Abstract

We present a theory of deformation of ribbons made of nematic polymer networks (NPNs). These materials exhibit properties of rubber and nematic liquid crystals, and can be activated by external stimuli of heat and light. A two-dimensional energy for a sheet of such a material has already been derived from the celebrated neo-classical energy of nematic elastomers in three space dimensions. Here, we use a dimension reduction method to obtain the appropriate energy for a ribbon from the aforementioned sheet energy. We also present an illustrative example of a rectangular NPN ribbon that undergoes in-plane serpentine deformations upon activation under an appropriate set of boundary conditions.

Keywords: Nematic polymer networks, Soft matter elasticity, Nematic elastomers, Ribbon theory, Photoactivable elastic materials

Introduction

Photoactivation of elastic materials promises to make an old dream come true: to convey energy from a distance so as to induce matter to do work with no direct, material contact with the energy source. In particular, photoactive nematic elastomers seem especially promising materials. These are rubber-like elastic solids whose constituting polymer chains incorporate photoactive molecules into nematic liquid crystal elastomers.

A typical example is the azobenzene molecule, which goes from a rod-like to a V-shaped conformation (a process called the trans-cis isomerization) when absorbing a photon of the appropriate frequency.1 Current wisdom has it that the change in shape induced by the (few) photoactive molecules present in the polymer chains (mostly constituted by nematogenic rod-like molecules unaffected by illumination) has the potential to alter the nematic orientational order reigning among the latter molecules, in a way comparable to what a change in temperature may achieve. Completely disordered molecules render the polymer network isotropic, a symmetry inherited by the macroscopic elastic response. Ordered molecules will instead grant an anisotropic response, which to first approximation is described by the neo-classical theory presented in the book by Warner and Terentjev [1] (the abundant literature that precedes it [2–7] is also of interest for the theoretician).

An interesting mechanical theory for photoactive nematic elastomers, which blends Warner and Terentjev’s with the classical approach to the ordering nematic phase transition by Maier and Saupe [8], has recently been proposed in [9] (see also [10–12] for the relevant statistical mechanics antecedents). A vast body of reviews is available that also includes the specific topic of photoactivation of nematic elastomers [13–18], to which [19] should also be added, which is broader in scope and perhaps more germane to a mechanician’s taste. General continuum theories for nematic elastomers are also available in the literature, mostly in the 3D Euclidean setting [20–22]. As for specific applications of programmable liquid crystal elastomers, we refer the reader to a recent special issue [23].

Our development here will not be tied to a specific mechanism capable of inducing an ordering change in the nematogenic polymer chains that constitute the material. We shall be content to say that there is a scalar parameter that characterizes the order in the reference configuration and another scalar parameter, , which characterizes the order in the current configuration, the difference between them being, however produced (either by light or by heat), the drive for the spontaneous deformation of the body.

The ordering of nematic molecules in both the reference and current configurations is further described by the director fields and , which represent the average molecular orientation in the corresponding configurations.2

We shall assume that the reference configuration is where the cross-linking takes place, so that both and are known at the start. is induced by external stimuli, whose origin and nature will not play a specific role in our development.

The director can be tied to the deformation of the body in several ways, including complete independence and complete enslaving. The nematic elastomers that we shall consider are of a special type; for them the cross-linking is so tight that the nematic director remains enslaved to the deformation.3 These material are called nematic polymer networks (NPNs).4

Perhaps the most interesting manifestations of the ability of NPNs to produce changes in shape capable of doing work are achieved when they take the form of thin sheets. We represent one such sheet as a slab of thickness which in its reference configuration extends itself symmetrically on both sides of a planar surface . The director is blueprinted [26] on (in its own plane) and extended uniformly across the thickness of , with the same scalar order parameter .

External stimuli can act on the molecular ordering so as to change into , in a programmable way. The system is thus kicked out of equilibrium and a spontaneous deformation ensues, which makes the elastic free energy attain its minimum under the changed circumstances.

An elastic free-energy density (per unit volume), , was put forward in [2]. This energy is delivered by a “trace formula”, which was derived by assuming an anisotropic Gaussian distribution for the polymer chains in the rubber matrix.5 This formula features both the deformation of the three-dimensional slab and the (tensorial) measures of order in both the reference and current configurations (see Sect. 2). For a sufficiently thin slab , however, one would like to reduce to a function of the mapping that changes the flat reference mid-surface into the orientable, curved surface in the current configuration that can be regarded as the core of the deformed slab , although it need not be its mid-surface.

For a NPN, for which ultimately depends only on , such a dimension reduction was performed in [29] by extending a standard method of the theory of plates, known as the Kirchhoff-Love hypothesis [30]. As expected, this method delivers a surface elastic free-energy density with two components, a stretching component scaling like , and a bending component scaling like ; depends only on the two-dimensional stretching (or metric) tensor , while also depends on the invariant measures of curvature of and the relative orientation of in the frame of the principal directions of curvatures of .

Not only do and scale differently with , they also bear a different meaning in regard to the embedding of in space. By Gauss’ theorema egregium [31, p. 139], the Gaussian curvature of is fully determined by the metric tensor , thus deserving the name of intrinsic curvature, whereas other measures of curvature of , not determined by the metric, are called extrinsic and are affected by how is embedded in space.

Now, depends only on the intrinsic curvature, whereas also depends on the extrinsic ones. Studying the equilibria of under the blended effect of both energy components and has proven a formidable task; a number of approximations have been proposed [32, 33], but no satisfactory unified, general treatment of the blended surface energy has so far become available.

In this paper, we shall move yet a further step in the dimensional reduction cascade, by considering the ribbon limit for and its activated, deformed companion . We shall describe as generated by a centerline and the imprinted director field , which in this limit reduces to a unit vector field defined on . As a consequence, too will be described by a curve in space, enriched with a unit vector field , which is entrained by the deformation of . In our model, in accord with a large body of literature (see, for example, Sect. 5.2 of [35]), a NPN ribbon is a decorated curve retaining the essential geometric ingredients to represent a two-dimensional body, with one side much smaller than the other and retained only at the lowest order. This implies that the bend of the nematic director field vanishes both in the reference and deformed configurations. A different, more elaborate model of ribbon, contemplating non-vanishing nematic bend and accounting for higher-order terms in the ribbon’s width, was proposed in [34] starting from a membrane Hamiltonian, which however appears to be divorced from the trace formula of three-dimensional elastomers, which is our main thrust here.

