Abstract

Although the best-known use of the different species of earthworm is the production of organic fertilizer, they can also be considered a rich source of biologically and pharmacologically-active compounds, for use in the treatment of various diseases. In recent decades, with the development of biochemical technologies, research on the pharmaceutical effects of compounds extracted from different species of earthworms has begun. Enzymatic hydrolysis is the most common and widely used technique for producing bioactive hydrolysates, because it uses moderate operating conditions, with a certain specificity for the substrate. In the present study, the objective was to optimize and scale up the enzymatic hydrolysis of Eisenia foetida protein to obtain peptides with biological activity. The substrate characterization was carried out according to AOAC, a response surface design was performed for the optimization of the enzymatic hydrolysis and then the scaling was performed by means of dimensional analysis. The results show that the major component of the paste is protein, 65% of which is albumin, and the absence of pathogenic microorganisms was also found. Regarding optimization, it was found that the optimal hydrolysis conditions are achieved with pH = 8.5; temperature = 45 °C; amount of substrate = 125 g and volume of enzyme = 1245μL. For the scaling, 4 dimensionless pi-numbers were calculated which describe the process with no statistically significant differences between the model and the prototype; it can be concluded that the enzymatic hydrolysate of Eisenia foetida presents high values of antioxidant activity evaluated by different methodologies.

Keywords: Earthworm, Protein, Hydrolysis, Antioxidant, Scale-up

1. Introduction

On the one hand, agro-industrial development represents the increase in food availability and improvement in the quality of life of the population. However, on the other hand, it entails the production of a high volume of waste, which can have a significant environmental impact [1]. The use of this waste represents a challenge, since it is not only about mitigating the environmental impact generated by its dumping, but also about revaluing it under conditions that have real possibilities of reaching the productive sector. In this sense, vermiculture emerges as a viable alternative, since it is a biological process that converts plant residues into agricultural inputs of interest, as is the case of humus, both solid and liquid [2]. Thanks to an ability to process agroindustrial waste and obtain nutrient-rich materials, this activity has shown considerable growth in recent years, mainly because worms are easy to care for, prolific, and have accelerated growth [3]. In addition, they are a source of high-quality protein, which can be used in both human and animal feed [4].

Although the best known use of the different species of earthworm is the production of organic fertilizer [5], they can also be considered a rich source of biologically and pharmacologically-active compounds, for use in the treatment of various diseases [6]. They have been used for therapeutic purposes since ancient times, especially by the Chinese and Hindu cultures [7]. The use of different varieties of earthworm have long been documented, and about five hundred years ago, Shizhen Li compiled the famous book “Compendium of Material”, in which the earthworm was recorded as a prescription drug for antipyretic and diuretic purposes in dry powder form, which continues to be implemented today [8]. In recent decades, with the development of biochemical technologies, research on the pharmaceutical effects of compounds extracted from different species of earthworms [9] has begun. These have been shown to be nutritionally dense and have antipyretic, antispasmodic, detoxifying, diuretic, antihypertensive, antiallergic, antiasthmatic, antioxidant, antimicrobial, anticancer, anti-inflammatory, and anti-ulcer properties [7].

Protein hydrolysis involves the breaking of a peptide bond by the action of water and enzymatic or chemical catalysis [10]. Due to the hydrolysis process, the molecular properties of proteins change, producing fragments of lower molecular weight, increased charge and the release of hydrophobic groups, among others [11]. These changes lead to improving the nutritional value and functional properties of proteins (texture or flavor), either by reducing allergenic compounds or by obtaining bioactive peptides. Enzymatic hydrolysis is the most common and widely used technique for producing bioactive hydrolysates [12], because it uses moderate operating conditions, with a certain specificity for the substrate [13]. One of the most widely used enzymes is Alcalase®, which has multiple advantages for obtaining antioxidant and antihypertensive peptides with metal chelating properties, mainly because it is an endo-protease [14]. In previous works, different enzymes have been evaluated on the Californian red worm, reporting that under the conditions of these works, Alcalase 2.4 L® was found to be the enzyme with the highest catalytic efficiency for the hydrolysis of Californian red worm proteins, reaching a degree of hydrolysis of 13%, two and four times higher than that achieved with Flavourzyme and Neutrasa, respectively [15].

Moreover, the enzymatic hydrolysis of different species of earthworm such as Eisenia Andrei [16], Lumbricus rubellus [17] and Eudrilus eugeniae [12] has been investigated to obtain peptides with biological properties, such as antioxidant capacity and antimicrobial activity, among others [6,18]. However, there are few reports in the literature on the enzymatic hydrolysates of Californian red worm (Eisenia foetida) and their possible biological properties [19]. Therefore, the purpose of this study was the optimization and scale up of the enzymatic hydrolysis of Californian red worm protein (Eisenia foetida), to obtain peptides with biological activity.

2. Material and methods

2.1. Chemical and reagents

The reagents 2,2′-azino-bis(3-ethylbenzothiazoline)-6-sulfonic acid (ABTS), 6-hydroxy-2,5,7,8-tetramethylchromo-2-carboxylic acid (Trolox), 3-(2-pyridyl), 2, 2′-Azobis (2-methylpropionamidine) dihydrochloride (AAPH) and Fluorescein-12-UTP were obtained from Sigma-Aldrich (Oakville, Ontario, Canada) and 2,4,6-Tri-2-pyridyl-s-triazine (TPTZ) was supplied by Merck (Darmstadt, Germany). Alcalase® 2.4 L (commercial protease obtained from fermentation of Bacillus licheniformis, non-specific serine endopeptidase) was supplied by Novozymes (Bagsværd, Denmark). All reagents implemented in this study were analytical grade.

2.2. Obtaining worm paste

Initially, the worms are manually separated from the substrate on which they feed, they are washed with drinking water to remove substrate residues, they are purged for 4 h with a 4% sodium bicarbonate solution by immersion in a plastic container, then a washing with drinking water is performed to remove bicarbonate residue the residues from the purge of the red California earthworm. Afterwards, they are sacrificed by immersing them in a 7% saline solution for a period of 30 min in a plastic container. Finally, the paste is washed with potable water and frozen at −20 °C for hydrolysis processes.

