Graphical abstract

Keywords: Water desalination in MENA, Renewable energy resources, Solar energy, Wind energy, Geothermal energy, Energy storage

Highlights

-

•

Availability of RES in the MENA region was summarized.

-

•

Suitable renewable energy storage systems in MENA was introduced.

-

•

Desalination plants powered by RES in MENA were investigated.

-

•

Al-khafji solar seawater RO plant in KSA was discussed.

Abstract

Background

The Middle East and North Africa (MENA) countries are rapidly growing in population with very limited access to freshwater resources. To overcome this challenge, seawater desalination is proposed as an effective solution, as most MENA countries have easy access to saline water. However, desalination processes have massive demand for energy, which is mostly met by fossil fuel-driven power plants. The rapid technological advancements in renewable energy technologies, along with their gradually decreasing cost place renewable energy-driven power plants and processes as a promising alternative to conventional fuel-powered plants.

Aim of Review

In the current work, renewable energy-powered desalination in the MENA region is investigated. Various desalination technologies and renewable energy resources, particularly those available in MENA are discussed. A detailed discussion of suitable energy storage technologies for incorporation into renewable energy desalination systems is also included.

Key Scientific Concepts of Review

The progress made in implementing renewable energy into power desalination plants in MENA countries is summarized and analyzed by describing the overall trend and giving recommendations for the potential amalgamation of available renewable energies (REs) and available desalination technologies. Finally, a case study in the MENA region, the Al Khafji solar seawater reverse osmosis (SWRO) desalination plant in the Kingdom of Saudi Arabia KSA, is used to demonstrate the implementation of REs to drive desalination processes.

1. Introduction

The scarcity of freshwater resources is the most critical issue of the 21st century. By 2030, it is expected that water scarcity will affect 40 % of the world population [1]. Unfortunately, most of the water available on Earth is saline water from oceans and seas, with less than 3 % of the global water resources being freshwater, i.e. accpeted salinity level [2], [3]. Also, less than 1 % of available freshwater can be directly used for: drinking, agriculture, and industrial applications, as the rest is locked as ice [4]. Due to population growth, urbanization, industrialization, and improved life quality in the MENA region, the demand for freshwater is both undeniable and increasingly unsustainable. The freshwater availability in MENA is very limited due to the low precipitation, hence the low availability of surface fresh water and groundwater resources; and most MENA countries historically rely on groundwater as their primary source of freshwater [5]. Groundwater is readily available across the entire region, however, due to the dry climate and high evaporation rates, along with low recharge rates, groundwater is not considered a sustainable water source [6]. This, along with the increased demand for freshwater, significantly stresses the need for a sustainable source of freshwater.

To achieve water sustainability, requirements include having a sustainable water supply that is powered by a sustainable energy source [4], [7]. In addition, it is also important that the water supplied is efficiently used in domestic, industrial, and agricultural sectors. One of the possible solutions for water sustainability is water desalination. Seawater desalination is a process where seawater undergoes either a: thermal, mechanical, electrical, or chemical treatment to extract freshwater [8], [9], [10]. International Desalination Association (IDA) has reported that Kingdom of Saudi Arabia KSA, the United Arab Emirates UAE, and the United States of America USA are the largest desalinated water producers [11]. The current annual global installed desalination capacity amounts to 97.2 million m3 from about 16,876 plants, out of the annual global cumulative desalination capacity of 114.9 million m3 from 20,971 projects [12]. In total, the MENA region embraces around 47.5 % of the world’s desalination capacity, out of which 62.3 % is for municipal applications, followed by 35 % for industrial applications.

Desalination is to a large extent an energy-extensive process, with the majority of desalination plants relying on fossil fuels as their primary energy resource [13], [14]. This is no longer a sustainable option for several reasons. One of the most important reasons is the severe environmental impacts and harmful emissions that result from fossil fuels [15], [16]. The quantity and effects of these emissions are no longer negligible, and must seriously be taken into consideration [17]. Table 1 summarizes the energy requirements and associated emissions for different desalination processes. Thermal desalination processes such as multistage flash distilation (MSF) and multieffect distilation (MED) with their high electrical and thermal energy requirements have severe environmental impacts in terms of emissions. The table shows as well that the utilization of waste heat to supply thermal energy demand results in a significant reduction of associated emissions. Another significant reason is the gradually increasing cost and consistently depleting quantities of fossil fuels, which makes them also a less economically viable option [18], [19]. Due to these undeniable disadvantages, renewable energies (REs) present themselves as a promising alternative to conventional energy sources [20].

