ABSTRACT

The genetically engineered bollworm-resistant Bt cotton hybrid varieties offer opportunities for reducing crop losses and enhancing productivity. In Eastern Africa region, Sudan, Ethiopia, and Kenya have approved and released Bt cotton in 2012, in 2018, and in 2019, respectively. The region has potential to grow cotton in over 5 million hectares. For commercial plantings in Ethiopia, Sudan and Kenya, hybrid Bt cotton seeds have been imported from India. Due to the COVID-19 pandemic-induced supply chain disruptions, high shipment costs, bureaucratic procedures for importing seeds, and foreign exchange shortages, farmers have not been able to access Bt cotton seeds. Stakeholders are seeking local production of seeds to provide sustainable access by farmers at affordable cost. Country case studies reveal the importance of enhancing capacity for local seed production and extension advisory services. Revival of the cotton sector needs enhanced public-private partnerships to pave the way for sustainable seeds access in the region.

KEYWORDS: Biotechnology, Cotton, Eastern Africa, Ethiopia, Genetic engineering, Gmos, Kenya, Seeds, Sudan

1. Introduction

Cotton is one of the strategic crops in Africa with Eastern and Western Africa countries contributing the major share of cotton production in Africa. It is an important cash crop produced in large scale, and a source of income also for millions of smallholder farmers.1;. 2 Cotton is a key commodity for the textile and garment industries that played a role in the economic and social transformation of many countries. It is often considered a starter sector on the road to industrialization.3 Globally the cotton boom has had multiple economic impacts on engineering, inventions, business, transport and agriculture sector itself.4

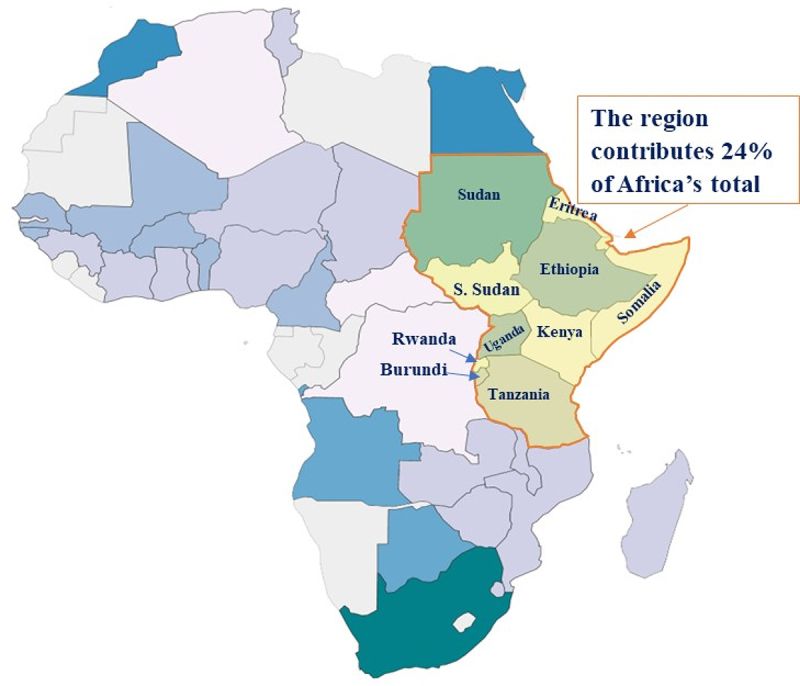

According to the United Nations Conference on Trade and Development,5 sub-Saharan Africa (SSA) countries export more than 90% of the raw cotton lint they produce and earned approximately US$15.5 billion in 2018 exporting over 1.5 million metric tons of lint. The Eastern Africa region shown on the map (Fig. 1) that includes Ethiopia, Kenya, Tanzania, Sudan, and Uganda is an important cotton growing region covering nearly a quarter (24%) of the current total cotton production of Africa (FAO, 2018) but claims to have a cumulative potential up to 5 million hectares6;7;. 8

Figure 1.

Eastern African regions contribute 24% of Africa’s total cotton production .

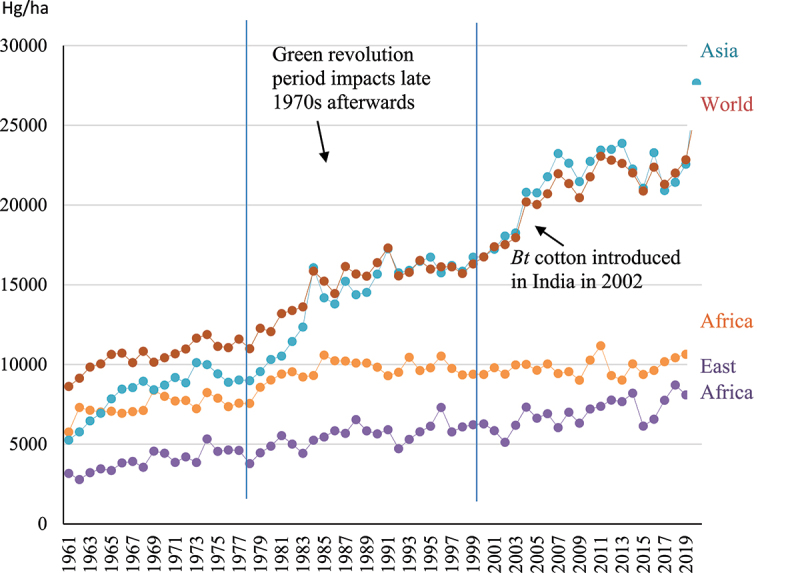

Governments of African cotton-producing countries are actively promoting the development of their textile sector because of its ability to spur a manufacturing-based economy.8 However, the highly traditional cotton production system is not supported with technologies, best practices and incentives. This has rendered the cotton production, marketing and processing schemes in the region to be among the lowest performing in the world (Fig. 2) in terms of productivity and efficiency. The cost of production for cotton is lower due to lower labor rates in Africa as compared to other countries. However, the continent represents only 5% of global cotton production and shares only 9% of the world market.9 Further to this paradox, cotton production in Kenya, Ethiopia, and Uganda has steadily declined. Declining productivity and returns from cotton make it difficult for farmers to support their livelihoods and for the sub-sector to contribute to the countries’ economies.

Figure 2.

Cotton productivity in Eastern Africa, Africa, Asia, and the world. (Data Source10: .

Cotton production follows diverse farming systems in the region. It is grown either as rain-fed, irrigated or supplemented with seasonal irrigation. It grows in arid and semi-arid environments under small, medium and large-scale production systems. In Kenya it is grown in Western, Eastern, Central, Rift Valley and Coastal Provinces on arid and semi-arid land and different moisture regimes with some areas under marginal conditions.11 In Ethiopia, cotton is grown at altitudes of 300 meters above sea level (masl) up to 1200 masl. In most of the Eastern Africa countries, smallholders are dominant producers. In some countries like Sudan and Ethiopia mixed systems of small- and large-scale production are common.

In Ethiopia 33% of cotton is cultivated by smallholders mostly as a rain-fed crop, 45% by private farms and 22% by state-owned irrigated farms. The potential land conducive for growing cotton in Ethiopia is close to 3 million hectares, but the country produces only 5% of total cotton produced in Africa.8

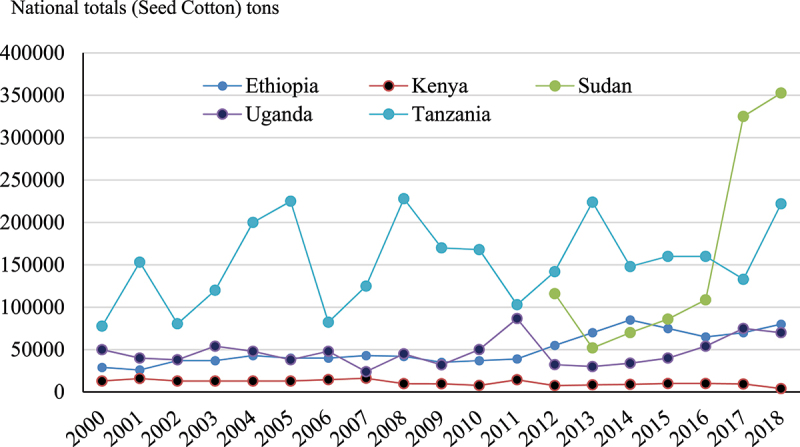

For several decades now, farmers in many developing African countries have not changed their cotton varieties or the traditional cultural practices. The age-old cotton culture in Eastern Africa regions has become less productive and vulnerable to insect pests, diseases and climate changes with low yield records, about 2.0 tons per hectare, even lower than the African average (Table 1) and often fails to meet marketing quality standards. Eastern Africa’s productivity is not only lower but also scarcely improving, with seed cotton yield growing from 0.32 to 0.78 tons per hectare in 50 years (Fig. 2 and 3). Varieties that were introduced 2–3 decades ago are still dominating production despite that they are genetically highly deteriorated and mixed. Cotton growers complain about poor input supply and second rate seed quality from ginners, mostly mixed and untreated, resulting in low germination, poor stand, and low in seed cotton yields.8; 12; .13 Availability of genetically superior, insect resistant, high-quality seed supply is a core problem in nearly all cotton producers regions in East Africa.