What is characteristic of our model compared to the varieties studied in classical elasticity [35, Chap. 5] is the material nature of the directors and : they are linked to the nematic order of molecules present in the polymer network. Other studies on ribbons of activable elastomers populate the recent literature. We refer, in particular, to [36], where a ribbon model is derived via -convergence from a plate energy [37] phrased in the language of non-Euclidean elasticity [38]. Besides the method used, the major difference between these studies and ours lies in the assumption about the imprinted director , which is uniform throughout the cross-section of the parent sheet in our setting, whereas it is not uniform in those others, being there a possible source for kinematic incompatibility.

Our main purpose here is to derive the ribbon energy for a NPN from the plate energy obtained in [29] with no specific assumption on the ribbon’s geometry. This goal is achieved in Sect. 4, after having set the necessary kinematic preliminaries in Sect. 3. Section 5 is devoted to a special geometric setting: we study a rectangular ribbon, for which we find the explicit equilibrium planar solutions for a class of boundary conditions compatible with activable serpentine modes. We shall see how an activated serpentine shape of the ribbon is determined by the director field imprinted in its reference configuration. Finally, in Sect. 6, we collect our conclusions and comment on the implications of our work and its possible future extension. The paper is closed by three technical appendices, where details of our development are expounded for the ease of the demanding reader.

Thin Sheet Energy

Following in part [32], we recall in this section the plate-like theory for NPNs obtained in [29] through the dimension reduction method illustrated in [30].6 This method was applied to the “trace formula” for the elastic free-energy density (per unit volume) that had been put forward for nematic elastomers [2, 40–42] (see also [1, Chap. 6] for a comprehensive account of this theory) as an extension to anisotropic solids of the classical Gaussian theory for rubber elasticity (racapitulated in the landmark book [43]).

Two director fields feature in this theory, and , the former defined in the reference configuration of the slab and the latter defined in the current configuration , where is a diffeomorphism of in three-dimensional Euclidean space ℰ. In each configuration, the corresponding director represents the average orientation of the nematogenic molecules appended to the rubber polymeric matrix. They are more properly defined through the tensorial measures of material anisotropy that describe the end-to-end Gaussian distribution of polymer strands. These are the step-length tensors and , in the reference and current configurations, respectively, which, following [7] and [44], we write as

| 1 |

Here is the identity (in three-dimensional space), and are positive geometric parameters (representing the persistence length perpendicular to and , respectively), and are nematic scalar order parameters (related to the Maier-Saupe scalar order parameter, as shown in Appendix A).

The neo-classical theory of nematic elastomers expresses the elastic free-energy density (per unit volume in the reference configuration) as

| 2 |

where is the deformation gradient and is an elastic modulus. This is quite broadly known as the trace formula.

In nematic polymer networks, is enslaved to . In these materials, with which we are concerned in this paper, the director field is blueprinted in the elastic matrix [26] and conveyed by the deformation into , which is thus delivered by

| 3 |

In general, elastomers are incompressible, and so must satisfy

| 4 |

Both (3) and (4) will be enforced as constraints on all admissible deformations of .

With (and ) imprinted in the reference configuration at the time of cross-linking and enslaved to the deformation, the only residual freedom lies with , which can be changed by either thermal or optical stimuli.

It was shown in [29] that by use of (1) and (3) can be given the following form

| 5 |

where is the right Cauchy-Green tensor associated with the deformation and

| 6 |

It is not difficult to show (see, for example, [32]) that subject to (4) is minimized by

| 7 |

where

| 8 |

which shows how spontaneous deformations can be induced in these materials. For example, by heating the sample above the cross-linking temperature, we reduce the nematic order of the chains, so that . This in turn induces a spontaneous deformation so as to minimize the total elastic free energy: fibers along are shortened, whereas those in the plane orthogonal to are dilated. Clearly, the reverse behaviour is expected upon cooling. Thus, can be regarded as the activation parameter of our theory, driven by external stimuli. For definiteness, we shall conventionally assume that both and range in the interval .7

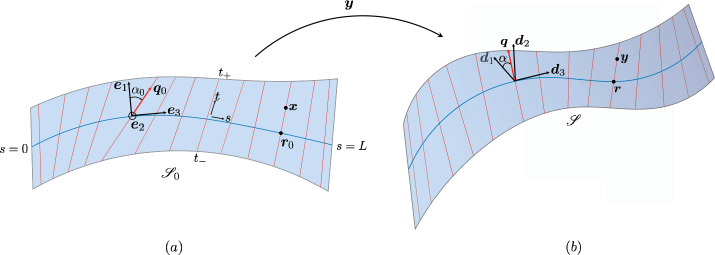

Here we are interested in thin sheets and in the appropriate dimension reduction of to be attributed to the mid surface of the slab of thickness . Formally, is a flat region in the plane of a (movable) Cartesian frame with fixed in space, and is the set in ℰ defined as . The mapping describes the deformation of into the orientable surface in the deformed slab ; we shall assume that is of class and that is a two-dimensional field imprinted on , so that (see Fig. 1).8

Fig. 1.

(a) The reference configuration of a planar ribbon, ruled by the directrix and the generators in the direction of the unit vector . An orthonormal set of directors are adapted to the centreline such that is tangential to , and is pointing out of the plane of the paper. The angle between and is denoted by . (b) A current, non-planar, configuration of the ribbon with the directrix denoted by , and the direction of the generators given by . An orthonormal triad is attached to the centreline with oriented along the tangent vector, and in the tangent plane at . The angle between and is shown by

Applying (3) to the present setting, we obtain that

| 9 |

In [29], we extended the classical Kirchhoff-Love hypothesis [30] to obtain a dimension reduction of in (6), that is, a method that convert in (5) into a surface energy-density (to be integrated over ). As standard in the theory of plates, such a surface energy is delivered by a polynomial in odd powers of , conventionally truncated so as to retain the first two relevant ones, the first and the third power. The former is the stretching energy , accounting for the work done to alter distances and angles in , while the latter is the bending energy , accounting for the work done to fold . Thus, dropping the scaling constant , which has the physical dimensions of an energy per unit volume, we can write

| 10 |

where (up to an inessential additive constant)

| 11a |

| 11b |

Here is the two-dimensional stretching (or metric) tensor, , and are the mean and Gaussian curvatures of , defined as

| 12 |

in terms of the (two-dimensional) curvature tensor , where is a unit normal field to , and

| 13 |

The (scaled) total elastic free energy then reduces to the functional

| 14 |

where is the area measure.