Table 1.

Specific energy requirements of different desalination technologies and related GHGs (based on 1 m3 of desalinated water) [15], [21].

| Technology | Energy, kWh | CO2, kg | NOx, g | SOx, g | PM10, g |

|---|---|---|---|---|---|

| SWRO | 3.7–4.5 | 3.01 | 7.20 | 6.83 | 0.20 |

| MSF | 4kWh (+333 MJ) |

23.41 | 28.29 | 27.92 | 2.04 |

| MSF-WHa | 1.98 | 4.27 | 14.79 | ||

| MED | 2kWh (+263 MJ) |

18.05 | 21.41 | 26.49 | 1.02 |

| MED-WHa | 1.11 | 2.42 | 16.12 |

WH = Waste heat utilized for the supply of thermal energy.

The theoretical energy requirements for desalination and the work or heat needed for separation are controlled by the thermodynamics of the system. The least exergy of separation is equal to the change of Gibbs free energy of the system, which is solely a function of the concentration and composition of feed and product streams and recovery of the system [22], [23], [24]. For the actual system, this theoretical energy of separation is hardly achieved, and the actual amount of energy is much higher due to system irreversibility and efficiency, with current processes running at about 35 % of the thermodynamic limit [25]. Mistry and Lienhard have proposed a generalized equation for the least energy of separation in desalination processes which is derived from the second law of thermodynamics [26]. The generalized equation handles both heat and work as inputs to the desalination process, which was later verified by the higher thermodynamic efficiencies of work-driven processes such as reverse osmosis (RO) over thermal-driven processes such as MSF and MED, which has been realized for decades at actual plant scale. The case of having two possible energy inputs, i.e., heat and work, raises the need to define a primary energy unit in order to uniform the scale of energy consumption among different desalination processes. Shahzad et al. proposed redefining the performance ratio of energy efficiency of desalination processes to account for the different quality of energy input, i.e. higher quality work vs lower quality heat [25]. The work incorporated conversion factor for each of thermal, electrical, and renewable energies to obtain a universal performance ratio. The work was further expanded to develop a primary standard energy approach to be used to compare the energy efficiency of different desalination processes [27].

Desalination as the most extensive-energy water treatment process consumes about 75 TWh annually, which is almost 0.4 % of the global energy electricity and produces about 76 Mt-CO2 annually and is expected to reach 218 Mt-CO2 annually in 2040 due to increased water desalination installed capacities [25]. This high interaction has resulted in what is commonly known as the water-energy-environment nexus given the high dependence of these three pillars on one another [28], [29]. The analysis of the water-energy-environment nexus has revealed as well the impact of unlinking the nexus and the domino effect of working on reducing the energy consumption on other pillars [30]. In this regard, the utilization of REs for desalination is considered an effective tool to reduce the fossil energy burden of desalination hence reducing the interaction and minimizing the environmental impacts of desalination processes with respect to energy consumption. Although REs are believed to be more environmentally friendly, in reality, it has some associated environmental impacts as any other product, but still much less as compared to fossil energy [31], [32].

REs have been extensively studied to drive different desalination processes, with many combinations given the varieties of each, i.e., REs and desalination processes [33], [34]. The literature is rich with many works exploring different combinations of REs and desalination processes aiming at analyzing its energy efficiency, estimated fossil energy saving, water productivity, etc. [35], [36]. The combination has been further extended to include energy storage systems as a means to smooth water productivity and overcome the intermittent nature of REs. Many literature reviews have been made to deeply discuss and analyze the progress and advances in this specific area. Eltawil et al. reviewed earlier in 2009 the integration of REs into desalination processes, indicating that the penetration of the integrated system is still very low although the maturity of the two technologies [37]. This was partially associated with the high cost of REs as compared to fossil fuels and the technical experience and skills required to install and operate REs projects by that time. Table 2 below summarizes the most recent review works (over the last five years) in the literature related to RE-driven desalination processes.

Table 2.

