Abstract

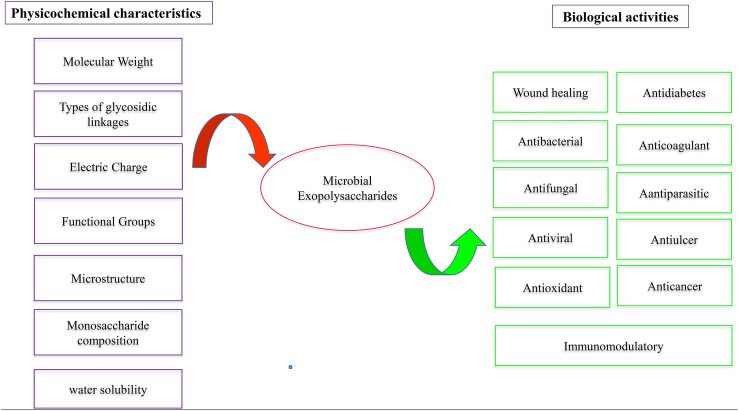

Microbial exopolysaccharides (EPSs) are valuable extracellular macromolecules secreted as capsules or slime layers. Various microorganisms, including bacteria, yeasts, fungi, and algae have been studied for their ability to produce EPSs. Microbial EPSs exist as homopolysaccharides or heteropolysaccharides with various properties such as different monosaccharide compositions, structural conformation, molecular weight, and functional groups. They are cost-effective alternatives to plant and animal-derived polysaccharides because the microbial cells produced them in large quantities by biotechnological processes using low-cost substrates such as industrial wastes in a short time. Microbial EPSs are safe, biodegradable, and compatible polymers. They have extensive bioactivities, including antibacterial, antifungal, antiviral, antioxidant, antitumor, antidiabetic, antiulcer, anticoagulant, antiaging, immunomodulatory, wound healing, and cholesterol-lowering activities. Microbial EPSs owing to biological activities, special biochemical structures, and attractive physicochemical properties find plenty of potential applications in various industries. The enhancement of the production of EPSs and improving their properties can be provided by genetic engineering methods. The current review aims to provide a comprehensive examination of the therapeutic activities of microbial EPSs in infectious diseases and metabolic disorders, with a focus on the mechanisms involved. Also, the effect of the physicochemical characteristics of EPSs on these bioactivities was discussed to reveal the structure-activity relationship.

Keywords: Exopolysaccharides, Bacteria, Bioactivities, Physicochemical properties

Introduction

Microorganisms have considerable biosynthetic potentials to produce various bioactive substances with unique chemical scaffolds and functionalities. These compounds displayed pharmaceutical potential. For example, they suppress the growth of infectious bacteria and fungi, mitigate multiplication of cancerous cells, scavenge free radicals, reduce inflammation, and accelerate wound healing. These bioactive metabolites can be peptides, lipopeptides, polypeptides, lactones, fatty acids, polyketides, isocoumarins, terpenoids or exopolysaccharides (Ramezanzadeh et al. 2021; Salimi et al. 2022; Almasi et al. 2021; Salimi and Mohammadipanah 2021).

Polysaccharides can be produced by various natural sources like plants, animals and microorganisms (Li et al. 2022). Exopolysaccharides (EPS) are extracellular carbohydrate polymers which are synthesized by different microbial cells, including bacteria, yeasts, fungi, and microalgae during their growth and metabolism. EPSs can be secreted from microbial cells or attached to their cells (Arayes et al. 2023). EPSs are composed carbohydrates (main part) and some non-carbohydrate substituents like acetate, pyruvate, succinate, and phosphate. Various monosaccharides such as fructose, glucose, arabinose, mannose, rhamnose, and xylose can be present in EPS structure (Al-Nabulsi et al. 2022). EPSs provide microenvironments, which protect bacteria at extreme conditions, help bacterial colonization and pathogenicity, and facilitate genes and metabolites exchange within bacterial communities (Arayes et al. 2023). Microbial EPSs can be produced in a short time in high quantity under controlled conditions. Therefore, they can be cost-effective substituents to the plant and algal derived polysaccharides. Also, production cost can be reduced by using cheaper substrates, improving product yield through optimizing fermentation conditions and downstream processing, or developing higher yielding strains (Freitas et al. 2011).

According to the literature, microbial-derived EPSs have desirable biological functions and high-value applications as well as they have no toxic and side effects on body tissue cells. These biopolymers are biocompatible and biodegradable (Li et al. 2023). EPSs with favorable thermal stability and water retention ability have proper candidate for biomedical applications (Andrew and Jayaraman 2022). Due to the toxicity of chemical therapies or emerging resistance to current drugs(Al-Nabulsi et al. 2022), EPSs have the potential of replacing chemical drugs and are considered medically, pharmaceutically impotent carbohydrates (Ji et al. 2022; Zhou and Huang 2023). In addition to these, EPSs are being used for drug delivery, and scaffold synthesis in tissue engineering (Andrew and Jayaraman 2022). Also, the microbial EPSs have potential applications in food, feed, packaging, chemical, textile, agriculture, and cosmetic industries (Ates 2015; Tang and Huang 2022; Zhou and Huang 2023). Since great efforts have been made in recent years on characterization and studying the bioactivities of microbial EPSs, reviewing the recent articles helps better understanding between their properties and biomedical activities. In this review, we attempt to review research on bioactivities of microbial EPSs, including antibacterial, antifungal, antiviral, antioxidant, antiulcer, immunostimulant, or immunosuppressive activities. Furthermore, the impactful physicochemical properties of EPSs on their various biological activities will be reviewed.

Classification and properties of microbial EPSs

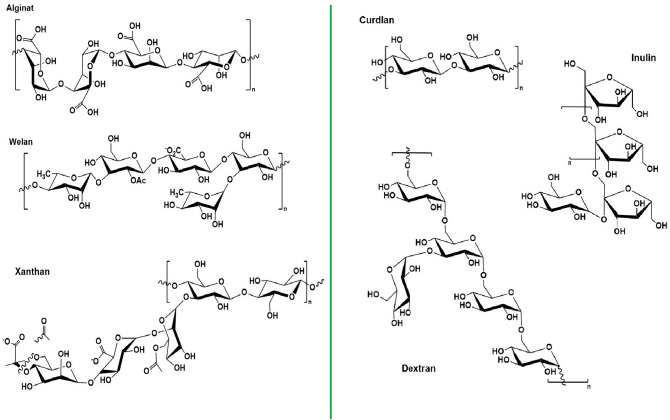

EPSs produced by microbial cells have diverse chemical composition, and they can be categorized into two groups of homopolysaccharides (HoPS) and heteropolysaccharides (HePS) (Fig. 1).

Fig. 1.

Chemical structure of some heteropolysaccharides (left) homopolysaccharides (right)

Homopolysaccharides

Homopolysaccharides (HoPSs) are contained of repeating one kind of monosaccharide with the molecular mass of ~ 107 Da (Panchal et al. 2022). They can be further classified into α-d-glucans, β-d-glucans, and fructans (Panchal et al. 2022; Bajpai et al. 2016; Nwodo et al. 2012). Examples of bacterial HoPSs with the main characteristics of them are summarized in Table 1.

Table 1.

Examples of microbial HoPSs and HePSs (Abarquero et al. 2022; (Jurášková et al. 2022; Moradi and Kalanpour 2019; Sun and Zhang 2021)

| EPS | Composition | Maine linkage bond | Branched linkage bond |

|---|---|---|---|

| HoPS | |||

| α-d-glucans | |||

| Dextran | d-glucopyranose | α-(1→6) | α-(1→2), α-(1→3), α-(1→4) |

| Mutan | d-glucopyranose | α-(1→3) | α-(1→6) |

| Alternan | d-glucopyranosyl | α-(1→3), α-(1→6) | – |

| Reuteran | d-glucopyranose | α-(1→4), α-(1→6) | α-(1→4)/α-(1→6) |

| β-d-glucans | |||

| Curdlan | d-glucopyranose | β-(1→3) | – |

| Cellulose | d-glucopyranose | β-(1→4) | – |

| Salecan | d-glucopyranosyl | β-(1→3) | – |

| Fructans | |||

| Levan | d-fructofuranose | β-(2→6) | β-(2→1) |

| Inulin | d-fructan | β-(2→1) | – |

| Fructooligosaccharide | d-fructosyl | β-(2→1) | – |

| HePS | |||

| Gellan | [4)-l-rhamnopyranose-α-(1→3)-d-glucopyranose-β-(1→4)-d-glucopyranuronic acid-β-(1→4)-d-glucopyranose*-β-(1→]n | – | |

| Welan | l-rhamnopyranose or l-mannopyranose linked through α-(1→3) bond to the glucose moiety indicated with an asterisk. | ||

| Diutan | l-rhamnopyranose-α-(1→4)-l-rhamnopyranose linked through α-(1→3) bond to the glucose moiety indicated with an asterisk. | ||

| Kefiran | [6)-d-glucopyranose-β-(1→6(2))-d-galactopyranose*-β-(1→4)-d-galactopyranose-α- (1→3)-d-galactopyranose-β-(1→4)-d-glucopyranose-β-(1→]n | d-glucopyranose linked through β-(1→2(6)) bond to the galactose moiety indicated with an asterisk. | |

| Xanthan | [4)-d-glucopyranose-β-(1→4)-d-glucopyranose*-β-(1→]n |

d-mannopyranose-β-(1→4)-d-glucopyranuronic acid-β-(1→2)-d-mannopyranose. The last mannopyranose linked through α-(1→3) bond to the glucose moiety indicated with an asterisk. |

|

| Hyaluronic acid | [4)-d-glucuronic acid-β-(1→3)-d-N-acetylglucosamine-β-(1→]n | – | |

| Alginate | [4)-d-manopyranuronic acid-β-(1→4)-d-manopyranuronic acid-β-(1→4)-d-manopyranuronic acid-β-(1→4)-l-guluronic acid-β-(1→4)-d-manopyranuronic acid-β-(1→]n | – | |

Dextran and mutan belong to α-d-glucans. In contrary to dextran, mutan is a water-insoluble HoPS. Dextran (Fig. 1) is produced by various genera such as Leuconostoc, Lactobacillus, Limosilactobacillus, Weissella, Streptococcus, Lentilactobacillus, and Latilactobacillus. Streptococcus downei, Streptococcus mutans, Streptococcus salivarius, and Limosilactobacillus reuteri are examples of bacteria producing mutan. Alternan and reuteran are two other α-d-glucans, which are soluble in water. Alternan can be produced by Leuconostoc mesenteroides, L. citreum, and Streptococcus salivarius. The generation of reuteran was also reported by Limosilactobacillus reuteri (Jurášková et al. 2022). Curdlan, cellulose, and salecan are unbranched β-d-glucans, which among them, salecan is water-soluble (Guo et al. 2017; Sun and Zhang 2021). Curdlan (Fig. 1) is produced by Agrobacterium sp. ATCC 31,749 (Ruffing and Chen 2012), Cellulomonas flavigena KU (Kenyon and Buller 2002), Alcaligenes faecalis, Rhizobium meliloti, and Agrobacterium radiobacter (Prete et al. 2021). Acetobacter, Pseudomonas, Agrobacterium, and Rhizobium genera have ability to generate cellulose (Vu et al. 2009). Agrobacterium sp. ZX09 can produce salecan as a HoPS (Sun and Zhang 2021). Levan, inulin, and fructooligosaccharide are members of fructan that all of them have solubility in water (Jurášková et al. 2022). Limosilactobacillus reuteri, L. mesenteroides, Streptococcus mutans, Bacillus subtilis, and Streptococcus salivarius are levan producer strains (Jurášková et al. 2022; Prete et al. 2021). Streptococcus mutans, Limosilactobacillus reuteri, Leuconostoc citreum, and Lactobacillus johnsonii have ability to generate inulin (Jurášková et al. 2022). Fructooligosaccharide is also detected in the culture of Lactobacillus reuteri 121 (Sun and Zhang 2021).