Ribbon Kinematics

We first establish the kinematics of the deformation of a planar ribbon . We choose on a material line , where is its arc-length coordinate. We call this line the directrix in consonance with the mathematical terminology of ruled surfaces. The centreline is endowed with an ordered orthonormal frame of directors oriented such that, , is a constant vector pointing out of the plane of the surface, and . Due to the orthonormality of the frame, we can associate with it a Darboux vector such that it satisfies , . Since is a planar curve, can be fully described by just one component in the director frame, i.e. .

The planarity of the reference configuration allows us to describe it using the following parametrisation of a ruled surface,9

| 15 |

where is a unit vector given by,

| 16 |

and is a coordinate along . We also define for later use,

| 17 |

Hereafter, will be identified with the imprinted nematic director , and so it acquires a material significance,

| 18 |

A planar strip on is represented in the coordinates as the set , where the functions are such that corresponds to the edges of the strip (see Fig. 1).

Upon deformation, the centreline is convected into a curve . Similar to , we associate an ordered orthonormal director frame with such that

| 19 |

with defined as the stretch of the centerline. The orthonormality of the directors , , allows us to associate with it a Darboux vector such that . The director components of represent the bending strains about the corresponding directors.

The deformation of the reference configuration into the current configuration is represented by the following map,

| 20 |

where is a unit vector given by,

| 21 |

Equation (20) has an antecedent in equation (1) of [50], whose style and notation are often echoed here.

To obtain the deformation gradient induced by the mapping (20), we consider a curve in represented by , parametrised by some parameter . On differentiating (15) and (20) with respect to , it follows that the curve and its image in the current configuration satisfy,

| 22a |

| 22b |

where the superimposed dot denotes differentiation with respect to . The deformation gradient can be represented as,

| 23 |

where vectors and are respectively the images of and in the current configuration. Requiring that the identity be valid for all , we obtain using (22a), (22b) and (23),

| 24a |

| 24b |

Using , and equations (16), (17), and (19), we give (24b) the following simpler form,

| 25 |

With the kinematics of the deformation established, we next enforce the constraint of inextensibility on the material of the ribbon, and compute its consequences.

Incompressibility Constraint

Nematic elastomers are subject to the constraint (4). Using (23), (24a), and (25), this constraint is also expressed as

| 26 |

To solve (26) we first compute the following useful relations,

| 27 |

where . Making use of (27), we see that the most general solution of (26) is the following,

| 28a |

| 28b |

| 28c |

| 28d |

Details of the computations leading to (28a)–(28d) are outlined in Appendix B. One consequence of (28a)–(28d) is the following useful relation,

| 29 |

which we shall repeatedly invoke later. Correspondingly, we see that relations (28a)–(28d), upon using (29), simplify the representation for and from (24a) and (25) to the following,

| 30a |

| 30b |

In light of (9), (18), and (23), we also see that (30a) implies that

| 31 |

Developability of the Deformed Configuration

The representation of the deformed configuration assumed in (20) is that of a ruled surface. However, since there exist ruled surfaces that are not developable, it needs to be determined whether or not (20) represents a developable surface. We show in this section that as a consequence of (28a)–(28d), the surface representation (20) is indeed developable. We also show that the normal to the surface coincides with the corresponding along a given generator.

Whenever (26) is satisfied, the unit normal to the surface is defined as . Using (30a), (30b), one immediately sees that can be written as,

| 32 |

and so it turns out to be independent of .

Next we show that the Gaussian curvature , confirming that the mapping under consideration results in a developable configuration. Resorting again to a generic curve we can write,

| 33 |

where again a superimposed dot denotes differentiation with respect to and is the surface gradient on the deformed surface. By (22b), we see that the curvature tensor (which is symmetric) must be of the form

| 34 |

an expression already obtained in [50] (see their equation (73)), implying that the Gaussian curvature of the deformed configuration vanishes identically. Inserting (34) into (33) and by use of (29), can be written as,

| 35 |

which completes the determination of the curvature tensor.

Isometric Limit

We now consider the limit in which the deformation map is an isometry,10 and compare the results with some of the standard strip models in the literature such as Wunderlich’s [66] and Sadowsky’s [67] models.11 The Cauchy-Green tensor of the deformation as characterized by (28a)–(28d) can be written as,

| 36 |

where and . It is then a simple matter to see, by use of (28b) and (30a), (30b), that , where is the two-dimensional identity, if and only if

| 37 |

in accord with equations (18) and (19) of [50], which further implies from (28a)–(28d) that and .

In this case, we can further characterize the generatrix of the deformation in (20). Letting and denote the curvature and torsion of , for we can also represent as

| 38 |

where is the unit tangent to the directrix . By computing from this equation and combining the result with (29), we see that if and then

| 39 |

where is the principal normal of . By use of the Frenet-Serret equations, we easily convert this dichotomy into the following alternative.

| 40a |

| 40b |

where is the binormal unit vector. Correspondingly,

| 41 |

Combining (38), (40a), (40b), and (41), we can write

| 42 |

which, once inserted into (20), delivers a formula that differs only by a sign12 from equation (1.6) of [70].

In our approach, a material frame is preferred to the Frenet-Serret frame to describe the orientation in space of the ribbon, with the advantage of being also applicable at points where .

Ribbon Energy

In this section we carry out the further dimension reduction of the (scaled) per area energy of a thin sheet of NPN in (14) to obtain a one-dimensional energy for a ribbon. In (14), we set and . Furthermore, it results from the kinematic analysis performed in the preceding section that and are given by

|

43a |

| 43b |

The expression for in (43b) embodies a significant simplification of equation (11b) due to the fact that and in our current setting. Also, where is the mean curvature. The expression on the right in (43a) corresponds to equation (11a). Also, it is worth recalling that in writing (43a), the unit vector has been identified with the director field imprinted on the reference configuration, as postulated in (18). While is determined at the time of cross-linking, we recall that can be affected by external stimuli (such as light and heat); it is precisely the difference that can be induced (by external agents) between and that drives the spontaneous deformation of a NPN sheet.

We first compute the area element of the reference configuration which we would require for later use for dimensional reduction. The area element is given by,

| 44 |

The (scaled) total elastic free energy ℱ of the full surface in (14) can then be written as,

| 45 |

where is the length of the directrix in the reference configuration and represents the (scaled) energy per unit arc-length of the directrix . After some lengthy, but not difficult computations, we obtain the following representation of the reduced energy,

| 46 |

where

| 47a |

| 47b |

| 47c |

| 47d |

| 47e |

Details of this derivation are presented in Appendix C. Although has a direct geometric meaning, which can be read off from (36), we find it convenient to express it via (28a) in terms of two other measures of deformation, namely, and the angle that makes with ,

| 48 |

In this way, equation (28b) is effectively incorporated.