Summary of literature work on renewable energy-driven desalination.

| Remarks | Ref. |

|---|---|

| The review has explored renewable energy desalination in terms of viability with respect to productivity and cost. Small capacity plants were found to be of high cost making them uncompetitive with conventional plants. However, it can be only viable for remote locations hence eliminating water transportation and grid connectivity costs. The typical cost for different rE-driven desalination was provided.

|

2017, [38] |

| Exploring PV-RO, Wind-RO, and hybrid wind-PV-RO systems: Overall desalination cost is the main barrier to the wide implementation of rE-driven desalination at a large scale as compared to the current benchmark seawater desalination cost of $0.5/m3.

A flow chart was proposed for designing a hybrid rE-desalination system considering capacity required and location among other factors for technoeconomic assessment. |

2018, [4] |

| The work has explored the specific application of solar energy to drive desalination processes, which was found more suitable for RO and EDR desalination. The desalination cost for seawater and brackish water feed was found as follows:

|

2018, [39] |

| The work explored the integration of membrane desalination processes to REs specifically, assessing their potential for coproduction of water and energy. The work concluded that only rE-MD process can realize coproduction of water and energy, which is enhanced by further integration of pressure retarded osmosis PRO and reversal electrodialysis RED. |

2018, [40] |

| The work has discussed the recent progress on rE-driven desalination processes indicating PV-RO to be of the highest potential in terms of performance and efficiency. The efficiency of solar thermal desalination can be further improved by using nanofluids as operating fluids. Tidal-RO has a 31–41 % reduced cost as compared to conventional RO at 40 % recovery and 56 bars. |

2018, [41] |

| The work explored the reliability of PV-RO systems for brackish water desalination at a small scale, indicating high reliability for up to 20 years at 1.5–3 kWh/m3, hence suggested working at a lower recovery of 30 % for lower energy consumption, and to mitigate membrane fouling as well, hence longer membrane life. Although of the lower recovery, the system will maintain technoeconomic feasibility due to a longer lifetime and less operating cost for the replacement of different parts. |

2019, [42] |

| The work summarizes the recent developments and status of CSP-driven desalination with more focus on thermal processes as more compatible with CSP. In thermal-only integration, solar collector temperature has to match the operating temperature of the desalination process for improved performance and efficiency. |

2019, [43] |

The integration of the HDH desalination process with low-grade waste heat from REs, namely geothermal, solar PV, and solar thermal was explored.

|

2020, [7] |

| The study reviewed the work related to the desalination of geothermal water using REs, including geothermal energy, to drive the desalination processes of RO and CDI. The review has indicated a wide range of reported specific energy consumption and hence cost, depending on the combination studied. |

2021, [44] |

| The review provides a comprehensive discussion on the integrated REs-desalination systems. The works show that effective expansion of REs-driven desalination systems is mainly hindered by technoeconomic factors with recommendations to make favorable regulations for such systems. The work has compiled as well database for rE-driven desalination units, mainly at pilot and small scale. The database has been associated with information on capacity, specific energy consumption, and desalination cost. |

2021, [45] |

| The work has reviewed the optimization of different REs-Ro systems, with RO as the most studied and lowest energy requirement. The work recommends combining the size, operability, and thermodynamics of the system, and to incorporate economic and reliability factors into the objective function. Additionally, the incorporation of demand response has been recommended as well for demand side management, which can help minimize cost while maximizing productivity. |

2021, [46] |

| The review has focused on the applicability of combined solar PV-T to drive different desalination processes providing both electricity and heat. Solar PV/T-driven desalination was found comparatively better than individual solar PV and thermal-driven desalination. PV/T-HDH system was found to have higher generated electricity and less energy requirements. PV/T-RO system was found to have less area requirement and energy consumption of 43.33 % and 23.61 % than the PV-RO, respectively. |

2021, [47] |

| The work has focused on summarizing and comparing the performance of wind-RO, wind-PV-RO, and wind-PV-grid-RO systems. The system performance was found to largely depend on the configuration implemented. |

2022, [48] |

| This review has discussed the application of artificial intelligence AI for REs-driven desalination processes, more specifically for site selection, energy prediction, desalination process selection, and parameter optimization. The application of AI was found to realize cost minimization and efficiency maximization by almost 10 %, along with the release of human resources. Artificial neural networks and genetic algorithms were found to be the most utilized algorithm for such multi-objective non-linear problems. |

2022, [49] |

The information presented in Table 2 can be summarized as follow:

-

•

The topic of RE-driven desalination has drawn much attention for research and development given its importance in securing water supply in an environmentally friendly manner.