Heteropolysaccharides

Heteropolysaccharides (HePSs) are complex because of two or more kinds of monosaccharides in their structures. Pentose, hexose, N-acetylated monosaccharide, and non-carbohydrate units can be present in branched or unbranched HePSs (Jurášková et al. 2022; Abarquero et al. 2022). The molecular mass of HePSs is within 104 to 106 Da (Panchal et al. 2022). The structure of some HePSs is presented in Table 1. The backbone of gellan, wellan, and diutan are the same, and it constructs from l-rhamnopyranose, d-glucopyranose, and d-glucopyranuronic acid subunits. Gellan (Fig. 1) is linear, however, wellan, and diutan have different branched structures (Sun and Zhang 2021). All of them are water-soluble (Nadzir et al. 2021; González et al. 2019; Li et al. 2020), and their production reported by Sphingomonas and Pseudomonas strains (Sun and Zhang 2021). Kefiran is another branched HePS, which is made from d-glucopyranose and d-galactopyranose units. Kefiran is a water-soluble polysaccharide, and several species of Lactobacillus such as L. kefir, L. parakefir, L. kefiranofaciens, L. kefirgranum, and L. delbrueckii subsp. bulgaricus have the ability to generate it (Moradi and Kalanpour 2019). The composition of the xanthan backbone is similar to cellulose, while its branch structure makes from d-mannopyranose and d-glucopyranuronic acid. Xanthan (Fig. 1) is water-soluble EPS (Nadzir et al. 2021), which can be produced by Xanthomonas campestris and Sphingomonas paucimobilis (Jurášková et al. 2022). Hyaluronic acid (Fig. 1) with the composition of d-glucuronic acid and d-N-acetylglucosamine is linear water-soluble HePS (Sun and Zhang 2021; Nadzir et al. 2021). Streptococcus equi, S. zooepidemicus, S. pyogenes, Pasteurella multocida, and Cryptococcus neoformans are natural bacteria that produce hyaluronic acid (Sze et al. 2016). Alginate is linear HePS with solubility in water (S et al. 2020). Its subunits consist of d-manopyranuronic acid and l-guluronic acid (Sun and Zhang 2021). Pseudomonas aeruginosa and Azotobacter vinelandii are main producer of alginate (Nadzir et al. 2021).

Antibacterial activities

Microbial EPSs showed considerable inhibiting effects on adherence, colonization, or growth of various Gram-positive (e.g. Listeria monocytogenes, Micrococcus luteus, Bacillus subtilis, Bacillus cereus and Staphylococcus aureus, Staphylococcus petrasii, Enterococcus faecalis) and Gram-negative (e.g. Salmonella enteritidis, Escherichia coli, Heliobacter pylori, Acinetobacter baumannii, Proteus mirabilis, Enterobacter cloacae, Pseudomonas aeruginosa, Shigella flexneri) bacterial pathogens. These bacteriostatic or bactericidal EPSs are produced by bacteria belonging to Lactobacillus, Lactococcus, Streptococcus, Bifidobacterium, Bacillus, Weissella, Leuconostoc, Limosilactobacillus genera (Table 2). Some of these microbial EPSs showed broad-spectrum activities while others act specifically (Angelin and Kavitha 2020).

Table 2.

Antibacterial activities of microbial EPSs

| EPS producing species | Concentration | Constituents | Assay | Antibacterial activity | Other activities | References |

|---|---|---|---|---|---|---|

| Molecular Weight (kDa) | ||||||

| Lactobacillus plantarum EPLB | 0.064–1 mg/ml | NR | Microdilution | Antibacterial activity against S.aureus, S. typhimurium, P. aeruginosa, and L. monocytogenes | Antioxidant and antibiofilm activities | Mahdhi et al. (2017) |

| 36 | ||||||

| Lactobacillus kefiranofaciens DN1 | 1 and 2.5% w/v | Man, Ara, Glc, Gal, Rha | Growth curve analysis | Bactericidal effect on L.monocytogenes, and S. enteritidis | NR | Jeong et al. (2017) |

| NR | ||||||

| Bacillus licheniformis Dahb1 | 25–100 µg/ml | NR | Agar diffusion and microdilution tests | Antibacterial activities against P.aeruginosa, P. vulgaris, B. subtilis, and B. pumilus | Antioxidant, antibiofilm, larvicidal activities | Abinaya et al. (2018) |

| NR | ||||||

| Weissella cibaria 27 | NR | Glc | Agar spot test | Antibacterial activities against E. coli, B. subtilis, and S. aureus | NR | Yu et al. (2018) |

| 12,000 | ||||||

| Leuconostoc pseudomesenteroides YB-2 | 2–3 mg/ml | Glc | Agar spot test and microdilution | Antibacterial activities against E. coli and S. aureus | Rheological property | Ye et al. (2019) |

| 767 | ||||||

| Lactobacillus gasseri FR4 | 10 mg/mL | Glu, Man, Gal, Rha, Fruc | Agar well diffusion | Antibacterial activities against E. coli, L. monocytogenes, S. aureus, and E. faecalis | Antioxidant and anti-biofilm activities | Rani et al. (2018) |

| 186 | ||||||

| Lactobacillus plantarum YW32 | 0.2–5 mg/ml | Man, Fruc, Gal, Glc | Crystal violet assay | Antibiofilm activity against E.coli, S. flexneri, S. aureus, and S. typhimurium | Antioxidant and antitumor activities | Wang et al. (2015b) |

| 103 | ||||||

| Lactococcus lactis F-mou strain | 100–300 mg/mL | Glc, Gal, Fruc | Agar diffusion method | Antibacterial activity against S. aureus, P. aeruginosa, E. coli, L. monocytogenes, B. cereus, P. mirabilis, A. baumannii, E. cloacae | Inhibitory effect on Candida albicans, antioxidant and emulsifying activities | Nehal et al. (2019) |

| NR | ||||||

| Lactobacillus sp. Ca6 | 10 mg/ml | Glc | Agar-well diffusion assay | Antibacterial activity against S. enterica, and M. luteus | Antioxidant and wound healing activities | Trabelsi et al. (2017) |

| NR | ||||||

| Lactobacillus johnsonii FI9785 | NR | Glc, Gal | Crystal violet assay | Competitive inhibition of pathogens through surface hydrophobicity and auto-aggregation | NR | Dertli et al. (2015) |

| NR | ||||||

| Lactobacillus plantarum C70 | 5 mg/ml | Ara, Man, Glu, Gal | Growth curve analysis | Antibacterial activity against E. coli, S. aureus, S.typhimurium, L.monocytogenes | Rheological properties, antioxidant, antidiabetic, and anticancer activities | Ayyash et al. (2020b) |

| 380 | ||||||

| Lacticaseibacillus paracasei M7 | 0.025–0.4 mg/ml | Man, Glc Gal | Crystal violet assay | Antibiofilm effect on E. faecalis, B.subtilis, B. cereus, S. aureus, Klebsiella sp., P. aeruginosa | Hypocholesterolemic, emulsifier, and antioxidant activities | Bhat and Bajaj (2019) |

| NR | ||||||

| Lactobacillus fermentum LB-69 | 0.1–1.0 mg/mL | Man, Glc | Crystal violet assay | Antibacterial activity against L. monocytogenes, E. fecalis, B. cereus, P. aeruginosa | Prebiotic activity | Sarikaya et al. (2017) |

| NR | ||||||

| Lactobacillus rhamnosus strains | 5 mg/ml | NR | Agar well diffusion | Antibacterial effects on E. coli and S. typhimurium | Antibiofilm, flocculating, emulsifying, antioxidant, and antitumor activities | Rajoka et al. (2018) |

| NR | ||||||

| Streptococcus S.thermophilus GST | 10 mg/ml | Glu, Gal/NR | Agar diffusion test | Antibacterial activity against S.typhimurium, E.coli, S. aureus | Antioxidant activity | Zhang et al. (2016) |

| NR | ||||||

| Lactococcus garvieaeC47 | 5 mg/ml | Glc, Ara, Xyl | Growth curve analysis | Antibacterial activity against S. aureus, S. typhimurium, L. monocytogenes, E. coli | Rheological properties | Ayyash et al. (2020a) |

| 7300 | ||||||

| Lactobacillus delbureckii subsp. Bulgaricus | NR | Rib, Xyl, Ara, Rha, Fruc, Glc, Man, and Gal | Agar Well Diffusion method | B. subtilis, S. aureus | Antioxidant and immunomodulatory activities | Adebayo-Tayo and Fashogbon (2020) |

| NR | ||||||

| Lacticaseibacillus paracasei AS20(1) | 1.5–100 mg/ml | Glc/ Fruc/NR | Spot-on-lawn antimicrobial assay, MIC and MBC | L. monocytogenes, Y. enterocolitica and B. cereus | Antibiofilm, Anticancer | Amini et al. (2022a, b) |

| Enterococcus durans DU1 | 0.195–12.5 mg mL − 1 | Glc, Fruc/NR | Crystal violet assay | Y. enterocolitica, S. aureus, and B. cereus | NR | Soliemani et al. (2022) |

| Pichia sp. DU2 | 0.195–12.5 mg mL − 1 | Glc, Fruc/NR | Crystal violet assay | Y. enterocolitica and B. cereus | Emulsifying activity | Salimi and Imanparast (2022) |

NR Not reported

Antibacterial mechanisms of microbial EPSs may be related to disrupting the structure of bacterial cell membrane, cell wall, or respiratory chain, affecting cell division machinery (Hu et al. 2019; Hasheminya and Dehghannya 2020; Wu et al. 2010). Microbial EPSs cannot permeate to the other cells so probably impose their antibacterial activity by combining with oligopeptides or acyl-homoserine lactone in Gram-positive and Gram-negative bacteria, respectively. These compounds are biofilm-related signal molecules. EPSs via this mechanism disrupt cell communication and suppress formation of biofilm (Spanò et al. 2016). Therefore, microbial EPSs could be effective therapeutic molecules in ameliorating biofilm-related chronic and recurrent infections (Fig. 2).

