Abstract

Additive manufacturing (AM) is an emerging area with the potential to modify present business models in the near future. In contrast with conventional manufacturing (CM), AM allows the development of a product from a smaller amount of raw material, while allowing an improvement in properties in terms of weight and functionality. Its production flexibility and creativity in terms of materials have enabled not only the industry to use this technology, but also has been used in healthcare (e.g., in the production of human tissue) and by the final consumer. Despite the invaluable opportunities that this technology could provide, the uncertainties concerning its future developments and impacts on business models remain. New business models in AM will convey the need to: specialize the workforce in the design of new parts produced locally or remotely; regulation in the use and sharing of intellectual property rights by partner companies or between users; regulate the possibility of reverse engineering of highly customized products; etc. The present research proposes a conceptual maturity model to support the phases of evolution of AM in the industry, in supply chains, and in terms of open business models.

Keywords: Additive manufacturing, 3D printing, Knowledge management, Maturity model

Highlights

-

•

A conceptual maturity model to support the phases of evolution of AM in industry and supply chains.

-

•

A maturity model to support AM evolution phases in terms of open business models.

-

•

Model based on literature review regarding knowledge management maturity in AM, focusing on business models.

-

•

This proposed model can serve as a scale for different organisations to estimate their degree of readiness.

-

•

It contributes to the development of the existing literature concerning maturity models.

1. Introduction

The ever-growing frequency of transformations witnessed in the economic, political and social fields are constantly changing the business environment [[1], [2], [3]]. Thus, living in an increasingly complex scenario, professionals, researchers and policy makers are required to understand the complex phenomena that happen in the world [4]. Among others, this can be achieved through Knowledge Management (KM). KM comprises the identification, creation and distribution of knowledge in an organization, being extremely important in supporting decision making [5]. Knowledge has become the main capital of companies as processes tend to be progressively more knowledge intensive. Consequently, companies seek to harness the potential of their intangible resources to increase their competitive advantage [6]. One way to achieve this competitiveness is to employ disruptive technologies by correctly managing knowledge as it expands [7].

Additive manufacturing (AM) also known as 3D printing, is a type of technology closely linked to Industry 4.0 and is transforming manufacturing and production processes. AM is considered by the European Commission as key technologies enabling the industrial digital transformation and transforming the future of manufacturing [8]. Since this technology is able to deposit materials to create objects from precise 3D models, this technology can substitute, in different contexts, the more costly subtractive manufacturing technologies, such as machining. This type of manufacturing allows you to create unique objects, eliminate losses, optimize processes and generate a series of benefits for different applications [9]. AM is capable of simplifying many types of fabrication processes by reducing the use of raw materials, while at the same time, it is also capable to improve the properties of the final product regarding functionality and weight. Consequently, the present business paradigm has a high chance of being profoundly changed by AM, and as such, lead to the appearance of innovative business models based on AM [10]. AM is also a practical technology that helps mitigating project delays for the maintenance and operations processes [11].

At an industrial level, AM turns possible to produce products in one location and directly from raw materials. Through this technology it is possible to replace many interrelated production steps and even eliminate one or more suppliers at the supply chain level [12]. AM was initially created for the prototype manufacturing, however this technology is currently capable to produce entirely functional parts and can be easily integrated in the production line [13]. AM also allows for consumers to turned into producers by being able to manufacture their own products, being for their own consumption, or to supply it to their clients. Consequently, reports show that AM has the capacity to meaningfully affect several fields and provide the basis for enterprises to be able to foster different business models [10].

Two approaches occur in industry. One is the gradual implementation of AM, along with conventional manufacturing processes for producing final products and spare parts. Another one is substituting conventional manufacturing process with AM [[14], [15], [16]]. By employing AM, in supply chain management, final products and parts can be manufactured from raw materials in just one place. Also, initiatives of collaboration among customers could lead, in certain cases, to collaborative production as an alternative to manufacturing. At the center of this transformation, KM faces difficult challenges. One of these obstacles is how can KM facilitate the emergence of new models while another is how can KM will regulate and normalize the knowledge that is formed, gathered, applied, diffused and saved [12]. Original business models in AM will have to be prepared for specializing the personnel in being capable of designing new parts. It will also be required to regulate the share and use of intellectual property rights by stakeholders or among users and also to be aware of the likelihood of reverse engineering of very personalized and unique products [17].

The benefits of employing AM are usually perceived in terms of its capability to manufacture certain products with a varying degree of complexity in a more economical manner. AM processes, for instance, are able to generate structures that display a high degree of functional, shape, and hierarchical complexity. A key advantage is also considered to be the high material complexity, such as the existing variety in material properties or composition of a part. Such types of technical gains lead to a disruptive innovation in business practices and market supply chains, thus having the capacity to displace established market-leading products and firms [18] and proposing new possibilities for innovation in services and products [19]. However, specialized knowledge in this technology is scarce, thus training specialized professionals and developing new knowledge that will solve the current technological limitations and challenges of AM becomes essential.

In industries, the adoption of AM allows the materialization of knowledge, since new work structures and skills sets are required as well as skilled professionals in order to be able to operate the AM and modeling equipment [10]. The expansion of this technology depends essentially on printing time, cost, quality, size and the variety of materials and their environmental impacts, namely energy use and the toxicity of printing materials. Despite the popularity that this technology has been displaying lately and its innovative and profound impacts to selected industries, several studies show that there is still a great lack of knowledge regarding the maturity of the knowledge of this technology in the various sectors where its growing application may have significant impacts [10,20,21].

A knowledge maturity model for a technology defines the state of knowledge of that technology in a given organization or sector as well as in successive stages that may allow a significant improvement in global practices and processes that lead to maximizing the efficiency and effectiveness of the business model [[22], [23], [24]]. The current scenario of product development through AM doesn't have a significant level of maturity [25] and, since AM has the potential of reaching a substantial level of technological maturity, the challenge becomes to skillfully employ this type of technology at an industrial scale [26]. However, a fairly small amount of work has been put into the question of how can be knowledge gained, effectively located, and used through previous innovations in AM [19]. Therefore, the purpose of this study is to research the level of knowledge management (KM) maturity of the additive manufacturing technology, building the foundations of a theoretical model for evaluating the maturity of the knowledge of businesses that use additive manufacturing technology.

The research is qualitative and exploratory, based on KM maturity literature review models. The scarcity of information on the subject and the lack of consensual, reliable and maturity knowledge assessment models adapted to the specificities of additive manufacturing technology demonstrates that the organisations’ knowledge of this technology is still in an early stage, even though it is growing up. Furthermore, it is concluded that the literature on decision models, based on additive technology is scarce and fragmented, requiring integrative and practical studies.

2. Theoretical background

2.1. Additive manufacturing

Businesses are being compelled to embrace mass customization as customers continue to demand individual products. Companies must be able to manufacture customized products in order to respond to this trend [27]. This challenge can be addressed primarily through complicated geometric structures which can be created during the design phase of the process. Additive manufacturing is the most appropriate technology for such designs [28]. A growing number of products are being manufactured through additive manufacturing (3D printing). Originally intended to produce prototypes and models, additive manufacturing have found application in series production today. Additive manufacturing has become a major tool in product development and production in almost all industries [29]. This technology, known as 3D printing, can reduce resource consumption by only using material at the point where it is functionally required, thus using less resources and protecting the environment [30]. Additive manufacturing is becoming more popular as companies seek higher quality and more efficient components [31].

For the construction of components, additive manufacturing offers no end to the possibilities: complex geometries can be realized, and lightweight construction features can also be utilized. This improves the quality of components and thus the entire array of products [32]. However, the high costs and low productivity of additive production force companies to select components in a meaningful way [33]. As of yet, additively manufactured components lack reliable criteria and procedures for testing and quality assurance. Because of this, use in applications like aircraft parts or medical devices, which require reliability and safety, is still contentious, and it is still very complex under current conditions. There are still many challenges associated with this technology, and its rapidly evolving changes must be addressed [34].

2.2. Maturity models

A maturity model has many definitions. Klimko [35] characterizes it as a conceptual framework comprised of elements that depict the progress of a certain domain of interest over a period of time, while Becker et al. [36] classifies maturity models as “artifacts that aim at solving the problems of determining a company's status quo of its capabilities and deriving measures for improvement.” A maturity model can also be described, according to Mullaly and Thomas [37], as a process, or a form of assessment, by which an organization can improve by developing its capabilities and by adopting advantageous practices.

