Abstract

The cashew apple is a tropical pseudo fruit, with high fiber content, high nutritional value, and therapeutic compositional profile. Consuming cashew apples can help with several health-related problems, such as obesity, stomach ulcers, and gastritis. It has even demonstrated anti-tumor and anti-carcinogenic effects, and its antioxidants can help with wound-healing. Despite such benefits, the cashew apple is frequently considered as waste generated by cashew nut industries, since its commercial applications are restricted by the astringency and poor storability. This astringency is primarily due to the presence of tannins; and a lack of proper, efficient, and economical astringency reduction strategy is accountable for major waste generation. This review compiles pieces of information on the causes of astringency, as well as tannin reduction methods, such as clarification, thermal treatments, microfiltration, and fermentation. These methods aim to either just reduce tannin content or to valorize this by-product in a less-astringent better product. Both routes will eventually help with the better utilization of said organic food waste, which is critical for sustainable development.

Keywords: Cashew Apple, Astringency, By products, Microfiltration

Introduction

Cashew apples are the products of tropical/sub-tropical shrubs and trees indigenous to Brazil, which were first introduced to other parts of the world in the 16th century. They are members of the family Anacardiaceae, where over 400 species are related to the genus Anacardium. The word Anacardium itself has a Greek origin, symbolizing the “inverted heart” shape of cashew apples (Oliveira et al. 2020). The various species of cashew trees are defined by diverse characteristics, where one can be as tall as 40 m (Anacardium giganteum), and some can be as small as 80 cm (Anacardium humile) (Oliveira et al. 2020). However, the most common cashew apples come from the species Anacardium occidental L. The economically significant production of cashew apples typically begins with 8-year old trees. The best temperature range for their growth is 21–28 °C. These trees are extremely drought tolerant, allowing young trees to survive up to five months without any irrigation (Jeyavishnu et al. 2021). The “true” fruit of cashew trees is the chestnut, which is an almond wrapped in a hard shell, growing at the bottom of a carbohydrate-rich juicy “pseudo” fruit (cashew apples or peduncle) connected to the stem (Oliveira et al. 2020). The weight of a cashew apple is 6–7 times more than the nut itself. In fact, nuts make up only 10% of the overall fruit weight. With nuts being a commercially important product, their processing generates a considerable amount of waste or by-products in the form of cashew apples (Honorato et al. 2007). Cashew apples are enriched with sugars (mainly glucose and fructose) and other nutrients, including vitamins (B1, B2 and C), minerals like Ca and P, antioxidants, organic acids (acetic, citric, tartaric, oxalic, and fumaric acid), bioactive compounds like tannins and flavanols (3-o-galactoside of quercetin, Myricetin-3-o-rhamnoside, and quercetin 3-o-rhamnoside), and dietary fibers (Poornakala et al. 2020; Adou et al. 2011; Gordon et al. 2012). The consumption of a cashew apple or its juice can help with many ailments such as chronic dysentery, bone demineralization, muscle cramp, stomach ulcers, and gastritis (Preethi et al. 2019). It has anti-carcinogenic and anti-tumor properties, and its antioxidants have demonstrated anti-inflammatory and wound-healing effects (Preethi et al. 2019; da Silveira et al. 2015).

In nature, cashew apples’ varietals are present in several colors, ranging from yellow to red. The yellow ones are rich in ascorbic acid and low in tannin content, while the opposite is true for the red cashew apples. Even the carotenoids are more abundant in red cashew apples (Assunção and Mercadante 2003). Its juice has 6–8 times the ascorbic acid content of orange juice, and 12 times the ascorbic acid content of pineapple juice (USDA 2002). The physicochemical composition of the cashew apple is greatly dependent on the cultivation conditions like climate, soil type, geography, and degree of ripening (Sivagurunathan et al. 2010; Gordon et al. 2012). Therefore, variations in the composition of cashew apples in different areas are caused by changes in soil conditions, agricultural methods, and climatic parameters like temperature and humidity (Egbekun and Otiri 1999). Adou et al. (2012) analyzed the composition of yellow and red varieties of cashew apples, cultivated on the Ivory Coast. The findings supported the fact that yellow cashew apples contain more ascorbic acid than red ones. A slightly higher amount of fructose was also found in the yellow varieties. Figueroa-Valencia et al. (2019) examined red and yellow varieties of cashew apples grown in Mexico. Their data showed the difference in the phenolic contents and antioxidant activity of these varieties: total phenolic compounds in red and yellow varieties were found to be about 159.75 ± 12.91 GAE mg/100 g db and 151.9 ± 5.23 GAE mg/100 g db respectively; while the antioxidant activity was 77.65 ± 1 µmol Trolox/g db and 56.53 ± 1.2 µmol Trolox/g db respectively.

Table 1 shows the basic composition of the cashew apples, where the presence of a high proportion of ascorbic acid and carbohydrates reveals their potential as a promising energy source (ICAR 2008). Whereas, a high amount of moisture has a negative impact on the storability. Table 2 indicates the approximate chemical composition of some of the Indian varieties of cashew apples (Preethi et al. 2019).

Table 1.

A general composition of cashew apples

| S. no | Parameters | Contents |

|---|---|---|

| 1. | Moisture | 86.1 g/100 g |

| 2. | Minerals (ash) | 0.3 g/100 g |

| 3. | Fibers | 0.6 g/100 g |

| 4. | Carbohydrates | 12.6 g/100 g |

| 5. | Calcium | 0.2 mg/100 g |

| 6. | Phosphorous | 19 mg/100 g |

| 7. | Iron | 0.4 mg/100 g |

| 8. | Vitamin B1 and B2 | 0.2 mg/100 g |

| 9. | Vitamin C (ascorbic acid) | 240 mg/100 g |

| 10. | Vitamin B3 (niacin) | 0.5 mg/100 g |

Table 2.