Figure 3.

Seed cotton total production (tons) in five Eastern African Countries (2000–2018).

Table 1.

Current area under production of cotton in East African region.

| Country | Current area under production of cotton (ha) | Total production (tons) | Yield (ton ha−1) |

Cotton Export (Mill USD) |

|---|---|---|---|---|

| Sudan | 240,000* | 58,181 | 2.40 | 156.3 |

| Ethiopia | 80,000 | 35,000 | 2.29 | 5.2 |

| Kenya** | 10,000 | 3,495 | 2.86 | 1.7 |

| Tanzania | 450,000 | 297500 | 1.51 | 43.1 |

| Uganda | 100,000*** | 20,000 | 1.5–2.0 | 37.5 |

| Total | 820,000 | 414,176 | 1.98 | 243.5 |

In most production seasons farmers incur losses from pests. Pink Bollworm (Pectinophora gossypiella), African bollworm (ABW) (Helicoverpa armigera), Mealy bug, and Flea Beetle cause about 36–60% yield loss in some countries of the region and up to annual loss of 2 billion US dollars in different crops around the globe.14; .15 There are no resistant varieties available so far. Growers usually use chemical pesticides to manage these insect pests and they have evolved resistance to pesticides. Producers who do not use insect resistant GM cotton varieties containing Bacillus thuringiensis (Bt) cotton commonly spray 5–10 insecticide sprays without promising result and unaware the impact of repeated spray and selection pressure which often results in insect resistance buildup. In large farms, pest control account to 30–40% of the total production cost. Repeated chemical sprays also brings significant health and environmental damage. Cotton as a commercial crop receives the bulk (25% of the total) of pesticide usage in Africa followed by cocoa, and coffee that receive 40%, and 15%, respectively.16

Unlike the presumption that the farm labor in Africa is cheaper and abundant, commercial cotton farms suffer shortages of labor at planting, weeding, and harvesting operations. Delays in farm practices affect cotton quality and yield. Limited availability of quality inputs, including seeds and fertilizer, and the pest challenges have restricted the anticipated economic benefits from cotton farming and constrained the growth of the cotton industry in the region. The objective of this study is to identify sustainable options for access to hybrid Bt cotton seeds by farmers in Eastern Africa as a step toward successful commercialization and deployment of the Bt cotton technology.

Information included in this paper is a part of desk survey and assessment on the Bt cotton commercialization in Eastern Africa region. Country cases of Ethiopia, Kenya, and Sudan have been prepared by country experts who have played a key role in Bt cotton research, development, or regulatory approval in these countries. The study considered the condition of the cotton sector in the region through assessing recent reports of the sectors in the different countries (Kenya, Ethiopia, Sudan, Tanzania, and Uganda). Issues related to commercialization have been obtained from discussions with various stakeholders including interviews with farmers, private and public sector representatives, regulatory and research professionals. Long-term data was accessed from UN-FAO data repositories and verified when appropriate with individual country reports.

2. Bt Technology and Bt Cotton – Global Overview

Growing interest for biological insecticides that was developing in the mid-1970s is said to have revived later in the early 1980s because of increasing insect resistance to synthetic chemical pesticides. The delay was due to the introduction of the pyrethroid insecticides in 1978 and afterward. The problem with wider use and building of resistance to pyrethroid revived the global concern over environmental contamination.17 As a result, research in biopesticides such as Bacillus thuringiensis (Bt) were initiated as faster, safer and cheaper alternatives. The Bt technology is among the first successfully commercialized protection targeted biotech crops against insect pests.18 Several years of research and product development were required to deliver the trait in the best varieties of cotton.19; .20 Studies included safety of the produced proteins, food/feed composition, and environmental safety.21; .22 Bt cotton plants contain one or more foreign Bt genes derived from naturally occurring soil bacterium.

Several of these genes that confer the resistance trait are used through genetic transformation of cotton varieties. The insertion of the Bt genes enables the cotton plant cells to produce crystal proteins also known as Cry proteins such as Cry1Ac, Cry1Ab, Cry2Aa, Cry1F with varying degree of insecticidal properties.19 When insects attack and eat the cotton plant with the Cry gene, the produced Cry toxins, crystal proteins, are dissolved due to the high pH level of the insect’s stomach and gets activated. The activated Cry molecules bind to specific receptors, cadherin-like proteins present on the epithelial cells of the midgut and ion channels are formed which allow the flow of potassium. Regulation of potassium concentration is essential and, if left unchecked, causes death of cells. Due to the formation of Cry ion channels sufficient regulation of potassium ions is lost, resulting in the death of epithelial cells. The death of such cells creates gaps in the brush border membrane and allow Bt and bacteria spores to enter cavity and kill the insect.23; .24 Cry1Ac was used in the early generation GMO crops. Later Cry2Aa mutant was found with four- to six-fold higher toxicity effectively killing the most devastating caterpillar pests of cotton, such as the larvae of cotton leaf worm (Spodoptera litura), and cotton bollworm (H. armigera)19; .25 Bt toxin levels in the Bt cotton varieties commercialized in the region may vary based on environment, and due to the proprietary nature of these technologies, this information is not readily available in various reports.

Biotechnology thus helped to alleviate cotton production problems through better pest resistance and improved global cotton production to meet the ever-growing demand.18; .26,27 Global cotton demand is rising, and the global cotton market has been projected to register a compound growth of 4.1% between 2021 and 2026. Projections that population growth, rising levels of disposable income, and urbanization in developing countries would drive demand for cotton textiles in the future. In 2019 GM cotton resistant to insects and tolerant to herbicide reached 25.7 million hectares, covering 79% of the global area of cotton in 2019.28 Use of Bt cotton Cry1Ac proteins (Bollgard I) and Bt cotton containing Cry1Ac and Cry2Ab2 proteins (Bollgard II) and a next generation GM cotton with added multiple (triple herbicide tolerance to dicamba, glyphosate and glufosinate) herbicide tolerant cotton (Bollgard II® XtendFlex® technology) and Bollgard® 3 ThryvOn™ cotton with XtendFlex® Technology have considerably improved the global cotton production. The later stacked traits are mostly used by the U.S. farmers.

Adoption and Commercialization of the Bt Cotton

In 1996 Bollgard® cotton containing Cry1Ac for protection on tobacco budworm and pink bollworm was planted on 800,000 hectares. By 2000, the global transgenic cotton covered 5.3 million hectares.28 In 2005 India reported substantial increase (160%) in Bt cotton area coverage over 200428 and subsequent rapid adoption and expansion took place. The time corresponds to the high rise in cotton productivity observed in India during the period from 2002–2014 (Fig. 2).

In 2016 the commercialization of Bollgard® 3 XtendFlex® Cotton was announced by the U.S. based Monsanto company, the first commercial cotton product with full federal approvals for the trait and in-crop herbicide system to combine three modes of action for lepidopteran insect control and herbicide tolerance. By this time Bt cotton (Bollgard® & Bollgard®II) products coverage has already reached 64% of global cotton area (22.3 million hectares) in a total of 14 countries28 and a cumulative 0.34 billion hectares of biotech cotton in 21 years.28 The countries included India (10.8 million hectares), USA (3.7 million), Pakistan (2.9 million hectares) and China (2.8 million), Brazil, Australia, Argentina, Myanmar, Sudan, Mexico, Paraguay, Colombia, South Africa, and Costa Rica.

In some countries, including India, the adoption of B.t. cotton reached to 96% of the total cotton area under cultivation in 2016. In Africa, South Africa adopted Bt cotton as early as 1998 followed by Burkina Faso in 2008, and Sudan in 2012. Burkina Faso suspended production in 2016. In 2018 and 2019, four countries Ethiopia, Malawi, Kenya, and Nigeria commercialized Bt-cotton. Nevertheless, the Africa total cotton acreage is still below 0.4 million hectares with South Africa adopting 100% of its 40,000 hectares cotton28–30 followed by Sudan with over 95% adoption of its current estimated production of near quarter a million hectares.

Choudhary and Gaur31reported that in thirteen-year period from 2002 to 2014, India tripled cotton production from 13 million bales (2.8 million tons) to 39 million bales (8.4 million tons). Stone and Flachs32however argue that the largest production gains in cotton could have come from prior widespread seed adoption and must be viewed in line with changes in fertilization practices and other pest population dynamics. This argument depicts the cotton production and yield dynamics since the green revolution where considerable improvement in Indian cotton productivity was registered from the late 1970s until 1990 (Fig. 2). In the U.S. in 2005, adoption was over 80% with over 70% of the Bt cotton area planted to varieties with stacked genes of herbicide tolerance and the dual Bollgard II, with only 1% deployed with single Bt gene (Cry1Ac) varieties.