Since is known, by use of (48), for prescribed and , ℱ becomes a functional in the triple of functions subject to the boundary conditions appropriate to the specific problem at hand. For the minimizing triple, both (28c) and (28d) then also provide and , thus completing the description of the shape acquired by the actuated NPN ribbon.

Next we reduce the general energy function (46) to a simple case of rectangular geometry, and present an example where the ribbon undergoes in-plane serpentine deformations.

Rectangular Geometry

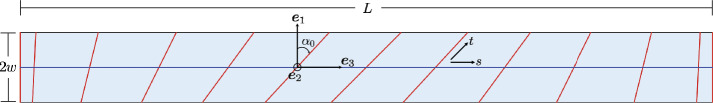

In this section, we consider a special NPN ribbon whose stress free natural configuration is a rectangle of width and length (see Fig. 2). We shall take the centerline to lie along the axis, so that and . We further let be a smooth function such that

| 49 |

so that the short sides of the ribbon are both along . With such a geometric choice,

| 50 |

Thus, the contributions to in (46) that are quadratic in vanish identically, and we obtain,

| 51 |

where we have divided the numerator and the denominator inside the ln by .

Fig. 2.

Natural configuration of a rectangular ribbon

We briefly digress here to compare the above expression for a rectangular ribbon of finite width with that of Wunderlich’s model, which considers isometric deformations. We set , and as per the conclusions reached in (37), along with . Under these conditions, and from (47d) and (47e). Substituting these in (51), and identifying with and , the energy density above reduces to,

| 52 |

which differs from the Wunderlich’s energy for a rectangular strip of finite width by an inessential additive constant. It is then easy to see that at the lowest order in , the above expression reduces to Sadowsky’s energy for rectangular ribbons with small width.13

Returning to our main discussion, at the lowest order in in expression (51), and using (48), (47d) and (47e) we obtain the following energy functional,

| 53 |

which, in particular, is independent of .

The boundary conditions that we now consider will identify one special case, where the deformed ribbon is expected to be in the reference plane, while taking on a serpentine configuration.

Serpentining Ribbon

Now, we fix the end-point at of the ribbon and clamp the corresponding edge, so that frames and coincide for , while both the end-point at and the corresponding edge are left free. Clearly, is compatible with all these boundary conditions and, furthermore, minimizes ℱ in (53) for any , as is independent of both and . Consequently, by (28c) and (28d), we conclude that also and

| 54 |

where we have used the relation , with being the angle between and . Expression (54) is to be integrated, once both and are determined, with the initial condition .

Since neither nor feature in ℱ, the optimal and are the minimizers of the integrand of ℱ. Despite the apparent complexity of the task, finding these minimizers is boring, but not difficult. Only one such minimizing pair actually exists and is delivered explicitly by

| 55a |

| 55b |

where, for brevity, we have set

| 56 |

It follows from (55a), (55b) that and

| 57 |

which determines the deformed shape of the ribbon’s centerline through the following quadratures,

| 58 |

while its total length is given by

| 59 |

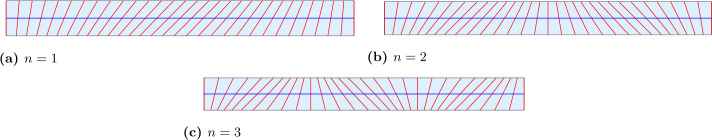

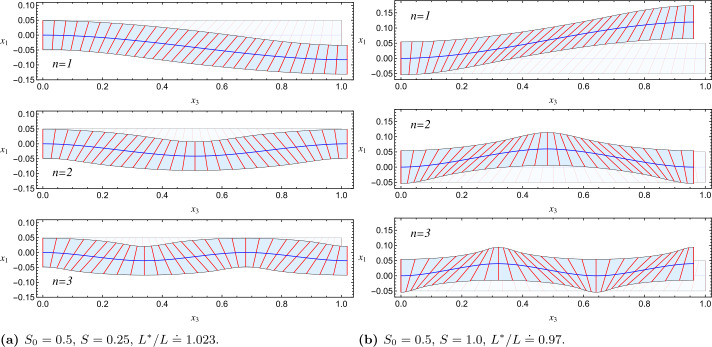

As an illustration, we determine the deformed centerline of the ribbon when the imprinted nematic director is described by

| 60 |

where is an integer. Figure 3 shows the decoration of the undeformed ribbon for , while the corresponding deformed centerline is depicted in Fig. 4 for both and ; they represent serpentining ribbons with bends swerving on opposite sides of the undeformed ribbon. The planar deformed configurations corresponding to the three patterns of the imprinted director are shown in Fig. 4. The planar bending of the centerline is a vestige of the anisotropic stretching of the NPN sheet the ribbon was carved from.

Fig. 3.

Representation of in (60) for a straight undeformed ribbon. The bends in the imprinted director will result in bends of the ribbon’s centerline upon activation. The width of the ribbons is exaggerated for clarity of presentation

Fig. 4.

Serpentining shapes of the ribbons depicted in Fig. 3 upon activation. Lengths are scaled to the length of the undeformed ribbon. , the length of the deformed centerline, is the same for all . The number of bends equals

Conclusion

Motivated by a growing body of studies, both experimental and theoretical in nature, about the photoactivation of nematic elastomers (see, for example, [72]), we derived the elastic free-energy functional whose minimizers are the spontaneous equilibrium shapes of a NPN ribbon activated by a mismatch in molecular order induced by an external agent. Our starting point for this derivation was the plate theory that had been developed in [29] from the neo-classical formula for the energy density of nematic elastomers in three-dimensional space.

The explicit expression for the elastic energy-density (per unit length of the undeformed ribbon’s centerline) is admittedly rather involved, but only because it is very general: the ribbon’s centerline can be arbitrarily stretched, although the ribbon is itself an inextensible surface, and virtually no geometric limitations are imposed on the deformation of the ribbon.

The elastic free-energy functional we obtained was compared to the classical Sadowsky’s and Wunderlich’s functionals, valid only for isometric deformations, which represent limiting cases of deformations allowed in our model. This is where our development intersected the vast literature on the equilibria of a Möbius band, but with a major, essential difference: in our theory the straight lines that decompose the developable surfaces representing the ribbon in both reference and current configurations are material in nature, as they are determined by the imprinted nematic director.

