Abstract

The present study was conducted out to develop nutritionally enriched noodles by supplementing wheat flour with mushroom and chickpea starch at different concentrations and its effect on physico-chemical, bioactive, cooking, microbial and sensory properties, morphological and textural properties has been investigated. The prepared noodles contained high levels of protein, and low levels of carbohydrate, energy with the incorporation of mushroom flour and chickpea starch concentration. The lightness (L*) (71.79–53.84) decreased and yellowness (b*) (19.33–31.36) and redness (a*) (1.91–5.35) increased with the incorporation of mushroom flour and chickpea starch. The optimum cooking time decreased while as the water absorption capacity and cooking loss increased with increase in mushroom flour and chickpea starch concentration. The microstructure study and textural properties depicted the clear picture of protein network, with smooth outer surface, and the decrease in hardness with increased concentration of mushroom flour and chickpea starch. XRD and DSC results revealed that the prepared noodles contained more complete crystallites and high fraction of crystalline region and the linear increase in the gelatinization temperature with increase in composite flour concentration. The microbial analysis of noodles showed the decrease in microbial growth with the incorporation of composite flour.

Keywords: Mushroom, Noodles, Nutritional value, Microstructure, Shelf life, Chemical composition

Introduction

Mushroom is considered the functional food as it is low in fat and calories but rich source of protein and dietary fibers. Button mushroom (Agaricus bisporus) is widely produced and consumed throughout world, with a high nutritional content in various forms, and it accounts for roughly 40% of total global mushroom production (Ghahremani-Majd and Dashti 2015). The button mushroom is more popular among consumers, commands higher prices, but have higher nutritional value. Mushrooms are the most expensive vegetable not because of their nutritional content, but due its distinct aroma and flavour. Fresh mushrooms have an approximate moisture percentage of 85–95%, 3% protein, 4% carbohydrate, 0.3–0.4% fat, and 1% minerals and vitamins (Kumar et al. 2013). As mushrooms are highly perishable, the fresh fruiting bodies are subjected to various processing operations to increase their shelf life (Monika and Karuna 2018). Drying of mushrooms is carried out to eliminate free water in order to decrease the biochemical and microbiological activities attributed to reduced water activity.

Chickpea (Cicer arietinum) is a major legume due to its high economic importance and a major source of proteins and carbohydrates in the diets of people in India, Afghanistan, Turkey and Pakistan (Kaur and Singh 2005). After isolating proteins from beans, the starch is commonly neglected as a by-product. Starch is the most abundant carbohydrate present in chickpea and is considered to be competitive in food industries (Goni and Valentín-Gamazo 2003). It is due to higher amylose (30%) content present, which confer poor functional properties when compared with cereal starches and makes it beneficial for the utilization of diabetic foods (Anderson and Guraya 2006). Chickpea starch has been characterized by high solubility, water binding capacity, and low swelling power and pasting properties (Jagannadham et al. 2017).

Noodle can be used as food replacement of the staple food. It is mostly utilized for breakfast or side-dishes. The world consumption of noodles is second only to bread. Instant noodles are the utmost popular convenience food but are mostly under speculation for its nutritional profile and impact on human health. Amalgamation of chickpea starch and button mushroom powder in formulation of noodles and cookies will increase their protein content (Bindvi and Mridula 2014), and will impart desirable functional properties, modify texture, consistence, digestibility, and functionality (Ward et al. 2008). The practical applications of protein-rich ready-to-cook instant noodles are developed to meet the growing needs of families (Arora et al. 2018). Recent studies have evaluated the effect of mushroom powder on nutritional properties of developed noodles mostly but did not focus on the thermal, microstructural, textural characterization of mushroom developed products. Thus, the prime aim of the current study was to assess the effect of incorporation of button mushroom flour and chickpea starch on physico-chemical, bioactive, cooking, sensory properties, morphological, thermal and textural attributes of noodles.

Materials and methods

Procurement of raw material

Wheat flour, chickpea and salt were purchased from local market of Jammu, J&K, India and were used without any modifications.

Mushroom powder

Button mushroom (Agaricus bisporus) were selected, washed, and cut into thin slices. The sample was incorporated with 20% Soy protein isolate by adding 25 ml distilled to make it paste for proper mixing and dried freeze dryer. In freeze dryer, mushroom slices were frozen in a conventional freezer, and kept in a freeze-drier for 38 h at a temperature − 80 °C, and a pressure of 5 mTorr (0.666 Pa) till constant weight was attained followed by grinding using grinder. Freeze drying was done to reduce the heat damage to prepared mushroom samples than other drying methods.

Extraction of chickpea starch

The chickpea seeds were steeped overnight at 20 °C in deionized water with 0.2% sodium hydrogen sulphite and testa was physically removed thereafter. A mixture or blender was used to grind the decorticated grains. After that, the powdered slurry was filtered using100-mesh sieve before being centrifuged at 2000 rpm for 10 min. Using distilled water, the sediment was completely cleaned. The washing procedure was continued until the starch became colourless and the supernatant had become clear. The starch was then collected and dried in a 40 °C oven for 12 h.

Noodle processing

Noodle dough was prepared by thoroughly blending all ingredients: wheat flour, mushroom powder, chickpea starch, and salt (2.5%) in a Kent noodle & pasta maker (Model no. 16009 from Kent RO System Ltd. (India)) and adding water to form dough up to the cleanup step. After that, the dough was covered and left for around 30 min to achieve equilibrium and consistent hydration. To enhance flexibility and elasticity, the dough (100 g) was sheeted 10 times manually. The noodle-making machine was then used to prepare the noodles. Each strand of noodle was 1.5 × 1.5 mm wide (thickness × width). The collected noodles were cooked in a steamer for 5 min before drying. The noodles were dried at 105 °C in a hot air oven for 10 min. After that, the samples were placed in LDPE plastic bags.

Physico-chemical properties of noodles

The AOAC (2012) technique was used to determine the moisture content, crude protein content, fat content, ash content, total carbohydrate content, and energy content of noodle samples.