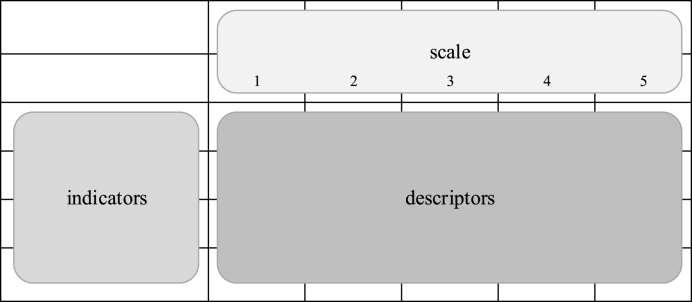

As a maturity model, an artifact usually takes the shape of an analytical evaluation rubric that should comprise the following elements depicted in Fig. 1:

-

•

A scale that illustrates maturity stages or levels;

-

•

Indicators showing areas of application of a certain domain;

-

•

Descriptors capable of defining the performance necessary for reach a certain level of a certain indicator.

Fig. 1.

The constructive elements of a maturity model.

Maturity models can be used to:

-

•

Describe an organization's current practices;

-

•

Prescribe a plan to guide progress toward an objective;

-

•

Compare an organization's current practices to standards and other companies' best practices [38].

Thus, maturity models can be a very relevant tool not only in the identification and knowledge of the current state of companies in terms of additive manufacturing, but also in the definition of strategies to proceed towards the implementation and development of this manufacturing process.

There are several articles in the scientific literature that have used maturity or readiness scales to evaluate additive manufacturing processes. The terms “maturity” and “readiness” are closely related. Maturity models support the identification of installed capabilities as well as the recognition of strengths and critical points [39] with the aim of providing extensive guidance and establishing mechanisms to enable continuous improvement [39,40]. Readiness models allow clarifying whether or not the organization is ready to start a development process or perform a certain task [41,42].

The Manufacturing Readiness Level (MRL) and Technology Readiness Level (TRL) criteria have been among the most widely used to assess the maturity and readiness of additive manufacturing processes. These two criteria are linked and often used together as manufacturing readiness is usually paced by technology readiness [43]. The maturity of manufacturing processes will only be possible when product technology and product designs are consolidated [43].

The TRL, initially developed by the National Aeronautics and Space Administration (NASA) in the 1970s [44], are used to assess the maturity or readiness level of a specific technology [45]. They are composed of nine levels (TRL 1 to TRL 9) and also allow the maturity of different types of technology to be assessed and compared, and their readiness to act as part of a larger system [43,46].

The MRL, developed by The United States Department of Defense, allows for the assessment of manufacturing maturity and risk [43]. Using ten levels (MRL 1 to MRL 10), the MRL allow for a structured assessment of manufacturing processes, procedures, and techniques for technology, items, components, and systems [43].

Ma et al. [47] formulated an estimate of the TRL of extrusion-based 3D concrete printing processes to help identify the frontiers of current development, as well as providing concrete guidance so that the risk of investment in research and development could be properly assessed. Ryan et al. [48] used TRL to assess the technological readiness of electrospun, additive manufactured and imprinted medical devices, alone or in combination with functional molecules and/or viable cell populations.

Strantza et al. [49] developed an effective structural health monitoring system that detects cracks through a structure with an embedded capillary system, produced through additive manufacturing. The authors used the criteria set out in the TRL to prove that the developed system achieved technology readiness level 3 (TRL 3) [49].

Schneck et al. [50] proposed a breakthrough of multi-material technology by fabricating a complex, industrial multi-material part as a prototype fabricated by laser-based powder bed fusion. With this work, the authors concluded that a maturation of this type of fabrication to a higher MRL was possible [50]. Wu et al. [51] performed a literature review and evaluated bioprinting based on the proposed criteria of the MRL.

In order to understand the current status of maturity models related to additive manufacturing, a literature review was conducted in the Scopus database. For the screening, articles that simultaneously met the following criteria were considered: i) publications proposing a new maturity or readiness model, or adapted from an existing model that included a new approach; ii) publications with maturity models targeting additive manufacturing or 3D printing, either those developed specifically for this manufacturing process or those with a broader scope, but which still included additive manufacturing as one of the aspects included in the analysis framework or a practical application.

From the screening, 5 publications of maturity models related to additive manufacturing resulted, which are listed in Table 1. In addition to the maturity levels and dimensions considered in the different models, a brief description is also included in the table. The maturity or readiness models are presented in descending order of the relevance of additive manufacturing in the proposed model. The exceptions are the last three, which, with similar relevance, are ordered by decreasing order of publication date.

Table 1.

Existing maturity and readiness models in additive manufacturing.

| Maturity Model | Maturity levels | Dimensions | Description | Year | Ref. |

|---|---|---|---|---|---|

| Classification of the part as AM category I, II, III, or IV | AM category I: High maturity (MRL 9–10: capability to initiate or demonstrate full rate production); AM category II: Medium maturity (MRL 7–8: capability to produce a system in a production or pilot line environment); AM category III: Low maturity (MRL 4–6: capability to produce a prototype in a laboratory or production environment); AM category IV: Lowest maturity |

Mission risk class; AM process' manufacturing readiness level (MRL); and rigor of material properties | The classification of the part as AM category I, II, III, or IV, depends jointly on the mission risk class, the manufacturing readiness level (MRL) of the AM process and the rigor of the material properties. This classification appears as one of the steps of the flow diagram proposed in the study for the development of AM parts for unmanned space programmes | 2019 | [52] |

| Assessment model to measure the level of implementation of Industry 4.0 technologies/Industry 4.0 maturity levels | Level 1: Minimal (score between 23 and 46: the firm does not expose any technical or behavioural attribute linked to Industry 4.0); Level 2: Development (score between 47 and 69: some of the practices are visible with the clear intention of further development); Level 3: Defined (score between 70 and 92: well-established practices and behaviour); Level 4: Excellence (score between 93 and 115: aspect of best practice or excellence) |

‘Factory of the Future’ (composed of 8 technological innovations: additive manufacturing, cloud, manufacturing execution system, internet of things and cyber physical systems, big data, sensors, e-value chains, and autonomous robots); ‘People and Culture’ (key attributes: innovation openness, and continuous improvement capabilities); and ‘Strategy’ (key attributes: technological investment, agility vision, and manufacturing strategy) | Industry 4.0 maturity is measured through an assessment framework that includes three dimensions: “Factory of the Future”, “People and Culture”, and “Strategy”. The first is the main one and is composed of eight attributes, one of which is additive manufacturing. The second and third are composed of two and three attributes, respectively. The maturity assessment results from the sum of the scores attributed to the various dimensions, which are the result of the scores of the various attributes that constitute them. In turn, the score of each attribute results from the sum of the various constituent derived items. The proposed model was developed, tested, and validated using a defence manufacturing company | 2018 | [53] |

| Technology Readiness Level (TRL) scale for innovative structural materials and fabrication processes | Adaptation of the following TRL scale for innovative structural materials and manufacturing processes: TRL 1: Basic principles observed and reported; TRL 2: Technology concepts and options evaluated and/or applications formulated; TRL 3: Proof-of-concept demonstrated at laboratory scale; TRL 4: Component/subsystem validation in laboratory environment; TRL 5: Component and/or subsystem validation in relevant conditions; TRL 6: System/subsystem model or prototype demonstration in relevant environment; TRL 7: System prototype demonstration in operational conditions; TRL 8: Actual system completed and qualified through test and demonstration; TRL 9: Actual system proven through successful operations. Commercial-scale fabrication |

Proposal of a Technology Readiness Level scale, adapted from Ref. [54], to estimate the maturity of innovative structural materials and manufacturing processes, such as additive manufacturing, by incorporating experimentation, irradiation, and qualification/licensing based aspects | 2021 | [55] | |

| Bibliometric Method for Assessing Technological Maturity (BIMATEM) | Emerging TLC stage corresponding to TRLs 1–5 when technological concepts are observed (TRL 1), formulated (TRL 2), experimented (TRL 3), validated in the laboratory (TRL 4), and validated in a relevant condition (TRL 5); Growing TLC stage corresponding to TRLs 6 and 7 when prototypes are demonstrated; Mature TLC stage corresponding to TRLs 8 and 9 when the technology is proven, and deployed in an operational environment; Declining TLC stage |

