Abstract

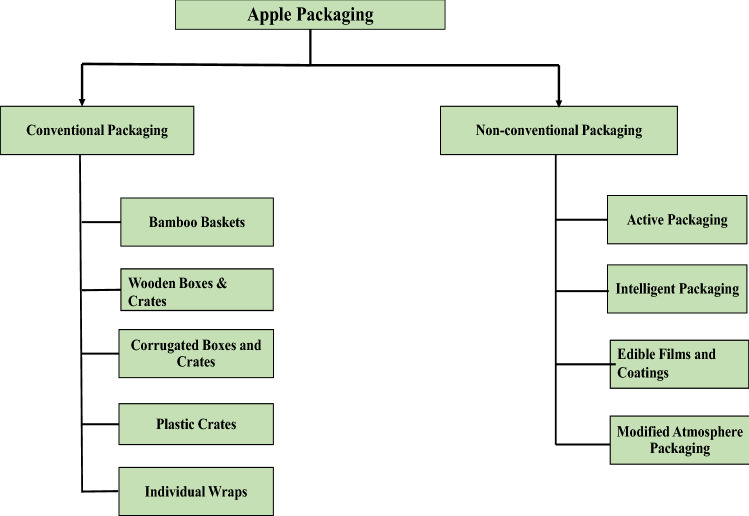

Apple (Malus domestica) belongs to the family Rosaceae. It is one of the most commonly cultivated fruit in all temperate zones of the world and holds an equally important place in the global economy. Apple is a climacteric fruit and undergoes metabolic changes even after the harvest and thus prone to post-harvest losses. The packaging of apples plays an important role in extending the shelf life of the apples and also maintains the quality during distribution and transport. The prime role of packaging is to contain the food commodity and protect the enclosed product from external damage. But other functions such as traceability, convenience and temper evidence are of secondary importance. Different packaging techniques are employed for the packaging of apples which include both conventional (wooden boxes, corrugated fiber boxes, crates) and non-conventional packaging like modified atmosphere packaging (MAP), active packaging, edible coatings, etc.

Keywords: Apple, Packaging, Shelf life, Quality, Post-harvest

Introduction

Fruits and vegetables have been known to form a prime part of the diet of the human population worldwide as they are rich in nutritious and health-promoting compounds. The demand for vegetables and fruits is increasing with the increase in the global population. It has been reported in United Nations Food and Agriculture Organization (FAO 2016) data that about 1.07 billion tons of fresh vegetables and 865 million tons of fresh fruits were produced globally (Elik et al. 2019). Being living commodities, fruits and vegetables undergo continuous changes even after harvesting owing to metabolic processes such as respiration. During respiration the reservoir of carbohydrates and other substrates like organic acids, proteins and fats are metabolized, thus cannot be replenished after harvesting. Gradually with time, the quality of fruits and vegetables deteriorates after harvesting. Fruits and vegetables being highly perishable are prone to post-harvest losses and this acts as one of the major obstacles in making these nutritious commodities available to consumers. Packaging is one of the most important post-harvest operations which has a major role in the control of post-harvest losses. Forming an essential part of the supply chain, packaging plays a crucial role in enhancing the shelf life of perishable commodities like fruits and vegetables. It protects fresh produce during post-harvest handling, transportation and storage, hence ensuring availability to consumers in the best possible form. The main function of packaging is to protect the packed food commodity against external deteriorating factors such as heat, light, pressure, microorganisms, dust, dirt, etc. The secondary but equally important functions encompass traceability, tamper indication, etc. This review aims at compiling information regarding the advances in packaging with respect to apples especially focusing on advanced packaging techniques such as modified atmosphere packaging, active and intelligent packaging, edible packaging films and coatings.

Apple

Apple, scientifically known as Malus domestica belongs to the family Rosaceae. It is one of the most commonly cultivated fruit in all temperate zones of the world and holds an equally important place in the global economy. Apple holds an important place in human nutrition and is widely consumed in both fresh and processed forms (Patocka et al. 2020). Its cultivation is spread to all the temperate regions around the globe. This fruit has a firm texture, whitish pulp, sour–sweet flavor and has numerous varieties developed and evolved. Some of the common and well-known varieties include Boskoop, Cox's Orange, Golden Delicious, Red Delicious, Maharaji, American, Balgaria, Kinor, Jonagold and Gravensteiner (Dobrzański et al. 2006). Apples ranked second in world fruit production after banana in 2018 with a production of 86 million tons. Around 96 countries across the globe grow apples for sale in their domestic markets and export (Vasylieva and James 2021). The world production of apples is dominated by China, as it is the leading country in terms of total growing area and export. As per the data compiled by United Nations Food and Agriculture organization (2013), the annual production of fresh apples was about 39.7 million tons in China which accounted for 49% of global apple production. The European Union and the United States hold 2nd and 3rd rank in the list of top producers of apple in the world (FAO 2016). India ranks 7th in global apple production with an average yield of about 7.24 tons per hectare of land under cultivation. Though a great variety of fruits are grown in the Indian Himalayan region, apple holds a special status over the other horticultural crops. The three states of India falling in the north-western zone of Himalayas that is Jammu and Kashmir, Himachal Pradesh and Uttarakhand dominate the apple production in the country (Basannagari and Kala 2013). The apple production in the Union Territory of Jammu and Kashmir accounts for approximately 67.7% of the total apple production in the country with Baramulla, Shopian, Pulwama, Anantnag, Budgam and Kulgam being the major contributing districts (Ahmad Bhat and Choure 2014). The apple production across the globe continues to grow, however, its consumption is stable. Fresh consumption of apples accounts for 70–75% of total production while, 25–30% is processed into various value-added products such as juice, wine, jams and dried products (Lyu et al. 2020). The presence of various phytochemicals, nutrients and dietary fibers in the apple are mainly responsible for various health benefits associated with its consumption. It has been linked to the prevention of various chronic diseases owing to the presence of a fair amount of bioactive compounds particularly anti-oxidants (Devic et al. 2010). Apples have a high content of carbohydrates, accounting for about 14% of the nutritional composition. A large percentage of the total carbohydrates of apples is present as fructose and glucose. They also contain a low amount of fat ranging between 0.16 and 0.18% and fiber ranging between 2 and 3%. The insoluble fiber such as cellulose and hemicellulose form the predominant component of fiber while pectin forms the major soluble fiber. Apples are also a rich source of minerals particularly potassium and magnesium, vitamins (vitamin C and E), polyphenols and triterpenoids (Koutsos et al. 2015; Skinner et al. 2018). Apples are rich in polyphenols, particularly hydroxybenzoic acids, hydroxycinnamic acids and their derivatives, flavanols, dihydrochalcones, anthocyanins, monomeric flavanols and oligomeric flavanols (Hyun and Jang 2016). These polyphenolic compounds are not evenly distributed in the fruit tissues. Apple peel that forms a small percentage (6–8%) of the total fruit weight, contains the highest content of phenolic compounds particularly flavonols, anthocyanins, dihydrochalcones and procyanidins. The flesh is rich in chlorogenic acid and some dihydrochalcones (Łata et al. 2009; Karaman et al. 2013; Francini and Sebastiani 2013). A heterogeneous mixture of skin, flesh, seeds and stem remaining after the juice extraction from apples is termed as apple pomace. Skin (peel) and flesh constitute the main portion of apple pomace forming about 95%, followed by 2–4% seeds and 1% stems (Bhushan et al. 2008). It has been identified as a potential source of phytochemicals especially polyphenols such as cinnamate esters, flavanols, flavonols and dihydrochalcones. Apple pomace is also rich in antioxidant compounds such as quercetin glycoside and phloridzin. Apart from phytochemicals and antioxidant compounds, apple pomace also contains a significant amount of carbohydrates, proteins, vitamins and minerals. Seeds which also form a part of pomace are rich in fatty acids present in the form of linoleic and oleic acid (Lu and Yeap Foo 2000; Lyu et al. 2020).

