Abstract

Population growth inevitably gives rise to an increase in consumption of products and services. This has the domino effect of more exploitation of already scarce natural resources, with its concomitant pollution from the industries that process these natural resources into products and services for man. At the end of life of these products, they are disposed of as waste to landfills. All these issues threaten the sustainable development of any society. To proffer sustainable solutions to the environmental problems associated with the process industry, it has incorporated the concepts of process intensification via modularization, lean manufacturing, and industrial ecology into its operations. These same concepts are used by nature, though in a different way. As nature has survived for billions of years, looking to nature for inspiration – biomimicry, might be the only sustainable solution to the planet's problem. This paper, reviews nature's strategies that have been tested, and are relevant to the process industry. It highlights biomimicry as a powerful tool for achieving sustainability in the people-process-planet relationship as it assists to reduce waste, increase process efficiency and reduce reliance on scarce natural resources. As the process industry seeks to reduce its negative impact on the planet, biomimicry offers a promising approach to creating a more sustainable future.

Keywords: Industry, Environment, Sustainable development, Nature, Inspiration

1. Introduction

1.1. The industrial revolutions

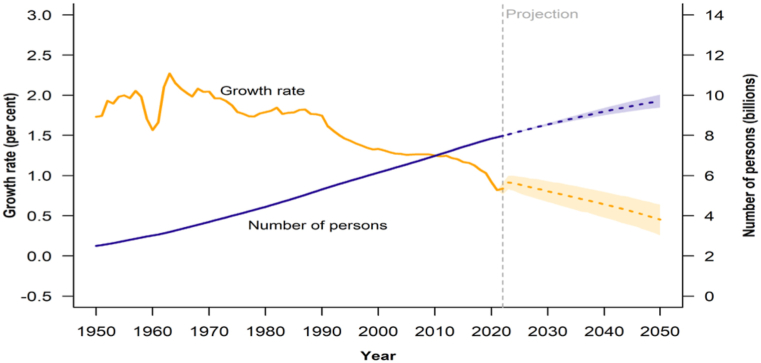

The early man lived in harmony with the environment in which he found himself; hunting and gathering his food from the environment and making use of what was readily available within his vicinity: vegetation, stone, wood, animal, wind, sun, and water were his main sources of food and energy. As time progressed, man started to exploit and dominate his environment, and thus began the industrial revolutions. The discovery of metals led to the construction of machines, followed by the discovery of steam energy and electricity. This aided the transition from manual to mass production with an increase in the number of processing industries. Man was mastering his environment and advancing as evidenced in the different industrial revolutions [1], but not without deleterious effect on the environment. Natural resources were fast being depleted. The processing of these natural resources into finished products and services for man gave rise to air pollution, water pollution, land pollution and so many other types of pollution: the environment all living things depend on for survival, was being threatened. There seems to be no end in sight, because as population increases so does consumption of products and services. The world's population is currently 8 billion [2] and this is predicted to grow, though at a slowing rate (Fig. 1). Therefore, consumption which is currently responsible for 60–80% of the earth's environmental degradation [3] will rise, leading to more resource depletion, and environmental degradation. The fourth industrial revolution brought in the information age, with smart industries using the concepts of Internet of Things, Big Data, Machine Learning, Artificial Intelligence, to revolutionize the workplace, with increased efficiency and productivity but having deleterious effects on humans [4,5] as robots replace human jobs, an unnatural phenomenon.

Fig. 1.

Estimate of world population and growth rate [2].

The word ‘robot’ was coined from a 1920 play, Rossum's Universal Robots, R.U.R, in which human machines (robots) perform tasks for man. However, the last act of the play showed the robots revolting against their human creator: coming events, is said to always, cast their shadows before they occur. Not only has robotics increased productivity in the workplace, but it has also helped in increasing the rate at which resources are being depleted and the planet polluted.

The industrial revolutions are as a result of man using his scientific knowledge to exploit and adapt nature to his aspirations and inclinations, and this has come with a lot of benefits, but with a cost: depletion of natural resources, as man is exploiting and consuming resources from the environment at a rate much faster than these resources can be replenished; in processing these resources into finished product and services for the benefit of man, a lot of toxic substances are released into the same environment man needs for his survival. At the end-of-life of these products, or when they become obsolete, and are ‘unwanted’, they are disposed of as waste, which has and is still creating a humongous solid waste issue with its attendant environmental problems. Man has indeed, impacted on his planet, howbeit, negatively, and the planet is no longer sustainable, man has become a victim of his own revolutions.

1.2. The process industry

The process industry is key to man's survival on earth: it exploits raw materials from the environment and processes them to services and products for the benefit of man. This industry includes industries such as chemicals, pharmaceuticals, food processing, petrochemical, paper and pulp, textile, steel, plastic, glass, mining, cement, paint, detergent, fertilizer, to mention a few. The process industry and the industrial revolutions are closely intertwined, with each driving and benefiting from the other's advancement: what was once manual labour was transformed to machine-based production, later, fully automated, and computerized industry, and now a smart, digitized and highly interconnected, data driven, internet-based industry.

1.3. The process industry, industrial revolution, and the sustainability of the planet

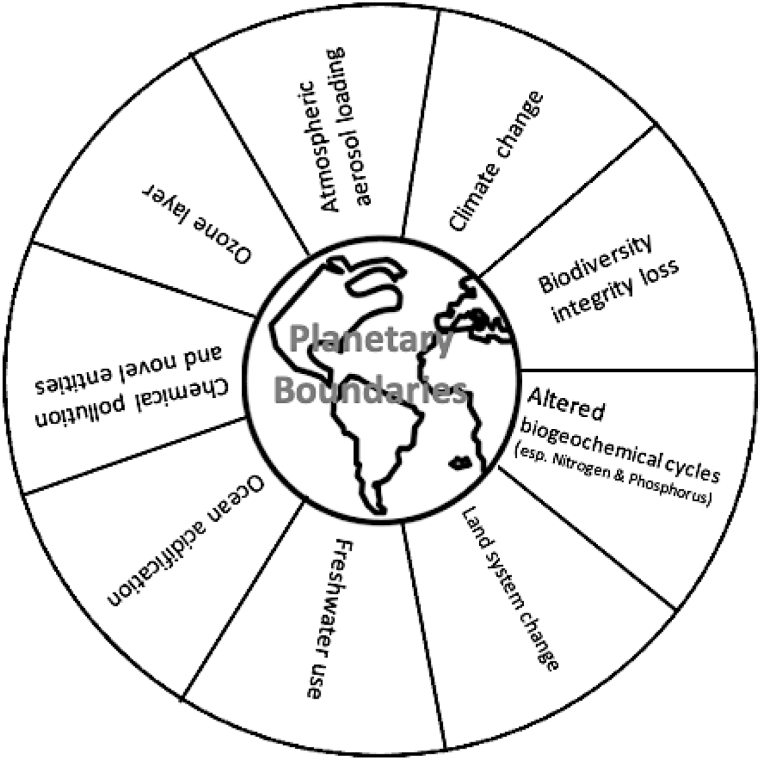

In all these revolutions, it is paramount to take into cognizance the burden bearing capacity of the planet, as it is now obvious that the planet is bulging under the weight of man's industrial revolutions. To ensure the survival and wellbeing of the planet and her people for generations to come, Rockstrom et al. [6] and Steffen [7] proposed a framework that consists of 9 planetary boundaries (Fig. 2) within which man must operate, of which the first four are already beyond their critical threshold [[8], [9], [10]] as shown in Table 1.