-

•

Most of the reported studies are either performed at modeling and simulation levels or a lab scale, with very less studies performed at the pilot scale.

-

•

There is a wide range of reported values for the overall desalination cost of RE-driven desalination processes, which are still much higher than those realized for conventional desalination processes.

-

•

The wide implementation of RE-driven desalination has been historically hindered by cost and other technological challenges. However, with the recent developments in RE technologies, hence reducing its energy cost, the implementation is closer than ever.

-

•

Given the complexity of RE-Desalination interaction in terms of RE and desalination plant sizing and technology selection, along with site or geographical location characteristics, there has been a need for applying different multi-criteria decision-making approaches and even artificial intelligence algorithms.

The summary presented in Table 2 shows the need to have a recent overview exploring the recent advances in this specific area, considering different REs. This review considers to fulfill the following gaps in the literature related to RE-driven processes:

-

•

Present, discuss, and analyze the recent advances in the area of RE-driven desalination.

-

•

Explore and compare the combination of different REs with different desalination processes.

-

•

The work specifically considers the MENA region given its unique characteristics of high water desalination capacity with its huge energy and cost burden, with almost half of the world's desalination capacity.

-

•

The work discusses the RE potentials of the study area, the MENA region, and its alignment with different RE-driven desalination processes.

-

•

The work compiles, reviews, and discusses the work performed mostly at the lab and pilot scale for RE-driven desalination in the MENA area specific to each country.

-

•

Discuss the first-ever large-scale photovoltaic PV-RO desalination plant, Al Khafji desalination plant, starting its operation recently.

This work aims to discuss the application of different REs to efficiently drive desalination processes. The discussion starts with a description of the major desalination processes in section 2, with a focus on well-established technologies such as reverse osmosis as the benchmark membrane desalination process. Multistage flash distillation MSF and multi-effect distillation MED have been considered the benchmark thermal desalination processes. The discussion continues in section 3 to describe the different REs, namely solar (both photovoltaic and thermal), wind, hydro, bioenergy, and geothermal as the major REs. The work then continues to discuss the different energy storage systems (ESSs) in section 4 as a necessity for smooth power generation from REs. The thermal and electrical EESs are the core of the discussion given their wide applicability and suitability for RE-desalination systems. Next, in section 5 the various sources of REs in the MENA region are critically analyzed and discussed at the country level, and countries with the highest potential for each RE are highlighted. A comprehensive summary of the work on implementing different REs for desalination is then described and analyzed in section 6, along with a discussion of the obtained results. Finally, the largest RE-powered desalination plant, Al Khafji solar-powered desalination plant is discussed in section 7 as a typical case study. The work then present a concluding remarks and recommendations on the utilization of REs to drive desalination processes to maximize economic and environmental benfits.

2. Desalination processes

A wide range of desalination processes has been developed, which vary with respect to the driving force, and working principles [50]. Accordingly, many classifications can be adopted to classify such processes. Desalination processes can be classified into a thermal, membrane, and other processes with different working principles [9], [51], [52]. Thermal processes rely on heat addition or abstraction to drive the separation of freshwater in association with phase change. Thermal processes in their very simple principles mimic the natural water cycle, in which solar thermal energy drives the water evaporation from large water bodies such as oceans and seas, followed by condensation and precipitation. Examples of thermally-driven desalination processes include multistage flash distillation (MSF), multi-effect distillation (MED), thermal vapor compression (TVC), membrane distillation (MD), adsorption desalination (AD), humidification/dehumidification (HDH), and freeze desalination (FD) [53], [54], [55], [56]. Mechanically-driven desalination processes involve the application of pressure to separate water molecules through a semi-permeable tight membrane. This includes reverse osmosis (RO), nanofiltration (NF), and pressure-assisted osmosis (PAO). Alternatively, the pressure can be lowered to enhance the water vaporization as in the case of mechanical vapor compressions (MVC).