Packaging of apples

Maintenance of food quality and safety along with reduction of post-harvest losses is necessary to maintain a sustainable food system. Food packaging is one of the most important post-harvest operations which is the essential component of the food industry. Proper packaging helps and ensures the food to retain the optimum quality throughout its storage period. Containment, protection, convenience and communication are the four main and interconnected functions of packaging. The prime role of packaging is to contain the food commodity and protect the enclosed product from external influences and damage. The other functions such as traceability, convenience and tamper indication are of secondary importance (Robertson 2014). Packaging offers an additional layer of protection to fresh produce to preserve its quality while, it is being transported to far-off markets for sale. An ideal packaging for fruits and vegetables should have the following characteristics (Bala and Kumar 2018).

The packaging material should possess good mechanical strength

It should ease handling during the course of the supply

It should have good compression strength and puncture resistance to tolerate the load during stacking in a warehouse or transportation

It should be cost-effective

It should not hinder the normal metabolic process of fruits and vegetables i.e.; it should have proper ventilation to support aerobic respiration and the exchange of gases to maintain the quality of the product

It should prevent moisture loss to retain freshness

It should fulfill all the legislative requirements to safeguard consumer health

It should have proper labeling which provides all the necessary information regarding the enclosed product

Various types of packing materials such as corrugated fiber boxes, plastic trays or crates, wooden crates, shrink wraps are used for the packaging of fruits and vegetables (Bala and Kumar 2018). The packaging materials used for apples are discussed as follows:

Bamboo baskets

Earlier the concept of packaging was not broad enough and was only concerned with transporting the produce from farms or storage rooms to local markets for sale. For fulfilling this purpose bamboo baskets were put to use and no attention was given to other technological requirements for the packaging of fruits and vegetables. Bamboo baskets are used commonly in many developing countries such as India; however, the design of these baskets limits their use in long-distance transportation (Ladanyia and Ladaniya 2010). It is quite well known that apple production areas are greatly confined to hilly areas where the fruit after harvesting is transported to various nearby collection centers or markets using conical bamboo baskets. This traditional form of packaging is still prevalent however, it has been rendered inconvenient, especially for long-distance transportation. It is also associated with apparent and visible damages caused to the fruit due to scratches, compression, impact and vibrations during transportation. Bamboo baskets have not been considered of great use due to inconvenience in handling and stacking during storage and transportation (Subedi et al. 2017). With time the science of packaging evolved and the focus shifted to other packaging materials and methods for retaining the quality attributes of the fruit during storage and transportation. The packaging designed for fruits and vegetables should be strong enough to tolerate shocks, vibration and mechanical pressure/stacking pressure during loading and unloading, shipments, storage and market conditions.

Wooden boxes or crates

Wooden boxes or crates have been extensively used for the packaging of fruits, especially apples. These boxes or crates possess good stacking strength and are durable. However, relatively high cost of wood has been a great concern in its use as a packaging material and is being slowly replaced by other alternative materials. The use of wooden crates has been linked to mechanical damage of the product during handling and transportation. The efficiency of wooden crates as packaging material for apples has been studied and it was suggested that apples packed in wooden crates were prone to mechanical damage during transportation (Acican et al. 2007). The mechanical force applied showed a linear correlation with the damage in both apple varieties namely Granny Smith, Stark Spur and Golden Delicious. Moreover, damage at the lower and upper layers of fruit showed a significant difference in both apple cultivars.

Corrugated boxes

Paper-based packaging in the form of a corrugated board is one of the cardinal packaging materials used in the horticultural sector. The corrugated fiberboard boxes are known for many advantages which include low mass, strong and stiff built, ease of handling and exceptional stacking strength. The structure of corrugated fiberboard consists of two main parts namely medium and liner, arranged in a form of a sandwich. A central paper corrugated medium is placed in between corrugated or fluted liners or two papers without corrugations. Corrugated fiberboard packaging is capable of reducing the intensity of mechanical impacts and vibration, which are the main source of damage to fruit and vegetables during transportation. The corrugated fiberboard boxes are designed to handle the commodity in a single layer or multiple layers. In a multi-layer design, a layer of product is separated from another layer with trays, bubble wraps, or other cushioning material to ensure that chances of mechanical damage are reduced. The corrugated boxes have been reported to possess excellent properties as packaging material, reducing mechanical damage to apples (Pathare and Opara 2014). In one of the research study it was reported that a seven-ply corrugated fiberboard box of 10 kg capacity and bursting strength of 180 Psi was an efficient packaging option for packaging and long-distance transportation of apples (Subedi et al. 2017).

Plastic crates

Reusable plastic containers, made from a recyclable plastic material such as polyethylene are widely used as shipping packages or containers for fruits and vegetables globally. These containers are often preferred due to their lightweight, recyclability, biodegradable nature and more cost-effectiveness (Mukama et al. 2020).

Individual packaging of apples

Apples are exposed to various compressive forces leading to mechanical damage and bruises. These compressive forces may also be exerted by apples upon each other inside the package due to high bin depth or carton stack height or by forcing the cartons shut or into a tight space. Apart from this, vibration forces also lead to mechanical damage of apples during the supply and are almost impossible to avoid. Various packaging materials like plastic foam nets and paper wrap materials are employed to cover individual apples to provide cushioning to avoid adverse damages during handling and distribution (Hussein et al. 2020). The effect of individual cushioning of apples on bruise damage caused by various compressive and vibrational forces was also observed (Eissa et al. 2013). It was observed that foam-net and paper-wrap reduced bruise volume per fruit effectively in comparison to bruise incidence in un-cushioned apples. Moreover, it was also reported that foam-net individual packaging was much more effective than paper-wrap materials in reducing bruise damage. (Jarimopas et al. 2007) also reported that plastic and paper-based protective wraps can act as effective cushioning material for apples. Shrink-wrap technology in packaging has been employed for fruits and vegetables to delay physiological deterioration and also prevent condensation of water droplets within the package. It is also reported that individual shrink-wrapping of the fresh produce provides optimum gas and humidity conditions for maintaining the quality of the product during the supply chain. It also provides an attractive appearance to the product which enhances consumer acceptability (Sharma and Pal 2009).

Engineered plastic films for wrapping purposes can reduce shrinkage of fresh produce particularly fruits due to the prevention of moisture loss and protecting the product from any mechanical damage. Moreover, wraps also provide a good surface for stick-on labels. It also protects the fruit from some damage by abrasion during transport. (Thakur et al. 2017) presented a research report evaluating the effectiveness of polymeric shrink-wrap to individual apples and apples in a tray-wrap. Apples shrink-wrapped using 15 and 25-micron films retained organoleptic quality for about 4 weeks under the ambient condition as compared to unwrapped apples which were found to be unacceptable after only two weeks. It was also noted that 25-micron shrinkable film showed better quality retention of apples as compared to 15-micron films. (Sharma et al. 2013) studied the impact of heat-shrinkable films on shelf life and quality of apples (Royal Delicious apples) kept under ambient conditions. Three different shrink-wrap films namely Cryovac, polyolefin and LDPE were evaluated for their effectiveness to be used as a packaging material for apples. Based on the observation of various quality parameters, Cryovac films were found to be best for the packaging of apples over other films examined. Apples could be packed in Cryovac heat-shrinkable films for about 35 days without any detrimental effect on the overall quality of fruit. Apples wrapped with Cryovac films of 9-micron thickness showed the least weight and decay loss and a higher juice recovery and TSS over other film-wrapped apples and control. In one of the early studies the changes in the quality of shrink-wrapped and unwrapped apples (Starkrimson cultivar) over a storage period of 38-weeks at a temperature of 26 °C and relative humidity ranging between 40 and 42% were recorded (Heaton et al. 1990). Shrink-wrapped apples possessed acceptable organoleptic quality throughout the storage period. The timeline of different packaging materials used for apple is shown in Fig. 1.

