Abstract

COVID-19 hits the global supply chains in a non-paradigm manner unfolding new and systemic complexity. Therefore, the unexpected and frequent disruptions forced the concern of preventing or creating supply chain resilience capabilities. This paper aims to provide theoretical and practical reflections on resilience in supply chains of essential goods during pandemics using a systems approach. Documental research was performed in order to characterize business practices in consulting reports and interviews with managers published in business communication media. Thus, a careful content analysis was carried out, including the coding and categorization of the leading practices indicated by these vehicles. We suggest categories of resilience factors as new concepts to face the new normal in the supply chains. These categories are Technology and People, Sourcing, Customer, Ecosystem, and Financial Assets. The systems approach consists of more qualified supply chain management stimulating several inputs and synchronized actions to sense and respond to the external environment dynamics.

Keywords: COVID-19, Resilience, Supply chain management, Systems approach

1. Introduction

Unfortunately, the impacts of coronavirus will not stop soon, affecting businesses and policies for a long time (Magableh, 2021). Since March 2020, the Covid-19 outbreak has pushed companies and their global supply chain into a new scenario. This situation has caused simultaneous shocks on the global supply chains, both upstream and downstream, showing how our current recovery models are not fully applicable to manage the uncertainty of the pandemic situation (Paul and Chowdhury, 2021). Thus, all these raised discussion in several areas of knowledge. It includes the management field (Reeves et al., 2020) and, more specifically, supply chain management (Ivanov, 2020; Musazzi et al., 2020).

Due to the pandemic, there is an undoubtedly massive phenomenon changing supply chain management. The abrupt decrease in the demand for non-essential products, the innocuousness of organizational strategies are grand challenges for societies and governments (Ivanov, 2020). The supply chain management has adopted resilience as a critical variable since Christopher and Peck's seminal paper (2004). In this sense, there is an increasing interest in this topic, revealing the complexity of this construct. Primarily, early studies indicate the causes of disruptions as geographically isolated phenomena, likewise terrorism and natural disasters (Christopher and Peck, 2004; Christopher and Holweg, 2017), political instability (Natarajarathinam and Narayanan, 2009), and labor strikes (Tang, 2006).

However, disruptions are happening everywhere globally, not only in specific geographic places, generating severe impacts on supply chains. The unexpected and frequent disruptions forced the concern of preventing or creating supply chain capabilities (e.g., Sheffi and Rice Jr., 2005; Pettit et al., 2010; Jüttner and Maklan, 2011; Poberschnigg et al., 2020). Therefore, COVID-19 hits the global supply chains in a non-paradigm manner unfolding new and systemic ambiguousness. Traditional theoretical perspectives of supply chain resilience cannot solve the current crises and their disruptions impacts (Ivanov, 2020). This challenge may reflect a broader and deeper understanding of resilience in supply chains beyond organizational capabilities as the essential prevention strategy.

For example, after COVID-19, it is common to differentiate disruptions from voluntary (Djalante et al., 2020) and involuntary (Arabi et al., 2020) The population's fear, the lack of adequate medical treatment, and the absence of legal procedures produce involuntary disruptions. Simultaneously, voluntary disruptions may emerge from the drastic reduction in the demand for non-essential products due to abrupt changes in consumers’ purchasing behavior. The lockdowns are also another source of voluntary disruptions that generate impacts over many types of supply chain.

Thus, the COVID-19 has reinforced that global crises produce pervasive effects on the macro and micro agents of the supply chains, requiring analysis through approaches able to reveal sources of the problem, bottlenecks, and strategies through a systemic perspective . Companies need to maintain the status quo while changing to be resilient and recover from external instability as soon as possible. This homeostasis phenomenon (Churchman, 1968) is especially critical to industries affected by the pandemic in the first-order loop as medical supplies, fuels, and food. The time orientation for organizations (Bansal and DesJardine, 2014a) also changes in the pandemic.

However, the supply chain management poorly discusses resilience under a systemic approach (; Nandi and Kaynak, 2020), with exception of some isolated efforts that bring potential factors that could give support or enable the known resilience capabilities (e.g. Djalante et al., 2020; Reeves et al., 2020; San Lau et al., 2020). These efforts bring contributions to the literature published before COVID-19, and may be organized as a set of three resilience factors: 1) mechanisms for coordination and information sharing, 2) emphasis on local supply chains, reuse and redundancy of essential materials, 3) reduction of inequalities and prejudices. These resilience factors may support the understanding and practical implementation of the capabilities studied in the extant literature.

In this sense, this research proposes the following research questions: How could resilience capabilities recover the supply chain's efficiency during and after the pandemic? As an initial attempt to discuss this research gap, this paper aims to provide theoretical and practical reflections on resilience in supply chains of essential goods during pandemics using a systems approach. Systems approach is adopted to deal with dynamic complexity and time disorientation.

2. Literature review

2.1. Resilience in COVID-19 scenario

Covid-19 has caused impacts on social, economic, and environmental aspects of life. The response to the global virus included social distancing, closing non-essential businesses, canceling events, public campaigns to stay home, and a profound rethink of ways to work and live (Sarkis, 2021). Putting together the systemic impacts of COVID-19 has generated large-scale disruptions in the supply chain network (Das et al., 2021).