The previous processes are mainly working on separating and extracting water from saline water, which requires high energy. On the other hand, electrically-driven desalination processes work on the principle of separating ions present in water from the bulk of the solution, i.e. saline water. These processes include capacitive deionization (CDI), electrodialysis ED, and electrodialysis reversal EDR [57], [58]. Finally, some processes are not placed under any of the previous classes. This includes forward osmosis (FO), which is a natural osmotically-driven process, that mimics the natural osmosis process by which plants extract water [59], [60]. Generally, RO, NF, PAO, and FO are classified as membrane processes [61], [62]. It is worth mentioning that ED and EDR processes involve a special type of membrane which is an ion-exchange membrane that allows either cations or anions to pass, similarly MD involve hydrophobic membrane for enhanced vapor/liquid seprartion.

The three most widely used desalination technologies in MENA and worldwide are RO, MSF, and MED. However, there are emerging desalination technologies, that have not yet been fully developed for large-scale applications. These technologies include ED/EDR, FO, CDI, and FD. The RO dominates the desalination market in terms of desalination capacity and the number of plants with 69 % and 84.5 %, respectively [12], [51]. MSF and MED as the main thermal desalination processes come second with about 25 and 7.7 % for desalination capacity and the number of plants, respectively. This is mainly because most thermal desalination plants are of large capacity to enhance energy efficiency, while RO plants are very flexible and modular in size.

2.1. Reverse osmosis (RO)

The most dominant desalination process used worldwide is RO, in which saline water is pressurized and forced to pass through a tight semi-permeable membrane, which restricts the passage of solute to large extent, and permeates water. In RO desalination, the saline water is pressurized to a value higher than the osmotic pressure, to extract product water through the RO membrane, leaving out a higher concentration stream usually called brine, reject, or concentrate, which is charged back to the sea [11], [63]. The operating pressure for seawater reverse osmosis (SWRO) is typically between 50 and 70 bars, which has to be higher than the respective osmotic pressure of the brine stream. Currently, the most used membrane types are cellulose acetate/triacetate (CA/CTA), or thin-film composite membrane (TFC) mainly made of polyamide active layer over polysulfone support layer [64]. The common membrane configurations are spiral-wound (SW) and hollow-fiber (HF) membranes [65]. A typical SWRO plant, as illustrated in Fig. 1 consists of intake, pretreatment, high-pressure pumps, RO modules, energy recovery device (ERD), and product post-treatment to make it suitable for specific domestic or industrial applications. According to the IDA, RO is the fastest-growing technology and recently is being employed in the MENA rather than traditionally employed thermal desalination processes. This is mainly due to several factors, including lower energy requirements, and enhancements in membrane technologies making it suitable for high-temperature and high-salinity feedwaters [66], [67]. The Specific Energy Consumption (SEC) of SWRO, has declined from 20 kWh/m3 in the 1980 s, to less than 3–4 kWh/m3 recently making it more attractive [14], [68], [69], [70], [71].

Fig. 1.

Schematic for typical Seawater reverse osmosis process (LLP: Low-pressure pump, HPP: High-pressure pump, ERD: Energy recovery device, RO: Reverse osmosis).