The method aims at quantitatively estimating the level of technological maturity through the comparison of technology records contained in scientific literature, patents, and news databases (bibliometric records) with each stage of the technology life cycle (TLC). The estimate of technological maturity is materialised through the technology readiness level (TRL), as an approximation of the TLC stages | 2018 | [56] | |

| Education Readiness Levels (ERLs) | General definitions of Education Readiness Levels (ERLs) for each scale: ERL 9: Scope for alterations with multiple iterations; ERL 8: Actual course completed and qualified; ERL 7: Criteria validation in an operational environment; ERL 6: Revaluation after trial completed with changes; ERL 5: Criteria validation in trial environment; ERL 4: Criteria validation in controlled environment; ERL 3: Active proof of concept developed for estimate; ERL 2: Consideration of factors affecting criteria; ERL 1: Basic numbers estimated and reported; ERL 0: No information received; NA: Not Applicable for this Critical Element |

Critical elements: class size, cost, depth of content, facilities, instructor(s), course material, and target audience | Education Readiness Levels aim to assess the “readiness” of courses and training modules based on seven critical elements. To this end, 10 readiness levels have been defined for each element, based on the Technology Readiness Level (TRL) and Manufacturing Readiness Level (MRL) definitions. This scale was applied to a dataset of courses provided by America Makes, the National Additive Manufacturing Innovation Institute | 2017 | [57] |

O'Brien [52] proposed a framework for the development and qualification of additively manufactured parts for unmanned space programmes. The author mentions the requirements for mission assurance for the space industry and according to these requirements proposes a qualification strategy for additive manufacturing, which includes an assessment of the maturity of the additive manufacturing part. The author classifies the part as AM category I, II, III and IV, with I being the most mature and IV being the least mature [52]. This classification of the part depends simultaneously on the mission risk class, the manufacturing readiness level (MRL) of additive manufacturing process and the stringency of the material properties [52]. Three case studies are also presented on the development and qualification of additive manufacturing for the space industry with the purposes of improving the reliability of the technology and its maturation [52].

Bibby and Dehe [53] developed an assessment framework to measure the level of implementation of Industry 4.0 technologies, i.e. their maturity. The assessment is centred around three dimensions: ‘Factory of the Future’, ‘People and Culture’, and ‘Strategy’ [53]. The first, considered the main dimension, is composed of eight attributes, one of which is additive manufacturing. The second and third are composed of two and three attributes, respectively. Maturity assessment is performed by assigning a score to the different items belonging to each of the attributes, which in turn are associated with one of the three main dimensions. At the end the scores of each item are added up and the value of each attribute is calculated. The sum of the eight, two and three attributes will represent the value of the dimensions ‘Factory of the Future’, ‘People and Culture’, and ‘Strategy’, respectively. The final score resulting from the sum of the three dimensions as well as each dimension can be compared with a range of scores representing each maturity level. The authors defined a maturity scale comprising 4 levels (Level 1 to Level 4). The model was tested and validated using a defence manufacturing company [53].

Balbaud et al. [55] proposed a TRL scale (adapted from Ref. [54]) to estimate the maturity of innovative structural materials and innovative manufacturing processes, incorporating aspects based on experimentation, irradiation, and qualification/licensing. The proposed methodology has been applied to assess the TRL level of projects of The Nuclear Energy Agency (NEA) Expert Group on Innovative Structural Materials (EGISM) members on innovative materials and advanced manufacturing solutions, such as additive manufacturing [55].

Lezama-Nicolás et al. [56] developed a Bibliometric Method for Assessing Technological Maturity (BIMATEM), based on bibliometric analysis of technology records, to quantitatively estimate the level of technological maturity through TRL. The method is based on the assumption that technology records contained in scientific literature, patents and news databases can be compared with each stage of the technology life cycle (TLC). Subsequently the TRL can be estimated as an approximation of the TLC phases [56]. The method was applied to seven additive manufacturing technologies, each of them being assigned a maturity level [56].

Dinda et al. [57] introduced Education Readiness Levels (ERLs) as a tool to assess the readiness of courses, programmes and educational modules. Using the definitions of the Technology Readiness Level (TRL) and Manufacturing Readiness Level (MRL) scales, the authors created a scale with 10 readiness levels that allow seven elements considered critical to be assessed [57]. Based on the information obtained about the course, a readiness level is established for each of these elements [57]. The scale has been applied to several projects funded by America Makes, the first Manufacturing USA Institute, which focuses on additive manufacturing and 3D printing [57].

In addition to these studies, there are also others that, although they are directed to Industry 4.0, refer to additive manufacturing as a technology related to it. Gallego-García et al. [58] developed a sequence model for the application of technologies related to Industry 4.0, with the aim of enabling continuous and sustainable improvement. In this study the importance of the existence of a maturity model as a tool to monitor and develop organisations is highlighted. With clear and well-established objectives, the identification of the maturity level through real-time knowledge of the organisation's capabilities, can serve as a basis for the definition of strategic programmes [58].

The existing maturity assessment models, although they have been significantly applied in the last years, lack an understandable definition and contextualization [59]. In addition, from the literature review carried out, it was possible to conclude that the existing maturity or readiness models related to additive manufacturing, besides being very few in number, also present some limitations.

The analysis performed to the publications shows that although some of them take additive manufacturing into consideration, the proposed models are not directed to this process, and therefore many of the relevant aspects to classify maturity or readiness are not considered. Although one of the papers is specifically for additive manufacturing, its application is limited because it is inserted in a framework aimed at developing and qualifying parts produced by additive manufacturing for the space industry. In addition, none of the studies refers to knowledge management. Thus, this paper aims to fill this gap in research by proposing a conceptual maturity model to support the evolution stages of additive manufacturing.

3. Methodology

As mentioned above, the main objective of this study is to propose a conceptual maturity model to support companies in assessing their readiness for additive manufacturing.

The development of this maturity model was based on following steps of the maturity models’ research design from Refs. [[60], [61], [62]]: 1) Identify the need and specify problem domain; 2) Define scope of model application; 3) Design model structure; 4) Populate model structure; 5) Validation; and 6) Reflect evolution – Model deployment and continuous learning.

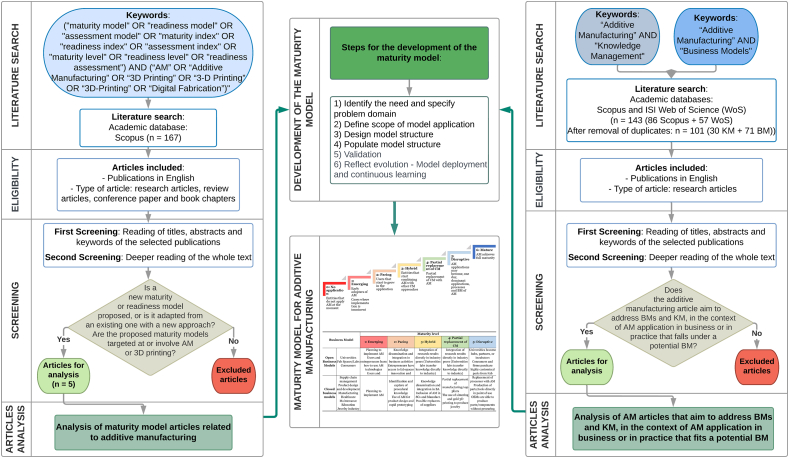

The research conducted necessary for the fulfilment of these steps, was based on literature review models, as illustrated in Fig. 2. In a first phase to analyse the existing maturity models and their limitations, in order to identify the research gap and better define and specify the problem domain. In a second phase, the literature review, was carried out on additive manufacturing articles that aim to address BMs and KM, in the context of the application of AM in business or in practice that fits a potential BM, with the aim of populating the maturity model.

Fig. 2.

Flow diagram of the methodology used.

