.108990. [DOI] [PubMed] [Google Scholar]

- Lucey JA, Singh H. Formation and physical properties of acid milk gels: a review. Food Res Int. 1997;30:529–542. doi: 10.1016/S0963-9969(98)00015-5. [DOI] [Google Scholar]

- Madhubasani G, Prasanna P, Chandrasekara A, Gunasekara D, Senadeera P, Chandramali D, Vidanarachchi J. Exopolysaccharide producing starter cultures positively influence on microbiological, physicochemical, and sensory properties of probiotic goats' milk set-yoghurt. J Food Process Preserv. 2020;44:e14361. doi: 10.1111/jfpp.14361. [DOI] [Google Scholar]

- Mahomud MS, Katsuno N, Nishizu T. Formation of soluble protein complexes and yoghurt properties influenced by the addition of whey protein concentrate. Innov Food Sci Emerg Technol. 2017;44:173–180. doi: 10.1016/j.ifset.2017.05.010. [DOI] [Google Scholar]

- Mortazavian, A. M. and Sohrabvandi, S. (2004). Sensory characteristics of yogurt, A.M. Mortazavian (Ed.). Eta Publication, Iran [In Persian].

- Mwizerwa H, Abong GO, Okoth MW, Ongol MP, Onyango C, Thavarajah P. Effect of resistant cassava starch on quality parameters and sensory attributes of yoghurt. Curr Res Nutr Food Sci. 2017;5:353–367. doi: 10.12944/CRNFSJ.5.3.21. [DOI] [Google Scholar]

- Nagaoka S. Yogurt Production. In: Kanauchi M, editor. Lactic Acid Bacteria: Methods and Protocols. New York: Springer; 2019. pp. 45–54. [Google Scholar]

- Nguyen PT, Kravchuk O, Bhandari B, Prakash S. Effect of different hydrocolloids on texture, rheology, tribology and sensory perception of texture and mouthfeel of low-fat pot-set yoghurt. Food Hydrocoll. 2017;72:90–104. doi: 10.1016/j.foodhyd.2017.05.035. [DOI] [Google Scholar]

- Pakseresht S, Tehrani MM, Razavi SMA. Optimization of low-fat set-type yoghurt: effect of altered whey protein to casein ratio, fat content and microbial transglutaminase on rheological and sensorial properties. J Food Sci Technol. 2017;54:2351–2360. doi: 10.1007/s13197-017-2675-8. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Pang Z, Deeth H, Yang H, Prakash S, Bansal N. Evaluation of tilapia skin gelatin as a mammalian gelatin replacer in acid milk gels and low-fat stirred yogurt. J Dairy Sci. 2017;100:3436–3447. doi: 10.3168/jds.2016-11881. [DOI] [PubMed] [Google Scholar]

- Pavlou A, Melikidou I, Petridis D, Panayiotou C, Ritzoulis C. Winery by-product hydrocolloids as texture modifiers in yogurt formulations. J Culin Sci Technol. 2020;19:1–20. doi: 10.1080/15428052.2020.1768996. [DOI] [Google Scholar]

- Roefs SPFM, Van Vliet T. Structure of acid casein gels 2. Dynamic measurements and type of interaction forces. Colloids Surf. 1990;50:161–175. doi: 10.1016/0166-6622(90)80260-B. [DOI] [Google Scholar]

- Saha D, Bhattacharya S. Hydrocolloids as thickening and gelling agents in food: a critical review. J Food Sci Technol. 2010;47:587–597. doi: 10.1007/s13197-010-0162-6. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Saleh A, Mohamed AA, Alamri MS, Hussain S, Qasem AA, Ibraheem MA. Effect of different starches on the rheological, sensory and storage attributes of non-fat set yogurt. Foods. 2020;9:61. doi: 10.3390/foods9010061. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Sánchez L, Pérez MD, Parrón JA. HPP in dairy products: impact on quality and applications. In: Barba F, Tonello-Samson C, Puértolas E, Lavilla M, editors. Present and future of high pressure processing. 1. Amsterdam: Elsevier; 2020. pp. 245–272. [Google Scholar]

