Abstract

The circular economy concept is popular among developed countries contributing to sustainable production, efficient resource utilization, a new economic model, and higher skill job creation. In production and consumption, it is inevitable in our modern life that we are used to the traditional linear economy cradle-to-cradle model. With the gap in developing countries within the Southeast Asia region, this research aims to understand the motivators and barriers to circular economy business model adoption among the manufacturing firms in Malaysia. Subsequently, the impact of sustainable production will be studied based on the circular economy business model adoption. Using the Theory of Planned Behavior and Partial Least Squares Structural Equation Modeling, this study assesses the responses of 102 respondents from various industries with environmental management systems within Malaysia. Survey-based primary data was gathered to understand motivators and barriers that negatively influence the circular economy business adoption, affecting sustainable production. The findings show that motivators have a positive impact while barriers have a negative impact on circular economy business model adoption. Apart from the barriers and motivators, the research also assesses the level of circular economy adoption among manufacturing firms with certified environmental management systems. This implies a general overview for manufacturing firms in Malaysia regarding circular economy adoption and contributes to the studies done in developing nations. In conclusion, motivators positively impact the adoption of the circular economy business model, while barriers have a negative effect. In addition, adopting the circular economy model has a positive relationship with sustainable production.

Keywords: Barrier, Motivator, Circular economy, Sustainable production, EMS firms

Introduction

The projected increase of the total world population to approximately nine (9) billion which includes three (3) billion new middle-income consumers is bound to exert pressure on resources to fulfill future demand. A higher population entails more consumption of durable and non-durable goods and services. According to the World Bank, the concept of circular economy entails production to be restorative and regenerative by intention where nothing produced within the circular economy becomes waste. Recycling, downcycling and upcycling will be the epitome of a circular economy. The circular economy includes CO2 sequestration to rebalance carbon flux via sequestration methods, expanding biofuels, and production of energy-valuable gases via fermenting phytomass (Mohan et al., 2016; Lausselet et al., 2017; Tebbiche et al., 2021; Marousek & Trakal, 2022; Mardoyan & Braun, 2015 inter alia).

The adoption and implementation of the circular economy concept differ significantly between developed and developing countries. Circular economy first gained traction and is currently championed by developed countries, particularly in the European region with most initiatives, achievements, studies, and collaboration among the country members. The UK Germany, France, and Italy emerged as countries with the highest average circular investments over the period of one decade from 2006–2016 out of 28 countries in the European Union (Marino & Pariso, 2020). Studies on the framework, implementation actions, possibilities, and opportunities for improvement of the circular economy are concentrated in developed countries (Halog & Anieke, 2021). In contrast, the circular economy concept received very little attention. Malaysia for example is ranked as Asia’s second-largest plastics user for annual per capita use at 16.78 kg per person by World Wide Fund for Nature (WWF). This ranking emerged above other Asia larger nations including China, Indonesia, Thailand, and Vietnam (Solhi, 2020).

The circular economy is still a nascent concept in developing countries where consumers and producers are still attached to the linear consumption model (Abdul Hamid, 2020). The urgency to move onto a sustainable path with no procrastination is shared by many countries and organizations. There is an urgent need for developing countries to champion circular economy adoption and implementation for long-term economic growth, environmental protection, and social inclusiveness. The public has to be aware that a circular economy is “beyond waste management and recycling”. Hence, this study focused on the firm business model for circular economy adoption and its impact on sustainable production.

However, the implementation of a circular economy is not without challenges. Kirchherr et al. (2018) found that the most pressing circular economy barriers for firms in European Union are related to cultural, regulatory, market, and technology. The finding is consistent with the review by Grafstrom and Aasma (2021) on publications not limited to European Union where barriers are categorized into social, institutional, market, and technological. A past study focused on the palm oil industry on Industry 4.0 in a circular economy showed a slight difference in the circular economy barriers (Abdul-Hamid et al., 2020). Thus, the question is whether the difference is industry-specific or whether barriers may not be the same as those from developed countries versus developing countries with high circular economy recognition in European Union.

The call for a circular economy in developing countries has yet to be resonated with local firms and the public with low awareness in general. Apart from understanding the barriers to better address the issue, the motivators are equally important to catalyze the adoption of the circular economy model. Hence, the perception of a firm’s business model on circular economy adoption needs to be analyzed to examine its impact on sustainable production. Since the circular economy strategies in development are mainly championed by the government, this paper focuses on the firm level which is the main driver for growth and development, and the key player to determine circular economy success. Looking into what motivates the firm to adopt a circular economy business model allows a more effective policy and regulation to support the industry ecosystem from the social, economic, and technological perspectives (Garces-Ayerbe et al., 2019). Reducing and removing the barriers makes it easier for circular economy adoption but focusing on the motivators will accelerate the process. This is crucial as most developing nations still lack the understanding of the synergy between circular economy and sustainability, especially when faced with a growing waste crisis.

Replication of a more successful implementation model and action plan can accelerate the circular economy implementation in developing nations. This study determined the barriers from different categories in past studies from other countries to understand them within a developing economy context. By understanding the obstacles toward circular economy adoption, local manufacturing firms, policymakers, and organizations adopting the circular economy concept will have ideas on which area to focus. In addition, developing countries could learn from successful implementation in countries like Germany and Brussels if the mapping of barriers indicates possible common situations among these countries. Hence, the objective of the study is to examine the effect of circular economy motivators and barriers on business model adoption and the impact of circular economy business model adoption on sustainable production.

Furthermore, the main contribution of this paper is the empirical evidence on the extent of the circular flow economy adoption among small group manufacturing firms in a developing country. The findings in this paper can be used by manufacturing firms in developing countries as a benchmark and serve as a guide in exploring opportunities and advancement for circular economy practices. The method employed in this study is limited to a questionnaire survey while longitudinal exercise could not be undertaken due to lack of microdata. The remaining sections are organized as follows. The next section provides the literature review followed by the theoretical model. The fourth section illustrates the estimation method used in this paper. The fifth section presents the results. The penultimate section provides a discussion of the results and the final section concludes.

Literature review

Most of the original literature was undertaken in countries with high circular economy adoption and implementation, for example in the European region (Kirchherr et al., 2018). There were very few studies within the Asia region that share a closer background with Malaysia due to geographical and cultural aspects due to our low adoption of the circular economy model. Only a handful of studies were done in Malaysia in past few years which were included in the literature review to provide an understanding of the progress of circular economy-related activities in Malaysia. As the circular economy is gaining more traction within the past decade, the studies reviewed mainly is within five years to reflect more up-to-date information and findings. The circular economy business model provides structure and guidance for the circular economy implementation process to be done systematically. The firm can establish a systematic business process model to develop a circular economy methodology within respective relevant areas. The mapping of the business model ranges from repair and maintenance, reuse and distribution, recycling, and circular supplies. Boyer et al. (2021) indicated that recirculated products could compete with new products with similar premium features in the marketplace. This shows that circular economy products are perceived as equal if not better than the new linear production goods. The wide range of business models is not a one size fits all solution where a firm could implement everything at one go. The firm needs to analyze and focus on the relevance strategy to its own business nature. The adoption and implementation plan should be assessed thoroughly and must be relevant to the potential challenges of the firm’s business environment. As the business model can differ from one firm business nature to another, the firm will only embark on the business model that is relevant to their business and expand progressively thereafter.

Implementation of a circular economy business model requires extensive planning with a business process where Pieroni et al. (2021) create circular economy business models as a guide to support strategic development for the implementation. The model varies in approaches and provides multiple sectors and context-specific solutions to stimulate broader adoption across manufacturing sectors. A circular economy business model by Pollard et. al (2021) incorporates a circular economy within the business environment suggesting how businesses could consider the challenges and opportunities to facilitate the adoption and implementation process. To understand the circular economy business model adoption in manufacturing firms within the Malaysian context, this paper adopted and adapted the characteristic from existing studies that incorporate the challenges and opportunities effect of circular economy business model adoption.