Bt Cotton Adoption and Commercialization in Eastern Africa

Many countries in Africa are still debating the pros and cons of adopting Bt cotton technology that has been developed against the most limiting factor in their cotton productivity, the African Bollworm. Limited approval and adoption of GM cotton is observed for major target pests and traitis in few countries in the region (Table 2). On the other hand, according to ISAAA28global acreage of GM cotton was 25.7 million hectares, covering 79% of the global area of cotton in 2019. The total acreage for Bt cotton in Africa is below 0.4 million hectares with Sudan taking the lead (about 240,000 ha) followed by South Africa (100,000 ha), Ethiopia (about 11,000 ha in 2022 - Personal communication, Samson Assefa, February 2022) and eSwatini (250 hectares).28 In 2019, Ethiopia, Malawi and Kenya approved GM cotton for the first time. GM cotton covers 100% of South Africa and 95% of Sudan cotton cultivation.33 The South African biotech cotton includes multi-stack genes for insect resistance and herbicide tolerance production and is supported with resistance management strategies where farmers are required to maintain a refuge of 5% of their crops unsprayed with pesticides and 20% sprayed to prevent resistance development to Bt by the target pest (Juyek, 2002).

Table 2.

Major pests targeted and trait adopted in the region.

| Country | Major pests of cotton | GE cotton trait approved | |

|---|---|---|---|

| Ethiopia | African bollworm (ABW) (H. armigera) and pink bollworm (P. gossypiella), mites, aphids (Aphis gossypii)37; .15 |

Bacillus thuringiensis (Bt)-Cotton (insect resistance); (Bt- insect resistance and HT (−herbicide tolerance) in process of field testing |

|

| Kenya | African bollworm (H. armigera), Cotton Stainer (Dysdercus spp.), Cotton aphid (Aphis gossypii), Cotton red spider mite (Tetranychus telarius), seed bugs.48 | Bt-Cotton (BollgardII – insect resistance) | |

| Malawi | Elegant grasshopper (Zonocerus elegans) and termites, Aphis, red spider mites (Tetranychus spp.), and jassids (Jacobiella fascialis), bollworms (H. armigera) and Earias spp., Malawi pink bollworm (P. gossypiella). | Bt-Cotton (insect resistance) | |

| Sudan | Cotton jassids (J. lybica), bollworm,, whitefly (Bemisia tabaci) | Tripple gene Bt-Cotton (Bt- insect resistance and HT -herbicide tolerance) in process of approval | |

| Tanzania | American bollworm (H. armigera), Fall armyworm (S. Frugiperda), Jassids, Lygus bugs, Aphids. | None | |

| Uganda | American bollworm (H. armigera), spotted bollworm (Earias insulana); pink bollworm (P. gossypiella), Stainers (Dysdercus cingulatus); Mites (Tetranychus urticae, Koch:the yellow tea mite and red spider mite); Aphids, Whitefly, and Jassid69; 70 | None |

In East Africa, Sudan commercialized Bt cotton in 2012 (Table 3) using the technology from a private company JK Seeds in India. Among the five countries with high potential for cotton production in the sub-region, the early adopter Sudan has both open pollinated genotypes CN-C02 and SCRC37 carrying Bt gene Cry 1A originally from China-aid Agricultural Technology Demonstration Center (CATDC) (Kedisso et al., 2022). In 2016, two Indian Bt -cotton hybrids; JKCH1947 (Hindi1) and JKCH1050 (Hindi2) carrying an X-gene (Cry1Ac), were released for commercial production.34 By 2021, the total Bt -cotton cultivated area occupied 98% of the country’s total cotton acreage by 2021. Sudan is also testing hybrid varieties carrying triple gene traits for Cry1Ac+Cry2A and glyphosate herbicide tolerant trait CP4 ESPS (GTG) for approval for further commercialization.

Table 3.

Confined field trials, approval and commercialization of Bt cotton in the region.

| Country | Bt cotton CFT (Year) | Biosafety approval for general release (Year) | Bt cotton commercialized (Year) |

|---|---|---|---|

| Sudan | Yes (2009–2018) | Yes | 2012 |

| Ethiopia | Yes (2016–2017) | Yes | 2018 |

| Kenya | Yes (2004–2010) | Yes | 2020 |

| Tanzania | No | No | No |

| Uganda | Yes | No | No |

Source29:.

3. Commercialization of the Bt Cotton in Eastern Africa – Country Case Studies

The Bt cotton technology was field-tested and was given approval for general release through appropriate biosafety regulatory processes and technology licensing agreements by governments of Ethiopia, Sudan, and Kenya. The following three case-studies provide information on Bt cotton commercialization experiences of these three countries.

Ethiopia

Cotton Production

Cotton is the most important industrial fiber crop and a major cash industrial crop grown in Ethiopia in the lowlands where about three fourth (45%) of the current production is mostly large scale and mono-cropping system, the remainder (33%) is under small-holder rain-fed system.8 The medium staple cotton (G. hirsutum L.) makes up more than 95% of the total production. Ethiopia has an excellent cotton-growing environment with an estimated 3.0 million hectares suitable but only 3% of this is currently growing cotton. Ethiopian national policy gives priority for development of the textile, a sector that demands a well-functioning and competitive cotton sector (Table 4).35

Table 4.

Cotton production distribution across Administrative Regions in Ethiopia.

| Region | Area (ha) | Yield (ton SC/ha) | % Area managed under |

|||

|---|---|---|---|---|---|---|

| Large scale | Small scale | Irrigation | Rain-fed | |||

| Amhara | 27831 | 1,59 | 39 | 61 | 9 | 91 |

| Tigray | 12397 | 1,47 | 93 | 7 | - | 100 |

| Benishangul | 6229 | 1,54 | 100 | - | - | 100 |

| Gambela | 5653 | 1,46 | 100 | - | - | 100 |

| Afar | 16734 | 2,22 | 84 | 16 | 100 | - |

| SNNPR | 10769 | 1,76 | 73 | 27 | 64 | 34 |

| Oromia | 212 | 2,10 | 100 | - | - | 100 |

| Total | 79826 | 1,70 | 70 | 30 | 26 | 74 |

Source: The Cotton Seed System in ETHIOPIA; GIZ, CIRAD, 2017.

Total cotton utilization in Ethiopia is increasing while production has been declining.8 In 2019, demand from textile factories was expected to be around 111,081 ton of lint cotton annually at full production capacity.8 In 2015/16 the country produced around 230,000 tons of seed-cotton/year but faced a shortage of about 70,000 tons during the same year. At the same time, farmer interest for exporting cotton products has been on the rise. Ethiopian government launched New Cotton Development Strategy (NCDS), which laid out plan for 15 years (2017–2032) to make Ethiopia one of world’s largest cotton producers with annual lint production of 1.1 million metric tons (Table 5). The new strategy proposes establishing the Ethiopian Cotton Development Authority to oversee and implement plans to realize the envisaged competitive sector. This ambitious plan of Ethiopian government is based on potential assessment and trends of growth from textile industry. The country’s conducive environment provides high potential to grow a wide range of cotton varieties both in rain-fed and irrigated systems in different cotton growing regions. Despite such needs for diverse environment, farmers had limited choice of improved varieties and the variety Delta pine (DP)-90 currently covers more than 90% of cotton production areas which has been in production for the past many years.8

Table 5.

Targets of Ethiopia’s National Cotton Development Strategy (2017–2032).

| 2017 | 2020 | 2025 | 2032 | |

|---|---|---|---|---|

| Cultivated Area (1000 ha): | ||||

| Smallholder (rain-fed + irrigated) | 27.0 | 50.0 | 265.0 | 300.0 |

| Large farms (rain-fed + irrigated) | 53.0 | 200.0 | 400.0 | 7000.0 |

| Total | 80.0 | 250.0 | 665.0 | 1000.0 |

| Productivity (kg seed cotton/ha): | ||||

| Smallholder | 2.0 | 2.1 | 2.5 | 2.8 |

| Large farms | 2.0 | 2.1 | 2.5 | 2.8 |

| Average | 2.0 | 2.1 | 2.5 | 2.8 |

| Yield (kg lint/ha) | 642 | 783 | 969 | 1,116 |

| Domestic mills lint use (‘000 MT) | 40.0 | 100.0 | 350.0 | 600.0 |

| Lint Exports (‘000 MT) | 11.4 | 95.8 | 294.7 | 516.3 |

Source: Adapted from National Cotton Development Strategy (2017–2032)36

According to the new strategy by the Ethiopian Textile Industry Development Institute (ETIDI), by 2032, the country will have grown cotton on one million hectares, which is a third of the identified highly suitable area for cotton production; 1.1 million tons of lint and 1.4 million tons of cotton oil seed. Based on the new strategy, the annual cotton production could reach 2.6 million tons of seed cotton (Table 5).36 However, cotton production in the country is facing multi-dimensional problems related to low productivity, input delivery, quality, social, and environmental issues, and seasonal shortage of labor all of which require appropriate interventions. Generally, yield per hectare is low compared to the main cotton producing countries in the world and the productivity suffers from old varieties and deteriorated seeds, weak seed system, lack of incentive and extension advisory support.