To put our theory to the test, we considered the case of a rectangular ribbon, on which modulated director fields were imprinted at the time of cross-linking. The boundary conditions were compatible with spontaneous in-plane deformations, which we determined explicitly, showing how the serpentining shape of the deformed ribbon resonates with modulated director fields. Clearly, this is a quite simple application of our theory, where its potential of describing out-of-plane activated shapes of a ribbon is not fully deployed. To accomplish this latter task, which is presently being undertaken, we shall adapt to the present setting the theory put forward in [73], as we found intractable the Euler-Lagrange equations to the functional (53) derived from the classical formulae for the strains in terms of the representation of the director frame in a fixed, reference frame (see p. 301 of [74]).

In this paper, and in many others, the effect of an external stimulus is described in a simple, phenomenological way: we assume that it can be reduced to a uniform change in a scalar order parameter, which drives the ribbon out of equilibrium. This approach might not be sufficient to describe the details of photoactivation, which was the original inspiration of this work. Light is absorbed in solids in a way that depends on how it propagates, as described, for example, by Beer’s law [75] (see also Chap. 1 of [76]), which here becomes more stringent, as in general the activable mesogens are just a fraction of polymer strands. Implementing these details in our ribbon theory might make it applicable to real-life experiments, where the induced elastic behaviour also depends, possibly quite dramatically, on the direction of propagation of light (see, for example, [77, 78]).

Acknowledgements

H.S. acknowledges partial support by Swiss National Science Foundation Grant to J.H. Maddocks.

Appendix A: Step-Length and Nematic Order Tensors

In this appendix, we relate explicitly the geometric activation parameter that features in the step-length tensor in (1) to the Maier-Saupe scalar order parameter for the rod-like molecules that constitute the polymer strands in the network. As can be altered in response to a temperature change, so can also be .

We assume that all polymer strands are constituted by rigid rods, each of length ,14 freely jointed, one to the next, at their end-points, so as to form a flexible chain. The span vector of a chain is given by

| 61 |

where is the unit vector oriented along the -th rod. The step-length tensor is defined as

| 62 |

where the brackets denote local ensemble average. Since all rods are equally free to rotate in all directions, , for all , which implies , so that represents the lowest measure of geometric order in the system. The mutual independence of the rods then readily leads us to conclude that

| 63 |

where is the identity tensor and

| 64 |

is the nematic quadrupolar order tensor. Assuming that is uniaxial about the nematic director , we can write

| 65 |

Here is the scalar order parameter, which can also be expressed in the form

| 66 |

where is the Legendre polynomial of degree 2 and is the angle that the unit vector makes with the director .

Clearly, ranges in the interval , the upper bound of which is attained (in the unphysical case) when all rods are aligned along , while the lower bound corresponds to the case where all rods are randomly distributed in the plane orthogonal to . When vanishes so also does and reduces to , which represents the isotropic distribution of rods.15

By use of (65) in (63), we arrive at (see also [10, 12])

| 67 |

which is the same tensor in (1), where we can now make the following identifications,

| 68 |

Since is an increasing function of , an increase in order, such as that produced by a decrease in temperature, delivers an increase in . Contrariwise, an increase in order determines a decrease in .

Alternatively, has also been represented as follows [7],

| 69 |

where is the principal chain step length in the direction orthogonal to and is the principal chain step length in the direction parallel to . Comparing (69) and (67), we easily identify the relations

| 70 |

In the main text of the paper, two step-length tensors have played a role: the one associated with the nematic order established at the time of cross-linking, and the one associated with the nematic order induced by the activation process at work; we have denoted them as and , with nematic directors and and scalar order parameters and , respectively. These are related via (70) to the standard scalar order parameters and and to the corresponding amplitudes and . Following [10, 12, 29], one then realizes that the physical constant on the right side of (5) can also be written as

| 71 |

where is the number of polymer strands per unit volume, is the Boltzmann constant and the absolute temperature.

Appendix B: Derivation of the General Solution

Here we present the details of the computations that result in the general solution (28a)–(28d) from the inextensibility constraint (26). Multiplying both sides of equation (26) with the denominator on the left, and using (21) we obtain,

| 72 |

Since the right hand side is a second degree polynomial in , and the only dependent function on the left is , one can conclude from (72) that must be linear in . Combining this with the requirement that , leads to equation (28a). Thereafter, equating the zeroth, first, and second order terms in on both sides, one arrives at equations (28b), (28c), and (28d) respectively.

Appendix C: Details of Energy Reduction

Here we provide details of some computations needed to obtain the reduced energy density stated in (46). From the last equality in (45), the reduced energy (per unit ) can be written as,

| 73 |

where and are given by equations (43a) and (43b). Using (16) and (36), the expression for can be further simplified to

| 74 |

where and are the magnitudes of the vectors and from (24a) and (25). While is a basic unknown, can be read off from (25) as

| 75 |

Upon substituting for and from (74) and (43b), and using (35) and (75) thereafter, integral (73) can be rearranged in the following form,

| 76 |

where and are defined in (47d) and (47e). A straightforward integration of the three integrals above delivers expression (46).

Funding Note

Open access funding provided by Università degli Studi di Pavia within the CRUI-CARE Agreement.

Footnotes

Thermal relaxation then induces the reverse shape change, restoring the molecule’s ground state.

We shall see in Sect. 2 and Appendix A how and are related to the step-length tensor and to the quadrupolar order tensor , two related measures of molecular order for nematic elastomers.

What this constraint precisely entails will be shown shortly below, in Sect. 2.

This name was proposed in [24]. Others prefer to call them nematic glasses (see, for example, [25]).

An interesting extension of the classical formula can be found in [27], which builds on Edward’s tube model [28] for entangled rubber elasticity.

The reader will find in [39] an alternative plate theory for nematic elastomers.

Although, as shown by (68), the upper limit could be much larger.

In , is extended uniformly away from , so as to be independent of the coordinate.

Which is standard in the general theory of ribbons, as recounted for example in [45] (see also the discussions in [46–49], not necessarily in unison).

Here is where our development crosses path with the vast literature on the equilibrium shapes of an elastic Möbius band, represented, as suggested in [46], by the following (incomplete) list of studies [51–65].

At variance with [70] (see their equation (5.3)), we adopted a convention for the sign of according to which the third Frenet-Serret equation reads as .

Leaving aside the somewhat exotic generalization proposed in [71].

The notation “” here is unrelated to, and should not be confused with, the scalar function introduced in equation (28a) in the main text.

The strand is then statistically equivalent to a globule of radius , thus fully justifying the scaling adopted in the definition (62).

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Contributor Information

Harmeet Singh, Email: harmeet.singh@epfl.ch.