As more organization across different countries begin to understand the importance of the circular economy, more institutional framework was introduced to promote the adoption of the circular economy. The laws and regulations have created a motivating environment for firms to pursue the circular economy concept. Jesus and Mendonca (2018) classified motivators into a few groups, namely organizational, market, social, and economy. Another classification of motivators into soft and hard drivers. Internal factors are the main drivers of a circular economy (Jabbour et al., 2020) which is related to pressure from shareholders, support from the management, structure, and culture change, skilled labor, connectivity among companies, and technology processes. Improvement of material efficiency with the implementation of a circular economy in the supply chain potentially increases long-term income generation (Franklin-Johnson et al., 2016), the firm can indicate a circular economy as part of the business model strategy through effective recycling and remanufacturing activities. With technological advancement, the firm has the incentive and convenience to adopt a circular economy easily. Blockchain, the Internet of Things (IoT), radio-frequency identification (RFID), machine learning, big data, artificial intelligence, and other technology are the enablers of circular supply chain management implementation (Tura et al., 2019).

For external factors apart from organizational, the key stakeholders are mainly customers, suppliers, competitors, and government policymakers. Apart from that, there is also concern about the scarcity of resources which was the main driver for developed nations with limited resources, particularly within the European region. Tura et al. (2019) considered resource scarcity as one of the main factors firms seek circular economy to recirculate resources into a production and consumption cycle. A similar understanding is shared by countries and organizations around the world seen by the commitment of UN SDGs to responsible production and consumption effort.

Wu et al. (2021) stated that there are many challenges in creating a balance between economic development and environmental sustainability. Developing solutions to achieve this goal requires overcoming barriers to circular economy adoption. Barriers to a circular economy are classified into a few groups which are financial, structural, operational, attitudinal and technological (Ritzen & Sandstrom, 2017). The classification in these pillars allows the discussion of challenges in a macro environment to provide a general overview insight into different industry players, policymakers, and other organizations.

Out of the five most pressing barriers, three came from cultural barriers in a study by Kirchherr et al. (2018) which shows the difference between the key circular economy barriers suggested by academic literature and business practitioners. The barriers highlighted were ‘lacking consumer interest and awareness’, ‘hesitant company culture’, and ‘operating in a linear system’ which were adapted into this research to examine the situation in Malaysia. A study on Industry 4.0 in circular economy barriers in Malaysia’s palm oil industry by Abdul-Hamid et al. (2020) ranked high investment as the top reason and low management support and dedication as the last out of 18 challenges accepted. This indicates the difference between developed and developing countries in terms of challenges in circular economy adoption and implementation. Hence, this paper covers various industries that could further confirm the difference or provide a different perspective on circular economy adoption without industry-specific restrictions.

Changes in process of production and new product development are the challenges firm faced in circular economy practices besides external barriers such as governmental policies and consumer behavior (Jesus & Mendonca, 2018). These are considered “soft” factors which found to be driving a circular economy globally. However, the “hard” factors related to technical solutions and technology advancement are considered essential in overcoming circular economy adoption barriers. Apart from this classification and the one mentioned earlier, Jabbour et al. (2020) also examine circular economy barriers in the context of financial, structural, operational, behavioral, and technology. Based on the similarity identified from multiple study sources, a compilation, and adaptation were undertaken to avoid absolute duplication. Internal factors within the firms such as unclear responsibilities and difficulty in communication among departments are the main barriers identified suggested by Jabbour et al. (2020). Hence, the barrier factors in this research mainly consist of internal factors over external factors.

The circular economy is known for its effectiveness in maximizing resource utilization and minimizing pollution which integrates clean production for sustainable consumption (Ying & Li-jun, 2012). The comprehensive integration of environment, society, and economy was measured to calculate the circular economy capabilities index. The main assessment for the impact of sustainable production at the firm level is based on the resources allocated by the firm in the event and process that focus on sustainability throughout internal production. Jabbour et al. (2020) claimed that their circular economy practices affect the firm’s sustainable performance. The performance is reflected by cost reduction, resource efficiency improvement, and enhanced public reputation. The focus is consistent with the targeted respondent profile in this research which is a manufacturing firm with a certified environmental management system.

Another study from an emerging economy, in South Africa, found that sustainable manufacturing practices which utilized environmentally-friendly materials to be recirculated in the system have a positive association with circular economy capabilities (Bag et al., 2021). Circular economy capabilities include the adoption methods of recycling, recovery, remanufacturing, reducing, repairing, and other elements detailed in a circular economy business model. In another study of China’s eco-industrial park firms, all respondents focused on environmental protection issues that probe into the sustainable supply chain management (SSCM) and circular economy capabilities antecedent relationship (Zeng et al., 2017). SSCM is found to be a vital antecedent affecting the firm’s circular economy capabilities while sustainable supply chain design has no significant effect. Based on the future research recommended, the focus should be on the sustainable supply chain in the process rather than design in order to validate the hypothesis. This research adopted the variables under SSCM to have a holistic view of the context of Malaysia’s EMS-certified manufacturing firms.

Development of theoretical framework

The Theory of Planned Behavior (TPB) serves as the basis for the formation of a theoretical framework. TPB originated from the Theory of Reason Action (TRA) which accounts for various factors that affect human intentions or attitudes toward actual behavior, subjective norms, and perceived behavioral control. In this paper, the definition of attitude is known as “the extent of circular economy business model adoption is valued by firm decision-maker, either great or little extent”. The subjective norm in society refers to respective industry players from the respondent’s industry where decisions made were influenced by the behaviors of peers within the same industry whether are they adopting circular economy business model adoption. Ajzen defines subjective norm as “the perceived social pressure to perform or not to perform the behavior”. In this paper, we modified the TPB model to assess three variables namely motivators, barriers (Arroyo & Carrete, 2019; Visschers et al., 2016), and enablers as direct factors that affect an organization’s behavior in a circular economy in line with the modifications by Whitten et al., (2009) and added variables that influence the behavior instead of explaining the influences (Khan et al., 2021; Yuriev et al., 2020). The theoretical framework based on Khan et al. (2021) and Whitten et al., (2009) is illustrated in Fig. 1.

Fig. 1.

Proposed Research Theoretical Framework

Hypothesis development

Hypothesis development is based on motivators, barriers, and enablers. We argue that motivators and barriers influence the circular economy business model adoption which then creates an impact on sustainable production among the firms in Malaysia. Firms with high motivator factors will have higher adoption of the circular economy business model while the firms with high barrier factors will have lower adoption of the circular economy business model. Better circular economy business model adoption will have a positive impact on sustainable production. The detailed formation of the hypothesis is as follows.

Motivators and the adoption

Jesus and Mendonca (2018) classify motivators for circular economy adoption into a few categories namely economic, financial, market, and institutional and regulatory organizations. The economic factors include the availability of raw materials, access to appropriate technology, and financial motivators means access to adequate funding and other financial benefits. The market represents consumers’ inclination toward greener products and services, leading to both products and services being produced and priced accordingly in a sustainable manner. Institutional and regulatory motivators indicate enactments and enforcement of laws and regulations for cleaner and sustainable manufacturing.

Bag et al. (2021) found that government, customers, peers, and management of the company have an indirect affirmative association with circular economy adoption. The circular economy adoption also has a positive association with sustainable manufacturing practices. The methods mentioned in the study include recover, recycle, repurpose, remanufacture, refurbish, repair, re-use, reduce, rethink, and refuse. The finding from Bag et al. (2021) also resonated with results obtained from Jabbour et al. (2020) where the stakeholder pressure positively affects motivators of circular economy adoption. The hypothesis for motivators and the adoption based on the proposed model in this research is detailed below:

H1

The motivation factors positively affect circular economy business model adoption.