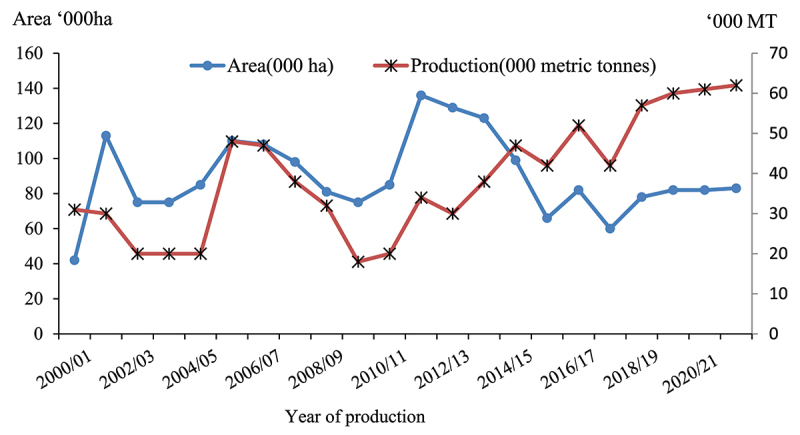

Among several species of pests reported on cotton in Ethiopia, African bollworm (ABW) (H. armigera) and pink bollworm (Pectinophora gossypiella) pose major threat to the production15,37 causing high (36–60%) yield losses. In Ethiopia, bollworm complexes cause high yield losses. In large farms pest control amounts to 30–40% of the total production costs. Repeated chemical sprays not only enhance pest resistance to pesticides but high risk to human and environmental health. Thus, the declining productivity trend for the last 10 years is associated with increasing insect pressures and repeated use of old varieties and poor cultural practices for long period (Fig. 4).

Figure 4.

Trend in production of cotton (lint in ‘000 MT) and acreage of production in hectares from 2000/01–2020/21 in Ethiopia.

The Bt-cotton technology is proven to be safer and has associated enormous benefit to farmers and the environment for high yield and good lint quality results, less cost and reduced pesticide use. Ethiopia’s Biosafety Bill passed in 2015 has allowed the safe applications of such technologies and as a result Bt-cotton performance trial was initiated after accessing Bt cotton hybrids from the JK Agri Genetics Ltd company in India and producers from Sudan. Multi-location field testing across cotton production areas took place in the year 2017/18. Two Bt cotton hybrids were released for commercial use after two years of field and laboratory supported research and evaluation.

The forecast for increased cotton utilization in Ethiopia is based on growing demand from existing and newly installed spinning mills and increased number of textile industrial parks. The traditional handloom subsector is projected to show vibrant growth although the subsector mostly consumes cotton produced by smallholder farmers. According to ETIDI, there are at least a dozen spinning mills in the pipeline to address some of the expected demand for yarn. These planned facilities, plus the 15 existing spinning mills currently operating, will bring the country’s installed annual processing capacity of lint cotton to 200,000 metric tons.

Cotton Production Constraints

Domestic cotton production and productivity is constrained by several biotic, abiotic and socio-economic factors. Abiotic factors include moisture stress in rain-fed areas, soil health–related stress, poor crop management and poor-quality seeds, agro-chemicals, farm machinery and ginneries and labor problems.38

Among biotic factors, insect pests are major cause of losses in yield and quality in addition to low productivity of existing varieties. More than 60 insect and 2 mite species were reported on cotton, but African bollworm (ABW) (H. armigera) and pink bollworm (Pectinophora gossypiella) were shown to be the key insect pests37 and15 causing high-frequency chemical pesticides sprays and rising cost of production and leading to low yield rendering cotton production unattractive venture.

Other constraints including labor shortage, poor harvesting mechanism, prohibitive cost of inputs, and weak financial support to smallholder farmers contribute to low productivity. Chemical pesticides have proved ineffective and unsustainable. Cotton growers spray a minimum of five to ten insecticidal applications and no germplasm has proven resistant against the major pest, bollworms. Large farms pest control amounts to 30–40% of the total production costs. Repeated use of chemical pesticides has triggered development of pesticide resistance and repeated use of high dose pesticides have exerted significant negative health and environmental effect.

Due to the high production cost and low yield growers have been looking for better technologies. The introduction of Bt cotton is an opportunity to improve the current production conditions and productivity challenges. Due to increasing local demand, the government banned export of cotton in 2010 to meet the needs of expanding domestic textile production. However, the ban was lifted in 2012,38 but the export revenue for Ethiopia from cotton has dropped from about US$40 million in 2013 to below US$10 million in 2019 and US$5.18 million in 2020.39

Cotton production in Ethiopia has a considerable potential to increase if its market flaws are improved (USDA Grain Report No. ET1906). Advancing reliable market information and proper market linkages between cotton producers (smallholders, large-scale commercial farmers, and cooperative unions), ginneries and textile mills is required through strengthening the cotton value chain. Advance contract farming and out-grower initiatives would allow farmers to obtain relatively better access to market, improved seeds, other inputs including technical trainings on agronomic practices and farm management. Insufficient access to finance and foreign exchange, power outages, logistical challenges, among others, are factors that constrained the full-scale operation of existing facilities.

Adoption of the Bt Cotton

After obtaining a “Special permit,” a procedure in the Biosafety Law in Ethiopian Biosafety framework for research purposes, the Ethiopian Institute of Agricultural Research (EIAR) introduced two Bt cotton hybrids from India and one open-pollinated variety (OPV) Bt-cotton from Sudan in 2015. The three genotypes (JKCH1050 & JKCH 1947) from India (JK Seed Company) and an OPV (Sudan-1) from Sudan including two local checks were tested under confined field trials (CFTs) at several locations in cotton growing areas of Ethiopia.

Two CFT trials were conducted, both funded by the Ethiopian Government, using the above three Bt cotton varieties and local commercial varieties for comparison both under irrigated and rain-fed conditions. Data were collected from the CFTs in 2016 and Bt-cotton adaptation trial was repeated in 2017 cropping season at different agro-ecologies, overlapping efficacy test and adaptation. In the second year, the multilocation CFT was done by overlapping the NPTs (national performance trials) across 8 cotton growing locations. The growth and yield performance results were used to evaluate adaptability and efficacy of the Bt cotton varieties by the National Variety Release Committee for eventual release in 2018. Efficacy demonstrated in the CFTs and laboratory trials showed that the testing environments vary widely in infestation levels and where there is infestation of bollworm, the Bt cotton varieties demonstrated superior performances (Table 6). There were not any observed unintended effects on non-target species and the environment in the testing areas as confirmed by the regulatory review of data and approvals later.

Table 6.

Mean seed cotton yield and ginning percentage of Bt cotton and local improved genotypes in Ethiopia.

| Variety | Bilen (slightly infested) |

Gewane (heavily infested) |

||

|---|---|---|---|---|

| SCYLD (t ha−1) |

GINPCT (%) |

SCYLD (t ha−1) |

GINPCT (%) |

|

| Sudan-1 (Bt OPV) | 2.11 | 41.79 | 3.37 | 40.13 |

| JKCH 1947 (Bt hybrid) | 3.54 | 42.38 | 4.77 | 37.97 |

| JKCH 1050 (Bt hybrid) | 3.44 | 41.06 | 4.67 | 38.59 |

| Weyito 07 | 2.14 | 35.57 | 0.30 | 36.68 |

| Stam-59A | 1.75 | 38.87 | 0.39 | 36.17 |

| DP-90 | 2.46 | 38.44 | 1.03 | 35.15 |

| Mean | 2.57 | 39.69 | 2.42 | 37.45 |

| CV | 0.017 | 3.26 | 0.02 | 5.19 |

| P | P < .01 | P < .001 | P < .001 | NS |

| LSD | 0.818 | 2.35 | 0.984 | |

SCYLD = seed cotton yield, GINPCT = ginning percentage.

Source40:.

Bt cotton hybrids JKCH 1947 and JKCH 1050 provided maximum protection and the conventional improved varieties gave 3–10 fold lower yield at one of the best cotton growing locations, Gewane in Ethiopia during the NPTs in 2017 (Table 6). Damage to the cotton ball ranged between 10 and 20% in the Bt hybrids compared to well over 90% in the local varieties (Gudeta et al., 2022). Despite promising results and subsequent demand for the approved Bt cotton, the expansion has been severely limited due to poor access to seed. The Bt cotton hybrid seeds were locally unavailable and required to be imports. Due to the decline in total exports merchandize during the COVID-19 Pandemic and foreign currency expenditure shortage for imported goods, the Bt cotton seed supply system also suffered from foreign exchange restrictions to purchase seeds.

Absence of local seed company investing on hybrid seeds production has been one of key challenges facing the Bt cotton commercialization in Ethiopia,40 under publication). Currently estimated only 3,500–4,000 hectares of Bt cotton is grown across the Sudan boarder mainly illegally imported or smuggled from Sudan (Table 7). According to informal sources, the variety being imported illegally is expected to be different from the officially registered JKCH- varieties from India.

Table 7.