Fig. 1.

Different packaging materials used for apple

Technological advances in packaging

There has been a tremendous change in consumer lifestyle, behavior and market trends due to the advancements in technology with time. Currently, people around the globe demand foods which are minimally processed, retaining fresh-like qualities with enhanced shelf life. This has led to the development of advanced novel packaging technologies such as modified atmosphere packaging, controlled atmosphere packaging, edible packaging, active packaging, intelligent packaging, smart packing, etc., particularly in the last two decades. These packaging technologies have been known to prolong the shelf life of produce with better freshness and quality retention. Apart from performing the basic function of containment, the novel packaging enhances the margin of food quality and safety, hence aiding in fulfilling the global demands of fresh/quality fruits (Bodbodak and Rafiee 2016; Majid et al. 2018).

Modified atmosphere packaging

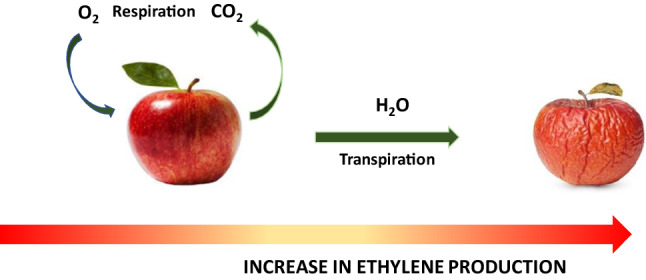

Fruits and vegetables go through three important phases namely growth, maturation and senescence. Ripening, which involves the onset of catabolic processes leading to aging and death of tissue begins at the later stages of maturation (Robertson, 2014). Fruits and vegetables continue their metabolic processes including respiration even after being detached from the parent plant. Apple is a climacteric fruit that undergoes ripening even after harvesting depending entirely on the food reserves and moisture content. It is characterized by a dramatic increase in the respiration rate and ethylene production during the ripening stage (Fig. 2) (Fuentes et al. 2019).

Fig. 2.

Metabolic processes occurring in apple after harvesting

Modified atmosphere packaging involves the enclosure of fresh products within a package wherein the atmosphere is altered to enhance the product's shelf life. The alteration of the package atmosphere can be achieved either naturally due to the respiration of fresh produce and the transfer of gases through the packaging material or by using gas absorbers or scavengers to attain a desired atmosphere within the package. The modified atmosphere can also be created by replacing or displacing the gases within the package. The most commonly used gases in MAP are oxygen, nitrogen and carbon dioxide used singly or in combination, while, other gases namely carbon monoxide, sulfur dioxide, nitrous oxide, ozone, chlorine and argon have also been investigated for their effectiveness to modify the atmosphere (Davies 2003; Oliveira et al. 2015). It is also necessary that there is a certain level of interaction between the packaging material employed and the respiring produce to establish a desired and balanced atmosphere within the package. The modified atmosphere commonly used to pack fresh fruits and vegetables consist of lower oxygen and a comparatively higher level of carbon dioxide than the normal atmospheric percentage to reduce the normal respiration rate and ethylene production, hence prolonging the shelf life of the packed commodity (Cortellino et al., 2015). Maintenance of optimum levels of carbon dioxide and oxygen within the package is important to inhibit the growth and proliferation of various microorganisms. The tolerance of carbon dioxide levels depends on the type of produce with the value ranging from 2% for apples to about 15% for berries. Levels higher than the tolerance limit can result in tissue breakdown of the commodity (Wilson et al. 2019). The recommended modified atmosphere conditions for apples consist of 1–3% oxygen, 1–5% carbon dioxide and a temperature ranging between 0 and 5 °C (Soltani et al. 2015).

It has been observed that packaging of fresh-cut Fuji apples under oxygen-free conditions resulted in complete inhibition of ethylene (Gil et al. 1998). Fresh cut Golden Delicious apples packed in a nitrogen-rich atmosphere or an atmosphere having a combination of nitrogen and carbon dioxide did not produce ethylene in detectable levels (Anese et al. 1997; Soliva-Fortuny et al. 2002). It was also reported that the ethylene production in Golden Delicious apple slices packed in 99% nitrogen and 1% oxygen or in 90% nitrogen, 5% oxygen and 5% carbon dioxide was very low, reaching a maximum level of 15 mmol/kg as compared to apples packed with a normal atmosphere wherein the ethylene concentration ranged between 51 and 58 mmol/kg (Cortellino et al. 2015). Moreover, the research also pointed out the effectiveness of conventional gas mixture (90% N2, 5% O2 and 5% CO2) over modified mixture having argon (25%) and nitrous oxide (65%) in controlling the ethylene production. The microbiological stability of apple slices was enhanced under MAP using naturally-occurring antimicrobial agents namely citron essential oil, hexanal, 2-(E)-hexenal, citral and carvacrol was enhanced (Siroli et al. 2014). It was also reported that apple slices treated with these anti-microbial agents and packed in an active modified atmosphere (7% O2 and 0% CO2) showed good retention of firmness along with reduced yeast cell loads throughout 35 days of storage. Browning reaction which results in quality deterioration of fruits and vegetables can be controlled by MAP. The main determinants of the rate of enzymatic browning in fruit and vegetables are the concentration of enzyme polyphenol oxidase, pH, temperature and oxygen availability. Oxygen which plays a key role in the activity of polyphenol oxidase, when excluded from the package prevents the onset of browning reaction. Inhibition of browning reaction in apple slices packed in modified atmospheric conditions (90% nitrogen, 5% carbon dioxide and 5% oxygen and 65% nitrous oxide, 25% argon, 5% carbon dioxide and 5% oxygen) has been studied by Rocculi et al. 2004. Under both the packaging conditions apple slices exhibited good values of whiteness index and hue angle as well as lower chroma as compared to the slices packed under normal atmospheric conditions. Different modified atmospheric packaging conditions for various varieties of apples are given in Table 1.

Table 1.

Different MAP conditions applied to a few apple varieties. Source: (Soliva-Fortuny et al. 2001; Kumar Anurag et al. 2018)

| Commodity | Type of plastic film | Atmospheric composition (%) | Temperature (°C) | Storage period |

|---|---|---|---|---|

| Apple (variety-Bravo de Esmolfe) | Polypropylene | Oxygen-5% | 2 | 6.5 months |