Barriers and the adoption

Barriers in this research are defined as traits that hinder the progress of firms in adopting the circular economy business model. These traits create uncertainty and hesitation for decision-makers in considering the circular economy adoption and implementation plan. Kirchherr et al., (2018) discussed the barriers to circular economy adoption in a few categories namely cultural, regulatory, market, and technology. Examples of cultural factors is the lack of willingness to operate in a collaborative value chain system while regulatory factors come in the form of inconsistent policy and guidelines from local or global authorities resulting in a lack of consensus as to what constitutes the adoption of a circular economy.

The market factor involves initial high investment costs and difficulty to access funds to support the circular business models. Technological barrier denotes the lack of proven track records of successful large-scale projects to serve as a benchmark which helps explain why funding is difficult to secure since data on the benefits of circular business models are limited in nature. Jabbour et al. (2020) validated that barriers to adoption negatively affect circular economy principles. The study also stated that a common finding shows government actions play a crucial role in circular economy adoption. The absence of government commitment will hinder the progress of uptake among organizations. The hypothesis for barriers to a circular economy based on the proposed model in this research is detailed below:

H2

The barrier factors negatively affect circular economy business model adoption.

The adoption and sustainable production

Circular economy adoption enables organizations to achieve sustainable performance from the aspect of profitability, social metrics, and environmental concern. By having the internal policy and guidelines created revolving around the circular economy concept in the business process, the firm is on the journey of sustainable production. This is achieved by the business process and products and services produced. Jabbour et al. (2020) claimed that circular economy adoption allows firms to reduce costs related to raw material consumption and improve resource efficiency. Overall the study also confirms the expectation of a circular economy where it improves firms’ sustainable performance. This is supported by the finding from Trujillo-Gallego et al. indicates that organizational performance and environmental collaboration have a positive, significant effect on sustainable production practices. The hypothesis for the circular economy business model adoption effect for sustainable production based on the proposed model in this research is detailed below:

H3

The circular economy business model adoption positively affects sustainable production.

Methodology

This study is exploratory in nature and non-experimental which will involve minimum researcher interference. Furthermore, the study is a cross-sectional study called one shot to be distributed to the respondents. The targeted units are the manufacturing firms with environmental management systems (EMS) and the target respondents are supply chain managers, individuals who manage production lines, or individuals with critical roles and authority in circular economy implementation decisions. Manufacturing firms with EMS are chosen on the basis that these firms are more likely to have knowledge and interest in sustainability since they need to adhere to certain rulings of sustainable production to obtain the EMS certification.

Based on the Directory of Standards Malaysia by Malaysian International Trade and Industry (MITI) in 2022, there are 975 manufacturing firms in Malaysia with EMS. A total of 975 firms was listed specific to the environmental management system and 413 firms were selected from 16 sectors as targeted respondent. According to Roscoe’s rule of thumb, the minimum sample size should be at least 10 times the number of variables (in this study, there were 120 variables). However, due to the study’s limited sample frame and the potential of a low response rate from the postal survey, a stratified random sampling of 30% of each category was used. In addition, since data collection was undertaken during the COVID-19 pandemic, the expected appropriate sample size is approximately 100 respondents (Jabbour et al., 2020; Kumar et al., 2019).

Survey instrument

The study chooses a questionnaire survey as primary data to obtain quantitative data to validate the developed hypotheses for this study. A questionnaire survey is often regarded as a weak method and arguably, longitudinal studies may serve as a better alternative. However, we argue that using questionnaires in behavioral studies would still serve the intended objectives. Studies on environmental related issues such as recycling behavior (Aboelmaged, 2021), habits on recycling waste (Abd’Razack et al., 2017), and intention to recycle (Ali & Yusof, 2018), inter alia, effectively use survey questionnaires to test their hypotheses. In addition, environmental microdata is unavailable in most countries, hence, restricting longitudinal studies.

Questionnaires have several advantages. It is a quick, effective, and economical technique for acquiring significant amounts of information from sizeable sample sizes. However, questionnaires are the weakest scientific method which is of supportive importance. These instruments are especially efficient when it comes to gauging the behavior, preferences, intentions, attitudes, and views of subjects. In addition, the design of the measurements allows the study to respond to the research questionnaire and achieve its objectives. Othman et al. supported this form of data collection in their study as the ideal way to include businesses that have embraced new technologies.

In order to analyze and quantify each variable in the conceptual framework that was established, the literature research served as the foundation for the measurements that were taken. The responses to the questions in this study, with the exception of the demographic profile, are measured on a scale that ranges from one to five points and is based on the Likert scale. The majority of Likert measures include both positively worded questions as well as negatively written questions. The purpose of both types of questions is to urge respondents to analyze all items thoroughly rather than answer in a predictable manner. The operationalization of each variable in the theoretical framework is shown in Table 1, which also outlines the construction of measuring items.

Table 1.

Factors, Likert Scales and Sources

| Likert scales | Adopted from | ||

|---|---|---|---|

| Motivation factors | |||

| 1 | Achieve cost savings | 1 “Very little extent”, 2 “Little extent”, 3 “Some extent”, 4- “Great extent” and 5 “Very great extent” |

Bag et. al (2021), Jesus and Mendonca (2018), Zeng et. al (2017) |

| 2 | Enhance our green/sustainability credentials | ||

| 3 | Respond to competitors’ actions | ||

| 4 | Respond to downward pressure on our revenue or profit margin | ||

| 5 | Respond to explicit customer demand/preferences | ||

| 6 | Move toward a circular economy model | ||

| 7 | Respond to concerns about the scarcity of natural resources | ||

| Barrier factors | |||

| 1 | Lack of knowledge of management systems | 1 “Very little extent”, 2 “Little extent”, 3 “Some extent”, 4 “Great extent” and 5 “Very great extent” | |

| 2 | Absence of governmental pressure |

Abdul-Hamid et al. (2020), Jabbour et al. (2020), Garces-Ayerbe et al. (2019), Jesus & Mendonca (2018), Kirchherr et al. (2018) |

|

| 3 | Lack of evidence of profitability | ||

| 4 | Poor company CE operations vision/mission | ||

| 5 | Lack of skills and qualifications | ||

| 6 | Lack of regulatory framework | ||

| 7 | Difficulty accessing suitable financing | ||

| 8 | Absence of consumer demand | ||

| 9 | Perception of high business risk | ||

| 10 | Dominant position of key market players | ||

| 11 | Lack of capabilities to reconfigure the production pattern | ||

| 12 | Lack of closed-loop control | ||

| 13 | Lack of knowledge base | ||

| 14 | Lack of organizational and process changes | ||

| 15 | Lack of process design | ||

| 16 | Unstable connectivity among companies | ||

| 17 | Lack of understanding of CE implications | ||

| Sustainable production | |||

| 1 | Spend on recyclable/renewable materials compared to direct material spend | 1 “None”, 2 “Minimal influence”, 3 “Moderate”, 4 “Some influence” and 5 “Strong influence |

Bag et al., (2021), Wojnarowska, et al. (2021), Zeng et al. (2017) |

| 2 | Spend on their indirect material spend on recyclable/renewable materials from the supply chain | ||

| 3 | Report their productions are emission control over their productions time | ||

| 4 | Fully customizes their products to cleaner production | ||

| 5 | Report that they do report their environmental activities | ||

| 6 | Recycle their labeling at the end-of-life of products | ||

| 7 | Report their products are designed for environmental management | ||

| 8 | Recycle their production waste | ||

| 9 | Share their packaging that is dedicated to end-of-life | ||

| 10 | Practice sustainable delivery of their products | ||

| 11 | Practice environmental activities for their warehouse | ||

| Circular economy sub-business models | |||

| 1. Build to last—Design products that are durable and easy to repair | 1 “Not considering this”, 2 “Don’t know”, 3 “Trying to learn more before deciding whether to implement”, 4 “Moving toward this as part of our business strategy” and 5 “Adopted a circular economy framework” |