Thus, the first literature review was performed using the Scopus database and aimed to understand the current state of maturity models related to additive manufacturing. A structured search string with several keywords was used in order to make the search as comprehensive as possible. Thus, the full search string was used:

(“maturity model” OR “readiness model” OR “assessment model” OR “maturity index” OR “readiness index” OR “assessment index” OR “maturity level” OR “readiness level” OR “readiness assessment”) AND (“AM” OR “Additive Manufacturing” OR “3D Printing” OR “3-D Printing” OR “3D-Printing” OR “Digital Fabrication”).

The searches yielded 167 documents, including Article, Review, Conference Paper, Conference Review, Book Chapter, Book, Erratum and Short Survey. Articles not written in English, as well as Erratum and Short Survey documents were excluded, resulting in 155 articles. The publications were then screened, in which the title and abstract were read in order to exclude the articles that did not meet the inclusion criteria. If any doubts remained about the exclusion of the article, a deeper reading of the entire text was performed. No time frame was imposed and all articles that simultaneously met the following criteria were included: i) publications that proposed a new maturity or readiness model, or adapted from an existing one that included a new approach; ii) publications with maturity models targeted at additive manufacturing or 3D printing, either those developed specifically for this manufacturing process or those with a broader range, but which still included additive manufacturing as one of the aspects included in the analysis framework or a practical application. From the screening, 5 publications of maturity models related to additive manufacturing resulted.

To populate the maturity model, as stated above, a second literature review was conducted on AM articles that aim to address BMs and KM, in the context of AM application in business or in practice that fits a potential BM. The research was conducted in Scopus and ISI Web of Science (WoS) databases, where a total of 143 articles were found. Research was limited to journal articles and the keywords were searched in title, keywords and abstract. From the articles found, duplicate records were excluded, obtaining a total of 101 articles for screening, 30 referring to knowledge management and 71 relating to business models. Then, each article was verified to find the ones that address impacts or potential impacts in existing or future BMs.

4. Development of a knowledge maturity model for additive manufacturing business models

The development the maturity model was based on following steps of the maturity models’ research design from Refs. [[60], [61], [62]]:

-

1.

Identify the need and specify problem domain

-

2.

Define scope of model application

-

3.

Design model structure

-

4.

Populate model structure

-

5.

Validation

-

6.

Reflect evolution – Model deployment and continuous learning

4.1. Problem domain

The maturity model purpose is to characterize companies’ profile with regards to the use of AM. The model intends characterizing the object of the use of AM in the business model (BM) (i.e., the purpose for which AM is being used and in which context). Additionally, it intends to characterize the practices employed by entities (public, private or individuals) that allow the activation of the technologies of AM for the production of the object. The characterization of the object and practices will focus on KM within the types of business models resulting from the use of AM.

4.2. Scope of model application

According to de Bruin et al. [60], determining the scope of the desired model will set the outer boundaries for model application and use. The scope was defined according to the perspectives [62]: scope definition, model design, model validation and model evolution.

4.2.1. Scope definition

The model focuses on the study of the application of AM in the various business models documented in the literature (e.g., supply chain management, manufacturing, consumers, etc.). The objective is to analyse the state of maturity of the use of AM at three levels: at the organizational level (e.g. how companies manage the knowledge and deploy resources to implement AM); at the inter-organizational level (e.g. collaborations between universities and companies to deploy AM Technologies [63]); and at the global and societal level (e.g. impact of AM business models on society such as production by consumers [64].

Regarding the novelty of the AM application phenomenon, the application of AM, as well as the business models generated from it, is far from reaching maturity [65]. In this sense, the maturity model explores the application of AM from emerging to disruptive phenomena, which will one day be the greatest trend in the use of AM and will, in turn, reach maturity. The model is not specifically focused on AM technologies, but on their use. For this reason, it is aimed at technology users (e.g. consumers and companies) and managers who want to exploit the technology for their business. Given the extent of the use of AM that is visible in closed and open business models, the dissemination of this model will be open.

Table 2 summarizes the maturity model's scope definition aspects.

Table 2.

Maturity model's scope definition decision considerations.

| Decision parameter | Characteristic |

|---|---|

| Focus | Specific issue – AM application in business models |

| Level analysis | Organizational considerations Inter-organizational considerations Global and societal considerations |

| Novelty | Emerging Pacing Disruptive |

| Audience | Management and technology oriented |

| Dissemination | Open |

4.2.2. Model design

Based on the model scope definition, the model design is achieved by making considerations regarding the [62]: maturity definition, goal function, design process, design product, application method and respondents. It is considered that maturity in the AM application in business is achieved by the organization or entity as a whole. Hence, maturity in an AM organization is a combination of people's skills and proficiency, practices, processes and technologies. The conceptual objective of the model is to achieve maturity by progressing along the several levels that result from a combination of the presented organizational perspectives. Consequently, the maturity model should aim at distinct objectives that allow companies to attain higher benefit and competitive advantage from the use of AM.

The model design is based on literature findings rather than practitioner based. Though, most literature in AM application reports on the achievements from AM practice in several areas. Consequently, to design the model, AM and KM literature was reviewed. To achieve that, research was conducted in Scopus, Web of Science and EBSCO databases. Later, the validation of the model will allow to confirm theoretical findings and provide insights and new perspectives about the AM application by individual and collective entities.

The final product of the model development is an instantiation, in form of matrices with maturity levels, that can be used as an assessment tool for AM users. The data collection for the model validation and implementation will be performed in a multi-perspective fashion. Depending on the complexity of AM implementation and from organization or individual that implements AM, when the maturity model is used it should capture this complexity. Hence, the respondents for this model should be managers, staff and business partners.

Table 3 summarizes the maturity model's design considerations.

Table 3.

Maturity model's design decision considerations.

| Decision parameter | Characteristic |

|---|---|

| Maturity definition | Combination of process, object and people focused |

| Goal function | Multi-dimensional |

| Design process | Practitioner-based |

| Design product | Instantiation (assessment tool) |

| Application method | Self-assessment |

| Respondents | Management/Staff/Business partners |

4.2.3. Validation

The maturity model's accuracy and validity will be conducted after its development (ex-post). In the present work the model's conceptual development steps are reported. In subsequent work is intended to conduct the model validation through case studies in industry.

Table 4 summarizes the maturity model's validation.

Table 4.

Maturity model's validation considerations.

| Decision parameter | Characteristic |

|---|---|

| Subject of evaluation (what) | Design product |

| Timeframe (when) | Ex-post |

| Evaluation method (how) | Case study (ies) |

4.2.4. Model evolution

Since AM and its applications are currently evolving and, still, far from maturity, it is possible that current AM knowledge is subject to change in a near future. Accordingly, the present maturity model should be open for future adaptations. Because, while it is not yet possible to predict the future business models in, for instance, supply chain, some tendencies, like original equipment manufacturers (OEM) producing parts instead of procuring them [66], can be traced in literature. In the future, these pre-conceptions can be either proven or refuted. Accordingly, the model should be continuously reviewed to adapt to change in AM application. Also, since this contribution is still conceptual, adaptations in form (model schema) and functioning (the way the model is applied) will be required.

Table 5 summarizes the maturity model's evolution process.

Table 5.

Maturity model's evolution process considerations.

| Decision parameter | Characteristic |

|---|---|

| Subject to change | Form and functioning |

| Frequency | Continuous |

| Structure of change | Open |

4.3. Design model structure

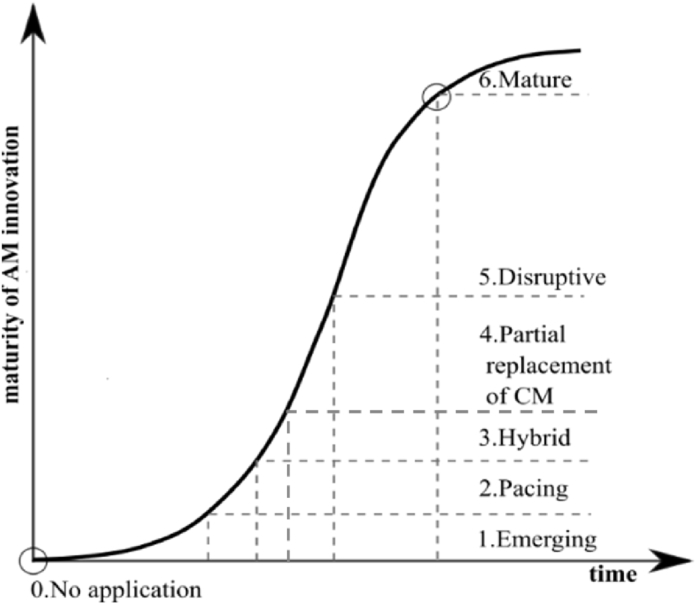

The purpose of the model is to map AM applications by maturity level and by BM. To keep track of AM maturity, the following seven levels are proposed (see Fig. 3): 0 – no application; 1- emerging; 2 – pacing; 3 – hybrid; 4 – partial replacement of CM with AM; 5 – disruptive; and 6 - mature.