Fig. 2.

Antibacterial mechanisms of microbial EPSs

Also, microbial EPSs via protecting their producing cells from a strong immunological response of the host (Paynich et al. 2017) or through acting as prebiotics enhance adherence and subsequent the colonization of microflora on host cells. So, they can competitively inhibit colonization of bacterial pathogens. Also, microbial EPSs can reduce the autoaggregation of bacterial pathogens and make bacterial pathogens more susceptible to immunological response inside the host (Dertli et al., 2015). EPS-producing probiotics can attach to microbial pathogens through their EPS. This coaggregation accelerates their antimicrobial functions through blocking the receptors or channels on the outer membrane of the Gram-negative pathogenic bacteria (Abdalla et al. 2021).

Microbial EPSs have various functional groups, including hydroxyl, phosphate, and carbonyl groups. It has been suggested that these functional groups are involved in the interaction of microbial EPSs with the cell membranes or cell walls of bacterial pathogens. So, they play a critical role in exerting antimicrobial activities (Fig. 3) (Riaz Rajoka et al. 2020).

Fig. 4.

Anticancer mode actions of microbial EPSs

Antifungal activities

Some microbial EPSs, especially negatively charged ones, show antifungal activity. The negative charge provides better electrostatic interactions with fungi. L. rhamnosus GG produces EPS, which inhibited the hyphal formation of Candida in in vitro cell culture. Furthermore, this EPS in a gut model, decreases the hyphal elongation of C. albicans. The dextran of Weissella confuse has the ability to significantly inhibit the biofilm formation of C. albicans SC5314. Moreover, EPS produced by Lactobacillus strains shows antifungal activity (Abdalla et al. 2021). The EPS of Gloeocapsa sp. and Nostoc entophytum prevents the growth of C. albicans (Najdenski et al. 2013). According to the report of Abinaya et al. (2018), Bacillus licheniformis Dahb1 EPS showed antibiofilm activity toward C. albicans.

Antiviral effects

Microbial EPSs can exert their antiviral effects locally or systemically. In local mode action, the EPSs directly interact with either the viruses or the receptors on the host cell. So, block viral adsorption while in systemic mode actions microbial EPSs stimulate the innate and adaptive immunity or suppress viral replication enzymes (Saadat et al. 2019).

Some microbial EPSs, mainly sulfated polysaccharides like dextran exhibited both inhibitory mode actions (Bell and Lu, 2010; Lin and Huang 2022). L. sakei MN1-derived dextran inhibited infectious pancreatic necrosis virus and infectious hematopoietic necrosis virus. The in vivo treatment of trout with the EPS, decreased their mortality rate of these viruses and considerably enhanced the expression of interferon (IFN)-1 (Vázquez et al., 2017). In the following, the antiviral activities of some microbial exopolysaccharides are represented.

Treated cells with EPS 26a-derived Lactobacillus spp. completely suppressed viral adsorption and the formation of infectious human adenovirus C serotype 5 particles as well as their release (Biliavska et al. 2019).

Kim et al. (2018), demonstrated that L. plantarum LRCC5310 EPS hindered the attachment of the rotavirus and subsequently reduced diarrhea duration, epithelial lesions, rotavirus replication in the intestine, and the recovery time of young mice. Also, L. delbrueckii TUA4408L-derived HePS reduced viral replication and regulated inflammatory response consequently enhanced the resistance of porcine intestinal epitheliocytes to rotavirus infection. This EPS considerably increased the expression of the antiviral (IFN)-β, MxA, and RNase L (Kanmani et al. 2018a; Mizuno et al. 2020), also reported that the EPS of S. thermophilus ST538 activated TLR3 in porcine intestinal epitheliocytes subsequently modulated the innate antiviral immune response.

Microbial EPS also can suppress respiratory viruses. Kanmani et al. (2018b), demonstrated that oral administration of L. delbrueckii OLL1073R-1 HePS considerably reduced influenza virus titer and increased IgA and IgG1. Furthermore, it activated natural killer cells. Also, Lactobacillus plantarum SN35N-derived EPS suppressed the influenza A virus and Vesivirus Feline calicivirus (Noda et al. 2021). Also, EPSs from Haloarcula hispanica ATCC33960 suppressed binding spike protein of SARS-CoV-2 to Vero E6 and bronchial epithelial BEAS-2B cells (Xu et al. 2022b).

Microbial EPSs also can be considered promising anti-herpes virus polymers. Since, Bacillus licheniformis-derived EPS-1 impaired Herpes Simplex Virus type 2 (HSV-2) replication in human peripheral blood mononuclear cells (PBMC) through induction of IL-12, IFN-g, IFN-a, TNF-a, and IL-18 (Arena et al. 2006). Also, EPS-2 produced by Geobacillus thermodenitrificans hindered HSV-2 replication in PBMC through the induction of cytokine production (Arena et al. 2009; El Awady et al. 2019), reported antiviral activities of Streptomyces hirsutus NRC2018-derived EPS on HSV1, Hepatitis A virus, and Coxsackie B-4. Also, Reichert et al. (2017), demonstrated that EPS of A. platensis hindered koi herpesvirus replication in common carp brain cells. Finally, Arthrospira platensis-derived EPS exhibited inhibitory activities on vaccinia and ectromelia viruses (Radonić et al. 2011), and EPS from Weissella paramesenteroides MN2C2 exhibited antiviral activity against Coxsackie virus (Amer et al. 2021).

Anticancer activities

Microbial EPSs have displayed antiproliferative properties against various cancers, including colon, breast, pancreatic, leukemia, and cervical cancers (Jurášková et al. 2022). The chemical characteristics of microbial EPSs like molecular composition, molecular weight, the presence of uronic acid and sulfate groups as well as β-type glycosidic bonds are influential factors in their anticancer activities (Ismail and Nampoothiri 2013; (Wang et al. 2014a; Hou et al. 2021). Microbial EPSs probably through the following mechanisms exert their anticancer activities: act as antioxidants, bind to genotoxic carcinogens, induce apoptosis, and improve immunity (Fig. 4) (Koller et al. 2008).

L. plantarum and L. rhamnosus-derived EPSs can bind to various mutagens, like 2-nitrofluorene, heterocyclic amines, and 4-nitroquinoline-N-oxide reduce their mutagenic potential (Tsuda et al. 2008; Thapa and Zhang 2009).

Studies have shown that microbial EPSs can be effective against various colon cancer cell lines, including HT-29, Caco-2, and CT26. Antiproliferative effects of EPSs produced by L. casei 01 (Liu et al. 2011a) and L. plantarum 70,810 (Wang et al. 2014a), L. rhamnosus ATCC 9595 (Kim et al. 2006), L. brevis and L. delbrueckii subsp. bulgaricus on the HT-29 malignant cell line was reported.

EPSs with antioxidant activity may suppress cancers. It has been shown that the anti-HT-29 activity of L. plantarum 70,810 EPS can be related to its antioxidant activity and it was increased after acetylation modification (Wang et al. 2014a). Also, L. rhamnosus SHA111 EPS with ability to scavenge hydroxyl and superoxide radicals displayed antitumor activity against the Caco-2 cell line (Rajoka et al. 2018).

Also, microbial EPSs through apoptosis induction can exert their anticancer activities. Apoptosis can occur through caspase-dependent intrinsic and extrinsic pathways. In the intrinsic pathway caspase-3, caspase-9, BCl-2, and BAX are expressed and expression of caspase-8 and caspase-10 are done in the extrinsic pathway. Caspase-3 activation is indicating that cell shrinkage, nuclear fragmentation, and chromatin condensation have been occurred in cancerous cells without affecting surrounding healthy cells or tissues (Angelin and Kavitha 2020).

For example, Lactobacillus kefiri EPS the upregulated the expression of Cytochrome-c, Bax, Bad, Caspase-3, -8, and -9 in HT-29 cancerous cells (Rajoka et al. 2019). Also, Lactobacillus strain SB27-derived EPS increased activation of caspase-3 and subsequently induced apoptosis and arrested cell cycle. Moreover, Lactobacillus casei SB27 EPSs (LW1 and LW2) significantly inhibited the proliferation of HT-29 colorectal cancer cells through upregulation of Bad, Bax, Caspase-3, and -8 gene expressions (Di et al. 2017).

Kim et al. (2010), reported the Lactobacillus acidophilus 606 EPS exert its antitumourigenic activity against HT-29 colon cancer cells by activating autophagic cell death which was promoted through inducing of Beclin-1, Grp78, Bcl-2, and Bak.

Tukenmez et al. (2019), showed that EPSs of four Lactobacillus spp. were capable to induce apoptosis in HT-29 via increasing the expression of Bax, Caspase-3 and -9 while decreasing Bcl-2 and Survivin. Among these EPSs, EPS of L. delbrueckii ssp. bulgaricus B3 which contained the highest amount of mannose and the lowest amount of glucose showed the highest apoptosis induction.

Anticancer activity of microbial EPSs on other colon cancer cell lines like Caco-2 and CT26 have also been reported. For example, Lactobacillus fermentum YL-11 EPS suppressed the proliferation of HT-29 and Caco-2 colon cancer cells (Wei et al. 2019). El-Debb et al. (2018), reported that the HePS produced by L. acidophilus 20,079 displayed anti-Caco-2 activity via apoptotic and NF-κB inflammatory pathways. Also, The Lactobacillus acidophilus 20,079-derived EPS suppressed cell proliferation of the CaCo-2 cell line (El-Deeb et al. 2018).

Zhou et al. (2017), demonstrated the inhibitory activity of Lactobacillus plantarum NCU116-derived EPS on the proliferation and survival of CT26 cell line (a murine colorectal carcinoma cell line) through induction of apoptosis.

Inhibitory activity of microbial EPSs on other cancerous cells is also reported. For example, L. plantarum and L. helveticus EPSs suppressed breast cancer and gastric cancer cell lines, respectively (Ismail and Nampoothiri 2013; Li et al. 2014). Pediococcus pentosaceus M41 EPS displayed inhibitory activity against Caco-2 and MCF-7 cells (Ayyash et al. 2020c). Lactococcus lactis subsp. lactis EPS was found to affect the production of inflammatory cytokines and considerably increased TNF-α and inducible nitric oxide (NO) synthase release in MCF-7 cells in comparison with control cells (Wu et al. 2016).

Microbial EPS also can exert their anticancer activity through stimulating cell-mediated immune responses, like tumoricidal activity of natural killer cells, the proliferation of t-lymphocyte, and phagocytic capacity of mononuclear cells. In this regard, it has been reported that L. lactis subsp. lactis EPS induced the apoptosis of MCF17 cells along with nuclear condensation and cell shrinkage, enhancing intracellular calcium levels and production of inflammatory cytokine (Wu et al. 2016).

Lactobacillus plantarum RJF4 EPS showed inhibitory activity against the MiaPaCa2-pancreatic cancer cell line. Its antiproliferative activity can be due to its antioxidant activities (Dilna et al. 2015; Chen et al. 2015), demonstrated that Pseudoaltermonas sp. S-5 EPS suppressed the proliferation of human leukemia K562 cells.