The resilience literature details several disruption concepts. We find local, global, voluntary, and involuntary disruptions (Tang, 2006; Pettit et al., 2010; Christopher and Holweg, 2017). In the context of COVID-19, voluntary disruptions are governmental or market regulations such as social isolation and factory closures (Djalante et al., 2020) to avoid contagion. Involuntary disruptions are behavioral changes in consumption reduction or supply problems linked to infrastructure, management failures or unexpected bottlenecks in the supply chain (Arabi et al., 2020).

This new scenario of multiple disruptions has shown the importance of understanding both firms and the whole supply chain to build resilience investment (Li et al., 2021). “The outbreak of the COVID-19 virus has prompted organizations to be vigilant and reinvent their architectures amid the pandemic and in light of future trade challenges. The lack of preparedness for the sudden pandemic is reflected in several missing links in the global supply chains” (Zhang et al., 2021)

This lack of preparedness has shown how our traditional risk management strategy may not be capable of building a resilience response at the same pace as global supply chain disruptions (Hoek, 2020). For instance, the food supply chain has struggled to build resilience and protect customers and employees while confronting a COVID-19 pandemic (Mollenkopf et al., 2021). In this sense, recent literature has dived into practitioners' activity (Sarkis, 2021), exploring empirical research to address the gap between the conceptual literature and how the industry has developed supply chain resilience (Hoek, 2020).

The resilience capabilities in the supply chain operations can help recover and prevent crises, becoming critical to the firm's competitive advantage in a coronavirus scenario (Zhang et al., 2021). In the case of pandemics, chaos generates disruptions in several industries at the same time. The literature presents several resilience capabilities, not specifically about pandemics, but mostly related to local and regional events regarding terrorism, natural disasters, political instability, as shown in Table 1 .

Table 1.

Capabilities for supply chain resilience in the general literature.

| Capability | Definition | Authors |

|---|---|---|

| Redundancy | Using safety stock to maintain the capacity to respond to any disruption in the supply chain | Sheffi and Rice Jr. (2005); Ali et al. (2017); Adobor and McMullen (2018) |

| Flexibility | The creation of capabilities to perceive and respond to the threat of disruption. It represents investments in people's skills and infrastructure, a production system that accommodates multiple products, and flexibility in sourcing and order-fulfillment | Christopher and Peck (2004); Ali Mahfouz and Arisha (2017), Adobor and McMullen (2018) |

| Visibility | Knowledge about the availability of the operating assets, coordination mechanisms, risks, and chain environment | Christopher and Peck (2004); Pettit et al., (2010); Jüttner and Maklan (2011) |

| Agility | The ability to quickly respond to market changes, and potential and actual interruptions | Kendra and Wachtendorf (2003); Christopher and Peck (2004); Jüttner and Maklan (2011) |

| Adaptability | The ability of the organization to make changes in their operations to address challenges or seize opportunities | Fiksel (2003); Pettit et al., (2010) |

| Collaboration | Collaborative forecasting, relationship management with customers, and internal and external communication. There is a close link between this capability and the literature on cross-functional integration about formal and informal mechanisms | Christopher and Peck (2004); Pettit et al., (2013) |

Despite the cited efforts in Table 1, the current situation of COVID-19 requires a broader view to deal with a global and joint disruption of several types of supply chains. This situation requires some reflections on alternative capabilities to open the analysis lens from a local to a global disorder. Given the complexity of the Covid-19 pandemic scenario, the systemic approach became an adequate perspective to study resilience in supply chains, rather than just addressing them in an isolated and linear way. This complexity requires a more fluid vision, focused on change, unpredictability, persistence, and capacity for transformation (). In this perspective, resilience may be seen as the ability of a supply chain to persist, adapt or transform in the face of change (). Additionally, in another perspective called the "Intertwined Supply Network" or "ISN", resilience, along with robustness and stability, becomes the tripod of supply chain viability, which is related to survival in a changing environment, focusing on the long time (Ivanov, 2020).

Several alternative strategies and analyses emerged from the literature about resilience capabilities since the beginning of the COVID-19 outbreak. Based on these specific works, it is possible to suggest three resilience factors designed explicitly for the living of these particularities in the COVID-19 pandemic to address its issues: 1) mechanisms for coordination and information sharing, 2) emphasis on local supply chains, reuse, and redundancy of essential materials, 3) reduction of inequalities and prejudices. These resilience factors may support the understanding and practical implementation of the capabilities mentioned in Table 1.

2.2. Mechanisms for coordination and information sharing

This feature of resilience consists of developing the ability to manage coordinated solutions between various private sector agents, governments, and NGOs to reduce the effects of the pandemic (Djalante et al., 2020).

(Ivanov, 2020) identified several variables that can be tracked and managed to manage coordination between entities in the supply chain in the event of the COVID-19 pandemic:

-

•

the timing of the closing and opening of the manufacturing and distributors (it may become an essential factor that determines the impact of the epidemic on the chain performance);

-

•

the delivery time, the speed of propagation of the epidemic upstream and downstream of the chain;

-

•

the duration of interruptions in the chain.

Other variables include the coordination of supply chains, the communication syntony between members, risk assessment, and joint risk strategy among the supply members (Musazzi et al., 2020). An additional method is preparing the population to feel prompt to responsively act to eventual situations that could occur around them (Djalante et al., 2020). This strategy represents helping in emergency health situations and guiding precautions on lifestyles and attitudes that can prevent or improve the quality of life and reduce contagion potential.

Despite this factor involving several agents from different sectors, the governments have an essential role in coordinating national and regional plans, aligning the country-level strategies with the WHO's recommendations compliance. Multi-country coordination can avoid unilateral decisions taken by country leaders (Nature, 2020).