Fig. 2.

The nine planetary boundaries.

Table 1.

Planetary Boundaries and their threshold values.

| Earth-system process | Parameters | Proposed boundary | Current status | Pre-industrial value | ||

|---|---|---|---|---|---|---|

| 1. | Climate change | Atmospheric CO2 concentration (ppm by volume) | 350 | 398.5 | 280 | |

| 2. | Change in biodiversity integrity | Extinction rate (species per million species per year) | 10 | >100 | 0.1–1 | |

| 3. | Altered biogeochemical cycles (esp. For Nitrogen & Phosphorus) | Nitrogen Cycle | Amount of N2 removed from the atmosphere for human use (millions of tonnes per year) | 62 | 150 | 0 |

| Phosphorus cycle | Quantity of P flowing into the oceans (millions of tonnes per year) | 11 | 22 | −1 | ||

| 4. | Change in land use | Area of forested land as % of original forest cover | 75 | 62 | Low | |

| 5. | Global freshwater use & the global hydrological cycle | Consumption of freshwater by humans (km3 per year) | 4000 | 2600 | 415 | |

| 6. | Ocean acidification | Global mean saturation state of aragonite in surface water | 2.75 | 2.90 | 3.44 | |

| 8. | Ozone layer | Concentration of ozone (Dobson unit) | 276 | 283 | 290 | |

| 7. | Chemical pollution and introduction of novel new entities | Amount emitted (of organic pollutants, radioactive materials, nanomaterials, micro-plastics, and synthetic chemicals) to the environment an affecting ecosystem and the functioning of the earth's systems. | Yet to be quantified | |||

| 9. | Atmospheric aerosol loading | Overall particulate concentration in the atmosphere, on a regional basis | Yet to be quantified | |||

Similarly, the United Nations, concerned about the survival of the next generation, at its September 2015 summit, came up with 17 sustainable development goals, SDGs (Fig. 3), to help transform our current planet, and make it sustainable before 2030.

Fig. 3.

United Nation's 17 sustainable development goals [11].

1.4. Achieving sustainability in the process industry: past to present

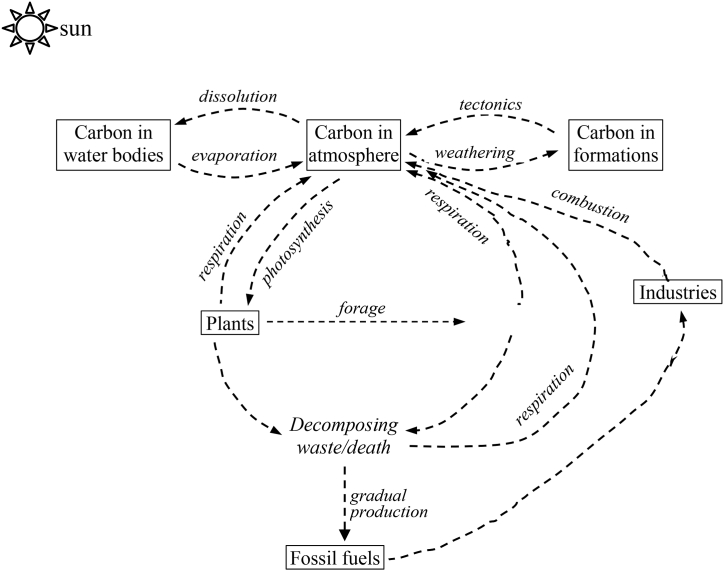

To minimize the negative impact of the process industry on the planet, different strategies have been proposed, the main ones being: lean manufacturing, process intensification and modularization, and industrial ecology. Lean manufacturing is based on the Japanese way of production and pioneered by Toyota [12]. It seeks to eliminate waste within the production process while at the same time maximizing production. It is a thinking process that understands, and then identifies what value is, and what activities and resources are necessary to create that value. Once this is established, everything else is waste and must be eliminated. This identified value must also be generated in as rapid a flow as possible, from raw material to finished product, to prevent the buildup of waste. Waste elimination is also achieved by pulling the product flow from demand. Process intensification (via modularization) seeks to improve the manufacturing process by developing techniques that will reduce equipment volume, and the number of operations required to achieve a desired production objective. This ultimately leads to a reduction in capital cost, operating cost, energy consumption, environmental impact, and safer plants. As it happened in the Communications-Information-Telecommunication (CIT) industry, the process industry, will become increasingly miniaturized and highly efficient. Process intensification makes small scale modular manufacturing possible, and instead of having a big manufacturing plant in one location, modules can be placed at different locations [13]. Industrial ecology - according to Commoner's 4 laws of ecology [14]: everything is connected to everything else, everything must go somewhere, nature knows best, and there is no such thing as a free lunch. These laws of ecology are best depicted by the biogeochemical cycles of nature. Carbon is one of the big 6 macronutrients essential for all organisms: it combines with hydrogen and oxygen to form carbohydrates; with nitrogen, it forms proteins; phosphorus is the energy element of the cells; calcium, the structure element, and sodium and potassium are elements for nerve signal transmission. To ensure the ever-availability of these chemicals which make life on earth possible, nature recycles them within its geographical features (atmosphere, water, rocks, and soil). Fig. 4 shows a basic carbon cycle flow diagram.

Fig. 4.

Basic carbon cycle flow diagram.

As living and non-living organisms in the natural ecosystems interact one with another, industrial ecology seeks to imitate this and encourages industries to do same. Industrial ecology is the transfer of ‘methods’ from the biogeochemical cycles of nature to the industrial setting. The concept of industrial ecology can be said to date back to pre-1980 when Frosh and Gallopoulos [15] proposed the idea of industrial systems being made to behave like an ecosystem, where the waste of a specie is the resource to another specie, thus reducing the use of raw materials, pollution, and saving on the waste that has to be treated or disposed of.

1.5. Sustainability

The singular purpose of the three strategies: lean manufacturing, process intensification and industrial ecology, is the sustainability of the planet and that of the process industries which both exist for the benefit of the people. Sustainability has been defined by the Brundtland report [16] as the ability to meet the needs of the present generation without compromising the ability of future generations to meet their own needs. Liverman et al. [17] further defined sustainability as the indefinite survival of the human species through the maintenance of basic life support systems (air, water, land, biota) and the existence of infrastructure and institutions which distribute and protect the components of these systems.” Just as a stool requires a minimum of three legs for stability, the sustainability stool (Fig. 5) can only be stabilized by: economic viability for the industry - Profit oriented, environmental protection - Planet oriented, and social equity – People oriented, the 3 P s of sustainability. The process industry can be seen to be the seat that holds the three legs of the stool together, in that, its inputs and outputs are both from and to the environment, for the benefit of the people, and it must run profitably for its survival.

Fig. 5.

The sustainability stool.

