Abstract

The baked balls (traditional Indian snack litti) were formulated along with the standardization and optimization of different ingredients and recipe. The optimization was done by using response surface methodology. Box behnken model was selected for the optimization in which wheat flour (40–80%), roasted bengal gram flour (10–50%), and pumpkin peel powder (2.5–15%) were selected as an independent factor for the standardization of baked balls recipe against the dependent factors including sensory attributes (colour and texture), moisture content and water activity. The proximate analysis of optimized baked balls resulted in energy, carbohydrate, protein, fat, dietary fibre, calcium, iron, and zinc value as 310 kcal, 55.6 g/100 g, 13.78 g/100 g, 2.73 g/100 g, 40.18 mg/100 g, 4.57 mg/100 g and 2.97 mg/100 g respectively. Additionally, carotenoid content of control and optimized baked balls was found to be 284 µg/100 g and 838.93 µg/100 g whereas the ascorbic acid content was observed as 1.84 mg/100 g and 5.82 mg/100 g respectively. It showed a significant increase in nutritional parameters when compared with control (wheat flour) baked balls. This study also evidenced that pumpkin peel powder can be used as a food supplement for various nutritional components.

Keywords: Box behnken design, Baked balls, Carotenoids, Pumpkin peel powder, Sensory evaluation

Introduction

Despite of knowing the importance of several fruits and vegetables, are not being exploited appropriately. Even though being a good source of fibres, carbohydrates, fats, proteins, minerals, and vitamins, are often wasted from agricultural land to the final stage of production in the form of leaves, peels, and seeds. Hence, it becomes crucial to utilize such crops or their waste for the development of enriched food products. Pumpkin is one amongst those crops and the demand of pumpkin has increased over a period of time due to its well-known nutritional value. Jun et al. (2006) reported that pumpkin could be used in various food products as it is rich in carotene, pectin, mineral (calcium, phosphorus), vitamins (vitamin A, vitamin B-complex), and bioactive components such as phenolic compounds, para-aminobenzoic acid, terpenoids, and moderate amount of carbohydrate (Mishra and Sharma 2019; Crozier 2003; Murkovic et al. 2004).

Pumpkin (Cucurbita máxima L.) is one of the commonly used vegetables in India. It belongs to Cucurbitaceae family and grown all over the world. When it is in immature form then it is used as vegetable whereas the mature pumpkin is used for the production of various confectionary items. Moreover, it was also reported that pumpkin pulp and peel could help to control the serum insulin and blood glucose levels, and improves the glucose tolerance level as well (Li et al. 2005). Pumpkin is specifically recommended to diabetic patients (Ahmed et al. 2014). It has been reported to use as iron supplements, and can also be incorporated for the development of functional food products (Stevenson et al. 2007). Pumpkin peel can be used as a gelling agent or thickening agent due to its high pectin content. It was observed that incorporation of pumpkin peel powder to cereal flours for the development of bakery products such as bread, cakes, and cookies helps in maintaining the desirable flavour, sweetness, and deep yellow colour whereas the powder can also be added in soups, sauces and extruded products to improve the quality attributes of a product (Roongruangsri and Bronlund 2015; Cumarasamy et al. 2002). Mishra and Sharma (2019) mentioned that pumpkin peel contains good amount of proteins and fibres, along with ascorbic acid and calcium. Therefore, the use of pumpkin peel along with wheat flour may lead to the production of nutritionally improved food products.

Baked balls (Litti) is one of the Indian traditional snack, is prepared by using wheat flour and sometimes can also be blend with bengal gram flour to enhance the nutritional value of the end product. The use of cereals such as wheat, rice, maize, sorghum, and millets like pearl millet, proso millet, foxtail millet, and finger millet for the formulation of baked balls are known to be essential source of carbohydrates, dietary fibres, proteins, vitamins, and minerals (Blandino et al. 2003). Wheat is one of the essential grains used for the formulation of various baked products in India. The quality characteristics of different wheat products are mainly dependent on variety of wheat, its processing conditions, and processing method. There are several pre-treatment and processing methods such as cooking, germination, milling, and fermentation are usually employed to improve the nutritional quality of cereals (Ben Jeddou et al. 2017). Vadnerkar (2004) had prepared chapaties from whole-wheat flour by adding soy flour to improve the protein content in it. Many researchers have mentioned that bran and germ portion of wheat grain is considered as a good source of minerals, phytochemicals, and amino acids (Dewettinck et al. 2008). In view of the above fact, the present work was designed to standardize the recipe of baked ball made with the addition of pumpkin peel powder, so that the nutritionally rich and sensory acceptable product can be produced.

Materials and methods

Collection of raw materials

All the raw materials i.e. wheat flour, roasted bengal gram flour (sattu flour), pumpkin, ginger, garlic, bengal gram flour, fennel seed powder and other additives were purchased from the local market of Dwarka, sector 10, New Delhi, India. The selected ingredients were taken from ISO: 22,000 and FSSAI (Food Safety Standard Authority of India) certified food industry, which was processed and packed by well known Indian brands.

Preparation of pumpkin peel powder

The pumpkin peel was collected, washed under running tap water, and dried in tray drier (Tray Drier Digital, JUPITER Scientific Company, Haryana, India) at a temperature of 60 °C for a period of 4–5 h. Dried pumpkin peels (PP) were ground into grinder (SUJATA BRAND) and sieved through a mesh size of 100 ASTM. The sifted powder was collected and packed in air tight containers and stored at 4 °C until used.