Water activity (aw)

The sample was filled (3/4th) in a cup of water activity meter (Aqua lab Pre, Decagon Device, USA). Water activity meter was calibrated as per the instruction given in manual calibration. The sample was kept in a cup till constant reading was obtained.

Hunter colour value

Colour was measured in terms of L*, a*, and b* values, with L* denoting lightness/whiteness, a* denoting redness/greenness, and b* denoting yellowness/blueness. A typical black tile was used to calibrate the device, followed by a white tile. The L*, a*, and b* readings were recorded using a sample handling plate filled with dried powder and placed on the analyzing port.

Cooking properties of developed noodles

Cooking loss

The amount of solids lost in cooking water was used to compute sample cooking loss. In the beaker, 10 g of sample was added in 300 ml boiling water. The cooking water was then collected in an aluminium dish and dried in the oven at 105 °C. The residue was weighed and calculated as a percentage of initial material. The following formula (Eq. 1) was used to compute the cooking loss.

| 1 |

Water absorption capacity

The water absorption capacity was evaluated according to the AOAC (2012) technique. The weight of cooked noodle samples was divided by the weight of noodle samples before cooking to measure water absorption. The water absorption was evaluated using Eq. (2).

| 2 |

Cooking time

The cooking time was computed using the AOAC (2012) technique. The disappearance of the opaque centre during the cooking of noodle samples in water was used to estimate the cooking time. The sample (5 g) was mixed with 75 mL distilled water in a beaker. Every 30 s, noodle strands were pressed between two glass plates. The optimal cooking time was evaluated when the white bubble response of the cooked noodle samples subsided,

Sensory evaluation

The sensory evaluation of different noodle samples was conducted using 9-point hedonic scale.

Bioactive properties of developed noodles

Total phenolic content

The total phenolic content was determined Folin-Ciocalteu technique following the method suggested by Wani and Basir (2018). The gallic acid standard curve was used to calculate TPC, and the findings were expressed as mg of gallic acid equivalents (GAE) per gram of dry weight.

DPPH radical scavenging activity

The DPPH radical scavenging activity was measured using method given by Wani and Basir (2018), with few alterations. The extract (0.2 mL) was combined with a DPPH solution (3.8 mL) (0.1 mM DPPH in methanol). The prepared mixture was left to incubate for 30 min in the dark at room temperature. In a UV–visible spectrophotometer, the sample's absorbance was measured at 517 nm after incubation. The radical scavenging activity of DPPH was calculated using the formula stated in Eq. (3).

| 3 |

where Ac represented absorbance of the control, A is the absorbance of sample.

IC50 value (Concentration of sample extract necessary to inhibit 50% DPPH activity) was obtained from the graph plotted between each concentration and percentage inhibition.

Reducing power activity assay

The reducing power activity assay of samples was evaluated by a technique mentioned by Wani and Basir (2018), for calculating the reducing powder. The standard curve was plotted using various amounts of ascorbic acid. g ascorbic acid per g dry weight was used to represent the reducing powder. The reducing powder was represented by µg ascorbic acid per g dry weight.

Texture profile analysis

The noodle sample (30 g) was cooked in 300 ml boiling water for 8 min, then cooled for 30 s before being held for 2 min to drain the excess water. To examine texture profiles, 50 mm long and 1.5 mm thick noodles were made using a texture analyzer (TA HD-plus, Stable Micro Systems Ltd., Surrey, UK). A cylindrical probe (T/36R) with a diameter of 36 mm was used. The test settings were 1 mm/s pre-test speed, 5 mm/s post-test speed, 1 mm/s test speed, 20 g trigger force, and 80% strain. The parameters investigated were adhesiveness, hardness, springiness, cohesiveness, chewiness, and gumminess (Kang et al. 2017).

Differential scanning calorimetry

The thermal properties of the sample were examined using a Differential Scanning Calorimeter (DSC-7, PerkinElmer, Norwalk, CT) as given by González et al. (2007), with a few modifications. In an aluminum pan, 2 g of sample was measured, then distilled water was added with a Hamilton micro syringe to generate a 70% water aqueous suspension, which was sealed and equilibrated for 1 h at ambient temperature before analysis. The gadget was calibrated using indium, with an empty aluminum pan serving as a reference. The sample pans were then heated at a rate of 10 °C/min from 20 to 160 °C. The gelatinization enthalpy (H), onset (To), peak (Tp), and conclusion temperature (Tc) were evaluated from the obtained data.

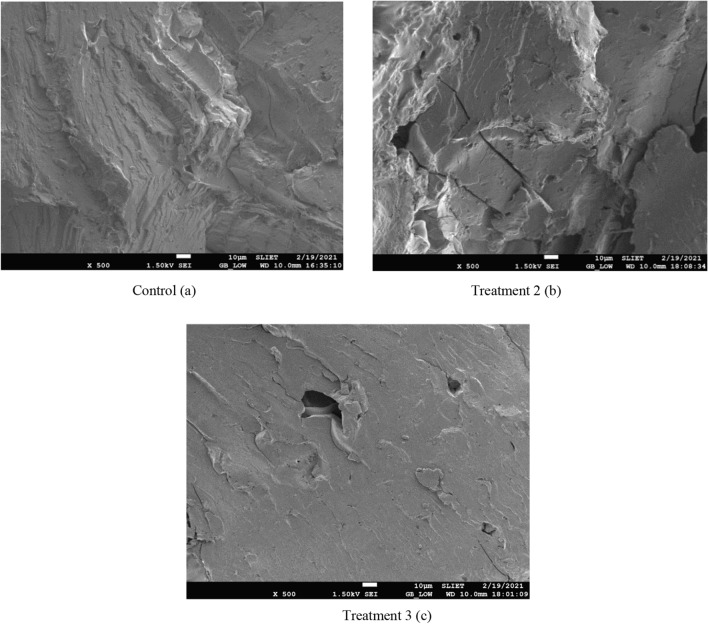

Scanning electron microscopy (SEM)

The dry noodle samples were cross-split with a sharp blade, then placed on colloidal graphite specimen holders, sputter-coated with gold, and observed at a magnification of 500 using a scanning electron microscope (Model: JSM7610F-plus by Jeol). The number and size of pores in the experimental and control samples were analysed. The SEM images were processed using the MATLAB 7.0 image analysis programme (MathWorks, USA).