2.3. Bromatological and microbiological characterization

The proximal characterization of the worm paste was carried out in accordance with the provisions of the Association of Official Analytical Chemists (AOAC) [20]. Moisture content was determined according to standard 930.15, drying the sample at 105 °C for 8 h; the protein according to the Kjeldahl method, 954.010; total ash content according to standard 942.05. Furthermore, the content of ethereal extract (lipid contents) was carried out according to standard 920.39 following the soxhlet methodology. The quantification of protein types (albumins, globulins, glutelins and prolamins) was performed using the method of Osborne (1907) [21].

The microbiological characterization was carried out with the parameters established by the Colombian Technical Standard NTC 3688, which describes the analysis of aerobic mesophiles, total and fecal coliforms, Salmonella Spp., and molds and yeasts for these types of products.

2.4. Enzymatic hydrolysis

The enzymatic hydrolysis process is carried out in a 0.5 L glass reactor which is fully loaded with the working solution. For pH and temperature control, a combined glass electrode was implemented, connected to a TitroLine 6000 automatic titrator (SI Analytics GmbH, Germany). The reaction was monitored over time for 4000 s by means of the degree of hydrolysis (GH), which is defined as the ratio between the number of peptide bonds hydrolyzed at a given time (h) and the number of total peptide bonds in the reaction. Native protein per unit weight (ht: 8.1 mequiv/g) which is calculated by adding the total moles of amino acids contained in substrate [22]. The method used for the determination of GH was the proton titration or pH-static method. This is based on the fact that as hydrolysis progresses in an alkaline medium, the terminal carboxyl group dissociates completely and the released protons are distributed according to the protonation balance of the released α-amino groups, with which a decrease in pH can occur [23]. The number of moles of base needed to keep it constant is equivalent to the moles of broken peptide bonds. In this case, a basic solution (1 N NaOH) was added. To calculate the GH, equation 1was implemented [22].

| (1) |

B corresponds to the volume of sodium hydroxide consumed in L; MP is the mass of protein loaded in the reactor in kg; NB the normality of sodium hydroxide, and α the degree of dissociation of the amino groups released in the hydrolysis. The value of α is calculated as a function of the temperature and the pK of the reaction, according to equations (2), (3)), respectively.

| (2) |

| (3) |

2.5. Optimization of enzymatic hydrolysis

For the optimization of the enzymatic hydrolysis, an experimental central composite design of response surface was used, with five points at the center. Four factors were considered, pH (7–9), temperature (40–60 °C), earthworm paste mass (100–200 g) and alcalase enzyme (500–1500 μL) corresponding to 1.5–4.5 UA-U of enzyme activity, taking as response variables, GH, and TEAC and FRAP antioxidant activity. The stirring speed was kept constant in all experiments at a value of 240 rpm. The design delivered 21 randomized experimental runs, as shown in Table 1. The effects of the factors and the value of the coefficients estimated in the model were determined from the Analysis of Variance (ANOVA), for which the P-value was considered, with a confidence level of 95%. Based on the ANOVA, the mathematical models that describe the responses based on the factors were obtained. These models were subjected to an optimization process to maximize the response values. The Design-Expert® 8.0.5 software (Stat-Ease, USA) was used for the generation, optimization, and analysis of the design data.

Table 1.

Experimental design of enzymatic hydrolysis.

| Run | A: pH | B: Temperature | C: Substrate | D: Enzyme | GH % | FRAP (u eqmol trolox/g) | TEAC (u eqmol trolox/g) |

|---|---|---|---|---|---|---|---|

| 1 | 8.5 | 55 | 125 | 750 | 13.09 | 68.04 | 1210.34 |

| 2 | 8 | 50 | 100 | 1000 | 8.54 | 75.2979 | 1235.98 |

| 3 | 8 | 50 | 150 | 1000 | 9.93 | 65.2541 | 1075.04 |

| 4 | 8 | 50 | 150 | 500 | 9.13 | 66.7932 | 1054.54 |

| 5 | 8.5 | 55 | 175 | 750 | 11.33 | 80.2514 | 1028.92 |

| 6 | 8 | 50 | 150 | 1500 | 9.24 | 63.2855 | 1075.21 |

| 7 | 8.5 | 45 | 175 | 1250 | 19.52 | 63.423 | 1128.61 |

| 8 | 8 | 50 | 150 | 1000 | 9.69 | 64.0075 | 1105.99 |

| 9 | 8 | 50 | 150 | 1000 | 9 | 61.0337 | 1033.45 |

| 10 | 7 | 50 | 150 | 1000 | 5.88 | 67.0889 | 821.11 |

| 11 | 8 | 50 | 200 | 1000 | 8.95 | 51.3473 | 823.666 |

| 12 | 7.5 | 55 | 125 | 1250 | 6.92 | 68.115 | 1027.46 |

| 13 | 7.5 | 45 | 175 | 750 | 8.5 | 55.2378 | 829.591 |

| 14 | 8 | 60 | 150 | 1000 | 6.59 | 64.2792 | 842.231 |

| 15 | 8.5 | 45 | 125 | 1250 | 14.76 | 81.5723 | 1479.96 |

| 16 | 8 | 50 | 150 | 1000 | 9.46 | 62.5723 | 1040.05 |

| 17 | 9 | 50 | 150 | 1000 | 19.58 | 75.9116 | 1367.97 |

| 18 | 8 | 50 | 150 | 1000 | 9.22 | 62.8308 | 1007.68 |

| 19 | 7.5 | 55 | 175 | 1250 | 6.58 | 55.6187 | 685.087 |

| 20 | 7.5 | 45 | 125 | 750 | 9.37 | 72.9962 | 1106.63 |

| 21 | 8 | 40 | 150 | 1000 | 11.39 | 65.1236 | 1104.99 |

2.6. Antioxidant activity of the hydrolysate

2.6.1. TEAC (trolox equivalent antioxidant capacity) measurement

This was performed following the method described by Re et al. (1999), in which 20 μL of the sample or Trolox standard are mixed with 180 μL of the ABTS* solution and incubated at 30 °C for 30 min. After this, the absorbance measurements are taken at 730 nm, in a Varioskam Lux multiplier reader equipment (Thermo Fisher Scientific, USA). As standard for the calibration curve, trolox was used in concentrations between 0 and 500 μM. Results are expressed as micromoles of Trolox equivalents per gram of hydrolyzed protein (μmolET/g).