2. Biomimicry: the future of sustainability for people, process and planet

The process industry, while exploiting for raw materials and processing such to finished products for the benefit of man, tends to have deleterious effects on the environment. There is the over-exploitation of raw materials which leads to loss of natural resources; waste from the process industry is discharged to air, water, and land causing a gradual destruction of the environment man relies on for survival. A quote by Charles Percy Snow, a novelist and physicist, says “Technology is a queer thing, it brings you great gifts with one hand and stabs you in the back with the other”. This ought not to be. Janine Benyus [18] noted that other organisms, flora and fauna, share the same environment with man and have succeeded in carrying out their activities without the “stabbing of themselves in the back”. These organisms inherently and unconsciously imbibe the concepts of lean manufacturing, process intensification and ecology, but in a more nature-friendly way, and have survived the billions of years of earth's existence. She coined the word biomimicry from two Greek words: bios - life, and mimesis, - to imitate. Biomimicry (to imitate life) is the study of nature's forms, processes, and ecosystems for the purpose of drawing inspiration to be used in designing innovative engineering solutions that are in concert with the environment. Nature's guiding principles as enumerated by the Biomimicry institute are discussed in Ajayi [1] and can be summarized as: nature uses energy from the sun; uses only what is needed; fits form to function; recycles everything; rewards cooperation; banks on diversity; curbs excess from within; works within safe limits; uses local expertise; and works with information. The author also discussed the science of applying these principles learnt from nature (biomimetics) for developing new technologies and solutions, as it relates to architecture, medicine, communication, materials, and product designs. This review paper looks to the literature for biomimetics as it relates to the process industry, advocates the use of biomimicry to reverse the harmful impact of the industrial revolutions, and addresses the 9 planetary boundaries and goals 7, 12, 13 and 15 of the sustainable development goals.

How can biomimicry be incorporated into the process industry? Engineers design and operate these process industries and biomimicry seeks to foster collaboration between the biologists, who have a deeper insight into the natural world, and the engineers for a sustainable future. To set in motion this collaboration, two international standards were developed in 2015. The first, ISO 18458, Biomimetics - Terminology, concepts, and methodology. This standard describes terms used in biomimetics, and its potential as an innovation approach or as a sustainability strategy is illustrated. An overview of the various areas where it can be applied (where nature has produced a similarity to the desired technical target) is also given. The second, ISO 18459, Biomimetics - Biomimetic structural optimization illustrates the use of biomimetic for the analysis and optimization of a linear structure under static and fatigue stress.

The principles embedded in lean manufacturing, process intensification and industrial ecology are what nature has used to sustain the earth all these years of her existence; they are nature's inherent rule for sustainability [19] and have been integrated into the biomimicry design lens (Fig. 6) by the Biomimicry Institute. The process of inculcating these principles into the design and operation of industrial processes necessitates seeing nature as a model, a measure, and a mentor [18], the 3Ms of biomimicry. As a model nature gives strategies that can be adopted or adapted to solve some of the problems facing man. Innovative solutions should imitate or be inspired by nature's designs, processes, and ecosystems. This will ensure sustainable innovations. As a measure, nature's principles can be used as a benchmark to judge the sustainability of any innovation, and as a mentor, nature is seen as having billions of years of experience to be learnt from.

Fig. 6.

Biomimicry design lens: Life's principles [20].

3. Biomimicry and the process industry

The process industry is responsible for virtually all the products and services that form part of man's everyday life, and as technology has evolved over the years, so has the products man needs to live in the modern era evolved. But how sustainable have these services, products and the processes that generate them been? A lot of materials and energy goes into the processes that make these products, most of which end up as waste: electronics which are now an integral part of our everyday life, have printed circuit boards, of which, only 7% of the lead/tin used for soldering goes on the board, the remaining 93% is toxic waste that has to be disposed [21]. This is not so with nature; it abhors waste and fits form to function.

This review paper extracts from the literature biomimetics that are relevant to the process industry in the areas of optimization, energy conservation, process efficiency, water management, and resource conservation and recovery.

3.1. Biomimicry in optimization

In the design of products and processes, there are always so many alternatives to choose from and optimization helps to find the best solution that achieves maximum profit, minimum production cost, minimum environmental impacts, minimum use of resources, and maximum yield. One of the most effective and common methods used to solve process optimization problems is the golden section method, a line search method for one dimensional, unimodal, and non-differentiable objective functions. This method was inspired by nature's golden ratio, the Fibonacci sequence, believed to be the underlying geometry of spiral things ubiquitous in nature (Fig. 7). This sequence and ratio has also been utilized by user interface and graphic designers to create visually appealing displays to draw the attention of consumers [22].

Fig. 7.

The Fibonacci sequence in nature, aka the golden spiral. (For interpretation of the references to colour in this figure legend, the reader is referred to the Web version of this article.)

Left to right, top to bottom: seed pattern of sunflower, leaves on an aloe vera plant, sea shell, galaxies, the Fibonacci sequence, seed pattern of dandelion, a full cycle of the DNA molecule has a ratio of length to width of 1.619, uncurling fern (same for millipede), and hurricane [23].

Over the years a lot of biomimetic optimization algorithms have been developed. These methods are not as deterministic as the conventional methods and they have been found to be more effective in solving complex and challenging problems that could not be handled by the conventional methods [24,25]. Some of these algorithms and their sources of inspirations are given in Table 2 and are attestations to the fact that there are a lot to learn from nature.

Table 2.

Some Biomimetic algorithms for optimization.

| Optimization method | Inspiration |

|---|---|

| Simulated annealing | Annealing in metal processing, to increase the ductility of metal, by quick heating to a high temperature followed by slow cooling. |

| Genetic Algorithm | Darwin's evolution and selection process of biological systems |

| Ant colony optimization | Behaviour of ants searching for food. |

| Artificial Bee Colony Optimization | Foraging behaviour of honeybees |

| Particle swarm optimization | Fish & bird schooling in nature |

| Differential evolution | Natural phenomenon of evolution |

| Harmony Search | Music |

| Bat algorithm | Echolocation behaviour of bats in darkness to map their environment and distinguish prey from objects and predators |

| Firefly algorithm | Signalling technique of flashing patterns and rhythms used to liaise with other fireflies |

| Cuckoo search | Parasitic brooding of cuckoo who never build a nest and lay their eggs in the nest of another bird. |

| Flower pollination algorithm | Flowering plant reproduction strategy through pollination |

| Self-defence algorithm | Self-defence mechanism of plants from predator insects |

3.2. Biomimicry in energy conservation, efficiency, and environmental performance

Harman [26] devised an impeller, which was originally designed as a propeller for boats, for use in water storage tanks of municipal water and wastewater treatment plants. This impeller, termed the lily impeller, was inspired by nature's ubiquitous spiral shape (Fig. 7) and the calla lily (Fig. 8). The lily impeller with a height of 8 inches circulates hundreds of millions of gallons of water with the same energy footprint as a light bulb, thus reducing energy usage by 80%, noise reduction by 75%, and reducing the use of disinfectants, to treat stagnant water, by 85%.

Fig. 8.

The calla lily, and the inspired lily impeller [27].