Fig. 3.

Maturity levels for AM innovation in business.

The s-curve in Fig. 3 represents the transition between the seven maturity levels according to AM innovation over time. At the lowest level (level 0, no application) are represented the entities that do not apply AM at the moment. The next level of maturity (level 1, emerging), represents the early adopters of AM (e.g. consumers and small inventors that produce for own consumption [64]. It also encompasses cases where implementation is imminent, i.e., although not currently in used, there is potential, and its implementation is being considered. In level 2, AM users that start to grow in the application are represented. These ones are occasional AM users that start to implement AM, although this is not their main activity. Levels 3 and 4 represent a more advanced AM application state. In level 3, are considered entities that start combining AM with other CM approaches. In turn, in level 4, the partial replacement of CM with AM is contemplated. The fifth level traduces the disruptive phase of AM application. AM applications at this maturity levels may become, one day, dominant applications, processes, and business models of AM. Last, in level 6, is represented the moment when AM achieves full maturity.

In addition to maturity levels, the proposed maturity model focuses on AM business models. AM's accessibility has allowed BMs, which generally are focused on companies and manufacturers, to be open to the participation of consumers and other non-business entities. In some cases, consumers are leading business models parallel to industry, where consumers cooperate to produce and disseminate goods (e.g. “prosumers” [63,67]). In a more cooperative scenario, universities and Fab spaces play an important role in cooperating with industry and disseminating knowledge, not only with industry, but also with the consumer community [63]. Accordingly, in the maturity model AM BMs in closed and open categories are addressed. The objective of the model is to track maturity in these BM to help companies in these sectors to assess their AM preparedness. Specific detail about each business model is provided in section 3.4.

The model is structured in the form of a matrix as presented in Table 6.

Table 6.

AM maturity model matrix.

| Business Model | Maturity level |

|||||

|---|---|---|---|---|---|---|

| 1: Emerging | 2: Pacing | 3: Hybrid | 4: Partial replacement of CM | 5: Disruptive | ||

| Open Business Models | Universities Fab Spaces/Labs Consumers |

|||||

| Closed business models | Supply chain management (SCM) Product design and development Manufacturing Healthcare Maintenance Education Jewelry industry |

|||||

Inside the model are registered business practices that aid in the AM implementation in each maturity level and business model. These practices refer to approaches of entities to exploit AM to create value. Though, in some cases, depending on literature findings, these practices may also specify technologies, users, processes, and products.

4.4. Model contents development

To populate the maturity model, was conducted a literature review on AM articles that aim to address BMs and KM, in the context of AM application in business or in practice that fits a potential BM. The research was conducted in Scopus and ISI Web of Science (WoS) databases, where a total of 143 articles were found (only research articles were considered). After the exclusion of duplicate records, each article was verified to find those that address the impacts or potential impacts on existing or future BMs. Table 7 shows the total articles obtained from the scientific databases Scopus and Web of Science, the duplicates, and the totals that were considered for screening.

Table 7.

Detail on AM literature that address BMs and KM.

| Subject | Total (Scopus) | Total (Web of Science) | Duplicates | Total |

|---|---|---|---|---|

| Knowledge Management | 24 | 13 | 7 | 30 |

| Business Models | 62 | 44 | 35 | 71 |

| Overall | 86 | 57 | 42 | 101 |

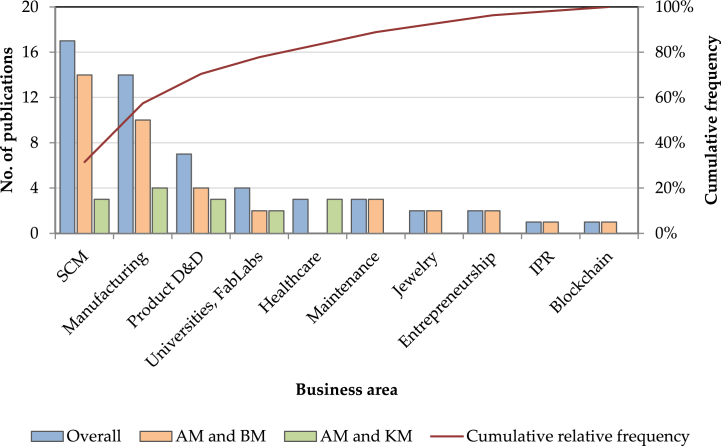

From the research that was conducted, it was possible to conclude that publications on the topics covered in this study have been growing significantly over recent years, as illustrated in Fig. 4. Furthermore, it is noticeable that there are more articles that explore BMs rather than KM. Though, there is no constant pattern in the number of articles per year. 2020 and 2021 were the years when most BM articles were published. In the KM perspective, 2021 was the most fruitful year.

Fig. 4.

AM article distribution by subject (BMs and KM) and year.

From the researched literature, is noteworthy that most articles that address BM lack in specifying actual implications of AM in BMs and, also, explore possibilities without approaching AM practice or actual implications in practice and in business. Regarding KM literature, most articles focus on knowledge engineering rather than in KM practices or processes involved in AM organizational practice.

Regarding the area of application, Fig. 5 shows the distribution of the articles selected after the screening, by business area. In blue, orange, and green are represented the number of overall, BM and KM publications, respectively. The blue line represents the cumulative relative frequency of overall articles. Analyzing Fig. 5, one can notice that supply chain management (SCM), manufacturing and product design and development are the areas where most articles are published, representing 70% of the considered articles. Other areas are very scarce with about 1 to 4 articles each area. In addition, there are some gaps in BMs and KM coverage. BM articles do not cover healthcare. On the KM perspective, these articles do not yet address subjects as maintenance, jewelry, entrepreneurship, intellectual property rights (IPR) and blockchain.

Fig. 5.

AM articles by business area.

Based on literature findings, a maturity model was developed in accordance with each business areas. Hence, in the next sub-sections is presented the maturity model and findings by BMs categories (open and closed) and by business area.

4.4.1. Open business models

4.4.1.1. Universities and fab spaces

Universities and Fab Spaces are entities that participate in the AM movement at socio-economical (macro), firm (meso) and individuals (micro) levels [63,68]. Both these entities have an open contribution to AM. Their involvement ranges from knowledge dissemination to knowledge integration in individuals and organisations. The role of universities is highly emphasized by Ref. [63]. The author points out that these organisations, as producers, disseminators, and preservers of new knowledge, are increasingly moving closer to the material economy. Universities nowadays participate both as knowledge dissemination but also as integrators of research results in industry. This contribution is generically performed in two ways: exclusive and open. Exclusive access to AM is provided to students or researchers who are involved in academic and research activities, respectively. The employment of recently graduated students and the universities’ participation in research projects are vectors of AM knowledge dissemination to organisations. In turn, the open access to AM is provided in the form of Fab Spaces. Fab Spaces are defined as organisations that provide manufacturing tools and technology that, usually, are openly accessible for general public. Fab spaces are a special steppingstone in AM movement. Their contribution to AM landscape is twofold. They are seen both as sources of innovation and production [68]. Although many Fab Spaces are not associated with universities, they have the shared role of disseminating knowledge and giving access to technology to general public.

The contribution of universities and Fab Spaces has led to the emergence of new BMs in AM where these entities are involved. Regarding the maturity scenario, AM application in universities and Fab spaces ranges from low to high level of maturity. In Table 8 we present the maturity levels for AM in universities and Fab Spaces. Maturity levels are distinguished in two perspectives of the Fab spaces’ participation: knowledge sharing for innovation and production.

Table 8.