2.6.2. FRAP (ferric ion Reducing Antioxidant Power) measurement

This was carried out with the methodology described by Benzie & Straint, (1996), where 175 μL of the FRAP reagent (with TPTZ, FeCl and sodium acetate buffer) are mixed with 25 μL of the sample or Trolox standard and incubated at 37 °C for 30 min. After this time, the absorbance at 595 nm is read in a Varioskam Lux multiplier reader equipment (Thermo Fisher Scientific, USA). Trolox was used as a standard for the calibration curve in concentrations between 0 and 500 μM. Results are expressed as micromoles of Trolox equivalents per gram of hydrolyzed protein (μmolET/g).

2.6.3. ORAC (oxygen radical absorbance capacity) measurement

The ORAC assay was performed according to the method of Ou et al. (2001). All working solutions of AAPH (2,2ʹ-Azobis-(2-amidinopropane), 2HCl, 2,2ʹ-Azobis-(2-methylpropionamidine)), fluorescein, and worm hydrolyzate were diluted in 75 mM phosphate buffer (pH 7.4) and the final reaction mixture was 200 mL. Hydrolyzate (50 μL) and fluorescein (50 μL; 78 nmol/L final concentration) solutions were placed in the 96-well black microplate. The mixture was pre-incubated for 15 min at 37 °C before adding AAPH (25 μL; 40 mmol/L final concentration). Fluorescence was recorded every minute for 120 min. Fluorescence measurements were performed at 37 °C. Excitation and emission filters were at 485 and 520 nm, respectively using a Varioskam Lux multiplier reader (Thermo Fisher Scientific, USA).

2.7. Enzymatic hydrolysis scale-up

Normally, the scale-up process is based on the so-called “chemical, biological and geometric similarity principle”, in which the differences in properties between the two systems maintain a constant ratio, and the reaction is carried out under the same conditions [24]. In some cases, only dynamic similarity is used, but in others it is necessary to use dimensional analysis [25,26]. The theory on which this model is based states that “two processes can be considered completely similar if they have spatial geometrical similarity and if each of the dimensionless numbers required to describe them have the same numerical value (π_i = idem)." This is because the Pi space is invariant and independent of the scale on which one is working. “Each of the points determined by a Pi relation will correspond to an infinite number of possible ways of being realized".

The scale-up process was carried out going from a 0.5 L reactor (laboratory model) to a 7.5 L reactor (bench scale prototype), presenting a scale-up ratio of 1:15, as shown in Fig. 1 [27]. Enzymatic hydrolysis in the scale up was performed for both scales under the optimal conditions defined in the experimental design. It starts from a small-scale geometric model with some characteristics similar to the prototype and from the understanding of the physical properties of the fluid and the system, as well as the dimensions of the work systems [28]. The dimensional analysis establishes that a physical phenomenon can be formulated in a dimensionally homogeneous way following the subsequent three steps.

-

1.

Make a list of the most important variables, including the physical variables of influence on the model system, which must be independent of each other and which must be considered account with respect to the quantity to be produced.

-

2.

Verify the dimensional homogeneity of the physical content converting it to a dimensionless structure.

-

3.

Calculate a set of dimensionless Pi numbers, using a transformation matrix, being this known as "Pi's theorem”, which indicates that to adequately describe a technological system at least 2 dimensionless numbers are required [25].

Fig. 1.

Dimensions of model reactor (left) and prototype reactor (right).

3. Results and discussion

3.1. Physicochemical and microbiological characterization

Table 2 shows the proximal composition of the Californian red worm paste. The paste has a high protein content compared to its other macro components, this being mainly albumins, globulins and glutelins with 65.25%, 20.12% and 11.87%, respectively. This protein value is within the normal range, according to what is reported in the literature, where it is mentioned that the earthworm has protein values higher than 60% [16,29,30]. Additionally, the high content of minerals present is highlighted in the worm paste, with 5.82% in the nutritional composition.

Table 2.

Bromatological composition of red Californian earthworm paste.

| Component | Californian red worm |

|---|---|

| Moisture (%) | 84.87 ± 0.06 |

| Protein (%)a | 67.06 ± 0.08 |

| Lipids (%) | 1.42 ± 0.38 |

| Ask (%) | 5.82 ± 0.39 |

| Albumins (%) | 65.25 ± 0.28 |

| Globulins (%) | 20.12 ± 0.12 |

| Prolamins (%) | 2.85 ± 0.07 |

| Glutelin (%) | 11.87 ± 0.09 |

Dry base.

On the other hand, Table 3 shows the microbiological characterization of the Californian red worm paste obtained for this study, which highlights the absence of pathogenic microorganisms such as fecal coliforms, Salmonella Spp. and Clostridium sulfite reducing spore, as well as the low concentration of aerobic mesophilic batteries, molds and yeasts and total coliforms, which are within the parameters established by current regulations. This indicates that the worm paste has the appropriate characteristics to be implemented in processes aimed at human consumption.

Table 3.

Microbiological analysis of Californian red earthworm slurry.

| Analysis | Value | Requirementsa |

|---|---|---|

| Aerobic mesophiles (ufc/ml) | 5 × 102 | 10 × 105 |

| Total coliforms (ufc/ml) | 3.5 × 101 | 10 × 104 |

| Fecal coliforms | Absence | Absence |

| Salmonella spp | Absence | Absence |

| Clostridium sulfite spore | Absence | 20 × 101 |

| Molds and yeasts (ufc/ml) | 8.2 × 101 | 10 × 104 |

Directiva técnica DIP 30- 100 – 001; Instituto Colombiano de Agricultura (ICA).