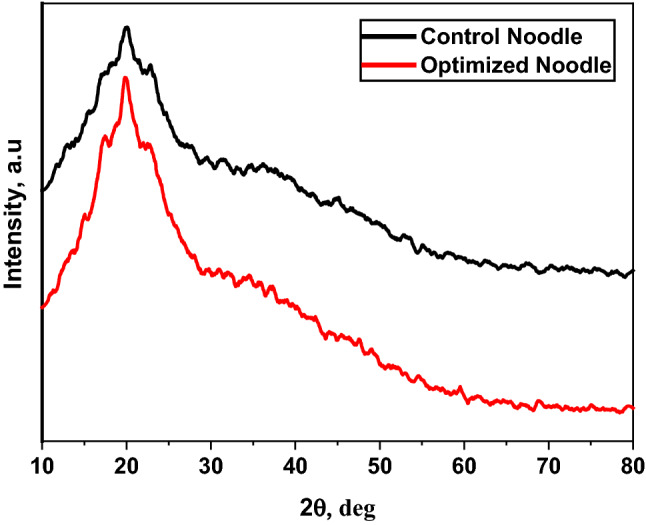

Structural characterization by X-ray diffraction

The XRD patterns of noodles were created using an X-ray diffractometer (Panalytical, The Netherlands) equipped with Cu-K radiation at a wavelength of 1.5406 Å. Measurements were taken at room temperature with a step size of 0.016°, a scanning rate of 20 s per step, and a diffraction angle range of 10–100° (2−θ°), where θ represents the angle of incidence of the X-ray beam on the sample. The diffraction patterns were examined using EVA software.

Statistical analysis

All samples were made in pairs and tested at different carrier agent concentrations. The results were presented using means and standard deviations. The significant differences between the samples were investigated using one way post-hoc ANOVA test at 5% level of significance. All statistical analyses were carried out using SPSS software.

Results and discussion

Physico-chemical properties of developed noodles

The moisture content, crude protein content, fat content, ash content, total carbohydrate content, and energy content of noodle samples are presented in Table 1. However, the energy content decreased from treatment Tc to treatment of T2 having value of 381.13 to 379.07 kcal/100 g, while as the total energy content was increased in treatment T3 and treatment T4 having value of 379.95 and 380.32 kcal/100 g respectively. The results, however, revealed that the variation in energy content between formulations was not statistically significant (p > 0.05). Same trend was also observed by Parvin et al. (2020). As the energy value depends on crude fat and crude protein content which are decreasing with the incorporation of mushroom flour in macaroni, thus a reduction in energy value was found (Chauhan et al. 2017). However, Torres et al. (2007) showed that spaghetti enriched with germinated pigeon pea flour depicted an increase in the calorific value when compared to the control spaghetti (320 kcal/100 g).

Table 1.

Physico-chemical properties of button mushroom powder and chickpea starch-based noodles

| Treatments (WF:BMP:CS) | Moisture content (%) | Crude Fat content (%) | Crude Protein content (%) | Ash content (%) | Carbohydrate content (%) | Energy content (Kcal/100 g) | Water activity |

|---|---|---|---|---|---|---|---|

| Tc (100:0:0) | 5.27 ± 0.21a | 0.93 ± 0.02a | 9.97 ± 0.18a | 0.61 ± 0.02a | 83.22 ± 0.01a | 381.13 ± 0.89a | 0.449 ± 0.006a |

| T1 (90:5:5) | 4.91 ± 0.06b | 0.87 ± 0.05b | 14.36 ± 0.23b | 0.98 ± 0.02b | 78.88 ± 0.25b | 380.79 ± 0.43ab | 0.428 ± 0.006b |

| T2 (80:10:10) | 4.33 ± 0.20c | 0.63 ± 0.02b | 16.58 ± 0.26c | 1.69 ± 0.04c | 76.77 ± 0.13c | 379.07 ± 0.75bc | 0.401 ± 0.006c |

| T3 (70:15:15) | 3.83 ± 0.07d | 0.55 ± 0.02d | 19.36 ± 0.31d | 1.87 ± 0.03d | 74.39 ± 0.29d | 379.95 ± 0.30bc | 0.381 ± 0.008d |

| T4 (60:20:20) | 3.58 ± 0.06e | 0.48 ± 0.04e | 21.43 ± 0.28e | 1.94 ± 0.02e | 72.57 ± 0.28e | 380.32 ± 0.36ab | 0.373 ± 0.003e |

WF Wheat flour, BMP Button Mushroom powder, CS Chickpea starch

Different letters in the same column indicate statistical significance differences (p < 0.05)

Water activity

The data pertaining to the water activity of button mushroom powder and chickpea starch based noodles in Table 1 showed that water activity varied significantly (p < 0.05) with treatments. The higher water activity of 0.449 was observed in treatment Tc and the lower water activity of 0.373 was observed in treatment T4. Similar trend was also observed by Vadukapuram et al. (2014) in flaxseed fortified extruded snacks using pinto and navy corn.

Colour profile

Colour is an important parameter affecting the consumer acceptability of the foods. The colour values of button mushroom powder and chickpea starch-based noodles was measured in terms of Hunter L* (lightness), a* (redness) and b* (yellowness). Table 2 depicted the impact of treatments on L*, a* and b* values on button mushroom powder and chickpea starch-based noodles. The L* value of the noodles decreased while as the a* and b* values increased significantly (p < 0.05) with the incorporation of mushroom powder and chickpea starch. The highest L* value of 71.79 was observed in treatment Tc and the lowest L* value of 53.84 was observed in treatment T4. While as the lowest a* and b* values of 1.91 and 19.33 was recorded in treatment Tc respectively, and the highest a* and b* values of 5.35 and 31.36 was observed in treatment T4 respectively. Same trend was also obtained by Nordiana et al. (2019) who observed that the incorporation of mushroom flour into the developed pasta resulted in low L* values as compared to control sample, the lightness of the pasta was found between 44.28 to 52.60 L* values whereas the control pasta had L* value of 56.08. Oliver et al. (1993) also observed that the fortification of pasta with mushroom resulted in a decreased brightness (L* value) of uncooked pasta, may be due to the high moisture of mushroom and ash content of semolina.