Maturity levels for AM knowledge use on universities and Fab spaces.

| Business Model | Maturity level |

||||

|---|---|---|---|---|---|

| 1: Emerging | 2: Pacing | 3: Hybrid | 4: Partial replacement of CM | 5: Disruptive | |

| Universities and Fab Spaces/Labs (knowledge dissemination perspective) | Users and entrepreneurs learn how to use AM technologies | Knowledge dissemination and integration in business activities (Universities) [63] | Integration of research results directly in industry peers (Universities labs transfer knowledge directly to industry) [68] | Integration of research results directly in industry peers (Universities labs transfer knowledge directly to industry) [68] | Universities become hubs, partners or incubators [63] |

| Universities and Fab Spaces/Labs (production perspective) | Users and entrepreneurs use AM for their own benefit | Entrepreneurs have access to fab spaces innovation and production capabilities [68] | Consumers and firms purchase highly customized parts from Fab Spaces | ||

The contribution of universities and Fab spaces ranges from low to high levels of maturity. At the lowest level, they enable individuals (users and entrepreneurs) to learn, use and exploit this technology (e.g. Ref. [69]). This trend is visible in both knowledge dissemination and production perspectives. In most of the cases, users and entrepreneurs contribute to their individual knowledge that allows the knowledge and innovation creation (and for Fab-spaces also production) to occur between partners [68,70].

More advanced levels are achieved differently in the case of universities and fab spaces. The prime function of universities is linked to knowledge dissemination. Birtchnell et al. [63] studied universities and fab spaces participation at micro, meso and macro levels. The authors concluded that these entities are reorganizing themselves as triple helix collaborators and aligning the production of knowledge assets (inventions, patents, and designs) with industrial capacities for materializing intellectual capital. That means that these initiatives contribute diversely for AM knowledge dissemination. At the lowest level, small networks of actors (e.g., start-ups, SME, makers, suppliers and manufacturers) support innovation processes that may either perish or flourish. This environment of open collaboration provides the opportunity for new businesses to emerge and use AM.

In higher levels of maturity universities contribute as knowledge suppliers in collaboration with other businesses. Birtchnell et al. [63] addresses two distinct cases that fit levels 3 to 5: the Lancaster Product Development Unit (LDPU) and “America Makes” program. In the first, SMEs are coupled with suppliers and universities to: perform collaborative research, engage students, provide facilities, give professional training, and commercialize intellectual property. Knowledge transfer occurs by means of workshop, courses, events, and conferences.

In the second case, the “America Makes” program reflects the influence of statewide intervention on AM knowledge dissemination. The program enabled the participation that a large consortium of participants, composed by companies, universities, and other organisations in several defense projects. This innovative collaboration constitutes one of the highest levels of maturity for university involvement in AM.

From the fab spaces’ perspective, in the highest level, they have a more active participation in economy. For instance, fab spaces as Ponoko or Shapeways produce highly customized products whereas a user or company makes an order providing the respective CAD drawing [71]. Opendesk is a service that connects buyers with a community of designers and local individuals skills to design and manufacture furniture via fab spaces [68].

4.4.1.2. Consumers

In Table 9 the maturity levels for AM knowledge use by consumers are presented.

Table 9.

Maturity levels for AM knowledge use by consumers.

It is an advantage for many small inventors that they can print prototypes and test out ideas without formal knowledge regarding AM. This can include trial and error, using designs found online, among others. AM has become a great tool for customers making parts without prior knowledge about it [64].

The more traditional role of consumers will shift to that of producers, as will the roles of small and medium businesses, and both were recently coined as “prosumers” [67]. This type of prosumer can be involved in part or all of the design and printing of the product. However, this transition is unlikely to occur without hurdles, given the steep learning curve intrinsic to the AM technology [72]. The integration of AM services and goods is envisioned as to be part of a new industrial revolution - Industry 4.0 [73]. Some believe that emancipating consumers will be an inherently uncertain process, due to uncertainty about whether or not people will really want to print [74]. A policy shift of this magnitude would require foresight, regardless of consumer participation, given the profound disruptions that would impact on present-day social orders [75]. As 3D printer technology matures, consumer willingness to engage with the technology is steadily and firmly increasing, according to survey data [63,76].

The whole system comprised of manufacturing, distribution, and consumption could all be impacted if this becomes mainstream [63].

The industrial sector has a major role in expanding 3D printing outside the conventional area of rapid prototyping, but universities can also significantly contribute to the AM business and developing this technology. Besides offering a vast range of opportunities to the broader consumer and industry sectors as well as the public, the academic community might become knowledge clusters for AM [63].

4.4.1.3. Collaboration perspective

Researchers at other universities have also developed remote manufacturing systems for AM that provide distributed enterprises with a platform for sharing machines, like most enterprises already do. Yet they still offered three elements when compared to other similar systems: online manufacturing services, online data management, and online commerce. Three complementary software packages were provided in this case: one for self-checking and self-repairing STL files, one for collaboration and monitoring via web, and one for remote control and monitoring [77].

Open business models allow the collaboration and sharing of resources from different organisations and entities. This type of model besides increasing organizational flexibility [78], and being a source of value creation and capture [79], contributes in a very significant way to innovation [80]. Furthermore, this cooperation and the use of knowledge from external sources [81] can be a driver for the implementation and development of additive manufacturing. This sharing of techniques, processes and procedures represents an added value and promotes a more sustainable knowledge management, both for those who are starting in additive manufacturing, corresponding to a lower level of maturity, and for those who are already at a more advanced level of implementation. However, knowledge sharing between different partners brings several challenges. The lack of shared practices and language [82], by its nature, brings some limitations.

In addition, additive manufacturing involves an increasing amount of data that is important for decision making [83]. Data Analytics can contribute to facilitate the decision-making process [84] and to the identification and prioritisation of opportunities [83] in additive manufacturing by extracting and generating a large amount of relevant information. However, this requires interdisciplinary knowledge and consequently the existence of different experts, whose coordination is not always easy [83]. Park et al. developed a methodology to overcome this barrier and enable the management of different experts' knowledge, which takes into account the Collaborative Knowledge Management approach [83]. This methodology incorporates three different components, a set of experts, the Data Analytics Opportunity Knowledge Base, and a prioritisation tool [83].

4.4.2. Closed business models

4.4.2.1. Supply chain management

In Table 10, similarly to the previous ones, the maturity levels for the use of AM knowledge concerning supply chains are represented. In this table, supply chain management and retail are included.

Table 10.

Maturity levels for AM knowledge use on supply chains.

| Business Model | Maturity level |

||||

|---|---|---|---|---|---|

| 1: Emerging | 2: Pacing | 3: Hybrid | 4: Partial replacement of CM | 5: Disruptive | |

| Supply chain management | Possible replacement of suppliers. Centralized manufacturing instead of global procurement [11,13,63] |

OEMs are able to produce parts replacing part of the SC | OEMs are able to produce parts/components without procuring suppliers [66] | ||

| Shorter SCs (shorter lead-times) [11] | |||||

| Retail | Production of final customized products directly in stores/retail [66] | ||||

Several advantages can be obtained by staring to use AM and these are as follows: dematerialized supply chains, nearer production sites to end customers, lower inventories and reduced logistics costs, diminished amount of waste, lower production lead times, a higher potential of customization [9,85,86].

As a result, open business models encouraging the sharing of intellectual property obtained through paid efforts and the disregard for quality requirements do not create interest in either end-users or manufacturers [12].

In the current system of distribution, consumption, and production, AM won't merely be a substitution for transportation. The likelihood is, however, that it could dissociate transportation from object procurement [63,87].

Another core industry link is with a universally operating provider of spare parts and consumables [63].

Researchers have observed that AM can cost up to 25 times as much as a part produced using traditional manufacturing methods [11]. A number of AM machine manufacturers claim that AM can improve lead times by up to 90% [11].

An important aspect of additive manufacturing that it gives an advantage to the environment since it allows us to reduce the amount of inventory by printing items only as needed. This method of manufacturing is also less wasteful of raw materials than subtractive methods [88]. However, long-term environmental impacts have not been previously researched and must be considered as well [64].

4.4.2.1.1. Centralization

When the enterprise uses centralized AM deployment models, it owns the machines and purchases the raw materials to make the parts. The engineering resources required to operate AM machines are available for hire and deployed at the customer's location through consignment services [11].

