Abstract

The non-linear mixed convective heat and mass transfer features of a non-Newtonian Casson liquid flow over a stretching surface are investigated numerically. The stretching surface is embedded in a Darcian porous medium with heat generation/absorption impacts. The fluid flow is assumed to be driven by both buoyancy and Arrhenius kinetics. The governing equations are modelled with the help of Boussinesq and Rosseland approximations. The similarity solutions of the non-dimensional equations are obtained using two numerical approaches, namely fourth fifth Runge - Kutta Fehlberg method and the shooting approach. The velocity, temperature and concentration profiles are discussed for important physical parameters through various graphical illustrations. The skin friction, the non-dimensional wall temperature, and the concentration expressions were derived and analysed. The results indicate that the increasing values of linear and nonlinear convection due to temperature, nonlinear convection due to concentration, and heat of reaction increase the dimensionless wall temperature. The dimensionless wall concentration rises with the increasing values of heat of reaction, linear and nonlinear convection due to temperature, and nonlinear convection due to concentration parameters.

Keywords: Arrhenius kinetics, Casson liquid, Darcian porous medium, Nonlinear mixed convection, Stretching surface

1. Introduction

The fluid flow along with heat and mass transport in a porous medium has gained major attention of researchers in the previous few decennaries. The thermo-physical properties of the fluid and the features of the permeability of the porous medium possess a primary role in controlling the performance of heat and mass transfer in fluids. The number of research studies in this topic has increased because of its various engineering applications, such as geophysical, crystal growth in fluids, pollutant dispersion in aquifers, petroleum reservoirs, nuclear waste repositories, chemical catalytic reactors, ground hydrology, solidification of casting, thermal and insulating engineering, etc. To predict the fluid flow in a porous space, the law of Darcy has been widely used by researchers [1]. The law of Darcy is a proportional relationship between the viscosity of fluid, the immediate expulsion rate through porous space, and the pressure drop over a certain distance. It is valid only for laminar, viscous, and slow fluid flow where the inertial effects are neglected. The advancement in porous medium studies has been summarised in the following books [[2], [3], [4], [5], [6]].

Non-Newtonian liquids are liquids that exhibit a nonlinear relationship among the shear rate and shear stress. The rheological behaviour of these liquids plays a dynamic role in many cosmetic, pharmaceutical, and chemical industries. It is very difficult to derive a single model to predict non-Newtonian liquids due to the nonlinear relationship between stress and strain movement. Several researchers have developed various mathematical models of non-Newtonian liquids, such as Walter-B [7,8], Maxwell [9], viscoelastic type [10], Casson [11], Brinkman type [12], Jeffrey [13], power law [14], second-grade [15] model, Bingham plastic [16], and Oldroyd-B [17]. Casson liquid is a subset of a non-Newtonian model that acts like an elastic solid. These liquids have infinite viscosity at zero shear rate as well as infinite shear rate at zero viscosity. Human blood, concentrated juices, honey, and lubricants are some of the Casson liquid examples [18]. The Casson property of the fluids is also important in industrial processes such as coating, manufacturing, metal spinning, biomimetics, etc. In addition to this, the theoretical investigations on mixed convection flow of non-Newtonian fluids over a stretching material problem might have enormous economic and energy saving implications for the industries that involve extrusion of molten polymers, hot rolling, food stuffs processing, paper production, and glass fibre production. The Newtonian/non-Newtonian fluid flow problems over a stretching surface in a porous medium have attracted many researchers in recent years [[19], [20], [21], [22], [23], [24]].

Bhattacharyya [25] examined the two-dimensional stagnation point flow of Casson liquid towards a stretching surface with magnetic field effects and found that Casson fluid has a thicker velocity boundary layer than Newtonian fluid. Shehzad et al. [26] investigated the 3D (three-dimensional) flow of Casson liquid in a Darcian porous medium with a uniform heat source/sink and magnetic field effects. Their investigation showed that a greater Casson value increased the skin friction coefficient. Mabood et al. [27] inspected the Casson liquid flow under MHD effects in a Darcian porous medium, taking into account of melting heat transfer and radiation, and reported that the Casson parameter enhances the heat transfer rate. The impacts of cross diffusion and a heat source on the boundary layer flow of Casson liquid in the porous medium in the presence of non-linear thermal radiation were analysed by Patel [28]. The same author [29] studied the Casson liquid flow over an oscillating plate embedded in a porous space under the effects of heat generation, hall current, and radiation. The heat and mass transport characteristics of Casson liquid over a shrinking sheet in a porous medium in the presence of a heat source/sink were examined by Awais et al. [30]. Nandkeolyar and Chamkha [31] analysed the unsteady Casson liquid flow in three-dimensional stretching material in a porous medium with Hall and MHD effects. Eldabe et al. [32] discussed the impacts of the electromagnetic field on the heat and mass transfer of Casson liquid in a porous medium.

The present study mainly focused on the mixed convection flow of Casson liquid, which is purely driven by the heat provided to the fluid due to exothermic surface reactions and non-uniform internal heat generation/absorption over a stretching surface in a Darcian porous medium. The exothermic reactions were derived and utilised by the following researchers [[33], [34], [35], [36], [37], [38]]. The derived model was dependent on the Arrhenius temperature and a first order kinetics. The forth mentioned model was successfully applied to the boundary layer flow problems over a stretching sheet [[39], [40], [41], [42], [43], [44], [45]]. Very recently, the second grade nanofluid boundary layer flow was investigated over a stretching surface that was driven by Arrhenius kinetics [46].

To the best of the author's knowledge, the problem of nonlinear mixed convection flow of Casson liquid over a stretching surface in a porous medium driven by Arrhenius kinetics, which has applications in many engineering processes as mentioned earlier, has not been considered yet. Hence in the present work, Arrhenius kinetically driven boundary layer flow of non-Newtonian Casson liquid over a stretching surface in a Darcian porous medium with the impacts of thermal radiation, non-uniform heat generation, and heat absorption. The numerical results are obtained for the governing equations through the fourth fifth Runge-Kutta Fehlberg method along with shooting technique. The results are discussed through graphical illustrations.