The self-Cleansing paint, Lotusan inspired by the hydrophobic and dust resistant rough surface of the Lotus flower [28] was found to be more favourable than conventional paints, both in terms of economic and environmental performance [29].

Cypris Materials [30] inspired by the wings of morpho butterflies, produced paint whose vibrant colours are obtained by nanostructures, made from synthetic polymers. These nanostructures can manipulate and reflect light wavelengths. This technology avoids the use of toxic pigments and dyes, and the solar reflective coating gives an added advantage of significant savings in energy by reducing cooling cost.

Wu et al. [31,32] drew inspiration from plants to create an artificial photosynthesis process to use the excess CO2 in the atmosphere to generate energy. The process uses cuprous oxide as a catalyst to produce methanol as shown in Fig. 9.

Fig. 9.

CO2 reduction to methanol by photocatalysis.

Novomer [33], a company has also designed a photosynthesis-inspired catalyst that combines CO2 and limonene (which can be extracted from waste citrus peels) at low temperatures to make biodegradable polycarbonates.

3.2.1. The process industry, energy source and energy efficiency

The process industry is powered by energy, and taking a cue from nature, earth is powered by the sun, a renewable source of energy. According to the U.S. Department of Energy [34], the Sun deposits 120,000 TW (TW) of power to the earth's surface, while humans consume approximately 13 TW per year; the sun therefore provides the earth with more energy in one day than can consumed by the entire human race in a year [35].

As global warming continues to threaten the earth, the use of fossil fuels as the main source of energy will continue to be downplayed and solar energy, with other forms of renewable energy, will become the energy of the future. The BP Statistical Review of World Energy [36], reported coal as the dominant fuel for power generation in 2018–38%, followed by gas – 23.2%. Even though renewables contributed only 9.3% to global power generation, solar had the fastest growth rate per annum of 28.9% followed by wind,12.6%, and others, 7.0%.

Currently, solar cells made with silicon have a typical range of 15–20% efficiency [37], and at best, perovskite solar cells can have efficiencies up to 27.3% [38,39]. The moth eye structure has inspired the design of highly efficient solar cells to absorb more wavelengths of light, without reflection between films, thus boosting solar cell efficiency [40,41].

Wind energy follows solar as the next thriving source of clean, renewable, and affordable energy. Wind energy is harnessed when turbines are used to convert the kinetic energy in the wind into mechanical power, which in turn spins a generator to create electricity. These turbines are normally arranged on a windy area called a wind farm. When placed too close together, turbulence creates wake effects which disrupts and lowers the efficiency of the system. Various researchers [[42], [43], [44], [45], [46], [47], [48]] have proposed solutions, inspired by nature, for the design of wind propellers and for their optimal layout on farms. Cognet et al. [49], inspired by dragonflies, designed flexible propellers which could adapt to the wind speed, thereby making them 35% more efficient than the rigid propellers. Anis Aouini and Hassine Labaied of Saphron Energy inspired by the way sailboats convert wind energy to mechanical energy, developed the no-propellers wind turbine, known as the Saphonian. This device is noiseless, bird-friendly, 45% cheaper to manufacture and 2.3 times more efficient than the conventional turbines [50,51]. Saphron energy also mimicked the flapping of the hummingbird to invent the Tyer wind, another no-propellers turbine. Whittlesey et al. [52] observed that the V-shape formed by geese flying in the air reduces the amount of energy that is exerted by each individual bird and makes them move 70% farther than they would have moved alone. This same shape was also observed in a school of fish navigating ocean current and this has inspired a new layout for wind turbines on wind farms.

Studying the effect of bumps on the flippers of the humpback whale, Van Nierop et al. [53] studied the aerodynamic effect, while Fish et al. [54] studied the hydrodynamic effect, and their studies revealed that these bumps reduced drag by 32% while increasing lift by 8%. Introducing bumps on wind turbines showed they were more stable, quiet, durable, and more efficient than the unmodified conventional turbines and are being proposed for use also on fans, airplanes, and other propellers.

3.3. Biomimicry in water management - the Aquaweb

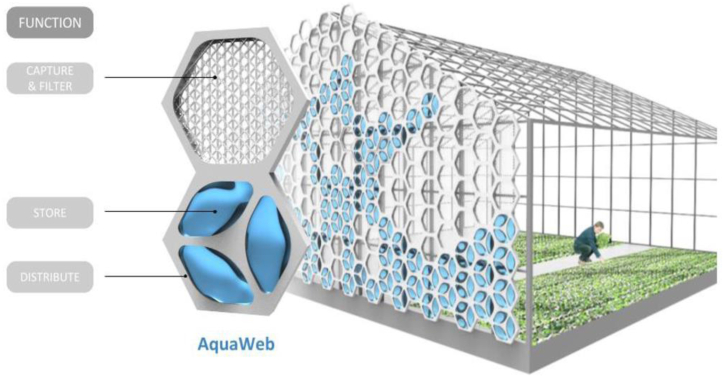

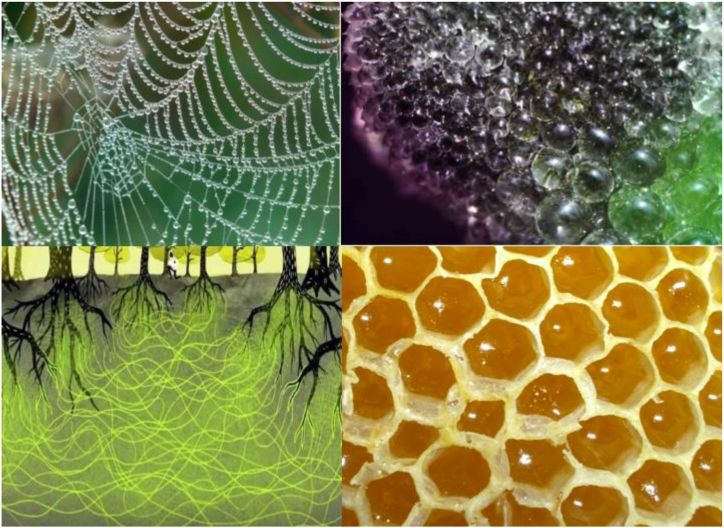

The process industry uses a lot of water and can take a cue from the Aquaweb. Since world population growth, has shown in Fig. 1, will lead to increase in food demand and its domino effect on freshwater withdrawal for agricultural purposes, a water challenge was envisaged for the future. Team Nexloop, who won the 2017 Ray of Hope prize of the Biomimicry Institute [55] designed a water management system, the Aquaweb (Fig. 10), that draws its inspiration from the works of various researchers: the ability of the cribellate spider, Uloborus Walckenaerium, to capture and direct water from the atmosphere [56]; the water storage technique of the ice plant in surface bladder-like cells [57,58]; the distribution of resources among plants by a fungal network present in the soil [59]; and the hexagonal shape of the beehive which gives it its extraordinary structural strength such that a comb made of 40 g of wax and 37 cm × 22.5 cm in size holds about 1.8 kg of honey [60]. These natural cues are shown in Fig. 11.

Fig. 10.

The AquaWeb [61].

Fig. 11.

