Abstract

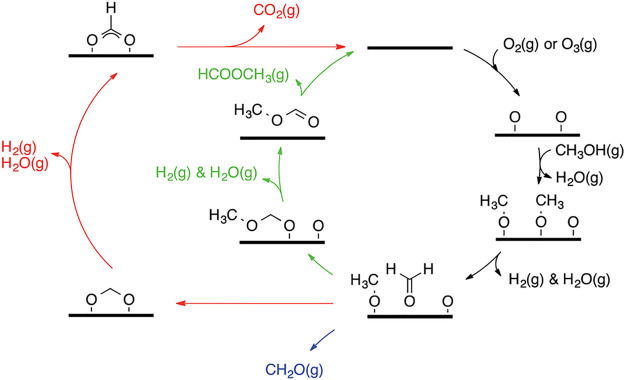

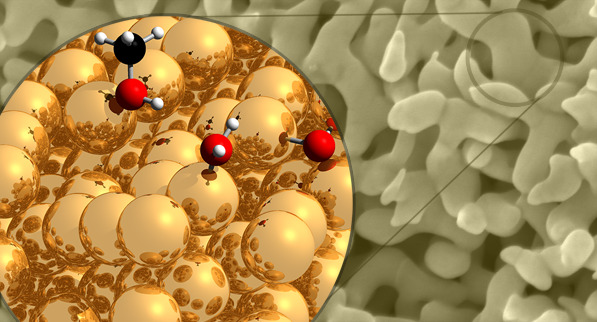

Nanoporous gold (NPG) is characterized by a bicontinuous network of nanometer-sized metallic struts and interconnected pores formed spontaneously by oxidative dissolution of the less noble element from gold alloys. The resulting material exhibits decent catalytic activity for low-temperature, aerobic total as well as partial oxidation reactions, the oxidative coupling of methanol to methyl formate being the prototypical example. This review not only provides a critical discussion of ways to tune the morphology and composition of this material and its implication for catalysis and electrocatalysis, but will also exemplarily review the current mechanistic understanding of the partial oxidation of methanol using information from quantum chemical studies, model studies on single-crystal surfaces, gas phase catalysis, aerobic liquid phase oxidation, and electrocatalysis. In this respect, a particular focus will be on mechanistic aspects not well understood, yet. Apart from the mechanistic aspects of catalysis, best practice examples with respect to material preparation and characterization will be discussed. These can improve the reproducibility of the materials property such as the catalytic activity and selectivity as well as the scope of reactions being identified as the main challenges for a broader application of NPG in target-oriented organic synthesis.

1. Introduction

Nanostructuring is one of the most successful strategies to prepare materials with new or improved chemical properties. Catalysis, being one of the core technologies of chemical industry and being involved in about 80–90% of all industrial processes, is closely linked to the current quest to reduce our energy and CO2 footprint. Heterogeneous catalysis has used nanostructuring early on as seen by the large fraction of heterogeneous catalysts which are nanostructured materials. Heterogeneous gold catalysts are a prototypical example for appearance of new chemical functionality upon nanostructuring. In particular, gold nanoparticles grafted on a suitable oxide support were found to be good catalysts for a range of low temperature oxidation reactions back in the 1980s of the last century,1−378 while macroscopic gold is inactive. The size (maximum activity for CO oxidation is found at a diameter of around 5 nm) as well as the support of the Au nanoparticles were identified as crucial parameters for the catalytic activity. Hence, the first reports about a high catalytic activity of nanoporous gold (NPG) for CO oxidation in 2006/2007 by some of the authors5 as well as by Ding and co-workers6 came as a surprise because NPG not only lacks a support but also exhibits characteristic length scales (ligament and pore sizes) that are about an order of magnitude larger than the size of active Au nanoparticles. The interest into NPG as a catalytic material was further enhanced by the first report on its potential as a highly selective partial oxidation catalyst as exemplified by the aerobic oxidation of methanol to methyl formate.7

NPG is prepared by dealloying, a process resulting in the spontaneous, self-organized creation of a nano- or microscale, bicontinuous network structure (continuous in both the material and the void space) from a previously homogeneous solid by selective removal of the less noble component.8−11 The pore sizes typically found in NPG (from about 10 to a few 100 nm) mostly fall in the range that is classified as mesopores comprising pore sizes of 2–50 nm according to IUPAC.12 Nonetheless, the term “nanoporous gold” is almost13 universally used for the material6,7,9,14−17 and sometimes extended even to other types of porous gold.18−21 Modern approaches to use dealloying as a material’s preparation method were pioneered by Sieradzki,13 and the class of nanoporous metals gained additional widespread interest by conceptual work of Erlebacher and co-workers,9 who not only linked the dealloying process to modern concepts of pattern formation in nonequilibrium processes but also effectively popularized the visual appeal of the resulting structures. One of the most attractive properties of nanoporous materials in general (and NPG in particular) is the outstanding definition, uniformity, and reproducibility of its nanoscale structure. Moreover, the possibility to control the characteristic pore and ligament sizes, the ability to modify the surface properties, and the lack of support effects render this material particularly well suited as a model system for understanding size and interface effects at the nanoscale in several fields, including mechanics,8,14,22−27 plasmonics,28−31 or (electro-)catalysis.7,16,23,32−43

Dealloying of AgAu alloys typically results in NPG, which predominantly consists of Au with only a small fraction (a few %) of the remaining less noble element (LNE; i.e., Ag in this case). As NPG is predominantly consisting of Au, it was suggested that its catalytic properties are largely based on the surface chemistry of gold.7 This notion was substantiated by comparing the oxidation chemistry on Au and Ag single-crystal surfaces studied under ultrahigh vacuum (UHV) by the Madix group44−46 with the aerobic catalytic oxidation on NPG.7 The insight that the oxidation chemistry of NPG is mainly due to Au17,47 was the basis for variety of experiments on Au single-crystal surfaces as well as theoretical studies. These studies have contributed significantly to the current microscopic understanding, including aspects such as the mechanism of oxidation reactions,48,49 the importance of the less noble element (LNE), mostly Ag, for oxidative catalysis,50,51 the activation of molecular oxygen,52−54 or the role of water.55 With respect to catalysis, it is particularly appealing that NPG can be used for gas phase,56,57 liquid phase,58−60 as well as electrocatalysis61,62 for the same reaction (e.g., partial oxidation of methanol), which allows elucidation of similarities and differences between the different scenarios.

A number of reviews are available on different aspects of NPG and its application, including structure evolution,63 mechanical properties26 and actuation,64 plasmonics,31 sensing,65,66 biomedical interfaces,27,67,68 energy conversion,69 or catalysis.16,38,40,63,70,71 We will review the recent developments with respect to oxidation catalysis, which aim at identifying decisive properties influencing catalytic performance and the ability to alter them by tuning these properties. As the catalytic properties are intimately linked to the structural and chemical properties of the materials, we set out by discussing preparation strategies for NPG, the measures of its nanostructure, and the development of these properties during catalysis. Detailed knowledge of the morphological properties is important for catalysis as mass transport of the reagents is an important aspect to be considered not only in liquid but also in gas phase catalysis. Hence, we will not only briefly introduce the conceptual framework (tortuosity) to describe diffusive transport in a nanoporous network, but will also discuss experimental approaches to quantify these aspects and show their impact on the catalytic performance. The microscopic understanding of the reaction mechanism in gas phase catalysis being a crucial ingredient to understand the catalytic properties of NPG is based on UHV experiments on single-crystal surfaces and to a large part on theory. Emphasis will be put on comparing the mechanistic pictures in gas phase catalysis evolving from the theoretical calculations with various experimental approaches on a system with systematically increasing complexity ranging from single-crystalline model surfaces to NPG. The catalysis at the gas/solid interface will be compared to results in liquid phase as well as electrocatalysis, furthermore highlighting current developments which afforded microscopic insight into the properties decisive for catalysis under these conditions.

2. Tuning of Structure and Composition during Dealloying

2.1. Nanoporous Gold by Dealloying

The notion of “dealloying” refers to a family of processes in which one chemical element is selectively removed from a solid solution or compound. The removal of this sacrificial element can exploit various mechanisms, for instance, evaporation at elevated temperature,72,73 dissolution in a molten metal,11,74,75 or corrosive attack in acid or aqueous electrolyte.9,13,14,76 An important commonality is that dealloying converts the uniform and massive (not porous) initial crystal into a nanoporous product crystal; the characteristic size of the pores represents a new length scale that is generated by nanoscale self-organization processes. Although experimental preparation protocols differ greatly among the dealloying variants, the atomic-scale processes that drive the nanostructure formation are quite similar.11 In each case, they rely on a competition between the active process of dissolution of the sacrificial element and a passivating process mediated by diffusive rearrangement of the conserved element.77,78

The present section focuses primarily on nanoporous gold (NPG) made by dealloying, emphasizing protocols for preparing macroscopic volumes of the material in clean and uniform quality (section 2.4). Why a focus on macroscopic volumes? First, it is a distinguishing feature of NPG that one and the same material provides—at the atomic scale—the catalytically active sites and—at the meso- or macroscale—the strong scaffold structure, which supplies and stabilizes the pore channels that bring the large area of surface and that enable access to its active sites. Second, macroscale samples of nanoporous gold have been the subject of intense studies with respect to their mechanical behavior. This behavior is not only important for the stability of the scaffold, it is also extremely sensitive to heterogeneity. Therefore, the excellent agreement of independent studies of mechanical behavior by several groups26 provides a signature of exceptional uniformity and reproducibility in NPG preparation. This distinguishes the underlying protocols as a unique basis for meaningful model studies of NPG in any field, and specifically including studies of catalysis.

For catalysis, the absence of an extrinsic scaffold material endows monolithic bulk samples of NPG with a unique conceptual simplicity. Yet, long transport pathways through a confined pore space can impair the catalytic conversion rates. This section also addresses four approaches to preparing samples that can mitigate this issue. First, monolithic NPG with a hierarchical pore structure (section 2.5) combines large pores for accelerated transport with small pores for high specific surface area and function. Second, cavity microelectrodes filled with μm-scale particles of powdered NPG (section 2.7) combine large open pathways (between the powder particles) with small active volume for enhanced kinetics and equilibration. Third, a similar effect is achieved with substrate-supported thin films of NPG (section 2.6), which have at least one external sample dimension in the range of 1 μm or below. Fourth and last, NPG nanoparticles (section 2.8) have an external size in the order of 100 nm or below in all three dimensions. Such particles can be employed in classic catalysis scheme, with particles attached to an extrinsic support scaffold, yet they profit from the enhanced specific surface area and activity of NPG.

2.2. Overview on Phenomenology and Processes during Dealloying

Preparation of the uniform, load bearing, monolithic macroscopic NPG that forms the focus of this section has been demonstrated with dealloying in aqueous media and near room temperature, in the form of either free or electrochemical corrosion. Here, bulk diffusion is exceptionally slow and can be neglected.79 The nanostructure formation is then simply the result of the two elementary processes, dissolution and surface diffusion. The related phenomenology has been investigated for more than a century in metallurgy, specifically in the contexts of alloy corrosion and stress corrosion cracking. The reader is referred to related review articles for details, and the following, incomplete list may serve as a starting point:8,10,80−85 The simplest concepts are that (i) the mole fraction xLNE (also referd to as “atom fraction”) of the sacrificial element (here the less noble element, LNE) needs to exceed a minimum value, the parting limit, xP, and that (ii) the dealloying potential, ED, (i.e., the electrode potential applied during electrochemical dealloying) needs to exceed the critical dealloying potential, EC. The parting limit is related to the requirement for a percolating cluster of the LNE in the master alloy,86 and the critical potential is related to the requirement that the corrosion is driven sufficiently fast to proceed into the depth before the lateral rearrangement of the more noble element (MNE) by surface diffusion can form a closed layer of pure MNE that passivates the corrosion surface.87,88