Composition of few Indian varieties of Cashew Apples which are popular in specific areas

| S. no | Area (State Names) | Varietal Names | Colour | Total Sugars (~ %) | Vit C (~ mg/100 g) | Juice recovery (~ %) |

|---|---|---|---|---|---|---|

| 1. | Maharashtra | Dhana | Yellow | 12 | 270 | 80 |

| Vengurla-4 | Orange | 10 | 341 | 82 | ||

| Vengurla-2 | Red | 8 | 332 | 85 | ||

| 2. | Andhra Pradesh | BPP-5 | Yellow Red | 9 | 300 | 86 |

| BPP-3 | Yellow | 8 | 316 | 86 | ||

| BPP-6 | Yellow | 11 | 211 | 84 | ||

| 3. | Odisha | BPP-8 | Yellow | 10 | 275 | 86 |

| Jagannath | Yellowish green | 12 | 212 | 83 | ||

| 4. | Karnataka | Bhaskara | Reddish Yellow | 9 | 219 | 88 |

| NRCC-2 | Reddish Yellow | 11 | 195 | 77 | ||

| Chintamani-1 | Reddish Yellow | 9 | 210 | 71 | ||

| Ullal-4 | Yellow | 9 | 214 | 75 | ||

| 5. | Kerala | Priyanka | Reddish Yellow | 10 | 222 | 73 |

| Kanaka | Yellow | 10 | 338 | 85 | ||

| 6. | West Bengal | Jhargram-1 | Yellow | 9 | 196 | 72 |

| 7. | Goa | Goa-1 | Yellow | 13 | 189 | 76 |

| Vengurla-2 | Red | 8 | 332 | 85 |

Currently, around 32 nations are involved in the production of cashew apples, with Ivory Coast, India, Vietnam, and Brazil being prominent cultivators (Rabelo et al. 2009). Vietnam ranked as the world’s largest producer and exporter of processed cashew nuts in 2020 (VNA 2020), while India ranked second in terms of shelled (unprocessed) cashew nut production (NationMaster 2021). India also ranked as the second largest exporter of cashew nuts in 2019 (Tridge 2020). In the fiscal year 2019–20, India’s raw cashew production touched the mark of 742,000 tonnes, and the country is also the largest consumer of cashew kernels (The Financial Express 2020). Table 3 provides an additional data on countries with the highest production of shelled cashew nuts in 2020. While the primary goal of cashew tree cultivation is to generate revenue by marketing and exporting almond nuts, a plethora of products can be manufactured from cashew apples as well. It can be used in the production of ice cream (Dèdéhou et al. 2015), vinegar, alcoholic beverages, fermented products (Venkatesh et al. 2009; Kuila et al. 2011), carbonated beverages, marmalades, chutneys, jams, candies, pickles, and other value-added products. Being rich in ascorbic acid, cashew apple juice can also be used for improving the vitamin C profile of products. A demonstration of this was performed by Abdulraheem et al. (2013), where cashew apple was used for fortifying sorghum-based malt drink. Instead of wheat flour, dehydrated juice powder of cashew apples can be incorporated into the cookie formulations, which can improve the nutritional profile of the product, specifically the fiber content (Uchoa et al. 2009). Cashew apple juice can also be used for synthesizing oligosaccharides, by acting as a substrate for Lactic Acid Bacteria, such as Leuconostoc citreum B-742. This microbe produces dextransucrase, dextran (prebiotic carbohydrates), along with lactic acid (Rabelo et al. 2009). Silveira et al. (2012) showed the potential of cashew apple juice for producing lactic acid, by employing Lactobacillus casei B-442, and achieved yield of 95%.

Table 3.

A brief data of cashew nuts production in 2020, sourced by the official website of APEDA AgriExchange (Agricultural and Processed food products Export Development Authority)

| S. no | Country (descending order) | Quantity (∼ metric tonnes) |

|---|---|---|

| 1. | Ivory Coast (Côte d’Ivoire) | 8,48,700 |

| 2. | India | 7,72,778 |

| 3. | Vietnam | 3,48,500 |

| 4. | Burundi | 3,00,910 |

| 5. | Philippines | 2,55,910 |

| 6. | Brazil | 1,39,920 |

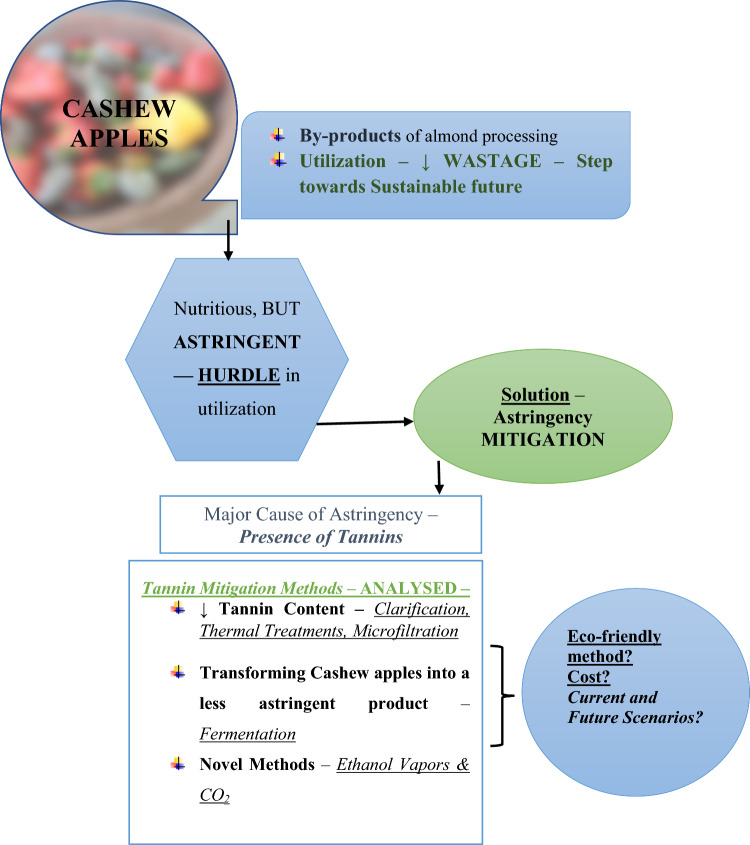

Despite such potential applications, the commercial utilization of this by-product is still restricted (Preethi et al. 2019). Around 90–95% of the cashew apple is actually wasted due to two major causes: high perishability leading to a low shelf life; and astringency (acrid taste), affecting consumer acceptability (Gawankar et al. 2018). Other barriers include the fruit’s high susceptibility towards physical damage, lack of efficient processing techniques and storage facilities, and the seasonal nature of the fruit (Bidaisee and Badrie 2001; Mishra et al. 2021). These obstacles must be overcome to limit waste production while efficiently reaping the benefits. There is a Cashew Research Station in Kerala (India), which is the first licensed unit in the country to develop technologies for the astringency reduction in cashew apples and ensuring their availability in the off-season (Mathew et al. 2015). Such dedicated technologies will eventually ensure the efficient utilization of cashew apples, while simultaneously reducing the organic food waste load on the environment (Srivastava et al. 2022). As summarized in Fig. 1, this review article will highlight a few techniques of astringency mitigation and the future scope of this area.

Fig. 1.