Preparation of baked balls

All the dry ingredients (wheat flour, roasted bengal gram flour and pumpkin peel powder) were added in an appropriate amount and mixed properly. The dough was developed by adding the required amount of water. A dough loaf of equal size was cut and shaped into small size balls. A uniform mixture consisting of 70% roasted bengal gram flour, 10% fine chopped onion, 5% pumpkin peel powder, 4% fine chopped green chili, 4% ginger paste, 3% garlic paste, 2% black salt, 1% fennel seed and 1% black pepper was prepared for stuffing the balls. Furthermore, it is a traditional Indian popular product prepared with wheat flour along with stuffing of bengal gram flour and spices (Raghav et al. 2021), therefore control was prepared with wheat flour and the same stuffing was used in control. The stuffing was done into the dough ball by pressing the center portion and then made into ball form by pressing and rolling simultaneously. Furthermore, the ball was coated with butter and placed inside the baking oven at 180 °C for about 30 min. After complete baking it was removed out and cooled at room temperature. The cooled baked balls were stored in air tight containers until taken for analysis.

Experimental design for the optimization of flour for the preparation of baked balls (Litti)

Response Surface Methodology (RSM) can be used as one of the most important optimization method. In RSM, various components can be optimized for the development of products. It is an appropriate method to design, improve, and formulate the process parameters for the development of new products for better retention of its physicochemical, nutritional, and chemical composition. In this study, Box Behnken design of response surface methodology was chosen for the optimization of different flours, and pumpkin peel powder for the formulation of baked balls (Fig. 1). The design includes three independent variables (Wheat flour, bengal gram flour, and pumpkin peel powder) and four dependent variables (moisture content, texture, water activity and colour). The range of independent variables was obtained from the previous research papers such as wheat flour (40–80%), bengal gram flour (10–50%), and pumpkin peel powder (2.5–15%). Response surface methodology was implied to the experimental factors by using commercial statistical design expert version 11 (Statease Inc., Minneapolis, MN, USA). Box behnken design with 3 levels and five factors resulted in total number of 17 runs with 5 replicates at centre point to achieve the optimum level of independent variables for the development of baked balls (Table 1). The coded variables in the model resulted in second order and quadratic equations which was further used to direct the individual response as a function of independent factors. The obtained equations for various factors such as colour, texture, water activity, and moisture content have been mentioned below as coded variables where A, B, and C represent wheat flour, bengal gram flour, and pumpkin peel powder respectively.

| 1 |

| 2 |

| 3 |

| 4 |

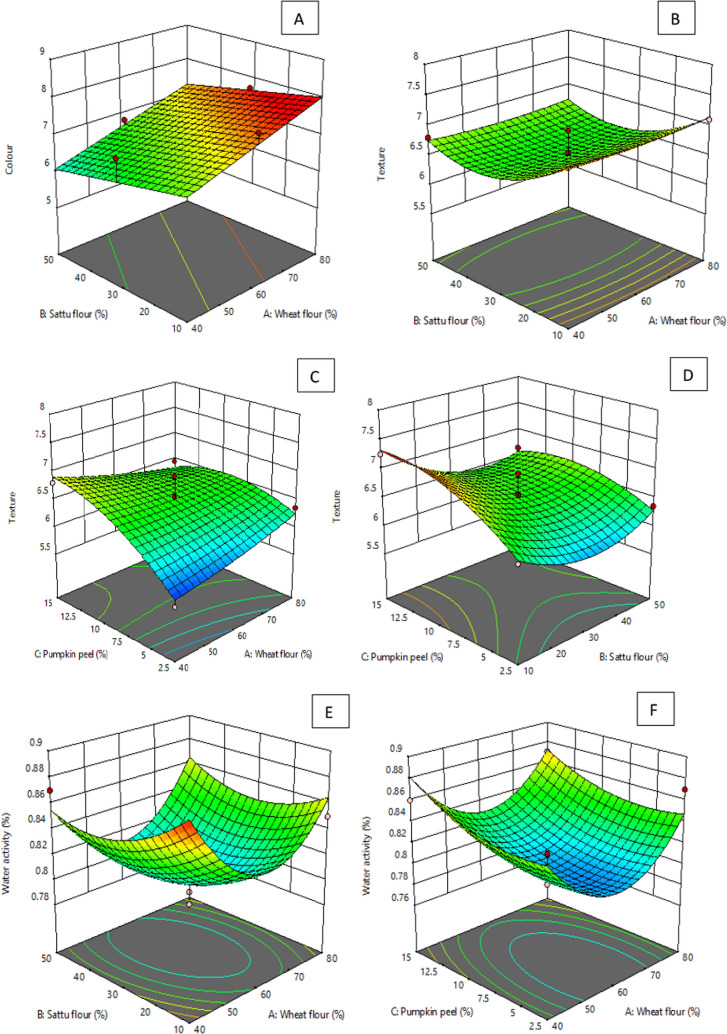

Fig. 1.

Response surface (3-dimensional) graphs illustrate the effect of independent factors like wheat flour, roasted bengal gramflour, and pumpkin flour on Colour (A), Texture (B–D), Water activity (E–G), and Moisture content (H–J) of baked balls

Table 1.