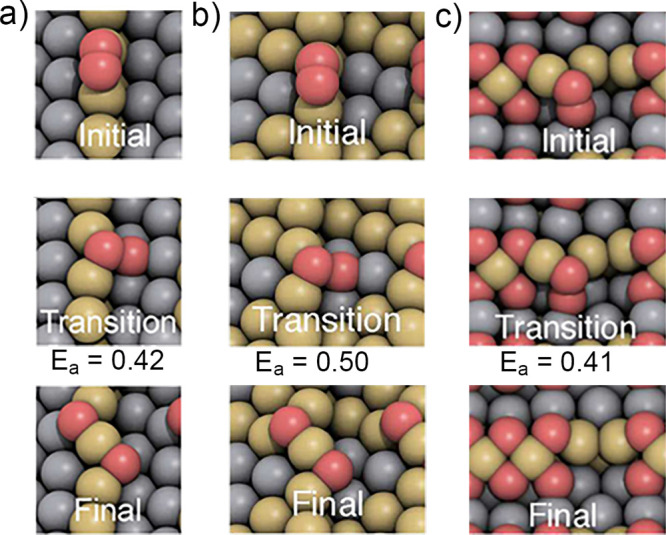

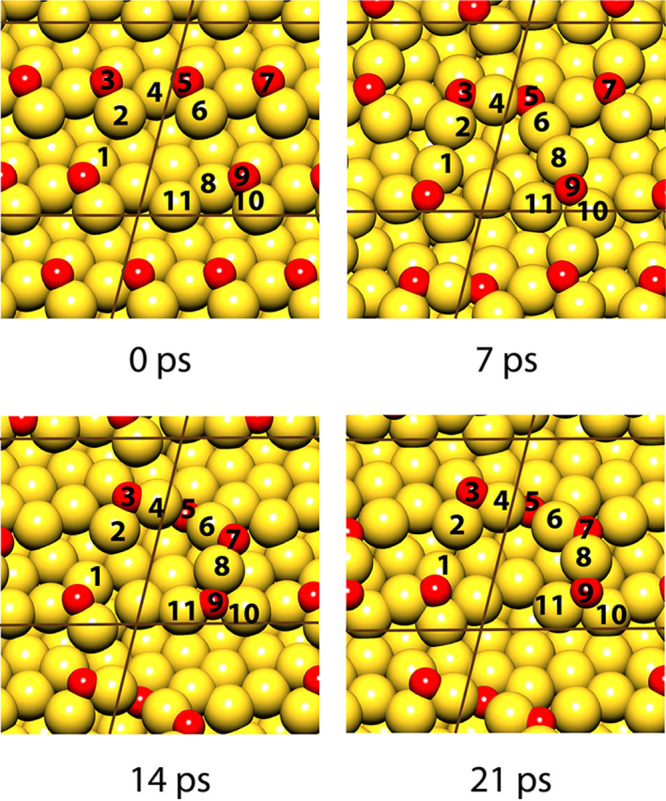

The current understanding of the atomic-scale processes behind the above phenomena rests largely on kinetic Monte Carlo (KMC) simulation studies.9,86−90 Working with a minimal and physically motivated set of materials parameters, this approach reproduces many of the key experimental observations, thereby validating the underlying model. Early work suggested that a spinodal decomposition process in an adatom gas of the more noble element on the surface was responsible for the characteristic length scale of the nanoporosity.9 Yet, more detailed inspection of the KMC results identifies the nucleation of vacancy islands on crystal terraces, followed by dissolution from receding step edges, as a more appropriate scenario.88Figure 1A illustrates the roughened external surface in this early stage of dealloying. In principle, the just-mentioned processes link the characteristic ligament or pore size, L, to the magnitude of ED. Yet, this link has not been understood in all detail, and a predictive theory for L as the function of ED is missing.90

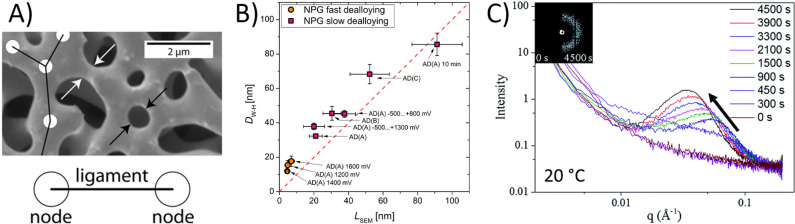

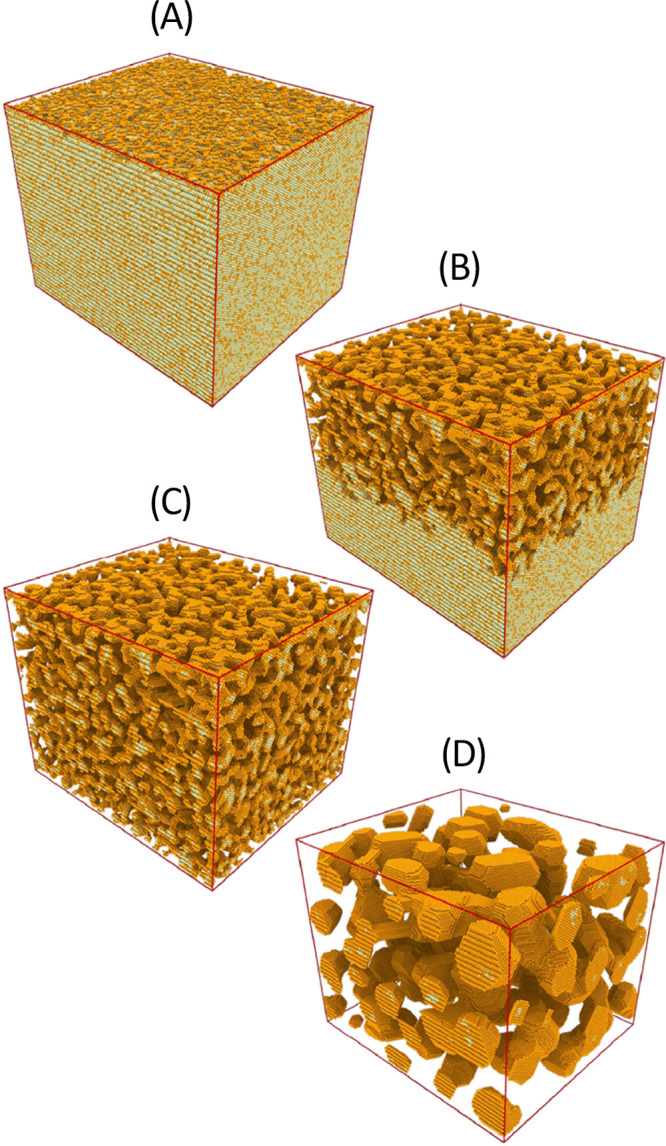

Figure 1.

Porosity evolution during dealloying modeled by kinetic Monte Carlo simulation. Primary dealloying (A–C) starts with surface roughening and formation of passivated mounds (A). Small ligaments form by undercutting and the corrosion front proceeds inward, leaving a high concentration of less noble species in the ligaments’ interior (B,C). Secondary dealloying coarsens the structure and reduces the residual amount of less noble element (D). Reproduced with permission from ref (90). Copyright 2022 Elsevier.

The corrosive attack on the bulk is carried by the formation of pore channels which bifurcate on a characteristic scale that establishes the initial pore size (Figure 1B,C). That process of “primary dealloying”91 is followed by the coarsening of the porous structure by surface diffusion (Figure 1D). During coarsening, isolated domains (sometimes referred to as “clusters” because they represent percolating clusters of Ag atoms on the crystal lattice)89,90 of precursor alloy that had previously been buried in the interior of the primary dealloyed ligaments are exposed to the corrosive environment. “Secondary dealloying”91 then further dissolves the LNE, leading to an ongoing reduction in the residual LNE content. As an immediate consequence, the residual sacrificial element content systematically decreases with increasing, as-prepared L.92 A fraction of the buried Ag-rich domains survive in the as-prepared material and can be imaged with element-sensitive microscopy techniques.89,93,94 Ligament sizes, L, in as-prepared NPG thus reflect the initial, very small structure size during primary dealloying, convoluted with substantial coarsening during secondary dealloying.

The atomic-scale processes that act during dealloying do not, as a general rule, include the nucleation of new crystals. As will be addressed in section 3.6, dealloying can thus conserve the grain size, often several tens of μm, of the master alloy. In other words, dealloyed nanoporous metals can be single crystals when viewed at the scale of few ligament sizes. There is, however, a volume contraction that implies that the pore volume is typically smaller than the volume that was taken up, in the master alloy, by the dissolved LNE atoms. Section 3.7 addresses this issue, and it also points out that samples of NPG can exhibit a densified skin layer at their external surface, with the thickness comparable to the ligament size. The skin layer has little effect on the external dimensions or on the mean solid fraction of macroscopic samples, yet it contributes decisively to the densification of nanoporous nanoparticles.

Empirically, the structural evolution during dealloying can be, to some extent, controlled. To name a few, dissolution and interface diffusion rate are determined by temperature,78,95,96 electrolytic environment,80,97 alloy composition,98−100 and, in case of electrochemical dealloying, the dealloying potential.9,101−104 Furthermore, various postdealloying treatments have been demonstrated. They include the deposition of conformal oxide coatings along the pore surfaces by atomic layer deposition105 or of metal monolayers by underpotential deposition,106,107 and the functionalization of the pore surfaces by electroactive polymers such as polyaniline108 or polypyrrole109,110 or by organic molecules such as thiols,111 nucleic acids, or antibodies.27

An example for the control of the structural evolution during dealloying is the addition of Pt to the master alloy.99,112−114 Dealloying Ag–Au–Pt produces nanoporous Au–Pt with L as small as 4 nm, substantially less than the 20–40 nm that are typical for as-prepared NPG.115−118 The extremely small L in nanoporous Au–Pt has been attributed to the low surface diffusivity of Pt, which slows down microstructural coarsening. With attention to catalysis, it is relevant that Pt is strongly enriched at the surface of as-dealloyed nanoporous Au–Pt and that the Pt/Au atom fraction at the surface can be tuned in a wide interval by annealing.119

The trend of nanoporous metals to coarsen by surface diffusion underlies a simple and powerful postdealloying treatment. Enhancing the diffusivity, either by thermal or by electrochemical annealing, can be exploited for tuning L in an interval ranging from the as-prepared value, which can be as small as 4 nm, all the way up to several micrometers.13,120,121 The continuous tunability of its characteristic length scale by 3 orders of magnitude distinguishes NPG from practically all other nanomaterials.

A classic theory of microstructure evolution by diffusion predicts that L depends on time, t, as L ∝ t1/4 during coarsening.122 Atomistic numerical simulation confirms this prediction.123 Some experimental studies of NPG coarsening support the t1/4 law,124,125 while others report large confidence limits for the exponent.95,126−128 A data mining survey of the literature favors t1/8 (emphasizing that this has no support from theory), yet ultimately qualifies the available data as inconclusive.129 If the power law is accepted, then the ramifications of its low exponent merit a closer look. The exponent 1/4 implies that the time increment for a given relative increase in ligament size varies as L4. In other words, local regions in the high-L tail of the size distribution coarsen more slowly than the remaining microstructure, allowing the smaller ligaments to catch up. The scenario is similar to the diffusion-controlled Ostwald ripening of precipitates. That process exhibits a similarly low time exponent (1/3 as opposed to the present 1/4) and, by virtue to the Lifshitz–Slyozov–Wagner (LSW) theory, a quasi-stationary size distribution even after extended coarsening.130,131 Quite analogously, NPG typically maintains a highly uniform microstructure, even after extended coarsening (see also section 3.9). When NPG coarsens outside the corrosive environment, then residual LNE exposed to the surface is not dissolved. The substantial relocation of atoms will then also affect the distribution of LNE within the ligaments. Their composition field may be homogenized, or an LNE-enriched layer at the surface may be formed. See section 3.13 for details.

Control over the dealloying process parameters is a prerequisite for the successful design of preparation protocols for nanoporous metals. This will be discussed in the following section.