3.2. Effect of factors on the enzymatic hydrolysis of Californian red worm (Eisenia foetida) proteins

Table 1 shows the results of each of the response variables for each of the experimental runs defined in the experimental design. Likewise, Table 4 presents the results of the analysis of variance of the experimental design for each of the response variables. For the three response variables, the high values of the coefficient of determination (R2) indicate that the adjusted model assertively predicts the result for the degree of hydrolysis and the antioxidant activities TEAC and FRAP. Similarly, for the three response variables, there is no lack of fit, which means that the relationship between the experimental factors and the response variables was adequately described [16,31].

Table 4.

analysis of variance (ANOVA).

| Source | p-value |

||

|---|---|---|---|

| GH (%) | TEAC (μ eqmol trolox/g) | FRAP (μ eqmol trolox/g) | |

| Model | <0.0001 | <0.0001 | <0.0001 |

| A-pH | <0.0001 | <0.0001 | 0.0172 |

| B-Temperature | <0.0001 | <0.0001 | 0.7513 |

| C-Substrate | – | <0.0001 | <0.0001 |

| D-Enzyme | – | – | 0.1244 |

| AC | – | – | 0.0026 |

| BC | – | – | 0.0001 |

| BD | – | – | 0.0222 |

| CD | – | – | 0.0021 |

| A2 | – | – | 0.0004 |

| Lack of Fit | 0.0641 | 0.2683 | 0.1946 |

| R2 | 0.9333 | 0.9544 | 0.9371 |

Table 1 shows that GH varied between 5.88 and 19.58%, depending on the conditions implemented. The factors that presented statistically significant effects (P < 0.05) on GH are pH and temperature. Equation (4) presents the mathematical model that describes this effect of these two variables on GH. It shows that, as the pH increases and the temperature decreases in the working range, there is an increase in the degree of hydrolysis of the Californian red worm protein.

The degree of hydrolysis is significantly affected by temperature and pH, as these modify the spatial structure of the enzyme, generating a change in the exposure of its active sites, which leads to the breaking of the peptide bonds of the native protein [32]. The increase in temperature increases the kinetic energy of the molecules, generating a greater probability of the enzyme-substrate union. However, due to the protein nature, the enzymes are mainly affected in their tertiary structure at certain temperatures, producing a denaturation, and decreasing the probability of protein binding and peptide production [33]. This produces a loss of catalytic capacity when the process is carried out above said temperature [34,35]. Concerning the pH, it modifies the distribution of charges and the conformation of proteins, generating an effect on the substrate but also on the enzyme [36]. The pH can additionally modify the dissociation of the active enzymatic sites, which changes the dynamics of association and generation of the enzyme-substrate complex [37,38].

Similar trends were reported by Rodrigues et al. en 2017, in the optimization of the enzymatic hydrolysis conditions of earthworm (Eiseina andrei), indicating that the increase in pH, the agitation speed and the enzyme/substrate ratio and the decrease in temperature and of the hydrolysis time provides the most favorable conditions for the enzymatic hydrolysis of the earthworm (Eiseina andrei) [16].

| (4) |

Despite the importance of GH, given its relationship with the progress of the reaction, the most relevant response variables in this case are those that define the biological activity of the hydrolysates. Since all the work is oriented to find the process conditions that allow obtaining the highest production of compounds with antioxidant activity. The trolox equivalent antioxidant capacity (TEAC) is influenced in a statistically significant way by the amount of substrate, as well as temperature and pH. According to equation (5), the increase in pH, the reduction in temperature and substrate concentration, have a positive effect on antioxidant activity. This effect is directly related to the mechanisms of hydrolysis. Differences have been observed in peptide release kinetics when the initial amount of protein in the reaction medium is modified, generating a change in the selectivity of the enzyme [39]. According to this, if the affinity of the enzyme for the native protein is changed by the change in the substrate concentration [40], the degree of hydrolysis, the size and the final composition of the peptides of the generated hydrolysates will change [39], which leads to obtaining peptides with variable antioxidant activities. In this sense, the transfer of electrons for the inhibition of free radicals is more active when there are peptides and molecules of lower molecular weight, allowing them to act as electron donors [41]. These factors were reported by Suarez et al., 2021 as the main variables with effects on the optimization of enzymatic hydrolysis of cassava leaf with antioxidant activity, using similar ranges of pH and temperature. Finally, the Ferric ion Reducing Antioxidant Power (FRAP) is the response variable that presents the greatest number of factors and interactions that have a statistically significant influence, as seen in equation (6). The independent factors, amount of substrate and pH of hydrolysis, are the variables that present the predominant effects for the FRAP antioxidant capacity, while the temperature and amount of enzyme factors do not present significant effects. However, these cannot be eliminated from the mathematical model, and their interactions do have effects.

| (5) |

| (6) |

Fig. 2 (A-C) presents the response surface graphs for the degree of hydrolysis and the antioxidant activities TEAC and FRAP with respect to the factors that have the greatest influence for each of the response variables.

Fig. 2.

Response surface experimental design A. Degree of hydrolysis. B. TEAC. C. FRAP.

3.3. Optimization of the hydrolysis conditions to maximize the activities of the hydrolysates

Equations (4), (5), (6) were subjected to a multi-objective optimization process that provided the values of pH, temperature, substrate and enzyme concentration, which maximized the values of GH, ABTS and FRAP. Taking the desirability as a parameter as well, for which it was obtained that, with its maximum value of 98%, it is reached with a pH = 8.5; temperature = 45 °C; amount of substrate = 125 g and volume of enzyme = 1245 μL, maintaining constant stirring at 240 rpm for the established period of 4000 s in the 0.5 L reactor. Table 5 shows the verification of the predicted values by means of the experimentally optimized model, where the excellent correlation between the predicted values and those measured experimentally is highlighted.