2. Problem formulation

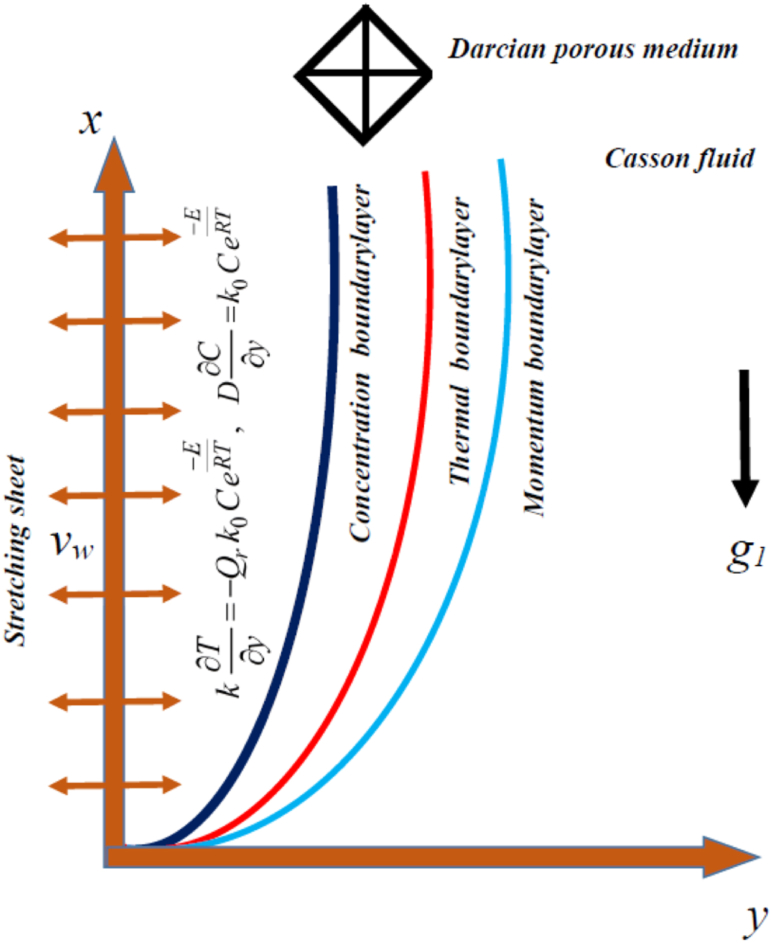

We consider the steady, incompressible, two-dimensional, nonlinear mixed convection flow of a non-Newtonian Casson liquid over a stretching surface that is embedded in a porous medium. The porous medium is considered as a Darcian porous medium. The impacts of space and temperature dependent heat generation/absorption, and Rosseland thermal radiation impacts are taken into account with negligible viscous dissipation impacts. Flow is assumed to be happening in a cartesian framework in which the x axis is taken along the surface and the y axis vertical to it (Fig. 1). The stretching surface is assumed to be at temperature Tw (ambient temperature ) and concentration Cw (ambient concentration ) with stretching velocity . The exothermic reaction is presumed to take place at the surface.

Fig. 1.

Physical configuration of the present problem.

The governing equations can be written under the above and Boussinesq assumptions as [[27], [28], [29], [30]].

| (1) |

| (2) |

| (3) |

| (4) |

Where u and v are the velocity components along x and y axes respectively, β1 is the Casson parameter, is the kinematic viscosity, is acceleration due to gravity, βt1 is first order thermal expansion coefficient, βt2 is second order thermal expansion coefficient, βc1 is the first order solutal coefficient, βc2 is the second order solutal coefficient, T is the temperature of the fluid, kp is the permeability of the porous medium, ρ is the density of the Casson liquid, k is the thermal conductivity, Cp is the specific heat capacitance, C is the concentration of fluid, and D is the molecular diffusion coefficient.

The non-uniform heat generation/absorption can be chosen as [47].

| (5) |

where Q1 is the parameter for space dependent heat generation/absorption and Q2 is the parameter for temperature dependent heat generation/absorption. It should be mentioned here that Q1 < 0 and Q2 < 0 represent the heat absorption case, while Q1 > 0 and Q2 > 0 represent the heat generation case.

Utilising the linear Rosseland formulation for radiative heat flux qr, which can be defined as [27].

| (6) |

where σsb is the constant of Stefan-Boltzmann and kab is the coefficient of mean absorption. The 4th power of temperature can be expressed as a linear function of temperature as follows:

| (7) |

Invoking eqs (5), (6), (7) in (3), we get

| (8) |

The boundary conditions for the catalytic surface are [[40], [41], [42], [43], [44], [45], [46]].

| (9) |

Where E is the activation energy Qr is the exothermicity of reaction and R is gas constant.

| By introducing the following dimensionless transformations [46] |

| (10) |

the governing equations in (2), (3), (4), (8) are transformed into the following dimensionless form and also the transformations in (10) satisfies the continuity eq. (1),

| (11) |

| (12) |

| (13) |

Consequently, the corresponding boundary conditions in (9) become

| (14) |

Where is the mixed convection parameter due to temperature, is the nonlinear convection parameter due to temperature, is the mixed convection parameter due to concentration, is the nonlinear convection parameter due to concentration, is the porous medium parameter, is the radiation parameter, is the Prandtl number, is the Schmidt number, is the heat of reaction parameter, is the reaction rate and is the activation energy parameter.

3. Physical quantities of attention

The physical quantities on which present research focuses are the skin friction coefficient, non-dimensional wall temperature and non-dimensional wall concentration.

The shear stress at the surface of the wall is given by

The skin friction coefficient Cf can be defined as

The non-dimensional wall temperature and wall concentration can be obtained from the following equations.

4. Method of solution

The governing eqs (11), (12), (13) along with the boundary conditions in (14) are numerically solved using fourth fifth Runge-Kutta Fehlberg integration scheme along with the shooting iteration approach. Runge-Kutta Fehlberg method is a numerical scheme of order two with an error estimator of order 5 that is used to solve ordinary differential equations. The steps involved in the numerical procedure are as follows:

First the boundary value problem is transformed into the following first order initial value problem:

| (18) |

with the boundary conditions

| (19) |

The initial guesses (, and ) are chosen, and the Runge Kutta Fehlberg method is used to integrate the first order systems. Then the computed values are compared with the boundary conditions. The shooting method is used to update the initial guesses to satisfy the boundary conditions, and the process is repeated until the results reach the preferred accuracy of 10−6.