2.3. Approaches to Dealloying

In principle, NPG can be prepared in every shape and dimension, as long as the precursor alloy and a surrounding electrolyte share a common interface. Geometries range from nanoscale particles,132 wires,133 films,134−136 and leaves80,102,137−139 to μm-thick coatings,140 pillars,141,142 and sheets,143−146 up to mm-100,116,118,147−150 or cm-size151 bulk samples. The making of even larger parts from NPG, for instance in the form of macroscale scaffolds for catalysis, has been demonstrated based on 3D printing.152

Precursor alloys need to meet certain requirements to ensure successful dealloying. The corrosion potentials between the noble and less-noble species must differ by typically a few 100 mV. Also, the master alloy should be a single phase of uniform composition, either in the form of a solid solution, a glass, or an intermetallic compound. Both criteria can be readily met by various master alloys for NPG. Specifically, preparation protocols for NPG have been based on alloys containing Ag,13,76,92 Cu,153−157 Ni,100 Al,158,159 Sn,135 Zn,140,160,161 Li,162 and multicomponent glasses.163−165 However, in macroscopic dimensions, i.e., for at least mm-sized samples, preparation of NPG has so far been limited to alloys prepared by classical metallurgical methods such as Au–Cu, Au–Ni, and, as the by far most commonly used alloy system, Au–Ag.13,118,148−150 The parting limit for Au–Ag is 45 at. % Au.10,86,166 Monolithic mm-size samples of NPG have been prepared from master alloys with gold atom fractions between 5 at. %167 and 42 at. %.168

Dealloying can be prompted by free80,92,118,139,169−172 or by electrochemically9,13,76,92,103,118,150,173,174 controlled corrosion. Electrolytes include aqueous solutions across the whole pH range13,92,96,135,146,174 as well as ionic liquids.140,160,175 However, the majority of preparation protocols for NPG use acidic environments. For Au–Ag master alloys, free corrosion is generally carried out by concentrated HNO3,80,92,118,139,169−172 while electrochemical dealloying typically uses dilute HClO4 solutions.9,13,76,92,118,150 Both free and electrochemical dealloying can produce large monolithic volumes of NPG with comparable microstructure.176 For samples with identical L and master alloy composition, similar mechanical properties are observed irrespective of which corrosion method is used.118,176 This suggests comparable sample quality and comparable microstructure. Yet, electrochemical dealloying offers a more direct control over the corrosion process. For example, variation of ED is a facile method to control the final L. Here, higher ED result in smaller L.102,103

Dealloying does not dissolve the LNE entirely. The residual content of LNE can vary between <1 at. %148 and up to 80 at. %.177 The retained amount of LNE is crucial for the preparation of hierarchical nanoporous structures by sequential dealloying.167,177 This will be explained in section 2.5. More importantly, the LNE content may be decisive for the catalytic performance of NPG. This will be inspected in sections 4–6. Here again, the electrochemical (as opposed to free) corrosion affords tuning the preparation protocol toward a direct control of the residual LNE content. The next section will elaborate in more detail on preparation protocols.

2.4. Preparation Protocols for Nanoporous Gold: A Case Study

2.4.1. Motivation

Among the many preparation protocols for NPG, few can produce the macroscale, uniform, crack-free, monolithic bodies with exceptionally clean surfaces that are the signature of high-quality NPG. The present section attempts a critical discussion of relevant process parameters for preparing NPG, and it also proposes a “best practice” guide for that material. The protocol is based on an approach developed in the teams of Jin and of Weissmüller more than a decade ago178−180 and refined subsequently in both teams.116−118,147,148,150 Results consistently show that macroscopic samples with a homogeneous microstructure can be obtained that are free of macro-defects such as cracks, show little dealloying-related shrinkage, and exhibit a low residual LNE content.116−118,148,150 The consistency of the mechanical behavior of samples prepared by the protocol116,118,148,150 testifies to an exceptional reproducibility. This is major asset and a motivation for describing that particular protocol here.

2.4.2. Master Alloy Selection and Preparation

In this case study, the master alloy is AuAg, the most commonly used precursor system in the preparation of NPG. The main advantage of AuAg is the continuous series of solid solutions in the equilibrium alloy phase diagram, in other words, full miscibility at any composition and at all temperatures up to the solidus.181 By contrast, AuCu and AuNi, the other binary alloy systems used for the preparation of macroscopic NPG, exhibit multiple ordered superstructure phases (AuCu)182 or a miscibility gap (AuNi)183 at room temperature. In order to avoid phase separation, careful heat treatment is required during preparation of AuCu and AuNi precursor alloys.100,154,156 Even when the master alloy is prepared in the form of a uniform solid solution, AuCu-based NPG has been found to exhibit poor mechanical properties in the form of brittle deformation behavior. This is the result of microstructural heterogeneity, and specifically of crack formation along grain boundaries that were weakened during dealloying.154 While macroscopic bodies of NPG dealloyed from AuNi show high strength and ductility, the ligament size tends to be large, L ≈ 120 nm.100 Because many application scenarios proposed for NPG require both uniform microstructure and small L, AuAg is often the master alloy system of choice for making of NPG.

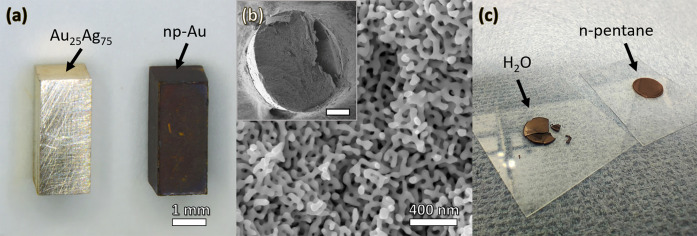

The present example uses master alloys Au25Ag75, prepared from Au and Ag wires (≥99.99% purity) by arc melting. The ingot is then encapsulated in evacuated fused silica and homogenized by annealing for 5 days at 850 °C. Afterward, numerous conventional metal shaping techniques, such as rolling, drawing, and cutting can be applied to prepare the precursor samples; an example of a cuboid sample before and after dealloying is shown in Figure 2a.

Figure 2.

Preparation of nanoporous gold (NPG) by electrochemical dealloying. (a) Au25Ag75 precursor (left) and as-dealloyed NPG sample (right). (b) Microstructure of NPG imaged by scanning electron microscopy. Inset shows the cross section of a sample that was intentionally cleaved using a scalpel; the scale bar corresponds to 300 μm. (c) Nanoporous gold disks air-dried after preparation. The samples were wetted by H2O (left) and n-pentane (right) before drying. Note, capillary-induced stresses cause bending and breaking of samples wetted by H2O which can be avoided by a final transfer to n-pentane. (a,b) Reproduced with permission from ref (192). Copyright 2020 The Author.

It is emphasized that a homogeneous precursor microstructure is important for obtaining high-quality nanoporous samples. Therefore, a final recovery anneal may be required to annihilate lattice dislocations and relax residual stress that result from the final machining. For AuAg alloys, an annealing temperature of 300 °C has been found suitable for recovery.

2.4.3. Potentiostatic or Galvanostatic Dealloying

The present protocol uses electrochemically controlled dealloying under conditions of constant applied potential, in other words, potentiostatic dealloying. In rare cases, galvanostatic control (constant net current, I) is used during electrochemical dealloying.184,185 This approach results, in principle, in a constant dissolution rate of the less noble species. That may seem an appealing concept for uniform dealloying. However, it may be argued that constant I does explicitly not lead to uniform dealloying conditions. This is so because the active surface area, A, as well as the alloy composition, vary as the dealloying procedes. In the early stages of dealloying, A of the smooth surfaces of the pristine master alloy sample is small. Therefore, the dissolution current density, j = I/A, is initially high. As soon as the rough corrosion front of primary dealloying is formed, A increases significantly and this decreases j. With progressing dealloying, dissolution by secondary dealloying becomes more important, as ions not only dissolve at the dealloying front but also in the trailing volume. It can be seen that secondary dealloying introduces a time dependence to the magnitude of A and thereby to j. Moreover, as soon as primary dealloying is complete and residual species are solely dissolved by secondary dealloying, the corrosion acts on a surface that is effectively quite dilute in LNE. In order to maintain the required high dissolution current, the dealloying potential then needs to be controlled to very positive values. That changes the oxidation state of the surface, and it may move the dissolution process into a different regime of the Pourbaix diagram. Clearly, those features of galvanostatic dealloying are not compatible with constant and uniform corrosion conditions. The effect of specific adsorbates on the dealloying process is discussed later in this section.

The by far most common electrochemical dealloying procedure is potentiostatic dealloying. Regarding the dealloying process, a constant ED corresponds to an invariant driving force for the LNE dissolution. As the elemental composition changes during the dealloying process, a static potential causes a gradual reduction in j. Although dissolution conditions vary during both electrochemical preparation methods, potentiostatic dealloying can be considered the more uniform preparation technique because every volume element is subjected to the same dissolution progression irrespective of its location within the sample. In this case study, potentiostatically controlled dealloying is used. A three-electrode configuration is mandatory, not the least because the dissolved LNE, a large amount of matter, is deposited on the counter electrode.

2.4.4. Choice of Electrolyte

As with most of the above-mentioned electrochemical dealloying protocols, the present case study uses dilute, namely 1 mol L–1, HClO4 as the electrolyte. In this environment, the surface diffusivity of Au atoms is rather slow. This results in a low coarsening rate during secondary dealloying and thereby reduces the final L.97 Additions of halide-ions (Cl–, Br–, and I–) have been reported to significantly increase the Au surface diffusion rate of HClO4-based electrolytes.97 This may shorten the overall dealloying time, yet at the expense of considerably larger L.

While HClO4 is unsuspicious of specific adsorption on gold,186 adsorbates formed by impurities may influence the dealloying process and the catalytic performance of the nanoporous material. For example, during the long period of dealloying Cl– impurities may enter the electrolyte when reference electrodes with a KCl environment are used, such as Ag/AgCl or calomel. In this case study, the issue is avoided by usage of a pseudoreference electrode in the same solution, namely a AgCl-coated Ag wire (+0.52 V (SHE) in 1 mol L–1 HClO4). This minimizes contamination, due to the extremely low solubility of AgCl. It is good practice to calibrate pseudoreference electrodes against more stable ones, such as the standard hydrogen electrode (SHE), before each dealloying run. When calibrated, other pseudo reference electrodes may also be appropriate, such as the reversible hydrogen electrodes (RHE). In order to minimize impurities, ultrapure water (≥18.2 MΩ cm) is used to prepare all aqueous solutions.

It should be noted that dealloying in electrolytes that are, in pristine condition, devoid of ions of the less noble species exhibits poorly defined starting conditions because the Nernst potential is very low or ill-defined at the onset of corrosion. This issue settles once ions dissolve into the electrolyte. Still, as the dealloying critical potential depends on the Ag+ concentration in solution, the dealloying conditions in the just-mentioned media may vary with the electrolyte volume and with the ion transport kinetics.101 An approach that circumvents this issue is dealloying of Au–Ag in AgNO3 solutions.146,174 However, due to the formation of passivating AgO layers, the residual Ag mole fraction, xAgres, in as-dealloyed NPG was found to be very high (xAg > 30%).146 Addition of AgClO4 into HClO4 solution is another strategy to obtain well-defined dealloying conditions.101 Although this dealloying approach has been reported two decades ago,101 systematic addition of AgClO4 into electrolytes for the purpose of making of NPG under even better controlled conditions has not been implemented so far.

2.4.5. Dealloying Potential and Postdealloying Conditioning

The dealloying critical potential of Au–Ag exhibits comparatively high values in pure HClO4-based electrolytes.98 The present protocol features potentiostatic dealloying of Au25Ag75 precursors at ED = 1.27 V (SHE), i.e., 0.75 V (pseudo Ag/AgCl). Dealloying is considered as complete when the current decays to a few tens of μA. For cylindrical Au25Ag75 precursors with a diameter of 1 mm and a length of 2 mm a value of 10 μA is used. As a result of the quite positive value of ED, oxygen species adsorb on the Au surface.187 The adsorption impairs surface diffusion and slows down the dealloying rate. In alloy systems with a less noble sacrificial element, such as Au–Ni, oxidation of the Au surface can be mitigated by dealloying at lower E.100 Oxygen adsorption on NPG also embrittles the material, as lattice dislocation end points are pinned at adsorbate sites.188 While oxygen species adsorption on Au thus seems unfavorable, it can be used to hinder coarsening at ambient conditions. Thus, deliberate oxidation may enhance the shelflife of stored samples of NPG.

After dealloying by the steps described so far, samples of NPG exhibit L ≈ 20 nm115 and a high xAgres, around 20 at. %.116 The next step in the preparation protocol is designed to reduce xAg further. To this end, the sample is first polarized at E = 1.37 V (SHE) until the current diminishes. Afterward, the electrolyte (1 mol L–1 HClO4) is renewed and 20 potential cycles (0.12 to 1.62 V vs SHE) are applied at a scan rate of 5 mV s–1. The two steps, polarization and potential cycles, are then repeated once. In each case, the potential cycling is concluded by an anodic scan to the electrode potential 0.82 V (SHE). This corresponds to an adsorbate-free Au surface state.189 This preparation routine results in clean and reduced metallic Au surfaces. Note also that the dealloying and conditioning do not involve organic solvents. This is one more distinctive feature of dealloying that affords exceptionally clean surfaces.