Nature's inspiration for the AquaWeb–Spider web captures water and directs to centre [62], ice plant surface stores water [63], fungal network distributes nutrients to plants [64] and the strong hexagonal shape of the beehive [65].

The Aquaweb captures water from the air, stores and distributes the water saving on water and energy cost.

3.4. Biomimicry for resource conservation and recovery

The process industry is the chief culprit of inefficient use of nature's resources and environmental pollution leading to unsustainable development. To meet the needs and wants of man, industries exploit the earth for raw materials which are transformed into products and services for man. During the process of transformation, a lot of ‘unwanted materials’ are generated and because they are unwanted, they are discharged to either the air, water bodies or land. Initially, the earth, using its self-cleansing mechanism could cope with these discharges, but the rate at which man is discharging these unwanted materials far exceeds the earth's cleansing capacity. Man has impacted the earth, the earth is sick and is now impacting on man. There is, therefore, a need to emulate nature's strategies, discovered by Benyus [18] and discussed in Ajayi [1] which nature has used to survive these 3.5 billion years of its existence.

Commoner [14] observed that everything in nature is connected to everything else and everything must go somewhere, and this was depicted in the carbon cycle of Fig. 2. Observing nature's processing systems, they all operate cyclically in a closed loop manner, whereas the process industry operates in a linear, open loop format as shown in Fig. 12. This format is not only destructive to the earth as it exploits and depletes limited resources, but also pollutes the earth through its numerous points of discharges of waste to the environment. This is not so with nature, who has practically zero waste, as everything is recycled in a materially closed system. Humans seem to be the only organism on planet earth that produce ‘waste’ that is not useful for something else. There is a need to draw inspiration from the sustainable cycles of nature and close the loop - interacting one with another, taking less from the environment and discharging less to the environment. To achieve this, El-Haggar [66] proposed the 7Rs to innovation: regulations as a tool for enforcement, reducing to minimize the waste generated from source, reusing to find another use for the waste, recycling to use waste as raw materials for other products, recovery to generate material or energy from waste, rethinking and renovating as alternatives to disposal for any inevitable and unmanageable waste that still exist. The Kalundborg story, though not initially set out to demonstrate industrial ecology, closes the loop and is an excellent attestation to the effectiveness of industrial ecology.

Fig. 12.

Industry's linear/open loop system.

3.4.1. The Kalundborg story

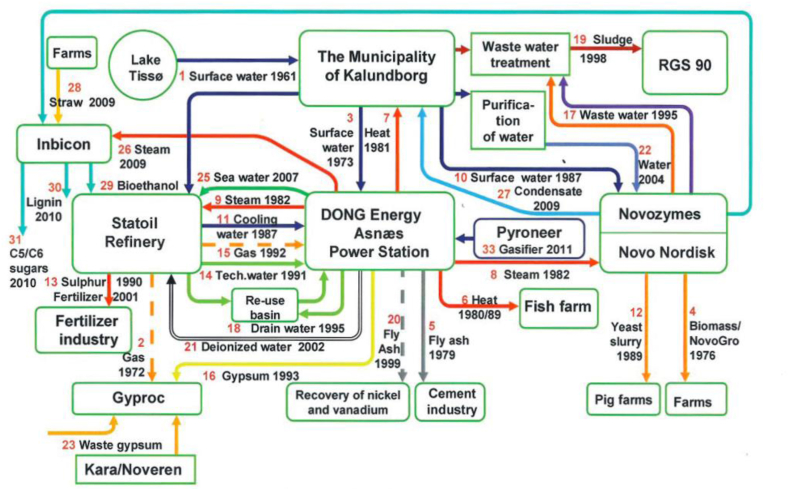

The collaboration between the enterprises in Kalundborg developed spontaneously over five decades. In 1959, Denmark's 1500 MW coal fired power plant, Asnaes Power Station (now Dong Energy) produced power for Kalundborg's 4500 households and other industries in the estate using underground water. NovoNordisk and Novozymes were pharmaceutical industries producing almost 50% of the world's supply of insulin and industrial enzymes. In 1961 Statoil (then Esso) refinery started operation and used water from lake Tisso. In 1972 Gyproc, a gypsum plasterboard company used waste gas from the statoil refinery for drying its plasterboard. In 1973 Asnaes stopped the use of underground water and connected to Statoil's water pipe. The status of the Kalundborg collaboration as of 1975 is shown in Fig. 13. After a period, Asnaes produced steam for Novo Nordisk, Novozymes and Statoil refinery, gypsum for Gyproc from its flue gas desulphurization plant, excess heat in its cooling water was sent to the municipality and to the fish farm, and most of its fly-ash was used by the cement company. Statoil made enough fertilizer for Denmark from its desulphurization plant. The status of the Kalundborg collaboration in 2011 is shown in Fig. 14.

Fig. 13.

The collaboration in Kalundborg as at 1975 (adapted from Saikkuu [67]).

Fig. 14.

Kalundborg collaboration status as at 2011 [70].

The collaboration between industries in Kalundborg resulted in reduction of resource consumption, and remarkable cutback in environmental pollution: in a year, CO2 emissions reduced by 635,000 tons, waste exchange comprised some 2.9 million tons of materials, collective water consumption reduced by 3.6 million m3 (25%), the power station reduced its water use by 60% through recycling and 100 GW h of energy was saved [68]. As at 2015.

Novo Nordisk and Novozymes converted 330,000 tons of spent yeast to fertilizer for 50,000 acres, and biogas for 6000 homes. The savings for the collaborating industries was in the tune of $27 million [69]. Just as nature recycles everything, rewards cooperation, banks on diversity, demands on local expertise, and curbs excess from within, the Kalundborg collaboration, where one company's waste became the resource for another, proves that emulating these principles of nature in our process industries will go a long way in resource conservation and pollution prevention thus ensuring a sustainable environment.

3.5. Biomimicry and process (chemical) engineering

The main responsibility of the process industry is the transformation of raw materials to finished products for the benefit of mankind, and the chemical (process) engineering profession is responsible for the development, designing and operation of these processing industries. A major challenge for the profession is the ability to combine environmental friendliness and profitability when designing these processes and products. Coppens [71] echoed Benyus concept of biomimicry in recommending Nature Inspired Chemical Engineering (NICE), as the way to go for sustainable process engineering, where nature is seen as a rich reference to design new sustainable products, processes, and services, thus ensuring a sustainable future. In line with this new paradigm, University College London, in 2013, established a centre for nature inspired engineering and in 2014 an elective course, Nature Inspired Chemical Engineering (NICE) was introduced into the chemical engineering curriculum [72]. Gerbaud et al. [73] also summarises recent nature-inspired chemical engineering processes.

4. Adopting and implementing biomimicry in the process industry

Biomimicry is a design concept that has gained popularity in recent years due to the growing awareness of the impact of human activities on the environment. It is the process of taking inspiration from nature's form, functions, processes, and systems to create innovative solutions that meet human needs while minimizing environmental impact. This section seeks to highlight how the principles of biomimicry can be adopted and implemented in the process industry for the benefit of both people and planet.

-

1.

One of the guiding principles of Biomimicry is ‘nature abhors waste – therefore it recycles everything’. It is therefore important for industries to rethink and renovate waste, thereby using it as a resource for another industry, as was done in Kalundborg.