5. Results and discussion

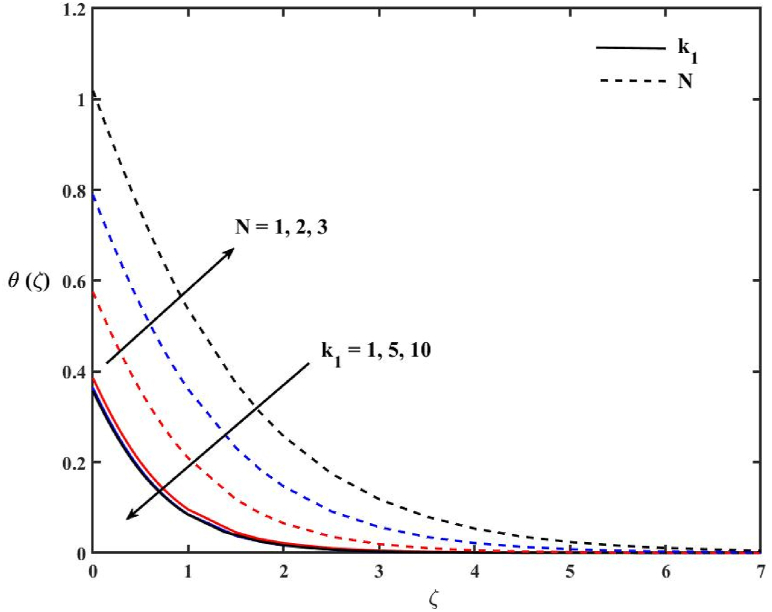

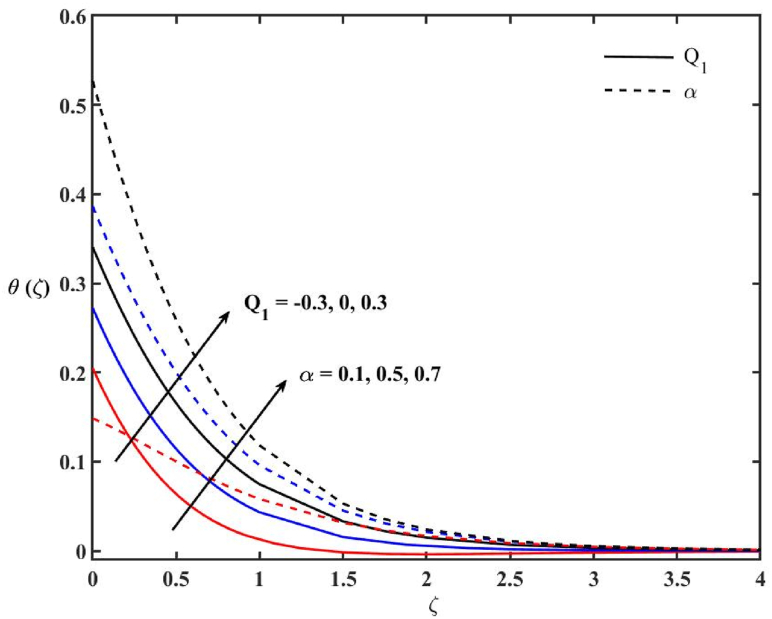

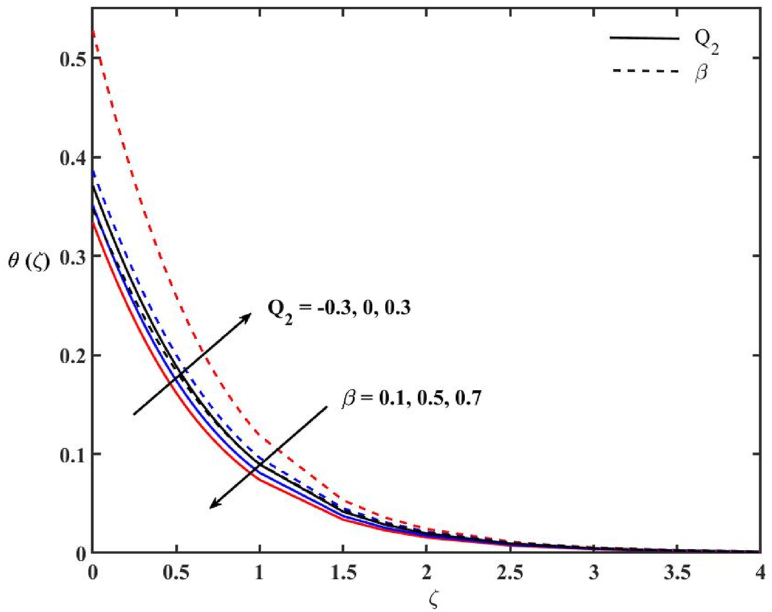

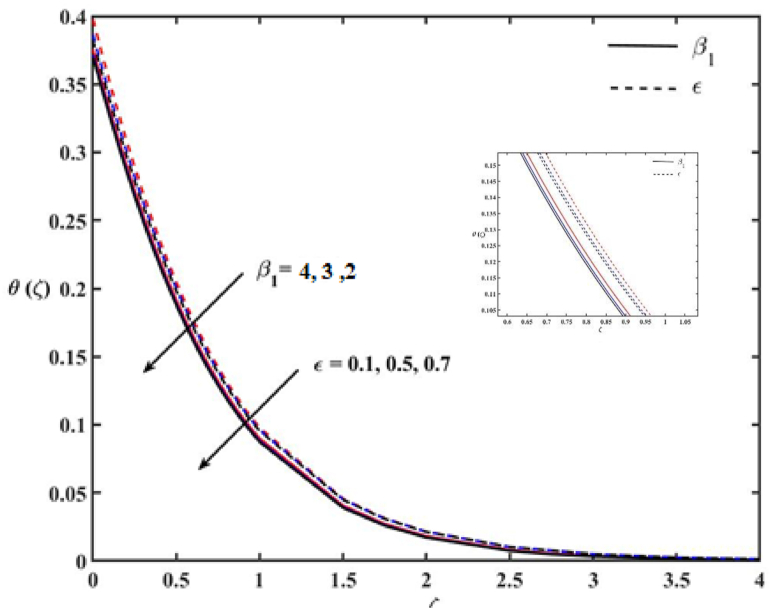

The set of first order ordinary differential eq. (18) and the corresponding initial conditions (19) with guess values are numerically solved using the Runge - Kutta Fehlberg method along with the shooting approach. The present numerical code is validated with those of Khan and Pop [48] and Ullah et al. [49]. The comparison results are tabulated in Table .1. An excellent agreement is observed in the (0) values for various Prandtl numbers in the absence of β1 and α = 0, β = 0, N = 0, k1 = 0, Q1 = 0, Q2 = 0, Ɛ = 0, λt1 = 0, λt2 = 0, λc1 = 0, λc2 = 0 and Sc = 0. The impacts of the radiation parameter (N), porous medium parameter (k1), space dependent heat generation/absorption parameter (Q1), temperature dependent heat generation/absorption parameter (Q2), heat of reaction parameter (α), reaction rate parameter (β), Casson parameter (β1) and activation energy parameter (Ɛ) on Casson liquid velocity, temperature, and concentration profiles are plotted in Fig. 2- 13. The variation of skin friction, non-dimensional wall temperature, and concentration are illustrated in Fig. 14, Fig. 15, Fig. 16. We fixed Pr = 3, β1 = 1, α = 0.5, β = 0.5, N = 1, k1 = 1, Q1 = 0.5, Q2 = 0.5, Ɛ = 0.5, λt1 = 0.5, λt2 = 0.3, λc1 = 0.4, λc2 = 0.5 and Sc = 1 throughout the investigation when studying a particular parameter. It is worth mentioning that when , the present Casson liquid model is reduced to a Newtonian liquid case, the present problem is also be reduced to a problem of Casson liquid flow over a flat catalytic surface when λt1 = 0 and λc1 = 0.

Table 1.

Comparison of (0) in the absence of β1 and α=0, β=0, N=0, k1=0, Q1=0, Q2=0, Ɛ=0, λt1=0, λt2=0, λc1=0, λc2=0 and Sc = 0 with boundary condition and .

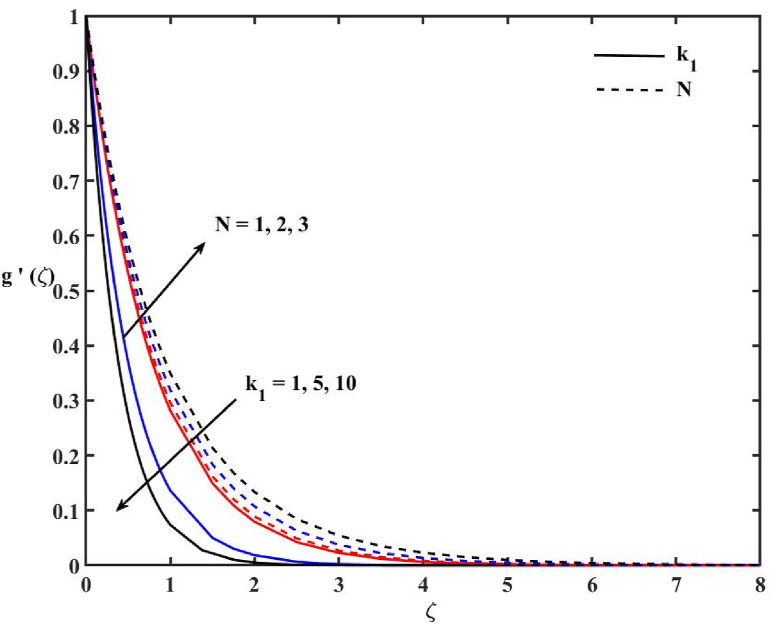

Fig. 2.

Effects of N and k1 on velocity profile.