Outline of clarification process

Cause of astringency

As per the American Society for Testing and Materials (ASTM 1995), exposure to substances like tannins, acids, or alums causes the shrinking or puckering of the epithelium, leading to complex sensations, known as astringency. Several pieces of research have indicated that astringency is caused by the precipitation of salivary proteins, specifically proline-rich proteins (PRPs) and glycoproteins (such as mucins), by astringent compounds like polyphenols and acids (Lee et al. 2012). In the case of astringent fruits, the precipitation of salivary proteins is mainly caused by the formation of insoluble complexes between the proteins and tannins (astringent polyphenolic compounds). This further affects the normal lubrication on the mouth’s surface, increasing friction and causing the tactile sensation of ‘astringency’ (Tezotto-Uliana et al. 2018). An example of an astringent compound is a condensed tannin—proanthocyanidins—formed by the polymerization of flavan-3-ols (catechins) and flavon-2,4-diol (leucoanthocyanidins); this condensed tannin is present in the skin and pulp of cashew apples (Tezotto-Uliana et al. 2018). Cashew apples contain ∼ 0.64 mg/100 g of total hydrolyzable tannins and 0.18 mg/100 g of condensed tannins (Ebere and Emelike 2016). Hydrolyzable tannins are further categorized as gallotannins and ellagitannins, and upon their hydrolysis, gallic and ellagic acids are formed respectively; the higher the gallolylation level of such tannins, the greater their affinity to bind with salivary proteins and cause astringency (Soares et al. 2020). Apart from polyphenols (∼ 35% tannins), astringency in cashew apples can be attributed to the presence of unidentified oily compounds (∼ 3%) in the waxy layer of the skin (Talasila et al. 2012). Although the quantity of condensed tannin in the fruit decreases with maturity, these astringent compounds were found in fully ripe cashew apples as well, indicating the need for mitigation. Other than causing astringency, polyphenols can be oxidized with proteins and carbohydrates, by poly phenol oxidase (PPO) enzyme, to produce melanins, which can adversely affect both the nutritional profile and palatability of the product (Das and Arora 2017). Furthermore, tannins can also bind with proteins and minerals, causing nutritional deficiency by hindering the assimilation of such nutrients in the body (Preethi et al. 2019). Thus, tannin reduction would simultaneously improve both the palatability and nutritional value of cashew apples.

Astringency reduction methods

Use of clarifying agents

Clarification is a primary method of astringency reduction. In food processing, the process of ‘clarifying’ beverages, such as fruit and vegetable juices, aims to completely remove various kinds of coarse and suspended particles (Mishra et al. 2015). Basically, clarifying agents can attach themselves to certain particles, or cause these particles to stick to each other through charged ions, which makes the targeted particles heavier, forcing them to settle at the bottom under the influence of gravity (Benitez and Lozano 2007). Examples of clarifying agents include gelatin and bentonite, which can coagulate and precipitate tannins (Benitez and Lozano 2007). Zoecklein (1988) classified clarifying agents according to their nature: proteins (such as gelatin, casein, ising glass); polysaccharides (such as agar); earthy materials (such as kaolin clay); synthetic polymers such as poly vinyl pyrrolidone (PVPs); silicon dioxides; other chemicals, like metal chelators and enzymes such as tannase.

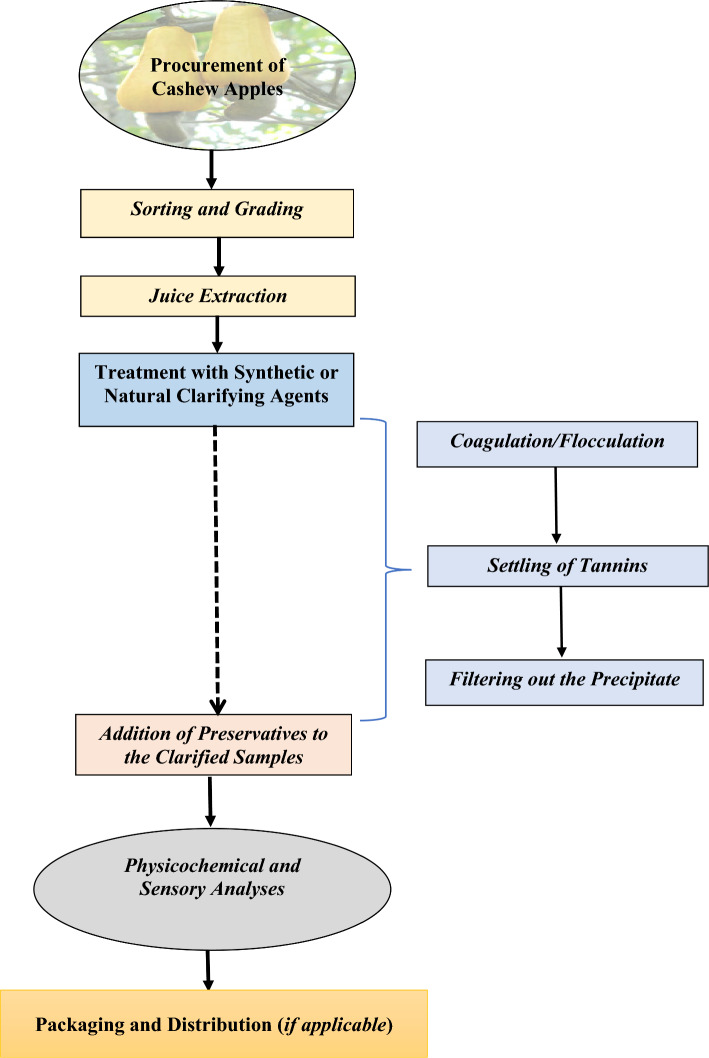

For clarifying cashew apple juice, the clarifying agents are chosen based on their ability to reduce the tannin content in the final product. Several experiments have been conducted to test various clarifying agents such as cassava starch, rice starch, gelatin, PVPs, and tannase enzyme (Talasila et al. 2012). Figure 2 depicts an outline of the steps followed in the clarification process.

Fig. 2.

Outline of clarification process

The efficiency of any clarifying agent depends on the following major factors:

The concentration of clarifying agent and its composition

Characteristics of tannin

pH and temperature conditions

Storage time

Quoc et al. (1999) investigated the feasibility of using a combination of clarifying agents. According to their findings, a combination of gelatin and XAD-16 adsorbent resins performed better than gelatin alone, and reduced around 99% of total tannin content. This improved the taste of the end product, but a loss of nutrients in terms of vitamin C was also observed. Couri et al. (2003) concluded by their experiments that the tannase enzyme is more efficient for reducing the total and hydrolyzable tannin content by 46 and 88% respectively, while gelatin is more efficient in terms of reducing polyphenol proanthocyanidin content by 32%. Jayalekshmy and John (2004) comparatively analyzed the efficiencies of different clarifying agents, such as cassava starch, PVP, rice starch, and gelatin powder. They concluded that cassava starch is more effective and has greater commercial potential. Talasila et al. (2012) used 2 g/l of sago starch, which decreased the tannin content by 42.85%, and improved the visual clarity by up to 94%. It was reported that gelatin and cassava starch are quite ineffective at lower concentrations due to a lack of a sufficient number of attraction sites, but the opposite is true with sago. In addition, integrating the same methodology with sterile filtration improved the juice clarity by up to 96% and reduced tannins by 41.75%. Dèdéhou et al. (2015) demonstrated the differences in the tannin reduction behaviour of rice starch and cassava starch. They found that at 6.2 ml/l dosage, cassava starch decreased the tannin content by 34.2% in 300 min, with a visual clarity of 93.75%; whereas rice starch, at 10 ml/l dosage, reduced the tannins by 42% in 193 min, with 94.8% clarity. Despite these differences, they both showed potential as low-cost clarifying agents. According to Das and Arora (2017), qualitatively, juice recovered after cassava starch, PVP, and rice starch-based treatments, is almost similar, but the juice recovery rate is slightly higher in the case of cassava starch. They came to the conclusion that the structure of starch plays a key role in the flocculation of tannins. Prommajak et al. (2018) attempted to analyze an optimal tannin reduction condition by using gelatin as a clarifying agent. These conditions were found to be the use of 0.67% (w/v) gelatin for 15 min. Dagadkhair et al. (2018) investigated the efficiency of 3 cost-friendly and food-grade materials as clarifying agents: defatted soybean meal, dried potato powder, and pearl millet (bajra) flour. The results showed that the protein-rich soybean meal was the most effective at reducing tannins (∼ 34% reduction), with a better juice recovery rate. Ugwuoke et al. (2020) used powder of Moringa oleifera (drumstick) seeds, which reduced the tannin content in cashew apple juice by ∼80%, with the optimum concentration of the seed powder being 10 g/250 ml of the juice. Abdullah et al. (2020) attempted to optimize the efficiency of the tannase enzyme in reducing tannins in the blended pulp of cashew apples. Using Response Surface Methodology (RSM), the optimum process conditions were found to be the use of 0.079% tannase enzyme for 85 min (incubation), at 46 °C temperature. On the other hand, Artificial Neural Network (ANN) model proposed the optimum conditions to be 0.085% tannase for 89 min, at 39 °C. Using the ANN model resulted in a maximum reduction of 68.85%. Recently Danait-Nabar and Singhal (2022) published the first report on modifying laccase enzyme by acid anhydrides (2-octenyl succinic anhydrides) and phthalic acid. These modified enzymes were then comparatively analyzed for cashew apple juice clarification, and a notable polyphenol and condensed tannin reduction was reported with acid anhydride-based modification.

Thermal methods

Other than clarification, thermal treatments are one of the most effective methods for reducing astringency. However, the loss of volatile and heat-labile compounds is a significant barrier to their applications. Das and Arora (2017) explained that one of the reasons for techniques like steaming to work is that the majority of the tannins are concentrated on the skin of the cashew apple’s peel. When steam enters, it partially degrades these compounds, resulting in astringency reduction.

Ebere and Emelike (2016) compared different cashew apple juice processing techniques: hot water treatment (blended cashew apple was immersed in hot water for 20 min); pressure treatment (wrapped in cellophane, and treated in a pressure cooker for 5 min, at 10–15 lb pressure); pasteurization (in a water bath for 15 min, at 80 °C); gelatin treatment (for 2 h); salt treatment (for 30 min); and carbonate treatment (with sodium carbonate, for 6 h). After these treatments, the juice was extracted and analyzed for different parameters. The hot water treatment resulted in a maximum tannin reduction of 96%, leading to a significant astringency reduction and an improvement in sensory attributes. The highest efficiency of hot water treatment was followed by salt, pressure, and pasteurization treatment, while carbonate treatment was the least effective in terms of tannin reduction. Das et al. (2020) compared the effectiveness of thermal and non-thermal processing methods: hot water, steaming, and microwave treatments as thermal methods; and use of bio-coagulants, in the form of dried okra pod and drumstick seed powder, as the non-thermal method. Okra pod powder proved to be the best in terms of reducing tannin, while retaining nutritional and other sensory attributes. They concluded that the optimum conditions obtained by experimentations can be used as a guideline for industrial applications.

Microfiltration

Microfiltration is a physical membrane technology, that employs membranes with pore sizes ranging from 0.1 to 10 μm (Prommajak et al. 2020). Microfiltration, like all membrane processes, is a pressure-driven technique, which is beneficial for retaining both, the sensory characteristics and heat-sensitive compounds (such as ascorbic acid or vitamin C).

Abreu et al. (2005) worked on cashew apple juice and found that 0.1 and 0.2 μm cross-filtration, at 30 °C, produced the best results for retaining ascorbic acid and eliminating phenolic compounds. Cianci et al. (2005) used a 3 step-protocol—treating pulp with enzymes (tannase/cellulase); followed by microfiltration of the juice; and reverse osmosis for concentrating the clarified juice. The results were encouraging and it was concluded that the microfiltration membrane successfully removed the tannins. Here, the enzymatic treatment facilitated the fractionation of insoluble polysaccharides and reduced the viscosity of juice (improving the efficiency of the microfiltration process). de Andrade et al. (2018) mentioned that microfiltration can reduce up to 97% of the tannin content. Abdullah et al. (2022) integrated the microfiltration and centrifugation techniques, and used Artificial Neural Network algorithm for finding the optimum process parameters. This combination of non-thermal techniques not only reduced tannin content by 88%, but also preserved 87% of ascorbic acid content, resulting in a turbid-free and highly nutritious product.

Fermentation

Fermentation is a metabolic process in which organic substrates (generally, carbohydrates, such as glucose and lactose) are broken down by microbial action into organic acids, ethanol, and CO2. This is usually an anaerobic process, however, some fermentation processes, such as the Crabtree effect, can occur aerobically as well. For centuries, food fermentation has been used to preserve food, improve its organoleptic properties, and boost the nutritional profile. For the same reason, cashew apples or their juice can be transformed into a functional product through microbial action. This technique not only reduces the astringency but also valorizes the cashew apples.

Pereira et al. (2011) fermented cashew apple juice with a probiotic lactic acid bacteria (LAB)—L. casei NRRL B-442. The optimum fermentation conditions were found to be 30 °C temperature, 6.4 initial pH, and a fermentation period of 16 h, with inoculation level being 7.48 log CFU/ml. The fermented product was also monitored during refrigerated storage (4 °C) period of 42 days, and growth in the microbial count was observed during this period. This study proved the efficiency of cashew apple juice as a healthy probiotic beverage. Medeiros et al. (2017) utilized cashew apple bagasse for a large-scale fermentation with Candida guilliermondii CCT-3544, to produce ethanol and xylitol. The maximum production of both of these products was found to be after 48 h of fermentation. Kaprasob et al. (2018) investigated the changes in physicochemical properties and astringency of cashew apple juice after fermentation with the Lactobacillus plantarum TISTR-543 strain. The fermentation decreased the astringency-related metabolites in terms of hydrolyzable tannins over a 72h fermentation period; however, there was an increase in terms of condensed tannins. There was also an increase in desirable volatile compounds and phytochemicals related to the flavour, and a notable amount of antioxidants were also found to be present.