The postdealloying treatment procedure reduces the overall Ag content, as determined by energy dispersive X-ray analysis, to values below xAgres < 1%. X-ray photoelectron spectroscopy (XPS) suggests that the remaining Ag preferably accumulates at the surface.34,190,191 With the present protocol, the XPS (near-surface) Ag fraction was determined at xAg = 8%.191 Final ligament diameters, as determined by scanning electron microscopy, are around 40 nm.116,117,192

2.4.6. Drying

Drying is an often a neglected topic in the preparation of nanoporous metals. Throughout the dealloying and conditioning, the samples are wetted by electrolyte. Upon drying, the surface tension of the receding liquid–vapor meniscus, γLV, introduces a pressure, p, in the pore fluid according to the Young–Laplace equation, namely

| 1 |

Here r denotes the radius of the meniscus, approximately equal to the pore radius.193 Given that the pore size of NPG is only a few tens of nm, p takes on values of around 10 MPa for water (γLV = 72 mJ/m2)193 in the pore space. However, significantly higher values of p, exceeding the yield strength, can ensue at local constrictions. As a result, improper drying procedures can cause severe deformation or spontaneous fracture of nanoporous metals, as demonstrated in Figure 2c. Although this issue has been well-known for many decades, for example, in the fields of porous semiconductors193−195 or silica aerogels,196 it is hardly appreciated in the context of nanoporous metal preparation. The drying technique below, adopted from protocols for mesoporous silicon,193 has proved useful in the making of nanoporous metals.197,198

An efficient way to minimize capillary-induced stresses is to transfer the nanoporous metals from the preparation medium first into water, then into ethanol and finally into n-pentane, whereupon the samples are deposited on glass and allowed to dry. This procedure profits from the considerably lower surface tension of n-pentane, which is γLV = 14 mJ/m2 as opposed to the 72 mJ/m2 of water. The contrasting juxtaposition of NPG sheets displayed in Figure 2c clearly emphasizes the need for consideration of capillary-induced stresses when crack-free monolithic bodies of NPG are required. A drawback of the drying routine is its use of organic solvents that may alter the surface state of the porous metal. Therefore, drying in n-pentane is not established as a standard preparation step in the presented case study, and application should be made dependent on need. Other, more laborious techniques such as freeze- and supercritical drying avoid the organics but appear not to have been applied to nanoporous metal so far.

2.5. Hierarchical Nanoporous Gold

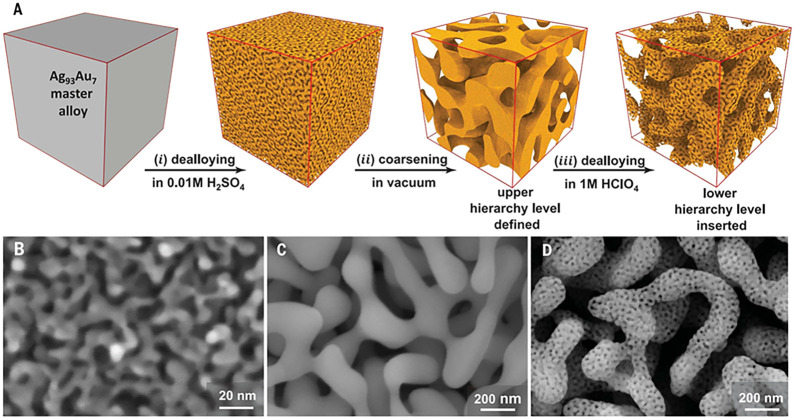

So far, this section 2 addressed the formation mechanisms behind the evolution of the lowest level microstructure required to form bodies of NPG. Most of the unique properties of NPG can be directly attributed to its small ligament size. Yet, the small size may also have adverse effects, specifically in slowing down mass transport through the pore space. This is of obvious relevance for the performance in catalysis. Structuring on multiple length scales may solve the dilemma by admitting both small pores for achieving a high specific surface area and large pores for transport. Nanoporous metals with multiple microstructural length scales have been the subject of considerable interest in recent years.199−201 The lowest structural level of multimodal NPG is typically made by dealloying, and numerous approaches toward the higher structural levels have been proposed, such as templating,202,203 additive manufacturing,152 and selective dissolution of multiphase alloys.158 A particularly stringent implementation of multileveled pore structures is hierarchical porous materials in which the structural organization at each of the individual hierarchy levels is geometrically similar, with identical geometry and topology at each level but distinctly different characteristic length scales. For the specific structural motive of NPG, networks nested on two separate hierarchy levels have been demonstrated and exemplify the stringent hierarchical organization.167,177,204−207 The microstructure of ”nested-network nanoporous gold”167 is illustrated in Figure 3. The straightforward architecture of such materials predestines them as model systems for understanding the impact of hierarchical structuring on properties and for the rational design on multiple microstructure levels.177 Below, we briefly indicate how the preparation protocol of the previous sections can be expanded to yield nested-network nanoporous gold with two hierarchy levels. The making of porous metals with other, less stringent multiscale geometries is described in several recent reviews.199−201

Figure 3.

Making of hierarchical nanoporous gold by dealloying. (A) Schematic illustration of the preparation steps: (i) first dealloying of a Ag-rich precursor alloy leaves a nanoporous network with high amount of residual Ag; (ii) coarsening of the ligament structure by thermal annealing; (iii) second dealloying forms the lower level nanoporous microstructure. (B–D) Scanning electron micrographs of the microstructure after the first dealloying (B), coarsening (C), and second dealloying steps (D). Reproduced with permission from ref (177). Copyright 2021 American Association for the Advancement of Science.

Figure 3A schematically illustrates the preparation of nested-network NPG by dealloying, as first reported in ref (167) and recently refined for robust macroscopic samples.177 While minor preparation details may vary in other studies,205,207Figure 3 captures the essentials. The master alloy is dilute in Au, e.g., Au7Ag93, and the dealloying conditions are carefully selected so that xAgres remains very high, affording a later, second dealloying step. The resulting, nanoporous Ag–Au (with, for instance, xAg = 76%)177 is then coarsened by annealing, which establishes the microstructure of the upper hierarchy level. The second dealloying then introduces porosity into the ligaments of that upper level, establishing the lower hierarchy level. The anticipated enhanced transport rate in nested-network nanoporous gold is indeed confirmed by experiment.167,207 Furthermore, the range of solid fractions accessible to dealloying is extended downward to as low as 0.12 while mass-specific mechanical strength and stiffness are superior to NPG with a single hierarchy level.177

2.6. Engineering the Macroscopic Shape of Nanoporous Gold

2.6.1. Machining the Master Alloy Preform

A wide variety of conventional metal forming approaches can be applied to master alloys for macroscopic samples of NPG. These include, for instance, cutting, milling, rolling, or wiredrawing. In principle, dealloying is a shape-conserving process. Size and shape of NPG samples may therefore be selected by appropriate machining of the master alloy. Yet, care has to be taken to choose the conditions for minimizing sample shrinkage during dealloying. Section 3.7 discusses phenomenology and mechanisms of shrinkage. Figure 4A shows a cm-size rectangular beam of (epoxy–resin infiltrated) NPG as an example for a machined macroscale geometry.

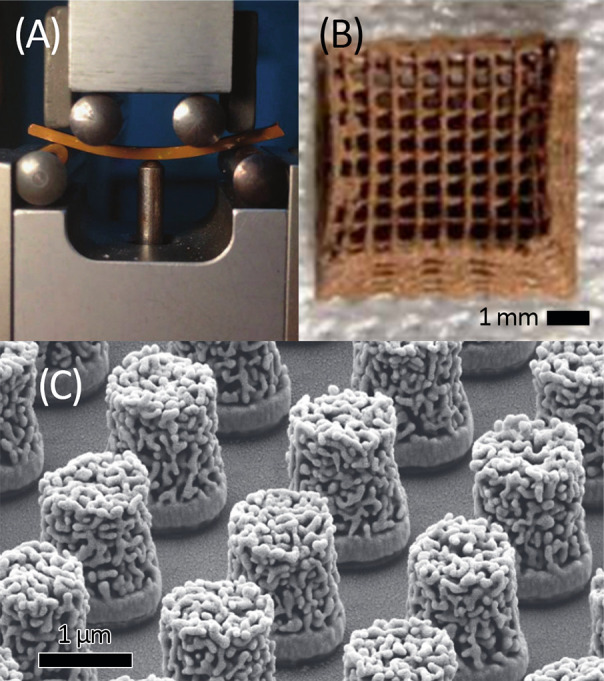

Figure 4.

Shaping samples of NPG. (A) A 1 mm × 2 mm × 26 mm size rectangular bar of epoxy–resin infiltrated NPG (center, brownish color), here subject to a four-point bending test. (B) 3D-printed, cm-size lattice of NPG. (C) NPG bumps with diameter of 1.0 μm on planarized CMOS chip. (A) Reproduced in part from ref (151) under Creative Commons license CC BY 4.0. Copyright 2015 The Authors. (B) Reproduced in part with permission from ref (152). Copyright 2018 The Authors. (C) Reproduced with permission from ref (220). Copyright 2022 IEEE.

2.6.2. 3D Printing the Master Alloy

Recently, it has been demonstrated that NPG catalyst samples with complex microscopic geometries can be produced by 3D printing. The process acts on an ink containing master alloy particles, which are dealloyed subsequent to printing the preform (Figure 4B).152

2.6.3. Nanoporous Thin Layers and Nanoporous Nanowires

Monolithic dealloyed bodies of NPG, of extended size in all three dimensions, are often not very well suited for the integration in reactors. That is a consequence of the inefficient mass transport in the pore space, in conflict with the need for mitigation of diffusive and resistive gradients in the reactor. Many studies have solved that problem by working with thin layers of NPG. These can be made by dealloying the free-standing thin (typically around 100 nm) master alloy sheets of Ag–Au that are commercially available as white gold leaf.80 Thin films based on vapor-deposited master alloys on planar substrates are also frequently explored.27 Alternatively, thin layers of NPG can be conformally deposited on current conductive support structures by galvanic deposition of an alloy that is subsequently dealloyed to NPG. Such processes can exploit the advantages of an all-wet-chemical processing of electrodes of almost any shape and size.208

Layers of NPG have been studied as cantilever actuators209,210 and sensors.211 Sensors with optical or electrical readout have been proposed for biomedical applications,27 substrates for surface-enhanced Raman scattering,212 studies of optical properties,28,213,214 energy-storage,215 electrocatalysis,216 and photoenhanced catalysis.29,217

Substrate-supported thin layers of master alloy for NPG can be structured by electron-beam lithography and subsequently dealloyed to produce thin structures of NPG with a wide range of 2D shapes. That is of interest because lithographic structuring may, in principle, be seamlessly integrated into microtechnology manufacturing schemes. Wire- and disk-shaped samples have been demonstrated,218−220 and an example is shown in Figure 4C.220

Nanoporous nanowires can also be made as freestanding objects. Several works have demonstrated that the master alloy can be electrodeposited into suitable nanoscale channels in a substrate, for instance, anodized alumina221,222 or ion-track-etched channels in a polymer.223 Removing the substrate and subsequently dealloying generates the nanowires. In a less controlled way, dealloying columnar microstructures in rapidly solidified metal ribbons may also yield rod-like nanoporous particles.224

Lastly, thin layers of nanoporous gold can be obtained by electrochemically roughening an initially flat Au electrode. A typical procedures involved anodization, followed by a reduction of the created oxide layers.20,225−229 The resulting morphology is similar to that of NPG obtained by dealloying (Figure 5A). The thickness of such layers of NPG may be restricted to few tens of nanometers. Roughening of initially flat Au electrodes has also been demonstrated by electrodepositon/alloying/dealloying cycles,140,160,230−232 often using Zn140,160,230 or Ag232 as the LNE. These can be applied to electrodes of nearly any size and shape, even when preassembled in an electrochemical cell of specific geometries such as microelectrodes for sensors.

Figure 5.

Preparation of porous gold by processes different than dealloying. (A) anodization in HCl solution; (B) H2 bubble templated deposition; (C) templated electrodeposition between sacrificial nanoparticles. (A) Reproduced with permission from ref (20). Copyright 2020 Elsevier. (B) Reproduced with permission from ref (252). Copyright 2014 Elsevier. (C) Reproduced with permission from ref (233). Copyright 2012 Wiley-VCH.

2.7. Nanoporous Powders

2.7.1. Making Powder from Bulk NPG

Electrodes for electrochemical applications have to be integrated with other electrodes into an electrochemical cell optimized for the specific application, such as a parallel plate reactor. The direct integration of NPG has only rarely been demonstrated in devices such as fuel cell234 or metal–air batteries.235,236 Nanoporous gold has also been used for alloy-type negative electrodes in Li-ion batteries.237 However, the overall accounts of such application has remained limited to date.