Optimization of independent factors by using Box–Behnken design for the development of baked balls

| Runs | Independent factors | Responses | |||||

|---|---|---|---|---|---|---|---|

| Wheat flour (%) | Bengal gram flour (%) | Pumpkin peel (%) | Colour | Texture | Water activity | Moisture content (%) | |

| 1 | 60 | 10 | 15 | 7.45 ± 1.04 | 7.25 ± 2.03 | 0.87 ± 1.18 | 33.25 ± 1.14 |

| 2 | 40 | 30 | 2.5 | 7.05 ± 1.10 | 5.60 ± 1.14 | 0.85 ± 1.12 | 25.7 ± 1.20 |

| 3 | 60 | 10 | 2.5 | 7.70 ± 1.14 | 6.31 ± 1.44 | 0.82 ± 1.18 | 24.82 ± 1.31 |

| 4 | 80 | 50 | 8.75 | 7.00 ± 1.11 | 6.56 ± 1.32 | 0.86 ± 1.24 | 25.60 ± 1.15 |

| 5 | 60 | 30 | 8.75 | 6.60 ± 1.12 | 6.55 ± 2.14 | 0.81 ± 1.25 | 22.05 ± 1.18 |

| 6 | 80 | 30 | 2.5 | 7.70 ± 1.14 | 6.35 ± 1.09 | 0.87 ± 1.11 | 24.01 ± 1.11 |

| 7 | 80 | 10 | 8.75 | 7.40 ± 2.08 | 7.10 ± 1.25 | 0.85 ± 1.14 | 23.80 ± 1.11 |

| 8 | 60 | 30 | 8.75 | 6.50 ± 1.12 | 6.42 ± 2.14 | 0.79 ± 1.25 | 22.64 ± 1.18 |

| 9 | 60 | 30 | 8.75 | 6.20 ± 1.12 | 6.35 ± 2.14 | 0.78 ± 1.25 | 23.65 ± 1.18 |

| 10 | 60 | 30 | 8.75 | 6.84 ± 1.12 | 6.29 ± 2.14 | 0.81 ± 1.25 | 23.74 ± 1.17 |

| 11 | 40 | 10 | 8.75 | 6.35 ± 1.18 | 7.35 ± 3.14 | 0.89 ± 2.07 | 26.53 ± 1.14 |

| 12 | 40 | 50 | 8.75 | 5.40 ± 2.14 | 6.80 ± 1.12 | 0.87 ± 1.14 | 27.60 ± 1.14 |

| 13 | 80 | 30 | 15 | 6.90 ± 1.10 | 6.45 ± 1.29 | 0.87 ± 0.23 | 26.60 ± 1.14 |

| 14 | 60 | 30 | 8.75 | 5.90 ± 1.12 | 6.92 ± 2.14 | 0.81 ± 1.25 | 24.42 ± 1.18 |

| 15 | 60 | 50 | 2.5 | 6.80 ± 2.15 | 6.35 ± 2.01 | 0.79 ± 1.37 | 23.54 ± 1.17 |

| 16 | 60 | 50 | 15 | 6.75 ± 0.14 | 6.65 ± 1.18 | 0.85 ± 1.19 | 34.80 ± 2.12 |

| 17 | 40 | 30 | 15 | 5.40 ± 1.21 | 6.80 ± 1.09 | 0.85 ± 1.14 | 39.29 ± 3.22 |

Variables mentioned in aforementioned equations correspond to different interactions among themselves. A, B, C, indicates the linear interaction. Regression coefficients interaction has been shown by AB, AC, BC whereas A2, B2, C2 signifies quadratic regression coefficients between variables. The level of significance was performed by analysing the analysis of variance for each response at 95% of significant level. The suitability of model was detected by analysing R2 value and F-value (lack of fit) which should not be significant for model fitting. Desirability function can be used to analyse the optimum level of independent factors. The aim of this response surface methodology was to obtain optimum percentage of wheat flour, bengal gram flour, and pumpkin peel powder to maximize the organoleptic properties of baked balls in terms of colour and texture and to minimise the water activity and moisture activity to extend the shelf life (Table 2).

Table 2.

Independent factors (process parameters) and their responses obtained for the development of Baked balls

| Constraints | Goal | Lower limit | Upper limit | Model |

|---|---|---|---|---|

| Wheat flour (%) | In range | 40 | 80 | – |

| Sattu flour (%) | In range | 10 | 50 | – |

| Pumpkin peel powder (%) | In range | 2.5 | 15 | – |

| Colour | In range | 5.4 | 7.7 | Linear |

| Texture | In range | 5.6 | 7.35 | Quadratic |

| Water activity | Minimize | 0.78 | 0.8382 | Quadratic |

| Moisture content (%) | Minimize | 22.05 | 39.29 | Quadratic |

Physicochemical and sensory analysis of baked balls obtained from various combinations by using response surface methodology

Moisture content

The moisture content of the obtained baked balls was determined by using hot air oven method mentioned in AOAC manuals (AOAC 2000). In this method, 2 g of the composite flour was taken into pre-weighed petriplate and kept in hot air oven at 105 °C for 4–5 h. Moisture content is calculated by using formula mentioned below.

| 5 |

Water activity

The prepared baked balls of composite flour with several combinations were taken to analyse for its water activity by using an electronic dew point water activity meter (Aqua lab Series, USA).

Sensory evaluation of baked balls

Sensory analysis of baked balls was done by a group of 30 members under ambient environmental condition. The sensory analysis was done at a temperature of 25 ± 5 °C in Food Technology Laboratory 1 of Bhaskaracharya College of Applied Science, Dwarka, New Delhi. The members were asked to evaluate the product with different sensory attributes like colour, appearance, taste, texture, and flavor. A hedonic scale of 9-point was used to assess the degree of like/dislike ranging from ‘Like very much’ to ‘Dislike very much’ with ‘Neither like nor Dislike’ as the average. The average scores were calculated. The data was analysed and computed the number of responses.

Nutritional analysis of control and optimized baked balls

The baked balls obtained after the optimization of flour composition was further taken for the nutritional analysis along with control sample (baked balls obtained from wheat flour only). The protein content, fat content, fibre content, moisture content, and ash content was determined by using micro-kjeldahl method, soxhlet extraction apparatus, acid–alkali wash method by using fibraplus, hot air oven method, and muffle furnace respectively whereas carbohydrate content was calculated by method of difference {100 − (moisture % + crude protein % + crude fat % + ash %)} (AOAC 2005). Crude dietary fibre was determined by using fibraplus fibre extraction instrument (Pelican equipment). Total energy estimation was done by multiplying the carbohydrate, crude protein and crude fat values by 4, 4 and 9 respectively. The mineral estimation (calcium, iron) was done by using Atomic Absorption Spectrophotometry method No. 922.06#960.0 (AOAC 2000).