Bt cotton area and production during the last five years.

| Season | Cultivated Area (ha) |

Total** production (tons) | Cotton Export/Import (tons) |

|---|---|---|---|

| 2016/2017 | - | ||

| 2017/2018 | 50 | 128.5 | None |

| 2018/2019 | 100 | 527 | None |

| 2019/2020 | 1,000 | 5,270 | None |

| 2020/2021 | 3,500* | 8,995 | None |

Source: (Personal communication); * expected at 11,000 ha in 2021/2022 because of cross border import from Sudan. ** Yield estimated based on mean yield at Bilen (2.57 t/ha) (Table 6).

Current Seed System and Challenges

One of the key problems in the cotton sector is the weak cotton seed system. Although some improved seed production practices exist, it is difficult to conclude that formal cotton seed system exists in Ethiopia. If it exists, it is in small quantities with negligible impact. The formal seed system working procedures starts from the breeder seed and proceeds to pre-basic seed generated from research centers and finally directly goes to seed cotton producers for seed multiplication. There has not been first-, second-, or third-generation certified seed supply in Ethiopian cotton seed market thus far. This remains a critical drawback of the country’s cotton industry development.

The traditional way that farmers get the seeds is from ginners or some local seed processers that uses neither pre-basic, basic nor certified seed. A few private seed companies prepare second-generation seed accessing from the research in extremely limited quantity. De-linting of seed requires specialized facilities mostly lacking in the country. However, good seed quality is an important input for best cotton performance both for smallholder and large-scale commercial cotton farms. Nationally large quantity of superior quality seed amounting to 1,200–1,600 MT is required each year, which might grow up to 2,400MT if acreage expands to 120,000 ha or more as has been in previous years.

For Bt cotton hybrids, the seed quantity can be reduced by half due to lower seed rates. This can only be provided through maintaining standard seed cleaning treatments and facilities. Currently no seed company gets seed certification because of limited capacity providing only seed germination test. Most farmers get seeds from ginneries whose source is unknown, mixed and of inferior quality. The existing seed certification does not differentiate between varieties, and whether seed is GM or non-GM. One can find a mixture of seeds from various sources, and this affects seed quality, crop agronomy, harvest, and market. Only a few large-scale commercial farms maintain their own seeds. ETIDI and stakeholders are now encouraging private producers to follow good seed management practices.

The Werer Agricultural Research Center (WARC) used to operate as center of excellence for cotton research for an extended period. Now it has shifted its objective to working on many other irrigated lowland crops. Land available for producing breeder and pre-basic cotton seeds has been reduced and the research has remained underfunded and operates below capacity rendering WARC incapable of producing sufficient breeder and pre-basic seed. There is no seed demand and production inventory and growers face information gap to know where they can find superior quality seeds.

The JK Seed Agri-Genetics Ltd Company from India which has two of its Bt cotton hybrid commercialized in Ethiopia is not present locally to supply the hybrid seeds. Importing hybrid seeds from India has been difficult and costly because of high seed prices including high transportation costs and shortage of foreign currency in Ethiopia. Despite best performance of the Bt cotton hybrids, seed access problem has hampered its widescale adoption. This has opened doors for informally imported Bt cotton seed from Sudan across border to Ethiopia including, in recent time, varieties with stacked traits for insect resistance and herbicide tolerance which has not been approved by the Ethiopian government. The informally imported seeds include unknown generation open pollinated GM varieties whose pedigree is unknown, and performance is less predictable.

Varieties differ in adaptability and demand for seeds depends on farmers preference and varieties performance across different cotton growing environment. For instance, variety DP-90 yield has been good under poor agronomy but under good management yield reaches 3.5–5.0 t/ha because of its adaptation under adequate irrigation in good soils.36,40 However, in infested fields with bollworm, yield is drastically reduced to almost nil. This variety has good fiber quality for fiber length, micronaire, and strength which does not fluctuate year to year unless attacked by insect pests.

Reports show that cotton investment support by the Government Development Banks has been misused and money diverted illegally into other sectors because of weak monitoring and control by the government itself. Policy support for cotton has been very weak and the governance structure or institutional set-up of the entire cotton sector has been poorly organized under Ministry of Industry (MoI) forming a weak link to research, agronomy and input delivery which are governed by the Ministry of Agriculture (MoA). This lack of coordination and cooperation among the two Ministries has contributed to the poor cotton sector development and cotton seed system in Ethiopia.

The entire agricultural seed regulatory system is managed under MoA which has no connection with the cotton sector therefore does not regulate cotton seeds. Lack of any link between these two ministries, as they operate independently, has over the years weakened the cotton sector. In all other crops breeder and pre-basic seed generated by the research institutes often directly goes to certified governmental or private seed multiplying companies and seed multiplication passes under a regulatory and certification process, where the seed marketing system is regulated. Therefore, improving the current cotton seed system in Ethiopia requires special intervention most notably through restructuring and incentivizing the sector itself to enable local production of certified seeds through supporting seed producers, strengthening the regulatory capacity to facilitate better access to improved seeds by farmers. The supply of improved quality seeds will remain a crucial component of sustainable cotton production that uses improved technologies like Bt cotton to acquire higher performance for best results.

Kenya

Cotton Production

In Kenya, cotton is grown in the semi-arid regions of Eastern, Central, Nyanza, Coast, Western and Rift Valley provinces.41 Cotton growing in Kenya was a major business in the 1980s and 1990s. National cotton production reached a peak of 38,000 metric tons of seed cotton in 1984/1985.42 Most farmers still look back with nostalgia of what went wrong with the cash crop they depended on for years to pay fees for their children’s education and generate income for other domestic engagements.

To revive the sector with the big 4 agenda, Kenyan cabinet approved commercialization of Bt cotton seeds in 201943 for the four Bt cotton hybrids namely MRC 7377, MRC 7361, MRC 7031, and MRC 7017.44 Bt cotton seed was distributed to farmers and according to a lead scientist at Kenya Agricultural Research and Livestock Organization (KARLO), 16.3 metric tons were distributed, and farmers reception of the technology was high although timeliness and adequacy in distribution was a significant challenge in many cases.45 The early returns from the farmers who grew Bt cotton were encouraging.

Going forward, Kenyan farmers want not to rely on government seed distribution as they are ready and willing to pay for the improved Bt cotton seeds. Toward this end Kenyan, government’s Agriculture and Food Authority (AFA) and Mahyco Seed Company from India, a private seed propagation company, has entered a partnership and working toward meeting the rising demand. This will be exercised whilst supporting farmers with agronomic knowledge through county government’s efforts.45 These steps will be key in achieving a sustainable Bt cotton production in Kenya.

Under rain-fed agriculture farmers can get up to 4.9 tons per hectare with proper irrigation.46 In 2021, about 6,196 bales of 185 kg of cotton lint were produced in 2020, valued at Sh206 million. This is an increase from 5,432 bales produced in 2019, valued at Sh190 million which shows that embracing Bt cotton can be a game changer to the cotton industry in Kenya. So far, the nation’s cotton seed production was 3,495 metric tons. This still is far below the satisfactory levels to allow farmers to plant all the cotton area under production. To optimize Bt cotton growing in the country, the matter of seed availability and adequacy must be looked at as a matter of urgency.

Cotton Production Constraints

Cotton is grown in 24 counties of Kenya while the country has only four operational ginneries while at the peak of cotton production in the past the country had 24 ginneries in operation. In Kenya, cotton is an important fiber crop that provides a source of income to farmers and fiber to the textile industries. The seeds provide an important source of oil and seed cake for livestock feed.47 About 40,000 farmers are involved in cotton farming, while the overall sector provides livelihood to about 200,000 households. Reports show that mismanagement, low prices, heavy infestation of pests and diseases and unfair competition from the cheap imports of secondhand clothes (mtumba) are among the major reasons that brought cotton growing in Kenya to its knees. Whereas Kenya has potential to produce 200,000 bales of cotton lint, the current production stands at a paltry 20,000 bales as of year 2021.46

The major challenges facing the sector, include low cotton prices, and lack of incentives, lack of access to certified seeds, pests and diseases, high production cost and lack of county government focus on cotton farming. The African bollworm is the most important pest in cotton fields especially during the reproductive phase, appearing at the squaring stage may cause severe yield loss if unchecked.41 Estimated yield loss due to pest (Bollworm) reaches 50% and in some cases up to 100%.48 Other prevalent pests are cotton stainer, cotton aphids and spider mites.48 These remain key challenges facing many cotton farmers in the various parts of the country where cotton was a major cash crop especially in Eastern, Nyanza and Coastal regions.

Adoption of the Bt Cotton

Kenya was the 7th African country to commercialize GMO cotton. Kenya is among the new entrants while South Africa, Nigeria and even Malawi have had a longer experience with Bt cotton growing. The first application for Bt cotton introduction in Kenya was made in 2001. The testing and approval took a long period and the process stalled after the ban on GM imports was instituted by the government in 2012 and faced additional hurdles due to strict regulatory framework under NEMA that classified GMOs as dangerous.43 However, after approval was granted for testing, the NPTs performance trials from 2018–2019 clearly showed superior results. The field trials over two seasons were conducted in seven and four sites with four Bt-Cotton hybrids, (MRC 7377, MRC 7361, MRC 7031, MRC 7017) with insect resistance (Bollgard II®) gene for bollworm protection along with their non-transgenic counterparts (C 567, C 571, C 569, C 570) were evaluated along commercial check varieties, (HART 89 M and KSA 81 M) were evaluated (Table 8). The first season trials were funded by the Government and second season funding by Mahyco and the Government.