And yet, in many countries, including the United States and the United Kingdom, governments have been making crucial decisions in secret and making announcements before publishing the evidence on which their decisions are based. This is not how governments should work. The secrecy must end (Nature, 2020, Editorial 19.03.2020, p. 319).

Closing borders can also be an efficient strategy, but if several countries members of a given supply chain already have a strong level of contamination, it may become less efficient (Reeves et al., 2020). WHO has identified practices that can effectively reduce contagion, based on China's experience: suspending public transport, closing entertainment venues, and banning public gatherings (WHO, 2019). These voluntary disruption decisions may generate numerous involuntary disruptions, impacting the economy and the supply chains' operational dynamics, which have to seek new ways to mitigate their effects.

WHO recommendations derive from a framework that guides governments and other actors to coordinate their actions to reduce the virus's contagion. At the same time, through collective decisions, they can minimize their economic losses, when possible, as in the case of essential goods:

2.3. Infrastructure and logistics

Supporting logistics will include stockpiling and prepositioning medicines and supplies, effective supply chains, and reliable transportation and telecommunications systems (WHO, 2019 p. 11).

2.4. Emphasis on local supply chains, reuse, and redundancy of essential materials

The concern around social isolation is essential, as there are no total efficiency or mass production and distribution of the vaccine against COVID-19 infection (Djalante et al., 2020). Therefore, several countries impose travel restrictions, which impacted several supply chains flow, mainly global operations, which depend on purchased items abroad. (Bandyopadhyay, 2020).

Musazzi et al. (2020) criticize the efficiency of global supply chains in the event of pandemics. According to this author, globalization has promoted factories and warehouses in , distant locations but efficient in cost and delivery time. However, in unexpected situations, essential products, such as medicines and medical equipment, may be inaccessible due to the closing of borders and physical distance between suppliers and demanders, challenging the resilience capabilities to the potential shortage of their products critical time due to the pandemic.

To alleviate and prevent the worsening of the COVID-19 outbreak, supply chains must rely more on local, and at most, regional supply to avoid disruptions caused by the impossibility of transporting supplies. Besides, essential products should adopt redundancy, increasing stocks at various levels in the chain to the detriment of the economic losses resulting from this practice (Djalante et al., 2020; Reeves et al., 2020). These strategies can reduce possible disruptions to limit the pandemic's harmful effects by minimizing the bottlenecks of supplying essential items

There is a growing concern about the scarcity of specific essential products in the supply chains, such as personal protective equipment (PPE). Some countries, such as Ireland, have sought sustainable solutions such as disinfection, sterilization, or reprocessing PPE's to be reused (Rowan and Laffey, 2020), paving the path to circular economy potential in dealing with crises.

2.5. Reduction of inequalities and prejudices

This factor may require government intervention and the reduction of inequalities. Since we can classify health and well-being as public subjects, there is the risk of potential systemic damage. Thus, it is crucial to identify the most vulnerable people and adequately include them in the prevention and recovery plans. (Djalante et al., 2020). According to this author, the low-income population can be vulnerable to the virus for a long time because they do not have access to treatment and the possible vaccine in the short term. Also, breaking social isolation for subsistence reasons becomes a potential band for maintaining the virus in society, primarily pushing governments to protect vulnerable communities.

San Lau et al. (2020) and Madhav et al. (2018) also believe that the low-income population should be monitored and treated in the public health service. These authors consider breaking prejudices with social positions (in their case, referring to refugees) as critical factors to reduce contagions through the development of interpersonal trust. In the case of emerging countries, this idea includes the majority of the population.

Displaced populations, including refugees and migrants, are often the first to be stigmatized and unjustly blamed for the spread of disease, yet they are also among the most vulnerable people during a pandemic to both the virus itself and the measures enacted to control it (San 2020 p.1)

Another social problem that inhibits the companies’ performance during the crisis is the prejudice with infected groups. The investment in science and education can help society understand health issues, reduce fake news beliefs, and prevent the negationist effect. Therefore, reducing inequalities and prejudices is a relevant factor in supply chains' resilience during pandemic contexts. Its origins belong to the macro-environment of the supply chains. As a matter of coordination, members have to invest time and money to develop strong relationships with industrial associations, cooperative organizations, and the government. But instead, it becomes a matter of developing negotiation and lobby skills to bargain for changes to improve the performance of certain industry players.

3. Methods

Due to the scarcity of empirical studies on this new scenario, this paper is based on a secondary data collection, presenting a robust content analysis of several practices from companies struggling with their supply chains' pandemic effects. It is essential to highlight that this paper is not only based on previous studies. In addition to the literature mentioned, business practices are analyzed, indicated by consulting reports and interviews with managers published in business communication media. Thus, a careful content analysis was carried out, including the coding and categorization of the leading practices indicated by these vehicles, aiming to explore what could be done so that the chains achieve resilience due to disruptions caused by the pandemic.

3.1. Data collection

Thirty-three publications containing companies’ cases, informative interviews with high-level managers, and consulting reports were analyzed. Coding and categorization procedures were performed to characterize the types of disruptions and organizational strategies during the pandemic. We proceed the search: 1) using the words “covid-19″, “pandemic,” “supply chain resilience”; 2) programming an alert from Google Search with these words from 2020 May and 2020 December; 3) excluding the reports that do not contain practical information from companies’ sample; 4) excluding theoretical analyses.