Using ethanol vapors and CO2

Treatment with ethanol vapors

Although this method is quite uncommon, a study by Tezotto-Uliana et al. (2018) demonstrated its efficiency. The enzyme alcohol dehydrogenase is naturally present in cells, and when ethanol vapors reach there via absorption through the fruit’s surface, the enzyme catalyzes the reverse reaction to convert ethanol into acetaldehyde. Furthermore, these acetaldehyde molecules will polymerize or condense with tannins, rendering them incapable of reacting with salivary proteins, and thus, eliminating astringency. Their study showed that applying ethanol vapors at 3.5 mL/kg of fruit for 12h efficiently reduced the astringency. Higher ethanol doses may cause fermentation and depigmentation, therefore identifying the optimal dosage and exposure time combination is critical to preserve the post-harvest quality of the cashew apples. It was also concluded that the tannin content in the final product is primarily determined by the dosage of ethanol vapors, rather than the exposure time. This technique is simple, low-cost, and efficient, indicating the need for further experimentations.

Treatment with CO2

A study by El-Wahab et al. (2017) conveyed that CO2 treatment is potentially more effective than ethrel and calcium carbide treatments in terms of astringency reduction. This experiment was carried out on “Costata” permission fruits to observe the effects of different ripening methods on the astringency of the end product, where CO2 treatment led to the maximum tannin reduction, followed by ethrel and calcium carbide-based ripening. The mechanism behind CO2 treatment, as reviewed by Monteiro et al. (2017), is the accumulation of acetaldehyde in tissues. The anaerobic condition, caused by the presence of CO2, induces the production of ethanol and acetaldehyde, and acetaldehyde then polymerizes with tannins, reducing the astringency effect. According to El-Wahab et al. (2017), exposing fruits to a low-oxygen environment with 95% CO2 causes oxidative stress and an accumulation of Reactive Oxygen Species (ROS), which increases the activity of ROS scavenging antioxidant enzymes, such as superoxide dismutase, catalase, peroxidase, etc. Furthermore, after the CO2 treatment, the total phenolic content also gets significantly reduced. Cruz and Tipayno (1999) worked with 40–80% CO2, which significantly lowered astringency. They found that an optimum exposure time of 48 h was sufficient to retain the firmness, vitamin C content, and titrable acidity of cashew apples, while also improving shelf life and minimizing weight loss.

There are some limitations with CO2 treatment as well, such as the need for a sealed chamber with controlled temperature and CO2 levels in order to maintain an anaerobic environment. Novel packaging techniques, modified atmosphere packaging, and vacuum packaging can assist in dealing with these issues. Monteiro et al. (2017) reported the potential of vacuum packaging with polyethylene-polyamide packs for reducing astringency in permission while simultaneously maintaining firmness. This technique hasn't been thoroughly researched with cashew apples, but the potential for astringency reduction is clearly demonstrated by the experiments with permission fruit, indicating a promising future in this area.

Current scenario and future prospects

While discussing the current scenario, it is critical to consider environmental sustainability, which means we must valorize industrial by-products (like cashew apples) in an eco-friendly manner. Because the majority of astringency reduction techniques rely on the clarification process, the choice of clarifying agent is a key factor. Researchers are focusing on optimizing bio-coagulants, such as rice starch, cassava starch, etc., for the same purpose. Table 4 summarizes the various techniques discussed in this paper. On the one hand, techniques such as clarification, thermal treatments, microfiltration, and ethanol/CO2 treatments are aimed to mitigate astringency from the cashew apples or their juice by lowering the tannin content, while technique like fermentation actually aims to transform the cashew apples into a better and less-astringent product. For example, Adeoye and Lateef (2021) used fungal fermentation (by a strain of Aspergillus niger) to produce citric acid from cashew apple juice. The resulting citric acid was also used as a coagulant in the production of soy cheese, and was found to be reasonably acceptable. It is to be noted that having an effective tannin reduction method is still important, as the combination of these methods with fermentation opens up a wide range of possibilities for valorizing cashew apples, which will reduce the waste load on the environment.

Table 4.

Brief summary of various astringency reduction methods

| S.no | Methods | Efficiency | Eco-friendliness | Commercial applicability | Drawbacks | Examples |

|---|---|---|---|---|---|---|

| 1. | Clarification |

Medium–High ( > 90%) (Depends on clarification factors) |

Depends on the choice of clarifying agent | Best agents can be expensive (example—PVPs and tannase) |

Possibility of after taste in some cases Can be time consuming |

Eco-friendly—Food grade materials like Cassava Starch, Rice Starch, and enzymes Non-eco-friendly—PVPs |

| 2. | Thermal treatments | High | Yes | High potential | Loss of heat labile and volatile compounds | Steaming, blanching, pateurization |

| 3. | Fermentation | High | Yes | High potential |

Tannin reduction is accompanied with the transformation of cashew apple juice In some cases, combined with clarification |

Probiotics, Fermented beverages |

| 4. | Microfiltration | Medium – High (upto 80–90%) | Can lead to membrane disposal issues | Cost of changing membranes limits the applications |

Membrane clogging Can be time consuming |

Cross-flow microfiltration Microfiltration + Tannase Microfiltration + Centrifugation |

| 5. |

CO2 treatment and ethanol treatment |

Medium | Need more experimentations | |||

Aside from finding efficient bio-coagulants, scientists are also working on optimizing other methods to reduce the tannin content. A recent study used ion-exchange resins for employing the adsorption mechanism to clarify cashew apple juice (Vidal et al. 2021). Tanex, a microporous basic resin, was used in this experiment, and the resin’s affinity for condensed tannins was confirmed. They proposed that the fixed-bed process with ion-exchange resins should be explored as an alternative technique for producing clarified cashew apple juice. Dao et al. (2022) used a thermal method to reduce the phenolic content of cashew apples while valorizing them as jellies. This work had three main processing stages: blanching (thermal treatment), osmotic, and drying. Thermal treatment reduced the total tannin content, and further production of dried jelly explored the way of adding value to cashew apples. Similar to Abdullah et al. (2022) and Abdullah et al. (2020), Aniama (2021) also used artificial intelligence (AI) algorithms to find an optimum method of clarification using gelatin. The use of such algorithms will assist in the development of state-of-the-art technologies. For increased efficiency and optimization, a combination of technologies, like microfiltration + clarifying agents, should also be explored.