Table 2.

Colour, Cooking, Sensory and microbial properties of button mushroom powder and chickpea starch-based noodles

| Treatments (WF:BMP:CS) | L* | a* | b* | Cooking loss (%) | Water absorption capacity (%) | Cooking time (minutes) | Overall acceptability | Microbial evaluation (× 103 c.f.u/g) |

|---|---|---|---|---|---|---|---|---|

| Tc (100:0:0) | 71.79 ± 0.49a | 1.91 ± 0.07a | 19.33 ± 0.29a | 4.19 ± 0.03a | 103.66 ± 0.40a | 7.32 ± 0.11a | 8.02 ± 0.50a | 0.42 ± 0.06a |

| T1 (90:5:5) | 69.58 ± 0.40b | 3.49 ± 0.06b | 25.41 ± 0.37b | 4.32 ± 0.14b | 114.54 ± 0.44b | 6.56 ± 0.26b | 7.78 ± 0.61a | 0.40 ± 0.08b |

| T2 (80:10:10) | 61.34 ± 0.75c | 3.85 ± 0.15c | 28.03 ± 0.45c | 4.73 ± 0.07c | 125.89 ± 0.51c | 5.27 ± 0.17c | 8.25 ± 0.37a | 0.37 ± 0.01c |

| T3 (70:15:15) | 59.52 ± 0.34d | 4.76 ± 0.15d | 30.82 ± 0.11d | 4.91 ± 0.07d | 135.91 ± 0.44d | 4.69 ± 0.27d | 7.64 ± 0.64a | 0.34 ± 0.01d |

| T4 (60:20:20) | 53.84 ± 0.20e | 5.35 ± 0.25e | 31.36 ± 0.71d | 5.24 ± 0.11e | 152.69 ± 0.478e | 4.35 ± 0.20e | 6.56 ± 0.26b | 0.32 ± 0.01e |

WF Wheat flour, BMP Button Mushroom powder, CS Chickpea starch

Different letters in the same column indicate statistical significance differences (p < 0.05)

While as, an increased a* values were found in spaghetti fortified with durum wheat (Aravind et al. 2012). Chauhan et al. (2017) also observed the similar pattern with an increase in a* and b* values in pasta developed from button mushroom and durum wheat semolina.

Cooking properties of developed noodles

Cooking loss

Cooking loss measures the weight of the total solid lost in cooking water. Table 2 showed the impact of treatments on cooking loss of button mushroom powder and chickpea starch-based noodles. With increase in mushroom powder and chickpea starch concentration, the cooking loss increased significantly (p < 0.05). The lowest cooking loss of 4.19% was recorded in treatment Tc and the highest cooking loss of 5.24% was observed in treatment T4. Cooking loss might be caused by a poor protein-starch interaction or a broken protein matrix between mushroom protein and wheat flour. Cooking loss was also enhanced in noodle supplemented with pea flour and defatted soy flour (Kaur et al. 2013). As the mushroom quantity increased, cooking losses can also be increased, which can be attributed to the mushroom's weak protein network (Chauhan et al. 2017). The major source of cooking loss in noodles can be due to the solubilization of weakly bound gelatinized starch on the noodle surface (Sung and Stone 2004).

Water absorption capacity

The impact of treatments on water absorption capacity of button mushroom powder and chickpea starch-based noodles is shown in Table 2. The data depicted that the water absorption capacity of noodles was significantly increased (p < 0.05) with increase in mushroom powder and chickpea starch. The lowest water absorption capacity of 103.66% was recorded in treatment Tc and the highest water absorption capacity of 152.69% was observed in treatment T4. The incorporation of mushroom powder to wheat flour enhanced the water absorption of the noodles, according to Parvin et al. (2020). This increase might be ascribed to the enriched fiber's increased capacity for water absorption and retention in the starch protein-polysaccharide network, causing the starch granules to enlarge. Similarly, Arora et al. (2018) discovered that adding mushroom powder to noodles improved their water absorption while cooking.

Cooking time

The effect of treatments on the cooking time of button mushroom powder and chickpea starch based noodles is depicted in Table 2. Cooking time was recorded to be greatly reduced as mushroom powder and chickpea starch concentrations were increased. Treatment Tc had the longest cooking time of 7.32 min and treatment T4 had the shortest cooking time of 4.35 min. The decrease in cooking time with the addition in mushroom flour concentration was also reported in previous studies (Wahyono and Bakri 2018). The decrease in cooking time with incorporation of mushroom flour might be due to the fact that adding mushroom flour lowered the quantity of gelatinized starch, possibly resulting in a loss of protein-starch network stability (Nordiana et al. 2019).

Sensory evaluation

Table 2 depicted the impact of treatments on overall acceptability of button mushroom powder and chickpea starch-based noodles. The higher overall acceptability score of 8.25 was observed in treatment T2. The variation on overall acceptability score of prepared noodles might be due to colour, texture and taste associated with the mushroom flour and chickpea starch. Same trend was also observed by Nordiana et al. (2019) who prepared pasta using mushroom flour. It was also revealed that certain attributes, like taste and overall acceptability, the mean scores of the noodles of treatment T2 were high as compared to the control sample.

Bioactive properties of developed noodles of noodles

Total phenolic content

The Table 3 depicted the impact of treatments on button mushroom powder and chickpea starch-based noodles. The lower total phenolic content of 14.56 mg GAE/100 g was recorded in treatment Tc and the highest total phenolic content of 17.45 GAE/100 g was observed in treatment T4. It was depicted that the total phenolic content was increased with increase in mushroom powder and chickpea starch. The decrease in total phenolic content with decrease in mushroom flour concentration in meat analog nuggets was observed by Bashir (2019). The increase in the phenol content of macroni with the increased mushroom concentration was also reported by Chauhan et al. (2017). Phenols are the major compounds in fresh mushroom which protects from free radicals which cause oxidative stress.

Table 3.