Table 5.

Experimental verification of optimum conditions.

| Sample | GH |

Protein |

TEAC |

FRAP |

|---|---|---|---|---|

| % | % | μ eqmol trolox/g prot | μ eqmol trolox/g prot | |

| Predicted | 16.53 | 3.38 | 1929.40 | 80.73 |

| Experimental | 16.55 | 3.27 | 2088.82 | 183.12 |

This validates the model for the response variables and confirms the existence of an optimal condition in the enzymatic hydrolysis of Californian red worm protein. The trolox equivalent antioxidant activity (TEAC) presents a higher value compared to studies reported by Sierra-Lopera & Zapata-Montoya, 2021 y Suarez et al., 2021 in the optimization of enzymatic hydrolysis of red tilapia scales (Oreochromis sp.) and cassava leaf (Manihot esculenta Crantz) presenting values of 1362.9 and 209.8 μmol trolox/g protein, respectively, indicating that the Californian red worm hydrolysate is an excellent source of peptides with antioxidant activity through the donation of cations [42,43].

3.4. Scale up of the enzymatic hydrolysis process of Californian red worm proteins (Eisenia foetida)

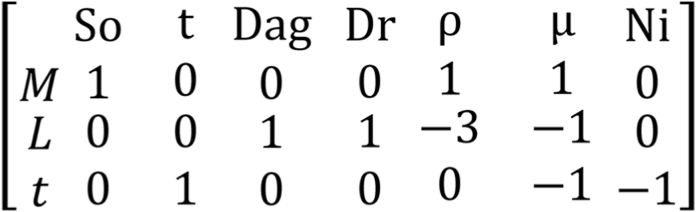

Assuming the dynamic similarity as a scale-up criterion, a dimensional analysis was applied, in which the diameter of the reactor (Dr) and the diameter of the stirrer (Ds) were taken as influential variables in the process, from the geometric point of view. Density (ρ), kinematic viscosity (ν), concentration of the substrate (So) was taken as physical properties of the fluid and the speed of the stirrer (Ni) and the reaction time (t), as dynamic parameters. In this sense, the relevance list was established as: So, Ds, Dr, ρ, μ, Ni and t. Moreover, the dimensions involved in the influence variables are M, L and t which are shown in equation (7), allow to calculate the range of the dimensional matrix.

| (7) |

Based on the previous result, the need for a total of four (4) dimensionless Pi numbers is defined. From the transformation of the relevance list into a dimensional matrix with the physical quantities, the matrix solution led to a reduced matrix (Fig. 3), which resulted in the four dimensionless Pi numbers (equations (8), (9), (10), (11))). These numbers, properly combined, result in the Pi number observed in equation (12), where it is identified that the dimensionless number that governs the enzymatic hydrolysis scale-up process is the Reynolds number [44,45].

| (8) |

| (9) |

| (10) |

| (11) |

Fig. 3.

Matrix of reduced dimensions.

The Reynolds number (Re) is related to the dynamic conditions of the reaction vessel. Therefore, the dimensioning was carried out maintaining its dynamic similarity, thus keeping the Re number constant between the laboratory system and the prototype. As established by the dimensional analysis procedure in the scale-up process, the parametric relationships of six dimensions were taken into account [26,27].

| (12) |

Consequently, the relationship shown by Pi number will be valid for the two study systems, with an increase in scale at the so-called operating point. This procedure was used since the prototype system was known. Of course, the concept of similarity does not guarantee that a process will be the same in the model and in the scale version in all aspects, since this method only reproduces the same process in the conditions analyzed, and those that were described by a certain Pi relationship. Both reaction systems were homogeneous and maintained a dynamic similarity, which is a requirement for scaling up any bioprocess (Fig. 1). The scale up based on the dynamic similarity of the system using the Reynolds number assumes that the inertial forces with respect to the viscous stresses remain constant in both scales. In this study, the constant Reynolds number criterion has been used, which, due to its theoretical and empirical nature, determines a similarity in the hydrodynamic flow pattern. This implies that the process must maintain the same degree of homogeneity in both systems [27,46]. With the increase of the scale, the stirring speed required to maintain the Reynolds constant decreases significantly, with the aim of achieving similar hydrodynamic behavior in both processes [24]. The condition to achieve hydrodynamic similarity is established in equation (13), where “m” corresponds to the model and “p” corresponds to the prototype; Ni is the stirring speed (rpm), and Ds is the diameter of the stirrer (m). In this case, the density and viscosity of the medium are constant in both systems and the only variation is in the diameter of the stirrers. In this sense, the speed of the (Ni)p prototype stirrer varies as a function of the size of the reaction system, as shown in equation (13).

| (13) |

The stirrer diameter of the 7.5 L reactor was 0.075 m and the respective diameter of the stirring bar in the 0.5 L reaction system was 0.05 m, presenting a scale-up relationship similar to those reported in the literature for protein hydrolysis processes [47]. The conditions established for enzymatic hydrolysis in the 7.5 L reactor are shown in Table 6, keeping the temperature and pH factors constant and adjusting the concentration of substrate and enzyme according to the total volume of reactor. The speed of the stirrer in the prototype was calculated with equation (13), presenting a reduction compared to the model of approximately 50%. Fig. 4 shows the kinetic behavior of the enzymatic hydrolysis under the optimal conditions of the experimental design, both in the 0.5 L and in the 7.5 L reactor. It was found that there were no statistically significant differences between the properties of the hydrolysates at the final stage of the process (4000 s) (Table 7).

Table 6.

Factors dimensioned for 7.5 L reactor.

| Factor | Units | Value |

|---|---|---|

| pH | 8.50 | |

| Temperature | ° C | 45 |

| substrate | g | 1501.05 |

| Enzyme | mL | 14.93 |

| Agitation | RPM | 122.45 |

Fig. 4.