2.2. Multistage flash (MSF)

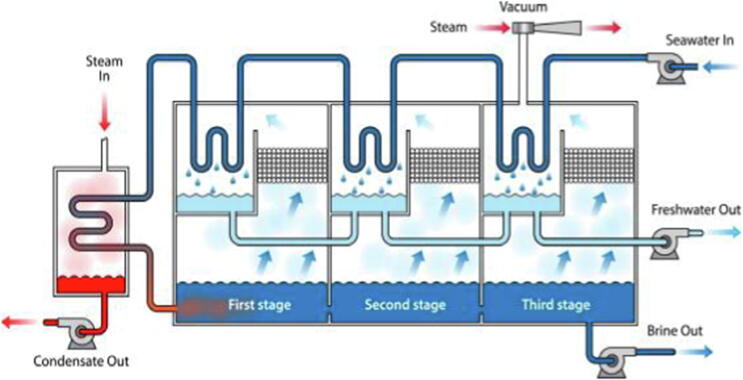

MSF process was initially established in the 1950s, making it one of the earliest developed desalination processes [72], [73]. MSF, as illustrated in Fig. 2, is comprised of multistage chambers, with each chamber maintained at a lower pressure than its predecessor using a steam ejector. The process starts with increasing the saline water’s temperature. It is then introduced to the first chamber or stage, where the hot feedwater partially evaporates, due to the lowered pressure. The vapor generated is condensed, while preheating the feedwater over tubes located at the top of each stage. The process is repeated in multiple stages to maximize water productivity and energy efficiency. Most current commercial MSF plants are equipped with 10 to 30 stages, with a temperature drop of 2 °C per stage [74]. Typical MSF plants have high production capacities, ranging from 4,000 to 30,000 m3/d, and operate at high temperatures (90–120 °C) [75]. Two major issues related to MSF (and other seawater distilleries) are corrosion and scaling due to working with saline water at high operating temperatures, i.e. boiling temperature [76]. To prevent scaling, the feedwater is chemically treated to reduce and prevent the presence of calcium and magnesium salts, which commonly precipitate at high temperatures as calcium and magnesium carbonates [77]. Corrosion, however, is a common issue that requires continuous maintenance and use of high-quality materials in heat exchangers and stages, along with corrosion inhibitors to be minimized. MSF is considered the most energy-intensive desalination process, with an SEC of 7.5–12 and 2.5–4 kWh/m3 of thermal and electrical energy, respectively [14], [50], [71], [78].

Fig. 2.

Multistage flash desalination process [79].

2.3. Multi-effect distillation (MED)

MED is the earliest desalination method that was first developed in the late 1800s and dominated the desalination market until MSF emerged in the 1950s. The principle of MED is similar to that of MSF, as they both rely on evaporating feedwater. In MED, as illustrated in Fig. 3, the inlet seawater is sprayed over evaporating tubes, which are heated using steam. The evaporating tubes and seawater sprayers are positioned in vacuum vessels called “Effects” [80]. After the seawater is sprayed on the evaporating tubes, it evaporates and leaves the first effect. The evaporated water, i.e., steam, from the first effect is then used to heat the second effect, where the steam is then cooled and condensed, and later collected as pure freshwater product [81]. The process is repeated in successive effects at lowered pressure and temperatures to maximize energy efficiency and water productivity. The MED process has many advantages, including lower operating temperatures (<70 °C), and high thermal efficiency compared to that of MSF. A typical MED can have an SEC of about 4–7 and 1.5–2 kWh/m3 of thermal and electrical energy, respectively [71], [82], [83]. The main advantage of MED over MSF is the better thermal performance, however; there are several important concerns regarding MED such as the high costs and scaling tendency [84]. Nowadays, MED is gaining more attention due to advances in technology, and this attention has led to the incorporation of stages that address these concerns, such as the addition of an adsorption stage and the possibilities of several brine recovery techniques.

Fig. 3.

Schematic diagram of a MED process [79].

2.4. Other desalination processes

Thermal desalination using MSF and MED processes has dominated the desalination market from the 1950s to the 1980s, then RO membrane desalination started to take off dominating the market with a share going up to 70 % recently [12]. The main drivers for developing new desalination processes have been always to minimize cost, mainly through lowering energy consumption, to suit a wide range of feedwater qualities, brackish water, seawater, brine…etc [68]. Given the high environmental and cost burdens of fossil fuels, there has been always an effort to improve the performance of existing desalination processes, i.e. RO, MSF, and MED, along with the utilization of REs. In parallel, there has been an extraordinary effort to develop new desalination processes with promising better performance in terms of energy consumption and lower cost as well as lower environmental impacts [21], [85]. However, most of these processes are still at lab or pilot scales due to some technical and technological challenges hindering their implementation at a large scale [45], [86].

2.4.1. Forward osmosis FO

FO is a natural membrane separation process that does not require external energy input, as it utilizes the natural tendency of water to permeate through the semi-permeable membrane from the lower salinity feed to a higher salinity draw solution [59]. FO is a spontaneous process with no need for external energy, such as hydraulic pressure for other membrane processes; hence, lower energy requirements, thus lower fouling propensity, operating, and capital costs. FO energy consumption can be as low as 0.25 kWh/m3 for fluid pumping [87]. However, the main challenge hampering the development of FO is water recovery as a product from the draw solution, hence it is regenerated and recycled back [88], [89], [90]. The FO membrane still has to possess the optimized membrane characteristics of high water permeability, high selectivity, ion rejection, and small structural parameter to reduce mass transfer resistance and concentration polarization [91], [92].