Bioactive properties of button mushroom powder and chickpea starch-based noodles

| Treatments (WF:BMP:CS) | Total phenol content (mg GAE/g) | DPPH scavenging activity (IC50; mg/ml) | Reducing power (EC50; mg/ml) |

|---|---|---|---|

| Tc (100:0:0) | 14.56 ± 0.15a | 0.45 ± 0.09a | 3.49 ± 0.08a |

| T1 (90:5:5) | 15.88 ± 0.22b | 0.38 ± 0.02b | 3.27 ± 0.05b |

| T2 (80:10:10) | 16.01 ± 0.28bc | 0.28 ± 0.02c | 3.01 ± 0.05c |

| T3 (70:15:15) | 16.26 ± 0.29bc | 0.21 ± 0.03d | 2.94 ± 0.02d |

| T4 (60:20:20) | 17.45 ± 0.08d | 0.13 ± 0.03e | 2.12 ± 0.11e |

WF Wheat flour, BMP Button Mushroom powder, CS Chickpea starch

Different letters in the same column indicate statistical significance differences (p < 0.05)

Antioxidant activity

Antioxidants are vital components possessing the ability to scavenge free radicals which can cause several degenerative diseases. The antioxidant activity of button mushroom powder and chickpea starch based noodles was measured in terms of DPPH scavenging activity and reducing power and were expressed in terms of IC50 (mg/ml) and EC50 (mg/ml) respectively. The lower values of IC50 and EC50 depicted higher DPPH scavenging activity and reducing power respectively. The data pertaining to the DPPH scavenging activity of noodles in Table 3 showed that the treatments had a significant impact on DPPH scavenging activity. The noodles prepared with higher concentration of mushroom depicted least IC50 value for DPPH scavenging activity and consequently higher antioxidant activity as compared to the noodles prepared with wheat flour. The lowest IC50 value of 0.13 mg/ml was recorded in treatment T4 while as the highest IC50 value of 0.45 was observed in treatment Tc. Also, the perusal data in Table 3 depicted that the reducing power of noodles varied significantly (p < 0.05) with treatments. Similarly, the noodles prepared with higher concentration of mushroom exhibited least EC50 value for DPPH scavenging activity and consequently higher antioxidant activity as compared to the noodles prepared with wheat flour. As depicted in Table 3, the lowest EC50 value of 2.12 mg/ml was recorded in treatment T4 while as the highest EC50 value of 3.49 was observed in treatment Tc. Antioxidant activity was increased with the incorporation of mushroom flour in noodles. This may be due to the inherent antioxidant components of mushrooms (Arora et al. 2018). The increase in antioxidant activity of macroni (pasta) with the increased mushroom concentration was also reported in previous studies (Oszmianski and Wojdyło 2009).

Texture profile analysis

The textural properties of noodles made from wheat flour, mushroom powder, and chickpea starch are depicted in Table 4. The wheat flour control sample had higher values for the majority of the textural attributes, indicating a clear trend. The hardness value, which represents the force required to chew through the mass of the noodle, was revealed to range between 3608.267 and 9050.2 g. The noodles made from wheat flour had a hardness value of 9050.2 g. The primary factor governing the hardness in wheat based noodles was the strength of the gluten network. As the concentration of mushroom powder and chickpea starch was increased, the hardness values of the noodles were decreased significantly (p < 0.05). The drop in hardness value might be due to the decrease in the strength of the gluten network of the mushroom powder and chickpea starch substituted noodle. The area under the force–time curve following the first compression was considered to evaluate adhesiveness. The higher viscosity of chickpea starch in comparison to wheat flour could be attributed to the strong adhesiveness of the noodle sample containing mixture of wheat flour, mushroom powder, and chickpea starch. The springiness continued in reduction in accordance with increased substitution levels of mushroom powder and chickpea starch. Following the hardness trend, gumminess and chewiness decreased, while mushroom powder and chickpea starch concentrations increased. This trend might be attributed to higher cooking loss values. The indicators of cohesion and springiness of mushroom powder and chickpea starch integrated noodles were significantly different (p < 0.05) from the control. Cohesiveness and springiness were characteristics that evaluated how well the sample remained or hold together after cooking. In this case, the cohesiveness and springiness of the mushroom powder and chickpea starch incorporated noodles were low than in the control sample. dos Reis Correia et al. (2017) also reported the decrease in the textural parameters with the incorporation of mushroom powder in pasta. It was reported that the reduction of textural parameters such as adhesiveness stickiness and firmness can be due to the presence of fibre content in mushroom powder which may disrupt the protein-starch matrix of pasta (dos Reis Correia et al. 2017). It was also observed that the fortification of extruded snack products with chestnut mushrooms results in decrease in hardness with increase in mushroom powder levels (Brennan et al. 2012). The supplementation of semolina with mushrooms can decrease the hardness, as the hardness and stickiness are related to the percentage of starch and starch gelatinization (Chauhan et al. 2017).

Table 4.

Textural properties of wheat flour, mushroom powder and chickpea starch-based noodles

| Treatments (WF:BMP:CS) | Hardness (g) | Adhesiveness (g sec) | Springiness | Cohesiveness | Gumminess | Chewiness | Resilience |

|---|---|---|---|---|---|---|---|

| Tc (100:0:0) | 9050.200 ± 12.239a | − 41.567 ± 1.794a | 0.590 ± 0.023a | 0.687 ± 0.017a | 6217.487 ± 37.627a | 3668.318 ± 28.614a | 0.338 ± 0.013a |

| T1 (90:5:5) | 7795.062 ± 11.471b | − 54.096 ± 2.681b | 0.520 ± 0.019b | 0.547 ± 0.031b | 4263.899 ± 18.835b | 2217.227 ± 14.719b | 0.309 ± 0.007b |

| T2 (80:10:10) | 5905.504 ± 18.575c | − 67.563 ± 1.917c | 0.460 ± 0.014c | 0.492 ± 0.018c | 2905.508 ± 24.691c | 1336.534 ± 12.925c | 0.284 ± 0.017c |

| T3 (70:15:15) | 4837.935 ± 9.701d | − 75.924 ± 1.825d | 0.410 ± 0.027d | 0.453 ± 0.015d | 2191.585 ± 13.572d | 898.550 ± 8.495d | 0.261 ± 0.015d |

| T4 (60:20:20) | 3608.267 ± 6.829e | − 89.559 ± 2.572e | 0.380 ± 0.011e | 0.418 ± 0.024e | 1508.256 ± 21.849e | 573.137 ± 5.826e | 0.239 ± 0.012e |