Epifanio G. Virga, Email: eg.virga@unipv.it

References

- 1.Warner M., Terentjev E.M. Liquid Crystal Elastomers. New York: Oxford University Press; 2003. [Google Scholar]

- 2.Bladon P., Terentjev E.M., Warner M. Deformation-induced orientational transitions in liquid crystals elastomer. J. Phys. II France. 1994;4:75. doi: 10.1051/jp2:1994100. [DOI] [Google Scholar]

- 3.Warner M., Bladon P., Terentjev E.M. “Soft elasticity”—deformation without resistance in liquid crystal elastomers. J. Phys. II France. 1994;4:93. doi: 10.1051/jp2:1994116. [DOI] [Google Scholar]

- 4.Terentjev E.M., Warner M., Bladon P. Orientation of nematic elastomers and gels by electric fields. J. Phys. II France. 1994;4:667. doi: 10.1051/jp2:1994154. [DOI] [Google Scholar]

- 5.Verwey G.C., Warner M. Soft rubber elasticity. Macromolecules. 1995;28:4303. doi: 10.1021/ma00116a036. [DOI] [Google Scholar]

- 6.Verwey G.C., Warner M. Multistage crosslinking of nematic networks. Macromolecules. 1995;28:4299. doi: 10.1021/MA00116A035. [DOI] [Google Scholar]

- 7.Verwey G.C., Warner M., Terentjev E.M. Elastic instability and stripe domains in liquid crystalline elastomers. J. Phys. II France. 1996;6:1273. doi: 10.1051/jp2:1996130. [DOI] [Google Scholar]

- 8.Maier W., Saupe A. Eine einfache molekulare Theorie des nematischen kristallinflüssigen Zustandes. Z. Naturforsch. 1958;13a:564. doi: 10.1515/zna-1958-0716. [DOI] [Google Scholar]

- 9.Bai R., Bhattacharya K. Photomechanical coupling in photoactive nematic elastomers. J. Mech. Phys. Solids. 2020;144:104115. doi: 10.1016/j.jmps.2020.104115. [DOI] [Google Scholar]

- 10.Corbett D., Warner M. Nonlinear photoresponse of disordered elastomers. Phys. Rev. Lett. 2006;96:237802. doi: 10.1103/PhysRevLett.96.237802. [DOI] [PubMed] [Google Scholar]

- 11.Corbett D., Warner M. Linear and nonlinear photoinduced deformations of cantilevers. Phys. Rev. Lett. 2007;99:174302. doi: 10.1103/PhysRevLett.99.174302. [DOI] [PubMed] [Google Scholar]

- 12.Corbett D., Warner M. Polarization dependence of optically driven polydomain elastomer mechanics. Phys. Rev. E. 2008;78:061701. doi: 10.1103/PhysRevE.78.061701. [DOI] [PubMed] [Google Scholar]

- 13.Mahimwalla Z., Yager K.G., ichi Mamiya J., Shishido A., Priimagi A., Barrett C.J. Azobenzene photomechanics: prospects and potential applications. Polym. Bull. 2012;69:967. doi: 10.1007/s00289-012-0792-0. [DOI] [Google Scholar]

- 14.Ube T., Ikeda T. Photomobile polymer materials with crosslinked liquid-crystalline structures: molecular design, fabrication, and functions. Angew. Chem. Int. Ed. 2014;53:10290. doi: 10.1002/anie.201400513. [DOI] [PubMed] [Google Scholar]

- 15.White T.J. Photomechanical effects in liquid crystalline polymer networks and elastomers. J. Polym. Sci., Part B, Polym. Phys. 2018;56:695. doi: 10.1002/polb.24576. [DOI] [Google Scholar]

- 16.Ula S.W., Traugutt N.A., Volpe R.H., Patel R.R., Yu K., Yakacki C.M. Liquid crystal elastomers: an introduction and review of emerging technologies. Liquid Cryst. Rev. 2018;6:78. doi: 10.1080/21680396.2018.1530155. [DOI] [Google Scholar]

- 17.Pang X., Lv J-a., Zhu C., Qin L., Yu Y. Photodeformable azobenzene-containing real polymers and soft actuators. Adv. Mater. 2019;31:1904224. doi: 10.1002/adma.201904224. [DOI] [PubMed] [Google Scholar]

- 18.Kuenstler A.S., Hayward R.C. Light-induced shape morphing of thin films. Curr. Opin. Colloid Interface Sci. 2019;40:70. doi: 10.1016/j.cocis.2019.01.009. [DOI] [Google Scholar]

- 19.Warner M. Topographic mechanics and applications of liquid crystalline solids. Annu. Rev. Condens. Matter Phys. 2020;11:125. doi: 10.1146/annurev-conmatphys-031119-050738. [DOI] [Google Scholar]

- 20.Anderson D.R., Carlson D.E., Fried E. A continuum-mechanical theory for nematic elastomers. J. Elast. 1999;56:33. doi: 10.1023/A:1007647913363. [DOI] [Google Scholar]

- 21.Zhang Y., Xuan C., Jiang Y., Huo Y. Continuum mechanical modeling of liquid crystal elastomers as dissipative ordered solids. J. Mech. Phys. Solids. 2019;126:285. doi: 10.1016/j.jmps.2019.02.018. [DOI] [Google Scholar]

- 22.Mihai L.A., Wang H., Guilleminot J., Goriely A. Nematic liquid crystalline elastomers are aeolotropic materials. Proc. R. Soc. Lond. A. 2021;477:20210259. doi: 10.1098/rspa.2021.0259. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 23.Korley L.T.J., Ware T.H. Introduction to special topic: programmable liquid crystal elastomers. J. Appl. Phys. 2021;130:220401. doi: 10.1063/5.0078455. [DOI] [Google Scholar]

- 24.White T.J., Broer D.J. Programmable and adaptive mechanics with liquid crystal polymer networks and elastomers. Nat. Mater. 2015;14:1087. doi: 10.1038/nmat4433. [DOI] [PubMed] [Google Scholar]

- 25.Modes C.D., Bhattacharya K., Warner M. Disclination-mediated thermo-optical response in nematic glass sheets. Phys. Rev. E. 2010;81:060701. doi: 10.1103/PhysRevE.81.060701. [DOI] [PubMed] [Google Scholar]

- 26.Modes C.D., Warner M. Blueprinting nematic glass: systematically constructing and combining active points of curvature for emergent morphology. Phys. Rev. E. 2011;84:021711. doi: 10.1103/PhysRevE.84.021711. [DOI] [PubMed] [Google Scholar]