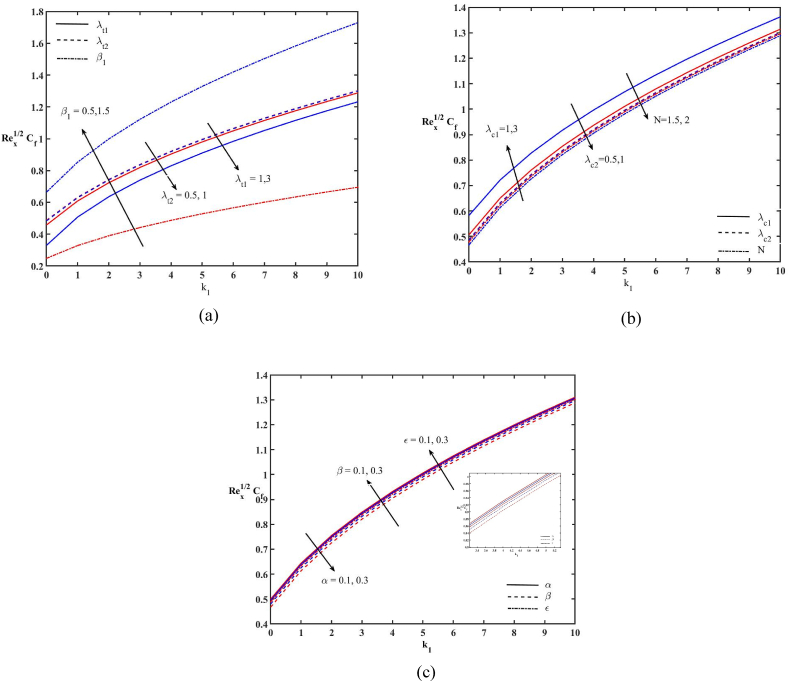

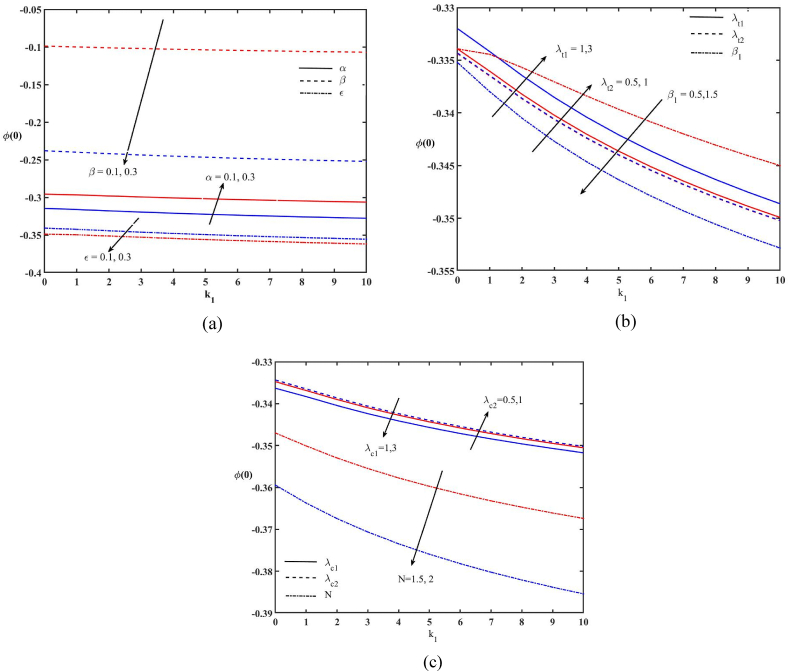

Fig. 14.

Variations of skin friction coefficient (a) Effects of λt1, λt2 and β (b) Effects of λc1, λc2 and N (c) Effects of α, β and Ɛ.

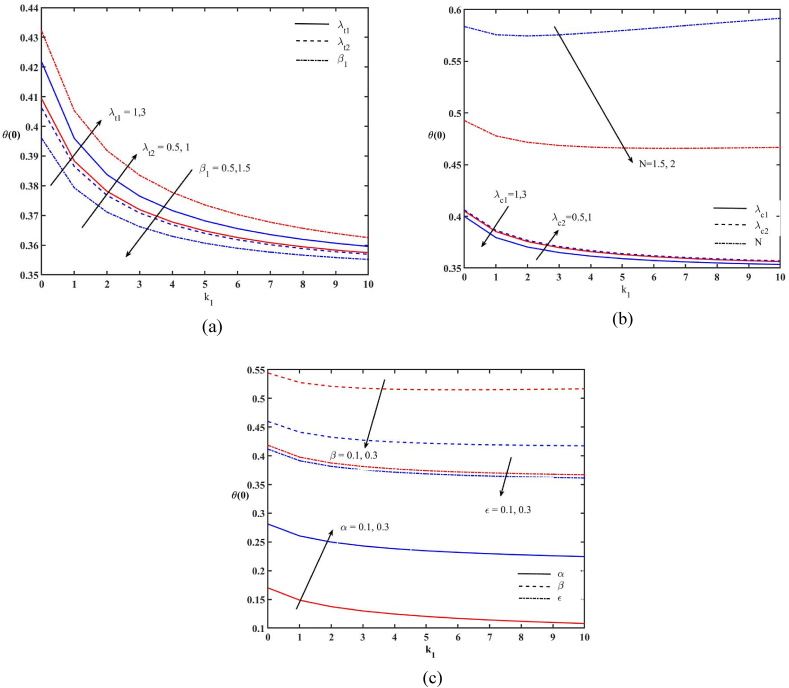

Fig. 15.

Variations of non-dimensional wall temperature (a) Effects of λt1, λt2 and β (b) Effects of λc1, λc2 and N (c) Effects of α, β and Ɛ.

Fig. 16.

Variations of non-dimensional wall concentration (a) Effects of λt1, λt2 and β (b) Effects of λc1, λc2 and N (c) Effects of α, β and Ɛ.