Aranda-Uson et al. (2020) Pollard et al. (2021) |

|

| 2. Circular supplies—Use recyclable materials in production, e.g., renewable and bio-based materials, chemicals & energy to increase recovery rates | |||

| 3. Share—Develop solutions that enable increased use of capacity | |||

| 4. Repair and Maintain—Deliver repair and maintenance services to extend the life of existing products in the market | |||

| 5. Upgrade—Improve product performance by upgrading existing components with newer ones | |||

| 6. Resell—Resell products that have reached their useful life to second and third-hand markets | |||

| 7. Remanufacture—Take back and perform industry-like restoration or improvement of the original functionality of products and remarket them | |||

| 8.Recycle / Upcycle—Collect and recover materials of end-of-life products and reuse them in your own production | |||

| 9. Return—Return wasted parts and materials to the source (e.g., waste and by-products from own production) | |||

| 10. Product as a Service—Offer customers to use a product against a subscription fee or usage-based charges instead of owning it | |||

| 11. Performance as a Service—Offer customers to buy a pre-defined service and quality level and commit to guaranteeing a specific result | |||

Validity and pilot study

A smaller group of respondents was used to evaluate the questionnaire’s substance and presentation. Ten experts, and circular economy specialists, answered the survey questionnaires to gain comments before contacting a wider number of respondents. Respondents were asked about survey clarity, relevancy, amount of questions, and experience. Feedback on question structure and wording prompted changes. The questionnaire was straightforward to comprehend, the right length, and collected enough data. No major changes were made from the initial form, therefore the questionnaire is ready for a bigger group. Since the variables were adopted from various sources, therefore, a pilot test was also done. Table 2 summarizes the reliability test, showing that all items have strong internal consistency with Cronbach’s Alpha values between 0.903 and 0.915 thus, no items need to be removed.

Table 2.

Summary of Reliability Test for Pilot Study (Sample Size: 30)

| Variable | Cronbach’s Alpha | No. of Item |

|---|---|---|

| Motivators | 0.909 | 7 |

| Barriers | 0.914 | 17 |

| Circular economy business model adoption | 0.903 | 11 |

| Sustainable production | 0.915 | 11 |

The questionnaire for the survey was sent out to the samples that have been targeted. A cover letter was attached to each copy of the questionnaire. This letter included general instructions on how to fill out the questionnaire, as well as an explanation of the goal of the study and the benefits of participating in the study. The questionnaire was then uploaded to an online survey platform known as Google Forms, and an email including a link to engage in this survey was sent out to the respondents. This approach of data collecting was supported by Othman et al. (2021) in their study as an ideal strategy to incorporate organizations that have implemented a circular economy as a new technology.

The gathering of the information took place over the course of two months in 2020, beginning in the middle of April and ending in the middle of June. Furthermore, contact with respondents was conducted through the use of online questionnaires during the course of the research since, at the time, there was an ongoing COVID-19 pandemic, which resulted in restrictions and a widespread tendency of avoiding face-to-face conversation. In order to assure a greater response rate, reminders were delivered in the form of phone calls to a shared contact number or a publicly available contact number.

Estimation method

Variance-based Structural Equation Modeling or PLS-SEM is used in this study to validate the measurement model and structural model in order to perform the hypothesis testing. The measurement model examines indicator reliability, internal consistency reliability, convergent validity, and discriminant validity. On the other hand, the structural model examines the coefficient of determination (R2) and predictive relevance. Both non-parametric bootstrapping and bootstrapping were done for model estimation. Bootstrapping is used to test the statistical significance and relevance of indicator weights. A large number of subsamples (typically 5,000) from the original data with replacement were drawn in bootstrapping. The significance of the immediate impacts specified by the examination model was assessed (Sarstedt et al., 2021).

Results

Purposive sampling was done based on the targeted respondent profile of a firm with environmental management system (EMS) with a total of 121 survey responses received via social media, e-mail, and messenger. There is no requirement for the study to carry out the bias test or to validate the information in order to determine the effect of responding through social media due to the fact that the respondents were given the option of responding to the survey either through the link or by returning the responses through the official social media of the center.

Firm in this research refers to a company with EMS that has environmental activities in daily activities and is considered as part of business strategy as confirmed by Darnall et al., (2008). The response rate is 29.3% out of 413 surveys distributed. This research aimed to obtain respondents from 16 main industries without restriction to the respondent from other industries. Responses were expected from each industry, however, there were only eight industries from the respondent profile after the result compilation. From the total of 121 responses, only 102 responses completed the survey. The usable response rate is 24.7%. The response rate and survey distribution are shown in Table 3.

Table 3.

Survey distribution

| Remark | Total |

|---|---|

| Total questionnaire distributed to the respondents | 413 |

| Questionnaire returned | 121 |

| Questionnaire not returned | 292 |

| Incomplete questionnaire returned (not usable) | 19 |

| Usable questionnaire | 102 |

| Overall response rate | 29.2% |

| Usable response rate | 24.7% |

Profiling analysis

Among 102 final usable firm samples, there are 39 females (38.2%) and 62 males (60.8%) with one respondent preferring not to disclose gender. With no preference for respondent gender selection, the majority manufacturing industry shows a male-dominated profile. The majority of the respondents are from the group of age 31 to 40 years old with 40 respondents (39.2%) followed by the group of 41 to 50 years old with 27 respondents (26.5%), more than 51 years old with 19 respondents (18.6%) and the least from a group of less than 30 years old with 16 respondents (15.7%).

A third of the respondent, 34 respondents (33.3%) has worked with the company for more than 30 years while only 13 respondents (12.7%) who worked less than 5 years with their company made up the least group. About one-fifth, 22 respondents (21.6%) worked between 6 to 10 years with their company while 17 respondents (16.7%) and 16 respondents (15.7%) worked for 21 to 30 years and 11 to 20 years with their company, respectively. Most of the respondent has bachelor’s degree qualification (33.3%) while the least qualified group is in high school (6.9%). The other respondents have qualifications of master’s degree (19.6%) and diploma (12.7%) while the remaining 27.5% chose not to disclose by not responding to the section.

The majority of respondents, 65.7% are Malaysian-owned companies while non-Malaysian-owned and local foreign joint-venture companies are 28.4 and 5.9%, respectively. The foreign ownership companies are mainly from the USA (7.8%) followed by the UK (4.9%), Japan (4.9%) Switzerland (2.9%), and other countries. Among them, the respondent with the highest frequency is 34 firms (33.3%) has established more than 30 years followed by 22 firms (21.6%), established for 6 to 10 years, 17 firms (16.7%) with the establishment of 21 to 30 years, 16 firms (15.7%) with establishment 11 to 20 years and the least group of firms with establishment less than 5 years at the frequency of 13 firms (12.7%). This shows a diverse maturity of firms with a majority having more than 10 years of establishment within respective industries.

Respondents came from diverse industry backgrounds with the majority, 30 respondents (29%) from the electrical and electronic industry, 14 respondents (14%) from other industries, 11 respondents (11%) from the plastic and resin industry, 10 respondents (10%) from both healthcare and energy industry respectively, 9 respondents (9%) from food and beverage industry, 7 respondents (7%) from rubber industry, 6 respondents (6%) from the automotive industry and 5 respondents (5%) from consumer goods industry. The size of the firms can be observed from the number of employees with 36 firms (36%) having less than 100 employees followed by 30 firms (29%) with more than 1,000 employees and an even distribution of 13 firms (13%) with 101 to 250 employees, 12 firms (12%) with 501 to 1,000 employees and 11 firms (11%) with 251 to 500 employees. Hence the largest group of respondents considered small and medium manufacturing firms followed by large manufacturing firms. The observation is consistent with the annual revenue where 49 firms (48%) have an approximately annual sales turnover of more than EUR 10 M followed by 24 firms (24%) with an approximate annual sales turnover of EUR 64 K to EUR 3 M. There is about one-fifth of the firms, 20 firms (20%) with an approximate annual sales turnover of EUR 3 M to EUR 10 M while the least group, 9 firms (9%) with an approximate annual sales turnover of less than EUR 64 K.