Sungur et al., reported the inhibitory effect of L. gasseri strains-derived EPSs on proliferation of cervical cancerous cells. These EPSs induced apoptosis, upregulated expression of Bax and Caspase-3 in Hela cells (Sungur et al. 2017).

EPS of Bacillus mycoides BS4 displayed antitumor activity on human hepatocellular carcinoma and colorectal adenocarcinoma cells. This microbial EPS demonstrated low cytotoxicity against the normal cell baby hamster kidneys (Farag et al. 2020). Therefore, microbial EPSs can be considered promising natural polymers to develop antitumor drugs with lower side effects than current chemical drugs.

Antioxidant activities

Microbial exopolysaccharides have displayed significant antioxidative activities (Table 3). Their subunits, monosaccharides, are considered reducing sugars because they possess aldoses and ketoses or they can interconvert into either form. The antioxidant potential of microbial EPS can be related to their various functional groups, including hydroxyl, carboxyl, sulfate, sulfhydryl, acetyl, carbonyl, sulfhydryl, thioether and amide groups. These functional groups donate electron pairs, lose a proton, or facilitate the metal binding process (Fig. 3). Subsequently, convert free radicals to stable substances. For instance, the phenomenal scavenging ability of chitosan is due to its hydroxyl and amino groups. Also, it has been stated that negatively charged functional groups by generating an acidic environment could facilitate EPS hydrolysis. Therefore, more exposed hemiacetal hydroxyl groups enhance antioxidant activity (Andrew and Jayaraman 2020; Lin and Huang 2022; Li and Huang 2022; Zhou et al. 2022).

Table 3.

Antioxidant activities of microbial EPSs

| EPS producing strain | Monosaccharide constituent/ Functional groups | MW | Concentration | References |

|---|---|---|---|---|

| Bacillus coagulans RK-02 |

Glc, Man, Gal, glucosamine, and Fruc CH, OH, CO |

30KDa | 50–500 µg/ml | Kodali et al. (2011; Kodali and Sen (2008) |

| Weissella cibaria GA44 |

Glc and Rha OH, CH, CO, COOH |

280KDa | 0.5–4 mg/ml | Adesulu-Dahunsi et al. (2018) |

| Lactobacillus plantarum C88 |

Gal and Glc OH, CH, RCOOR’, C–OH, C–O–C |

1150KDa | 0.5–4 mg/ml | Zhang et al. (2013) |

| Lactobacillusplantarum YML009 | NR/NR | NR | 5–40 mg/ml | Seo et al. (2015) |

| Lactobacillus gasseri FR4 |

Man, Gal, Rha Fruc OH, CH2, NH, COO−, C–O, C–O–C |

186 KDa | 4 mg/ml | Rani et al. (2018) |

|

Weissella cibaria SJ14 [EPS-1 and EPS-3] |

Man, Glc, Gal, Ara, Xyl, and Rha. Gal, Man, Glc, and Ara OH, CH, COOH, CO |

7.12 × 104 Da 3.01 × 104 Da | 0.1–8 mg/ml | Zhu et al. (2018) |

| Lactobacillus plantarum BR2 |

Glc and Man OH, CH,CO |

2380 kDa | 2–10 mg/mL | Sasikumar et al. (2017) |

| Lactobacillus paracasei ssp. paracasei NTU 101 and Lp Lactobacillus plantarum 102 |

Ara, Glc, Man, Fruc, Mal NR |

NR | 10 mg/ml | Liu et al. (2011b) |

|

Lactobacillus helveticus MB2-1 EPS-1, EPS-2 and EPS-3 |

Gal, Glc and Man OH, CH,CO, NH |

2 × 105 Da | 0.125–4 mg/mL | Li et al. (2014) |

| Lactobacillus plantarum YW11 |

Glc and Gal OH, CH, CO, NH, C–O–C |

1.1 × 105 Da | a high dose of EPS (50 mg/kg per day) | Wang et al. (2015a) |

| Lactobacillus plantarum RJF4 |

Glc and Man OH, CH, CO |

NR | 2–10 mg/mL | Dilna et al. (2015) |

| Lactobacillus plantarum SKT109 | NR/NR | NR | 5 mg/ml | Wang et al. (2018a) |

| Pediococcus acidilactici NCDC 252 |

Glc OH, CO, CH, COOH |

89.1 KDa | 0.1–2 mg/mL | Kumar et al. (2020) |

| Lactobacillus sanfranciscensis |

Glc OH, CH, CO, R-CH2–CH3 |

NR | 0.1–1 mg/ml | Zhang et al. (2019) |

| Lactobacillus plantarum YW32 |

Man, Fruc, Gal and Glc OH, CH2, NH, COO−, CO, C–O–C, |

1.03 × 105 Da | 5 mg/ml | Wang et al. (2015b) |

| Bifidobacterium animalis RH |

Rha, Ara, Gal, Glc, and Man OH, CH, COOH, |

21.3 kDa | NR | Shang et al. (2013); Xu et al. (2011) |

| Lactobacillus plantarum NTMI05 and NTMI20 strains |

Gal OH, C-C, CO |

NR | 100–500 µg/mL | Imran et al. (2016) |

| Leuconostoc pseudomesenteroides JF17 |

Glc OH, CH, C–O–C, CO |

NR | 0.2–5 mg/mL | Farinazzo et al. (2020) |

| Bacillus anthracis |

Glc NH, CH, C–C, C–N, CO, C–O–C |

1103 Da | 0.2–5 mg/mL | Banerjee et al. (2018) |

|

Lactobacillus fermentum S1 [EPS2 and EPS3] |

Glc, Gal, Man and Ara OH, CH, CO, S=O, |

4.45 × 106 Da 2.82 × 106 Da | 0–4 mg/ml | Wang et al. (2020b) |

| Pseudomonas sp. RD2SR3 |

Glc, Man, Gal and glucouronic acid OH, CH, CO, S=O, C–O–S, C–O–C, C–N |

3.75 × 104 g/mole | 25–200 µg/mL | Mahmoud et al. (2016) |

| Lactococcus pseudomesenteroides DRP-5 |

Glc OH, CO, C–O–C |

6.23 × 106 Da | 0–7 mg/ml | Du et al. (2018) |

| Lactobacillus kimchi SR8 | NR/NR | NR | 1–8 mg/ml | Zhang et al. (2021b) |

|

L. plantarum 70,810 r-EPS1 and r-EPS2 |

Man, Glc, and Gal OH, CH, CO, |

204.6 and 202.8 kDa | 0.125–4 mg/ml | Wang et al. (2014b) |

| Halolactibacillus miurensis |

Gal and Glc PH, COOH, C–N, NH |

NR | 0.2–3 mg/ml | Arun et al. (2017) |

| Lactobacillus plantarum KX041 |

Ara, Man, Glc and Gal OH, CH, C–O,C=O, COOH, NH |

38.67 KDa | 0.2–5.6 mg/ml | Wang et al. (2017) |

NR Not reported

Fig. 3.

Impactful physicochemical properties of microbial EPSs on their bioactivities

In this regard, chemical modification of the naturally occurring EPSs can be a promising and easy approach to make them more potent antioxidants. Phosphorylation, selenylation, carboxymethylation, sulfation, and acetylation are some of the possible and influential chemical modifications on microbial EPSs. In addition to functional groups, the monosaccharide constituent also affects antioxidant activities of EPSs. It has been observed that EPSs containing neutral monosaccharides like d-galactose, fucose, arabinose, mannose, glucose, and glucuronic acid showed more the antioxidant activities (Andrew and Jayaraman 2020).

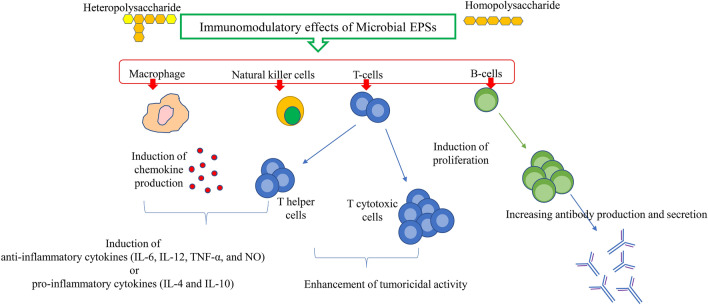

Immunomodulatory activities

Microbial EPSs can regulate the actions of innate and adaptive immunity, though acting as immunomodulatory agents (Tables 4 and 5). They interact with dendritic cells and macrophages, stimulate the proliferation of T/B lymphocytes and natural killer cells, improve antibody production, enhance cell tumoricidal activity, and mononuclear cell phagocytic capacity, increase the function of chemokines as well as affect the production of pro-inflammatory (IL-6, IL-12, TNF-α, and NO) and anti-inflammatory cytokines (IL-4 and IL-10) (Fig. 5) (Li and Shah 2016; Rajoka et al. 2020).

Table 4.

Immunostimulating activities of microbial EPSs

| EPS-producing strain | MW/HoPS or HePS | Model | Immunomodulatory effect | References |

|---|---|---|---|---|

| Lactobacillus helveticus LZ-R-5 | NR/HePS | RAW264.7 cells | Enhanced RAW264.7 cell line proliferation, their phagocytosis ability, acid phosphatase activity, production of nitric oxide (NO), and cytokine. | You et al. (2020) |

| Lactococcus lactis subsp. Lactis | NR/NR | Peritoneal macrophages and spleen lymphocytes | Enhanced proliferation of mouse spleen lymphocytes, phagocytosis, and production of NO, IFN-γ, IL-1, IL-6, and IL-12. | Pan et al. (2015) |

| Streptococcus thermophilus AR333 | 313.7 kDa/HePS | RAW 264.7 cell line | Promoted the NO production in macrophages RAW 264.7 | Zhang et al. (2018) |

| Pediococcus pentosaceus KFT18 | > 2560 KDa/HePS | IFN-c-primed RAW 264.7 macrophages and CD3/CD28-stimulated splenocytes | Stimulated synthesis of NO and TNF-α, IL-6 and IL-1β. Enhanced the splenocytes proliferation and IL-2 production. | (Shin et al. 2016) |

| Lactobacillus plantarum JLK0142 | 1.34 × 105 Da/HePS | RAW 264.7 macrophage cells and cyclophosphamide-induced immunosuppression mice | Improved lymphocyte proliferation, phagocytic activity and secretion of NO, sIgA, IL-2 and TNF-α. | Wang et al. (2018b) |

| Weissella confuse | NR/HePS | Treated female Swiss albino mice | Induced production of IgM and IgG. | Adebayo-Tayo et al. (2018) |

| Lactobacillus casei | NR/NR | Unstimulated or LPS-induced RAW 264.7 cells | Promoted the production of TNF-α in unstimulated RAW 264.7 cells as well as reduced levels of NO and iNOS in LPS-induced RAW 264.7 cells. | Xu et al. (2022a) |