WF Wheat flour, BMP Button Mushroom powder, CS Chickpea starch

Different letters in the same column indicate statistical significance differences (p < 0.05)

Gelatinization behaviour of noodles by differential scanning calorimetry

The differential scanning calorimetry study in five different types of noodles indicated a change in the heat flow rate to the sample when subjected to temperature alteration. The thermal transitions of various noodles prepared from wheat flour, mushroom powder, and chickpea starch indicated a single endotherms peak in the temperature range of 40–160 °C (Table 5). As compared to mushroom powder and chickpea starch integrated noodles, the control sample made from wheat flour had low gelatinization peak temperature. With increase in concentration of mushroom powder and chickpea starch, the onset gelatinization temperature was progressively increased from 61.69 to 73.87 °C. The conclusion gelatinization temperature for the five different samples was raised from 74.91 to 88.07 °C. The increase of gelatinization temperature was directly proportional to change in mushroom powder, and chickpea starch percent in the noodle formulation. The gelatinization peak temperature was enhanced in the presence of mushroom powder and chickpea starch. The results depicted that increasing the quantity of chickpea starch in the flour decreased its water activity, causing gelatinization and hardening of the flour. The incorporation of mushroom powder and chickpea starch to the finished product may change its arrangement and crystallinity which ultimately affected the gelatinization temperature in different formulations. It was observed that a sample containing 20% mushroom powder and 20% chickpea starch required high melting temperatures, resulting in a more stable product during heating. This suggested that this product (T4) had a higher crystalline order than the other four samples. The noodle with mushroom powder and chickpea starch showed greater enthalpy values than the control sample. The wheat flour-based noodle had an enthalpy value of 9.34 J/g starch. Lower ΔHg values in the control sample suggested that less endothermic energy was consumed to complete the gelatinisation transition. Lu et al. (2018) also observed that increasing mushroom powder can increase ΔH values of mushroom-enriched pasta as compared to control semolina pasta. Similarly, Ismail et al. (2021) observed that the noodle sample can form well-defined endothermic peak ranging from 101.25 to 115.91 °C reflecting the overall gelatinization event.

Table 5.

Differential scanning calorimetry of wheat flour, mushroom powder, and chickpea starch-based noodles

| Treatments (WF:BMP:CS) | Onset temperature To | Conclusion temperature Tc | Peak temperature Tp | Enthalpy of gelatinization ΔHg J/g |

|---|---|---|---|---|

| Tc (100:0:0) | 61.69 | 66.63 | 74.91 | 9.34 |

| T1 (90:5:5) | 65.73 | 70.20 | 77.74 | 11.78 |

| T2 (80:10:10) | 68.77 | 73.87 | 81.55 | 12.22 |

| T3 (70:15:15) | 71.81 | 76.93 | 85.35 | 13.66 |

| T4 (60:20:20) | 73.87 | 77.57 | 88.07 | 15.96 |

Scanning electron microscopy (SEM)

Scanning electron microscopy of the control and button mushroom flour and chickpea starch incorporated noodles are depicted in Fig. 1a, b, c. All the micrographs reveal the effect of the inclusion of pea starch powder on the morphological changes during noodle preparation. The uniform pattern could be seen in the surface microstructure with the amalgamation of starch granules with numerous small cavities resulting in the formation of porous structure. The micrograph reveals the presence of smooth surface with huge mass of protein -starch matrix. The intermixing of starch granules with gluten network might have resulted in the development of compact structural orientation. The clear picture of protein network with smooth outer surface was also observed by Chauhan et al. (2017). However, the micrographs in Fig. 1b reflect the presence of much fractured surface microstructure as compared to control sample Fig. 1a with much bigger cavities with the incorporation of chickpea starch flour. The micrograph reveals the presence of more disintegrated starch protein network. The disintegrated structural orientation may be responsible for more crisp textural attributes of the noodles. The similar pattern of well-formed starch-protein matrix of bread crumb having strong and complex connection in all the components, with some few cavities was also observed by Lu et al. (2021).

Fig. 1.

Scanning electron microscopy of button mushroom noodles

In the micrograph Fig. 1c, it can be seen that with increasing concentration of mushroom powder and chickpea starch flour there is development of more compact and uniform structural orientation with big cavity surrounded by two smaller cavities with no prominent disintegration of the chick pea starch and mushroom protein network. This may be due to the increase in the level of chickpea starch concentration imparting strong network formation attributed to the high binding property of chick pea starch resulting in the formation of uniform appearance of the surface microstructure of the noodles prepared from fortified from mushroom and chick pea starch. The similar findings were also supported by Cleary and Brennan (2006).

Structural characterization by X-ray diffraction

The diffractogram of both control and optimized noodle samples are shown in Fig. 2. Table 6 summarizes the findings of X‐ray diffraction analysis of control sample and optimized noodles made from wheat flour (60%), mushroom powder (20%), and chickpea starch (20%) extracted from several wheat varieties. The wheat flour noodle had a well-defined peak at 20.160, however the optimized noodle had modest displacement of the peak position (20.207), as illustrated in Table 6. The peak width is broader in case of control as well as optimized sample.as reflected from the diffractogram Fig. 2. It was revealed that both the samples are moreover amorphous and slightly crystalline in nature. The heat and shear during the noodle preparation process might had disrupted the crystallinity of the raw material. The narrow crystal line and incomplete crystallites contained in the amorphous structure were attributed to the wide diffraction, which showed changes in amorphous and crystalline regions caused by re-crystallization (Zhang et al. 2014). Pourmohammadi et al. (2019) also reported that the crystallinity of noodle containing corn and wheat resistant starch depicted the highest diffraction peak in the region of (15.21°, 17.05°, 20.45° and 22.42° 2θ) and (15.3°, 17°, 20.3° and 23.35° 2θ) peaks, respectively.