In item 3, discussed above, to limit the sample's suitability for the proposed objective, the reports were selected through a checking. In this case, the criteria for keeping each one in the sample were to present a condition experienced by the consulting firm or by the manager interviewed in the reports. We ended up with a selection of thirty-three reports that include twelve different country origins.

From the 33 selected reports, we found 74 strategies or disruptions. Each of these strategies became lines of register of a database, as explained in topic 3.2. These reports were obtained mainly from business magazines (65%) and consulting reports (30%) about the COVID-19 crisis. Among the remaining documents, we found disclosures information and communications to society from public and non-profit organizations. Eighty percent (80%) of the registers reveal systemic disruptions and resilience unrelated to an isolated event or a specific geographical area. We identified the supply chain member as Transportation companies (4%), Retailers (4%), Manufacturers(3%), consumers (3%), Wholesale and Distributors, Farmer (less than 1%).

3.2. Data analysis

We conducted content analysis in the selected reports (Bardin, 1977). Each of the 33 reports were submitted to an in-depth reading, to systematically fill an Excel® spreadsheet, containing one row for each document, and the following fields: title of the report, type of the source (e.g. magazine, consultancy report), companies involved, transcription of text parts containing strategies to solve disruptions, chain level mentioned, and impacts of the implemented system on supply chain resilience (improvements).

We code the data though two content analysis techniques: open coding and selective coding (Corbin and Strauss, 1990) Open coding was used for factors that emerged in the documents and were not presented in the literature. Selective coding was used for capabilities mentioned in the literature and also in the analyzed secondary data. Finally, the categorization of information was performed through the toll ‘PivotTable’, from Excel®. Data were consolidated to generate relationships between fields and to quantify the registers from content analysis.

4. Results

The global impact of the Covid-19 pandemic fosters simultaneous shocks at different places and magnitudes in the supply chain. Content analysis shows multiple dimensions of these impacts and how firms worldwide apply their capabilities to build a resilient response, revealing several characteristics regarding resilience during the pandemics. Firstly, we could identify five main categories in the reports and the number of times they were mentioned in the documents analyzed (Table 2 ).

Table 2.

Categories and frequency.

| Categories | Number of Registers |

|---|---|

| Technology and workforce | 24 |

| Sourcing | 19 |

| Customer aspects | 13 |

| Ecosystem | 9 |

| Financial and Assets Aspects | 9 |

| Total of Registers | 74 |

These categories, represent factors necessary to the existence of resilience, and embrace 18 related elements. Table 3 shows these items and also the number of times they were mentioned in the documents analyzed (Number of registers).

Table 3.

Categories and respective elements of the resilient supply chain against Covid-19.

| categories and elements | Number of Registers |

|---|---|

| Technology and workforce | 24 |

| Supply chain digitization | 21 |

| Workforce | 3 |

| Sourcing | 19 |

| Nearshoring | 8 |

| Distribution | 3 |

| Channels Diversification | 8 |

| Customer aspects | 13 |

| Adapting operations to reach new demands | 4 |

| Consumer changes | 4 |

| Customer Relationship Management | 3 |

| Home Delivery | 1 |

| Product origin | 1 |

| Ecosystem | 9 |

| Critical supply chains monitoring | 1 |

| Government regulation | 3 |

| Holistic approach | 3 |

| Stakeholders relationship | 2 |

| Financial and Assets aspects | 9 |

| Cash flow performance | 2 |

| Increased inventory | 5 |

| Profit margin reduction | 1 |

| Support to supplier | 1 |

| Total | 74 |

4.1. Technology and workforce

this category represents the vital role of tools and technological infrastructure in reorganizing the workforce. Supply chain activities do not lose the necessary agility and efficiency in the new challenging context. There is a critical mention of digitization or digital transformation among industry members. Digital challenges highlight the need for greater integration in supply chain processes, where exchanging information requires greater precision and speed to operations. In this sense, technological tools play an essential role since they push the workforce fundamental changes. It highlights the need, the challenge, and the resistance to adopt the worker to the new reality, which needs to manage time and professional/personal demands in the home office context.

4.2. Sourcing

This category represents the challenge of rethinking supply and distribution sources and structures, redesigning the supply chain based on new strategies, considering the local suppliers for agility/flexibility in distribution. The highlight is the Nearshoring element, revealing the need to outsource the resources origins, production, and distribution, for companies in a close or strategic country (offshoring).

The Distribution element proposes a change in conventional delivery processes since the means of transport and contact points with the end customer are suspended or limited. The initial distribution challenge was to guarantee essential products to combat the pandemic, such as medicines, hygiene and protection supplies, and medical equipment. The need to adapt distribution processes gave rise to the Channels Diversification element, which represents the effort of companies to diversify distribution structures by developing new channel formats, especially those supported by technology, which uses the Internet as a purchasing platform associated with express delivery services. This adaptation measure was necessary so that businesses could become flexible to the threats of interruption of supply.

4.3. Customer aspects

This category represents the impact of customers’ decisions in the way all chain performs. With the covid-19 pandemic, consumer relations have changed and continue to change. Consolidated industries, such as automotive, had to adapt to meet the pandemic's new demands. Besides, consumers have access to more information, and they can play an increasingly active role based on their expectations. Adapting operations to reach new markets enables the business to adapt and change together quickly. New opportunities can arrive, and with them, recent transactions. Former customers may not have their needs met, damaging the future relationship with companies without a pandemic. Consumer changes bring the necessity to adapt how we relate with customers. Direct communication can avoid uncertainties of everyday life consumption. Also, Customer Relationship Management shows that the lack of care with customers may damage the key suppliers' perception of corporate image. Finally, Home Delivery and Product origin elements bring to light new characteristics about consumption. Firstly, due to social isolation, consumers chose or were forced to consume at home. The origin perception is related to the conditions the product is manufactured. For example, the consumer is more concerned with social and environmental issues, and companies need to pay attention to this issue.