The need for tannin reduction has been discussed in terms of cashew apple valorization, but even these bioactive compounds must not be considered as ‘waste’. We must consider the value of every alleged waste material/compound in order to achieve sustainable development. Patra et al. (2021) successfully investigated optimum conditions for the microwave-assisted extraction of bioactive compounds from cashew apple bagasse, indicating that these compounds can be further used for medicinal purposes. Wang et al. (2022) reported that natural tannins extracted from fruits like cashew apples can even act as anti-SARS-CoV-2 compounds. Therefore, future studies can work on successfully separating tannins from cashew apples, in order to utilize both of them to their true potential.

Conclusion

It has been reported by FAO that over 1.3 billion tonnes of food waste are generated annually. Cashew apple is one such industrial food waste that is left over in large quantities after the processing of almond nuts. Utilizing such nutritious by-products is critical for reducing the environmental impact of organic food waste and moving towards sustainable development. Where the astringent nature of cashew apples is a critical problem, astringency mitigation techniques are available as a remedy. Few of the methods are covered in this paper, but using bio-coagulants is going to be a game-changer considering the cost, eco-friendliness, and post-processing quality of the product. In addition, the use of artificial intelligence is the future of determining the best process parameters, which will enable the process to be environmental-friendly and suitable for industrial applications.

Acknowledgements

Authors would like to thanks Gautam Buddha University (GBU), Greater Noida Uttar Pradesh to provide internet facility and study material in library. Thanks to all faculty member for supporting and encouraging us. The author thanks the faculties of the Department of Food Processing and Technology, School of Vocational Studies and Applied Sciences, Gautam Buddha University (SoVSAS, GBU), located in Greater Noida (Uttar Pradesh), for constant support and motivation throughout this work.

Declarations

Conflict of interest

The author(s) declares no conflict of interest.

Footnotes

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

References

- Abdullah S, Pradhan RC, Aflah M, Mishra S. Efficiency of tannase enzyme for degradation of tannin from cashew apple juice: modelling and optimization of process using artificial neural network and response surface methodology. J Food Process Eng. 2020;43:e13499. doi: 10.1111/jfpe.13499. [DOI] [Google Scholar]

- Abdullah S, Karmakar S, Pradhan RC, Mishra S. Pressure-driven crossflow microfiltration coupled with centrifugation for tannin reduction and clarification of cashew apple juice: modeling of permeate flux decline and optimization of process parameters. J Food Process Preserv. 2022;46:e16497. doi: 10.1111/jfpp.16497. [DOI] [Google Scholar]

- Abdulraheem MO, Aberuagba F, Okafor JO, Otaru AJ. Physiochemical properties of malted sorghum as material for mucamalt using cashew apple juice extract as vitamin C fortifier. J Appl Chem. 2013;4(2):67–78. [Google Scholar]

- Abreu F, Perez AM, Dornier M, Reynes M. Application of crossflow microfiltration in the production of clarified cashew juice by means of mineral membranes. Fruits. 2005;60(1):33–40. doi: 10.1051/fruits:2005010. [DOI] [Google Scholar]

- Adeoye AO, Lateef A. Biotechnological valorization of cashew apple juice for the production of citric acid by a local strain of aspergillus niger LCFS 5. J Genet Eng Biotechnol. 2021;19:137. doi: 10.1186/s43141-021-00232-0. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Adou M, Kouassi DA, Tetchi FA, Amani NG. Phenolic profile of cashew apple juice (Anacardium occidentale L.) from Yamoussoukro and Korhogo (Côte d‟Ivoire) J Appl Biosci. 2011;49:3331–3338. [Google Scholar]

- Adou M, Tetchi FA, Gbané M, Kouassi KN, Amani NG. Physicochemical characterization of cashew apple juice (Anacardium occidentale, L.) from Yamoussoukro (Ivory Coast) Innov Rom Food Biotechnol. 2012;11:32–43. [Google Scholar]

- Aniama SO. The use of artificial intelligence in improving the preservation and quality of cashew apple juice drinks for national development. Int J Biol Pharm Sci Archive. 2021;1(2):01–08. doi: 10.30574/ijbpsa.2021.1.2.0010. [DOI] [Google Scholar]

- ASTM (1995) Standard definitions of terms relating to sensory evaluation of materials and products. In: Annual Book of ASTM Standards, ASTM International, USA

- Assunção RB, Mercadante AZ. Carotenoids and ascorbic acid from cashew apple (Anacardium occidentale L.): variety and geographic effects. Food Chem. 2003;81(4):495–502. doi: 10.1016/s0308-8146(02)00477-6. [DOI] [Google Scholar]

- Benitez EI, Lozano JE. Effect of gelatin on apple juice turbidity. Latin Am Appl Res. 2007;37:261–266. [Google Scholar]

- Bidaisee G, Badrie N. Osmotic dehydration of cashew apple (Anacardium occidentale L.): quality evaluation of candied cashew apples. Int J Food Sci Technology. 2001;36:71–78. doi: 10.1111/j.1365-2621.2001.00422.x. [DOI] [Google Scholar]

- Cianci FC, Silva LFM, Cabral LMC, Matta VM. Clarification and concentration of cashew apple juice by membrane processes. Ciênc Tecnol Aliment. 2005;25(3):579–583. doi: 10.1590/S0101-20612005000300030. [DOI] [Google Scholar]

- Couri S, Ferreira de Menezes L, Saavedra Pinto GA, Souza MLM, Pereira Freitas S. Comparison of the cashew apple (Anacardium occidentale L.) juice clarification with tannase and gelatin. Bol do Centro de Pesquisa e Processamento de Aliment. 2003;20(1):41–54. [Google Scholar]

- Cruz D, Tipayno AC. Removal of astringency from cashew (Anacardium occidentale L.) receptacle by carbon dioxide application. Philippine J Crop Sci. 1999;24:52. [Google Scholar]

- da Silveira Vasconcelos M, Gomes-Rochette NF, de Oliveira ML, Nunes-Pinheiro DC, Tomé AR, Maia de Sousa FY, Pinheiro FG, Moura CF, Miranda MR, Mota EF, de Melo DF. Anti-inflammatory and wound healing potential of cashew apple juice (Anacardium occidentale L.) in mice. Exp Biol Med (Maywood) 2015;240(12):1648–1655. doi: 10.1177/1535370215576299. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Dagadkhair RA, Janani P, Preethi P, Raichurkar SJ, Athawale GH. Removal of tannins from cashew apple juice by using low cost food grade materials. J Pharmacogn Phytochem. 2018;7(6):220–223. doi: 10.13140/RG.2.2.28735.74406. [DOI] [Google Scholar]