Table 8.

Mean seed cotton yield and ginning percentage of Bt cotton and local improved genotypes at two bollworm infested cotton growing areas.

| 1st Season |

2nd Season |

|||

|---|---|---|---|---|

| Treatment | Yield (t/ha) | % Over the control | Yield (t/ha) | % Over the control |

| MRC 7377 | 3.8 a | 80 | 2.4 abc | 41 |

| C 571 | 3.4 b | 58 | 2.1 abc | 27 |

| C 569 | 3.3 b | 56 | 2.1 bcd | 23 |

| MRC 7031 | 3.1 bc | 47 | 2.7 a | 64 |

| MRC 7017 | 3.0 c | 42 | 2.2 abc | 33 |

| C 570 | 3.0 c | 42 | 2.1 abc | 27 |

| C 567 | 2.9 c | 35 | 2.0 cd | 22 |

| MRC 7361 | 2.6 d | 21 | 2.5 ab | 46 |

| Local 1 (HART89M) | 2.2 e | 1.6 d | ||

| Local 2 (KSA81M) | 2.1 e | 1.7 cd | ||

| LSD | 0.3590 | 0.7578 | ||

| P-value | <0.001 | <0.001 | ||

| CV (%) | 22.5 | 20.6 | ||

Source48: (Kenya Agricultural & Livestock Research Organization Report).

Higher incidences of bollworms were recorded in the non-Bt hybrids and local varieties compared to the Bt-hybrids and seed cotton yield results showed the presence of Bt trait in the hybrids conferring protection leading to lower incidence of bollworms (Table 8). Although there was variability between the two seasons in infestation levels and variety performance, the Bt cotton varieties efficacy and adaptability demonstrated yield advantage between 20–80% in the first season (Table 8). The highest yielding hybrids MRC 7377 and MRC 7031 particularly outyielded the local varieties by 80% and 64% in the first and second seasons, respectively.

These research results helped Kenya push the technology for commercialization. The process was accelerated through the Cabinet approval for commercial farming of Bt cotton granted on December 19, 2019. In 2020 the first batch of GMO cotton seeds imported from Mahyco Seeds Company in India were distributed to select farmers from Nyanza and western region. The commercialization was kicked off by planting of 1000 demonstration plots in 23 counties followed by full commercialization.49 In 2021, 16 metric tons of Bt cotton seeds were distributed to ten thousand farmers growing cotton. Farmers reported that the Bt cotton varieties have been fast growing requiring only 4–5 months to mature, high yielding (1 branch can yield up to 100 bolls unlike 30 for the conventional varieties), and not getting infected by pests compared to the conventional varieties. This has resulted in reduced numbers of pesticide sprays by most farmers by at least half.

Current Seed System and Challenges

Cotton growing in Kenya is done by 30,000 to 45,000 smallholder farmers in arid and marginal regions, under rain-fed conditions on small land holdings of about one hectare. Potentially 385,000 hectares of land is suitable for cotton production under rain fed agriculture while another 35,000 hectares can be utilized under irrigation agriculture. There is potential of producing 300,000 tons of cotton lint but currently only about 7,000 tons are produced. The Bt cotton being hybrid and not locally available, the Government in 2020 imported and distributed 24 tons of superior Hybrid Bt cotton seeds from the Mahyco Seed Company in India for planting by farmers. This timely effort led to an increase in cotton seed production from 3,015 tons in 2019 to 3,495 tons, an increase of 16%.50

Despite the government effort, access to high-quality seeds is a question not properly addressed in Kenya and has faced multiple challenges. In the 2021 distribution, some farmers in cotton growing areas of Siaya and Homabay and other counties of western Kenya did not receive the seeds on time although the seeds were made available later. Moreover, the farmers have urged the government to subsidize the Bt cotton seeds due to prohibitive cost .71 The price of seeds in the same year was at 2,300 KES per kilogram and quite out of reach of most farmers. These farmers have gone as far as requesting the government to offer seeds on credit that the farmers will repay after harvesting. Though the cost of seed is currently subsidized, the government is seeking private sector intervention to support revival of the sector as its approach is not sustainable.

From the government’s point of view, one of the key challenges is making seeds sustainably available11,29. The other challenge is that the extension support is inadequate to help farmers use the best agronomic and crop management practices (Ngotho, 2021). The Bt cotton seed access in Kenya remains a pertinent issue that needs to be well addressed by all stakeholders urgently to support the complete revival of the cotton sector. A recent study11 has shown some potential pathways to enhance Bt cotton hybrid seed access by farmers such as using farmers’ cooperatives or through establishing contract farming with ginneries supports as well as using open market schemes.

Sudan

Cotton Production

Cotton farming is a livelihood issue for more than 300,000 Sudanese farmers.51 Sudan has a long history in commercial cotton production since 1867 using traditional organic farming in the Eastern Sudan. The country’s cotton research program is extended for more than a century (since 1904). It has released several improved and adapted varieties with good fiber qualities and resistance to devastating prevailing pests and diseases.52 However, the cost of cotton production is steadily increasing in the country due to pest control. In Sudan, bollworm (H. armigera) is the main pest causing major loss in cotton yield whereas the whitefly (Bemisia tabaci, Aleyrodidae) induced stickiness is a serious bottleneck for cotton marketability.

Bt cotton production trend is rising in the country as seen in Table 9 due to high yield from varieties, lower production cost, reduction in pesticides and pesticides hazards, increased environmental safety, and higher cotton prices worldwide. Moreover, engagement of local and national investors from the private sector as a third party in the production process using contract farming adds to the progressive increase in the cultivated area and total yield. The current (2021/2022) growing season of Bt cotton is an unprecedented incidence in terms of cultivated area and high expected productivity due to positive impact of suitable production factors. The area under production is estimated at 420,000 ha with an expected productivity above 800,000 tons (Personal communication). In 2016 and 2017, high international prices and highly productive GMO varieties provided a new impetus to the sector that is now facing renewed optimism that the revenue will be high coinciding with high global rises in cotton prices.

Table 9.

Sudan Bt cotton area (1000 ha), production (tons) during the last five years.

| Season | Cultivated Area (1000 ha) |

Total production (1000 tons) |

|---|---|---|

| 2016/2017 | 120 | 36,363 |

| 2017/2018 | 150 | 45,454 |

| 2018/2019 | 240 | 58,181 |

| 2019/2020 | 370 | 67,272 |

| 2020/2021 | 180 | 47,272 |

Source: Personal communication (October 2022).

Cotton Production Constraints

In Sudan major cotton production constraints comprise of pests, labor shortage, low soil fertility, variability in yield between seasons and within farms, unaffordable cost of inputs together with lack of subsidy of inputs prices, and low farmers’ financial capabilities. Of all obstacles, insect pests, particularly the bollworm (H. armigera), pose a major production challenge, contributing significantly to high cost of production, low yield, and consequently less return. The bollworm control constitutes about 50% of the total costs of pest control.53 The cultivation of Bt cotton reduces the need for pesticides and consequently cost of production and contributes significantly to environmental safety. The high production costs and low yield together with adoption of low input production systems emphasize the need for breaking the cycle with introduction of Bt cotton to reduce cost and improve production practices.

Biotechnology and Biosafety Development

In Sudan, several national institutes are mandated to undertake research in all aspects of agricultural biotechnology research. However, the Agricultural Research Corporation (ARC) is the main science and technology arm of the Ministry of Agriculture. Biotechnology, including GM research, has limited applications in the country due to shortage in experienced personnel and limited biosafety capacity.72

The constitution of Sudan calls for a conservation of natural resources and protection of the environments from various hazards. Sudan has acceded to the Cartagena Protocol on Biosafety (CPB) since 2005, developed its National Biosafety Framework (NBF) in 2008 via full stakeholder’ participation through the GEF/UNEP assisted project also called “The National Biosafety Framework Project.” Sudan has received an award for having been among the first 20 countries in the world for finalizing a National Biosafety Framework (NBF). In 2010, a national biosafety law entitled “The National Biosafety Law for the Year 2010” was passed by the parliament. A National Biosafety Council has been established in 2012 headed by the Minister of Environment, Forestry and Physical Development. The council has its own technical committee on biosafety.54

The national biosafety law was amended to be a Miscellaneous Amendments Law (Unification of Environment Councils) and officially gazetted in Sudan (Gazette No. 1091). Articles amended are related to prerogatives of the General Secretariat and financial matters. However, the biosafety system improvement is imperative because much more must be done even after issuing of the amendments law with respect to the regulations, guidelines, and post-market monitoring.