4.4. Ecosystem

This category represents the holistic view of the system that embeds the chain. It concerns government actions, stakeholders, nature, among others. It corresponds to issues beyond the chain itself, fundamental to its functioning. For example, the holistic approach is about how the chain needs to integrate with the whole community, concerning survivability in the long run. More specifically, government regulation impacts the entire chain, from the taxation or non-taxation of some goods to stimulate or discourage consumption and reduce social inequalities. Relationships with Stakeholders should be strengthened, including collaborating with competitors so that the chain as a whole can survive - including themselves. Finally, Critical supply chain monitoring concerns a closer management/monitoring between the parties to ensure that actual products are always accessible in the chain.

The last category is the Financial and Assets. It represents the financial impact of adjusting costs and margins when demands deviate abruptly. Inventory level control may have a different orientation, increasing assets volume throughout the chain. The negotiations may change by adopting safety policies that keep suppliers and distributors with enough cash flow to maintain operations without disruption. This component reveals the Cash flow performance, a reaction to an instant reduction in regular cash flow caused by a demand breaking. In this sense, there is also concern about the Support to supplier element, where some members begin to depend on other members to maintain supply chain operations. Also, the Profit margin reduction points out to form a conciliation between agents in the chain. Finally, the Increased inventory was characterized by the need for flexibility and agility in the supply chain. In some cases, it was necessary to increase stocks to guarantee the supply of essential items. Naturally, this increase has a significant financial impact due to its high maintenance costs and invested capital.

The five categories of the proposed framework represent innovative ways to organizing resilience capabilities. This framework is a visual representation of guidelines that shed light on the supply chain's operational capacity. In this sense, each category indicates a specific form to define objectives and action plans: Technology and workforce, Sourcing, Customer, Ecosystem, Finance (Table 3).

Table 4 reveals that the new categories are linked to resilience capabilities. ‘Sourcing’ is linked to capabilities related to the operational activities of the supply chain. At the same time, Technology and workforce link with Visibility, which derives from developing three other capabilities: Adaptability, Agility, and Collaboration. However, they become more reliant on technology and people issues in emergent strategies development and resources management. We consider ‘Sourcing’ as using Adaptability, Agility, and Collaboration to develop partnerships, redundancy, and transportation flexibility.

Table 4.

Relations of resilience capabilities for systemic shocks.

| Row Labels | Customer aspects | Ecosystem | Financial and Assets Aspects | Sourcing | Technology and workforce |

|---|---|---|---|---|---|

| Adaptability | X | X | X | X | X |

| Agility | X | X | X | ||

| Collaboration | X | X | X | X | X |

| Flexibility | X | X | |||

| Redundancy | X | X | X | ||

| Sustainability | X | ||||

| Visibility | X | X |

Regarding ‘Ecosystem,’ it is linked to sustainability issues. The concept of this capability represents both the chain's capacity in producing goods and services under a responsible and cleaner frame and the ability to regulate the relationships their exchanges with the external environment. Finally, this capability is also related to the market concentration of the supply chains. Size, power, and influence can lead the chain's strategies if no efficient regulation prevents oligopolies. We face a risk of bankruptcy of less powerful members of the chain, stimulating disruption.

The data suggest that the same capability can generate different impacts according to the focus of its exploitation. For instance, Adaptability was a relevant capability to deal with the unexpected increase of delivery and takeaway. At the same time, it helps to reduce cash flow problems in the financial dimension.

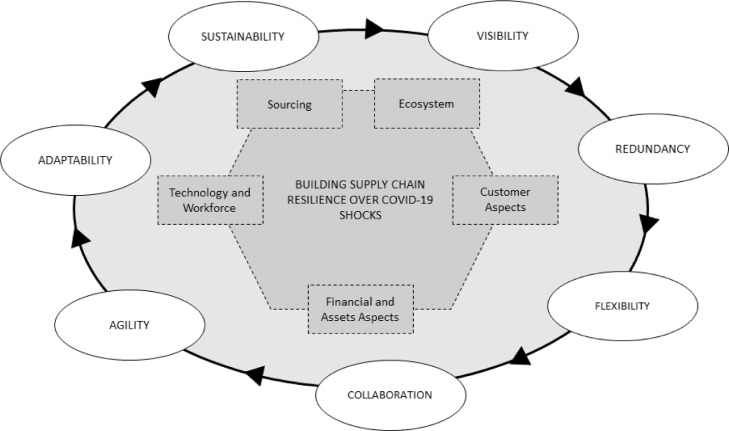

On the other hand, each focus (described in Table 2) might stimulate more than one capability integration. For example, some firms apply Redundancy to change procurement gaps while using Agility to facilitate product access. In this sense, Fig. 1 offers a systemic view of the capabilities surrounding different focuses related to Covid-19 shocks.

Fig. 1.

Building supply chain resilience over Covid-19 shocks.

Fig. 1 shows the general resilience capabilities surrounding the main COVID-19 shocks, which we identify in the content analysis. Organizational capabilities shape an interconnected whole where any stimulus influences others. In this sense, Fig. 2 connects the dots to address how capabilities foster supply chain resilience.