-

2.

Since nature has already solved many of the problems that humans are currently struggling with, by studying nature, more sustainable and efficient solutions can be created: there is therefore the need to develop a database of nature's form, functions, processes, and systems; a job for the biologist who understands nature. The engineer in collaboration with the biologist now searches the database for an appropriate strategy to adopt. Nature's strategies must be seen as the model to be adopted, the measure of how sustainability and planet-friendly the solution is, and a mentor - having billions of years of experience to be learnt from. One of such databases is AskNature, an online, open-source database of the Biomimicry Institute.

-

3.

The transfer of technology from nature to the process industry – implementing biomimicry - is a top-down approach with steps itemized as:

-

i.

Define the purpose of the process/product or service.

-

ii.

Identify the main objectives and translate them into technical terms. These technical objectives are then expressed in biological terms.

-

iii.

Using the biological objectives, a biological model (a natural process/product that achieves the same objectives as the desired process/product) is searched for and selected from nature's database.

-

iv.

The strategies used by the biological model are extracted and translated to technical terms, which in turn is used for design, experimentation, and prototyping.

-

v.

The obtained design solution is modeled, simulated, and improved upon, and as new findings emerge from simulation studies, previous objectives and conclusions might need to be revised, and the design process goes through an iterative process, as shown in Fig. 15, until a viable design solution is obtained.

Fig. 15.

A simplified flowchart for implementing biomimetics in the process industry.

5. Future challenges and research direction

Biomimicry has the potential to be the sustainable nexus in the people-process-planet relationship. However, there are several challenges and research directions that will be critical to address.

5.1. Identifying and understanding the complex biological systems

One of the biggest challenges in implementing biomimicry in the process industry is identifying and understanding the complex biological systems that could serve as inspiration for new technologies. This requires a deep understanding of biological processes and systems, as well as expertise in the relevant engineering fields to translate these biological processes to technical processes. It is also important that biomimicry research be conducted in an ethical and morally responsible manner.

5.2. Developing new materials

Many biological systems rely on unique materials that are not yet available in synthetic form. There will therefore be a need to develop new materials, albeit using the principles of biomimicry, that can mimic the properties of these natural materials.

5.3. Scaling up production

Many biomimetic technologies that have been developed are still in the prototype stage and have not been scaled up for large-scale production. There is the need to develop scale-up processes for these technologies.

5.4. Balancing performance and sustainability

Biomimetic technologies often perform well, but they may not always be the most sustainable option. Researchers will need to balance performance and sustainability to create technologies that are both effective and environmentally friendly.

5.5. Collaborating across disciplines

Biomimicry requires collaboration across a range of disciplines, including biology, chemistry, physics, and engineering. Researchers will need to work together to develop new technologies that integrate knowledge from these fields.

5.6. Educating and training the next generation

Biomimicry is a relatively new field, and there is a need to educate and train the next generation of researchers in this area. This includes developing new curricula and training programs that incorporate biomimicry principles and practices.

6. Concluding remarks

The industrial revolutions through the years is an evidence of man's mastering of his environment albeit in an environmentally-unfriendly way. Man has impacted his environment to the extent that the environment is now impacting on man and threatening man's existence on planet earth. To ensure the continuous survival of man, there must be a paradigm shift in man's relationship with his environment. This new way of thinking, for the survival of man on planet earth, can only occur by observing how nature has survived these 3.8 billion years of its existence and imitating nature – biomimicry.

Towards the end of his life, Steve Jobs said “I think the biggest innovations of the 21st century will be at the intersection of biology and technology. A new era is beginning.” This collaboration between biology and technology, in which technological innovations draw inspirations from biological and natural processes, to find solutions to some of man's problems, could be the most effective route to sustainable development.

In conclusion, biomimicry is a powerful tool for achieving sustainability in the people-process-planet relationship. This paper has reviewed how some of nature's practices have been put to use and encourages the process industry to look to the natural world for inspiration, imitate the forms, processes, and systems to create sustainable solutions that work in harmony with the environment. This will help to reduce exploitation of natural resources, reduce waste, increase efficiency, and support social and economic sustainability. As people, the process industry, and the planet continue to face environmental challenges, biomimicry offers a promising approach to creating a more sustainable future.

Author contribution statement

All authors listed have significantly contributed to the development and the writing of this article.

Data availability statement

No data was used for the research described in the article.

Declaration of competing interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

References

- 1.Ajayi T. 15th University of Lagos Annual Research Conference Proceedings and Book of Abstract. 2020. Nature inspired innovations, the panacea for our ailing and distressed planet earth; pp. 67–80. [Google Scholar]

- 2.United Nations Department of Economic and Social Affairs, Population Division (2022). World Population Prospects 2022: Summary of Results. UN DESA/POP/2022/TR/NO. 3.

- 3.Ivanova D., Stadler K., Steen-Olsen K., Wood R., Vita G., Tukker A., Hertwich E.G. Environmental impact assessment of household consumption. J. Ind. Ecol. 2016;20:526–536. [Google Scholar]

- 4.Aburumman O.J.N., Popp J., Khan M.A., Haddad H., Kitukutha N. Impact of industry 4.0 on environmental sustainability. Sustain. Times. 2020;12(11):1–21. [Google Scholar]

- 5.Khan I.S., Ahmad M.O., Majava J. Industry 4.0 and sustainable development: a systematic mapping of triple bottom line, Circular Economy and Sustainable Business Models perspectives. J. Clean. Prod. 2021;297 [Google Scholar]

- 6.Rockström J., Steffen W., Noone K., Persson Å., Chapin F.S., Lambin E.F., Lenton T.M., Scheffer M., Folke C., Schellnhuber H.J., Nykvist B., de Wit C.A., Hughes T., van der Leeuw S., Rodhe H., Sörlin S., Snyder P.K., Costanza R., Svedin U., Falkenmark M., Karlberg L., Corell R.W., Fabry J., Hansen J., Walker B., Liverman D., Richardson K., Crutzen P., Foley J.A. A safe operation space for humanity. Nature. 2009;461:472–475. doi: 10.1038/461472a. [DOI] [PubMed] [Google Scholar]

- 7.Rockström J., Steffen W., Noone K., Persson Å., Chapin F.S., Lambin E.F., Lenton T.M., Scheffer M., Folke C., Schellnhuber H.J., Nykvist B., de Wit C.A., Hughes T., van der Leeuw S., Rodhe H., Sörlin S., Snyder P.K., Costanza R., Svedin U., Falkenmark M., Karlberg L., Corell R.W., Fabry J., Hansen J., Walker B., Liverman D., Richardson K., Crutzen P., Foley J.A. Planetary Boundaries: exploring the safe operating space for humanity. Ecol. Soc. 2009;14(2) doi: 10.1038/461472a. art. 32. [DOI] [PubMed] [Google Scholar]

- 8.Steffen W., Richardson K., Rockström J., Cornell S.E., Fetzer I., Bennett E.M., Biggs R., Carpenter S.R., De Vries W., De Wit C.A., Folke C., Gerten D., Heinke J., Mace G.M., Persson L.M., Ramanathan V., Reyers B., Sörlin S. Planetary boundaries: guiding human development on a changing planet. Science. 2015;347 doi: 10.1126/science.1259855. [DOI] [PubMed] [Google Scholar]