Degree of hydrolysis in the model and the prototype.

Table 7.

Verification of enzymatic hydrolysis scale-up.

| SAMPLE | GH |

Protein |

TEAC |

FRAP |

ORAC |

|---|---|---|---|---|---|

| % | % | μ eqmol trolox/g prot | μ eqmol trolox/g prot | μ eqmol trolox/g prot | |

| Reactor 0,5 L | 16.552 | 3.27a | 2088.82a | 183.12a | 858.72a |

| Reactor 7,5 L | 16.202 | 3.15a | 2055.08b | 170.09a | 823.79a |

Different letters indicate statistically significant differences using the t-student test.

Different letters indicate statistically significant differences using the t-student test.

This validates and confirms that the scale-up process of the enzymatic hydrolysis of Californian red worm protein was carried out properly, and that the dimensionless Pi numbers found, and the constant Reynolds number is a valid criterion for the scale up of this type of process. Which is relevant, considering geometric differences between model and protype, since the model uses a magnetic stirring bar in a reactor without baffles, while prototype use a reactor with two baffles and two Rushton turbines. Similar results were reported by Gómez Grimaldos & Zapata, in 2021, in the increase of the enzymatic hydrolysis of bovine plasma protein to produce an antioxidant from a biological source, scaling from a 1 L to a 5 L reactor. Additionally, Pozdnyakov et al. in 2022, reported that there were no statistically significant differences in the results obtained in the kinetics of enzymatic hydrolysis of soy protein isolate between the laboratory scale and a semi-industrial scale.

4. Conclusions

The current study demonstrated the optimization of enzymatic hydrolysis of Californian redworm pasta proteins by implementing an endo-protease enzyme. The enzymatic hydrolysis of Californian red worm protein is significantly affected by the temperature and pH of the reaction medium, the optimal conditions being 45 °C and 8.5, respectively, achieving degrees of hydrolysis of 16%. On the other hand, the biological activities are additionally affected by the amount of substrate loaded in the reactor, reaching optimal values of 2088.82 and 183.12 μ eqmol trolox/g protein for TEAC and FRAP, respectively. The scale up of the reaction system from a 0.5 L reactor to a 7.5 L reactor using the dynamic similarity criterion based on the Reynolds number, allows to reproduce the optimal conditions obtained in the model system, which is essential to achieve its validation at pilot or industrial level. The Californian red worm enzymatic hydrolysate presents high values of antioxidant activity evaluated by different methodologies in comparison with protein hydrolysates from other animal sources, which is an important value for its implementation in functional foods or nutraceuticals.

Author contribution statement

Yhoan S. Gaviria G.: Conceived and designed the experiments; Performed the experiments; Analyzed and interpreted the data; Contributed reagents, materials, analysis tools or data; Wrote the paper.

José E. Zapata M: Conceived and designed the experiments; Performed the experiments; Analyzed and interpreted the data.

Data availability statement

Data included in article/supp. Material/referenced in article.

Additional information

No additional information is available for this paper.

Funding statement

The authors are grateful for the financial support provided by Comité para el Desarrollo de la Investigación en la Universidad de Antioquia (CODI) through sustainability program and MINCIENCIAS through the convening for strengthening knowledge on institutions of public superiority education. (Project Code 82,040).

Declaration of competing interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Acknowledgements

The authors are grateful for the financial support provided by Comité para el Desarrollo de la Investigación en la Universidad de Antioquia (CODI) through sustainability program and MINCIENCIAS through the convening for strengthening knowledge on institutions of public superiority education. (Project Code 82040).

References

- 1.Heller M.C., Keoleian G.A. Greenhouse gas emission estimates of U.S. Dietary choices and food loss. J. Ind. Ecol. 2015;19(3):391–401. doi: 10.1111/jiec.12174. [DOI] [Google Scholar]

- 2.Manjarres Alarcon, Evaluacion A.E. Universidad de La Salle; 2019. Formulación de Alternativas Para El Mejoramiento Del Proceso de Aprovechamiento de Residuos Industriales Generados Por Empresas de Alimentos Primordialmente, Que Son Llevados a Disposición Final a La Planta Crear Vida S.A.S. [Google Scholar]

- 3.Guerrero R.D. Earthworm culture for vermicompost and vermimeal production and for vermiceutical application in the Philippines (1978-2008) – a review. Glob. Sci. Books. 2009;3:89–97. [Google Scholar]

- 4.Sun Z., Jiang H. Nutritive evaluation of earthworms as human food. Futur. Foods. 2017 doi: 10.5772/intechopen.70271. [DOI] [Google Scholar]

- 5.Karsten G., Drake H. Denitrifying bacteria in the earthworm gastrointestinal tract and in vivo emission of nitrous oxide (N2O) by earthworms. Appl. Environ. Microbiol. 1997;63:1887. doi: 10.1128/aem.63.5.1878-1882.1997. 1882. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 6.Sun Z. Earthworm as a biopharmaceutical: from traditional to precise. Eur. J. Biomed. Res. 2015;1(2):28. doi: 10.18088/ejbmr.1.2.2015.pp28-35. [DOI] [Google Scholar]

- 7.Paoletti M.G., Buscardo E., VanderJagt D.J., Pastuszyn A., Pizzoferrato L., Huang Y.S., Chuang L.T., Millson M., Cerda H., Torres F., Glew R.H. Nutrient content of earthworms consumed by Ye'Kuana amerindians of the alto orinoco of Venezuela. Proc. R. Soc. B Biol. Sci. 2003;270(1512):249–257. doi: 10.1098/rspb.2002.2141. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 8.Pan R., Zhang Z.-J., He R.-Q. Earthworm protease. Appl. Environ. Soil Sci. 2010;2010:1–13. doi: 10.1155/2010/294258. [DOI] [Google Scholar]

- 9.Chen C. Effect of adding chicory fructans in feed on broiler growth performance, serum cholesterol and intestinal lenght. Int. J. Poultry Sci. 2003;3:214–219. doi: 10.3923/ijps.2003.214.219. [DOI] [Google Scholar]