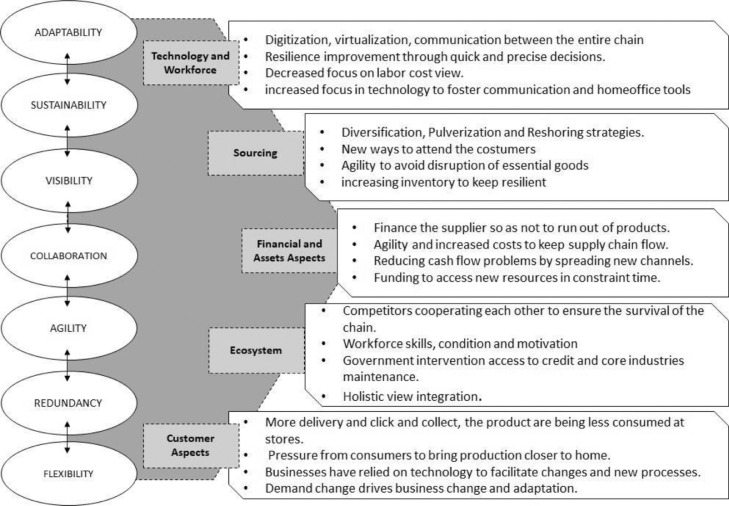

Fig. 2.

Multiple impacts and capabilities integration to overcome Covid-19 shocks.

Fig. 2 summarizes the multiple impacts on supply chain resilience. Results are identified from content analysis and reflect organizational practices. In this sense, Fig. 2 indicates pathways to business improvement and strength over Covid-19 challenges.

Due to Covid-19 challenges, firms must consider addressing their gaps holistically, understanding capabilities from a systemic perspective. These might include concerns with all members, stability, and equilibrium. The new dynamics of resilience bring real-time transparency with customers, fastened digitalization, collaboration, and agility. We understand supply as a system where firms interact with themselves, the customers, and the complex and changing environment. The five factors are how firms act and react, adapting to new supplies, and reshoring strategies, besides environmental modifications from the ecosystem and financial aspects.

The more flexible and circular supply flow occurs, the more systemic a chain is. This circularity is not limited to the reverse flux of products and information, but beyond that, it means that supply is more resilient to external shocks in a circle perspective. Each firm is an element of the system that has its internal complexity. The supply chain challenge is developing capable processes to cooperate, eliminating nodes, minimizing the supply breaks.

Our results group several emergent strategies that could help minimize demand reduction and deliberate actions and investments to strengthen the chains to recover their standard capacity after the crisis quickly.

From a systemic perspective, the five concepts of resilience capabilities are Technology and workforce, Sourcing, Customer aspects, Ecosystem, Financial and Assets Aspects. We recognize the disruption complexity and argue that there is no unique and straightforward solution to the COVID-19.

5. Discussion

A substantial part of the literature about resilience deals with the characteristics and effects of capabilities (Ex. Christopher and Peck, 2004; Sheffi and Rice Jr., 2005; Pettit et al., 2010; Christopher and Holweg, 2017). However, these capabilities may depend on other operational and macro-environmental factors to achieve their practical efficiency. This paper characterizes resilience factors that can provide managerial support or even determine capabilities linked to some variable of the system or ecosystem. These variables may or may not be favorable to recovery from disruption.

Specifically, about the unexpected impacts brought by COVID-19 pandemics, some isolated efforts bring potential factors related to resilience (e.g. Djalante et al., 2020; Reeves et al., 2020; San Lau et al., 2020). These efforts bring contributions to the literature published before COVID-19. They may be organized as a set of three resilience factors: 1) mechanisms for coordination and information sharing, 2) emphasis on local supply chains, reuse, and redundancy of essential materials, 3) reduction of inequalities and prejudices. Additionally, this paper analyzes 33 corporate reports, through which it was possible to identify five factors related to strategies to deal with the disruptions occurring due to COVID-19 pandemic. In these reports, the factor 'Customer aspects’ may support capabilities, such as adaptability, collaboration, flexibility, and visibility. The factor ‘Ecosystem’ brings elements of influence to the following capabilities: adaptability, cooperation, redundancy and a new proposal of capability that emerged from the reports, exploratorily named ‘sustainability. The factors ‘Financial and Assets Aspects’, ‘Sourcing’ and ‘Technology and workforce’ have a type of support relationship with the capabilities: adaptability, agility, and collaboration.

This paper also contributes to the enormous pool of capabilities, addressing specific abilities that are important for resilience. Besides, it explores a more complex understanding of building resilience capabilities from systemic properties, specially about recursivity and interdependence (Williams et al., 2021). The systems approach should inspire leaders' mindset to a more flexible and shared management that will strengthen them altogether.

Finally, the main contribution of system theory is considering simultaneous relations. Systems dynamics of the chain include stimulating several actions by different inputs at the same time. This requires complex and more qualified management of the supply chain. To embed this complexity, firms should have a better monitoring process to sense changes in the external environment with a more anticipated perception. It requires a broader level of analysis than the simple focus on the individual chains. The macro-environmental role is fundamental in developing resilience capabilities by governments, industrial associations, and partnerships between related and non-related supply chains. We then conclude that the ecosystem factor is the most crucial to the system approach in supply chains.

The systems coordination requires a supra-firm and supra-countries articulation, reaching new levels of circularity and flexibility. It suppresses the current management addressing of government and industry associations, for example, when car assemblers and parts manufacturers must produce respirators or when vaccines have to be distributed worldwide.