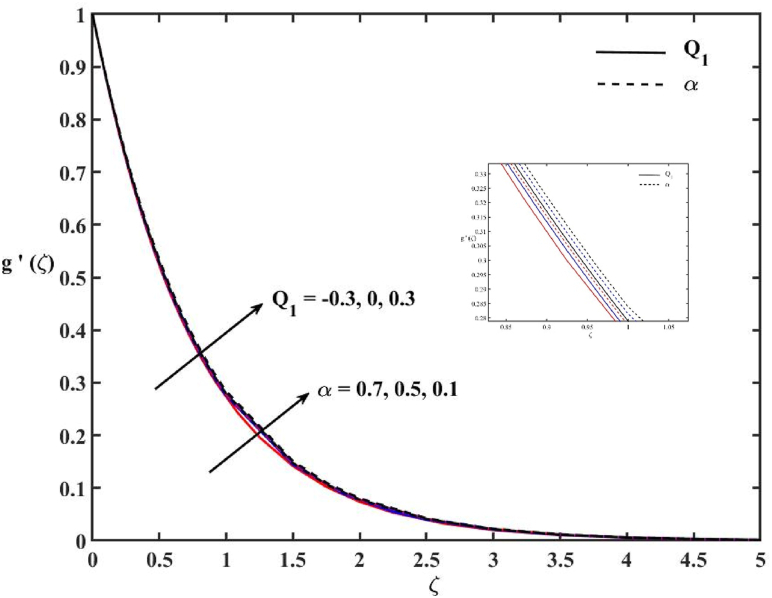

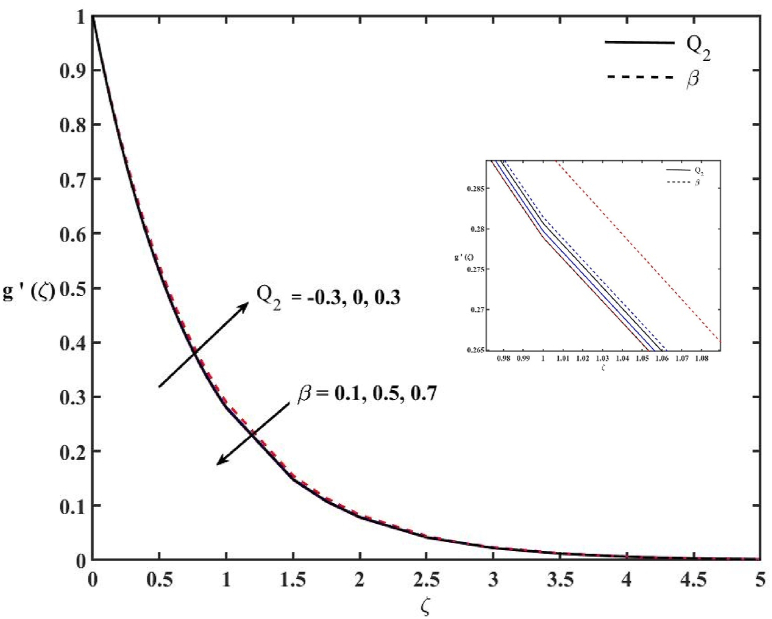

Due to the presence of concentration and thermal buoyancies in the momentum Eq. (11), the parameters N, Q1, Q2, α, β, and Ɛ have influence on the velocity profile of the Casson liquid. The combined impacts of N and k1 on the Casson liquid velocity profile are represented in Fig. 2. Both N and k1 show significant impacts on velocity profile (g '(ζ)). It is observed that the increase in N accelerates the velocity profile while the enhancement in k1 decelerates the velocity profile of the Casson liquid. This is because the increase in N enhances the velocity boundary layer thickness. The parameter k1 is related to the sizes of pores. From the definition of parameter k1, one may see that the increase of k1 leads to a decrease in the size of pores, which causes higher resistance to the Casson liquid flow inside the porous medium. Consequently, the velocity profile decreases with k1. Fig. 3 reveals the impacts α and Q1 on g ՛ (ζ). The positive value of Q1 denotes the presence of space dependent heat generation while the negative value denotes space dependent heat absorption. Both Q1 and α do not show a significant impact on g ՛ (ζ). A slight growth in the g ՛ (ζ) is traced when Q1 > 0, and a reverse trend is observed and felt when Q1 < 0. The reason for this is that the velocity boundary layer thickness reduces in the heat absorption case and enhances in the heat generation case. A slight enhancement is observed with the increase of the heat of reaction parameter α. The impacts of Q2 and β on g ՛ (ζ) are demonstrated in Fig. 4. It is observed that the impacts of Q2 are similar to those of Q1 on the g ՛ (ζ) as explained in the earlier figure. The increase in the reaction rate β gives a diminution in g ՛ (ζ), consequently shrinking the momentum boundary layer of the Casson liquid.

Fig. 3.

Effects of Q1 and α on velocity profile.

Fig. 4.

Effects of Q2 and β on velocity profile.

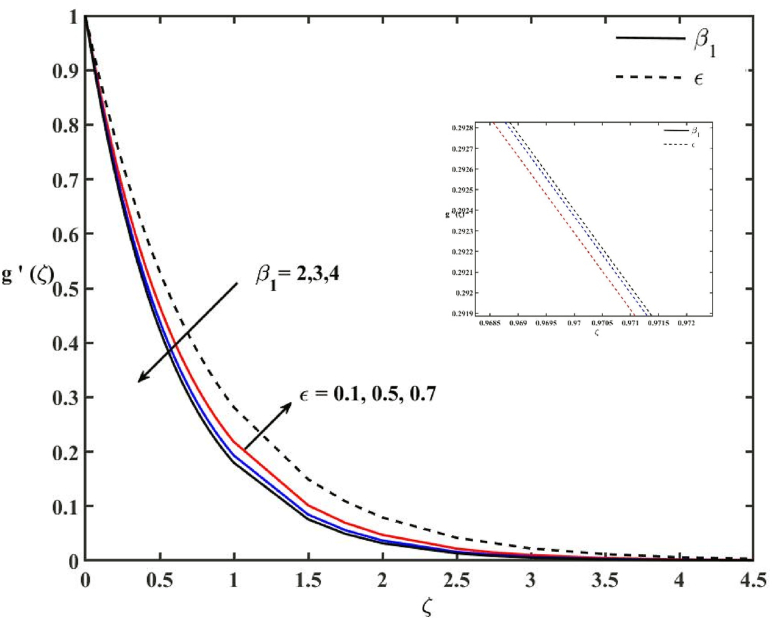

Fig. 5 shows the impacts of β1 and Ɛ on g ՛ (ζ). The results shown in this figure came in response to a suppression in fluid velocity due to increase in β1. An enhancement in β1 increases the viscosity of fluid, consequently momentum boundary layer thickness and velocity decreases. An insignificant enhancement is observed in the momentum boundary layer with the activation energy parameter (Ɛ).

Fig. 5.

Effects of Ɛ and β1 on velocity profile.

Fig. 6 indicates the impacts of N and k1 on the temperature profile Ɵ(ζ). The increase in N enhances Ɵ(ζ). The heat transfer rate reduces with higher k1. Hence, to enhance cooling from the stretching surface, the radiation parameter must be fixed low. A slight decrement in Ɵ(ζ) is observed with higher porous medium parameter in the catalytic surface. The impacts of α and Q1 on Ɵ(ζ) are shown in Fig. 7. The temperature profile enhances when Q1 > 0 and reduces when Q1 < 0. The heat generation parameter increases the temperature of the fluid molecules; consequently, the thermal boundary layer thickness enhances and the heat absorption parameter observes the temperature from the liquid molecules and reduces the thermal boundary layer thickness. The parameter α shows a considerable impact on Ɵ(ζ). The behavior of Ɵ(ζ) is directly proportional to the heat of reaction parameter. The rising value of α increases the thermal boundary thickness. Fig. 8 displays the impacts of Q2 and β on Ɵ(ζ). The impact of Q2 on the temperature profile is similar to Q1, but it is interesting to note that a good variation in thermal boundary layer is observed with Q1. The variation of Q2 does not show significant variation on the thermal boundary layer. The thermal boundary decreased with the increase of β. The impacts of β1 and Ɛ on Ɵ(ζ) are exhibited in Fig. 9. It can be seen that an increase in β1 implicating the higher viscosity of fluid, causes an increase in Ɵ(ζ) as a result of developing an ascending thermal boundary layer. With a larger value of the activation energy parameter (Ɛ), the thickness of the thermal boundary layer decreased slightly.

Fig. 6.

Effects of N and k1 on temperature profile.

Fig. 7.

Effects of Q1 and α on temperature profile.

Fig. 8.

Effects of Q2 and β on temperature profile.

Fig. 9.

Effects of Ɛ and β1 on temperature profile.