- Dao TP, Vu DN, Nguyen DV, Pham VT, Tran TYN. Study of jelly drying cashew apples (Anacardium occidentale L.) processing. Food Sci Nutr. 2022;10:363–373. doi: 10.1002/fsn3.2565. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Danait-Nabar S, Singhal RS. Chemical modification of laccase using phthalic and 2-octenyl succinic anhydrides: enzyme characterization, stability, and its potential for clarification of cashew apple juice. Process Biochem. 2022;122:181–195. doi: 10.1016/j.procbio.2022.08.033. [DOI] [Google Scholar]

- Das I, Arora A. Post-harvest processing technology for cashew apple—a review. J Food Eng. 2017;194:87–98. doi: 10.1016/j.jfoodeng.2016.09.01. [DOI] [Google Scholar]

- Das I, Sasmal S, Arora A. Effect of thermal and non-thermal processing on astringency reduction and nutrient retention in cashew apple fruit and its juice. J Food Sci Technol. 2020;58(6):2337–2348. doi: 10.1007/s13197-020-04744-4. [DOI] [PMC free article] [PubMed] [Google Scholar]

- de Andrade MIR, de Sousa ACR, de Abreu FAP, Ximenes SF, dos Santos Garruti D. Changes in Cashew Apple juice flavor after tangential microfiltration process. Ann Nutr Food Sci. 2018;2(4):1029. [Google Scholar]

- Dèdéhou ESCA, Dossou J, Ahohuendo B, Saïdou A, Ahanchédé A, Soumanou MM. Optimization of cashew (Anacardium occidentale L.) apple juice’s clarification process by using cassava and rice starch. J Appl Biosci. 2015;95:8989–9002. doi: 10.4314/jab.v95i1.9. [DOI] [Google Scholar]

- Ebere C, Emelike N. Effect of treatments on the tannin content and quality assesment of cashew apple juice and the kernel. Eur J Food Sci Technol. 2016;4(3):25–36. [Google Scholar]

- Egbekun MK, Otiri AO. Changes in ascorbic acid contents in oranges and cashew apples with maturity. Ecol Food Nutr. 1999;38(3):275–284. doi: 10.1080/03670244.1999.9991582. [DOI] [Google Scholar]

- El-Wahab SMA, Kamel HM, El-Rahman A, El-Hafeez A, Osman MT. Comparison of different ripening methods for removing astringency in “Costata” Persimmon Fruits. Middle East J Agric Res. 2017;6(2):569–583. [Google Scholar]

- Figueroa-Valencia M, Rosales-Martinez P, Santoyo-Tepole F, Ramos-Monroy OA, García-Ochoa F, Hernández-Botello MT, López-Cortez MS. Antioxidant properties of red and yellow varieties of cashew apple, nut and husk (Anacardium occidentale, L.) harvested in Mexico. J Antioxid Activity. 2019;1(4):19–32. doi: 10.14302/issn.2471-2140.jaa-19-2747. [DOI] [Google Scholar]

- Gordon A, Friedrich M, da Matta VM, Moura CFH, Marx F. Changes in phenolic composition, ascorbic acid, and antioxidant capacity in cashew apple (Anacardium occidentale L.) during ripening. Fruits. 2012;67:267–276. doi: 10.1051/fruits/2012023. [DOI] [Google Scholar]

- Gawankar MS, Salvi BR, Pawar CD, Khanvilkar MH, Salvi SP, Dalvi NV, Malshe KV, Kadam DS, Saitwal YS, Haldankar PM (2018) Technology Development for Cashew Apple Processing in Konkan region—a review Advanced Agric Res & Technol J II (1):40–47. https://www.researchgate.net/publication/328096084_Technology_Development_For_Cashew_Apple_Processing_In_Konkan_Region-A_Review

- Honorato TL, Rabelo MC, Gonçalves LRB, Pinto GAS, Rodrigues S. Fermentation of cashew apple juice to produce high added value products. World J Microbiol Biotechnol. 2007;23:1409–1415. doi: 10.1007/s11274-007-9381-z. [DOI] [Google Scholar]

- ICAR, National Research Centre for Cashew (Indian Council of Agricultural Research) (2008) Nutritive value of cashew https://cashew.icar.gov.in/wp-content/uploads/2017/04/Nutritive%20Value%20of%20Cashew.pdfRetrieved Apr 5 2023

- Jayalekshmy VG, John PS. Sago - a natural product for cashew apple juice clarification. J Trop Agric. 2004;42:67–68. [Google Scholar]

- Jeyavishnu K, Thulasidharan D, Shereen MF, Arumugam A. Increased revenue with high value-added products from Cashew Apple (Anacardium occidentale L.)—Addressing Global Challenges. Food Bioprocess Technol. 2021;14(6):985–1012. doi: 10.1007/s11947-021-02623-0. [DOI] [Google Scholar]

- Kaprasob R, Kerdchoechuen O, Laohakunjit N, Thumthanaruk B, Shetty K. Changes in physico-chemical, astringency, volatile compounds and antioxidant activity of fresh and concentrated cashew apple juice fermented with Lactobacillus plantarum. J Food Sci Technol. 2018;55(10):3979–3990. doi: 10.1007/s13197-018-3323-7. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Kuila A, Singh A, Mukhopadhyay M, Banerjee R. Process optimization for aqueous extraction of reducing sugar from cashew apple bagasse: a potential, low-cost substrate. Food Sci Technol. 2011;44:62–66. [Google Scholar]

- Lee CA, Ismail B, Vickers ZM. The role of salivary proteins in the mechanism of astringency. J Food Sci. 2012;77(4):C381–C387. doi: 10.1111/j.1750-3841.2012.02644.x. [DOI] [PubMed] [Google Scholar]

- Mathew J, Sobhana A, Mini C. Development of Technologies for the economic utilization of cashew Apple and its commercial Exploitation. Acta Hortic. 2015;1080:353–360. doi: 10.17660/ActaHortic.2015.1080.47. [DOI] [Google Scholar]

- Medeiros LL, Silva FLH, Santos SFM, Madruga MS, de Melo DJN, de Conrado LS. Bioconversion of hydrolyzed cashew peduncle bagasse for ethanol and xylitol production. Rev Bras Engagríc Ambient. 2017;21(7):488–492. doi: 10.1590/1807-1929/agriambi.v21n7p488-492. [DOI] [Google Scholar]

- Mishra A, Devi M, Jha P. J Food Sci Technology; New Delhi. 2015;52(7):4423–4431. doi: 10.1007/s13197-014-1521-5. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Mishra A, Upadhyay A, Jaiswal P, Sharma N. Effect of different drying method on the chemical and microstructural properties of Loquat slices. J Food process and preservation. 2021;45(3):e15105. doi: 10.1111/jfpp.15105. [DOI] [Google Scholar]