- 9.Whiteman G., Walker B., Perego P. Planetary boundaries: ecological foundations for corporate sustainability. J. Manag. Stud. 2013;50:307–336. [Google Scholar]

- 10.Persson L., Carney Almroth B.M., Collins C.D., Cornell S., de Wit C.A., Diamond M.L., Fantke P., Hassellöv M., MacLeod M., Ryberg M.W., Søgaard Jørgensen P., Villarrubia-Gómez P., Wang Z., Hauschild M.Z. Outside the safe operating space of the planetary boundary for novel entities. Environ. Sci. Technol. 2022;56:1510–1521. doi: 10.1021/acs.est.1c04158. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 11.United Nations Department of Economic and Social Affairs, Sustainable Development. (2016). Sustainable Development Goals: 17 Goals to Transform Our World. Available at: http://www.un.org/sustainabledevelopment (Accessed 21 March 2023).

- 12.Melton T. The benefits of lean manufacturing: what lean thinking has to offer the process industries. Chem. Eng. Res. Des. 2005;83:662–673. [Google Scholar]

- 13.Baldea M., Edgar T.F., Stanley B.L., Kiss A.A. Modular manufacturing processes : status , challenges and opportunities. AIChE J. 2017;63:4262–4272. [Google Scholar]

- 14.Gomeseria R.V. 2020, March 11. The Implication of Law of Ecology Means to the Environment We Live in. [Google Scholar]

- 15.Frosch R.A., Gallopoulos N.E. Strategies for Manufacturing the impact of industry on the environment. Sci. Am. 1989;261(3):144–153. [Google Scholar]

- 16.G. H. Brundtland, Our Common Future: Report of the World Commission on Environment and Development. Geneva, UN-Dokument A/42/427. http://www.un-documents.net/ocf-ov.htm.

- 17.Liverman D.M., Hanson M.E., Brown B.J., Merideth R.W. Global sustainability: toward measurement. Environ. Manag. 1988;12:133–143. [Google Scholar]

- 18.Benyus J.M. HarperCollins e-books; 2002. Biomimicry: Innovation Inspired by Nature. [Google Scholar]

- 19.Kennedy E.B., Marting T.A. 2016. Biomimicry: Streamlining the Front End of Innovation for Environmentally Sustainable Products. [Google Scholar]

- 20.Biomimicry 3.8. Biomimicry DesignLens; 2015. pp. 1–17. [Google Scholar]

- 21.Abdalla H.S., Ebeid M.A. Global Product Development; 2011. Global Product Development. [Google Scholar]

- 22.Judelman G. Proceedings. Eighth International Conference on Information Visualisation. vol. IV. 2004. Aesthetics and inspiration for visualization design: bridging the gap between art and science. [Google Scholar]

- 23.Educate Inspire Change, Learn about the Magic of Fibonacci in Nature – the Math of God. 2014. https://educateinspirechange.org/spirituality/learn-magic-fibonacci-nature-math-god/ accessed January 2, 2019. [Google Scholar]

- 24.Yang X.-S. first ed. Elsevier; 2014. Nature-Inspired Optimization Algorithms. [Google Scholar]

- 25.Yang X.-S. first ed. Springer; 2018. Studies in Computational Intelligence 744 Nature-Inspired Algorithms and Applied Optimization. [Google Scholar]

- 26.PAX WATER TECHNOLOGIES, Capturing the Force of Nature, (n.d.), https://paxscientific.com/water-tech (accessed April 8, 2020).

- 27.R. Topp. PAX SCIENTIFIC The Problem with Flow The PAX Solution [Internet]. Randy topp Business Improvement. (accessed March 17, 2023). Available from: http://rt-bi.nl/social-responsibility/bioinspiration/pax-scientific/.

- 28.Zari M.P. 2006. Biomimetic Approaches to Architectural Design. [Google Scholar]

- 29.Antony F., Grießhammer R., Speck T., Speck O. The cleaner, the greener? Product sustainability assessment of the biomimetic façade paint Lotusan® in comparison to the conventional façade paint Jumbosil. Beilstein J. Nanotechnol. 2016;7:2100–2115. doi: 10.3762/bjnano.7.200. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 30.Cypris A. 2020. New Color Paradigm.https://www.cyprismaterials.com/technology accessed November 24, 2020. [Google Scholar]

- 31.Wu Y.A., McNulty I., Liu C., Lau K.C., Liu Q., Paulikas A.P., Sun C.J., Cai Z., Guest J.R., Ren Y., Stamenkovic V., Curtiss L.A., Liu Y., Rajh T. Facet-dependent active sites of a single Cu2O particle photocatalyst for CO2 reduction to methanol. Nat. Energy. 2019;4:957–968. [Google Scholar]

- 32.Jo W.J., Katsoukis G., Frei H. Ultrathin amorphous silica membrane enhances proton transfer across solid-to-solid interfaces of stacked metal oxide nanolayers while blocking oxygen. Adv. Funct. Mater. 2020;1909262:1–11. [Google Scholar]

- 33.Novomer, A New Generation of Chemicals, (n.d.). https://www.novomer.com (accessed April 21, 2020).

- 34.Lewis N.S. 2005. Basic Research Needs for Solar Energy Utilization. [Google Scholar]

- 35.Morton O. A new day dawning. Nature. 2006;443:19–22. doi: 10.1038/443019a. [DOI] [PubMed] [Google Scholar]

- 36.Bp Statistical Review of World Energy, BP Statistical Review of World Energy, 2019.

- 37.Stropnik R., Stritih U. Increasing the efficiency of PV panel with the use of PCM. Renew. Energy. 2016;97:671–679. [Google Scholar]

- 38.Park N.G. Perovskite solar cells: an emerging photovoltaic technology. Mater. Today. 2015;18:65–72. [Google Scholar]

- 39.Kumari N., Patel S.R., Gohel J.V. 2018. Current Progress and Future Prospective of Perovskite Solar Cells : A Comprehensive Review. [Google Scholar]

- 40.Dacey J. 2009. Moth Eyes Inspire More Efficient Solar Cell.https://physicsworld.com/a/moth-eyes-inspire-more-efficient-solar-cell/ accessed April 10, 2020. [Google Scholar]

- 41.Boudoire F., Toth R., Heier J., Braun A., Constable E.C. Photonic light trapping in self-organized all-oxide microspheroids impacts photoelectrochemical water splitting. Energy Environ. Sci. 2014;7:2680–2688. [Google Scholar]

- 42.Samorani M. In: Handbook of Wind Power Systems. Pardalos P., Rebennack S., Pereira M.V.F., Iliadis N.A., Pappu V., editors. PowerLeeds School of Business; 2014. p. 852. [Google Scholar]

- 43.Feng J., Shen W.Z. Solving the wind farm layout optimization problem using random search algorithm. Renew. Energy. 2015;78:182–192. [Google Scholar]