| Lactococcus lactis ssp. cremoris | NR/NR | Mouse spleen macrophage cells | Stimulated the IFN-γ and IL-1α production. | Kitazawa et al. (1996) |

| Lactobacillus kefiranofaciens | NR/HePS | BALB/c mice | Increased IgA + cells in the small and large intestine lamina propria. | Vinderola et al. (2006) |

| Bacteroides fragilis | NR/NR | Infection model with Helicobacter hepaticus | Inhibited IL-17 production, and induced IL-10 production. So, protected animals from colitis induced by Helicobacter hepaticus. | Mazmanian et al. (2008) |

| Bifidobacterium breve UCC2003 | NR/NR | Infection model with Citrobacter rodentium | Diminished pathogen colonization, enhanced level of IL-12 and antibody-producing cells. | Fanning et al. (2012) |

| L. plantarum NTU 101 and 102 | NR/HePS | RAW264.7 macrophages | Stimulated production of TNF-α, IL-1β, and IL-6. | Liu et al. (2011b) |

| Lactobacillus plantarum RS20D | 1.69 × 106 Da/HePS | RAW264.7 macrophages | Stimulated the NO secretion and enhanced the expression of proinflammatory cytokine genes. | Zhu et al. (2019) |

| Lactobacillus plantarum JLAU103 | 12.4 KDa/HePO | RAW264.7 macrophages | Enhanced the production of Ig- A, IL-6, TNF-α, and NO. | Wang et al. (2020a) |

| Lactobacillus helveticus sp. Rosyjski and Lactobacillus acidophilus 5E2 | NR/HePS | HT29-19 A intestinal epithelial cell line | Enhanced production of pro-inflammatory cytokines, like interleukin-8 and toll-like receptors. | Patten et al. (2014) |

| L. rhamnosus KL37 | NR/NR | Peritoneal mouse macrophages | Induced the synthesis of pro-inflammatory cytokines, and anti-inflammatory cytokines. | Ciszek-Lenda et al. (2011) |

|

Lactobacillus delbrueckii spp. bulgaricus OLL1073R1 (Acidic EPS with high molecular weight ) |

2.9 × 106 Da/HePS | Pathogen-free C3H/HeJ and BALB/c male mice | Stimulated mouse splenocytes to produce INF-γ, and augmenting natural killer cell activity. | Makino et al. (2006) |

| Lactobacillus fermentum Lf2 | 1.23 × 106 Da/HoPS | Peripheral blood mononuclear cells | Enhanced cell proliferation and TNF-α production. | Vitlic et al. (2019) |

| Leuconostoc mesenteroides strain NTM048 | NR/HoPS | Ovalbumin-treated Wistar male mice | Enhanced mucosal IgA production | Matsuzaki et al. (2017) |

| Lactobacillus reuteri strain 100−23 | NR/HoPS | Lactobacillus-free mice | Enhanced proportions of regulatory T-cells marked by expression of the transcription factor Foxp3, and mitigated proinflammatory T-cell responses in the spleen | Sims et al. (2011) |

NR Not reported

Table 5.

Immunosuppressing activities of microbial EPSs

| EPS-producing strain | MW (Da)/HoPS or HePS | Model | Immunomodulatory effect | References |

|---|---|---|---|---|

| Bifidobacterium animalis subsp. lactis IPLA R1 | 3.5 × 106/HePS | Oral administration of LAB to male Wistar rats fed with a standard diet | Suppressed the pro-inflammatory cytokine IL-6 and induced the production of the regulatory cytokine TGF-β. | Leivers et al. (2011; Salazar et al. (2014) |

| Leuconostoc citreum L3C1E7 | 5·88 × 106/HoPS | LPS-stimulated HT-29 cells and a rat-induced allergic asthma model using ovalbumin | Reduced allergic responses and declined synthesis of allergen-specific IgE. | Domingos-Lopes et al. (2017) |

| Leuconostoc mesenteroides S81 | NR/HoP | HT-29 cell line | Induced the antiinflammatory cytokine IL-4. | Taylan et al. (2019) |

| Streptococcus thermophilus ASCC 1275 | NR/HePS | LPS stimulated RAW 264.7 macrophages | Decrease the pro-/anti-inflammatory cytokines, including IL-1β/IL-10, IL-6/IL-10, and TNF-α/IL-10 production | Li and Shah (2016) |

| Pediococcus parvulus 2.6 | β-glucan/HoPS | Human PMA-differentiated THP-1 cells and M1 pro-inflammatory monocyte-derived macrophages | Augmented the production of IL-10 by PMA-THP-1 cells | Notararigo et al. (2014) |

| L.rhamnosus RW-9595 M | 5.261 × 105/HePS | Macrophages and splenic lymphocytes of mice | Enhanced IL-10 synthesis. | Bleau et al. (2010) |

| Lactobacillus. paraplantarum BGCG11 | NR/HePS | A mouse peritonitis model induced by carrageenan | Reduced production of pro-inflammatory mediators like IL-1β, TNF-α and iNOS and increased production of anti-inflammatory IL-10 and IL-6 cytokines. | Dinić et al. (2018) |

NR Not reported

Fig. 5.

Immunomodulatory activities of microbial EPSs

It has been reported that acidic HePSs containing phosphate in their composition exert a pro-inflammatory effect and induce the immune response. According to the studies, the presence of the phosphate group and its subsequent chemical de-phosphorylation actives immune system through eliciting different immune cells like macrophages and lymphocytes (Saadat et al. 2019). The phosphate-containing dextran from Lactobacillus mesenteroides improve host immunity more compared to native dextran (Sato et al. 2004).

Immunomodulator activities of microbial EPSs may be interconnected to gut microbiota. Most EPSs can enhance the diversity and balance of microorganisms in the gut by promoting the growth of the intestinal microbiota. Several EPSs-derived from lactic acid bacteria (LAB), such as Lactobacillus plantarum, Pediococcus pentosaceus, Weissella cibaria, and Weissella confusa showed prebiotic characteristics and could encourage the growth of a probiotic strain, Bifidobacterium bifidum DSM 20,456, in vitro. Moreover, LAB derived EPSs can attach to intestinal epithelial cells, thereby hinder pathogen adhesion or stimulate immune cells (Chaisuwan et al. 2020).

The structures and the physicochemical characteristics of microbial EPSs play a pivotal role in their immunomodulatory potential. These properties include monosaccharide composition, molecular weight, electric charges, functional groups, linkage patterns, water solubility, and microstructures It has been reported that negatively charged EPS and/or small-size molecules have stimulating activities, while neutral and large EPS act as a suppressor (Fig. 3) (Werning et al. 2022; Ji et al. 2021).

Antiulcer activities

Helicobacter pylori infection and the usage of non-steroidal anti-inflammatory drugs are the major causes of peptic ulcers. The beneficial effect of some bacterial EPSs has been described in this context (Saadat et al. 2019; Nagaoka et al. 1994), reported that the oral feeding of isolated EPSs from Bifidobacterium breve YIT4014 and 4043, and B. bifidum YIT4007 exhibited antiulcer activity in rat models. The intragastric administration of purified EPS obtained from Streptococcus thermophiles CRL 1190 dissolved in reconstituted skim milk had an antiulcer effect in gastritis-induced mice. Whereas the suspension of the EPS in water did not show a protective effect, it assumes that the interaction of EPS and milk protein provides this gastroprotective effect (Rodríguez et al. 2009).

Other biomedical activities

In addition to the mentioned bioactivities of microbial EPSs, some other applications have been described for them. Antidiabetic property is one of the microbial EPS activities, which is measured by the inhibition of α-amylase and α-glucosidase. This inhibitory activity by the prevention of carbohydrate hydrolysis is helpful to diabetics. The extracted EPS from Enterococcus faecium MS79 showed 91 and 92% inhibitory activities against α-amylase and α-glucosidase, respectively (Ayyash et al. 2020d). EPS produced by several marine cyanobacteria with the potential to inhibit α-glucosidase showed antidiabetic activity. The isolated EPS from Pseudanabaena sp. and Chroococcus sp. inhibited α-glucosidase activity by 14.02 and 13.00%, respectively (Priatni et al. 2016). The α-amylase/α-glucosidase inhibitory mechanism of EPS is not clear. It seems that EPS by attaching to the active site of enzymes or substrates blocks hydrolysis (Ayyash et al. 2020d). The oral administration of purified EPS from Sorangium cellulosum NUST06 significantly reduced blood glucose levels in healthy and diabetic mice. Although the mechanism of action of EPS is not obvious, it is assumed that EPS by the activation of insulin receptors and enhancement of glucose utilization takes part in lowering glucose levels (Ding et al. 2004). Similarly, the administration of levan isolated from Bacillus licheniformis decreased plasma glucose levels by 52% in diabetic rats. The hypoglycaemic role of levan can be related to the stimulation of Langerhans islets, the increase of peripheral sensitivity to remnant insulin, and its antioxidant activity (Dahech et al. 2011; Ghoneim et al. 2016), in an in vivo study found that Bacillus subtilis sp. suppress produced EPS, and had the ability to decrease total cholesterol, low-density lipoprotein, very low-density lipoprotein, and triglycerides. Therefore, this EPS can be reduced the risk of hyperglycemia, dyslipidemia, and cardiovascular disease in diabetic rats. Jin et al. (2012), described that the oral feeding of diabetic mice with selenium-enriched EPS isolated from Enterobacter cloacae Z0206 caused a significant decrease in blood glucose levels, total cholesterol, and triglycerides. EPSs produced by Lactobacillus plantarum GA06 and GA11 had also 36.7% and 28.6% in vitro cholesterol removal efficiency, respectively. It seems that these EPSs had a binding ability to cholesterol (Avci et al. 2020). The EPS of Limosilactobacillus fermentum NCDC400 (EPS400) also showed high cholesterol-lowering activity in in vitro study (90.32%) (Gawande et al. 2021). One of the important properties of EPS produced by Leuconostoc mesenteroides LM187 was its cholesterol-lowering capability with the rate of 53% (Zhang et al. 2021a). The Feeding of mice with EPS-producing Lactobacillus paracasei NFBC 338 and L. mucosae DPC 6426 reduced cholesterol levels in serum and liver (London et al. 2014). Several Lactobacillus species (Uyen et al. 2021)d delbrueckii subsp. bulgaricus B3 (Tok and Aslim 2010) also had cholesterol removal activity.

Sulfated EPS released from Synechocystis aquatilis Sauvageau B90.79 showed anticoagulant and complement-modulating activities (Volk et al. 2006). The EPS produced by Alteromonas infernus after chemical modification of sulfation and depolymerization found anticoagulant activity (Jouault et al. 2001). Lactobacillus plantarum HY7714 produces an EPS with skin anti-aging activity. This EPS by the improvement of cytotoxicity induced by UVB and cellular hydration capacity can repair skin damage (Lee et al. 2021; Shirzad et al. 2018), reported the anti-elastase, anti-collagenase, antioxidant, and wound healing activities of EPSs generated by some Lactobacilli, which are converted into appropriate agents for skin anti-aging.