Adoption of the Bt Cotton

In Sudan, three CFTs of insect resistant cotton (Bt cotton) have been conducted in 2012, 2014 and 2018. In 2012, Sudan started commercialization of Bt cotton with first bollworm-resistant variety senni1 (Chinese hybrid cultivar) on 20,000 ha, planted by about 10,000 smallholder farmers.55,56 In 2013, the planted area was increased by 3-fold.73 Since then, the Bt cotton total cultivated area in the country has progressively increased and currently the technology is predominant. It is reported that planting Bt cotton reduces pesticides use and thus production cost; however, no environmental safety data has been collected (Brookes and Barfoot, 2018) and no comprehensive analysis on socio-economic impact has been conducted for the technology.

National assessment activities for Bt cotton commercialization and seed production system are either regularly conducted and/or monitored by a specialized monitoring committee formed as a task force for rapid assessment in case of emergent issues. During the commercial deployment of Bt-cotton the identity of seed, locally produced or imported, should be verified. During the production cycle field inspection is carried out by the seed administration of the Ministry of Agriculture for plant morphology as well as through sample collection for laboratory seed testing to ensure that seed meet the standards for certification. Moreover, the biosafety authority is responsible for ensuring the Bt gene is present in the seed via laboratory analysis for detection and confirmation of presence of the gene.

Current Seed System and Challenges

In Sudan, the precise assessment of the Bt cotton current seed system is challenging and needs special consideration because it is crucial for the sustainability of the technology. Therefore, partnership that encourages future seed industry development in the country and provides valuable current situation analysis in the national cotton sector is highly needed. Historically the formal seed sector, which started during the colonial era as early as 1902 through cotton introduction trials, was entrusted for provision of the service. Sudan enacted a new seed law in 2009. In Sudan, the Seed Administration of the Ministry of Agriculture is the national official seed authority and is responsible for certification and quality control of seeds in the local and international markets. The national seed council is responsible for the seed certification standards.

In the first season of Bt cotton commercialization in Sudan the availability of seeds was a limiting factor, but in the following seasons seed accessibility has improved and the planted area is consequently expanding.

Bt cotton seed production is dominated by the private sector because of high cost and special arrangements for quality seed production. The Bt cotton seed production is regulated in collaboration between the biosafety authority and the seed administration. However, national efforts are being made to improve quality seed production. Recently, developments were made regarding seed law revision which is in the legislative process as well as a separate plant variety protection act. Moreover, local public and private seed associations are playing a vital role in developing the local seed industry in Sudan.

Nevertheless, recently seed mixtures of Bt cotton hybrids and cotton open pollinated varieties have been reported. This could be attributed to noncompliance with guidelines for the Bt cotton seed production by seed producers. This certainly threatens the future of cotton biodiversity in Sudan as the country is home to Gossypium anomalum and the land race G. hirsutum var. punctatum. It is noteworthy that the cotton germplasm in Sudan contains diverse materials ranging from wild species, land races and improved varieties. Maintenance of existing improved cultivars is important and remains a major future concern. Bt cotton marketing is sufficiently important to merit an analysis particularly due to lack of national marketing policy. Sudan is vulnerable to climatic shocks and new cotton insect pests have been reported recently and this necessitates using environmentally benign technologies, adapted to the local conditions and efficient in supporting sustainable production. Sudan’s capability to produce good quality Bt cotton seed needs to be supported through establishment and promotion of partnerships. Most importantly, Sudan needs to build its seed system capacity and develop appropriate policy to ensure environmental safety and sustainable use of the GMO cotton technology.

4. Prospects of Bt Cotton Benefits to African Farmers

Benefits of Bt Cotton to Growers

Several studies have been made since the commercialization of Bt cotton technology on performance and potential economic benefits of GMO products in different countries.30,57,58,59 Vonzun et al., 2019.58 Biotech cotton offers improved insect control by reducing insect infestation levels and reducing the amount of insecticides spraying, thereby increasing boll number per plant at harvest and seed cotton yield as well as lint quality while reducing cost of chemicals needed to control insects. These studies also suggest that farmers, including small-scale cotton producers, benefit from it.

The main benefits of Bt technology are reduced losses associated with the pests; thus, the Bt cotton may provide such farmers with a more effective insect pest management system with added benefit of human health and environmental concerns from intensive use of synthetic chemical pesticides than the environmental friendly pest management practices.18,26

However, these benefits are counteracted by a different viewpoint, where some reasons that countries have prohibited GMO technology is due to concerns, especially regarding the long-term implications of introducing GMO cotton.30,57; .59 Authors argue that since Bt cotton has been continuously used to control one major cotton pest, but with resistance building in the same and other pests and surging populations of non-target pests, farmers can get forced to use more pesticides than before the introduction of Bt cotton. Furthermore, rising production costs for inputs, labor, and equipment and cotton price fluctuations in the world cotton market might exacerbate the situation. This can be particularly risky when economic loss occurs by small-scale, cash-poor farmers because of crop failure, which could limit their ability to purchase Bt cotton hybrid seeds and associated inputs in the subsequent seasons. However, such argument should not be taken as always to be the case since there are assumptions involved.

According to Kathagi and Qaim58 who did economic impact studies of Bt cotton in India between 2002 and 2008, they showed that Bt has caused a 24% increase in seed cotton yield through reducing pest damage and a 50% gain in cotton profit among smallholders. The benefits were seen stable and increasing over time. Moreover, there is a constant shift in technology and management options to mitigate or minimize resistance building in target pests. One such example is the introduction of integrated resistance management (IRM) using refugia in Bt cotton and other biotech crops. A strong integration of IRM approaches thus should be a key component of the scaling out and wider commercialization of Bt cotton technologies. The same study further showed adoption of Bt cotton to have created large and sustainable benefits and raised consumption expenditures by 18%, thus contributing to a positive economic and social development during the 2006–2008 period.58 There is also the added benefit from better protection to human and environmental health due to reduced chemical use.60 also reported that despite Mexico being among the early adopter of Bt cotton technology in 1996, there are no reports of insect resistance development and no effects have been observed on non-target organisms which is related to the strong practices of crop and herbicide rotations that is being practiced.

Meeting Technological Gap (Lessons from Indian Experience)

Fig. 2 shows how low the performance of the Eastern African region is in terms of productivity and production. On the other hand, it is also an example of how policy adjustment and technology injection help when productivity declines consistently. The green revolution impacts through input intensification and favorable policies have played the critical role in India for the rise in productivity during the late 1970s and mid-1990s. When this rise started subsiding the intervention with the Bt cotton hybrid technology began in the early 2000s in India that resulted in a second trajectory of productivity that was intensified through wider adoption of the technology in the years followed. Cotton producing countries whose national research programs adopted Bt technology to incorporate advanced varieties or breeding lines have benefited more. This is true when we see Bt cotton varieties developed locally and approved for commercial use resulting in a 95% nation-wide adoption in India in 201355 that had an estimated average yield gain of 31% over the years and tripled India’s cotton production by 2021.

Maintaining seed quality and improving cultural practices including good soil and fertilizer management, proper pesticide use, appropriate insect resistance management and crop rotation practices are components of the new improved technological packages destined for higher productivity. Although seed costs for Bt cotton are higher than the non-Bt, pesticide costs are effectively reduced with Bt cotton. It implies the gross margins of growers using the Bt cotton technology are in most cases higher than those of non-Bt growers. The cost of using hybrid Bt cotton seeds accounts for only around 5% of total production costs, however the benefits are tremendous. The significant increase in productivity and better economic returns can catalyze a new production and productivity trajectory through expansion of Bt cotton in East African countries. Only such measures that consider better technologies and improved input and management practices will be powerful enough to break away from decades-long stagnation of cotton productivity in Eastern African countries.

Better Control of Target Pests

Bt cotton provides effective control of the three major caterpillar pests in cotton, tobacco budworms, bollworms, and pink bollworms.61; . With Bt cotton, farmers worry less since the plant gets active protection throughout the growing season, irrespective of the level of infestation. As a result, the yield that a grower normally would give up to low-level infestations is maintained by Bt cotton, thereby improving the grower’s overall yield.62,63 The overall level of spraying chemical insecticide for controlling lepidopteran pests is highly reduced with Bt cotton varieties. However, if supplemental insecticide sprays are applied, they have greater efficacy on Bt than on non-Bt varieties.

Reduced Production Costs and Higher Yields

Bt cotton reduces the number of insecticide sprays necessary and impacts production costs associated with insect control. Studies by Benedict and Altman64 have shown that the main risk in cotton production is associated with the level of target-insect infestation. As infestations by pests rise, the economic benefit of using Bt cotton instead of conventional broad-spectrum insecticides also increases. In other words, Bt cotton eliminates the need for scouting, timing of insecticide applications, and other decisions need to control or minimize pest. Klümper and Qaim65 reported GMO technologies as providing significant economic and environmental benefits, such as reductions in chemical use by 37%, increasing yields by 22% and improving farm profits by 68% without taking in to account the health benefits to humans and the environment. In India yield has significantly increased for farmers in the last two decades with average gain higher than 30% due to the introduction of the Bt cotton technology. In South Africa, the high-level adoption of insect-resistant cotton is attributed to different benefits in yields, cost of production and overall profit by both large-scale and small-scale farmers.