- 10.Benitez R., Ibarz A., Pagan J. Hidrolizados de Proteína: procesos y aplicaciones. Acta Bioquim. Clin. Latinoam. 2008;42(2):227–236. [Google Scholar]

- 11.Li-Chan E.C.Y. Bioactive peptides and protein hydrolysates: research trends and challenges for application as nutraceuticals and functional food ingredients. Curr. Opin. Food Sci. 2015;1(1):28–37. doi: 10.1016/j.cofs.2014.09.005. [DOI] [Google Scholar]

- 12.Aldarraji M., Halimoon N., Majid N. Antioxidant activity and total phenolic content of earthworm paste of Lumbricus rubellus (red worm) and Eudrilus eugenia (african night crawler) J. Entomol. Nematol. 2013;5(3):33–37. doi: 10.5897/jen2013.0075. [DOI] [Google Scholar]

- 13.Suarez L.M., Fan H., Zapata J.E., Wu J. Optimization of enzymatic hydrolysis for preparing cassava leaf hydrolysate with antioxidant activity. Food Bioprocess Technol. 2021;14(12):2181–2194. doi: 10.1007/s11947-021-02693-0. [DOI] [Google Scholar]

- 14.Sierra-Lopera L.M., Zapata-Montoya J.E. Optimization of enzymatic hydrolysis of red Tilapia scales (Oreochromis sp.) to obtain bioactive peptides. Biotechnol. Reports. 2021;30 doi: 10.1016/j.btre.2021.e00611. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 15.Norena A., Gomez-sampedro L. Enzymatic hydrolysis of californian red worm (E isenia fetida) proteins with different proteases. Publicaciones E Investig. 2022:1–5. [Google Scholar]

- 16.Rodrigues M., Carlesso W.M., Kuhn D., Altmayer T., Martini M.C., Tamiosso C.D., Mallmann C.A., De Souza C.F.V., Ethur E.M., Hoehne L. Enzymatic hydrolysis of the Eisenia andrei earthworm: characterization and evaluation of its properties. Biocatal. Biotransform. 2017;35(2):110–119. doi: 10.1080/10242422.2017.1278754. [DOI] [Google Scholar]

- 17.Azmi N., Hashim P., Hashim D.M., Halimoon N., Nik Majid N.M. Anti-elastase, anti-tyrosinase and matrix metalloproteinase-1 inhibitory activity of earthworm extracts as potential new anti-aging agent. Asian Pac. J. Trop. Biomed. 2014;4(Suppl 1):S348–S352. doi: 10.12980/APJTB.4.2014C1166. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 18.Fiolka M.J., Rzymowska J., Bilska S., Lewtak K., Dmoszynska-Graniczka M., Grzywnowicz K., Kazmierski W., Urbanik-Sypniewska T. Antitumor activity and apoptotic action of coelomic fluid from the earthworm dendrobaena veneta against A549 human lung cancer cells. Apmis. 2019;127(6):435–448. doi: 10.1111/apm.12941. [DOI] [PubMed] [Google Scholar]

- 19.Qin L., Shi X., Xia X. Study on enzymatic technology of earthworm peptides produced by alcalase. Guizhou Agric. Sci. 2010;8:160–163. [Google Scholar]

- 20.AOAC . 17a editio. Association of Official Analysis Chemists International; Washington, USA: 2000. Official Methods of Analysis of AOAC International. [Google Scholar]

- 21.Osborne T.B. Carnegie Institution of Washington; Washington: 1907. The Proteins of the Wheat Kernel., Judd & Det. [DOI] [Google Scholar]

- 22.Adler-Nissen J. Elsevier Appl. Sci. Publ.; 1985. Enzymic Hydrolysis of Food Protein. [Google Scholar]

- 23.Gomez L.J., Zapata J.E. Efecto Del Nivel de Grasa y Velocidad de Agitación En La Hidrolisis Enzimática de Vísceras de Tilapia Roja (Orechromis Sp.) Inf. Tecnol. 2017;28(4):47–56. doi: 10.4067/S0718-07642017000400007. [DOI] [Google Scholar]

- 24.Ruiz Á.A., Álvarez H. Escalamiento de Procesos químicos y bioquímicos basado en un modelo fenomenológico. Inf. Tecnol. 2011;22(6):33–52. doi: 10.4067/S0718-07642011000600005. [DOI] [Google Scholar]

- 25.Marko Z. Wyley-VCH Verlag GmbH & Co. second ed. Alemania; 2006. Scale-up in chemical engineering: second, completely revised and extended edition. [Google Scholar]

- 26.Cacciuttolo M., Arunakumari A. I., Ed. Marcel Dekker; New York: 2005. Scale-Up Considerations for Biotechnology-Derived Products. [DOI] [Google Scholar]

- 27.Gomez Grimaldos N., Zapata J.E. Scaling up the enzymatic hydrolysis of bovine plasma protein to produce an 3 antioxidant from a biological source. Curr. Pharmaceut. Biotechnol. 2021;22:150–158. doi: 10.2174/1389201021666200807104636. [DOI] [PubMed] [Google Scholar]

- 28.Sofer G. 2003. Validation of Biotechnology Processes. [DOI] [PubMed] [Google Scholar]

- 29.Vielma Rondon R., Ovalles Duran J., Leon Leal A., Medina A. Valor nutritivo de La harina de Lombriz (Eisenia foetida) como fuente de Aminoácidos y su estimación cuantitativa mediante cromatografía en fase reversa (HPLC) y derivatización precolumna con o-ftalaldehído (OPA) Ars. Pharm. 2003;15:43–58. [Google Scholar]

- 30.Muller M., Uebel A., Nieland M., Dallazen M., Kuhn D., Etgeton H., Souza C., Giovanella C., Ethur E., Hoehne L. Study of different conditions of enzymatic hydrolysis in earthworms. Int. J. New Technol. Res. 2017;3(11) [Google Scholar]