In principle, powders obtained from NPG monoliths offer another pathway to shaping samples of NPG because they can be consolidated into appropriate shape. Cavity microelectrodes of NPG form an example, providing for particularly precise electrochemical characterization. Due to the limited material, the overall currents are small and thus the voltage drop Udrop = IRe (“IR drop”) is kept small. Voltammograms recorded with cavity microelectrodes have particularly little distortion, cf., Figure 6E vs D. Furthermore, the external mass transport (outside of the pore space) is controlled by the effective radial diffusion (Figure 6A). In addition, the exchange of the solution in the pore space is efficient.

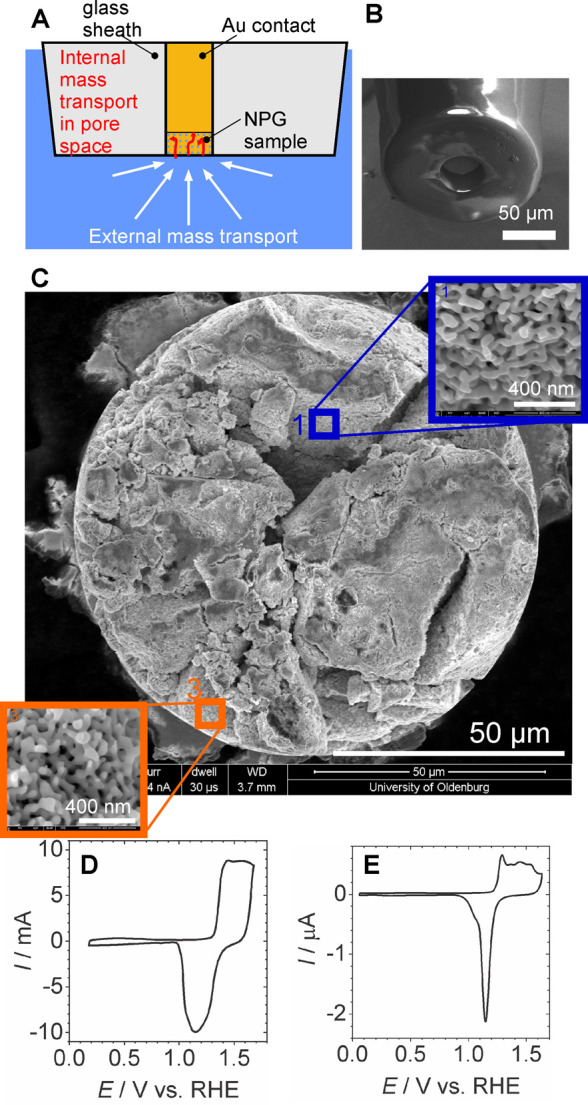

Figure 6.

Cavity microelectrodes. (A) Schematic cross section; (B) SEM image of empty cavity microelectrode produced by etching a glass-sealed gold wire; (C) SEM image of a cavity microelectrodes filled with NPG powder, insets show zoomed areas with NPG ligaments; (D) cyclic voltammogram of a macroscopic NPG monolith in 1 mol L–1 HClO4, potential scan rate v = 10 mV s–1; (E) cyclic voltammogram of the very same NPG material inside a cavity microelectrode in 1 mol L–1 HClO4, v = 10 mV s–1. (B) Reproduced with permission from ref (238). Copyright 2019 Wiley-VCH. (C) Adapted from ref (191) under Creative Commons license CC 4.0. Copyright 2020 The Authors. (D,E) Reproduced with permission from ref (638). Copyright 2022 The Author.

NPG monoliths can be powdered by mechanical impact, sonication, or similar processes. The powder can be filled in a cavity microelectrode (Figure 6A), while preserving the nanoscale structure, without the use of binder (Figure 6C).191 NPG can be released from cavity microelectrodes by intensive sonification, after which the same cavity may be washed and filled by another aliquote of the same NPG powder (Figure 6B). Using powders from identical starting material tends to decreases data scatter in electrochemical experiments with NPG by avoiding small variation between monoliths in the dealloying process.107

2.7.2. Processing NPG Powders

Instead of upscaling the size of the original NPG electrode, pulverized monoliths can be processed with binders to obtain porous electrodes coated on a back contact. The use of binders and the associated problems in reliably establishing electrical contact between particles removes many of the original advantages associated with the bicontinuous structure of NPG. Nevertheless, such processes may be required for the integration of NPG into devices.239−241

2.8. Dealloyed Porous Nanoparticles

Use of a dealloying process is increasingly extending from macroscopic materials to nanomaterials. Dealloying of binary and ternary alloy nanoparticles has become a broadly accepted facile synthetic route toward highly active and durable catalyst materials for heterogeneous and electrochemical reactions.42,63,79,242 The focus of this section is on the relation of nanosizing of binary alloy nanoparticles on the (electro)chemical dealloying and their comparison to bulk materials.

Dealloying of multimetallic nanoparticles covers a broad range of particle motifs like core–shell, hollow, donut-like to porous nanoparticles to tune their physicochemical and (electro)catalytic properties. In contrast to the macroscopic dealloyed materials, the fundamental dealloying mechanisms behind the formation of size-dependent particle morphologies are still poorly understood to date.

The critical dealloying potential is largely influenced by the initial composition of the master alloys. It is well studied that smaller monometallic nanoparticles tend to dissolve at lower anodic potentials compared to the bulk materials; this tendency is more pronounced with decreasing particle size.243 This shift of the dissolution potential as the function of the particle size can be related to the Gibbs–Thomson effect. With decreasing size, the fraction of low-coordinated surface atoms rises, resulting in an increase of the surface energy of these nanoparticles.

Recent KMC simulations have indicated how the size-dependent electrochemical properties of monometallic nanoparticles can be related to the critical dealloying potential of alloy nanoparticles.244 One of the key results is that the evolution of porosity in alloy nanoparticles takes place at higher critical dealloying potentials than in the corresponding bulk alloys. The increase of the critical potential in relationship to 1/rNP, where rNP is the radius of the alloy nanoparticle is based on kinetic effects. Compared to bulk Ag75Au25, the KMC simulations predicted an increase in critical dealloying potential by 25 mV for 17 nm and by 100 mV for 8 nm nanoparticles.244 As has been explained in section 2.2, the relative rates of (1) the dissolution rate of the LNE and (2) the passivation of the surface by diffusion of the remaining MNE are decisive for the nanostructure formation during dealloying. The ratio between these rates may be significantly modified in nanoparticles. According to these KMC simulations,244 the following time-dependent characteristics have been identified: In the initial stage of the dealloying process, Ag atoms at the top layer of the nanoparticles are dissolved very rapidly. During the intermediate time, the particle surface is entirely passivated by the very mobile Au surface atoms. The surface roughening induced by dissolution of Ag surface atoms enhances the formation of a monolayer of Au atoms as a passivation layer. Therefore, nanoparticles tend to form a passivation layer of MNE atoms very quickly. Only over longer times and at a constant potential, the fluctuations in the passivation layer might be sufficient for the dissolution of the Ag atoms from the subsurface layers. Smaller alloy nanoparticles with a high content of low-coordinated surface atoms and short-lived fluctuations in the structure of passivation layer do not tend to evolve pores. In contrast, the pore evolution is more favored if the fluctuations are long-lived and allow successive Ag dissolution, which is the case for larger particles.

Only few experimental studies have investigated the particle size effect on the morphology of dealloyed nanoparticles. One of the first systematic studies pointed out the particle size effect for electrochemical dealloying on binary alloy nanoparticles.242 In case of Ag–Au, the particle size effect on the morphology of 2–6 nm and 20–55 nm alloy has been studied by applying different constant potentials in acidic media and characterized by high-resolution microscopic techniques.79 In agreement with the reported KMC simulations,244 a superficial dealloying occurs at potentials above the critical potential of 2–6 nm AgAu nanoparticles. Due to the inappropriate ratio of surface atoms to bulk atoms, the pore evolution is not favored for small nanoparticles, and therefore the core–shell formation with an Au-rich particle shell takes place. For AgAu alloy nanoparticles larger than 40 nm, the pores form only above 0.75 V (SHE), and a significant shrinkage of these dealloyed particles is observed.

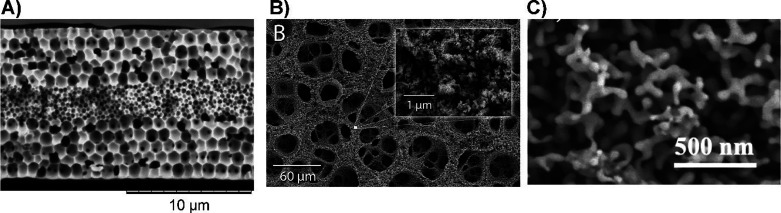

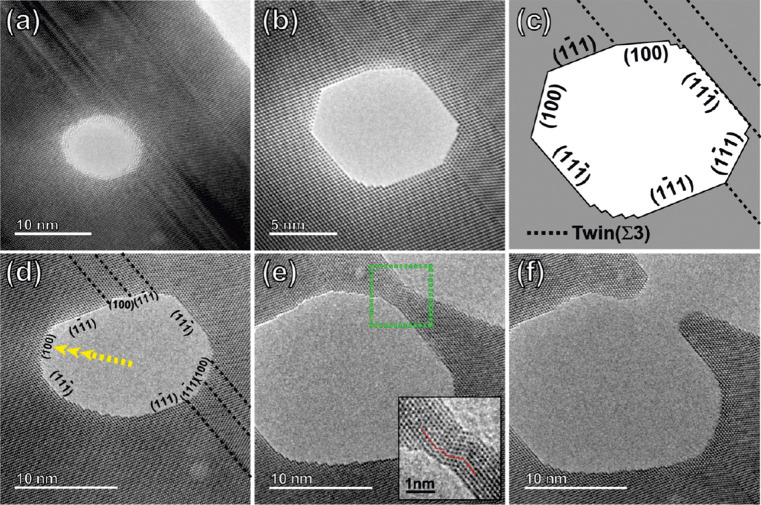

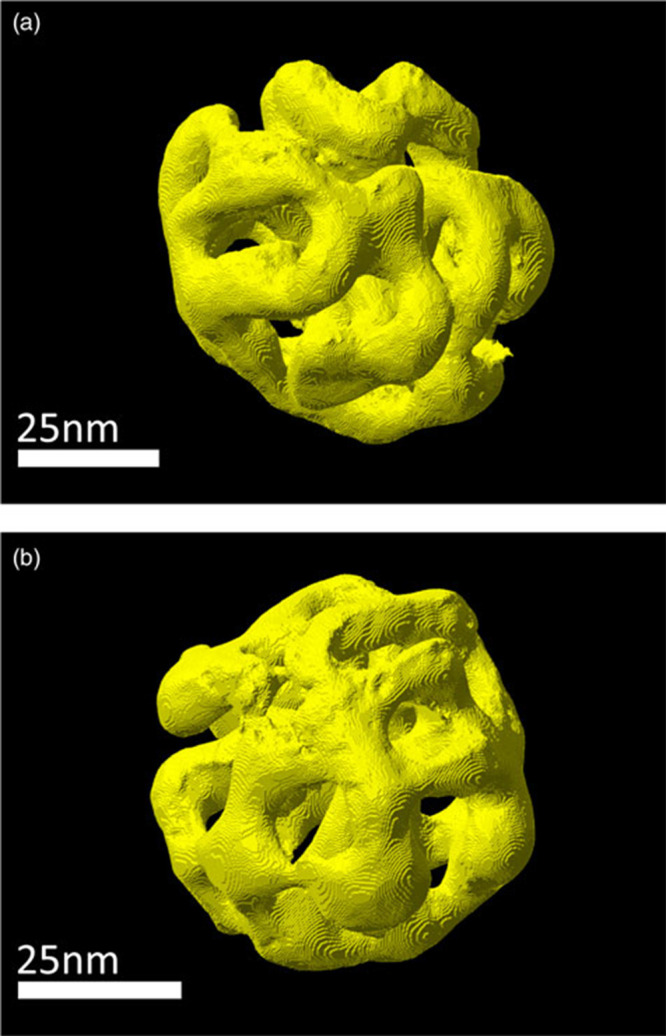

A comprehensive reconstruction study of porous Au nanoparticles prepared by dealloying has been reported.245Figure 7 illustrates a reconstruction of a single representative porous Au-rich particle prepared by electrochemical dealloying. Structural information like pore size, porosity, specific surface area, and tortuosity were determined for porous Au-rich nanoparticles with an initial diameter of 77 ± 22 nm, which can be used for the simulations and models of diffusion and mass transport phenomena in confined environments.246 Two types of dealloyed porous Au nanoparticles with different ligament size and residual Ag content could be identified: Porous nanoparticles with smaller ligaments (∼14 nm) show a low residual Ag content (xAgres ∼6%). In contrast, higher Ag content (xAg = 20%) is observed for porous nanoparticles with larger ligament sizes (∼23 nm). However, bulk nanoporous Au-rich materials prepared by dealloying show an opposite behavior. Moreover, the porosity and ligament size of the dealloyed nanoparticles were evaluated by a statistical analysis method, so-called chord length distributions.247−249 For these analysis a large number of arbitrary straight lines is placed within the reconstructed volume. The so-called chords can be divided whether they are within the material or pores and averaged over their length, giving statistical information on pore and ligament size. Very interestingly, the dealloyed nanoparticles published in ref (245) show less porosity compared to macroscopic materials published in ref (137). It is expected that a high porosity is associated with a large specific surface area. The bulk materials, yet possess a lower specific surface area compared to the porous nanoparticles. This discrepancy might be explained by the differences in the structure and interconnection between the ligaments and pores between bulk materials and nanoparticles.