Statistical analysis

The obtained results of the various analyses were indicated as mean ± standard deviation (SE) and analyzed by using the statistical package SPSS 20.

Results and discussion

Effect of variables on several responses obtained for prepared baked balls

The experimental design of the box behnken model has been shown in Table 1, which depicts the effect of various independent factors such as wheat flour, bengal gram flour, and pumpkin peel flour on colour, texture, water activity, and moisture content. The value of colour ranged between 5.4 and 7.45, texture (5.6–7.35), moisture content (22.05–39.29%), and water activity (0.78–0.87).

Figure 2a depicts the effect of wheat flour and bengal gram flour on colour of baked. Bengal gram flour and pumpkin peel powder did not show any change in colour value with increase in amount whereas with increase in wheat flour proportion resulted darker colour of the baked balls. Each combination of prepared baked balls showed significant effect on texture of baked balls shown in Fig. 2b–d. The 3-dimensional graphs of various factors indicates that with increase in amount of bengal gram flour up to 30% leads to decrease in textural attributes of the obtained baked balls whereas with further increase in its proportion corresponds to increase in texture value of the baked balls to 6.2. Texture value of the baked ball was noticed as 5.2 at 2.5% of pumpkin peel powder. On the other hand, texture value was reported to be 7.35 at a concentration of 8.75% of pumpkin peel powder. However wheat flour did not show any significant change in textural attributes of the baked balls.

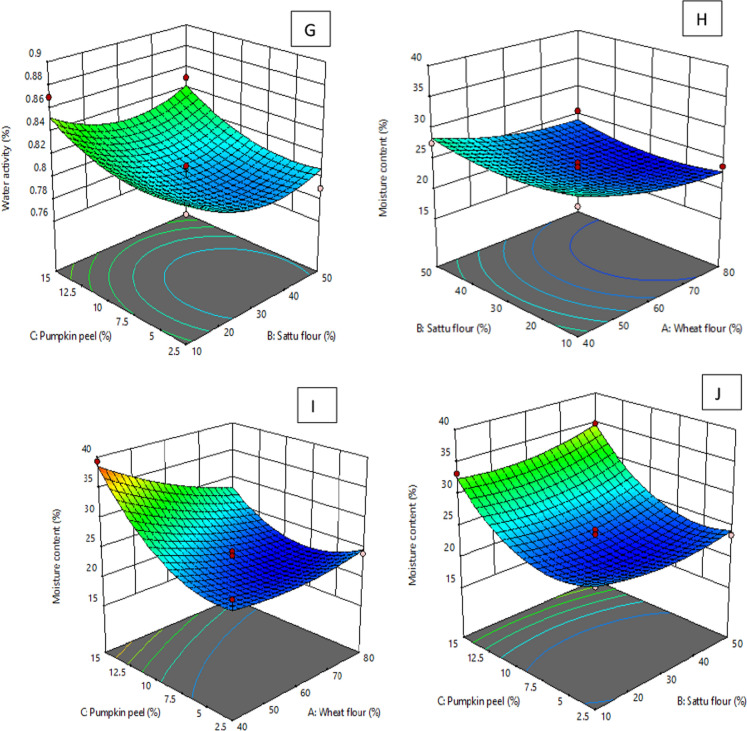

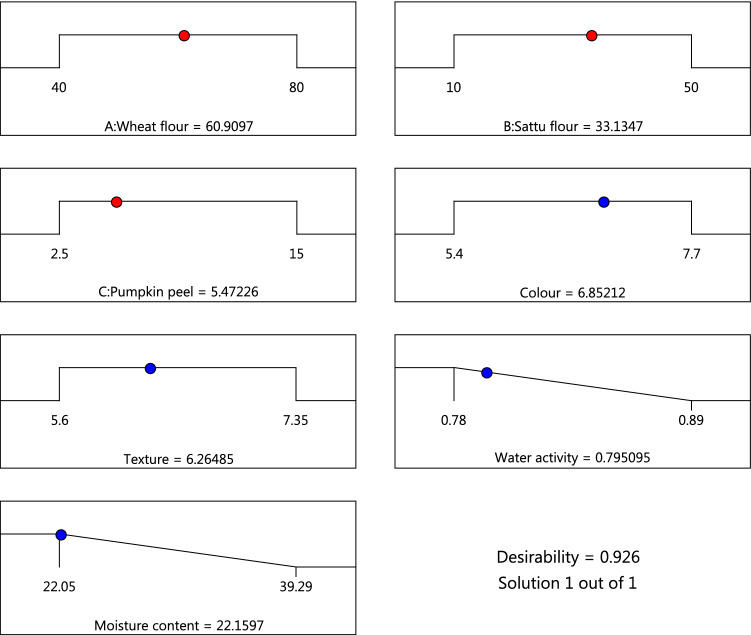

Fig. 2.