Since Speedfactory produces shoes in an exact number, storage of finished goods is no longer important or necessary. Moreover, the short distance between the manufacturing unit and the customer made it possible to deliver personalized models quickly and easily. In addition to the speedfactory's economic benefits, the machines operate in a continuous manner, which enhances the overall efficiency [66].

Vietnam, China, Indonesia, and Asia were previously Adidas' manufacturing centers. However, the process of delivering finished sneakers to Germany took three months. In 2018, KPMG established a new Speedfactory in Thailand that reduces completion times for one pair of shoes to just 5 h [66].

4.4.2.1.2. Decentralization

When AM machines are decentralized, such as in cases of AM service centers, another entity owns these machines and this entity also contracts for full services, such as design, or selects services from a customized menu [11].

According to some scholars, the existing patterns of production, based on economies of scale, will be transformed into a more personalized, inclusive manufacturing model, allowing individuals to design and produce products themselves. A widely used term for this shift is distributed manufacturing (DM). It defines geographically dispersed production processes and supply chains, in which products can be manufactured closer to consumers [68,89].

4.4.2.2. Product design and development

In Table 11, the maturity levels for AM knowledge use on product design and development are presented.

Table 11.

Maturity levels for AM knowledge use on product design and development.

Hagedorn et al. [19] present in a study an ontology that enables prior knowledge in DfAM. The authors present a knowledge-based method for generating AM design ideas, in addition to developing a set of modular, thoroughly constructed ontologies for capturing information regarding new and creative employment of AM.

For product development, a virtual prototyping system, integrating virtual reality and AM, was employed in Ref. [92]. In order to simulate AM processes based on powder and laminated sheets, two innovative simulation approaches were proposed: layer-based fabrication (slice based) and solid strip based fabrication [77]. An integrated rapid tooling manufacturing system based on additive manufacturing was proposed in Ref. [93]. The mold design and manufacturing process planning were optimized through the use of 3D CAD software and virtual prototyping [77]. Besides, in Ref. [94] the authors present a new device that is able to scan denture images and reconstruct 3D digital information from abrasive computer tomography of teeth models [77]. It is desirable to reduce the number of joins in parts that experience high pressure, like fuel nozzles. A nozzle previously made up of 18 pieces was redesigned by GE as a single piece by employing AM [11,91,95].

4.4.2.3. Manufacturing

In Table 12, the maturity levels for AM knowledge use on manufacturing are represented.

Table 12.

Maturity levels for AM knowledge use on manufacturing.

| Business Model | Maturity level |

||||

|---|---|---|---|---|---|

| 1: Emerging | 2: Pacing | 3: Hybrid | 4: Partial replacement of CM | 5: Disruptive | |

| Manufacturing | Hybrid methods (e.g. complementary use of machining and AM) [77] | ||||

In addition to eliminating tooling, AM systems would also remove most of the freight and retail in the process, as they would directly produce goods from digital data instead of resorting to tooling. Such type of development is a reflection of a challenge that goes further than high-volume manufacturing [96].

AM is uniquely positioned to maximize the value of early processes related to mission analysis or business analysis, including a higher amount of degrees of freedom and rapid prototyping. Lean manufacturing engineering systems and Agile development are both enabled by AM [11].

The lean manufacturing element of AM enables prototypes to be manufactured quickly and rapidly iterated while using less materials than subtractive methods [11,85].

AM could be perceived as a very lean technology, as it is able to address types of “wastes” related to supply chain management, such as inventory, transportation, waiting, motion, overprocessing, overproduction, and consequently – defects. Besides, in most cases, left over AM materials are reusable since the process is a net-shaped process [11,88].

Using new technologies, the manufacturer could respond quickly to customer requirements by combining digitization and manufacturing. This is achieved through information collection, restructuration and, implementation of the simulation and prototyping of the design and function, and then committing to manufacturing the chosen final product [77].

Based on reviews of literature it can be noticed that by comparing DM-HAM with conventional manufacturing processes, it is possible to produce near-net-shaped, highly accurate, and low-cost physical products [77].

4.4.2.4. Healthcare

In Table 13, the maturity levels for AM knowledge use on healthcare are presented.

Table 13.

Maturity levels for AM knowledge use on healthcare.

| Business Model | Maturity level |

||||

|---|---|---|---|---|---|

| 1: Emerging | 2: Pacing | 3: Hybrid | 4: Partial replacement of CM | 5: Disruptive | |

| Pharmaceutical | Planning to implement AM | Production of specific drugs [97] | Replacement of existing processes with AM [97,98] | ||

| Prosthetics | Rapid production of medical implants/prothesis [77,94] | Production of high-level customized prostheses [63] | |||

| Dentistry | Ontologies to support collaboration between designers and dentists to enhance dentistry product manufacturing [99] | ||||

| Medical imaging | Patient specific 3D-printed anatomical models – Imaging [64,77,98] | ||||

| Organ transplants | Patient specific 3D-printed anatomical models – Imaging [64,98] | Bioprinting of implantable organs [98] | |||

Currently, 3D printing technology is used most extensively in the prosthetics industry due to the high level of customization [63]. AM allows doctors to use manufactured custom surgical tools and prostheses, such as custom-made implants or surgical guides. Hence, AM reduces the cost of surgical tools and prostheses due to their customization [98,[100], [101], [102]].

Drugs printed in 3D can dissolve faster than ordinary pills since these are made from deposition of powdered drug layers [103]. A patient's needed quantity can also be customized [98,104].

Besides, in Ref. [94], the authors present a new device that is able to scan denture images and reconstruct 3D digital information from abrasive computer tomography of teeth models.

A major benefit of employing AM is that it can fabricate complex structures with high accuracy out of materials that are very attractive for both surgery and dentistry [105]. Increasingly, AM is being used in dental surgeries to make bridges and crowns directly [106]. By providing access to dental product manufacturing data across the entire domain, the user is able to design a new product that addresses factors such as maintenance costs, patient experiences, as materials used, among others [99].

In addition to personalized presurgical/treatment planning, AM can also be used for preoperative planning. This will result in a multistep process that integrates imaging and clinical information in order to find the optimal treatment method.

In many studies, it has been shown that patient-specific presurgical planning could possibly cut down operating room time and leading, in turn, to a lower amount of complications [98,107,108]. By using AM technology, a surgeon can formulate an accurate surgical plan by being provided with a physical representation of the respective anatomy of the patient and cross-sectional images. A model of the patient's specific anatomy can be used to create surgical tools or custom prosthetics [85,91,95,98].

Modeling implantable tissue is also possible by using AM. For example, 3D printed synthetic skin for grafting onto burn victims [98,109].

There are also other areas of application such as training and education, osteoporosis, forensic practice, rare cases, among others [98].

There are many opportunities and advantages associated with AM in the medical field, but the use of such a technology must be accompanied by a legal framework that is updated and current [98].

Aside from the fabrication of organs [110], researchers are also exploring methods of printing tumor replicas in order to investigate them without relying on cadavers or operating on live patients [111,112], as well as producing customized prosthetics [64,111].

4.4.2.5. Maintenance

In Table 14, the maturity levels for using AM knowledge on maintenance are presented.

Table 14.

Maturity levels for AM knowledge use on maintenance.

| Business Model | Maturity level |

||||

|---|---|---|---|---|---|

| 1: Emerging | 2: Pacing | 3: Hybrid | 4: Partial replacement of CM | 5: Disruptive | |

| Aeronautics and aerospace | Production of parts/tools directly in point of use [11,77,113] | ||||

| Paper and pulp industry | Local production of spare parts for machinery used in the pulp and paper industry [114] | ||||

| Manufacturing and delivering high quality spare parts | Local distributed manufacturing (companies located within the business park) of high quality spare parts using AM, and their supply [115] | ||||

When an enterprise uses service centers, it can provide the digital file specifications it needs to produce a part. For example, NASA uplinked an AM digital file to the International Space Station to print a tool that was needed for a repair [11].