Measurement model assessment

PLS is a structural equation modeling technique that was utilized to validate the data structure in this research which the structural model confirms all relationships by path analysis, while the measurement model assesses latent or composite variables. Thus, it is argued that the literature on circular economy-related subjects has to be much more precise in its usage of ideas derived from reference disciplines. The study of the circular economy is an example of interdisciplinary research; it seeks to find solutions to problems (such as those associated with engineering strategy) that are also studied by related fields like business, psychology, and management.

In light of this, it makes perfect sense for researchers working in the field of circular economy to familiarize themselves with the way PLS is applied in older and, statistically speaking, more established fields of study. PLS regression appears to be an alluring alternative for many researchers at first glance due to the fact that the method places very few requirements on the data. The proponents of PLS assert that it is possible to conduct theory-testing research of a high quality utilizing the method. When utilizing the tool, it is also reasonably simple to establish reliability and validity without having to become an expert in the complexities of principle components analysis, covariance analysis, factor analysis, or multiple regression. This makes the tool very convenient, however, PLS-based reliability and validity tests are not the dominant methodologies utilized elsewhere in the world. PLS regression also has the potential to produce results that may not generalize to alternative settings which makes it problematic when used to test theory. PLS-based research may also offer psychometrically fairly bad measures as reliable and valid, which may cause later researchers to naively depend on these measures in their own studies.

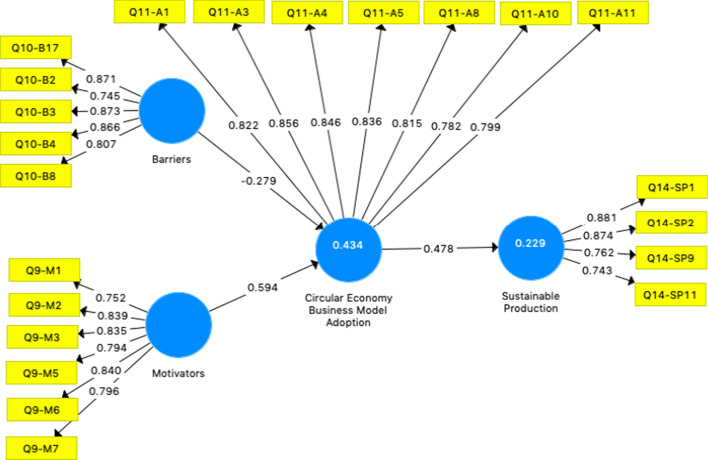

As this paper has demonstrated, there is certainly no universal agreement about the benefits of PLS regression over other methods (like SEM) for studying psychological constructs. Due to the firm-level metrics used in this study, thus, PLS regression may very well prove to be an effective tool in the course of this investigation. Data, which often involve formative indicators and are not concerned with psychological constructs. Figure 2 illustrates the results of the measurement model. The path coefficient tests multicollinearity among the variables which shows the direct effect of one variable on another. The motivators have a positive impact on circular economy business model adoption which, in turn, exerts a positive impact on sustainable production. The barrier items are negative, indicating a negative impact on circular economy business model adoption. All the path coefficient values are within the range of -1 and 1 rules out multicollinearity problems.

Fig. 2.

Results of Measurement Model Assessment

Indicator reliability

Table 4 shows that all indicator loading values were higher than 0.7, corresponding to their latent variables. The values shown were after the removal of several items with values lower than 0.7, which did not contribute to a higher AVE and CR to illustrate a better final model. All the remaining constructs have values above 0.7, with the lowest value of 0.743 in item SP11 and the remaining items are above 0.8, which is significantly higher than the minimum requirement. All AVE values are above 0.5, with the highest value indicated by sustainable production construct, 0.835, followed by barriers, circular economy business model adoption, and motivators. The results also signified that the lowest value for CR and Cronbach’s Alpha is 0.889 and 0.835, respectively, which are significantly higher than the minimum requirement of 0.7.

Table 4.

Reliability and Validity of Measurement Model

| Constructs | Item | Loadings | AVE | CR | Cronbach’s Alpha |

|---|---|---|---|---|---|

| Barriers |

B2 B3 B4 B8 B17 |

0.745 0.873 0.866 0.807 0.871 |

0.695 | 0.919 | 0.890 |

| Motivators |

M1 M2 M3 M5 M6 M7 |

0.859 0.850 0.876 0.897 0.864 0.874 |

0.656 | 0.920 | 0.895 |

| Circular economy business model adoption |

A1 A3 A4 A5 A8 A10 A11 |

0.822 0.856 0.846 0.836 0.815 0.782 0.799 |

0.677 | 0.936 | 0.920 |

| Sustainable production |

SP1 SP2 SP9 SP11 |

0.881 0.874 0.762 0.743 |

0.668 | 0.889 | 0.835 |

Internal consistency reliability

Cronbach’s alpha and composite reliability (CR) are the measurements for internal consistency reliability where both measurements should be higher than 0.7. CR is considered a better indication where a higher value represents a higher reliability level. However, Hair et al. (2019) suggest that Cronbach’s Alpha is a less precise measure. Based on Table 4, Cronbach’s Alpha and CR values for barriers construct are 0.919 and 0.890, motivators construct is 0.92 and 0.895, circular economy business model adoption is 0.889 and 0.920 and lastly, sustainable production construct is 0.889 and 0.835, respectively. All the construct values are higher than 0.7 which is above the threshold value suggested. Hence, it is acceptable to deduce that the result satisfied the criteria for internal consistency.

The average variance extracted (AVE) is the criterion in the assessment of convergent validity where the construct should exceed 0.5 to be considered adequate. The calculation of AVE is the mean of squared loadings of each indicator corresponding to the construct. Convergent validity shows how closely the indicator is related to each other within the same construct. Based on Table 4, all the AVE values are higher than 0.5 which the lowest AVE being 0.656 by the motivators construct and the highest value indicated by the sustainable production construct of 0.835. Since all the AVE values are higher than the minimum suggested value, the result indicates fulfillment of the convergent validity requirements. In other words, this shows that the indicators of specific constructs have a high proportion of common variance.

For the assessment of discriminant validity, Fornell and Larcker stated the use of the Fornell-Larcker criterion and Henseler et al. suggested the use of the Heterotrait-Monotrait (HTMT) ratio. Discriminant validity stipulates that two constructs have no correlations and are empirically distinct from one another, hence satisfying the validity requirements. The Fornell-Larcker criterion specifies that the square root of AVE for each construct should exceed the respective correlation with other constructs in order to demonstrate discriminant validity. The HTMT criterion is argued to be a better measurement compared to Fornell-Larcker which is defined as the average indicators’ correlations across constructs relative to the average indicators’ correlations within the same construct. The suggested value for the HTMT criterion for all constructs should be less than 0.85 (Kline, 2015) or 0.90. By referring to Table 5, the square root of each construct’s AVE exceeds the correlations of other latent constructs for Fornell-Larcker, and the values below a threshold of 0.85 for the HTMT ratio in Table 6, the results satisfy the recommended ideal values. Hence, the finding from this measurement model the satisfactory for discriminant validity.

Table 5.

Discriminant Validity (Fornell-Larcker Criterion)

| Barriers | BMA | Motivators | SP | |

|---|---|---|---|---|

| Barriers | 0.834 | |||

| CE Business Model Adoption (BMA) | − 0.285 | 0.823 | ||

| Motivators | − 0.011 | 0.597 | 0.810 | |

| Sustainable Production (SP) | − 0.064 | 0.478 | 0.437 | 0.817 |

Table 6.