| Carbon dioxide-3% | ||||

| Apple (variety-cox’s orange pippin) | LDPE | Oxygen-3% | 4 | 5 weeks |

| Carbon dioxide-3% | ||||

| Apple (variety-Fuji) | Polypropylene PVC | Oxygen -5% | 10 | 7 months |

| Carbon dioxide-4% | ||||

| Golden delicious | – | Oxygen -2.5% | 4 | 90 days |

| Carbon dioxide- 7% |

Active and intelligent packaging

Active and Intelligent packaging are innovative technologies that came into existence intending to satisfy the consumer demand for natural, fresh and minimally processed foods. Active packaging is a packaging technique where the package, the product and the environment interact with each other to extend the shelf life of the enclosed commodity or to maintain the quality and enhance the safety of the product (Kochhar and Prasad 2014). The condition within the package can be maintained at an optimum level by employing different and appropriate active packaging systems based on the product being packed. The active packaging systems are categorized into two broad categories namely absorbing systems (ethylene scavenging) and releasing systems. In absorbing systems the undesirable levels of various gases, moisture content, etc. can be removed through absorption/adsorption system. The releasing systems add certain compounds such as antioxidants, antimicrobials, etc. to the package to maintain a favorable condition within the package (Bodbodak and Rafiee 2016). The ethylene scavenging systems counter the action of ethylene on fresh produce within the package by the presence of active compounds that can adsorb, absorb, or chemically alter ethylene hormone. The basic ethylene removing packaging systems involves chemical compounds namely potassium permanganate, sodium permanganate and titanium dioxide which irreversibly oxidize ethylene to carbon dioxide and water. However, the absorption/adsorption based system use activated carbon, charcoal, zeolites, clays and metal–organic frameworks and can either adsorb or absorb ethylene. It has been noted that the use of ethylene scavengers in packaging has positively impacted the shelf life of apples (Awalgaonkar et al. 2020). One of the most commonly employed active packaging systems for apples includes the ethylene scavengers. The ripening process of apples is profoundly influenced by ethylene. MCP (1-Methylcyclopropene), a small hydrocarbon has been employed as an ethylene inhibitor in active packaging as it is non-toxic and highly efficient. MCP aids in extending the shelf life of climacteric fruits by preventing the over-ripening in post-harvest stages by competing with ethylene for ethylene receptors (AdERS1a, Ad-ETR2 and Ad-ETR3) and also inhibiting the expression of several transcription factors (Ad-ERF4, Ad-ERF6, Ad-ERF10 and Ad-ERF14). 1-pentylcyclopropene (1-PentCP) and 1-octylcyclopropene (1-OCP) which are structural analogs of 1-MCP also exhibit superior ethylene inhibiting power. Apart from inhibiting ethylene synthesis, 1-MCP also has been noted to play other physiological roles, though the mechanism underlying these roles has not been fully explained (Wei et al. 2021). Some of the commercially available active packaging systems are shown in Table 2.

Table 2.

Some of the commercially available active packaging systems. Source: (Cichello, 2015; Gaikwad et al., 2019; Souza Cruz et al., 2012; Biji et al., 2015)

| Company | Trade name | Active compound | Product form |

|---|---|---|---|

| Moisture absorbers | |||

| CSP Technologies, USA | Activ-Film™ | Silica | Film |

| CSP Technologies, USA | Fresh-R-Pax® | – | Tray |

| Sirane LDT UK | Dri-Fresh® | – | Pad |

| Oxygen absorbers | |||

| Mitsubishi Gas Chemical Co., Ltd. Japan | AGELESS® | Reduced Iron salts | Sachets and labels |

| Toyo Pulp Co. Japan | TAMOTSU® | Catechol | Sachets |

| Standa Industrie (France) | ATCO | Iron based | Sachets |

| Bioka ltd Finland | Bioka | Enzyme | Sachets |

| CMB Technologies (UK) | Oxbar | Cobalt catalyst/nylon polymer | Plastic bottle |

| Cryovac Sealed Air Co. (US) | OS1000 | Light activated scavenger | Plastic film |

| Ethylene Absorbers | |||

| Be fresh Technology, Spain | BEfresh | Natural clays impregnated with potassium permanganate | Sachets |

| Desiccare, USA | Ethylene elimination Pack | Zeolite | Sachets |

| Mitsubishi Gas Chemical Co. Ltd., Japan | SendoMate | Activated carbon with a metal catalyst | Sachets |

| AgraCo Technologies International, LLC, USA | Extend-A-Life™ | Zeolite coated with potassium permanga-nate | Sachet |

| Purafil, Inc., Doraville GA, USA | Purafil | Activated alumina impregnated with potassium permanganate | Sachets |

| E-I-A Warenhandels GmbH, Austria | Profresh | Minerals | Polymeric film |

| Anti-microbial | |||

| Addmaster Limited, USA | Biomaster® | Silver based | – |

| Life Materials Technology Limited, USA | Agion® | Silver based | – |

Incorporation of antimicrobial agents into packaging materials has been widely used form of active packaging to retard or inhibit the growth of microorganisms that may be present as contaminants in the packaged product or the packaging material. The antimicrobial agents used can be either natural or synthetic based on the source. The natural antimicrobial agents include extracts from cinnamon, clove, thyme, rosemary, oregano onion, garlic, radish mustard and horseradish. The natural antimicrobials also include compounds such as polypeptide nisin, natamycin and pediocin, produced by the action of bacteria or fungi. The synthetic antimicrobials include ethylene diamine tetraacetic acid (EDTA) and parabens (Biji et al. 2015; Huang et al. 2019). Pure and encapsulated potassium metabisulphite in the ratio of 1:1 applied on PVC film as an anti-microbial, antioxidant and anti-browning agent has been used to develop an efficient active packaging for apples. Fresh cuts of Gala apples when covered by PVC films with the active compound (potassium metabisulfite) exhibited an extended shelf life with lower browning index and microbial load as compared to control samples. Apples wrapped with PVC film with 2% potassium metabisulfite exhibited microbiological stability over the period of 20 days (Foralosso et al. 2014). An active package consisting of a peelable lid and double bottom tray with antimicrobial agents in the form of essential oils of palmarosa and star anise included in cyclodextrin complex was used to enhance the shelf life of apples inoculated with Penicillium expansum by suppressing the growth of this microorganism. Upon 12 days of storage at 23 °C a significant reduction in fungal growth was observed along with 50% less weight loss and less than 25% of loss in firmness of fruit (da Rocha Neto et al. 2019).

Intelligent packaging consists of a packaging system capable of monitoring the condition of the food within the package to provide necessary information regarding the quality of the packaged food during transport and storage. An intelligent packaging system performs an additional function to the conventional packaging as it continuously monitors and records the changes occurring in the internal and external surroundings of the packed commodity and provides the same information to the consumer (Majid et al. 2018). During the production, food products are subjected to various quality parameters to ensure their suitability for consumption. However, this is not possible during transportation and distribution. Intelligent packaging can thus play a key role and fill in the gap to ensure that good quality product is delivered to the consumer. It can also play an effective role in improving the quality analysis methods such as HACCP. The main elements put to use in intelligent packaging systems include indicators such as time–temperature indicators, freshness indicators, ripeness indicators and sensors. Apart from these elements, data carriers also form a part of intelligent packaging technology though they are mainly concerned with supply chain management (Drago et al. 2020). The freshness of fruits and vegetables often expressed as ripeness has always been a point of concern for consumers. It is very difficult to perceive whether a commodity has reached the desired level of ripeness or not and this hinders the consumer's purchasing decision. A New Zealand-based company named RipeSense™ (Table 3) has developed a ripeness indicator with sensors capable to detect aromas and volatiles being released during the course of fruit ripening. The sensor changes color from red to orange and finally to yellow depending upon the state of ripeness. This sensor has been used for pears and can also be applied to other fruits (Kuswandi 2017). However, the color based ripeness indicators for apples have been developed (Lang and Hübert 2012). The ethylene production during the ripening process of apples partially reduced molybdenum (VI) to molybdenum (V) resulting in a color change from white/yellow to blue which is correlated to the amount of ethylene emitted by the fruits. This color indicator can be used in combination with a color recognizing sensor for quantitative measurements of color changes. A label-based colorimetric sensor capable of detecting the aldehyde emitted from apples resulting in the change in basicity due to the nucleophilic addition reaction between aldehyde and hydroxide using methyl red indicator was also developed (Kim et al. 2018). When the indicator is exposed to ripening apples, the label changes color from yellow to orange, and finally to red. The color change on the label depicted a correlation with changes in the quality parameters.