Optimized conditions for the formulation of baked balls by using wheat flour, roasted Bengal gram flour, and pumpkin peel powder with a desirability of 0.926

All the independent factors showed significant difference on water activity value. The water activity of various combinations is shown in Fig. 2e–g. Increase in percentage of wheat flour resulted in decrease in water activity from 0.83 to 0.80 whereas further increase in wheat flour up to 80% resulted in higher value of water activity (0.85). Bengal gram flour showed slight decrease in water activity value up to 30% amount whereas with increasing percentage of bengal gram flour resulted in slightly increased value of water activity. Incorporation of pumpkin peel with increasing amount resulted in gradually increase in water activity value. The 3-dimensional figures for the moisture content have been shown in Fig. 2h–j. In which, increasing amount of both wheat flour and bengal gram flour did not show significant difference in moisture content whereas the pumpkin peel powder showed exponentially increase in moisture content up to 39%. Moreover, the addition of pumpkin peel could be a reason for increase in moisture due to its high water retention capacity as reported by Aziah and Komathi (2009). Jun et al. (2006) mentioned that fibrous flour with more carbohydrate content also increases the water holding capacity and thus leads to increase in water activity of the end product.

Regression equation and model fitting

The obtained regression coefficients of the quadratic polynomial models for the various responses of baked balls have been mentioned in Table 3. The regression coefficient values provide an estimated idea about the influence of independent factors on quality characteristics of the developed baked balls. After reviewing Table 3, analysis of variance of the selected quadratic model was reported as effective for the obtained data. The model was observed as significant for all the responses. The function of regression coefficient was found to be highly significant for all responses analysed for the baked balls with adequate value of coefficient of determination (R2). R2 value of colour was tabulated as 0.6315, texture (0.8643), water activity (0.8382), and moisture content (0.9512). Moreover, the lack of fit test did not show up significantly which corresponds to better affinity of the selected model. The model was considered to be sufficiently accurate for predicting the quality parameters of the baked balls.

Table 3.

ANOVA as a function of regression coefficient showing linear, quadratic, and interactive interaction between the independent factors on each response

| Source (P > F) | Colour | Texture | Water activity | Moisture content (%) |

|---|---|---|---|---|

| Model | 0.0038 | 0.0233 | 0.0399 | 0.0008 |

| A | 0.0031 | 0.8961 | 0.7447 | 0.0037 |

| B | 0.0447 | 0.0420 | 0.3433 | 0.5064 |

| C | 0.0589 | 0.0065 | 0.0816 | < 0.0001 |

| AB | – | 0.9863 | 0.4957 | 0.8245 |

| AC | – | 0.517 | 0.8176 | 0.0104 |

| BC | – | 0.02153 | 0.8176 | 0.4017 |

| A2 | – | 0.6560 | 0.0020 | 0.1674 |

| B2 | – | 0.0109 | 0.1078 | 0.1145 |

| C2 | – | 0.0579 | 0.2185 | 0.0007 |

| Lack of fit | 0.2725 | 0.5935 | 0.1171 | 0.0171 |

| R2 | 0.6315 | 0.8643 | 0.8382 | 0.9512 |

Validation of model

The optimization of multiple variables was performed by using Box Behnken model by measuring their responses to obtain the desired goal in order to develop baked balls. For the development of baked balls, independent parameters such as wheat flour, bengal gram flour, and pumpkin peel powder were optimized to minimize the moisture content and water activity whilst to maintain the texture and colour value in the given range. In order to optimize the various parameters such as wheat flour (40–80%), bengal gram flour (10–50%), and pumpkin peel powder (2.5–15%) were taken to achieve the desired goals for each independent factor and responses. The independent factors were maintained in range and responses were attributed to be in range or minimized according the maximum desirability functions. The optimum amount of flour and pumpkin peel powder for the formulation of baked balls with most desired characteristics were obtained and shown in Fig. 2. From the optimized conditions, the predicted value for texture, colour, moisture content, and water activity was reported as 6.26, 6.85, 22.15% and 0.795 respectively at desirability level of 0.926 which was found nearby to the experimental value as 6.24, 6.95, 22.08 and 0.768 respectively by using box behnken model. Hence, the selected model verified that it can be further used for the development of baked balls.

Sensory analysis of prepared baked balls

According to 9-point hedonic scale, sensory evaluation of baked balls was performed by a group of sensory panel members. The sensory score for both control baked balls (only wheat flour) and other combinations has been shown in Table 4. The obtained baked balls were analysed for their taste, colour, flavour, texture, and overall acceptability. It was noted that with increasing amount of pumpkin peel resulted in significant change in texture and colour of the baked balls whereas the baked balls obtained from wheat (control sample) alone was contributing better taste, flavour, and texture to the baked balls. The baked balls which were obtained with comparatively less percentage of pumpkin peel showed better taste, flavour, and colour to the end product. Significant change in taste and flavor of the baked balls with increasing pumpkin peel powder could be due to the higher percentage of phenolic content in peels (Sharma and Bhat 2021).

Table 4.

Sensory analysis of baked balls obtained by using various combinations of response surface methodology

| Runs | Colour | Texture | Taste | Flavour | Overall acceptability |

|---|---|---|---|---|---|

| Control | 7.88 ± 1.36 | 7.72 ± 1.13 | 7.17 ± 0.66 | 6.55 ± 1.24 | 7.38 ± 0.82 |