Fig. 2.

X-ray Diffraction of wheat flour, mushroom powder, and chickpea starch based noodles

Table 6.

X-ray Diffraction of wheat flour, mushroom powder, and chickpea starch-based noodles

| Sample | , deg | , deg | , rad | , rad | FWHM, rad | Beta, rad | D, rad |

|---|---|---|---|---|---|---|---|

| Control | 20.160 | 10.080 | 0.176 | 0.985 | 8.902 | 0.155 | 0.906 |

| Optimized | 20.207 | 10.104 | 0.176 | 0.984 | 8.451 | 0.148 | 0.955 |

Conclusion

The incorporation of button mushroom powder and chickpea starch improved the nutritional, bioactive, cooking, microstructure, textural and thermal properties of fortified noodles linearly without degrading the palatability aspects. There was increase in protein content and ash content from 9.97 to 21.43%, and 0.61–1.94% respectively. Total phenolic content was also observed to be increased from 14.56–17.45 mg/GAE/g. However, cooking time was observed to be decreased from 7.32 to 4.35 min while as cooking loss and water absorption capacity was found to be increased from 4.19–5.24 and 103.66–152.69% respectively. The gumminess, springiness, and chewiness of the noodles was found to be decreased significantly with increase in the concentration of mushroom powder and chickpea starch. The incorporation of mushroom powder was found to improve sensorial attributes of taste, colour and texture with good acceptability at 10% mushroom powder concentration. Thus, noodles can be a better source of nutritionally enriched instant food.

Acknowledgements

All authors are thankful to the Indian Council of Medical Research, for award of ICMR-Fellowship 2019 in favour of Ms. Rafeeya Shams (vide grant no. ICMR/SRF- 3/1/2/131/2019-(Nut).

Abbreviations

- PEM

Protein efficiency malnutrition

- DSC

Differential scanning calorimetry

- SEM

Scanning electron microscopy

- XRD

X-ray diffraction

Author contributions

RS, JS, KKD and AHD contributed to the conception and design of the study. JS and AHD proposed the title of the manuscript. RS wrote the original draft of the manuscript. JS, KKD, AHD and PSP have revised the manuscript critically. All authors collated papers, read and approved the final version of the manuscript.

Funding

The first author had received ICMR -Fellowship, 2019 (vide grant no.ICMR/SRF-3/1/2/131/2019-(Nut) for conducting this research.

Data availability

Data will be made available on reasonable request.

Declarations

Conflict of interest

There is no competing interest between the authors.

Consent for publication

Not Applicable.

Ethical approval

Not Applicable.

Consent to participate

Not Applicable.

Footnotes

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Contributor Information

Rafeeya Shams, Email: rafiya.shams@gmail.com.

Aamir Hussain Dar, Email: daraamirft@gmail.com.

References

- Anderson AK, Guraya HS. Effects of microwave heat-moisture treatment on properties of waxy and non-waxy rice starches. Food Chem. 2006;97(2):318–323. doi: 10.1016/j.foodchem.2005.04.025. [DOI] [Google Scholar]

- Aravind N, Sissons M, Egan N, Fellows C. Effect of insoluble dietary fibre addition on technological, sensory, and structural properties of durum wheat spaghetti. Food Chem. 2012;130(2):299–309. doi: 10.1016/j.foodchem.2011.07.042. [DOI] [Google Scholar]

- Arora B, Kamal S, Sharma VP. Nutritional and quality characteristics of instant noodles supplemented with oyster mushroom (P. ostreatus) J Food Process Preserv. 2018;42(2):e13521. doi: 10.1111/jfpp.13521. [DOI] [Google Scholar]

- AOAC . Official methods of analysis of the association analytical chemists. 18. Gaithersburg, USA: AOAC International Official Method; 2012. [Google Scholar]

- Bashir N (2019) Formulation and evaluation of functional met analog based on mushroom, flaxseed and amaranth. Ph. D. Thesis, Sher-e Kashmir university of agricultural sciences and technology- Jammu

- Bindvi A, Mridula D. Nutritional and sensory properties of mushroom fortified corn extrudates. Mushroom Res. 2014;23(1):89–97. [Google Scholar]

- Brennan MA, Derbyshire E, Tiwari BK, Brennan CS. Enrichment of extruded snack products with coproducts from chestnut mushroom (Agrocybe aegerita) production: interactions between dietary fiber, physicochemical characteristics, and glycemic load. J Agric Food Chem. 2012;60:4396–4401. doi: 10.1021/jf3008635. [DOI] [PubMed] [Google Scholar]

- Chauhan N, Vaidya D, Gupta A, Pandit A. Fortification of pasta with white button mushroom: functional and rheological properties. Int J Food Ferment Technol. 2017;7(1):87–96. doi: 10.5958/2277-9396.2017.00008.3. [DOI] [Google Scholar]

- Cleary L, Brennan C. The influence of a (1→ 3) (1→ 4)-β-d-glucan rich fraction from barley on the physico-chemical properties and in vitro reducing sugars release of durum wheat pasta. Int J Food Sci Technol. 2006;41(8):910–918. doi: 10.1111/j.1365-2621.2005.01141.x. [DOI] [Google Scholar]

- dos Reis Correia PM, Esteves SA, Guiné RPF (2017) Effect of mushroom powder in fresh pasta development. In: Baltic conference on food science and technology: conference proceedings. LLU

- Ghahremani-Majd H, Dashti F. Chemical composition and antioxidant properties of cultivated button mushrooms (Agaricus bisporus) Hortic Environ Biotechnol. 2015;56(3):376–382. doi: 10.1007/s13580-015-0124-z. [DOI] [Google Scholar]

- Goni I, Valentín-Gamazo C. Chickpea flour ingredient slows glycemic response to pasta in healthy volunteers. Food Chem. 2003;81(4):511–515. doi: 10.1016/S0308-8146(02)00480-6. [DOI] [Google Scholar]