Discriminant Validity (Heterotrait-Monotrait Ratio (HTMT))

| Barriers | BMA | Motivators | |

|---|---|---|---|

| Barriers | |||

| CE Business Model Adoption (BMA) | 0.307 | ||

| Motivators | 0.109 | 0.654 | |

| Sustainable Production (SP) | 0.127 | 0.530 | 0.501 |

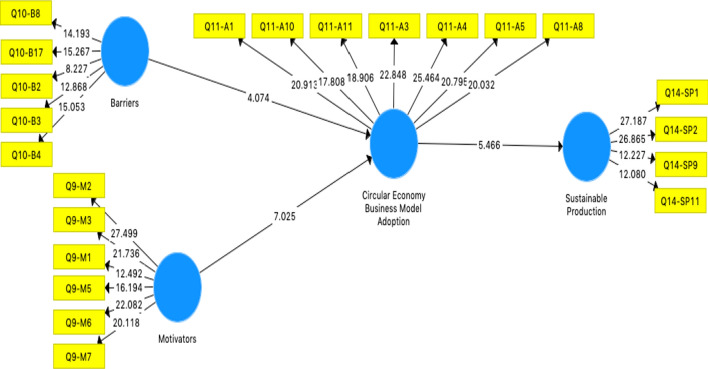

Structural model assessment

The R2 value for circular economy business model adoption is 0.434 and sustainable production is 0.229 shown in Fig. 3 Cohen suggests that R2 values of 0.02, 0.13, and 0.26 are, respectively, considered as small, medium, and large. The R2 values obtained from Fig. 3 are higher than the suggested values. Hence the research result for circular economy business model adoption and sustainable production shows satisfactory predictive power.

Fig. 3.

Results of Structural Model Assessment

Cross-validated redundancy, stone-Geisser’s Q2

Predictive relevance can be assessed by Stone-Geisser’s Q2 value which is obtained through the blindfolding procedure. The procedure involves a systematic data points deletion of a single point based on the omission distance defined and estimating the model parameters. The sample re-use technique is repeated in each round of data point omission until all the data point has been omitted and the model re-estimated. An omission distance between 5 to 12 is recommended by Hair et al. and an omission distance of 7 is used in this research. The rule of thumb for the Q2 value suggests that a higher value indicates higher accuracy and relevance. Besides, this also reflects the smaller difference between predicted values and the original values. The value of Q2 values higher than 0, 0.25, and 0.50 represent small, medium, and large predictive relevance, respectively, according to Hair et al. (2019). In our research, the Q2 value for circular economy business model adoption is 0.288 and sustainable production is 0.144. As both results are greater than zero, the predictive relevance of the structural model is confirmed.

Hypotheses testing

According to Ringle et al. (2015), path coefficients (standardized beta), t-values, and significance levels are assessed using the bootstrapping function (5,000 subsamples). The results are shown in Table 7. The recommended value for t-values is above 1.96 while p-values are below 0.05 in order to show a significant result to support the hypotheses. Comparing this research result to the recommended values, the findings were significant with the supported decisions for all the tested hypotheses.

Table 7.

Path Coefficient, T-statistics and significance level

| Hypothesis | Relationship | Path COEFFICIENT (β) | T-statistics | P-values | Decision |

|---|---|---|---|---|---|

| H1 | Barriers → CE Business Model Adoption | − 0.279 | 4.232 | 0.000* | Supported |

| H2 | Motivators → CE Business Model Adoption | 0.594 | 7.062 | 0.000* | Accepted |

| H3 | CE Business Model Adoption → Sustainable Production | 0.478 | 5.324 | 0.000* | Accepted |

*Significant where the t-statistics are above 1.96 and the p-value is below 0.1

Discussion

The circular economy has become an important issue in recent decades and continues trending as a topic worthy of further investigation. The role of a manufacturing firm is crucial in a circular economy due to the nature of the business operation nature relevance with energy and raw material utilization, generation of products and services, employment contribution, and potential value creation to decouple from linear consumption. Circular economy business model implementation among manufacturing firms faces challenges ranging from technical and non-technical, internally and externally. Recognizing the circular economy’s potential benefits, motivators play a critical role in translating the concept of the circular economy into corporate strategies and business models. United Nations Sustainable Development Goals (SDGs) have included multiple circular economy-related aspirations to be achieved by 2030 and Malaysia is one of the countries that pledge to achieve the SDG goals.

This paper provides findings that sustainability and environmental concern has some level of influence on the future growth strategy of most manufacturing firms. Assessing the current level of circular economy business model adoption among environment management system firms, the majority of the respondent is inclined toward the direction of moving toward this as part of our business strategy. As the targeted respondent for this research is a firm with a certified environmental management system, sustainable initiatives are expected as part of the firm’s strategic development actions. The result is consistent with the trend analysis by Ngan et al. focuses on the current state of the circular economy in developing countries. The concept has been adopted and adapted by many countries as a focus area. However, the transition requires all stakeholders from industry players to policymakers to shift from linear to circular methods of production. Thus, in this paper, the motivation and barrier factors from internal and external perspectives. Combining the finding will provide better visibility on the opportunities and gaps among firms in Malaysia to adopt the circular economy concept more effectively.

Government commitment and governance structure established to support the initiative, policy, and regulation should be developed to motivate firms on this sustainable production journey. Due to the rapid development required in the circular economy implementation, new job opportunities for high-skilled workers are created while low to medium-skill workers are expected to learn new skills. This paper focuses on a research gap in examining the circular economy motivating effect toward circular economy business model adoption. The main stakeholders, the company owners, and shareholders exert pressure to increase the adoption of the circular economy approach (Jabbour et al., 2020). The study also highlights that internal stakeholders play a greater role vis-a-vis external stakeholders in circular economy business model adoption. This is aligned with this research finding of the motivator with the highest mean—enhancing a firm’s green/sustainability credentials. The possible explanation might be firms seek to improve their performance indicator and social image by contributing to economic and environmental efficiency. The second highest mean motivator is responding to explicit customer demand/preferences supported by the earlier explanation which is followed by the response to competitors’ actions. Hence, the H1: The motivation factors positively affect circular economy business model adoption cannot be rejected.

The result mirrors previous studies (inter alia Zeng et al., 2017) where institution pressure factors contribute significantly to promoting a firm’s capability to improve sustainability supply chain management. Besides, Zeng et al. (2017) also stated the importance of balance between internal and external pressure as the classification by organization, economic and social constructs in this research. A similar result is echoed by Khan et al. (2020) where managerial and policy implications are important to identify circular economy capability and developing goals through implementation. Strategic planning moving toward a circular economy model require collaboration in the business model in the formulation of strategic partners, planning investments, and human resources. Environmental-conscious management tends to adopt a circular economy taking risk as eco-entrepreneur as they understand the implication and benefit in long term.

Next, this study examines the circular economy barriers’ effect on circular economy business model adoption. Barrier reduction increases the adoption of a circular economy; hence the relationship has a negative effect. In this research, the barrier with the highest mean score is difficulty in accessing suitable financing followed by the perception of high business risk and then lack of skills and qualifications. These gaps were highlighted by Abdul-Hamid et al. (2020) in circular economy challenges in Malaysia’s palm oil industry. This research finding suggests that similar barriers are not restricted to the palm oil industry but might be a common scenario in most industries in Malaysia. High upfront investment costs and limited funding for circular business models are among the most pressing barriers in the Netherlands where circular economy adoption implementation is high (Kirchherr et al., 2018). As a developing nation with lower popularity for the circular economy, firms in Malaysia faced this challenge as the most pressing barrier as shown in this research. Another two barriers in the top five of this research are the lack of a regulatory framework and the dominant position of key market players. This finding is consistent with the motivation factor where policy regulation and guidelines are important factors in circular economy adoption.

The barriers of the study can be referred to as the four levels of company-external barriers (technology, market, legislative, and society and consumers). The lack of institutionalized systems, such as collection, reverse logistics, or mobility systems, are barrier since companies lack the size to internalize such activities. Besides negative incentives for circular economy investments, burdensome legal prescriptions and customs duties hinder a circular economy. These are reflected in restrictive regulations and can lead to planning uncertainty and confusion given rapidly changing rules and bureaucratic burdens. Therefore, H2: The barrier factors negatively affecting the adoption of the circular economy business model cannot be rejected. The findings align with previous studies (Khan et al., 2020; Jabbour et al., 2020) that suggest similar barriers in terms of financial, structural, and operational which include both internal and external factors for the firms.