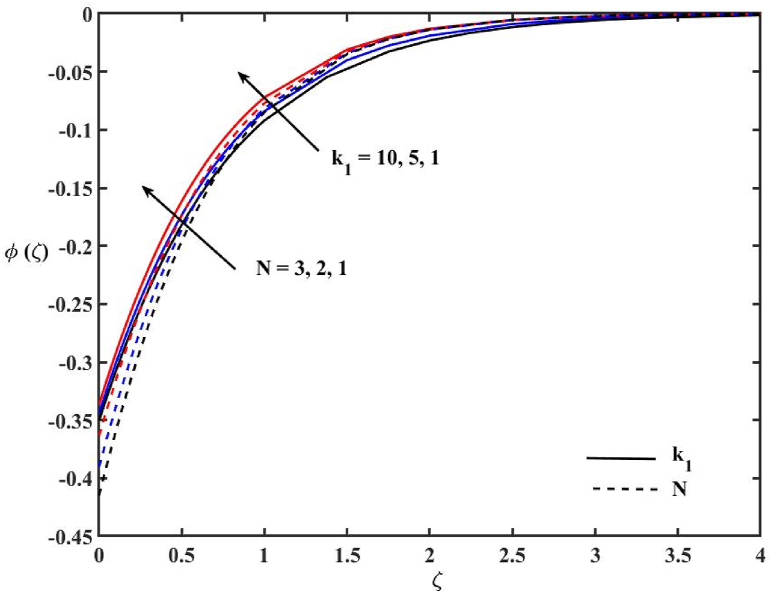

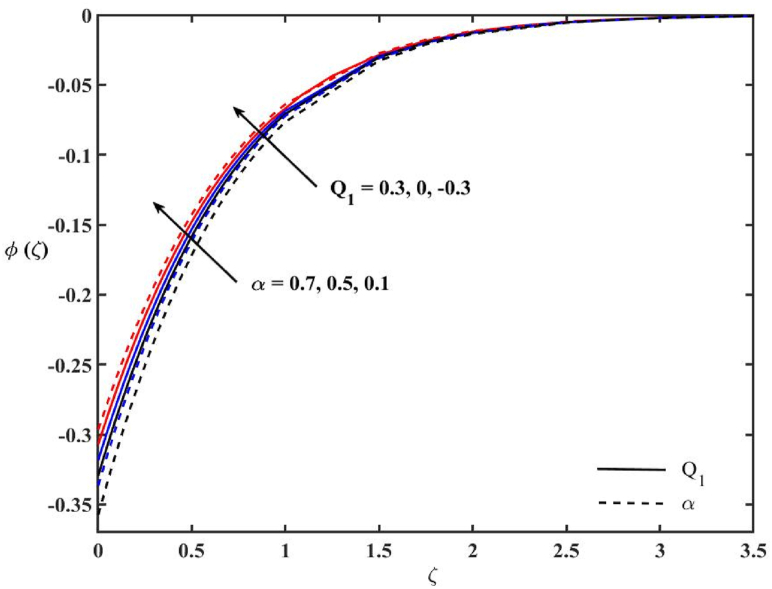

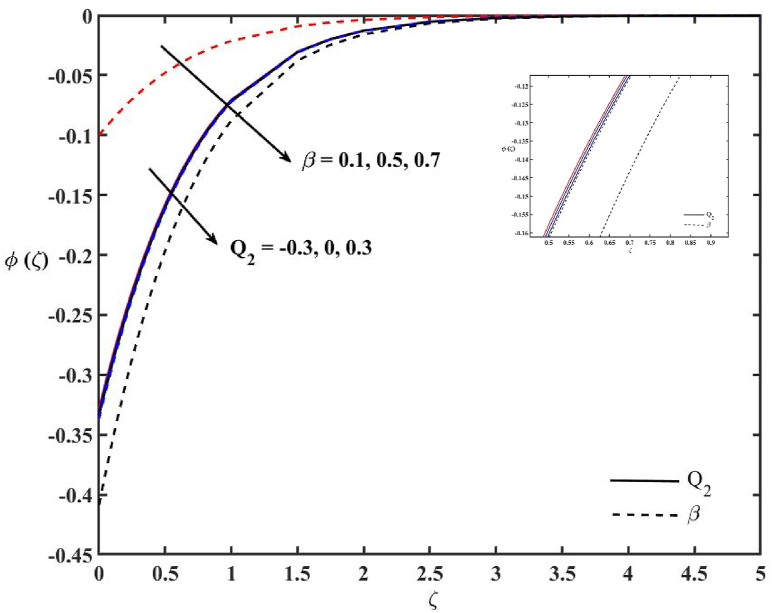

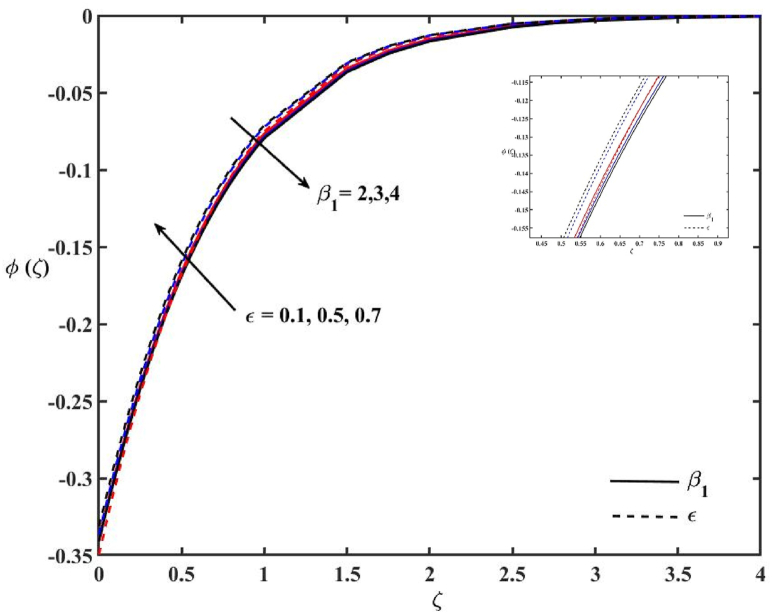

The impacts of N and k1 on concentration profile φ (ζ) are demonstrated in Fig. 10. It is noted that both N and k1 raise the concentration profile and reduce the thickness of the concentration boundary layer. Fig. 11 portrays the impacts of Q1 and α on the concentration profile. The concentration profile increases with α. It is also noted that the concentration profile is higher in the presence of heat generation and lower in the presence of heat absorption. The combined impact of α with heat generation decreases the thickness of the concentration boundary layer. The impacts of β and Q2 on the concentration profile is examined in Fig. 12. One may note that the temperature dependent heat generation/absorption parameter does not have significant impacts on the concentration profile. The concentration boundary layer increases with the increase of β. Fig. 13 is plotted to show the impacts of β1 and Ɛ on the concentration profile. It is observed that the increase in β1 reduces the concentration profile, while Ɛ enhances the concentration profile.

Fig. 10.

Effects of N and k1 on concentration profile.

Fig. 11.

Effects of Q1 and α on concentration profile.

Fig. 12.

Effects of Q2 and β on concentration profile.

Fig. 13.

Effects of Ɛ and β1 on concentration profile.

The variations of skin friction coefficient, non-dimensional wall temperature, and non-dimensional wall concentration are depicted in Fig. 14, Fig. 15, Fig. 16 respectively. The skin friction coefficient enhances with the increase of k1,β1, λc1, β and Ɛ; reduces with λt1, λt2, λc2, N and α (Fig. 14). The increasing values of λt1, λt2, λc2, α increase the non-dimensional wall temperature. The non-dimensional wall temperature decreases with β1, N, λc1, β, k1 and Ɛ (Fig. 15). The non-dimensional wall concentration rises with the rising values of α, λt1, λt2, and λc2 while it decreases with β, Ɛ, β1, N,k1 and λc1 (Fig. 16).

6. Conclusion

The nonlinear mixed convection flow of Casson liquid over a stretching surface is investigated numerically in a porous medium. The Arrhenius kinetics impact is considered at the boundary. The heat and mass transfer are analysed in the presence of space and temperature dependent heat generation/absorption and thermal radiation. The similarity solutions are obtained through the Runge-Kutta Fhelberg method along with the shooting technique. The key findings of the present study are:

-

•

Enhancing the radiation parameter, space and temperature dependent heat generation, heat of reaction, and activation energy accelerate the velocity profile, while the velocity profile decelerates with the increase of the porous medium parameter, space and temperature dependent heat absorption, reaction rate constant, and Casson parameters in the presence of nonlinear heat and mass transfer and Arrhenius kinetics.

-

•

The temperature profile increases with the increase of radiation, space and temperature dependent heat generation, heat of reaction, and Casson parameters and reduces with the porous medium parameter, space and temperature dependent heat absorption parameter, reaction rate, and activation energy parameters.