- González R, Carrara C, Tosi E, Añon MC, Pilosof A. Amaranth starch-rich fraction properties modified by extrusion and fluidized bed heating. LWT Food Sci Technol. 2007;40(1):136–143. doi: 10.1016/j.lwt.2005.09.003. [DOI] [Google Scholar]

- Ismail MH, Lik HC, Routray W, Woo MW. Determining the effect of pre-treatment in rice noodle quality subjected to dehydration through hierarchical scoring. Processes. 2021;9(8):1309. doi: 10.3390/pr9081309. [DOI] [Google Scholar]

- Jagannadham K, Parimalavalli R, Babu AS. Effect of triple retrogradation treatment on chickpea resistant starch formation and its characterization. J Food Sci Technol. 2017;54(4):901–908. doi: 10.1007/s13197-016-2308-7. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Kang J, Lee J, Choi M, Jin Y, Chang D, Chang YH, Lee Y. Physicochemical and textural properties of noodles prepared from different potato varieties. Prev Nutr Food Sci. 2017;22(3):246. doi: 10.3746/pnf.2017.22.3.246. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Kaur G, Sharma S, Nagi HPS, Ranote PS. Enrichment of pasta with different plant proteins. J Food Sci Technol. 2013;50(5):1000–1005. doi: 10.1007/s13197-011-0404-2. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Kaur M, Singh N. Studies on functional, thermal and pasting properties of flours from different chickpea (Cicer arietinum L.) cultivars. Food Chem. 2005;91(3):403–411. doi: 10.1016/j.foodchem.2004.06.015. [DOI] [Google Scholar]

- Kumar A, Singh M, Singh G. Effect of different pretreatments on the quality of mushrooms during solar drying. J Food Sci Technol. 2013;50(1):165–170. doi: 10.1007/s13197-011-0320-5. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Lu X, Brennan MA, Serventi L, Liu J, Guan W, Brennan CS. Addition of mushroom powder to pasta enhances the antioxidant content and modulates the predictive glycaemic response of pasta. Food Chem. 2018;264:199–209. doi: 10.1016/j.foodchem.2018.04.130. [DOI] [PubMed] [Google Scholar]

- Lu X, Brennan MA, Guan W, Zhang J, Yuan L, Brennan CS. Enhancing the nutritional properties of bread by incorporating mushroom bioactive compounds: the manipulation of the predictive glycaemic response and the phenolic properties. Foods. 2021;10(4):731. doi: 10.3390/foods10040731. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Monika T, Karuna S. Studies on nutritional, quality and sensory evaluation of value added baked products with button mushroom (Agaricus bisporus) powder. Int J Agric Sci. 2018;14(1):173–179. [Google Scholar]

- Nordiana AB, Wan Rosli WI, Wan Amir Nizam WA. The effect of oyster mushroom (Pleurotus sajor-caju) flour incorporation on the physicochemical quality and sensorial acceptability of pasta. Int Food Res J. 2019;26(4):1249–1257. [Google Scholar]

- Oliver JR, Blakeney AB, Allen HM. The colour of flour streams as related to ash and pigment contents. J Cereal Sci. 1993;17(2):169–182. doi: 10.1006/jcrs.1993.1017. [DOI] [Google Scholar]

- Oszmianski J, Wojdyło A. Effects of blackcurrant and apple mash blending on the phenolics contents, antioxidant capacity, and colour of juices. Czech J Food Sci. 2009;5:338–351. doi: 10.17221/20/2008-CJFS. [DOI] [Google Scholar]

- Parvin R, Farzana T, Mohajan S, Rahman H, Rahman SS. Quality improvement of noodles with mushroom fortified and its comparison with local branded noodles. NFS J. 2020;20:37–42. doi: 10.1016/j.nfs.2020.07.002. [DOI] [Google Scholar]

- Pourmohammadi K, Abedi E, Amiri MJ, Daneshgar MH, Torri L. The effect of thermal processing and different concentrations of resistant starch on X-ray pattern, crystallization kinetics and morphological properties of noodles supplemented with wheat and corn resistant starch. J Food Meas Charact. 2019;13(4):3149–3161. doi: 10.1007/s11694-019-00238-w. [DOI] [Google Scholar]

- Sung WC, Stone M. Characterization of legume starches and their noodle quality. J Mar Sci Technol. 2004;12(1):4. doi: 10.51400/2709-6998.2217. [DOI] [Google Scholar]

- Torres A, Frias J, Granito M, Vidal-Valverde C. Germinated Cajanus cajan seeds as ingredients in pasta products: chemical, biological and sensory evaluation. Food Chem. 2007;101(1):202–211. doi: 10.1016/j.foodchem.2006.01.018. [DOI] [Google Scholar]

- Vadukapuram N, Hall C, Tulbek M, Niehaus M. Physicochemical properties of flaxseed fortified extruded bean snack. Int J Food Sci. 2014;1:1–8. doi: 10.1155/2014/478018. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Wahyono A, Bakri A. Physicochemical and sensorial characteristics of noodle enriched with oyster mushroom (Pleorotus ostreatus) powder. J Phys Conf Ser. 2018;953(1):012120. doi: 10.1088/1742-6596/953/1/012120. [DOI] [Google Scholar]

- Wani S, Basir SF. Analysis of antioxidant activity, total phenolic and total flavonoid contents of Allium sativum, Mentha arvensis and Murraya koenigii. Int J Adv Res Sci Eng. 2018;7(4):2532–2646. [Google Scholar]

- Ward JL, Poutanen K, Gebruers K, Piironen V, Lampi AM, Nyström L, Shewry PR. The healthgrain cereal diversity screen: concept, results, and prospects. J Agric Food Chem. 2008;56(21):9699–9709. doi: 10.1021/jf8009574. [DOI] [PubMed] [Google Scholar]

- Zhang Y, Zeng H, Wang Y, Zeng S, Zheng B. Structural characteristics and crystalline properties of lotus seed resistant starch and its prebiotic effects. Food Chem. 2014;155:311–331. doi: 10.1016/j.foodchem.2014.01.036. [DOI] [PubMed] [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.

Data Availability Statement

Data will be made available on reasonable request.