The highest mean score for circular economy business model adoption is built to last and upgrade. The other business models that are currently being assessed include circular supplies, repair and maintenance, and share. As for sustainable production, the highest mean score items are related to end-to-life packaging, recycling production waste, and reporting design for environmental management. Zeng et al. (2017) found that sustainable manufacturing practices can be achieved in three ways by using environmental-friendly materials which can be recirculated in the system at the end of shelf life. On contrary, Marouek et al. (2022) have indicated that additional study investigations need to be carried out in order to evaluate the possible hazardous consequences of this chemical. It is common knowledge that the focus of the circular economy is on the reuse and regeneration of materials or products, in particular as a method of continuing production in a sustainable or environmentally friendly way; consequently, there is a pressing need for additional research that investigates the potential negative effects that could arise from the reuse and regeneration of materials or products.

Second, process efficiency and waste reduction with defect reduction with the use of advanced technology, and pollution-free technology. By having a circular supply, firms can recycle their waste and design products better for environmental management. In this research, H3: The circular economy business model adoption positively affects sustainable production is supported in the examination of the impact of circular economy business model adoption on sustainable production. The findings are consistent with previous studies (for example Bag et al., 2021) which suggest that sustainable manufacturing practices have a positive association with circular economy capabilities. The impact of the circular economy business model on operation management improves greener production, results in higher efficiency, and better use of resources. These lead to lesser waste and highly skilled work with the addition of technology.

The lack of synergy in sustainability production is one of the main reasons for the slow adoption of circular economy and sustainable production in Malaysia. This paper examines the root cause of this issue. Looking at both internal and external factors from motivators and barriers, the finding contributes an overview of the most pressing issues that need to be addressed. Thereafter the adoption of the circular economy business model can be increased leading to more sustainable production and consumption.

Practical implication

Following the triple bottom line approach, many researchers are increasingly focusing their attention on sustainable business models which highlight the ways in which a firm generates value, the value proposition it offers, and captures value. These models extend the scope of traditional business model research by combining the environmental aspects of sustainability with the economic dimensions of the company as well as the well-being of people. Circular business models are a sub-type of sustainable business models that define the way in which companies need to develop the business models that underpin their operations in order to achieve a circular economy. Designing and putting into practice circular business models can result in sustainable production which will affect the cost savings for the company. Sustainable production makes it possible for businesses to generate and seize new value and achieve a competitive edge.

This paper focuses on manufacturing firms associated with energy consumption in the production process and producing goods that can be designed to be environmental-friendly. Some of the key takeaways from this paper are the motivators and barriers focused on the organization which is the firm’s internal factors. Building an environmental-friendly and sustainable image along with the uncertainty elements in circular economy adoption is relevant to many firms in developing countries. However, the challenge reward in the implementation of circular economy practices is the path to sustainable production. Better performance in business processes through higher efficiency, clean production, skilled labor, and sustainable profit will be the incentive in the long term. Hence, it is worthwhile for firms to rethink the journey to pursue circular economy adoption as a replacement for the traditional linear model. A circular economy could boost higher revenue for companies in its practicality and relevancy. In addition, overpopulation and higher demand for goods causing negative impacts on the ecosystem can be resolved through sustainable consumption and production. The finding from this paper can be an indicator and tool for policymaking in developing countries in the industrial sector for a more effective circular economy adoption and implementation.

Research limitations and directions for future research

The number of firms that participated in this research is limited to 102 usable respondents which is rather low to represent the firms’ population in Malaysia. In addition, this paper focuses on firms with environmental management systems without industry restrictions. The survey was closed considering the lack of responsiveness and change in business operations which might not reflect the existing reality of the firm due to the COVID-19 pandemic. Hence, a generalization of this study across different industries can be replicated with a higher number of respondents. This study may have suffered from “social desirability bias”. This fact raised concern that the respondent profile for sustainability survey has inclined to be more socially favorable to sustainability-related questions. However, the probability is reduced when the invitation to respond survey questionnaire was directed to the director or owner of the company. This reduced the chance of a survey questionnaire being offered to any authorized personnel within a specific department creating the incident of bias. Another limitation of this study is data analysis for motivators and barriers were not classified into constructs such as organizational, cultural, and other groups. Besides, there is no moderator included in this research but focuses only on the direct relationship.

The circular economy offers a fresh and innovative strategy for achieving sustainable development. According to the findings of the study, the innovation strategy for Industry Revolution 4.0 and the circular economy is important, despite the fact that it is still relatively underexplored. There has not been a lot of research done looking at how the activities throughout value chains might be affected by the structure of those activities. However, in the future there will be a continued expansion of study on the incorporation of digitization into the circular economy, as well as how digital transformation might redefine circular economy practices in both the local and global value chain. In conclusion, there is a need for additional research not only on the comprehension of challenges and barriers but also on the comprehension of conflicting demands and interests from the various stakeholders in the implementation of digital strategy in the circular economy. The fact is that digital transformation is an essential topic for further study in order to address the difficulties and complexities associated with the circular economy. Based on the findings of this study, it appears that the impact on digital transformation growth of circular economy efforts plays a significant role in the increasing of sustainable production that occurs along the value chain. The extent to which digital transformation can increase the adoption of the circular economy may be the subject of upcoming research projects, as well as their impact on digital performance management.

Conclusions

The circular economy concept has gained immense attention in recent years across the world in both developing and developed nations. More governments, organizations, institutions, policymakers, and individuals embraced this paradigm shift as a way to move forward. This new pattern of growth is excellent for enhancing economic development, facilitating resource efficiency, and lowering environmental pollution, all of which are interconnected goals. As a result of this, several nations, including those that are members of the EU, have adopted the circular economy as a strategy for achieving sustainability, and they have also developed goals and measures related to the circular economy. In the future, more sustainable production and consumption should emerge, and the circular economy is the answer to this calling for a better world for the next generation. The main objective of this study is to examine the impact of circular economy business model adoption on sustainable production which is influenced by the level of circular economy business model adoption among firms in Malaysia.

Findings infer that internal stakeholders play a greater role in realizing the adoption of the circular economy business model. Firms seek to improve their performance indicator and social image by contributing to economic and environmental efficiency by responding to explicit customer demand/preferences toward the adoption of green production methods and also, as a response to competitors’ actions. In addition, the balanced role between internal and external stakeholders provides pressure that can significantly improve the sustainability of supply chain management while strategic planning moving toward a circular economy can expedite the formulation of strategic partners, planned investments, and planned human resources. Internal stakeholders who are environmental-conscious would be more willing to engage in a circular economy business model to reap the maximum benefit while minimizing potential losses.

Barriers to the adoption of a circular economy business model include high upfront investment costs, limited funding for circular business models, lack of regulatory framework for circular economy and the dominant position of key players in the industries may decelerate the adoption of circular business models in developing and less developed countries. Nevertheless, the emergence of new alternative funding such as green bonds and green sukuk in developing countries should partly assuage financing problems. Other firm-level barriers include the lack of an institutionalized system for collection, reverse logistics and mobility systems, burdensome legal constraints, erratic bureaucratic requirements, and high customs duties play vital roles in hindering circular economy business model adoption.

The circular economy business model aims at sustainable production which corroborates recirculating environmentally friendly materials, recycling production waste, and regenerating materials for further use. The lack of synergy in sustainable manufacturing may result in the slow adoption of a circular economy business model. In addition, there is a need for more research and development of potential effects that could arise from recycling and multiple regenerations of materials.

In conclusion, apart from the positive effects of a circular economy model on the environment and the economy, the circular economy may also help foster the development of new jobs, mitigate the social issues that are caused by unemployment, and advance the cause of social sustainability. There is a significant opportunity for the circular economy to drive societal evolution toward greater environmental, economic, and social sustainability.

Data availability

Data is available upon request.

Declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Footnotes

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Contributor Information

Lim Sin Ting, Email: 17077259@siswa.um.edu.my.

Suhaiza Zailani, Email: shmz@um.edu.my.

Noor Zahirah Mohd Sidek, Email: nzahirah@uitm.edu.my.