-

•

The concentration profile intensifies with the increase of the porous medium parameter, the radiation parameter, space dependent heat generation, heat of reaction, and activation energy, while it reduces with the reaction rate constant, and the Casson parameter.

-

•

The skin friction coefficient enhances with the porous medium parameter, Casson parameter, first order concentration buoyancy, reaction rate, and activation energy parameter and reduces with linear and nonlinear mixed convection due to temperature, and nonlinear convection due to concentration, radiation, and heat of reaction parameters.

-

•

The increasing values of linear and nonlinear mixed convection due to temperature and nonlinear convection due to concentration and heat of reaction increases the non-dimensional wall temperature.

-

•

The non-dimensional wall concentration rises with the rising values of heat of reaction, linear convection and nonlinear mixed convection due to temperature, and nonlinear convection due to concentration parameters.

The current study focused on the heat transmission from an exothermic process to the fluid surrounding it, which drives the convection flow of Casson fluid in a porous Darcian medium. The future directions of the present study are: the researchers may consider the flow of various non-Newtonian fluids, which is purely driven by the heat supplied to the fluid by an exothermic reaction.

Author contribution statement

N. Vishnu Ganesh; Qasem Al-Mdallal: Conceived and designed the experiments; Performed the experiments; Contributed reagents, materials, analysis tools or data; Wrote the paper. Kalaivanan Raja; Reena K: Analysed and interpreted the data; Contributed reagents, materials, analysis tools or data; Wrote the paper.

Data availability statement

Data included in article/supp. material/referenced in article.

Declaration of competing interest

None.

Acknowledgements

The authors wish to express their sincere thanks to the honourable referees for their valuable comments and suggestions that improved the quality of the paper. Additionally, all authors would like to express their gratitude to the United Arab Emirates University, Al Ain, UAE, for providing financial support with Grant No. 12S122.

Nomenclature

- C

concentration (kg/m3)

- Cw

concentration of the sheet (kg/m3)

concentration far away from the sheet (kg/m3)

- Cf

local skin friction coefficient

- cp

Specific heat capacity (J/kg K)

- D

molecular diffusivity (m2/s)

- E

the activation energy (kcal/mol)

- g1

acceleration due to gravity (m/s2)

- k

thermal conductivity (W/m K)

- kab

coefficient of mean absorption

- kp

permeability of the porous medium

porous medium parameter

radiation parameter

- p

pressure (kg m−1s−2)

- Pr

Prandtl number

- Qr

exothermicity of a reaction

- Q1

space dependent heat generation/absorption parameter

- Q2

temperature dependent heat generation/absorption parameter

- qr

radiative heat flux

- R

gas constant

- Rex1/2

Reynolds number

Schmidt number

- T

local temperature of the fluid (K)

- Tw

temperature of the sheet (K)

temperature of the fluid far away from the sheet (K)

velocity component in x and y direction (m/s)

- uw

velocity of stretching sheet (m/s)

- x,y

coordinates along and perpendicular to the sheet (m)

- X

reactant

- Y

produce species

Greeksymbols

heat of reaction

- β

reaction rate

- β1

Casson parameter

- βt1

first order thermal expansion coefficient

- βt2

second order thermal expansion coefficient

- βc1

first order solutal coefficient

- βc2

second order solutal coefficient

- σsb

constant of Stefan-Boltzmann

activation energy

density (kg/m3)

- g

dimensionless velocity

2)

mixed convection parameter due to concentration

Contributor Information

N. Vishnu Ganesh, Email: nvishnuganeshmath@gmail.com.

Qasem M. Al-Mdallal, Email: q.almdallal@uaeu.ac.ae.

References

- 1.Atangana A. Academic Press; 2017. Fractional Operators with Constant and Variable Order with Application to Geo-Hydrology. [Google Scholar]

- 2.Nield D.A., Bejan A. vol. 3. springer; New York: 2006. (Convection in Porous Media). [Google Scholar]

- 3.Bejan A., Dincer I., Lorente S., Miguel A., Reis H. Springer Science & Business Media; 2004. Porous and Complex Flow Structures in Modern Technologies. [Google Scholar]

- 4.Vafai K., editor. Handbook of Porous Media. Crc Press; 2015. [Google Scholar]

- 5.Ingham D.B., Pop I., editors. vol. 3. Elsevier; 2005. (Transport Phenomena in Porous Media III). [Google Scholar]

- 6.Ingham D.B., Bejan A., Mamut E., Pop I., editors. vol. 134. Springer Science & Business Media; 2012. (Emerging Technologies and Techniques in Porous Media). [Google Scholar]

- 7.Hakeem A.A., Ganesh N.V., Ganga B. Effect of heat radiation in a Walter's liquid B fluid over a stretching sheet with non-uniform heat source/sink and elastic deformation. J. King Saud Univ. Eng. Sci. 2014;26(2):168–175. [Google Scholar]

- 8.Mahabaleshwar U.S., Sarris I.E., Lorenzini G. Effect of radiation and Navier slip boundary of Walters' liquid B flow over a stretching sheet in a porous media. Int. J. Heat Mass Tran. 2018;127:1327–1337. [Google Scholar]

- 9.Asjad M.I., Ali R., Iqbal A., Muhammad T., Chu Y.M. Application of water based drilling clay-nanoparticles in heat transfer of fractional Maxwell fluid over an infinite flat surface. Sci. Rep. 2021;11(1):1–14. doi: 10.1038/s41598-021-98066-w. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 10.Megahed A.M., Reddy M.G. Numerical treatment for MHD viscoelastic fluid flow with variable fluid properties and viscous dissipation. Indian J. Phys. 2021;95(4):673–679. [Google Scholar]

- 11.Ganesh N.V., Al-Mdallal Q.M., Öztop H.F., Kalaivanan R. Analysis of natural convection for a Casson-based multiwall carbon nanotube nanofluid in a partially heated wavy enclosure with a circular obstacle in the presence of thermal radiation. J. Adv. Res. 2022;39:167–185. doi: 10.1016/j.jare.2021.10.006. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 12.Manaa S., Boulaaras S., Benseridi H., Dilmi M., Alodhaibi S. Analysis for flow of an incompressible brinkman-type fluid in thin medium with friction. J. Funct. Spaces. 2021 [Google Scholar]

- 13.Nazeer M., Hussain F., Ahmad M.O., Saeed S., Khan M.I., Kadryand S., Chu Y.M. Multi-phase flow of Jeffrey Fluid bounded within magnetized horizontal surface. Surface. Interfac. 2021;22 [Google Scholar]

- 14.Habib U., Hayat T., Ahmadand S., Alhodaly M.S. Entropy generation and heat transfer analysis in power-law fluid flow: finite difference method. Int. Commun. Heat Mass Tran. 2021;122 [Google Scholar]

- 15.Kalaivanan R., Ganesh N.V., Al-Mdallal Q.M. Buoyancy driven flow of a second-grade nanofluid flow taking into account the Arrhenius activation energy and elastic deformation: models and numerical results. Fluid Dynam. Mater. Process. 2021;17(2):319–332. [Google Scholar]

- 16.Ewis K.M. Analytical solution of modified Bingham fluid flow through parallel plates channel subjected to forchheimer medium and Hall current using linearized differential transformation method. J. Adv. Res. Num. Heat Trans. 2021;4(1):14–31. [Google Scholar]

- 17.Razzaq R., Farooq U. Non-similar forced convection analysis of Oldroyd-B fluid flow over an exponentially stretching surface. Adv. Mech. Eng. 2021;13(7) [Google Scholar]

- 18.Mukhopadhyay S., De P.R., Bhattacharyya K., Layek G.C. Casson fluid flow over an unsteady stretching surface. Ain Shams Eng. J. 2023;4(4):933–938. [Google Scholar]