Table 3.

| Trade name | Company |

|---|---|

| RipeSense | RipeSense™ (http://www.ripesense.co.nz) |

| SensorQ | DSM NV and Food Quality Sensor |

| Fresh Tag | COX Technologies |

Edible packaging films and coatings

Edible coatings or films have received a fair share of attention over the years as an alternative packaging technology. Materials such as polysaccharide, lipid and protein-based and their composites have been employed to develop edible packaging for foods and have several advantages over synthetic films. Edible films and coatings form an inseparable part of the food commodity, are environmental friendly, reduce waste generation apart from performing some basic functions of packaging (Saklani et al. 2019). Pullulan, a polysaccharide has been employed successfully in developing an edible coating for non‐climacteric and climacteric fruits. Pullulan-based coatings have been applied to apples to extend their shelf life. It has been noted that the coating acts as a physical barrier to moisture thereby preventing weight loss of the fruit upon storage. Pullulan coatings have also been used for fresh-cut apple slices (Farris et al. 2014). The bioactive components of apple have been more or less preserved during a storage period of 35 days at a temperature of 4 ± 1 °C using a chitosan coating film with olive leaf extracts at 2% concentration. The bioactive components in coated apples showed a comparatively gradual decline than uncoated apples (Khalifa et al. 2017). Essential oils of vanilla, lemongrass and oregano incorporated into apple puree-alginate coating have been employed to enhance the shelf life of fresh-cut ‘Fuji’ apples (Rojas-Graü et al. 2007). It was noted that apples coated with coatings containing a higher concentration of essential oils showed a decreased oxygen depletion and carbon dioxide production and the overall ethylene concentration also remained below 50 μL/L. The research study also evaluated the anti-microbial impact of essential oils using L. innocua which was inoculated on apple slices before application of coating. Lemongrass (1.0 and 1.5% w/w) and oregano oil containing coatings exhibited good antimicrobial activity against L. innocua with a 4-log reduction in the population. Edible coatings with anti-browning agents have also been employed to minimally processed apple slices which have been found to effectively enhance the shelf life of the product by about 2 weeks when stored at a temperature of 3 °C in packed trays (Lee et al. 2003). Aloe gel-based edible coatings have been employed in fresh-cut Royal Delicious apple wedges packaging as a carrier for anti-browning agents namely 4-hexylresorcinol (0.01%), ascorbic acid (0.5%), CaCl2 (0.2%) and cysteine (0.1%) with aloe vera gel (15%) (Kumar et al., 2018). The incorporation of fermented extract of tarbush (Flourensia cernua) in edible coatings made of candelilla wax proved to be a promising method to enhance and improve the quality and shelf life of golden delicious apples (De León-Zapata et al. 2015). Thyme essential oil incorporated into starch-gellan coating either directly or in encapsulated form did not effectively control the weight loss and respiration rate in apples but exhibited anti-fungal property by reducing the severity of gray mold caused by Botrytis cinerea in apples (Sapper et al. 2019). Incorporation of ferulic acid in concentrations ranging between 1.0 and 4.0 g /L in soy protein-based edible coating for fresh-cut apples has been studied and it has been observed that coatings with ferulic acid at 4.0 g/L and pH 7.0 extended the shelf life of the product (Alves et al. 2017). A recent study evaluated the use of corn starch and papaya polysaccharide-based films on fresh-cut apples. It was observed that coating fresh-cut apples with this film resulted in a positive influence on consumer acceptance and shelf life of the product. This film had excellent mechanical and optical barrier properties along with good tear strength (Ma et al. 2021). Composite films developed using chitosan, gelatin and tannic acid have been investigated for their effectiveness in the application of fresh-cut apples (Zhang et al. 2021). The tannic acid was added to the film as a cross-linking agent which enhanced the mechanical and barrier properties and also improved the anti-ultraviolet and antioxidant abilities of the packaging film. It was also found to decrease weight loss, delayed browning, inhibited lipid oxidase activity and decreased the malondialdehyde content during 10 days of storage under 4 °C. Anacardic acid extracted from cashew nut shell liquid oil was incorporated into chitosan films and investigated for its application as active packaging for fresh-cut horticultural produce particularly fresh-cut apples (Preethi et al. 2021). The extract exhibited anti-oxidant and anti-microbial effects on various foodborne pathogenic microbes such as Escherichia coli, Listeria monocytogenes, Streptococcus faecalis, Salmonella typhi and Shigella boydii. These films also showed excellent anti-browning action on fresh-cut apple slices. Whey protein isolate/montmorillonite bioactive films containing citric acid were found to be effective in reducing enzymatic browning and activity of polyphenol oxidase enzyme in minimally processed apples thus enhancing the shelf life of apples. Cassava starch-based edible coatings with cinnamon bark and fennel essential oils in the concentrations of 0.05% to 0.30% respectively were found to decrease respiration rates of coated apple slices as compared to uncoated apple slices. Moreover, the essential oil incorporated films exhibited antioxidant and antimicrobial activity with cinnamon bark oil and cassava edible film showed antimicrobial activity against Staphylococcus aureus and Salmonella choleraesuis (Oriani et al. 2014). Fresh cut Fuji apples coated with tapioca starch edible coating with a combination of ascorbic acid and calcium chloride as additives were found to be shelf-stable with an increase in shelf life up to 5–7 days under refrigerated storage. These slices also had enhanced qualities in terms of color and firmness (Pan et al. 2013). Carboxymethyl cellulose edible coating with calcium chloride and ascorbic acid in combination was used for apple slices and it was found to reduce the browning of apples thereby maintaining the quality during the storage period (Koushesh Saba and Sogvar 2016). Pectin obtained from apple pomace has been employed to prepare an edible coating for fresh-cut apples and an additional ability to function as an active packaging conferred to it by the inclusion of cinnamon oil as the prime antimicrobial agent. The coating in emulsion form was found to be effective in controlling the growth and proliferation of pathogenic microorganisms namely E.coli and Listeria monocytogens along with general microflora (Naqash et al. 2021). Aleovera gel and sodium alginate linked with calcium lactate based edible coatings with 10 mg/ml ferulic acid as an active compound have been employed to enhance the shelf life of fresh cut apple discs. The aloe vera gel coatings enriched with ferulic acid showed delayed browning in apple discs as compared to sodium alginate-based coatings. Moreover, these coatings were found to be effective in controlling the proliferation of Listeria monocytogenes by reducing the population by 2.3 ± 0.4 log CFU/g hence contributing to microbial safety of the packaged product (Nicolau-Lapeña et al. 2021). Bifidobacterium animalis subsp. lactis BB-12 entrapped in alginate and gellan-based edible coatings were used for apple slices. The bacterial strains showed cell count above the recommended levels upon 10 days storage period at 2 °C (Tapia et al. 2007). The flow chart of different packaging systems used for apple packaging is shown in Fig. 3.

Fig. 3.

Flowchart of different packaging systems used for apple packaging

Nanotechnology in packaging

Nanotechnology is an emerging technology that deals with the characterization, fabrication and manipulation of structures, devices, or materials that have a dimension between 1–100 nm. The growth of nanotechnology over the years has had a deep impact on food packaging. Various nanosized particles have been incorporated into packaging as functional additives. (Galindo-Pérez et al. 2015) evaluated the impact of the addition of tocopherol nanoparticles to xanthan gum coatings on the activity of polyphenol oxidase in fresh-cut Red Delicious apples. The nanoparticle incorporated xanthan gum coating resulted in lowering the initial respiration rate by 63% as compared to control samples. The effect of nanoparticles on the activity of polyphenol oxidase was related to the retention of phenolic compounds in apple slices. Polyvinyl Chloride (PVC) coating with zinc oxide nanopowder was used for fresh-cut fuji apples and was investigated for its impact on the quality of the product (Li et al. 2011). It was noted that the packaging was effective in controlling the decay rate along with a decrease in the accumulation of malondialdehyde within the package. Moreover, the activity of enzymes particularly polyphenol oxidase was suppressed, hence preventing the browning of apple slices. Pectin nanoemulsion coatings with cinnamon essential oil as an antimicrobial agent has been employed to effectively control the microbial quality of fresh-cut apples. It has been found that this pectin-based nanoemulsion edible coating is effective in inhibiting the growth of microorganisms, particularly the pathogenic ones such as E. coli (Naqash et al. 2021). Nanoemulsion of lemongrass essential oil added to sodium alginate-based edible coating in the concentrations 0.5% and 1% (v/v) exhibited potential for shelf life extension and quality maintenance in fresh-cut Fuji apples (Salvia-Trujillo et al. 2015).