Figure 7.

Three-dimensional STEM tomography reconstruction of porous nanoparticles prepared by dealloying. (a) particle I, (b) particle II. Reproduced with permission from ref (245) Copyright 2021 The Author(s) under License CC-BY.

2.9. Other Ways to Meso- or Macroporous Gold Electrodes

2.9.1. Direct Electrodeposition of Porous Gold Electrodes

Studies of nanoporous gold in the context of catalysis invite the comparison to other, meso- or macroporous gold electrodes. Selected procedures toward such electrodes will be briefly discussed here. Porous gold can be electrodeposited using sacrificial nanoparticles as templates.250,233,251 The template particles can be arranged to inverse opal structures followed by electrodeposition of gold, yielding a macroporous material that can be refined by the use of different template nanoparticles (Figure 5C).233 Instead of particle templates, H2 bubbles can serve as template.18,252−255 The resulting material has a wide distribution of pore sizes (Figure 5B), but the process can easily be applied to substrates electrodes of almost any shape and size. The direct deposition of alloys is also possible.18,255 Sophisticated template structures have been used such as diatoms, i.e., marine microorganisms with an exoskeleton.256 Those exoskeletons exhibit regular nanostructures in a large variety of shapes that can be selected by choosing a specific kind of diatom as template.

Electrodeposition can also be guided by electrolyte additives and control of the current density to yield directly a flexible porous material with interwoven needles similar to the structure of paper.257 Powders of different metals can also be sintered to a porous network of alloy materials with micrometer-sized feature sizes followed by dealloying to form NPG.206

2.9.2. Assembly of Nanoparticles to Porous Gold

Some other approaches shall be mentioned for the specific potential to alter either composition or the macroscopic shape of the resulting porous solid. Presynthesized metal nanoparticles can be combined to an interconnected aerogel using either only Au nanoparticles or mixtures of different nanoparticles.258,259 Those aerogels exhibit a much higher porosity than dealloyed NPG, and the size of the struts is related to the size of the used nanoparticles. The possible use of different nanoparticles provides means for exactly controlling the resulting overall composition. The local composition may greatly deviate from the mean composition and may be used for bifunctional catalyst materials. Presynthesized nanoparticles with a hydrophobic ligand shell can also be prearranged at the air–water interface of a Langmuir–Blodgett trough.21,260,261 After solution exchange the initially loosely arranged particles can be connected by electroless deposition of gold yielding a mesoporous membrane with a thickness similar to that of the original nanoparticles.21,260,261 Nanoporous gold has also been obtained by chemical reduction of aqueous 1 mmol L–1 H[AuCl4] by ascorbic acid and using 100 mmol L–1 of the ionic liquid tetrapropylammonium glycine to control the nucleation. The process yields a porous material of aggregated particles that was efficient for electroreduction of nitroaromatric compounds.262 This area has recently been reviewed.263

2.9.3. Coating of Au on Other Porous Electrodes

Further suggested procedures use hydrothermal growth on Ti264 or deposition of an Au monolayer on nanoporous copper by a galvanic displacement reaction.265 Galvanic displacements reactions have also been used to convert a nanostructured Co electrode to nanoporous Au/Pd electrodes.266

3. Microstructure and Metrics for its Description

3.1. Overview

As has been pointed out in section 2, the preparation and processing conditions of dealloying afford the controlled preparation of quite different microstructures in the nanoporous material. As the materials properties can be tuned along with the microstructure, the wide options for microstructure design provide a key asset of nanoporous gold. In consequence, understanding the microstructure–property relations is an important scientific challenge. Raising to this challenge requires, in the first place, that an appropriate and complete set of microstructural parameters is identified, that the implications of those parameters for scale and geometry of the microstructure are understood, and that their values are reliably measured for the material at hand. The present section exposes the relevant state of the art, highlighting as distinct metrics as the characteristic length scales, phase fractions, residual LNE content and distribution, connectivity, and tortuosity. Emphasis is on the relevance specifically in the field of catalysis. Recent reviews with reference to the parametrization of NPG’s microstructure can be found in refs (267 and 268).

3.2. Geometric Model for the Nanoporous Gold Microstructure

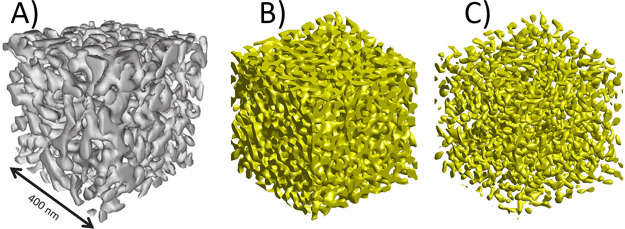

In the form of the “leveled-wave model”, we here introduce a toy model that provides illustration for our discussion of the microstructure metrics of NPG.269 Other models and approaches to 3D representation of NPG will be discussed in section 3.14. The leveled-wave model goes back to the seminal work on early stage spinodal decomposition by Cahn.270 Its underlying notion is that, out of a random spectrum of small fluctuations, the microstructural evolution of the decomposition selects those with a single characteristic wavelength for fastest growth. The selection results from a competition between interfacial energy and transport kinetics. Those factors are equally decisive in spinodal decomposition and in dealloying, even though the driving forces and the kinetics underlying those two processes are quite different. The resulting microstructure can be constructed in two simple steps, first superimposing plane waves of identical wavelength but different wave vector orientation and with random phase shifts, and second binarizing the resulting random field by a level cut that is selected to provide the desired phase fraction (for instance, the solid volume fraction in the case of a nanoporous solid).270,269 A simple strategy for selecting the wave vector directions provides the model with a 3D periodic structure, enhancing its appeal as a basis for numerical simulation.269 Earlier studies had generated model microstructures for NPG by following the spinodal decomposition numerically.271−274 The resulting geometry depends on the time at which the evolution is interrupted. The leveled-wave algorithm is free of that issue and generates random structures with unique statistical characteristics. The algorithm is also extremely facile to implement and execute.

Figure 8B,C illustrates a typical leveled-wave structure123,269 and sets it next to an experimental 3D tomographic reconstruction of NPG (Figure 8A).124 The close resemblance of the microstructural geometries is apparent. What is more, leveled-wave structures have been found to accurately reproduce, with no free parameters, the dependence of Young’s modulus, Poisson’s number, and yield strength on the solid fraction for as-prepared NPG.177,269 The model also accurately reproduces a topological feature, the scaled genus (see section 3.9) of as-prepared NPG.124,269 As an added benefit of the leveled-wave model, many of its microstructural metrics, including characteristic size, solid fraction, volume-specific surface area, and averages of the mean and Gaussian curvatures of the surface, are interrelated by exact analytical expressions.269

Figure 8.

3D geometry and topology of NPG’s microstructure. (A) Rendering of an experimental tomographic reconstruction; solid fraction φ = 0.30.124 (B) Rendering of a leveled-wave model generated structure with φ = 0.30.269 (C) Rendering of the identical realization of the leveled-wave model, yet with φ = 0.10.269 Note the remarkable qualitative agreement between experimental and model structures. Note also that the model structure with φ = 0.10 represents an array of disconnected clusters, not a percolating and loadbearing network. (A) Reproduced with permission from ref (124). Copyright 2016 Taylor and Francis Ltd. (B,C) Reproduced with permission from ref (269). Copyright 2016 The Authors.

The characteristic length-scale of the leveled-wave model is set by the underlying wavelength, which can be chosen at will. Applying the model to NPG rests on the tacit assumption that NPG microstructures of different characteristic microstructural length scale (different ligament size) are self-similar, which is discussed in section 3.9. Available studies present strong evidence for the applicability of the model to as-prepared NPG, irrespective of the specific preparation protocol or the ligament size.118,177,269

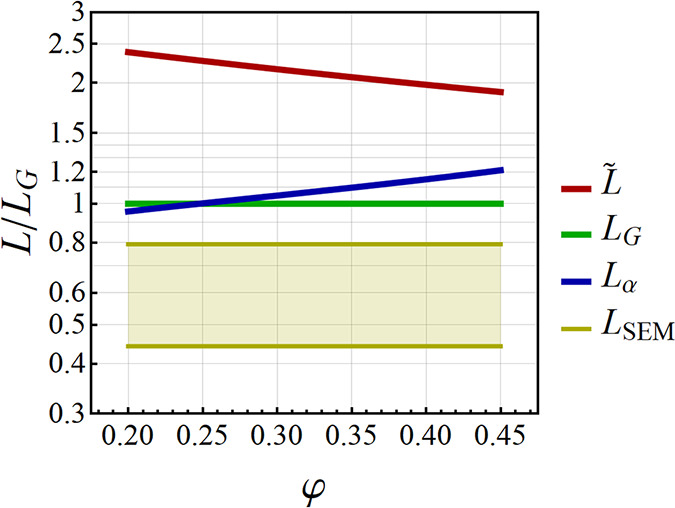

3.3. Metrics for the Characteristic Length Scale

Undisputedly, one of the most important microstructural parameters of any given sample of NPG is the magnitude of its characteristic length scale. This scale determines area per volume and, thereby, the fraction of atoms exposed at the surface and available for catalysis. It also determines size effects controlling mechanical strength,26,141,275 optical function,214,276,277 and electric resistance222,278,279 of the nanomaterial. The importance of the characteristic length scale for so diverse phenomena emphasizes that the option of tuning this scale within wide margins (section 2) is a distinguishing asset of NPG. Inspection of the microstructural geometry, for instance in Figures 8 and 9A, immediately reveals that any single notion of “size” may not adequately cover all relevant aspects of the geometry. One may focus on different features, e.g., a characteristic diameter of the struts or “ligaments” that make up the network material or, alternatively, a characteristic spacing between such features, and one may be interested in various measures for the distribution of the feature in question. In other words, there is no such thing as a unique definition of size, and one must expect that different measures for size may be relevant for different phenomena. That situation is ubiquitous in materials science, and specifically it can be relevant for the materials performance in catalysis.

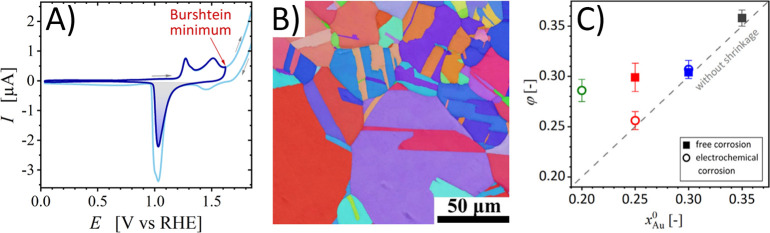

Figure 9.

Selected examples for signatures of and experimental approaches to the ligament size. (A) SEM-based evaluation of a size, LSEM, by analysis of the characteristic diameter of ligaments at their waist (white arrows).129 Pore size (dark arrows) and the skeleton of the ligament network (legend) are also indicated. (B) Analysis based on Bragg reflection width (Williamson–Hall analysis) in wide-angle X-ray powder diffraction.104 The Williamson–Hall size, DW–H, is systematically correlated to LSEM, validating this analysis for measuring the ligament size. (C) In situ small-angle X-ray scattering showing the characteristic interference peak of NPG and its evolution to lesser wave numbers as the structure coarsens during dealloying at 20 °C.283 The mean spacing between neighboring ligaments can be inferred from the peak position. (A) Reproduced with permission from ref (129). Copyright 2018 under license CC-BY-4.0. (B) Reproduced with permission from ref (104). Copyright 2017 under license CC. (C) Reproduced with permission from ref (283). Copyright 2017 under license CC 3.0.