5. Regional Perspective of Improved Access to Hybrid Bt Cotton Seeds

Cotton farmers in the Eastern African region suffer from similar production constraints. Most smallholders are producing cotton under poor growing conditions due to high levels of insect infestations, poor soil and water conditions and poor technology use. Most cotton productions are rain-fed, and farmers use age-old varieties that are highly deteriorated and poor yielding because they are susceptible to pests, use repeated chemical sprays to control pests but get poor results and continuously face access problem to quality seeds and other inputs. This can be very well understood from the performance of countries in the regions in cotton productivity that it has hardly improved in the past 50 years from 0.32 tons per hectare to 0.78 tons per hectare (Fig. 2).

In the last almost 10 years, however, in all countries of the region, the Bt cotton technology developed through genetic engineering which offers resistance to the major pest bollworm in all cotton growing countries in the region, has sparked optimism for a significant improvement recorded over the existing production situation. The potential of the Bt technology for reducing crop losses and enhancing productivity of farmers has also been evident in several countries worldwide. This technology has been tested and had shown very promising performances in Sudan, Ethiopia, and Kenya, who approved commercial release of Bt cotton varieties in 2012, 2018 and 2019, respectively.29 .27

On the other hand, Uganda and Tanzania had tested under confined fields and shown similar promising results. Rwanda is expected to follow suit having seen the performance of neighboring countries. National performance trials in countries that have commercialized have shown contrasting yield levels compared to traditional ones reaching up to 4–5 tons per hectare with improved packages as discussed earlier. Given estimated potential acreage of about 5 million hectares for cotton in the region, it is hard to imagine the huge forgone opportunity benefit that would have been realized through wide application and acceptance of the Bt cotton technologies in the Eastern Africa region.

A common problem observed again is the need for improved seeds access by farmers in all GM cotton adopting countries in the region. For commercial plantings by farmers in Ethiopia, Sudan, and Kenya, the hybrid Bt cotton seeds have been imported from two private seed companies in India. In these countries shortage of foreign exchange and high seed prices due to increased freight costs associated with the COVID-pandemic and high fuel process have been mentioned to constrain seed availability.11 For example, a freight cost for 1 ton of seeds to transport from India to Eastern Africa is about 7,000 USD which amounts to about 30–32 USD/Kg at FOB price in 2021/2022 (personal communication with JK Seed Agri Genetics Ltd). This was not affordable by the local farmers even if currencies could be available. Countries have declined importing Bt cotton seeds because of competing needs and priorities for foreign currency by the government.

The above problems coupled with weak seed system and poor supply chain has effectively disrupted access to Bt cotton seeds by farmers in the region. The stakeholders in all three countries are demanding local production of Bt cotton seeds at a country or regional level to provide sustainable access of Bt seeds at an affordable price from farmers. This created a strong interest for local seed production through enhancing local capacity for seed production and building effective extension advisory services through public-private partnerships.

More options need to be provided by the technology providers and local research and development services for best adapted varieties and extension packages for effective and sustainable commercialization of such improved technologies. If there are similar varieties grow across Eastern Africa region as is the case for instance the Bt cotton hybrids in Sudan and Ethiopia, which can expand to other countries in the region, then the seed companies may only require testing the performance of the parental lines to start producing the Bt cotton hybrid seeds locally. However, this will require sufficient IP (Intellectual Property) protection and allow proper product stewardship to build trust. Strengthening the collaboration through public and private sector partnership, assessing the market size, and identifying regional approaches to the seed access which include production, marketing and distribution will considerably improve the weak supply chain and marketing problems that are hindering the commercialization of Bt cotton hybrids.

The decision by seed companies to move into countries for seed production depends also on the scale of operation or size of market. However, seed production can be limited to a few places where there are favorable conditions for production and certification of seed quality, access to labor, among others. The new initiatives of Common Market for Eastern and Southern Africa (COMESA) i.e., the regional Seed Harmonization Implementation Plan (COMSHIP) can provide framework for harmonized modality and improved access to and wider adoption for similar technologies among member countries.66,67 The common varieties of Bt cotton hybrids commercialized across the region can use the above platform for harmonizing the seed demands and production and create better access to quality seeds. Creating a better local access of Bt cotton hybrid seed can involve adaptation testing of the parental lines and selection of the most suitable sites to establish the production in one or more countries in the region and may take only 2–3 years to reach farmers. However, stakeholders’ consultation around these approaches at both national and regional levels seems to be the most feasible way forward to resolve local seed production issues.

Continued consultation of stakeholders for common initiative may help identify better alternatives for solving common regional and local problems. Looking at Eastern African Bt cotton seeds access related challenges, promoting regional collaboration should be viewed as helping to pool capacities and share resources for the common good of pooling out the region and its cotton producing farmers from decades-long low productivity quagmire.

6. Conclusion and Way Forward

Technology providers in collaboration with cotton development institutions need to continue Bt cotton technology demonstrations/trials in key cotton growing regions to improve awareness and discussion. Establishing a clear stewardship/post-release monitoring plan would help ensure technology integrity and sustainability. The countries in the East Africa region have not developed their own Bt cotton technologies and varieties. Bt cotton varieties developed and deployed through genetic engineering are proprietary technologies protected through intellectual property rights. Access to these proprietary technologies was possible through licensing negotiations and technology transfer agreements and testing in local environments. The Bt cotton technology deployed in in this region came from two private companies in India and China through collaborative agreements with partners in Kenya, Ethiopia, and Sudan. Access to Bt cotton seeds from China and other countries would require similar approach and partnerships.

The Bt cotton seeds supply is likely continuing to suffer from foreign exchange restrictions across countries of the Eastern Africa region if the current model of importing seeds is pursued. Therefore, create favorable conditions for accessing Bt cotton seeds with competitive price, timely supply of quality certified seed to protect the interest of local farmers.11,29,34 Enhance local seed production capacities and regional production of seeds to create economies of scale and make it attractive to private sector to invest in local seed production in East Africa region. This will help reduce the cost of seeds.

Allow more players and alternatives to supply quality Bt cotton seeds to farmers. Improve Bt cotton variety maintenance and purification procedures and adoption of reliable testing system. Production of high-grade Bt cotton seeds in collaboration with national production schemes (local private producers) can be a key factor to successfully building trust by growers in the seed system.

Exploring appropriate Bt cotton supply schemes may include local contract farming to address issues of affordability and sustainability.11 Farmers should have freedom to purchase seeds from various sources. Mainstreaming will take some time and to facilitate the process for a robust seed scheme for the future, a consultative process among stakeholders is needed for ensuring reliable partnership. Such an approach can also take a regional form to improve the competitiveness and scale of operation for technology providers which will help cut operation costs, increase local presence of seed companies, and provide Bt cotton seed with affordable/attractive prices. Promoting contract farming, improved extension services and a cluster-based farming to allow farmers get better market access and greater bargaining power can help boost production through increased adoption of improved technologies and encourage price stability for cotton products.

Governments should play a role in accelerating seed availability through formation of Public Private Partnerships (PPPs) to increase improved seed volumes to meet demand. In addition, countries should work to revive the value chain actors including ginning mills, establish a certified seed system, empower farmers to form farmer-groups well linked to ginning factories, or own ginning and seed milling facilities as cooperatives and introduce quality-based pricing for cotton produce.

However, encouraging development of regional and international collaboration to promote technology and harmonization of seed industry will help the region acquire strategic advantage in developing the cotton sector. Under smallholder cotton farming, forming cotton farmers clusters and developing a mechanism of purchase of Bt cotton seeds through partnerships between public and private partners such as farmer cooperative, ginners and agro-dealers can be helpful.11 Improvement of institutional, policy and financial aspects encourages farmers to integrate and use improved technologies to sustain production and productivity, which means improvement in their livelihood. African cotton production systems can only rise to full potential and become competitive with improved use of technology and improved farming practices such as reliable access to high-quality seeds, irrigation, and integrated pest control practices, extension services, and good market outlet, among others.

Funding Statement

The author(s) reported there is no funding associated with the work featured in this article.

Disclosure statement

Authors have not declared any conflict of interests.

References

- 1.Amanet K, Chiamaka EO, Quansah GW, Mubeen M, Farid HU, Akram R, Nasim W.. Cotton production in Africa. In: Jabran K, Chauhan BSeditors. Cotton Production. 2020. ISBN: [Google Scholar]

- 2.Mehta M, Writer F. AGOA renewal raises African hopes of unhindered exports to U.S. RIS. 2015. [Google Scholar]

- 3.Reliefweb, OCHA Services . How the textile industry can help countries recover from COVID-19. 2020; https://reliefweb.int/report/world/how-textile-industry-can-help-countries-recover-covid-19

- 4.Wilde R. Did cotton drive the industrial revolution? ThoughtCo. Aug. 27, 2020. thoughtco.com/textiles-during-the-industrial-revolution-1221644 [Google Scholar]