Conclusion

Apple a living commodity undergoes normal metabolic processes such as respiration even after harvest. During respiration, the reservoir of carbohydrates, proteins, fats and organic acids are metabolized and cannot be replenished after harvesting. Being highly perishable in nature, apples are prone to post-harvest losses and this acts as a major obstacle in making this nutritious commodity available to the consumer in the best possible form. Packaging has been linked to the control of post-harvest losses, forming the heart of the food industry. As the apple is fresh produce, it is essential that the ideal packaging for it should be able to control the metabolic processes to a greater extent to ensure longer shelf life apart from performing the basic functions of containment and protection. Earlier the concept of packaging was not broad and included the use of bamboo baskets, wooden crates, plastic crates, etc. but with the time evolution of the science of packaging, the focus has shifted to more advanced packaging materials and techniques. The new advanced techniques namely modified atmosphere packaging, active packaging, intelligent packaging, edible films and coatings, etc. not only reduce the post-harvest losses but also maintain the quality of the produce for a longer time. The global awareness regarding the use of biodegradable materials for packaging has led to the use of nanotechnology in the packaging industry in the form of bio-nano composites which present a great potential to reduce the generation of non-biodegradable waste and can increase overall sustainability by replacing non-biodegradable plastics. It has been assumed that nanotechnology will become the advanced technology ruling the entire food packaging domain with an infinite growth rate by 2050 owing to its ability to provide eco-friendly solutions both at micro and macro levels. However, nanotechnology-based advanced packaging methods require further investigation so that they can be effectively put to use on a commercial scale to reduce the post-harvest losses and at the same time maintain the quality of produce to its maximum. The incorporation of health-promoting compounds into the edible films and coatings in nanoforms to enhance the overall value of the packaged produce can act as a basis for future scientific research in this field.

Author contributions

SAB (Writing, Literature survey), DR (Writing, Literature survey), SAM (Writing & Editing), SMW (Writing & Editing,), FAM (Conceptualization, Supervision).

Funding

Not applicable.

Declarations

Conflict of interest

The authors declare no conflicts of interest.

Ethical approval

Not required.

Consent to participate

All authors agree to participate in this review and have contributed to the preparation of this manuscript.

Consent to publication

The tables in this manuscript have been reproduced with proper citations. This manuscript has not been submitted to any journal for publication.

Data availability

Not applicable.

Code availability

Not applicable.

Footnotes

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

References

- Acican T, Alibaş K, Özelkök IS. Mechanical damage to apples during transport in wooden crates. Biosyst Eng. 2007;96:239–248. doi: 10.1016/j.biosystemseng.2006.11.002. [DOI] [Google Scholar]

- Almenar E (2020) Innovations in packaging technologies for produce. In: Controlled and modified atmospheres for fresh and fresh-cut produce. Elsevier, pp 211–264

- Alves MM, Gonçalves MP, Rocha CMR. Effect of ferulic acid on the performance of soy protein isolate-based edible coatings applied to fresh-cut apples. LWT - Food Sci Technol. 2017;80:409–415. doi: 10.1016/j.lwt.2017.03.013. [DOI] [Google Scholar]

- Anese M, Manzano M, Nicoli MC. Quality of minimally processed apple slices using different modified atmosphere conditions. J Food Qual. 1997;20:359–370. doi: 10.1111/j.1745-4557.1997.tb00479.x. [DOI] [Google Scholar]

- Awalgaonkar G, Beaudry R, Almenar E. Ethylene-removing packaging: basis for development and latest advances. Compr Rev Food Sci Food Saf. 2020;19:3980–4007. doi: 10.1111/1541-4337.12636. [DOI] [PubMed] [Google Scholar]

- Bala S, Kumar J (2018) Chemical science review and letters packaging of fruits and vegetables in India: A Review. Chem Sci Rev Lett 7

- Basannagari Basavaraj, Kala Chandra Prakash, Convertino Matteo. Climate Change and Apple Farming in Indian Himalayas: A Study of Local Perceptions and Responses. PLoS ONE. 2013;8(10):e77976. doi: 10.1371/journal.pone.0077976. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Bhat TA, Choure DT. Status and strength of Apple Industry in Jammu and Kashmir. Int J Res. 2014;1:277–283. [Google Scholar]

- Bhushan S, Kalia K, Sharma M, et al. Processing of apple pomace for bioactive molecules. Critical Rev Biotechnol. 2008;28:285–296. doi: 10.1080/07388550802368895. [DOI] [PubMed] [Google Scholar]

- Biji KB, Ravishankar CN, Mohan CO, Srinivasa Gopal TK. Smart packaging systems for food applications: a review. J Food Sci Technol. 2015;52:6125–6135. doi: 10.1007/s13197-015-1766-7. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Bodbodak S, Rafiee Z (2016) Recent trends in active packaging in fruits and vegetables. In: Eco-friendly technology for postharvest produce quality. Elsevier Inc., pp 77–125

- Cichello SA. Oxygen absorbers in food preservation: a review. J Food Sci Technol. 2015;52:1889–1895. doi: 10.1007/s13197-014-1265-2. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Cortellino G, Gobbi S, Bianchi G, Rizzolo A. Modified atmosphere packaging for shelf life extension of fresh-cut apples. Trends Food Sci Technol. 2015;46:320–330. doi: 10.1016/j.tifs.2015.06.002. [DOI] [Google Scholar]

- Davies AR (2003) Modified atmospheres and vacuum packaging. In: Food Preservatives. Springer, US, pp 218–239

- da Rocha Neto AC, Beaudry R, Maraschin M, et al. Double-bottom antimicrobial packaging for apple shelf-life extension. Food Chem. 2019;279:379–388. doi: 10.1016/j.foodchem.2018.12.021. [DOI] [PubMed] [Google Scholar]

- De León-Zapata MA, Sáenz-Galindo A, Rojas-Molina R, et al. Edible candelilla wax coating with fermented extract of tarbush improves the shelf life and quality of apples. Food Packag Shelf Life. 2015;3:70–75. doi: 10.1016/j.fpsl.2015.01.001. [DOI] [Google Scholar]

- Devic E, Guyot S, Daudin JD, Bonazzi C. Kinetics of polyphenol losses during soaking and drying of cider apples. Food Bioprocess Technol. 2010;3:867–877. doi: 10.1007/s11947-010-0361-1. [DOI] [Google Scholar]

- Dobrzański B, Rabcewicz J, Rybczyński R (2006) Handling of apple: transport techniques and efficiency vibration, damage and bruising texture, firmness and quality, 1st edn. B. DOBRZAŃSKI INSTITUTE OF AGROPHYSICS OF POLISH ACADEMY OF SCIENCES

- Drago E, Campardelli R, Pettinato M, Perego P. Innovations in smart packaging concepts for food: an extensive review. Foods. 2020;9:1628. doi: 10.3390/foods9111628. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Eissa AHA, Albaloushi NS, Azam MM. Vibration analysis influence during crisis transport of the quality of fresh fruit on food security. Agric Eng Int CIGR J. 2013;15:181–190. [Google Scholar]

- Elik A, Yanık DK, Yanik DK, et al. Strategies to reduce post-harvest losses for fruits and vegetables. Int J Sci Technol Res. 2019 doi: 10.7176/jstr/5-3-04. [DOI] [Google Scholar]

- FAO (2016) FAOSTAT Production Database. [2016-3-15]. Food and Agriculture Organization of the United Nations. http://faostat.fao.org