| 1 | 7.45 ± 1.17 | 7.25 ± 1.34 | 6.3 ± 1.82 | 6.5 ± 1.50 | 6.73 ± 1.21 |

| 2 | 7.05 ± 1.06 | 5.6 ± 1.26 | 6.2 ± 1.54 | 6.05 ± 1.60 | 6.07 ± 1.08 |

| 3 | 7.7 ± 1.37 | 6.31 ± 0.66 | 6.7 ± 1.15 | 6.5 ± 1.43 | 6.72 ± 0.88 |

| 4 | 7.17 ± 1.10 | 6.56 ± 1.06 | 6.15 ± 1.52 | 6.45 ± 1.38 | 6.73 ± 1.11 |

| 5 | 6.6 ± 1.47 | 6.55 ± 1.68 | 6.35 ± 1.66 | 6.95 ± 1.92 | 7.12 ± 1.45 |

| 6 | 7.7 ± 1.48 | 6.35 ± 1.26 | 6.6 ± 1.57 | 6.75 ± 1.58 | 6.93 ± 1.36 |

| 7 | 7.4 ± 1.88 | 7.1 ± 1.52 | 7.55 ± 1.32 | 6.85 ± 2.31 | 7.36 ± 1.24 |

| 8 | 6.5 ± 1.41 | 6.42 ± 1.73 | 6.75 ± 2.15 | 6.4 ± 2.31 | 6.87 ± 1.83 |

| 9 | 6.2 ± 1.28 | 6.35 ± 1.52 | 7.3 ± 1.63 | 7.2 ± 1.68 | 7.38 ± 1.28 |

| 10 | 6.84 ± 1.33 | 6.29 ± 0.83 | 6.65 ± 1.29 | 6.6 ± 1.42 | 6.7 ± 1.13 |

| 11 | 6.35 ± 1.32 | 7.35 ± 0.88 | 6.15 ± 0.74 | 6.4 ± 0.84 | 6.18 ± 0.82 |

| 12 | 5.4 ± 1.66 | 6.8 ± 1.13 | 6.35 ± 1.24 | 6.65 ± 1.41 | 6.37 ± 1.26 |

| 13 | 6.9 ± 1.11 | 6.45 ± 1.20 | 6.35 ± 1.37 | 6.55 ± 1.38 | 6.56 ± 1.33 |

| 14 | 5.9 ± 1.12 | 6.92 ± 1.41 | 6.17 ± 1.13 | 6.55 ± 0.66 | 6.74 ± 1.23 |

| 15 | 6.8 ± 1.42 | 6.35 ± 1.37 | 6.23 ± 1.28 | 6.28 ± 01.07 | 7.21 ± 0.25 |

| 16 | 6.75 ± 1.25 | 6.65 ± 1.12 | 6.51 ± 1.09 | 6.47 ± 0.65 | 6.87 ± 0.17 |

| 17 | 5.4 ± 1.14 | 6.8 ± 1.47 | 6.18 ± 1.64 | 6.78 ± 1.05 | 6.98 ± 0.29 |

Nutritional analysis of control and optimized baked balls

The nutritional composition of pumpkin peel powder, baked balls prepared by using wheat flour and baked balls prepared by using optimized composite flour has been shown in Table 5. Moisture content was found to be higher in optimized baked balls (15.32%) whereas the control sample showed comparatively lower moisture content (12.44%). This could be due to high water retention ability by composite flour from the environment. Moreover, the addition of pumpkin peel could be a reason for increase in moisture due to its improved water retention capacity as reported by Aziah and Komathi (2009). It was reported that products produced with flour such as polysaccharides, contain more hydrophilic molecules which results in increasing water holding capacity (Hodge and Osman 1976). The results were also in favour with the study conducted by Jun et al. (2006) who reported that high water holding capacity of fibrous fruits is linked to their pectin content.

Table 5.

Nutritional analysis of pumpkin peel powder, control baked balls, and optimized baked balls

| Components | Pumpkin peel powder | Control baked balls | Optimized baked balls |

|---|---|---|---|

| Energy (Kcal) | 186.17 ± 1.10 | 320.5 ± 2.18 | 310.42 ± 2.12 |

| Moisture content (%) | 10.16 ± 1.11 | 12.44 ± 1.14 | 15.32 ± 1.19 |

| Carbohydrate (g/100 g) | 26.24 ± 1.21 | 64.10 ± 2.33 | 55.61 ± 2.05 |

| Protein (g/100 g) | 18.39 ± 1.04 | 10.57 ± 0.14 | 13.78 ± 1.02 |

| Fat (g/100 g) | 0.85 ± 1.01 | 1.53 ± 1.11 | 2.73 ± 1.18 |

| Dietary fibre (g/100 g) | 28.94 ± 2.25 | 11.36 ± 1.02 | 12.56 ± 1.07 |

| Calcium (mg/100 g) | 2.58 ± 1.09 | 30.94 ± 2.29 | 40.18 ± 3.25 |

| Iron (mg/100 g) | 7.2 ± 2.32 | 4.10 ± 1.03 | 4.57 ± 1.11 |

| Zinc (mg/100 g) | 1.5 ± 1.11 | 2.85 ± 1.20 | 2.97 ± 1.18 |

| Carotenoids (µg/100 g) | 387.92 ± 1.18 | 284 ± 2.32 | 838.93 ± 3.04 |

| Ascorbic acid (mg/100 g) | 9.24 ± 3.14 | 1.84 ± 1.02 | 5.82 ± 2.21 |

Baked balls formulated by using optimized composite flour resulted in reduced carbohydrate content i.e. 55.61 g/100 g, on the other hand control baked balls revealed higher value of the carbohydrate content (64.10 g/100 g) which could be due to high percentage of starch in wheat flour alone. In composite flour the amount of starch was comparatively less. Kumar et al. (2011) wrote a review paper on composition of wheat by mentioning that wheat flour contains high amount of carbohydrates as compared to other end products of wheat grain such as wheat germ, white flour, wheat bran flour etc.

The protein content was observed as 13.78 g/100 g in optimized baked balls which was reported to be higher when compared with the baked balls prepared by using control flour. Improved in protein content could be due to the incorporation of pumpkin peel powder and bengal gram flour which is known as a good source of protein. Aziah and Komathi (2009) reported that the protein content of the peeled pumpkin flour showed reduced protein content whereas the unpeeled pumpkin flour showed high value of the protein content. Thereby we can understand that the addition of pumpkin peel flour for making any product could improve its protein content depending on quality of pumpkin. Sultana et al. (2014) also reported that addition of bengal gram flour resulted in increased protein content of the chapatti when compared with the chapatti made from wheat flour only. Even the protein content of wheat flour and bengal gram flour was noted as 10.5% and 24.5% respectively.