According to the conducted research, EPSs produced by some marine bacteria through the induction of proliferation and migration in fibroblasts and keratinocytes have wound-healing activity. EPS produced by Alteromonas sp. PRIM-28 (Sahana and Rekha 2019), Polaribacter sp. SM1127 (Sun et al. 2020), Pantoea sp. YU16-S3 (Sahana and Rekha 2020), and Lactiplantibacillus plantarum EI6 (Zaghloul and Ibrahim 2022) are examples of bioactive molecules, which can be used in wound-care products.

Improving the production and properties of microbial EPS by genetic engineering

Bacterial species generally produce EPS through four well-known mechanisms: the Wzx/Wzy- dependent pathway, the ATP-binding cassette (ABC) transporter-dependent pathway, the synthase-dependent pathway, and the extracellular synthesis by use of a single sucrase protein (Rana and Upadhyay 2020; Schmid et al. 2015). In each of these pathways, several enzyme-encoding genes take part in EPS biosynthesis. These genes usually cluster within bacterial genomes or plasmids (Schmid et al. 2015; Sun and Zhang 2021). Moreover, some housekeeping genes, which have a role in the formation of sugar nucleotides are important for EPS biosynthesis (Bajpai et al. 2016). By improving our knowledge about these genes and their regulations, the yield and properties of EPS can be altered through genetic engineering methods. Transposon engineering, degenerate PCR, gene knockout, gene overexpression, and gene editing by the CRISPR system can be used for generating modified EPS with new biological activities (Sun and Zhang 2021). Some successful research in which EPS production or its properties improved is briefly describes as follows. The yield of EPS in Streptococcus thermophiles enhanced from 0.17 to 0.31 g/mol when galU (UDP-glucose pyrophosphorylase) and pgmA (phosphoglucomutase) overexpressed simultaneously (Levander et al. 2002). By the overexpression of the nox gene in recombinant Lactobacillus casei LC-nox, the yield of EPS by 75% rising reached 263.7 mg/L in aerobic culture condition. nox encodes NADH oxidase which is related to energy metabolism and redox status (Li et al. 2015; Song et al. 2018), found that by the overexpression of LC2W_2179, LC2W_2188, and LC2W_2189 in L. casei LC2W the EPS production increased 16, 10, and 18% compared to the wild-type strain. The first gene encodes Glucose-1-phosphate thymidyltransferase and two other ones produce EPS synthesis proteins. Díaz-Barrera et al. (2012), reported the relation between alg8 (encoding the catalytic subunit of alginate polymerase) expression and alginate polymerization in Azotobacter vinelandii. Higher alg8 expression generates higher molecular weight alginate. The mutant strain of A. vinelandii (ATCN4) with inactive nqrE gene produced alginate with higher yield and improved rheological properties. The product of nqrE is a subunit of Na+-translocating NADH:ubiquinone oxidoreductase complex (Gayta´n et al. 2012). In another study, by the coexpression of gumB and gumC (genes involved in xanthan biosynthesis) in Xanthomonas campestris the viscosity of xanthan was increased. It seems that GumB and GumC control xanthan chain length (Galván et al. 2013). Hassler et al. (1990), also found that mutant strains of X. campestris produced xanthan with various viscosity due to the variable acetylation and pyruvylation levels, and the presence of different sugar residues at terminal side chains.

Conclusion

Microbial EPSs display great diversity. They are multifunctional carbohydrates with considerable health-improving potential. Recent investigations have revealed the great health improving properties of microbial EPS in industries that may be related to their novel and distinct properties compared to polysaccharides obtained from other natural sources. Now, a large proportion of commercially-available EPSs are derived from microorganisms. The main benefit of microbial EPSs is the adjustable chemical composition and structure, which demonstrates their specific usage in pharmaceutical and medical fields. This review points that microbial EPSs can be considered promising alternatives to chemicals likes chemical antibiotics, antioxidants, anticancer, antiviral and antifungal drugs. Microbial EPSs are nontoxic, biocompatible, thermally stable and biodegradable molecules. By applying antibacterial or antifungal EPSs, the antagonistic activity of normal flora against pathogens which is likely to be lost in antibiotic treatment is maintained. Also, microbial EPSs owning to reduced adverse effects, and immune-stimulating activities may be considered safe alternatives to synthetic anticancer drugs. Moreover, EPSs are considered promising green substitutes for synthetic antioxidants because they participate in the removal of oxidative stress through scavenging various free radicals, suppression of lipid peroxidation, reducing metal ion chelating activity, and promoting enzymatic and nonenzymatic antioxidant activities. As it was presented physicochemical characteristics of EPSs, including molecular weight, branching degree, monosaccharide composition, glycosidic bonds, electric charge, and functional groups influence on their functional behavior.

The study of structure-function relationship could result in smart chemical modification of discovered EPSs to have improved bioactivities or targeted screening and isolation of the microbial EPSs with desired bioactivity in the near future.

Therefore, finding microbial EPSs with suitable chemical architecture through screening studies from unexplored ecosystems, imposing chemical modifications or genetic and metabolic engineering could facilitate obtaining a bioactive polymer to be applied in cosmetics, medical, food products, textiles, pharmaceutical, agricultural and other types of industrial sectors. This study reviewed the studies conducted on microbial EPSs along with their microbial sources, physicochemical properties with particular attention to bioactivities, and their mode actions to provide a platform for researchers to identify the relationship of structure properties to bioactivities.

However, there are contradictions about the effects of these properties on various EPS’s bioactivities. This could be related to different in vivo and in vitro models used to evaluate biological activities as well as the lack of comprehensive knowledge on all microbial EPS structures. Therefore, more studies should be performed to explore the mechanism behind EPS’s bioactivities.

Acknowledgements

The authors acknowledge Damghan University.

Author contributions

FS and PF wrote the main manuscript text and FS. prepared Figs. 1–5. All authors reviewed the manuscript.

Funding

Authors state no funding involved.

Declarations

Competing interests

The authors declare no competing interests.

Informed consent

If the article is accepted for publication, the transfer of copyright from the author to this journal.

Footnotes

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

References

- Abarquero D, Renes E, Fresno JM, Tornadijo ME. Study of exopolysaccharides from lactic acid bacteria and their industrial applications: a review. Int J Food Sci Technol. 2022;57:16–26. doi: 10.1111/ijfs.15227. [DOI] [Google Scholar]

- Abdalla AK, Ayyash MM, Olaimat AN, Osaili TM, Al-Nabulsi AA, Shah NP, et al. Exopolysaccharides as antimicrobial agents: mechanism and spectrum of activity. Front Microbiol. 2021;12:664395. doi: 10.3389/fmicb.2021.664395. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Abinaya M, Vaseeharan B, Divya M, Vijayakumar S, Govindarajan M, Alharbi NS, et al. Structural characterization of Bacillus licheniformis Dahb1 exopolysaccharide—antimicrobial potential and larvicidal activity on malaria and Zika virus mosquito vectors. Environ Sci Pollut Res. 2018;25(19):18604–18619. doi: 10.1007/s11356-018-2002-6. [DOI] [PubMed] [Google Scholar]

- Adebayo-Tayo B, Fashogbon R. In vitro antioxidant, antibacterial, in vivo immunomodulatory, antitumor and hematological potential of exopolysaccharide produced by wild type and mutant Lactobacillus delbureckii subsp. bulgaricus. Heliyon. 2020;6(2):e03268. doi: 10.1016/j.heliyon.2020.e03268. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Adebayo-Tayo B, Ishola R, Oyewunmi T. Characterization, antioxidant and immunomodulatory potential on exopolysaccharide produced by wild type and mutant Weissella confusa strains. Biotechnol Rep. 2018;19:e00271. doi: 10.1016/j.btre.2018.e00271. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Adesulu-Dahunsi A, Sanni A, Jeyaram K. Production, characterization and in vitro antioxidant activities of exopolysaccharide from Weissella cibaria GA44. LWT. 2018;87:432–442. doi: 10.1016/j.lwt.2017.09.013. [DOI] [Google Scholar]

- Al-Nabulsi AA, Jaradat ZW, Qudsi A, Elsalem FR, Osaili L, Olaimat TM, et al. Characterization and bioactive properties of exopolysaccharides produced by Streptococcus thermophilus and Lactobacillus bulgaricus isolated from labaneh. LWT. 2022;167:113817. doi: 10.1016/j.lwt.2022.113817. [DOI] [Google Scholar]

- Almasi F, Salimi F, Mohammadipanah F. Microbial metabolites as promising anti-inflammatory resources in biomedicine. Adv Res Microb Metab Technol. 2021;4(1):1. [Google Scholar]

- Amer MN, Elgammal EW, Atwa NA, Eldiwany AI, Dawoud IE, Rashad FM. Structure elucidation and in vitro biological evaluation of sulfated exopolysaccharide from LAB Weissella paramesenteroides MN2C2. J Appl Pharm Sci. 2021;11(5):022–031. [Google Scholar]

- Amini E, Salimi F, Imanparast S. Optimization of lacticaseibacillus paracasei AS20 (1)-derived exopolysaccharide and its potential as an anti-biofilm and anticancer agent. BJM. 2022;11(44):105–118. [Google Scholar]

- Amini E, Salimi F, Imanparast S, Mansour FN. Isolation and characterization of exopolysaccharide derived from lacticaseibacillus paracasei AS20 (1) with probiotic potential and evaluation of its antibacterial activity. Lett Appl Microbiol. 2022;75(4):967–981. doi: 10.1111/lam.13771. [DOI] [PubMed] [Google Scholar]

- Andrew M, Jayaraman G. Structural features of microbial exopolysaccharides in relation to their antioxidant activity. Carbohydr Res. 2020;487:107881. doi: 10.1016/j.carres.2019.107881. [DOI] [PubMed] [Google Scholar]

- Andrew M, Jayaraman G. Molecular characterization and biocompatibility of Exopolysaccharide produced by moderately Halophilic Bacterium Virgibacillus dokdonensis from the Saltern of Kumta Coast. Polymers. 2022;14(19):3986. doi: 10.3390/polym14193986. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Angelin J, Kavitha M. Exopolysaccharides from probiotic bacteria and their health potential. Int J Biol Macromol. 2020;162:853–865. doi: 10.1016/j.ijbiomac.2020.06.190. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Arayes MA, Mabrouk ME, Sabry SA, Abdella B. Exopolysaccharide production from Alkalibacillus sp. w3: statistical optimization and biological activity. Biologia. 2023;78(1):229–240. doi: 10.1007/s11756-022-01233-1. [DOI] [Google Scholar]

- Arena A, Maugeri TL, Pavone B, Iannello D, Gugliandolo C, Bisignano G. Antiviral and immunoregulatory effect of a novel exopolysaccharide from a marine thermotolerant Bacillus licheniformis. Int Immunopharmacol. 2006;6(1):8–13. doi: 10.1016/j.intimp.2005.07.004. [DOI] [PubMed] [Google Scholar]