- Farris S, Unalan IU, Introzzi L, et al. Pullulan-based films and coatings for food packaging: present applications, emerging opportunities, and future challenges. J Appl Polym Sci. 2014 doi: 10.1002/app.40539. [DOI] [Google Scholar]

- Foralosso FB, Fronza N, dos Santos JHZ, et al. The use of duo-functional PVC film for conservation of minimally processed apples. Food Bioprocess Technol. 2014;7:1483–1495. doi: 10.1007/s11947-013-1233-2. [DOI] [Google Scholar]

- Francini A, Sebastiani L. Phenolic compounds in apple (Malus x domestica Borkh.): compounds characterization and stability during postharvest and after processing. Antioxidants. 2013;2:181. doi: 10.3390/ANTIOX2030181. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Fuertes G, Soto I, Carrasco R, et al (2016) Intelligent packaging systems: sensors and nanosensors to monitor food quality and safety. J Sensors

- Fuentes L, Figueroa CR, Valdenegro M. Recent advances in hormonal regulation and cross-talk during non-climacteric fruit development and ripening. Horticulturae. 2019;5:45. doi: 10.3390/horticulturae5020045. [DOI] [Google Scholar]

- Gaikwad KK, Singh S, Ajji A. Moisture absorbers for food packaging applications. Environ Chem Lett. 2019;17:609–628. doi: 10.1007/s10311-018-0810-z. [DOI] [Google Scholar]

- Galindo-Pérez MJ, Quintanar-Guerrero D, Mercado-Silva E, et al. The effects of tocopherol nanocapsules/xanthan gum coatings on the preservation of fresh-cut apples: evaluation of phenol metabolism. Food Bioprocess Technol. 2015;8:1791–1799. doi: 10.1007/s11947-015-1523-y. [DOI] [Google Scholar]

- Gil MI, Gorny JR, Kader AA. Responses of “Fuji” apple slices to ascorbic acid treatments and low-oxygen atmospheres. HortScience. 1998;33:305–309. [Google Scholar]

- Heaton EK, Dobson JW, Lane RP, Beuchat LR. Evaluation of shrink-wrap packaging for maintaining quality of apples. J Food Prot. 1990 doi: 10.4315/0362-028x-53.7.598. [DOI] [PubMed] [Google Scholar]

- Huang T, Qian Y, Wei J, Zhou C. Polymeric antimicrobial food packaging and its applications. Polymers (basel) 2019;11:560. doi: 10.3390/polym11030560. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Hussein Z, Fawole OA, Opara UL. Harvest and postharvest factors affecting bruise damage of fresh fruits. Hortic Plant J. 2020;6:1–13. doi: 10.1016/j.hpj.2019.07.006. [DOI] [Google Scholar]

- Hyun TK, Il JK. Apple as a source of dietary phytonutrients: an update on the potential health benefits of apple. EXCLI J. 2016;15:565–569. doi: 10.17179/excli2016-483. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Jarimopas B, Singh SP, Sayasoonthorn S, Singh JP. Comparison of package cushioning materials to protect post-harvest impact damage to apples. Packag Technol Sci Int J. 2007 doi: 10.1002/pts.760. [DOI] [Google Scholar]

- Karaman Ş, Tütem E, Başkan KS, Apak R. Comparison of antioxidant capacity and phenolic composition of peel and flesh of some apple varieties. J Sci Food Agric. 2013;93:867–875. doi: 10.1002/JSFA.5810. [DOI] [PubMed] [Google Scholar]

- Khalifa I, Barakat H, El-Mansy HA, Soliman SA. Preserving apple (Malus domestica var. Anna) fruit bioactive substances using olive wastes extract-chitosan film coating. Inf Process Agric. 2017;4:90–99. doi: 10.1016/j.inpa.2016.11.001. [DOI] [Google Scholar]

- Kim YH, Yang YJ, Kim JS, et al. Non-destructive monitoring of apple ripeness using an aldehyde sensitive colorimetric sensor. Food Chem. 2018;267:149–156. doi: 10.1016/j.foodchem.2018.02.110. [DOI] [PubMed] [Google Scholar]

- Kochhar A, Prasad P. Active packaging in food industry: a review. Artic IOSR J Environ Sci Toxicol Food Technol. 2014;8:1–07. doi: 10.9790/2402-08530107. [DOI] [Google Scholar]

- Koushesh Saba M, Sogvar OB. Combination of carboxymethyl cellulose-based coatings with calcium and ascorbic acid impacts in browning and quality of fresh-cut apples. LWT - Food Sci Technol. 2016;66:165–171. doi: 10.1016/j.lwt.2015.10.022. [DOI] [Google Scholar]

- Koutsos A, Tuohy KM, Lovegrove JA. Apples and cardiovascular health—is the gut microbiota a core consideration? Nutr. 2015;7:3959–3998. doi: 10.3390/NU7063959. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Kumar Anurag R, Mann Swati Sethi S, Kalnar Y (2018) Modified atmosphere packaging design for fruits and vegetables. Ludhiana, Punjab

- Kuswandi B (2017) Freshness Sensors for Food Packaging. 10.1016/B978-0-08-100596-5.21876-3

- Ladanyia M, Ladaniya M (2010) Citrus fruit: biology, technology and evaluation

- Lang C, Hübert T. A colour ripeness indicator for apples. Food Bioprocess Technol. 2012;5:3244–3249. doi: 10.1007/s11947-011-0694-4. [DOI] [Google Scholar]

- Łata B, Trampczynska A, Paczesna J. Cultivar variation in apple peel and whole fruit phenolic composition. Sci Hortic (amsterdam) 2009;121:176–181. doi: 10.1016/J.SCIENTA.2009.01.038. [DOI] [Google Scholar]

- Lee JY, Park HJ, Lee CY, Choi WY. Extending shelf-life of minimally processed apples with edible coatings and antibrowning agents. LWT - Food Sci Technol. 2003;36:323–329. doi: 10.1016/S0023-6438(03)00014-8. [DOI] [Google Scholar]

- Li X, Li W, Jiang Y, et al. Effect of nano-ZnO-coated active packaging on quality of fresh-cut ‘Fuji’ apple. Int J Food Sci Technol. 2011;46:1947–1955. doi: 10.1111/j.1365-2621.2011.02706.x. [DOI] [Google Scholar]

- Lu Y, Yeap Foo L. Antioxidant and radical scavenging activities of polyphenols from apple pomace. Food Chem. 2000;68:81–85. doi: 10.1016/S0308-8146(99)00167-3. [DOI] [Google Scholar]

- Lyu F, Luiz SF, Azeredo DRP, et al. Apple pomace as a functional and healthy ingredient in food products: a review. Process. 2020;8:319. doi: 10.3390/PR8030319. [DOI] [Google Scholar]

- Ma Y, Zhao Y, Xie J, et al. Optimization, characterization and evaluation of papaya polysaccharide-corn starch film for fresh cut apples. Int J Biol Macromol. 2021;166:1057–1071. doi: 10.1016/j.ijbiomac.2020.10.261. [DOI] [PubMed] [Google Scholar]

- Majid I, Ahmad Nayik G, Mohammad Dar S, Nanda V. Novel food packaging technologies: innovations and future prospective. J Saudi Soc Agric Sci. 2018;17:454–462. [Google Scholar]

- Mukama M, Ambaw A, Opara UL. Advances in design and performance evaluation of fresh fruit ventilated distribution packaging: a review. Food Packag Shelf Life. 2020;24:1004. doi: 10.1016/j.fpsl.2020.100472. [DOI] [Google Scholar]

- Naqash F, Masoodi FA, Ayob O, Parvez S. Effect of active pectin edible coatings on the safety and quality of fresh-cut apple. Int J Food Sci Technol. 2021 doi: 10.1111/ijfs.15059. [DOI] [Google Scholar]