6. Conclusions

This paper brings some analyses on practitioners perception about how firms could respond to adapt themselves to the new normal. It offers some ideas about how the current facts can provide reflections for supply chain resilience. COVID-19 pandemic impacted almost all the supply chains. Traditional supply chains suffered the immediate risk of disruption. Society can have no essential goods for firms failing, demands radically break downs, or potential bottlenecks of inputs.

Our suggestions to critical stakeholders are an intense investment in people, processes, and information systems to improve the monitoring of the external environment. Also, firms that are members of essential goods supply chains should constantly simulate supply disruptions to prepare for involuntary disorders. Finally, broadening the lens from a linear view to a circular view can benefit these production systems' resilience.

As a limitation, as this is a theoretical study, it brought little depth concerning the specific characteristics of certain supply chains. Instead, the focus of this article was directed to new possibilities to configure the concept of resilience and its respective capabilities that may emerge due to the impacts imposed by the pandemic in economic, managerial, and social aspects. Thus, future studies should explore empirically, and with primary data, details in specific supply chains. We also recommend future work to pursue empirical data to test and validate the principles laid out here. One suggestion is using artificial intelligence, simulation, or even system dynamics to develop these types of inquiry.

Declaration of Competing Interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Acknowledgments

The authors acknowledge the financial support from: National Council for Scientific and Technological Development (CNPQ), Processes: 314095/ 2018-7, 407896/2018-0, and Fundação de Amparo a Pesquisa do Estado de Minas Gerais (FAPEMIG), Process: PPM-00074-17..

Editor: Prof. Syed Abdul Rehman Khan

References

- Adobor H., McMullen R.S. Supply chain resilience: a dynamic and multidimensional approach. Int. J. Logist. Manag. 2018;29(4):1451–1471. [Google Scholar]

- Ali A., Mahfouz A., Arisha A. Analyzing supply chain resilience: integrating the constructs in the concept mapping framework via a systematic literature review. Supply Chain Manag. 2017;22(1):16–39. [Google Scholar]

- Arabi Y.M., Murthy S., Webb S. COVID-19: a novel coronavirus and a novel challenge for critical care. Intensive Care Med. 2020;46(5):833–836. doi: 10.1007/s00134-020-05955-1. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Bandyopadhyay S. Coronavirus Disease 2019 (COVID-19): we shall overcome. Clean Tech. Environ. Policy. 2020;22:545–546. doi: 10.1007/s10098-020-01843-w. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Bardin L. Análise de Conteúdo. 1st. Edições 70; Lisbon: 1977. [Google Scholar]

- Christopher M., Holweg M. Supply chain 2.0 revisited: a framework for managing volatility-induced risk in the supply chain. Int. J. Phys. Distrib. Logist. Manag. 2017;47(1):2–17. doi: 10.1108/IJPDLM-09-2016-0245. [DOI] [Google Scholar]

- Bansal P., DesJardine M.R. Business sustainability: it is about time. Strat. Organ. 2014;12(1):70–78. doi: 10.1177/1476127013520265. [DOI] [Google Scholar]

- Christopher M, Peck H. Building the resilient supply chain. Int. J. Logist. Manag. 2004;15(2):1–14. [Google Scholar]

- Churchman West C. Dell Publishing Company; New York: 1968. The Systems Approach. [Google Scholar]

- Corbin J.M., Strauss A. Grounded theory research: Procedures, canons, and evaluative criteria. Qualitative Sociology. 1990;13:3–21. doi: 10.1007/BF00988593. [DOI] [Google Scholar]

- Das D., Datta A., Kumar P., et al. Building supply chain resilience in the era of COVID-19: an AHP-DEMATEL approach. Oper. Manag. Res. 2021 doi: 10.1007/s12063-021-00200-4. [DOI] [Google Scholar]

- Djalante R., Shaw R., DeWit A. Building resilience against biological hazards and pandemics: COVID-19 and its implications for the Sendai Framework. Progr. Disaster Sci. 2020;6:1–7. doi: 10.1016/j.pdisas.2020.100080. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Fiksel J. Designing resilient, sustainable systems. Environ. Sci. Technol. 2003;37(23):5330–5339. doi: 10.1021/es0344819. [DOI] [PubMed] [Google Scholar]

- Hoek Remko van. Research opportunities for a more resilient post-COVID-19 supply chain – closing the gap between research findings and industry practice". Int. J. Oper. Prod. Manag. 2020;40(4):341–355. doi: 10.1108/IJOPM-03-2020-0165. [DOI] [Google Scholar]

- Ivanov D. Predicting the impacts of epidemic outbreaks on global supply chains: A simulation-based analysis on the coronavirus outbreak (COVID-19/SARS-CoV-2) case. Transportation Research Part E: Logistics and Transportation Review. 2020;136:1–14. doi: 10.1016/j.tre.2020.101922. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Jüttner U., Maklan S. Supply chain resilience in the global financial crisis: an empirical study. Supply Chain Manag. 2011;16(4):246–259. [Google Scholar]

- Kendra J.M., Wachtendorf T. Elements of resilience after the world trade center disaster: reconstituting New York City’s emergency operations center. Disasters. 2003;27(1):37–53. doi: 10.1111/1467-7717.00218. [DOI] [PubMed] [Google Scholar]

- Williams A., Whiteman G., Kennedy S. Cross-scale systemic resilience: implications for organization studies. Bus. Soc. 2021;60(1):95–124. [Google Scholar]