This storage of 3D files instead of physical parts can have a very positive impact on industrial maintenance, namely in the manufacturing of spare parts, particularly when the costs associated with the conventional logistics chain are disproportionately high. Additive manufacturing technologies allow these parts to be produced ‘on demand’ [116], which reduces the amount of stock, the costs inherent in this storage [117], the reduction in the size of warehouses, and the shortening of supply chains [114]. In addition to this, the reduction in emissions and material waste [118], freedom of design [119], reduced repair time [118], and longer equipment life cycle [114] make additive manufacturing a sustainable option for the manufacture of spare parts. Although the costs of additive manufacturing are still very high compared to subtractive manufacturing and the size of the components that can be produced is limited [118], this technology has much potential for the production of small, complex parts [118] and at low production volumes [114].

The cases mentioned in Table 14 are still at an intermediate level of maturity, except for aeronautics and aerospace which is at a higher level. However, there is much potential for the manufacture of spare parts through additive manufacturing, either as a complementary means to support the management of conventional manufacturing of these parts [117], being at an intermediate level of maturity, or in the replacement of current manufacturing technologies by those of additive manufacturing [119], thus reaching higher levels of maturity.

One of the cases represented in Table 14 involving an industrial park for the production and distribution of high quality spare parts [115] has enormous potential for the evolution of additive manufacturing maturity. The fact that several companies are involved in an industrial park, where the distances between them are relatively small, significantly reduces transport costs, and facilitates the creation of business models. Another advantage that these clusters can potentiate is the facilitation of learning, sharing and dissemination of knowledge of additive manufacturing by participants in the park's network, thus enabling higher levels of maturity to be achieved.

4.4.2.6. Education

In Table 15, the maturity levels for AM knowledge use for education are presented.

Table 15.

Maturity levels for AM knowledge use for education.

| Business Model | Maturity level |

||||

|---|---|---|---|---|---|

| 1: Emerging | 2: Pacing | 3: Hybrid | 4: Partial replacement of CM | 5: Disruptive | |

| Education | Model creation for training (regular and disabled students) [64] | ||||

In order to better plan rescue and evacuation efforts following Hurricane Katrina, 3D models and animations of calculus visualizations have been created for blind students [120]. It seems that the possibilities for AM applications in the near future are almost limitless [64].

4.4.2.7. Jewelry industry

In Table 16, the maturity levels for using AM knowledge in jewelry are presented.

Table 16.

Maturity levels for AM knowledge use on jewelry.

| Business Model | Maturity level |

||||

|---|---|---|---|---|---|

| 1: Emerging | 2: Pacing | 3: Hybrid | 4: Partial replacement of CM | 5: Disruptive | |

| Jewelry | The use of sintering and gold 3D printing to produce jewelry [121] | ||||

Cooper [121] discusses sintering and AM technologies applied to jewelry production. For instance, Birmingham School of Jewelry is currently teaching these technologies, but they are not currently applied in industry.

5. Discussion

This section aims to summarise the results, present a critical analysis of them, as well as the limitations of the study presented and future research prospects.

5.1. Summary of results

In order to develop the maturity model, as previously mentioned, a literature review was conducted on additive manufacturing articles that addressed business models. This process aimed to track the maturity of these business models and thus record business practices that could support companies in assessing their readiness for additive manufacturing and in defining strategies to proceed towards the implementation and development of this manufacturing process.

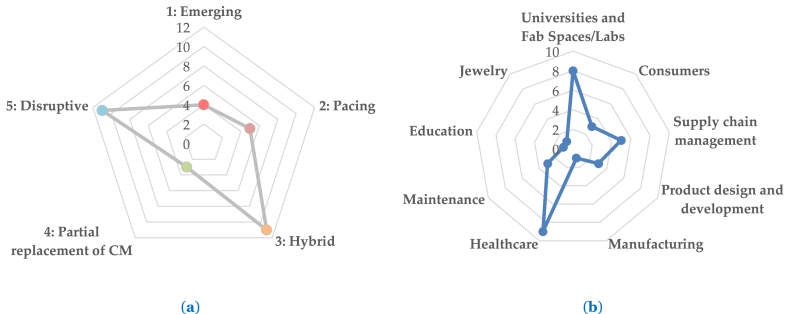

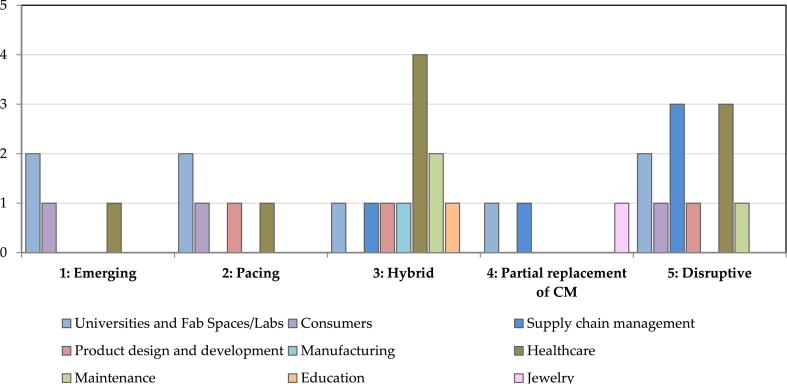

Regarding the number of occurrences by maturity level, the predominance of cases at level 3: Hybrid and 5: Disruptive is notable, representing 64.7% of the total, as illustrated in Fig. 6(a). These figures show that most business models published in the scientific literature are at a more advanced state of application of additive manufacturing. The lowest levels, 1: Emerging and 2: Pacing represent 26.5% of the cases and maturity level 4: Partial replacement of CM represents 8.8%.

Fig. 6.

Number of occurrences by (a) maturity level; and (b) business model.

Fig. 6(b) illustrates the number of occurrences by business model. Healthcare has the most cases, representing 26.5% of the total, followed by Universities and Fab Spaces/Labs, with 23.5%. In addition, Supply chain management (14.7% of the total), Consumers (8.8% of the total), Product design and development (8.8% of the total) and Maintenance (8.8% of the total) also show significant amounts of use of additive manufacturing in their business models. Finally, with lower values, are the business models linked with Manufacturing, Education, and Jewellery with 2.9% each. However, closed business models represent the vast majority of occurrences, 67.6% of the total, while open business models only correspond to 32.4%.

Fig. 7 illustrates the distribution of business models by maturity levels. As can be observed, it is notorious the scarcity of studies referring to all maturity levels for the different business areas. The greatest diversity of business models occurs in maturity levels 3: Hybrid and 5: Disruptive, which also present the largest number of occurrences. In the scientific literature surveyed, Universities and Fab Spaces/Labs are those that present business models at all maturity levels, with greater incidence at levels 1, 2 and 5, which illustrates the diversity of this open business model.

Fig. 7.

Distribution of the various business models across the different maturity levels.

Healthcare is the most representative, concentrating most of the cases in maturity levels 3 (4 articles) and 5 (3 articles). The Supply chain management presents occurrences in the highest maturity levels (3 to 5); however, it is in level 5 that presents the most occurrences, 60% of the total. Consumers are the ones that present business models at more distant maturity levels, with equal occurrences at levels 1, 2 and 5.

As previously mentioned, the proposed maturity model aims to map additive manufacturing applications by maturity level and business model. Thus, the process resulted in a set of seven steps (Fig. 8) and the creation of the Maturity Model presented in Table 17.

Fig. 8.

Levels of the maturity model for additive manufacturing.

Table 17.

A maturity model for additive manufacturing use in open and closed business models.

| Business Model | Maturity level |

|||||

|---|---|---|---|---|---|---|

| 1: Emerging | 2: Pacing | 3: Hybrid | 4: Partial replacement of CM | 5: Disruptive | ||

| Open Business Models | Universities Fab Spaces/Labs Consumers |

Planning to implement AM Users and entrepreneurs learn how to use AM technologies Users and entrepreneurs use AM for their own benefit |

Knowledge dissemination and integration in business activities (Universities) Entrepreneurs have access to fab spaces innovation and production capabilities Consumers produce parts for consumption or P2P sales |

Integration of research results directly in industry peers (Universities labs transfer knowledge directly to industry) | Integration of research results directly in industry peers (Universities labs transfer knowledge directly to industry) | Universities become hubs, partners, or incubators Consumers and firms purchase highly customized parts from Fab Spaces Networks of consumers replace manufacturing plants (Prosumers) |

| Closed business models | Supply chain management Product design and development Manufacturing Healthcare Maintenance Education Jewelry industry |

Planning to implement AM | Identification and capture of procedural knowledge Use of AM for product design and rapid prototyping |