- Arena A, Gugliandolo C, Stassi G, Pavone B, Iannello D, Bisignano G, et al. An exopolysaccharide produced by Geobacillus thermodenitrificans strain B3-72: antiviral activity on immunocompetent cells. Immunol Lett. 2009;123(2):132–137. doi: 10.1016/j.imlet.2009.03.001. [DOI] [PubMed] [Google Scholar]

- Arun J, Selvakumar S, Sathishkumar R, Moovendhan M, Ananthan G, Maruthiah T, et al. In vitro antioxidant activities of an exopolysaccharide from a salt pan bacterium Halolactibacillus miurensis. Carbohydr Polym. 2017;155:400–406. doi: 10.1016/j.carbpol.2016.08.085. [DOI] [PubMed] [Google Scholar]

- Ates O. Systems biology of microbial exopolysaccharides production. Front Bioeng Biotechnol. 2015;3:200. doi: 10.3389/fbioe.2015.00200. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Avci GA, Cagatay G, Cilak GO, Avci E. Probable novel probiotics: EPS production, cholesterol removal and glycocholate deconjugation of Lactobacillus Plantarum GA06 and GA11 isolared from local handmade-cheese. J Microbiol Biotechnol Food Sci. 2020;10(1):83–86. doi: 10.15414/jmbfs.2020.10.1.83-86. [DOI] [Google Scholar]

- Ayyash M, Abu-Jdayil B, Itsaranuwat P, Almazrouei N, Galiwango E, Esposito G, et al. Exopolysaccharide produced by the potential probiotic Lactococcus garvieae C47: structural characteristics, rheological properties, bioactivities and impact on fermented camel milk. Food Chem. 2020;333:127418. doi: 10.1016/j.foodchem.2020.127418. [DOI] [PubMed] [Google Scholar]

- Ayyash M, Abu-Jdayil B, Itsaranuwat P, Galiwango E, Tamiello-Rosa C, Abdullah H, et al. Characterization, bioactivities, and rheological properties of exopolysaccharide produced by novel probiotic Lactobacillus plantarum C70 isolated from camel milk. Int J Biol Macromol. 2020;144:938–946. doi: 10.1016/j.ijbiomac.2019.09.171. [DOI] [PubMed] [Google Scholar]

- Ayyash M, Abu-Jdayil B, Olaimat A, Esposito G, Itsaranuwat P, Osaili T, et al. Physicochemical, bioactive and rheological properties of an exopolysaccharide produced by a probiotic Pediococcus pentosaceus M41. Carbohydr Polym. 2020;229:115462. doi: 10.1016/j.carbpol.2019.115462. [DOI] [PubMed] [Google Scholar]

- Ayyash M, Stathopoulos C, Abu-Jdayil B, Esposito G, Baig M, Turner MS, et al. Exopolysaccharide produced by potential probiotic Enterococcus faecium MS79: characterization, bioactivities and rheological properties influenced by salt and pH. LWT. 2020;131:109741. doi: 10.1016/j.lwt.2020.109741. [DOI] [Google Scholar]

- Bajpai VK, Rather IA, Majumder R, Shukla S, Aeron A, Kim K, et al. Exopolysaccharide and lactic acid bacteria: perception, functionality and prospects. Bangladesh J Pharmacol. 2016;11:1–23. doi: 10.3329/bjp.v11i1.23819. [DOI] [Google Scholar]

- Banerjee A, Rudra SG, Mazumder K, Nigam V, Bandopadhyay R. Structural and functional properties of exopolysaccharide excreted by a novel Bacillus anthracis (strain PFAB2) of hot spring origin. Indian J Microbiol. 2018;58(1):39–50. doi: 10.1007/s12088-017-0699-4. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Bhat B, Bajaj BK. Hypocholesterolemic potential and bioactivity spectrum of an exopolysaccharide from a probiotic isolate Lactobacillus paracasei M7. Bioact Carbohydr Diet Fibre. 2019;19:100191. doi: 10.1016/j.bcdf.2019.100191. [DOI] [Google Scholar]

- Biliavska L, Pankivska Y, Povnitsa O, Zagorodnya S. Antiviral activity of exopolysaccharides produced by lactic acid bacteria of the genera Pediococcus, Leuconostoc and Lactobacillus against human adenovirus type 5. Medicina. 2019;55(9):519. doi: 10.3390/medicina55090519. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Bleau C, Monges A, Rashidan K, Laverdure JP, Lacroix M, Van Calsteren MR, et al. Intermediate chains of exopolysaccharides from Lactobacillus rhamnosus RW-9595 M increase IL‐10 production by macrophages. J Appl Microbiol. 2010;108(2):666–675. doi: 10.1111/j.1365-2672.2009.04450.x. [DOI] [PubMed] [Google Scholar]

- Chaisuwan W, Jantanasakulwong K, Wangtueai S, Phimolsiripol Y, Chaiyaso T, Techapun C, et al. Microbial exopolysaccharides for immune enhancement: fermentation, modifications and bioactivities. Food Biosci. 2020;35:100564. doi: 10.1016/j.fbio.2020.100564. [DOI] [Google Scholar]

- Chen G, Qian W, Li J, Xu Y, Chen K. Exopolysaccharide of Antarctic bacterium Pseudoaltermonas sp. S-5 induces apoptosis in K562 cells. Carbohydr Polym. 2015;121:107–114. doi: 10.1016/j.carbpol.2014.12.045. [DOI] [PubMed] [Google Scholar]

- Ciszek-Lenda M, Nowak B, Śróttek M, Gamian A, Marcinkiewicz J. Immunoregulatory potential of exopolysaccharide from Lactobacillus rhamnosus KL37. Effects on the production of inflammatory mediators by mouse macrophages. Int J Exp Pathol. 2011;92(6):382–391. doi: 10.1111/j.1365-2613.2011.00788.x. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Dahech I, Belghith KS, Hamden K, Feki A, Belghith H, Mejdoub H. Antidiabetic activity of levan polysaccharide in alloxan-induced diabetic rats. Int J Biol Macromol. 2011;49(4):742–746. doi: 10.1016/j.ijbiomac.2011.07.007. [DOI] [PubMed] [Google Scholar]

- Dertli E, Mayer MJ, Narbad A. Impact of the exopolysaccharide layer on biofilms, adhesion and resistance to stress in Lactobacillus johnsonii FI9785. BMC microbiol. 2015;15(1):1–9. doi: 10.1186/s12866-015-0347-2. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Di W, Zhang L, Wang S, Yi H, Han X, Fan R, et al. Physicochemical characterization and antitumour activity of exopolysaccharides produced by Lactobacillus casei SB27 from yak milk. Carbohydr Polym. 2017;171:307–315. doi: 10.1016/j.carbpol.2017.03.018. [DOI] [PubMed] [Google Scholar]

- Dilna SV, Surya H, Aswathy RG, Varsha KK, Sakthikumar DN, Pandey A, et al. Characterization of an exopolysaccharide with potential health-benefit properties from a probiotic Lactobacillus plantarum RJF4. LWT. 2015;64(2):1179–1186. doi: 10.1016/j.lwt.2015.07.040. [DOI] [Google Scholar]

- Ding X, Zhang J, Jiang P, Xu X, Liu Z. Structural features and hypoglycaemic activity of an exopolysaccharide produced by Sorangium cellulosum. Lett Appl Microbiol. 2004;38(3):223–228. doi: 10.1111/j.1472-765X.2004.01465.x. [DOI] [PubMed] [Google Scholar]

- Dinić M, Pecikoza U, Djokić J, Stepanović-Petrović R, Milenković M, Stevanović M, et al. Exopolysaccharide produced by probiotic strain Lactobacillus paraplantarum BGCG11 reduces inflammatory hyperalgesia in rats. Front Pharmacol. 2018;9:1. doi: 10.3389/fphar.2018.00001. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Dı´az-Barrera A, Soto E, Altamirano C. Alginate production and alg8 gene expression by Azotobacter vinelandii in continuous cultures. J Ind Microbiol Biotechnol. 2012;39(4):613–621. doi: 10.1007/s10295-011-1055-z. [DOI] [PubMed] [Google Scholar]

- Domingos-Lopes M, Nagy A, Stanton C, Ross P, Gelencsér E, Silva C. Immunomodulatory activity of exopolysaccharide producing Leuconostoc citreum strain isolated from Pico cheese. J Funct Foods. 2017;33:235–243. doi: 10.1016/j.jff.2017.03.054. [DOI] [Google Scholar]

- Du R, Qiao X, Zhao F, Song Q, Zhou Q, Wang Y, et al. Purification, characterization and antioxidant activity of dextran produced by Leuconostoc pseudomesenteroides from homemade wine. Carbohydr Polym. 2018;198:529–536. doi: 10.1016/j.carbpol.2018.06.116. [DOI] [PubMed] [Google Scholar]

- El Awady ME, Eldin MAN, Ibrahim HM, Al Bahnasy ME, Aziz SHA. In vitro evaluation of antioxidant, anticancer, and antiviral activities of exopolysaccharide from Streptomyces hirsutus NRC2018. J Appl Pharm Sci. 2019;9(11):010–018. doi: 10.7324/JAPS.2019.91102. [DOI] [Google Scholar]

- El-Deeb NM, Yassin AM, Al-Madboly LA, El-Hawiet A. A novel purified Lactobacillus acidophilus 20079 exopolysaccharide, LA-EPS-20079, molecularly regulates both apoptotic and NF-κB inflammatory pathways in human colon cancer. Microb Cell Factories. 2018;17(1):1–15. doi: 10.1186/s12934-018-0877-z. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Fanning S, Hall LJ, van Sinderen D. Bifidobacterium breve UCC2003 surface exopolysaccharide production is a beneficial trait mediating commensal-host interaction through immune modulation and pathogen protection. Gut Microbes. 2012;3(5):420–425. doi: 10.4161/gmic.20630. [DOI] [PubMed] [Google Scholar]

- Farag MM, Moghannem SA, Shehabeldine AM, Azab MS. Antitumor effect of exopolysaccharide produced by Bacillus mycoides. Microb Pathog. 2020;140:103947. doi: 10.1016/j.micpath.2019.103947. [DOI] [PubMed] [Google Scholar]

- Farinazzo FS, Valente LJ, Almeida MB, Simionato AS, Fernandes MTC, Mauro CSI, et al. Characterization and antioxidant activity of an exopolysaccharide produced by Leuconostoc pseudomesenteroides JF17 from juçara fruits (Euterpe edulis Martius) Process Biochem. 2020;91:141–148. doi: 10.1016/j.procbio.2019.12.005. [DOI] [Google Scholar]

- Freitas F, Alves VD, Reis MA. Advances in bacterial exopolysaccharides: from production to biotechnological applications. Trends Biotechnol. 2011;29(8):388–398. doi: 10.1016/j.tibtech.2011.03.008. [DOI] [PubMed] [Google Scholar]