The most common approach to parametrizing the characteristic length scale for NPG is evaluating “the ligament size” by measuring diameters along the waists of ligaments in scanning electron micrographs (Figure 9A).24,92,105,118,173,190,280−282 This is done manually for a certain number of ligaments, and the mean diameter, LSEM, is reported. Good practice requires that the number of ligaments counted and the variance of the diameters be specified. As macroscopic samples of NPG tend to have reduced (relative to bulk) LSEM close the external surface,34,92,173 good practice also requires that micrographs from the interior of the sample are examined and that their location is specified.

For nanoparticles and nanocrystalline materials, the evaluation of X-ray line broadening is a standard approach to characteristic size.284 The simple evaluation of the breadth of the strongest Bragg reflection in terms of the Scherrer formula must be rejected because it does not discriminate between size and microstrain broadening, thus it systematically and strongly underestimates the size. Variants of the Williamson–Hall approach avoid that error and are readily applied whenever a sufficient number of Bragg reflections are available.284,285 NPG exhibits substantial microstrain (section 3.12) that systematically increases with decreasing ligament size, emphasizing the need for Williamson–Hall type correction.104 In NPG, an apparent complication resides in the presence of a coherent crystal lattice that extends to dimensions much larger than L. That obliterates the simple analysis of the impact of coherency on the X-ray line broadening of the standard diffraction theory. Nonetheless, empirical data for NPG show an excellent correlation between the L values derived by Williamson–Hall and SEM (Figure 9B),104 validating X-ray line broadening analysis as a method for measuring the ligament size of NPG.

Experimentally more demanding approaches to measuring a mean ligament size involve the analysis of 3D reconstructions.124,126,137,245,286−288 This may provide variously defined measures for size. An example, based on “granulometry”, is the mean, LG, over all materials points in the solid phase, of the diameter of the largest in-fitting sphere containing the respective point.137,289 A closer inspection of such approaches reveals various issues that require attention.

First, the sampling of space in granulometry emphasizes the wider regions of the microstructure, providing a comparatively large characteristic size.289 A related algorithm, combining skeletonization with a euclidean distance transform,145,290 provides around 30% smaller size for NPG.268,291 This algorithm has been applied in a data mining approach to coarsening of NPG,129 yet its relation to other measures for L remains to be established.

Second, whenever there is a distribution of sizes, averaging is required for condensing the data into a single size parameter. The averaging involves a decision on the weighting function, for instance number-, area-, or volume-weighted averaging, and the resulting average values can differ strongly.292 Different materials phenomena may depend on different weighting functions, and this interrelation is poorly appreciated or understood in the field of NPG.

The characteristic spacing, L̃, between the centers of neighboring ligaments is another obvious measure for size.269,293 A robust signature for L̃ of aperiodic structures is provided by the position of the first maximum in their autocorrelation function. For NPG and the leveled-wave model, L̃ defined in this way has an immediate relation to the structure factor or interference function. As a result of the Debye formula,294,295 that function exhibits a distinct peak with a maximum at the wavenumber269

| 2 |

Indeed, experimental small-angle X-ray scattering data of NPG exhibit a pronounced interference peak (Figure 9C). Various studies have measured L̃ from the position of the peak in neutron8 or small X-ray angle scattering125,205,283,296 data, or from a maximum in the numerical Fourier transform of electron micrographs.93,293 In one instance,293 an equation similar to (eq 2) but without the prefactor was assumed ad hoc. The characteristic length evaluated in that way is smaller than the characteristic spacing L̃.

3.4. Specific Area of Surface

Another common microstructural parameter related to characteristic size is the “specific surface area”, which is again linked to the number of sites available for catalysis. The specific surface area also determines in how far capillary forces induce pressure in the bulk. As will be discussed in section 3.12, that surface-induced pressure generates strain throughout the crystal lattice, which in turn may affect the catalytic activity. The surface-induced pressure is also of relevance for actuation100,209,297−300 or active strain sensing301 with NPG and for its strength.111,188,302

The specific area of surface is sometimes specified as area per mass, αm, and then has no immediately obvious relation to size. Various scientific communities have their own distinct notions on how mass-specific surface area provides a figure of merit. Yet, the related numbers mix a microstructure property (area of surface per volume) with a materials parameter of the solid phase, namely its mass density. Obviously, the same microstructural geometry will provide vastly different αm, when it is realized as porous carbon as compared to porous gold. The parameter αm is therefore not very informative when it comes to understanding the microstructure; thus, its use in studies of NPG is discouraged.

The area, αV, per volume of the solid phase relates to microstructural geometry alone and should be preferred. In fact, this parameter has a particularly close relation to measures for the ligament size. That is apparent when one considers idealized cylindrical ligaments of diameter L, which have simply αV = 4/L. Consequently, a specific-surface-area related size, Lα, may be defined as

| 3 |

Through its product with the

surface stress, f, along with the generalized capillary

equation for solids,  ,303 the specific

surface area αV determines the surface-induced mean

pressure in a nanoscale solid. Thereby, αV also parametrizes

the impact of the microstructure on the size-induced change in the

mean lattice parameter of NPG (see section 3.12 below).

,303 the specific

surface area αV determines the surface-induced mean

pressure in a nanoscale solid. Thereby, αV also parametrizes

the impact of the microstructure on the size-induced change in the

mean lattice parameter of NPG (see section 3.12 below).

In most experimental situations, the mass density of the solid phase is known with sufficient confidence and accuracy to afford computing the volume of the solid phase based on the mass (which, typically, is readily measured). By contrast, determining the surface area of porous electrodes is a more complex issue. The topic has been thoroughly reviewed by the IUPAC commission.304 There are several options, and each has advantages and disadvantages. Their application to NPG has been evaluated and compared,173,305 leading to the recommendation that either the charge for surface oxidation and subsequent reduction should be evaluated or the charge consumed in the underpotential deposition (UPD) of Cu. UPD of Pb has also been used106 and provides additional information on the prevailing facets in NPG (see section 6.1.2 below).

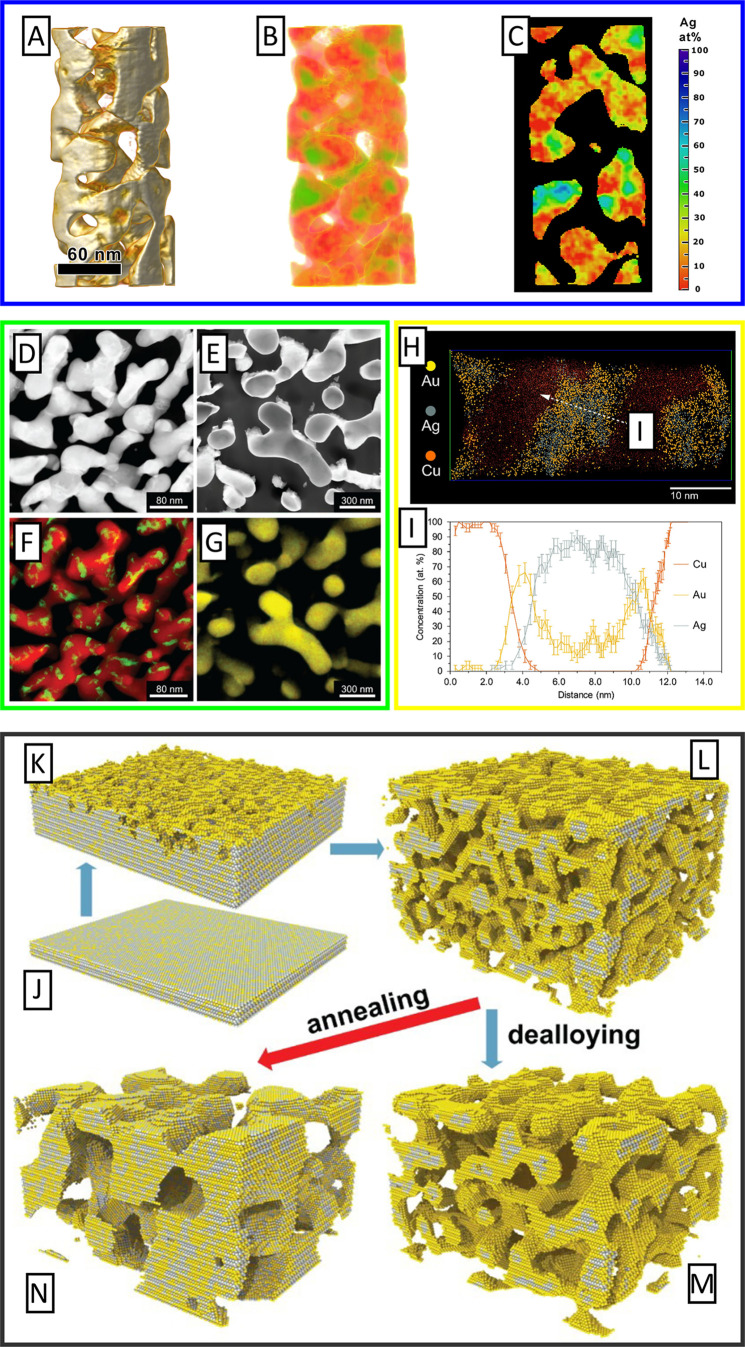

Because the UPD process ultimately changes the surface state, and it might be impossible to completely remove Cu2+ from the surface and the pore space, the authors of the present review prefer the determination based on the formation of surface oxides (Figure 10A). The surface is oxidized up to the Burshtein minimum306 at around 1.65 V in Figure 10A. At this potential, an AuO layer is formed on all facets of Au. Its reduction is associated with a charge of 386 μC cm–2,307 and dividing the net charge by that value defines the “electrochemically active surface area”, AECSA. This quantity may be identified with the geometric area of surface in a description of the NPG microstructure, permitting the computation of αV and, with eq 3, of the characteristic size Lα. Slightly different values for the area-specific reduction charge of an AuO layer have been determined by other authors. One advantage of the oxidation/reduction approach is that, even though the peak widths may vary, it can be applied in different aqueous electrolytes. The disadvantage is a possible change of the surface structure already during one potential excursion to the Burshtein minimum, which is especially evident in acidic electrolytes.191 This is related to the high mobility of Au on the rough surface that is generated, as a transient state, when the oxygen adsorbate layers are lifted.308 In fact, as one instance of electrochemical annealing, repeated oxidation/reduction cycles on NPG are sometimes deliberately instigated in order to induce coarsening.121

Figure 10.

Selected examples for additional microstructural signatures. (A) Cyclic voltammogram of current I versus electrode potential E for NPG in deaerated 0.1 mol L–1 NaOH. Dark blue: scan to the switching potential at the Burshtein minimum (indicated by label). The shaded area under the surface oxide reduction peak scales with the surface area and can be used to measure that quantity. Light blue: scan to larger positive switching potential; note the larger reduction charge. (B) Grain size of NPG from electron backscatter diffraction in a scanning electron microscope.115 Color codes crystallographic orientation, identifying individual crystal grains as regions of uniform color. Note up to 100 μm grain size, more than thousandfold larger than the ligament size, LSEM = 18 nm here. (C) Solid fraction, φ, of NPG versus initial Au fraction, xAu0, in the starting alloy.118 Strong deviation at low xAu shows that the starting alloy composition does not provide a good indicator of NPG solid fraction. Note also the dependency on the preparation protocol, free versus electrochemical corrosion. (B) Reproduced with permission from ref (115). Copyright 2021 from Elsevier. (C) Reproduced with permission from ref (118). Copyright 2021 The Authors.