- 31.Guerard F., Sumaya-Martinez M.T., Laroque D., Chabeaud A., Dufossé L. Optimization of free radical scavenging activity by response surface methodology in the hydrolysis of shrimp processing discards. Process Biochem. 2007;42(11):1486–1491. doi: 10.1016/j.procbio.2007.07.016. [DOI] [Google Scholar]

- 32.Singh T.P., Siddiqi R.A., Sogi D.S. Statistical optimization of enzymatic hydrolysis of rice bran protein concentrate for enhanced hydrolysate production by papain. Lwt. 2018;99:77–83. doi: 10.1016/j.lwt.2018.09.014. [DOI] [Google Scholar]

- 33.Noman A., Xu Y., Al-Bukhaiti W.Q., Abed S.M., Ali A.H., Ramadhan A.H., Xia W. Influence of enzymatic hydrolysis conditions on the degree of hydrolysis and functional properties of protein hydrolysate obtained from Chinese sturgeon (Acipenser sinensis) by using papain enzyme. Process Biochem. 2018;67(January):19–28. doi: 10.1016/j.procbio.2018.01.009. [DOI] [Google Scholar]

- 34.Prieto C.A., Guadix E.M., Guadix A. Influence of temperature on protein hydrolysis in a cyclic batch enzyme membrane reactor. Biochem. Eng. J. 2008;42(3):217–223. doi: 10.1016/j.bej.2008.06.018. [DOI] [Google Scholar]

- 35.Perez-Galvez R., Almecija M.C., Espejo F.J., Guadix E.M., Guadix A. Bi-objective optimisation of the enzymatic hydrolysis of porcine blood protein. Biochem. Eng. J. 2011;53(3):305–310. doi: 10.1016/j.bej.2010.12.004. [DOI] [Google Scholar]

- 36.Roslan J., Kamal S.M.M., Khairul K.F., Abdullah N. Optimization of enzymatic hydrolysis of Tilapia muscle (Oreochromis niloticus) using response surface methodology (RSM) Sains Malays. 2014;43(11):1715–1723. [Google Scholar]

- 37.Shi D., He Z., Qi W. Lumping kinetic study on the process of tryptic hydrolysis of bovine serum albumin. Process Biochem. 2005;40(5):1943–1949. doi: 10.1016/j.procbio.2004.07.009. [DOI] [Google Scholar]

- 38.Morales J.A., Figueroa O.A., Zapata J.E. Optimización de Hidrólisis Enzimática de La Fracción Globular de Sangre Bovina Por Metodología de Superficie Respuesta y Evaluación de Sus Propiedades Antioxidantes. Inf. Tecnol. 2017;28(2):75–86. doi: 10.4067/S0718-07642017000200009. [DOI] [Google Scholar]

- 39.Deng Y., Butre C.I., Wierenga P.A. Influence of substrate concentration on the extent of protein enzymatic hydrolysis. Int. Dairy J. 2018;86:39–48. doi: 10.1016/j.idairyj.2018.06.018. [DOI] [Google Scholar]

- 40.Butre C.I., Wierenga P.A., Gruppen H. Effects of ionic strength on the enzymatic hydrolysis of diluted and concentrated whey protein isolate. J. Agric. Food Chem. 2012;60(22):5644–5651. doi: 10.1021/jf301409n. [DOI] [PubMed] [Google Scholar]

- 41.Flores Anaya S.M., Guevara Perez A., Cordova-Ramos J.S., Solari-Godino A. Efecto del tiempo de Hidrólisis enzimática sobre las propiedades tecno-funcionales y capacidad antioxidante de La pota dosidicus gigas. Ciencia e Invest. 2020;23(2):15–21. doi: 10.15381/ci.v23i2.19377. [DOI] [Google Scholar]

- 42.Re R., Pellegrini N., Proteggente A., Pannala A., Yang M., Rice-Evans C. Antioxidant activity applying an improved abts radical cation decolorization assay. Free Radic. Biol. Med. 1999;26(9/10):1231–1237. doi: 10.1016/S0891-5849(98)00315-3. [DOI] [PubMed] [Google Scholar]

- 43.Sepulveda C.T., Zapata J.E. Effects of enzymatic hydrolysis conditions on the antioxidant activity of red Tilapia (Oreochromis Spp.) viscera hydrolysates. Curr. Pharmaceut. Biotechnol. 2020;21(12):1249–1258. doi: 10.2174/1389201021666200506072526. [DOI] [PubMed] [Google Scholar]

- 44.Banerjee G., Car S., Liu T., Williams D.L., Meza S.L., Walton J.D., Hodge D.B. Scale-up and integration of alkaline hydrogen peroxide pretreatment, enzymatic hydrolysis, and ethanolic fermentation. Biotechnol. Bioeng. 2012;109(4):922–931. doi: 10.1002/bit.24385. [DOI] [PubMed] [Google Scholar]

- 45.Palmqvist B., Kadic A., Hagglund K., Petersson A., Liden G. Scale-up of high-solid enzymatic hydrolysis of steam-pretreated softwood: the effects of reactor flow conditions. Biomass Convers. Biorefinery. 2016;6(2):173–180. doi: 10.1007/s13399-015-0177-3. [DOI] [Google Scholar]

- 46.Junker B.H. Scale-up methodologies for Escherichia coli and yeast fermentation processes. J. Biosci. Bioeng. 2004;97(6):347–364. doi: 10.1263/jbb.97.347. [DOI] [PubMed] [Google Scholar]

- 47.Martinez D., Menendez C., Hernandez L., Sobrino A., Trujillo L.E., Rodriguez I., Perez E.R. Scaling-up batch conditions for efficient sucrose hydrolysis catalyzed by an immobilized recombinant pichia pastoris cells in a stirrer tank reactor. Electron. J. Biotechnol. 2017;25:39–42. doi: 10.1016/j.ejbt.2016.11.003. [DOI] [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.

Data Availability Statement

Data included in article/supp. Material/referenced in article.