- 27.Kutter S., Terentjev E. Tube model for the elasticity of entangled nematic rubbers. Eur. Phys. J. E. 2001;6:221. doi: 10.1007/s101890170004. [DOI] [Google Scholar]

- 28.Edwards S.F. The theory of rubber elasticity. Br. Polym. J. 1977;9:140. doi: 10.1002/pi.4980090209. [DOI] [Google Scholar]

- 29.Ozenda O., Sonnet A.M., Virga E.G. A blend of stretching and bending in nematic polymer networks. Soft Matter. 2020;16:8877. doi: 10.1039/D0SM00642D. [DOI] [PubMed] [Google Scholar]

- 30.Ozenda O., Virga E.G. On the Kirchhoff-Love hypothesis (revised and vindicated) J. Elast. 2021;143:359. doi: 10.1007/s10659-021-09819-7. [DOI] [Google Scholar]

- 31.Stoker J.J. Differential Geometry. New York: Wiley-Interscience; 1969. [Google Scholar]

- 32.Pedrini A., Virga E.G. Ridge energy for thin nematic polymer networks. Eur. Phys. J. E. 2021;44:7. doi: 10.1140/epje/s10189-021-00012-1. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 33.Pedrini A., Virga E.G. Ridge approximation for thin nematic polymer networks. J. Appl. Phys. 2021;129:184701. doi: 10.1063/5.0045070. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 34.Grossman D., Sharon E., Diamant H. Elasticity and fluctuations of frustrated nanoribbons. Phys. Rev. Lett. 2016;116:258105. doi: 10.1103/PhysRevLett.116.258105. [DOI] [PubMed] [Google Scholar]

- 35.Audoly B., Pomeau Y. Elasticity and Geometry. Oxford: Oxford University Press; 2010. [Google Scholar]

- 36.Agostiniani V., DeSimone A., Koumatos K. Shape programming for narrow ribbons of nematic elastomers. J. Elast. 2017;127:1. doi: 10.1007/s10659-016-9594-1. [DOI] [Google Scholar]

- 37.Agostiniani V., DeSimone A. Rigorous derivation of active plate models for thin sheets of nematic elastomers. Math. Mech. Solids. 2020;25:1804. doi: 10.1177/1081286517699991. [DOI] [Google Scholar]

- 38.Efrati E., Sharon E., Kupferman R. Elastic theory of unconstrained non-Euclidean plates. J. Mech. Phys. Solids. 2009;57:762. doi: 10.1016/j.jmps.2008.12.004. [DOI] [Google Scholar]

- 39.Mihai L.A., Goriely A. A plate theory for nematic liquid crystalline solids. J. Mech. Phys. Solids. 2020;144:104101. doi: 10.1016/j.jmps.2020.104101. [DOI] [Google Scholar]

- 40.Warner M., Gelling K.P., Vilgis T.A. Theory of nematic networks. J. Chem. Phys. 1988;88:4008. doi: 10.1063/1.453852. [DOI] [Google Scholar]

- 41.Warner M., Wang X.J. Elasticity and phase behavior of nematic elastomers. Macromolecules. 1991;24:4932. doi: 10.1021/ma00017a033. [DOI] [Google Scholar]

- 42.Warner M., Terentjev E. Nematic elastomers—a new state of matter? Prog. Polym. Sci. 1996;21:853. doi: 10.1016/S0079-6700(96)00013-5. [DOI] [Google Scholar]

- 43.Treloar L.R.G. The Physics of Rubber Elasticity. 3. Oxford: Oxford University Press; 2005. [Google Scholar]

- 44.Nguyen T.-S., Selinger J. Theory of liquid crystal elastomers and polymer networks. Eur. Phys. J. E. 2017;40:76. doi: 10.1140/epje/i2017-11569-5. [DOI] [PubMed] [Google Scholar]

- 45.Dias M.A., Audoly B. “Wunderlich, meet Kirchhoff”: a general and unified description of elastic ribbons and thin rods. J. Elast. 2015;119:49. doi: 10.1007/s10659-014-9487-0. [DOI] [Google Scholar]

- 46.Chen Y-C., Fried E. Möbius bands, unstretchable material sheets and developable surfaces. Proc. R. Soc. Lond. A. 2016;472:20160459. doi: 10.1098/rspa.2016.0459. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 47.Chen Y.-C., Fosdick R., Fried E. Issues concerning isometric deformations of planar regions to curved surfaces. J. Elast. 2018;132:1. doi: 10.1007/s10659-017-9662-1. [DOI] [Google Scholar]

- 48.Chen Y.-C., Fosdick R., Fried E. Reply to the comment of van der Heijden and Starostin. Proc. R. Soc. A. 2022;478:20210856. doi: 10.1098/rspa.2021.0856. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 49.van der Heijden G.H.M., Starostin E.L. Comment on Y.-C. Chen, E. Fried, Möbius bands, unstretchable material sheets and developable surfaces. Proc. R. Soc. A 472, 20160459 (2016) Proc. R. Soc. A. 2022;478:20210629. doi: 10.1098/rspa.2021.0629. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 50.Chen Y.-C., Fosdick R., Fried E. Representation for a smooth isometric mapping from a connected planar domain to a surface. J. Elast. 2015;119:335. doi: 10.1007/s10659-015-9521-x. [DOI] [Google Scholar]

- 51.Schwarz G.E. The dark side of the Moebius strip. Am. Math. Mon. 1990;97:890. doi: 10.2307/2324325. [DOI] [Google Scholar]

- 52.Mahadevan L., Keller J.B. The shape of a Möbius band. Proc. R. Soc. Lond. A. 1993;440:149. doi: 10.1098/rspa.1993.0009. [DOI] [Google Scholar]

- 53.Randrup T., Røgen P. Sides of the Möbius strip. Arch. Math. 1996;66:511. doi: 10.1007/BF01268871. [DOI] [Google Scholar]

- 54.Hangan T. Elastic strips and differntial geometry. Rend. Semin. Mat. (Torino) 2005;63:179. [Google Scholar]

- 55.Sabitov I.K. Isometric immersions and embeddings of a flat Möbius strip in Euclidean spaces. Izv. Math. 2007;71:1049. doi: 10.1070/im2007v071n05abeh002376. [DOI] [Google Scholar]

- 56.Starostin E., van der Heijden G.H.M. The shape of a Möbius strip. Nat. Mater. 2007;6:563. doi: 10.1038/nmat1929. [DOI] [PubMed] [Google Scholar]