The commonly applied measurement of the double-layer capacity92,167,173,178,305,309,310 in the potential range below the onset of surface oxidation is plagued with several problems.304 It can only be recommended for a relative comparison of very similar samples within one laboratory after optimizing the procedure with respect to the used range of scan rates, the nature and the concentration of the electrolyte. An approach based on electrochemical impedance spectroscopy provided consistent values.305 However, those values were clearly distinct of the results obtained from UPD and surface oxide procedures.305

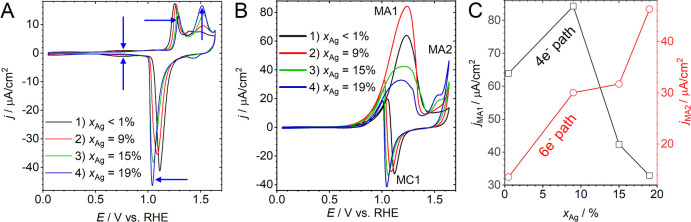

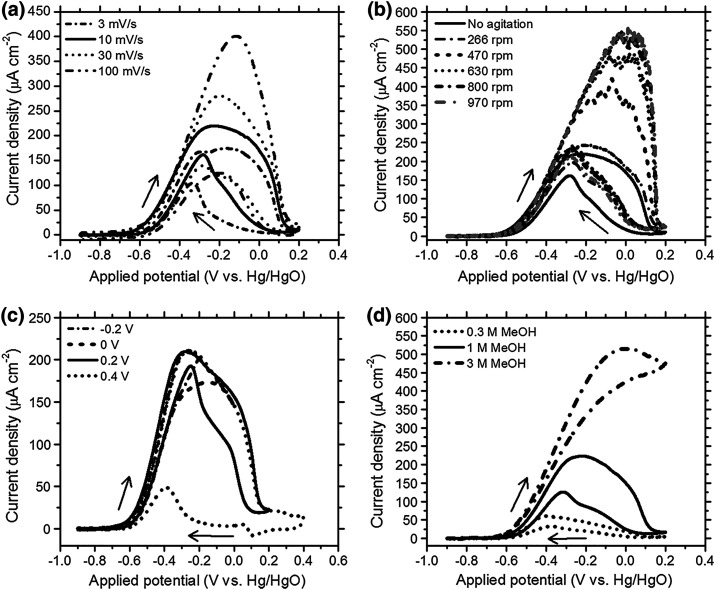

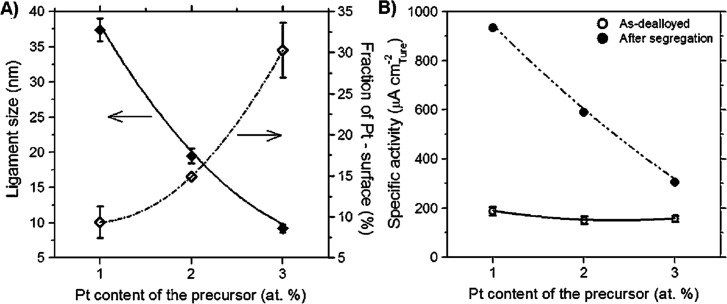

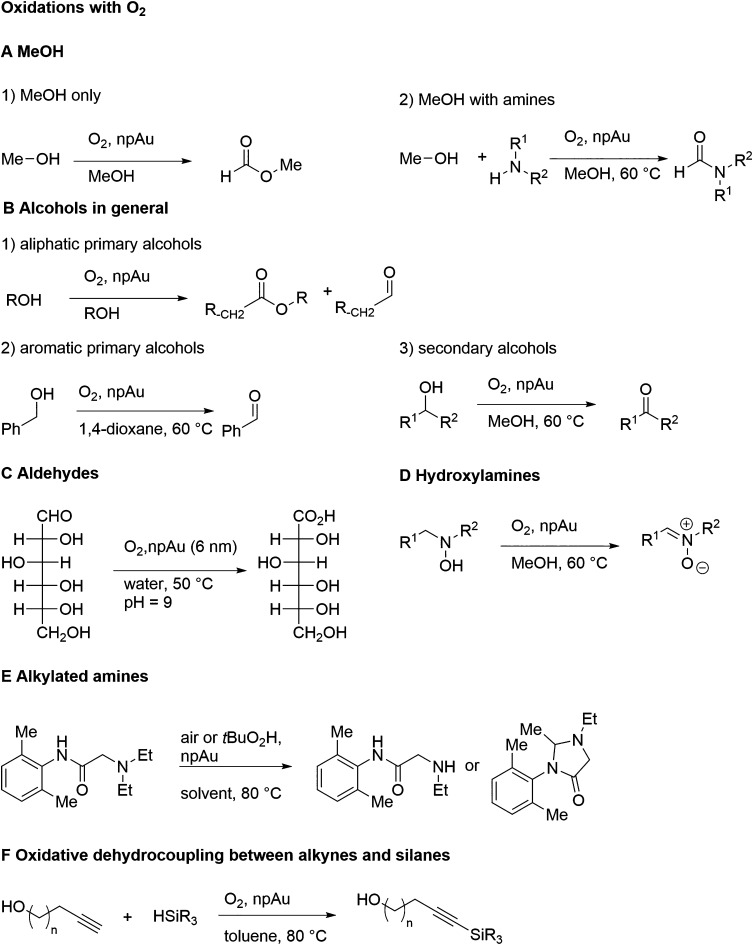

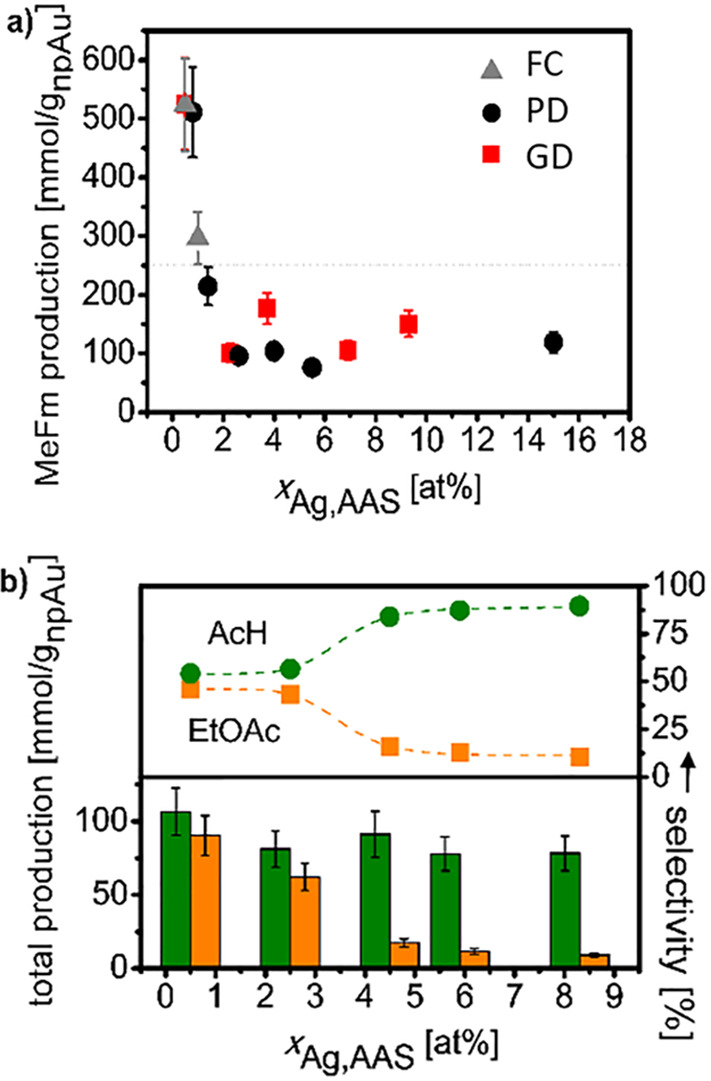

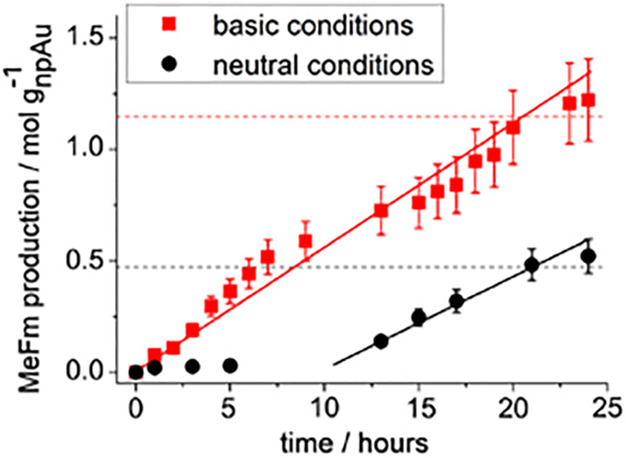

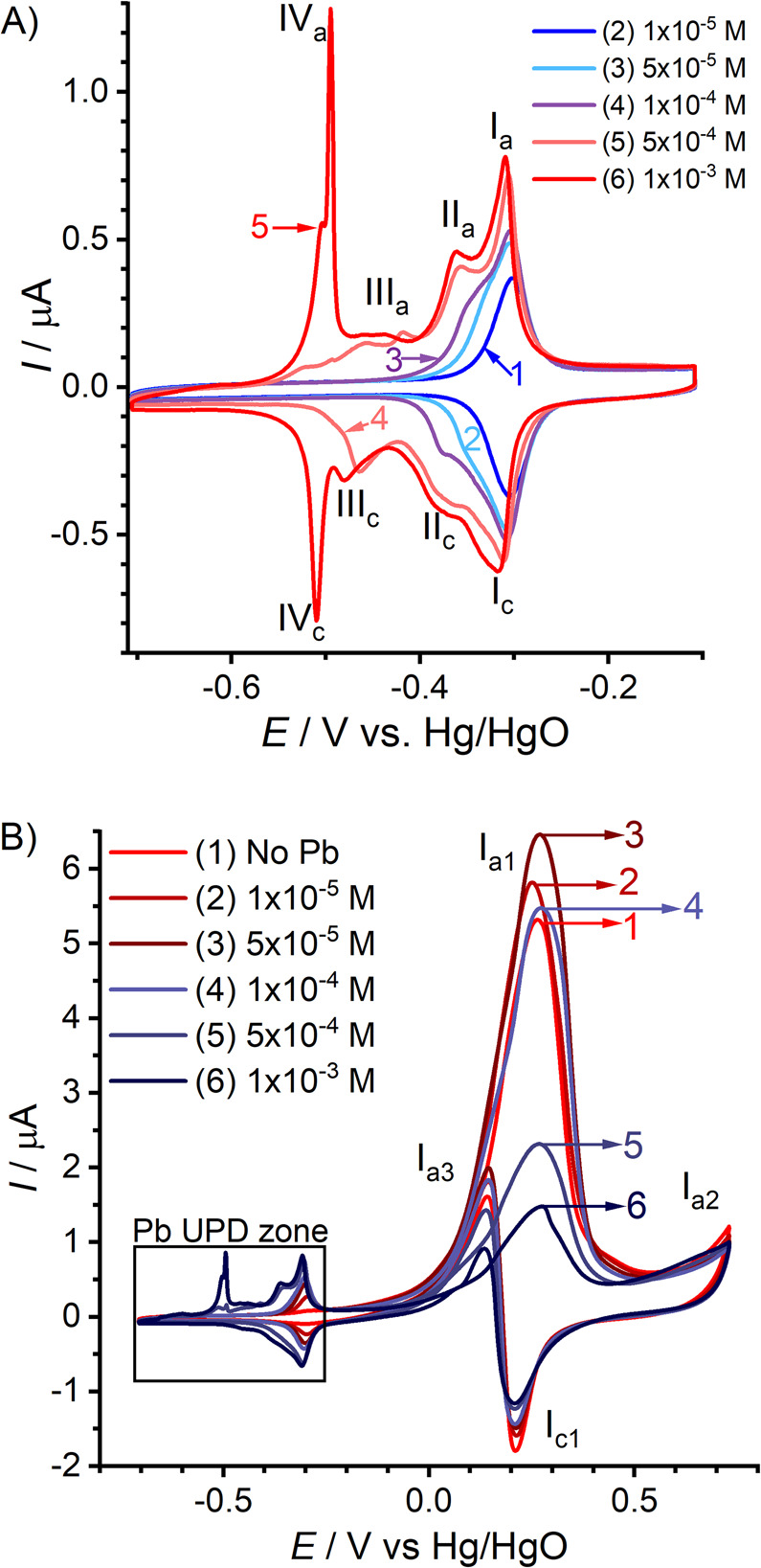

For catalysis with NPG, the numerical value of the material’s specific surface area is of relevance. As NPG can be prepared with a wide range of ligament sizes, αV can take on vastly different values. Inasmuch as αV can be approximated as 4/L, typical L values of 20–40 nm (see section 2.2) translate into volume-specific surface areas of αV ≈ 0.1–0.2 nm–1 and mass-specific areas of αm ≈ 5–10 m2 g–1. Yet, smaller ligament sizes can be stabilized, for instance, by alloying with Pt (see section 2.2). For L = 4 nm, one then expects αV and αm as large as ≈1 nm–1 and 50 m2 g–1, respectively.