- Galván EM, Ielmini MV, Patel Y, Bianco MI, Franceschini EA, Schneider JC, et al. Xanthan chain length is modulated by increasing the availability of the polysaccharide copolymerase protein GumC and the outer membrane polysaccharide export protein GumB. Glycobiol. 2013;23(2):259–272. doi: 10.1093/glycob/cws146. [DOI] [PubMed] [Google Scholar]

- Gawande K, Kolhekar M, Kumari M, Kapila S, Sharma P, Ali SA, et al. Lactic acid bacteria based purified exopolysaccharide showed viscofying and hypercholesterolemic capabilites. FHFH. 2021;1:100042. [Google Scholar]

- Gayta´n I, Pen˜a C, Nu´n˜ez C, Co´rdova MaS, Espı´n G, Galindo E. Azotobacter vinelandii lacking the Na+-NQR activity: a potential source for producing alginates with improved properties and at high yield. World J Microbiol Biotechnol. 2012;28(8):2731–2740. doi: 10.1007/s11274-012-1084-4. [DOI] [PubMed] [Google Scholar]

- Ghoneim MAM, Hassan AI, Mahmoud MG, Asker MS. Effect of polysaccharide from Bacillus subtilis sp. on cardiovascular diseases and atherogenic indices in diabetic rats. BMC Complement Altern Med. 2016;16:112. doi: 10.1186/s12906-016-1093-1. [DOI] [PMC free article] [PubMed] [Google Scholar]

- González CG, García MdSC, García JM, Alfaro-Rodriguez M-C. A comparison of the Effect of temperature on the rheological properties of Diutan and Rhamsan gum aqueous solutions. Fluids. 2019;4(1):22. doi: 10.3390/fluids4010022. [DOI] [Google Scholar]

- Guo MQ, Hu X, Wang C, Ai L. Polysaccharides: structure and solubility. In: Xu Z, editor. Solubility of polysaccharides. London: IntechOpen; 2017. pp. 1–17. [Google Scholar]

- Hasheminya S-M, Dehghannya J. Novel ultrasound-assisted extraction of kefiran biomaterial, a prebiotic exopolysaccharide, and investigation of its physicochemical, antioxidant and antimicrobial properties. Mater Chem Phys. 2020;243:122645. doi: 10.1016/j.matchemphys.2020.122645. [DOI] [Google Scholar]

- Hassler RA, Doherty DH. Genetic engineering of polysaccharide structure: production of variants of Xanthan Gum in Xanthomonas campestris. Biotechnol Prog. 1990;6(3):182–187. doi: 10.1021/bp00003a003. [DOI] [PubMed] [Google Scholar]

- Hou C, Yin M, Lan P, Wang H, Nie H, Ji X. Recent progress in the research of Angelica sinensis (Oliv.) Diels polysaccharides: extraction, purification, structure and bioactivities. Chem Biol Technol Agric. 2021;8:1–14. doi: 10.1186/s40538-021-00214-x. [DOI] [Google Scholar]

- Hu Y-Q, Wei W, Gao M, Zhou Y, Wang G-X, Zhang Y. Effect of pure oxygen aeration on extracellular polymeric substances (EPS) of activated sludge treating saline wastewater. Process Saf Environ Prot. 2019;123:344–350. doi: 10.1016/j.psep.2019.01.028. [DOI] [Google Scholar]

- Imran MYM, Reehana N, Jayaraj KA, Ahamed AAP, Dhanasekaran D, Thajuddin N, et al. Statistical optimization of exopolysaccharide production by Lactobacillus plantarum NTMI05 and NTMI20. Int J Biol Macromol. 2016;93:731–745. doi: 10.1016/j.ijbiomac.2016.09.007. [DOI] [PubMed] [Google Scholar]

- Ismail B, Nampoothiri KM. Exposition of antitumour activity of a chemically characterized exopolysaccharide from a probiotic Lactobacillus plantarum MTCC 9510. Biologia. 2013;68(6):1041–1047. doi: 10.2478/s11756-013-0275-2. [DOI] [Google Scholar]

- Jeong D, Kim D-H, Kang I-B, Kim H, Song K-Y, Kim H-S, et al. Characterization and antibacterial activity of a novel exopolysaccharide produced by Lactobacillus kefiranofaciens DN1 isolated from kefir. Food Control. 2017;78:436–442. doi: 10.1016/j.foodcont.2017.02.033. [DOI] [Google Scholar]

- Ji X, Peng B, Ding H, Cui B, Nie H, Yan Y. Purification, structure and biological activity of pumpkin polysaccharides: a review. Food Rev Int. 2021;1:1–13. [Google Scholar]

- Ji X, Hou C, Shi M, Yan Y, Liu Y. An insight into the research concerning Panax ginseng CA Meyer polysaccharides: a review. Food Rev Int. 2022;38(6):1149–1165. doi: 10.1080/87559129.2020.1771363. [DOI] [Google Scholar]

- Jin M, Lu Z, Huang M, Wang Y, Wang Y. Effects of Se-enriched polysaccharides produced by Enterobacter cloacae Z0206 on alloxan-induced diabetic mice. Int J Biol Macromol. 2012;50(2):348–352. doi: 10.1016/j.ijbiomac.2011.12.019. [DOI] [PubMed] [Google Scholar]

- Jouault SC, Chevolot L, Helley D, Ratiskol J, Bros A, Sinquin C, et al. Characterization, chemical modifications and in vitro anticoagulant properties of an exopolysaccharide produced by Alteromonas infernus. Biochim Biophys Acta. 2001;1528(2–3):141–151. doi: 10.1016/S0304-4165(01)00185-4. [DOI] [PubMed] [Google Scholar]

- Jurášková D, Ribeiro SC, Silva CC. Exopolysaccharides produced by lactic acid bacteria: from biosynthesis to health-promoting properties. Foods. 2022;11(2):156. doi: 10.3390/foods11020156. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Kanmani P, Albarracin L, Kobayashi H, Hebert EM, Saavedra L, Komatsu R, et al. Genomic characterization of Lactobacillus delbrueckii TUA4408L and evaluation of the antiviral activities of its extracellular polysaccharides in porcine intestinal epithelial cells. Front Immunol. 2018;9:2178. doi: 10.3389/fimmu.2018.02178. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Kanmani P, Albarracin L, Kobayashi H, Iida H, Komatsu R, Kober AH, et al. Exopolysaccharides from Lactobacillus delbrueckii OLL1073R-1 modulate innate antiviral immune response in porcine intestinal epithelial cells. Mol Immunol. 2018;93:253–265. doi: 10.1016/j.molimm.2017.07.009. [DOI] [PubMed] [Google Scholar]

- Kenyon W, Buller C. Structural analysis of the curdlan-like exopolysaccharide produced by Cellulomonas flavigena KU. J Ind Microbiol Biotechnol. 2002;29(4):200–203. doi: 10.1038/sj.jim.7000277. [DOI] [PubMed] [Google Scholar]

- Kim J-U, Kim Y-H, Han K-S, Oh S-J, Whang K-Y, Kim J-N, et al. Function of cell-bound and released exopolysaccharides produced by Lactobacillus rhamnosus ATCC 9595. J Microbiol Biotechnol. 2006;16(6):939–945. [Google Scholar]

- Kim Y, Oh S, Yun H, Oh S, Kim S. Cell-bound exopolysaccharide from probiotic bacteria induces autophagic cell death of tumour cells. Lett Appl Microbiol. 2010;51(2):123–130. doi: 10.1111/j.1472-765X.2010.02859.x. [DOI] [PubMed] [Google Scholar]

- Kim K, Lee G, Thanh HD, Kim J-H, Konkit M, Yoon S, et al. Exopolysaccharide from Lactobacillus plantarum LRCC5310 offers protection against rotavirus-induced diarrhea and regulates inflammatory response. J Dairy Sci. 2018;101(7):5702–5712. doi: 10.3168/jds.2017-14151. [DOI] [PubMed] [Google Scholar]

- Kitazawa H, Itoh T, Tomioka Y, Mizugaki M, Yamaguchi T. Induction of IFN-γ and IL-1α production in macrophages stimulated with phosphopolysaccharide produced by Lactococcus lactis ssp. cremoris. Int J Food Microbiol. 1996;31(1–3):99–106. doi: 10.1016/0168-1605(96)00968-3. [DOI] [PubMed] [Google Scholar]

- Kodali VP, Sen R. Antioxidant and free radical scavenging activities of an exopolysaccharide from a probiotic bacterium. Biotechnol J: Healthc Nutr Technol. 2008;3(2):245–251. doi: 10.1002/biot.200700208. [DOI] [PubMed] [Google Scholar]

- Kodali VP, Perali RS, Sen R. Purification and partial elucidation of the structure of an antioxidant carbohydrate biopolymer from the probiotic bacterium Bacillus coagulans RK-02. J Nat Prod. 2011;74(8):1692–1697. doi: 10.1021/np1008448. [DOI] [PubMed] [Google Scholar]

- Koller VJ, Marian B, Stidl R, Nersesyan A, Winter H, Simić T, et al. Impact of lactic acid bacteria on oxidative DNA damage in human derived colon cells. Food Chem Toxicol. 2008;46(4):1221–1229. doi: 10.1016/j.fct.2007.09.005. [DOI] [PubMed] [Google Scholar]

- Kumar R, Bansal P, Singh J, Dhanda S. Purification, partial structural characterization and health benefits of exopolysaccharides from potential probiotic Pediococcus acidilactici NCDC 252. Process Biochem. 2020;99:79–86. doi: 10.1016/j.procbio.2020.08.028. [DOI] [Google Scholar]

- Lee K, Kim HJ, Kim SA, Park S-D, Shim J-J, Lee J-L. Exopolysaccharide from Lactobacillus plantarum HY7714 protects against skin aging through skin–gut Axis Communication. Molecules. 2021;26(6):1651. doi: 10.3390/molecules26061651. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Leivers S, Hidalgo-Cantabrana C, Robinson G, Margolles A, Ruas-Madiedo P, Laws AP. Structure of the high molecular weight exopolysaccharide produced by Bifidobacterium animalis subsp. lactis IPLA-R1 and sequence analysis of its putative eps cluster. Carbohydr Res. 2011;346(17):2710–2717. doi: 10.1016/j.carres.2011.09.010. [DOI] [PubMed] [Google Scholar]

- Levander F, Svensson M, Rådström P. Enhanced exopolysaccharide production by metabolic engineering of Streptococcus thermophilus. Appl Environ Microbiol. 2002;68(2):784–790. doi: 10.1128/AEM.68.2.784-790.2002. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Li B, Huang G. Preparation, structure-function relationship and application of Grifola umbellate polysaccharides. Ind Crops Prod. 2022;186:115282. doi: 10.1016/j.indcrop.2022.115282. [DOI] [Google Scholar]

- Li S, Shah NP. Characterization, anti-inflammatory and antiproliferative activities of natural and sulfonated exo‐polysaccharides from Streptococcus thermophilus ASCC 1275. J Food Sci. 2016;81(5):M1167–M1176. doi: 10.1111/1750-3841.13276. [DOI] [PubMed] [Google Scholar]