Fat content of the control baked balls reported as 1.53 g/100 g which was found to be closer to the value obtained by Aziah and Komathi (2009) i.e. 1.38 g/100 g. Optimized baked balls showed comparatively high fat content (2.73 g/100 g) than control one. Various studies were conducted to determine fat content in bengal gram flour which have been reported as 6.1% by Sultana et al. (2014), 3.6–7.6% by Rico et al. (2020) and 4.69% by Yousaf et al. (2013). Moreover, Aziah and Komathi (2009) found that the fat content in unpeeled pumpkin flour showed high fat content as compared to the flour obtained from peeled flour.

Dietary fibre content did not show significant difference in produced baked balls. The dietary fibre content was found to be comparatively higher in optimized baked balls (12.56 g/100 g) as compared to baked balls obtained from wheat flour only (11.36 g/100 g) which might be due to the addition of wheat flour, and pumpkin peel flour. Aziah and Komathi (2009) in their study showed high fibre content in unpeeled pumpkin flour as compared to peeled one. Fibre content in pumpkin peel and pumpkin pulp was reported as 13.91% and 5.42% respectively (Mala and Kurian 2016).

The traditional baked balls obtained from the two different combinations were also analysed for their mineral content including calcium, iron, and zinc. Pumpkin peel powder was taken for the mineral determination and resulted in calcium content of 2.58%, iron 7.2% and zinc 1.5% (Table 5). Wheat grains are also rich in dietary fibres and some minerals such as potassium, phosphorus, magnesium, calcium in small quantities (Kumar et al. 2011). Due to the addition of pumpkin peel powder and bengal gram flour resulted in high mineral content in optimized baked balls as compared to the control one. Calcium, iron, and zinc content were observed as 30.94 mg/100 g, 4.10 mg/100 g, and 2.85 mg/100 g respectively in control baked balls whereas the optimized baked balls resulted in higher values of calcium (40.18 mg/100 g), iron (4.57 mg/100 g), and zinc (2.97 mg/100 g). Consumption of minerals plays an important role to maintain healthy diet. Calcium helps in maintaining the healthy tooth and also helps in controlling hypertension. Other minerals such potassium, magnesium helps in controlling the blood pressure whereas zinc helps in the development of immune cells as well as cure the wound at faster rate (Morais et al. 2017; Mallek-Ayadi et al. 2018). It should be noted that peels are good source of calcium, potassium, zinc, which corresponds to high percentage of ash content (Rico et al. 2020). Even the addition of pumpkin peel powder helps in improving the phosphorus and iron content which exhibits antioxidant activity due to the presence of polyphenolic compounds in it (Mala and Kurian 2016). Carotenoids are considered as one of polyphenolic compounds which help in controlling the oxidation and improve the nutritional quality which consequently improves the industrial value of the obtained products. Carotenoid content in optimized baked ball was found to be higher (838.93 µg/100 g) when compared with control baked balls (284 µg/100 g).

The produced baked balls were also analysed for the presence of ascorbic acid which is directly related to several metabolic reactions in human body. Ascorbic acid helps in safeguarding the immune cells from various foreign substrates. In our study, ascorbic acid content of control and optimized baked balls was observed as 1.84 mg/100 g and 5.82 mg/100 g respectively. Improve in ascorbic content in baked balls obtained from optimized composite flour could be due to the addition of pumpkin peel flour which showed ascorbic acid as 9.24 mg/100 g (Mala and Kurian 2016). Ascorbic acid can also be used as a cofactor in the biosynthesis of carnitine, which is required for the degradation of fatty acids and support in combating the improper collagen synthesis in several animals (Oguntibeju 2008).

Conclusion

The incorporation of pumpkin peel powder for the production of traditional baked balls resulted in improved nutritional value including carbohydrates, protein, fat, dietary fibres, minerals, carotenoids etc. This study focused on direct utilization of pumpkin peel powder into high value-added products with acceptable sensory score. The study suggest that pumpkin peel can also be used for the preparation of various other products, which may be healthy options for undernutrition community. Therefore, the supplementation of such food can add several biological activities and would also contribute to the dietary requirements of some important minerals.

Acknowledgements

The author would like to acknowledge the Department of Food Technology, Bhaskaracharya College of Applied Sciences, and University of Delhi for providing basic amenities for performing various experiments in the laboratory.

Author contributions

Every author who has significantly helped in drafting this manuscript were given authorship.

Funding

Not applicable.

Data availability

Not applicable.

Declarations

Conflict of interest

Not applicable.

Consent to participate

Each and every author have sent their consent for publishing the given research article.

Ethics approval

Not applicable.

Consent for publication

Every author of this manuscript have sent their consent for publishing the data.

Footnotes

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

References

- Ahmed J, Al-Foudari M, Al-Salman F, Almusallam AS. Effect of particle size and temperature on rheological, thermal, and structural properties of pumpkin flour dispersion. J Food Eng. 2014;124:43–53. [Google Scholar]

- AOAC (2000) Official methods of analysis of AOAC International, 17th edn. AOAC, Gaithersburg

- AOAC (2005) Official methods of analysis, 18th edn. Association of Official Analytical Chemists, Arlington

- Aziah AN, Komathi CA. Physicochemical and functional properties of peeled and unpeeled pumpkin flour. J Food Sci. 2009;74(7):S328–S333. doi: 10.1111/j.1750-3841.2009.01298.x. [DOI] [PubMed] [Google Scholar]