- 57.Starostin E.L., van der Heijden G.H.M. The equilibrium shape of an elastic developable Möbius strip. Proc. Appl. Math. Mech. 2007;7:2020115. doi: 10.1002/pamm.200700858. [DOI] [Google Scholar]

- 58.Kurono Y., Umehara M. Flat Möbius strips of given isotopy type in whose centerlines are geodesics or lines of curvature. Geom. Dedic. 2008;134:109. doi: 10.1007/s10711-008-9248-y. [DOI] [Google Scholar]

- 59.Chubelaschwili D., Pinkall U. Elastic strips. Manuscr. Math. 2010;133:307. doi: 10.1007/s00229-010-0369-x. [DOI] [Google Scholar]

- 60.Naokawa K. Extrinsically flat Möbius strips on given knots in 3-dimensional spaceform. Tohoku Math. J. 2013;65:341. doi: 10.2748/tmj/1378991020. [DOI] [Google Scholar]

- 61.Dias M.A., Audoly B. A non-linear rod model for folded elastic strips. J. Mech. Phys. Solids. 2014;62:57. doi: 10.1016/j.jmps.2013.08.012. [DOI] [Google Scholar]

- 62.Kirby N.O., Fried E. Gamma-limit of a model for the elastic energy of an inextensible ribbon. J. Elast. 2015;119:35. doi: 10.1007/s10659-014-9475-4. [DOI] [Google Scholar]

- 63.Starostin E.L., van der Heijden G.H.M. Equilibrium shapes with stress localisation for inextensible elastic Möbius and other strips. J. Elast. 2015;119:67. doi: 10.1007/s10659-014-9495-0. [DOI] [Google Scholar]

- 64.Shen Z., Huang J., Chen W., Bao H. Geometrically exact simulation of inextensible ribbon. Comput. Graph. Forum. 2015;34:145. doi: 10.1111/cgf.12753. [DOI] [Google Scholar]

- 65. Scholtes, S., Schumacher, H., Wardetzky, M.: Variational convergence of discrete elasticae (2019). 1901.02228 [math.NA]

- 66.Wunderlich W. Über ein abwickelbares Möbiusband. Monatshefte Math. 1962;66:276. doi: 10.1007/BF01299052. [DOI] [Google Scholar]

- 67.Sadowsky M. Ein elementarer Beweis für die Existenz eines abwickelbaren Möbiusschen Bandes und die Zurückführung des geometrischen Problems auf ein Variationsproblem. Sitz.ber. Preuss. Akad. Wiss. Phys.-Math. Kl. 1930;22:412. [Google Scholar]

- 68. Sadowsky, M.: Die differentialgleichungen des Möbiusschen bandes, Jahresbericht der Deutschen Mathermatiker-Vereinigung, 2. Abt. Heft 5/8, Jahresversammlung vom 16. bis 23. September 39, 49 (1929). See [82] for an English translation

- 69.Sadowsky M. Theorie der elastisch biegsamen undehnbaren Bänder mit Anwendungen auf das Möbius’sche Band. In: Oseen A.C.W., Weibull W., editors. Proc. of the 3rd Int. Congress of Applied Mechanics. Stockholm, Sweden: AB. Sveriges Litografiska Tryckerier; 1930. pp. 444–451. [Google Scholar]

- 70.Chen Y.-C., Fosdick R., Fried E. Representation of a smooth isometric deformation of a planar material region into a curved surface. J. Elast. 2018;130:145. doi: 10.1007/s10659-017-9637-2. [DOI] [Google Scholar]

- 71.Freddi L., Hornung P., Mora M.G., Paroni R. A corrected Sadowsky functional for inextensible elastic ribbons. J. Elast. 2016;123:125. doi: 10.1007/s10659-015-9551-4. [DOI] [Google Scholar]

- 72.Goriely A., Moulton D.E., Mihai L.A. A rod theory for liquid crystalline elastomers. J. Elast. 2022 doi: 10.1007/s10659-021-09875-z. [DOI] [Google Scholar]

- 73.Hornung P. Euler-Lagrange equations for variational problems on space curves. Phys. Rev. E. 2010;81:066603. doi: 10.1103/PhysRevE.81.066603. [DOI] [PubMed] [Google Scholar]

- 74.Antman S.S. Nonlinear Problems of Elasticity. New York: Springer; 1995. [Google Scholar]

- 75.Beer A. Bestimmung der Absorption des rothen Lchts in farbigen Flüssigkeiten. Ann. Phys. 1852;162:78. doi: 10.1002/andp.18521620505. [DOI] [Google Scholar]

- 76.Fox M. Optical Properties of Solids. 2. Oxford: Oxford University Press; 2010. [Google Scholar]

- 77.Camacho-Lopez M., Finkelmann H., Palffy-Muhoray P., Shelley M. Fast liquid-crystal elastomer swims into the dark. Nat. Mater. 2004;3:307. doi: 10.1038/nmat1118. [DOI] [PubMed] [Google Scholar]

- 78.Liu L., del Pozo M., Mohseninejad F., Debije M.G., Broer D.J., Schenning A.P.H.J. Light tracking and light guiding fiber arrays by adjusting the location of photoresponsive azobenzene in liquid crystal networks. Adv. Opt. Mater. 2020;8:2000732. doi: 10.1002/adom.202000732. [DOI] [Google Scholar]

- 79.Sluckin T.J., Dunmur D.A., Stegemeyer H. Crystals That Flow. London: Taylor & Francis; 2004. [Google Scholar]

- 80.Todres R. Translation of W. Wunderlich’s ‘On a developable Möbius band’. J. Elast. 2015;119:23. doi: 10.1007/s10659-014-9489-y. [DOI] [Google Scholar]

- 81.Hinz D.F., Fried E. Translation of Michael Sadowsky’s paper ‘An elementary proof for the existence of a developable Möbius band and the attribution of the geometric problem to a variational problem’. J. Elast. 2015;119:3. doi: 10.1007/s10659-014-9490-5. [DOI] [Google Scholar]

- 82.Hinz D.F., Fried E. Translation of Michael Sadowsky’s paper ‘The differential equations of the Möbius band’. J. Elast. 2015;119:19. doi: 10.1007/s10659-014-9491-4. [DOI] [Google Scholar]

- 83.Hinz D.F., Fried E. Translation of Michael Sadowsky’s paper ‘Theory of elastically bendable inextensible bands with applications to the Möbius band’. J. Elast. 2015;119:7. doi: 10.1007/s10659-014-9492-3. [DOI] [Google Scholar]