- Shaker RR, Jumah RY, Abu-Jdayil B. Rheological properties of plain yogurt during coagulation process: impact of fat content and preheat treatment of milk. J Food Eng. 2000;44:175–180. doi: 10.1016/S0260-8774(00)00022-4. [DOI] [Google Scholar]

- Snoeren T, Damman A, Klok H. The viscosity of skim-milk concentrate. Neth Milk Dairy J. 1982;36:305–316. [Google Scholar]

- Sodini I, Montella J, Tong PS. Physical properties of yogurt fortified with various commercial whey protein concentrates. J Sci Food Agric. 2005;85:853–859. doi: 10.1002/jsfa.2037. [DOI] [Google Scholar]

- Tamime AY, Robinson RK. Yoghurt: science and technology. 2end. New York: CRC Press; 1999. [Google Scholar]

- Tamime AY, Robinson RK. 5-Traditional and recent developments in yoghurt production and related products. In: Tamime AY, Robinson RK, editors. Tamime and Robinson's Yoghurt. 3. New York: CRC Press; 2007. pp. 348–467. [Google Scholar]

- Tang M-X, Zhu Y-D, Li D, Adhikari B, Wang L-J. Rheological, thermal and microstructural properties of casein/κ-carrageenan mixed systems. LWT. 2019;113:108296. doi: 10.1016/j.lwt.2019.108296. [DOI] [Google Scholar]

- Tribst AAL, Falcade LTP, Carvalho NS, de Oliveira MM. Using stirring and homogenization to improve the fermentation profile and physicochemical characteristics of set yogurt from fresh, refrigerated and frozen/thawed sheep milk. LWT. 2020;130:109557. doi: 10.1016/j.lwt.2020.109557. [DOI] [Google Scholar]

- Wang X, Kristo E, LaPointe G. The effect of apple pomace on the texture, rheology and microstructure of set type yogurt. Food Hydrocoll. 2019;91:83–91. doi: 10.1016/j.foodhyd.2019.01.004. [DOI] [Google Scholar]

- Wherry B, Barbano DM, Drake MA. Use of acid whey protein concentrate as an ingredient in nonfat cup set-style yogurt. J Dairy Sci. 2019;102:8768–8784. doi: 10.3168/jds.2019-16247. [DOI] [PubMed] [Google Scholar]

- Yemenicioğlu A, Farris S, Turkyilmaz M, Gulec S. A review of current and future food applications of natural hydrocolloids. Int J Food Sci Technol. 2020;55:1389–1406. doi: 10.1111/ijfs.14363. [DOI] [Google Scholar]

- Yildiz F. Development and manufacture of yogurt and other functional dairy products. New York: CRC Press/Taylor & Francis; 2010. [Google Scholar]

- Yousefi M, Jafari SM. Recent advances in application of different hydrocolloids in dairy products to improve their techno-functional properties. Trends Food Sci Technol. 2019;88:468–483. doi: 10.1016/j.tifs.2019.04.015. [DOI] [Google Scholar]

- Yousefi M, Khorshidian N, Hosseini H. An overview of the functionality of inulin in meat and poultry products. Nutr Food Sci. 2018;48:819–835. doi: 10.1108/NFS-11-2017-0253. [DOI] [Google Scholar]

- Zamberlin Š, Samaržija D. The effect of non-standard heat treatment of sheep’s milk on physico-chemical properties, sensory characteristics, and the bacterial viability of classical and probiotic yogurt. Food Chem. 2017;225:62–68. doi: 10.1016/j.foodchem.2017.01.001. [DOI] [PubMed] [Google Scholar]

- Żbikowska A, Szymańska I, Kowalska M. Impact of inulin addition on properties of natural yogurt. Appl Sci. 2020;10:4317. doi: 10.3390/app10124317. [DOI] [Google Scholar]

- Zhao L, Wang X, Tian Q, Mao X. Effect of casein to whey protein ratios on the protein interactions and coagulation properties of low-fat yogurt. J Dairy Sci. 2016;99:7768–7775. doi: 10.3168/jds.2015-10794. [DOI] [PubMed] [Google Scholar]