Mohd Rizaimy Shaharudin, Email: rizaimy@uitm.edu.my.

References

- Abd’Razack NT, Medayese SO, Shaibu SI, Adeleye BM. Habits and benefits of recycling solid waste among households in Kaduna, North West Nigeria. Sustainable Cities and Society. 2017;28:297–306. doi: 10.1016/j.scs.2016.10.004. [DOI] [Google Scholar]

- Abdul Hamid, T. (2020). Urgent need for a circular economy: New Straits Times. Retrieved March 13, 2021, from https://www.nst.com.my/opinion/columnists/2020/04/588010/urgent-need-circular-economy

- Abdul-Hamid A, Ali MH, Tseng M, Lan S, Kumar M. Impeding challenges on industry 4.0 in circular economy: Palm oil industry in Malaysia. Computers & Operations Research. 2020;123:105052. doi: 10.1016/j.cor.2020.105052. [DOI] [Google Scholar]

- Aboelmaged M. E-waste recycling behaviour: An integration of recycling habits into the theory of planned behaviour. Journal of Cleaner Production. 2021;278:124182. doi: 10.1016/j.jclepro.2020.124182. [DOI] [Google Scholar]

- Ali MSM, Yusof RNR. Intention to practice reduce, reuse & recycle (3R) among expatriates working in Malaysia. International Journal of Academic Research in Business and Social Science. 2018;8(3):276–295. [Google Scholar]

- Aranda-Usón A, Portillo-Tarragona P, Scarpellini S, Llena-Macarulla F. The progressive adoption of a circular economy by businesses for cleaner production: An approach from a regional study in Spain. Journal of Cleaner Production. 2020;247:119648. doi: 10.1016/j.jclepro.2019.119648. [DOI] [Google Scholar]

- Arroyo P, Carrete L. Motivational drivers for the adoption of green energy. Management Research Review. 2019;42(5):542–567. doi: 10.1108/mrr-02-2018-0070. [DOI] [Google Scholar]

- Bag S, Pretorius JH, Gupta S, Dwivedi YK. Role of institutional pressures and resources in the adoption of big data analytics powered artificial intelligence, sustainable manufacturing practices and circular economy capabilities. Technological Forecasting and Social Change. 2021;163:120420. doi: 10.1016/j.techfore.2020.120420. [DOI] [Google Scholar]

- Boyer RHW, Hunka AD, Linder M, Whalen KA, Habibi S. Product labels for the circular economy: Are customers willing to pay for circular? Sustainable Production and Consumption. 2021;27:61–71. doi: 10.1016/j.spc.2020.10.010. [DOI] [Google Scholar]

- Darnall N, Jolley GJ, Handfield R. Environmental management systems and green supply chain management: Complements for sustainability? Business Strategy and the Environment. 2008;18:30–45. doi: 10.1002/bse. [DOI] [Google Scholar]

- Franklin-Johnson E, Figge F, Canning L. Resource duration as a managerial indicator for Circular Economy performance. Journal of Cleaner Production. 2016;133:589–598. doi: 10.1016/j.jclepro.2016.05.023. [DOI] [Google Scholar]

- Garces-Ayerbe C, Rivera-Torres P, Suarez-Perales I, Leyva-de la Hiz DI. Is it possible to change from a linear to a circular economy? An overview of opportunities and barriers for European small and medium-sized enterprise companies. International Journal of Environmental Research and Public Health. 2019;16(5):851. doi: 10.3390/ijerph16050851. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Grafström J, Aasma S. Breaking circular economy barriers. Journal of Cleaner Production. 2021;292:126002. doi: 10.1016/j.jclepro.2021.126002. [DOI] [Google Scholar]

- Hair JF, Risher JJ, Sarstedt M, Ringle CM. When to use and how to report the results of PLS-SEM. European Business Review. 2019;31(1):2–24. doi: 10.1108/ebr-11-2018-0203. [DOI] [Google Scholar]

- Halog A, Anieke S. A review of circular economy studies in developed countries and its potential adoption in developing Countries. Circular Economy and Sustainability. 2021;1:209–230. doi: 10.1007/s43615-021-00017-0. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Jabbour CJC, Seuring S, de Sousa Jabbour ABL, Jugend D, Fiorini PDC, Latan H, Izeppi WC. Stakeholders, innovative business models for the circular economy and sustainable performance of firms in an emerging economy facing institutional voids. Journal of Environmental Management. 2020;264:110416. doi: 10.1016/j.jenvman.2020.110416. [DOI] [PubMed] [Google Scholar]

- Jesus A, Mendonça S. Lost in transition? Drivers and barriers in the eco- innovation road to the circular economy. Ecological Economics. 2018;145:75–89. doi: 10.1016/j.ecolecon.2017.08.001. [DOI] [Google Scholar]

- Khan O, Daddi T, Iraldo F. Sensing, seizing, and reconfiguring: Key capabilities and organizational routines for circular economy implementation. Journal of Cleaner Production. 2021;287:125565. doi: 10.1016/j.jclepro.2020.125565. [DOI] [Google Scholar]

- Kirchherr J, Piscicelli L, Bour R, Kostense-Smit E, Muller J, Huibrechtse-Truijens A, Hekkert M. Barriers to the circular Economy: Evidence from the European Union (EU) Ecological Economics. 2018;150:264–272. doi: 10.1016/j.ecolecon.2018.04.028. [DOI] [Google Scholar]

- Kumar V, Sezersan I, Garza-Reyes JA, Gonzalez EDRS, AL-Shboul MA. Circular economy in the manufacturing sector: Benefits, opportunities and barriers. Management Decision. 2019;57(4):1067–1086. doi: 10.1108/md-09-2018-1070. [DOI] [Google Scholar]

- Lausselet C, Cherubini F, Oreggioni GD, del Alamo Serrano G, Becidan M, Hu X, Strømman AH. Norwegian waste-to-energy: climate change, circular economy and carbon capture and storage. Resources, Conservation and Recycling. 2017;126:50–61. doi: 10.1016/j.resconrec.2017.07.025. [DOI] [Google Scholar]

- Mardoyan A, Braun P. Analysis of Czech subsidies for solid biofuels. International Journal of Green Energy. 2015;12(4):405–408. doi: 10.1080/15435075.2013.841163. [DOI] [Google Scholar]

- Marino A, Pariso P. Comparing European countries’ performances in the transition towards the Circular Economy. Science of the Total Environment. 2020;729:138142. doi: 10.1016/j.scitotenv.2020.138142. [DOI] [PubMed] [Google Scholar]

- Maroušek J, Trakal L. Techno-economic analysis reveals the untapped potential of wood biochar. Chemosphere. 2022;291:133000. doi: 10.1016/j.chemosphere.2021.133000. [DOI] [PubMed] [Google Scholar]

- Mohan SV, Modestra JA, Amulya K, Butti SK, Velvizhi G. A circular bioeconomy with biobased products from CO2 sequestration. Trends in Biotechnology. 2016;34(6):506–519. doi: 10.1016/j.tibtech.2016.02.012. [DOI] [PubMed] [Google Scholar]

- Pieroni MPP, McAloone TC, Pigosso DCA. Circular economy business model innovation: Sectorial patterns within manufacturing companies. Journal of Cleaner Production. 2021;286:124921. doi: 10.1016/j.jclepro.2020.124921. [DOI] [Google Scholar]

- Pollard J, Osmani M, Cole C, Grubnic S, Colwill J. A circular economy business model innovation process for the electrical and electronic equipment sector. Journal of Cleaner Production. 2021;305:127211. doi: 10.1016/j.jclepro.2021.127211. [DOI] [Google Scholar]

- Ringle, C.M., Wende, S., & Becker, J.-M., (2015). SmartPLS, p. 3.

- Ritzen S, Sandstrom GO. Barriers to the Circular Economy–integration of perspectives and domains. Procedia CIRP. 2017;64:7–12. doi: 10.1016/j.procir.2017.03.005. [DOI] [Google Scholar]