- Nicolau-Lapeña I, Aguiló-Aguayo I, Kramer B, et al. Combination of ferulic acid with aloe vera gel or alginate coatings for shelf-life prolongation of fresh-cut apples. Food Packag Shelf Life. 2021;27:100620. doi: 10.1016/j.fpsl.2020.100620. [DOI] [Google Scholar]

- Oliveira M, Abadias M, Usall J, et al. Application of modified atmosphere packaging as a safety approach to fresh-cut fruits and vegetables - A review. Trends Food Sci Technol. 2015;46:13–26. doi: 10.1016/j.tifs.2015.07.017. [DOI] [Google Scholar]

- Oriani VB, Molina G, Chiumarelli M, et al. Properties of cassava starch-based edible coating containing essential oils. J Food Sci. 2014 doi: 10.1111/1750-3841.12332. [DOI] [PubMed] [Google Scholar]

- Pan SY, Chen CH, Lai LS. Effect of tapioca starch/decolorized hsian-tsao leaf gum-based active coatings on the qualities of fresh-cut apples. Food Bioprocess Technol. 2013;6:2059–2069. doi: 10.1007/s11947-012-0907-5. [DOI] [Google Scholar]

- Pathare PB, Opara UL. Structural design of corrugated boxes for horticultural produce: a review. Biosyst Eng. 2014;125:128–140. doi: 10.1016/j.biosystemseng.2014.06.021. [DOI] [Google Scholar]

- Patocka J, Bhardwaj K, Klimova B, et al. Malus domestica: a review on nutritional features, chemical composition, traditional and medicinal value. Plants. 2020;9:1–19. doi: 10.3390/plants9111408. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Preethi R, Moses JA, Anandharamakrishnan C. Development of anacardic acid incorporated biopolymeric film for active packaging applications. Food Packag Shelf Life. 2021;28:100656. doi: 10.1016/j.fpsl.2021.100656. [DOI] [Google Scholar]

- Robertson GL (2014) Food packaging. In: Encyclopedia of agriculture and food systems. Elsevier, pp 232–249

- Rocculi P, Romani S, Dalla Rosa M. Evaluation of physico-chemical parameters of minimally processed apples packed in non-conventional modified atmosphere. Food Res Int. 2004;37:329–335. doi: 10.1016/j.foodres.2004.01.006. [DOI] [Google Scholar]

- Rojas-Graü MA, Raybaudi-Massilia RM, Soliva-Fortuny RC, et al. Apple puree-alginate edible coating as carrier of antimicrobial agents to prolong shelf-life of fresh-cut apples. Postharvest Biol Technol. 2007;45:254–264. doi: 10.1016/j.postharvbio.2007.01.017. [DOI] [Google Scholar]

- Saklani P, Kishor Das S, Mohan Singh S. A review of edible packaging for foods. Int J Curr Microbiol App Sci. 2019;8:2885–2895. doi: 10.20546/ijcmas.2019.807.359. [DOI] [Google Scholar]

- Salvia-Trujillo L, Rojas-Graü MA, Soliva-Fortuny R, Martín-Belloso O. Use of antimicrobial nanoemulsions as edible coatings: impact on safety and quality attributes of fresh-cut fuji apples. Postharvest Biol Technol. 2015;105:8–16. doi: 10.1016/j.postharvbio.2015.03.009. [DOI] [Google Scholar]

- Sapper M, Palou L, Pérez-Gago MB, Chiralt A. Antifungal starch-gellan edible coatings with thyme essential oil for the postharvest preservation of apple and persimmon. Coatings. 2019;9:333. doi: 10.3390/coatings9050333. [DOI] [Google Scholar]

- Sharma RR, Pal RK, Singh D, et al. Evaluation of heat shrinkable films for shelf life, and quality of individually wrapped royal delicious apples under ambient conditions. J Food Sci Technol. 2013;50:590–594. doi: 10.1007/s13197-011-0332-1. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Sharma,R.R. and Pal RK (2009) Promising Technologies : New Delhi

- Siroli L, Patrignani F, Serrazanetti DI, et al. Efficacy of natural antimicrobials to prolong the shelf-life of minimally processed apples packaged in modified atmosphere. Food Control. 2014;46:403–411. doi: 10.1016/j.foodcont.2014.05.049. [DOI] [Google Scholar]

- Skinner RC, Gigliotti JC, Ku KM, Tou JC. A comprehensive analysis of the composition, health benefits, and safety of apple pomace. Nutr Rev. 2018;76:893–909. doi: 10.1093/NUTRIT/NUY033. [DOI] [PubMed] [Google Scholar]

- Soliva-Fortuny RC, Grigelmo-Miguel N, Odriozola-Serrano I, et al. Browning evaluation of ready-to-eat apples as affected by modified atmosphere packaging. J Agric Food Chem. 2001;49:3685–3690. doi: 10.1021/jf010190c. [DOI] [PubMed] [Google Scholar]

- Soliva-Fortuny BC, Oms-Oliu G, Martín-Belloso O. Effects of ripeness stages on the storage atmosphere, color, and textural properties of minimally processed apple slices. J Food Sci. 2002;67:1958–1963. doi: 10.1111/j.1365-2621.2002.tb08752.x. [DOI] [Google Scholar]

- Soltani M, Alimardani R, Mobli H, Mohtasebi SS. Modified Atmosphere Packaging: A Progressive Technology for Shelf-Life Extension of Fruits and Vegetables. J Appl Packag Res. 2015;7:2. [Google Scholar]

- Souza Cruz R, Camilloto GP, Clarissa A, Pires S. Oxygen scavengers: an approach on food preservation. Struct Funct Food Eng. 2012 doi: 10.5772/48453. [DOI] [Google Scholar]

- Subedi GD, Gautam DM, Baral DR, et al. Evaluation of packaging materials for transportation of apple fruits in CFB boxes. Int J Hortic. 2017 doi: 10.5376/ijh.2017.07.0008. [DOI] [Google Scholar]

- Tapia MS, Rojas-Graü MA, Rodríguez FJ, et al. Alginate- and gellan-based edible films for probiotic coatings on fresh-cut fruits. J Food Sci. 2007 doi: 10.1111/j.1750-3841.2007.00318.x. [DOI] [PubMed] [Google Scholar]

- Thakur AK, Kumar R, Bhushan Shambhu V, Shekhar Singh I. Effectiveness of shrink-wrap packaging on extending the shelf-life of apple. Int J Curr Microbiol Appl Sci. 2017;6:3365–3374. doi: 10.20546/ijcmas.2017.612.273. [DOI] [Google Scholar]

- Vasylieva N, James H. Production and trade patterns in the world apple market. Innov Mark. 2021;17:16–25. doi: 10.21511/IM.17(1).2021.02. [DOI] [Google Scholar]

- Wei H, Seidi F, Zhang T, et al. Ethylene scavengers for the preservation of fruits and vegetables: a review. Food Chem. 2021;337:127750. doi: 10.1016/j.foodchem.2020.127750. [DOI] [PubMed] [Google Scholar]

- Wilson MD, Stanley RA, Eyles A, Ross T. Innovative processes and technologies for modified atmosphere packaging of fresh and fresh-cut fruits and vegetables. Crit Rev Food Sci Nutr. 2019;59:411–422. doi: 10.1080/10408398.2017.1375892. [DOI] [PubMed] [Google Scholar]

- Zhang C, Yang Z, Shi J, et al. Physical properties and bioactivities of chitosan/gelatin-based films loaded with tannic acid and its application on the preservation of fresh-cut apples. LWT. 2021;144:111223. doi: 10.1016/j.lwt.2021.111223. [DOI] [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.

Data Availability Statement

Not applicable.