- Monteiro MF, Aguila JSD, Pessoa CDO, Kluge RA (2017) Vacuum Packaging is efficient to remove astringency and to maintain the firmness of “Giombo” Persimmon. Revista Brasileira de Fruticultura 39(spe). 10.1590/0100-29452017129

- NationMaster (2021) Cashew Nuts Production.https://www.nationmaster.com/nmx/ranking/cashew-nuts-production Accessed Dec 25 2022

- Oliveira NN, Mothé CG, Mothé MG, de Oliveira LG. Cashew nut and cashew apple: a scientific and technological monitoring worldwide review. J Food Sci Technol. 2020;57(1):12–21. doi: 10.1007/s13197-019-04051-7. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Patra A, Abdullah S, Pradhan RC. Microwave-assisted extraction of bioactive compounds from cashew apple (Anacardium occidenatale L.) bagasse: modeling and optimization of the process using response surface methodology. J Food Meas Charact. 2021;15:4781–4793. doi: 10.1007/s11694-021-01042-1. [DOI] [Google Scholar]

- Pereira AL, Maciel T, Rodrigues S. Probiotic beverage from cashew apple juice fermented with Lactobacillus casei. Food Res Int. 2011;44:1276–1283. doi: 10.1016/j.foodres.2010.11.035. [DOI] [Google Scholar]

- Poornakala SJ, Indumathi VM, Shanthi K. Value addition in cashew apple: a review. Int J Chem Stud. 2020;8(6):819–825. doi: 10.22271/chemi.2020.v8.i6l.10871. [DOI] [Google Scholar]

- Preethi P, Rajkumar AD, Shamsudheen M, Nayak MG. Prospects of Cashew Apple — A Compilation Report, Technical Bulletin No. 2/2019. ICAR Directorate of Cashew Research, Puttur; 2019. p. 28. [Google Scholar]

- Prommajak T, Leksawasdi N, Rattanapanone N. Optimizing tannin precipitation in Cashew Apple Juice. J Nat Sci. 2018;17(1):13–23. doi: 10.12982/CMUJNS.2018.0002. [DOI] [Google Scholar]

- Prommajak T, Leksawasdi N, Rattanapanone N. Tannins in Fruit Juices and their removal. CMU J Nat Sci. 2020;19(1):76–90. doi: 10.12982/CMUJNS.2020.0006. [DOI] [Google Scholar]

- Quoc AL, Fustier P, Couture R, Castaigne F, Makhlouf J. Effect of various clarification agents on tannin removal, chemical composition, and stability of cashew juice. Sci Aliments. 1999;18(4):375391. [Google Scholar]

- Rabelo MC, Fontes CPML, Rodrigues S. Enzyme synthesis of oligosaccharides using cashew apple juice as substrate. Bioresour Technol. 2009;100:5574–5580. doi: 10.1016/j.biortech.2009.06.060. [DOI] [PubMed] [Google Scholar]

- Silveira MS, Fontes CPML, Guilherme AA, Fernandes FAN, Rodrigues S. Cashew Apple juice as substrate for lactic acid production. Food Bioprocess Technol. 2012;5(3):947–953. doi: 10.1007/s11947-010-0382-9. [DOI] [Google Scholar]

- Sivagurunathan P, Sivasankari S, Muthukkaruppan SM. Characterisation of cashew apple (Anacardium occidentale L.) fruits collected from Ariyalur District. J Biosci Res. 2010;1(2):101–107. [Google Scholar]

- Soares S, Brandão E, Guerreiro C, Soares S, Mateus N, de Freitas V. Tannins in food: insights into the molecular perception of astringency and bitter taste. Molecules. 2020;25(11):2590. doi: 10.3390/molecules25112590. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Srivastava A, Mishra A. Food waste valorization for handling environmental problems: a review. Environ Sustain. 2022;5:401–421. doi: 10.1007/s42398-022-00245-6. [DOI] [Google Scholar]

- Talasila U, Vechalapu RR, Shaik KB. Clarification, preservation, and shelf life evaluation of cashew apple juice. Food Sci Biotechnol. 2012;21:709–714. doi: 10.1007/s10068-012-0092-3. [DOI] [Google Scholar]

- Tezotto-Uliana JV, de Paula JT, Tessmer MA, Kluge RA. Ethanol vapor is efficient for reduction of astringency compounds in cashew apple. Postharvest Biol Technol. 2018;145:117–124. doi: 10.1016/j.postharvbio.2018.07. [DOI] [Google Scholar]

- The Financial Express (2020) Indian cashew crop during 2020-21 will be shorter by approximately 50,000 tonne. The Financial Express. https://www.financialexpress.com/market/commodities/indian-cashew-crop-during-2020-21-will-be-shorter-by-approximately-50000-tonne/2000289/

- Tridge (2020) Kernel Cashew Nut global export and top exporting countries. Tridge https://www.tridge.com/intelligences/cashew-nut/export

- Uchoa AMA, da Costa JMC, Maia GA, Meira TR, Sousa PHM, Brasil IM. Formulation and physicochemical and sensorial evaluation of biscuit-type cookies supplemented with Fruit powders. Plant Foods Hum Nutr. 2009;64(2):153–159. doi: 10.1007/s11130-009-0118-z. [DOI] [PubMed] [Google Scholar]

- Ugwuoke CU, Ugwuoke FG, Omeje BA, Eze GE, Monwuba NS, Ifeanyieze FO, Ukonze JA. Effect of Moringa oleifera seed powder on the clarity colloidal particles and nutritional contents of Cashew Apple Juice. Scientifica. 2020 doi: 10.1155/2020/4380407. [DOI] [PMC free article] [PubMed] [Google Scholar]

- USDA (2002) United States Department of Agriculture. Nutrition Database for Standard Reference Washington

- Venkatesh M, Pushpalatha PB, Sheela KB, Girija D. Microbial pectinase from tropical fruit wastes. J Trop Agric. 2009;47(1–2):67–69. [Google Scholar]

- Vidal RHL, Galiotto LS, Pereira CG. Study of adsorption isotherms and equilibrium for removal of tannins from cashew apple juice with ion exchange resin. J Chem Eng Catal. 2021;1:1–16. [Google Scholar]

- VNA (2020) Vietnam remains world’s largest producer, exporter of cashew nuts | Business | Vietnam+ (VietnamPlus). VietnamPlus. https://en.vietnamplus.vn/vietnam-remains-worlds-largest-producer-exporter-of-cashewnuts/191047.vnp

- Wang SC, Chou IW, Hung MC. Natural tannins as anti-SARS-CoV-2 compounds. Int J Biol Sci. 2022;18(12):4669–4676. doi: 10.7150/ijbs.74676. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Zoecklein B (1988) Bentonite fining of juice and wine. Department of Horticulture. Virginia Polytechnic Institute and State University Publication