- Li Y., Chen K., Collignon S., Ivanov D. Ripple effect in the supply chain network: forward and backward disruption propagation, network health and firm vulnerability. Eur. J. Oper. Res. 2021;291(3):1117–1131. doi: 10.1016/j.ejor.2020.09.053. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Madhav N, Oppenheim B, Gallivan M, Mulembakani P, Rubin E, Wolfe N. In: Disease Control Priorities. 3rd ed. Jamison DT, Gelband H, Horton S, Jha P, Laxminarayan R, Mock CN, editors. World Bank; Washington: 2018. Pandemics: risks, impacts, and mitigation pp. 315–345. , et al. 9. [Google Scholar]

- Magableh G.M. Supply chains and the COVID-19 pandemic: a comprehensive framework. Eur. Manag. Rev. 2021 doi: 10.1111/emre.12449. XXX. [DOI] [Google Scholar]

- Mollenkopf D.A., Ozanne L.K., Stolze H.J. A transformative supply chain response to COVID-19. J. Serv. Manag. 2021;32(2):190–202. doi: 10.1108/JOSM-05-2020-0143. [DOI] [Google Scholar]

- Musazzi U.M., Di Giorgio D., Minghetti P. New regulatory strategies to manage medicines shortages in Europe. Int. J. Pharm. 2020;579:1–11. doi: 10.1016/j.ijpharm.2020.119171. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Nandi S., Kaynak H. Circular economy business model practices: a multi-tiered supply chain perspective. Academy of Management Proceedings; Briarcliff Manor; 2020. p. 20291. NY 10510: Academy of Management. [Google Scholar]

- Natarajarathinam M., Capar I., Narayanan A. Managing supply chains in times of crisis: a review of literature and insights. Int. J. Phys. Distrib. Logist. Manag. 2009;39(7):535–573. doi: 10.1108/09600030910996251. [DOI] [Google Scholar]

- Nature (Editorial) COVID-19: what science advisers must do now. Nature. 2020;579(7799):319–320. doi: 10.1038/d41586-020-00772-4. Available at: https://media.nature.com/original/magazine-assets/d41586-020-00772-4/d41586-020-00772-4.pdf. [DOI] [PubMed] [Google Scholar]

- Paul S.K., Chowdhury P. A production recovery plan in manufacturing supply chains for a high-demand item during COVID-19. Int. J. Phys. Distrib. Logist. Manag. 2021;51(2):104–125. https://doi.org/10.1108/IJPDLM-04-2020-0127. [Google Scholar]

- Pettit T.J., Fiksel J., Croxton K.L. Ensuring supply chain resilience: development of a conceptual framework. J. Bus. Logist. 2010;31(1):1–21. doi: 10.1002/j.2158-1592.2010.tb00125.x. [DOI] [Google Scholar]

- Pettit T.J., Croxton K.L., Fiksel J. Ensuring supply chain resilience: development and Implementation of an assessment tool. J. Bus. Logist. 2013;34(1):46–76. [Google Scholar]

- Poberschnigg T.F.d.S., Pimenta M.L., Hilletofth P. How can cross-functional integration support the development of resilience capabilities? The case of collaboration in the automotive industry. Supply Chain Manag. 2020;25(6):789–801. doi: 10.1108/SCM-10-2019-0390. [DOI] [Google Scholar]

- Reeves M., Lang N., Carlsson-Szlezak P. Lead your business through the coronavirus crisis. Harv. Bus. Rev. 2020;27:2–7. [Google Scholar]

- Rowan N.J., Laffey J.G. Challenges and solutions for addressing critical shortage of supply chain for personal and protective equipment (PPE) arising from Coronavirus disease (COVID19) pandemic–Case study from the Republic of Ireland. Sci. Total Environ. 2020;725:1–9. doi: 10.1016/j.scitotenv.2020.138532. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Lau San, L Samari, G Moresky, T R., Casey S.E., Kachur S.P., Roberts L.F., Zard M. COVID-19 in humanitarian settings and lessons learned from past epidemics. Nat. Med. 2020;26(5):647–648. doi: 10.1038/s41591-020-0851-2. [DOI] [PubMed] [Google Scholar]

- Sarkis J. Supply chain sustainability: learning from the COVID-19 pandemic. Int. J. Oper. Prod. Manag. 2021;41(1):63–73. doi: 10.1108/IJOPM-08-2020-0568. No. [DOI] [Google Scholar]

- Sheffi Y., Jr Rice, J B. A supply chain view of the resilient enterprise. MIT Sloan Manag. Rev. 2005;47(1):41–48. [Google Scholar]

- Tang C.S. Robust strategies for mitigating supply chain disruptions. Int. J. Logist. 2006;9(1):33–45. doi: 10.1080/13675560500405584. [DOI] [Google Scholar]

- WHO – World Health Organization . Geneva: World Health Organization; 2019. Health Emergency and Disaster Risk Management Framework. Licence: CC BY-NC-SA 3.0 IGO. Available at: https://www.who.int/hac/techguidance/preparedness/health-emergency-and-disaster-risk-management-framework-eng.pdf. [Google Scholar]

- Zhang Z.(J)., Srivastava P.R., Eachempati P., Yu Y. An intelligent framework for analyzing supply chain resilience of firms in China: a hybrid multicriteria approach. Int. J. Logist. Manag. 2021 ahead-of-print No. ahead-of-print. https://doi.org/10.1108/IJLM-11-2020-0452. [Google Scholar]