- 44.Wu Y.K., Wu W.C., Zeng J.J. Key issues on the design of an offshore wind farm layout and its equivalent model. Appl. Sci. 2019:9. [Google Scholar]

- 45.Rehman S., Ali S.S., Khan S.A. Wind farm layout design using cuckoo search algorithms. Appl. Artif. Intell. 2018;32:956–978. [Google Scholar]

- 46.Hou P., Zhu J., Ma K., Yang G., Hu W., Chen Z. A review of offshore wind farm layout optimization and electrical system design methods. J. Mod. Power Syst. Clean Energy. 2019;7:975–986. [Google Scholar]

- 47.Amaral L., Castro R. Offshore wind farm layout optimization regarding wake effects and electrical losses. Eng. Appl. Artif. Intell. 2017;60:26–34. [Google Scholar]

- 48.Schubel P.J., Crossley R.J. Wind turbine blade design. Energies. 2012;5:3425–3449. [Google Scholar]

- 49.Cognet V., Courrech Du Pont S., Dobrev I., Massouh F., Thiria B. Bioinspired turbine blades offer new perspectives for wind energy. Proc. R. Soc. A. 2017;473 [Google Scholar]

- 50.Markham D. 2017. This Startup's Wind Generator Flaps its Wings like a Hummingbird.https://www.treehugger.com/wind-technology/startups-wind-generator-flaps-its-wings-hummingbird.html accessed April 6, 2020. [Google Scholar]

- 51.TheCivilEngineer.org . 2017. This Revolutionary Wind Converter Is Inspired by Hummingbird Wings, and Is Much More Compact and Silent than Conventional Ones.https://www.thecivilengineer.org/news-center/latest-news/item/1478-this-revolutionary-wind-converter-is-inspired-by-hummingbird-wings-and-is-much-more-compact-and-silent-than-conventional-ones accessed April 6, 2020. [Google Scholar]

- 52.Whittlesey R.W., Liska S., Dabiri J.O. Fish schooling as a basis for vertical axis wind turbine farm design. Bioinspiration Biomimetics. 2010;5 doi: 10.1088/1748-3182/5/3/035005. [DOI] [PubMed] [Google Scholar]

- 53.Van Nierop E.A., Alben S., Brenner M.P. How bumps on whale flippers delay stall: an aerodynamic model. Phys. Rev. Lett. 2008;100:1–4. doi: 10.1103/PhysRevLett.100.054502. [DOI] [PubMed] [Google Scholar]

- 54.Fish F.E., Weber P.W., Murray M.M., Howle L.E. The tubercles on humpback whales' flippers: application of bio-inspired technology. Integr. Comp. Biol. 2011;51:203–213. doi: 10.1093/icb/icr016. [DOI] [PubMed] [Google Scholar]

- 55.Biomimicry Institute . 2019. The Ray of Hope Prize.https://innovation.biomimicry.org/rayofhopeprize/ accessed January 2, 2019. [Google Scholar]

- 56.Zheng Y., Bai H., Huang Z., Tian X., Nie F.Q., Zhao Y., Zhai J., Jiang L. Directional water collection on wetted spider silk. Nature. 2010;463(7281):640–643. doi: 10.1038/nature08729. [DOI] [PubMed] [Google Scholar]

- 57.Agarie S., Shimoda T., Shimizu Y., Baumann K., Sunagawa H., Kondo A., Ueno O., Nakahara T., Nose A., Cushman J.C. Salt tolerance, salt accumulation, and ionic homeostasis in an epidermal bladder-cell-less mutant of the common ice plant Mesembryanthemum crystallinum. J. Exp. Bot. 2007 doi: 10.1093/jxb/erm057. [DOI] [PubMed] [Google Scholar]

- 58.Attenborough D. The Private Life of Plants; 1995. The Private Life of Plants. [Google Scholar]

- 59.Egerton-Warburton L.M., Querejeta J.I., Allen M.F. Common mycorrhizal networks provide a potential pathway for the transfer of hydraulically lifted water between plants. J. Exp. Bot. 2007;58(12):3484. doi: 10.1093/jxb/erm009. PMID: 17350936. [DOI] [PubMed] [Google Scholar]

- 60.Pallasmaa J. Suomen Rakennustaiteen Museo; 1995. Animal Architecture. [Google Scholar]

- 61.The Water Network . 2017. The AquaWeb - Nature-Inspired Water Collection System.https://thewaternetwork.com/_/sustainable-agriculture/article-FfV/the-aquaweb-nature-inspired-water-collection-system-F_qDnNZn7hRDhUPGo6cfKw [Google Scholar]

- 62.Team Ask Nature. Web Continuously Collects Water From Air. Asknature [Internet]. 2020;1. Available from: https://asknature.org/strategy/web-continuously-collects-water-from-air/(accessed March 17, 2023).

- 63.Schnobby. Iceplant. In: Wikemedia Commons [Internet]. 2011 (accessed March 17, 2023) Available from: https://commons.wikimedia.org/wiki/File:Eispflanze3.jpg#filelinks (accessed March 17, 2023).

- 64.Girardi P. 2020. Mushrooms below the Surface (Or Fungus Among Us) [Internet]https://www.urbanforestdweller.com/mushrooms-below-the-surface-or-fungus-among-us/ Available from: accessed March 17, 2023. [Google Scholar]

- 65.Topp R. Bees and Wasps [Internet]. Randy topp Business Improvement. Available from: http://rt-bi.nl/social-responsibility/biomimicry/bees-and-wasps/(accessed March 17, 2023).

- 66.El-Haggar S. 2007. Sustainable Industrial Design and Waste Management: Cradle-To-Cradle for Sustainable Development. [Google Scholar]

- 67.Saikkuu L. Publication s of Regional Council of Etela-Savo; Finland: 2006. Eco-Industrial Parks: A Background Report for the Eco-Industrial Park Project at Rantasalmi. [Google Scholar]

- 68.Jacobsen N.B. 2008. Low Carbon Business Park Manual : a Guide for Developing and Managing Energy Efficient and Low Carbon Businesses and Business Parks. [Google Scholar]

- 69.Kunzig R. National Geographic Magazine; 2020. Is a World without Trash Possible? [Google Scholar]

- 70.Timmerman J., Deckmyn C., Vandevelde L., Van Eetvelde G. 2014. Low Carbon Business Park Manual : a Guide for Developing and Managing Energy Efficient and Low Carbon Businesses and Business Parks. [Google Scholar]

- 71.Coppens M.-O. In: Proceedings of Symposia in Pure Mathematics in: Fractal Geometry and Applications: A Jubilee of Benoit Mandelbrot. Lapidus M.L., Van Frankenhuijsen M., editors. 2004. Nature inspired chemical engineering learning from the fractal geometry of nature in sustainable chemical engineering; pp. 507–532. [Google Scholar]

- 72.Lepek D., Coppens M.-O. ASEE Annual Conference & Exposition. 2016. Nature-inspired chemical engineering: course development in an emerging research area. [Google Scholar]

- 73.Gerbaud V., Xuereb C., Coppens M.O. Nature-inspired chemical engineering processes. Chem. Eng. Res. Des. 2020;155:200–201. [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.

Data Availability Statement

No data was used for the research described in the article.