- Ben Jeddou K, Bouaziz F, Zouari-Ellouzi S, Chaari F, Ellouz-Chaabouni S, Ellouz- Ghorbel R. Improvement of texture and sensory properties of cakes by addition of potato peel powder with high level of dietary fiber and protein. Food Chem. 2017;217:668–677. doi: 10.1016/j.foodchem.2016.08.081. [DOI] [PubMed] [Google Scholar]

- Blandino A, Al-Aseeri ME, Pandiella SS, CanteroD WC. Cereal-based fermented foods and beverages. Food Res Int. 2003;36:527–543. [Google Scholar]

- Crozier A. Classification and biosynthesis of secondary plant products: an overview. In: Goldberg G, editor. Plants: diet and health. Oxford: Blackwell Science; 2003. pp. 27–48. [Google Scholar]

- Cumarasamy R, Corrigan V, Hurst P, Bendall M. Cultivar differences in New Zealand “Kabocha” (buttercup squash, Cucurbita maxima) N Z J Crop Hortic Sci. 2002;30:197–208. [Google Scholar]

- Dewettinck K, Van Bockstaele F, Kühne B, Van de Walle D, Courtens TM, Gellynck X. Nutritional value of bread: Influence of processing, food interaction and consumer perception. J Cereal Sci. 2008;48(2):243–257. [Google Scholar]

- Hodge JC, Osman EM. Carbohydrates, principles of food science, Part I. In: Fennema RO, editor. Food chemistry. New York: Marcel Dekker Inc; 1976. pp. 97–200. [Google Scholar]

- Jun H, Lee C, Song G, Kim Y. Characterization of pectic polysaccharides from pumpkin peel. LWT-Food Sci Technol. 2006;39:554–561. [Google Scholar]

- Kumar P, Yadava RK, Gollen B, Kumar S, Verma RK, Yadav S. Nutritional contents and medicinal properties of wheat: a review. Life Sci Med Res. 2011;22(1):1–10. [Google Scholar]

- Li Q, Fu C, Rui Y, Hu G, Cai T. Effects of protein-bound polysaccharide isolated from pumpkin on insulin in diabetic rats. Plant Foods Human Nutr. 2005;60:1–4. doi: 10.1007/s11130-005-2536-x. [DOI] [PubMed] [Google Scholar]

- Mala KS, Kurian AE. Nutritional composition and antioxidant activity of pumpkin wastes. Int J Pharm Chem Biol Sci. 2016;6(3):336–344. [Google Scholar]

- Mallek-Ayadi S, Bahloul N, Kechaou N. Chemical composition and bioactive compounds of Cucumis melo L. seeds: potential source for new trends of plant oils. Process Saf Environ Prot. 2018;113:68–77. [Google Scholar]

- Mishra S, Sharma K. Development of pumpkin peel cookies and its nutritional composition. J Pharmacogn Phytochem. 2019;8(4):370–372. [Google Scholar]

- Morais DR, Rotta EM, Sargi SC, Bonafe EG, Suzuki RM, Souza NE, Visentainer JV. Proximate composition, mineral contents and fatty acid composition of the different parts and dried peels of tropical fruits cultivated in Brazil. J Braz Chem Soc. 2017;28(2):308–318. [Google Scholar]

- Murkovic M, Piironen V, Lampi AM, Kraushofer T, Sontag G. Changes in chemical composition of pumpkin seeds during the roasting process for production of pumpkin seed oil. Part I: Non-volatile compounds. Food Chem. 2004;84(3):359–365. [Google Scholar]

- Oguntibeju OO (2008) The biochemical, physiological and therapeutic roles of ascorbic acid. Afr J Biotechnol 7(25)

- Raghav PK, Kizhuveetil U, Joshi K, Kumari S. Development and standardization of naturally fortified Litti–Chokha. J Food Technol Nutr Sci. 2021;3(132):2–5. [Google Scholar]

- Rico X, Gullón B, Alonso JL, Yáñez R. Recovery of high value-added compounds from pineapple, melon, watermelon and pumpkin processing by-products: an overview. Food Res Int. 2020;132:109086. doi: 10.1016/j.foodres.2020.109086. [DOI] [PubMed] [Google Scholar]

- Roongruangsri W, Bronlund JE. A review of drying processes in the production of pumpkin powder. Int J Food Eng. 2015;11(6):789–799. [Google Scholar]

- Sharma M, Bhat R. Extraction of carotenoids from pumpkin peel and pulp: comparison between innovative green extraction technologies (ultrasonic and microwave-assisted extractions using corn oil) Foods. 2021;10(4):787. doi: 10.3390/foods10040787. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Stevenson DG, Eller FJ, Wang L, Jane J-L, Wang T, Inglett GE. Oil and tocopherol content and composition of pumpkin seed oil in 12 cultivars. J Agric Food Chem. 2007;55:4005–4013. doi: 10.1021/jf0706979. [DOI] [PubMed] [Google Scholar]

- Sultana A, Tanver Rahman MR, Islam M, Rahman M, Alim MA. Evaluation of quality of chapaties enriched with jackfruit seed flour and bengal gram flour. IOSR J Environ Sci Toxicol Food Technol. 2014;8(5):73–78. [Google Scholar]

- Vadnerkar AA (2004) Soluble fiber and resistant starch components in some Indian and Canadian Wheat varieties and in a wheat-soy product-chapati. In: Human nutrition, foods and exercise. M.S. Thesis, Blacksburg, Virginia

- Yousaf AA, Ahmed A, Ahmad A, Hameed T, Randhawa MA, Hayat I, Khalid N. Nutritional and functional evaluation of wheat flour cookies supplemented with gram flour. Int J Food Sci Nutr. 2013;64(1):63–68. doi: 10.3109/09637486.2012.694851. [DOI] [PubMed] [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.

Data Availability Statement

Not applicable.