- 19.Ganesh N.V., Kameswaran P.K., Hakeem A.K., Ganga B. Second order slip flow of water based nanofluids over a stretching/shrinking sheet embedded in a porous medium with internal heat generation/absorption and thermal jump effects. J. Nanofluids. 2019;8(3):526–542. [Google Scholar]

- 20.Ganesh N.V., Al-Mdallal Q.M., Kalaivanan R. Exact solution for heat transport of Newtonian fluid with quadratic order thermal slip in a porous medium. Adv. Theory Nonlinear Anal. Appl. 2021;5(1):39–48. [Google Scholar]

- 21.Reddy N.N., Rao V.S., Reddy B.R. Chemical reaction impact on MHD natural convection flow through porous medium past an exponentially stretching sheet in presence of heat source/sink and viscous dissipation. Case Stud. Therm. Eng. 2021;25 [Google Scholar]

- 22.Megahed A.M. Improvement of heat transfer mechanism through a Maxwell fluid flow over a stretching sheet embedded in a porous medium and convectively heated. Math. Comput. Simulat. 2021;187:97–109. [Google Scholar]

- 23.Ahmad S., Ali K., Rizwan M., Ashraf M. Heat and mass transfer attributes of copper–aluminum oxide hybrid nanoparticles flow through a porous medium. Case Stud. Therm. Eng. 2021;25 [Google Scholar]

- 24.Senge I.O., Oghre E.O., Ekang I.F. Influence of radiation on magneto-hydrodynamics flow over an exponentially stretching sheet embedded in a thermally stratified porous medium in the presence of heat source. Earthline J. Math. Sci. 2021;5(2):345–363. [Google Scholar]

- 25.Bhattacharyya K. MHD stagnation-point flow of Casson fluid and heat transfer over a stretching sheet with thermal radiation. J. Thermodynamics. 2013 [Google Scholar]

- 26.Shehzad S.A., Hayat T., Alsaedi A. Three-dimensional MHD flow of Casson fluid in porous medium with heat generation. J. Appl. Fluid Mech. 2016;9(1):215–223. [Google Scholar]

- 27.Mabood F., Abdel-Rahman R.G., Lorenzini G. Effect of melting heat transfer and thermal radiation on Casson fluid flow in porous medium over moving surface with magnetohydrodynamics. J. Eng. Thermophys. 2016;25(4):536–547. [Google Scholar]

- 28.Patel H.R. Effects of cross diffusion and heat generation on mixed convective MHD flow of Casson fluid through porous medium with non-linear thermal radiation. Heliyon. 2019;5(4) doi: 10.1016/j.heliyon.2019.e01555. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 29.Patel H.R. Effects of heat generation, thermal radiation, and hall current on MHD Casson fluid flow past an oscillating plate in porous medium. Multiphas. Sci. Technol. 2019;31(1):87–107. [Google Scholar]

- 30.Awais M., Raja M.A.Z., Awan S.E., Shoaib M., Ali H.M. Heat and mass transfer phenomenon for the dynamics of Casson fluid through porous medium over shrinking wall subject to Lorentz force and heat source/sink. Alex. Eng. J. 2021;60(1):1355–1363. [Google Scholar]

- 31.Nandkeolyar R., Chamkha A.J. A numerical investigation of Hall and radiation effects on MHD three-dimensional Casson fluid flow in a porous medium. J. Porous Media. 2021;24(6):15–30. [Google Scholar]

- 32.Eldabe N.T., Abou-Zeid M.Y., El-Kalaawy O.H., Moawad S.M., Ahmed O.S. Electromagnetic steady motion of Casson fluid with heat and mass transfer through porous medium past a shrinking surface. Therm. Sci. 2021;25:257–265. [Google Scholar]

- 33.Ikeda H., Libby P.A., Williams F.A., Sato J.I. Catalytic combustion of hydrogen-air mixtures in stagnation flows. Combust. Flame. 1993;93(1–2):138–148. [Google Scholar]

- 34.Puri I.K. Extinction criteria for buoyant nonpremixed flames. Combust. Sci. Technol. 1992;84(1–6):305–321. [Google Scholar]

- 35.Gray B.F., Merkin J.H. Thermal explosion: escape times in the uniform temperature approximation. Part 1.—effects of parameter perturbations. J. Chem. Soc., Faraday Trans. 1990;86(4):597–601. [Google Scholar]

- 36.Gray B.F., Merkin J.H. Thermal explosion: escape times in the uniform temperature approximation. Part 2. Perturbations of critical initial conditions. Math. Eng. Ind. 1993;4(1):13–26. [Google Scholar]

- 37.Gray B.F., Merkin J.H., Wake G.C. Disjoint bifurcation diagrams in combustion systems. Math. Comput. Model. 1991;15(11):25–33. [Google Scholar]

- 38.Sadiq M.A., Merkin J.H. Combustion in a porous material with reactant consumption: the role of the ambient temperature. Math. Comput. Model. 1994;20(1):27–46. [Google Scholar]

- 39.Chaudhary M.A., Merkin J.H. Free-convection stagnation-point boundary layers driven by catalytic surface reactions: I the steady states. J. Eng. Math. 1994;28(2):145–171. [Google Scholar]

- 40.Merkin J.H., Chaudhary M.A. Free-convection boundary layers on vertical surfaces driven by an exothermic surface reaction. Q. J. Mech. Appl. Math. 1994;47(3):405–428. [Google Scholar]

- 41.Chaudhary M.A., Linan A., Merkin J.H. Free convection boundary layers driven by exothermic surface reactions: critical ambient temperatures. Math. Eng. Ind. 1995;5(2):129–145. [Google Scholar]

- 42.Chaudhary M.A., Merkin J.H. Free convection stagnation point boundary layers driven by catalytic surface reactions: II times to ignition. J. Eng. Math. 1996;30(4):403–415. [Google Scholar]

- 43.Minto B.J., Ingham D.B., Pop I. Free convection driven by an exothermic reaction on a vertical surface embedded in porous media. Int. J. Heat Mass Tran. 1998;41(1):11–23. [Google Scholar]

- 44.Ingham D.B., Harris S.D., Pop I. Free-convection boundary layers at a three-dimensional stagnation point driven by exothermic surface reactions. Hybrid Methods Eng. 1999;1(4) [Google Scholar]

- 45.Merkin J.H., Pop I. Stagnation point flow past a stretching/shrinking sheet driven by Arrhenius kinetics. Appl. Math. Comput. 2018;337:583–590. [Google Scholar]

- 46.Ganesh N.V., Kalaivanan R., Al-Mdallal Q.M., Reena K. Buoyancy driven second grade nano boundary layers over a catalytic surface with reaction rate, heat of reaction and activation energy at boundary. Case Stud. Therm. Eng. 2021;28 [Google Scholar]

- 47.Zheng L., Wang L., Zhang X. Analytic solutions of unsteady boundary flow and heat transfer on a permeable stretching sheet with non-uniform heat source/sink. Commun. Nonlinear Sci. Numer. Simul. 2011;16(2):731–740. [Google Scholar]

- 48.Khan W.A., I Pop Boundary-layer flow of a nanofluid past a stretching sheet. Int. J. Heat Mass Tran. 2010;53(11–12):2477–2483. [Google Scholar]

- 49.Ullah I., Shafie S., Khan I. Effects of slip condition and Newtonian heating on MHD flow of Casson fluid over a nonlinearly stretching sheet saturated in a porous medium. J. King Saud Univ. Sci. 2017;29(2):250–259. [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.

Data Availability Statement

Data included in article/supp. material/referenced in article.