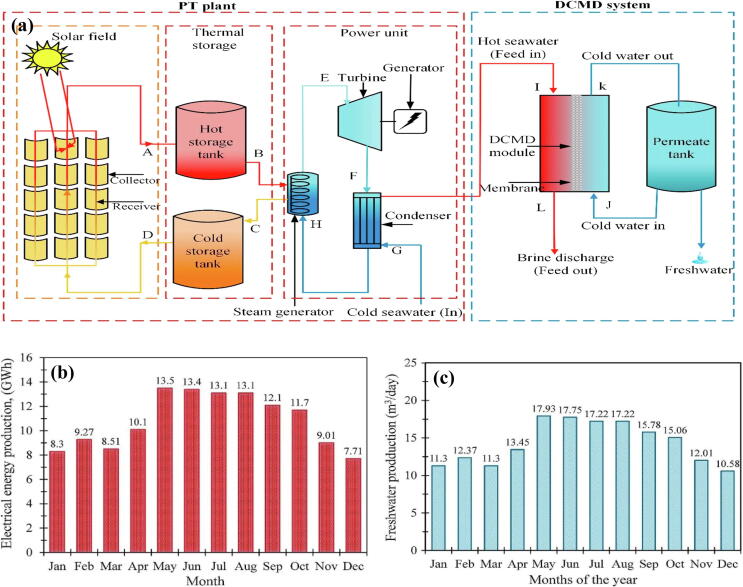

2.4.2. Membrane distillation MD

MD is a combination of the two well-established desalination processes of thermal and membrane desalination, however, it is generally considered a thermally-driven process [87]. In MD feedwater is heated below its boiling point to give off vapor, which then permeates through a hydrophobic membrane, that permeates only vapor but not liquid, which is condensed as a product [54]. MD process has many configurations, namely direct contact DCMD, air gap AGMD, vacuum VMD, and sweeping gas SGMD [93], [94]. The advantages of MD can be summarized as follows [93]:

-

•

Complete rejection of non-volatile solutes, i.e., salts.

-

•

Process efficiency and energy requirements are independent or slightly dependent on feed salinity, hence suitable for high salinity feedwater and brine.

-

•

High concentration factor, i.e., higher brine salinity to near-saturation level.

-

•

No applied pressure, hence less fouling, and less membrane deterioration.

-

•

High feasibility to utilize various waste heat sources, as it works at temperature reasonably below the boiling point of feed (i.e., 100 °C).

-

•

Possibility of sensible and latent heat recovery during vapor condensation.

2.4.3. Adsorption desalination AD

AD is similar to the MD process, with the use of adsorbent material rather than a hydrophobic membrane. In AD, water vapor from the heated feedwater, below boiling point, is adsorbed onto the adsorbent during the adsorption cycle and stripped or desorbed from the adsorbent during the striping cycle [95], [96]. AD has advantages similar to those of MD in terms of performance and energy consumption [97].

2.4.4. Freeze desalination FD

FD has been proposed to utilize cold energy, in which saline feedwater is cooled to freeze water as ice that is then separated leaving brine solution, but due to the higher energy requirements for cooling it was not fully developed [98]. Attention has been given recently to FD with the increased size of the liquefied natural gas LNG market, as it is shipped in liquefied form, requiring gasification at receiving terminal, making it possible to utilize such cold energy of gasification associated with LNG to drive FD [56], [99], [100]. FD has comparable advantages to that of MD and AD [101].

2.4.5. Humidification dehumidification HDH

HDH is a simple desalination process with lower energy requirements and no fouling propensity [102]. HDH is similar to MD and AD can utilize waste heat sources for its operation [103]. In HDH feedwater is preheated while condensing the product water from the humid air stream in the condenser, then feedwater is further heated in the preheater, where it gains most of its heating requirements, and finally fed to the humidifier where it is directly contacted with the coming dry fresh air to be saturated with water vapor to produce humid air stream. HDH has a gain over ratio GOR of 2.5–3.5, which is relatively lower than those for MED and MSF, which has a GOR of 10–12 and 8–10, respectively [104]. However, such lower GOR has been attained at a very low energy supply making it more economic and environmentally friendly [105].

2.4.6. Electrodialysis and electrodialysis reversal ED/EDR

ED/EDR utilize membrane separation of ions and charged molecules under electrical potential, hence it is removed from saline water [58], [106], [107]. ED/EDR has been explored for water desalination in specific applications of low salinity feed water desalination, such as brackish water [108], [109], or high salinity water, i.e., brine for minimization and increased productivity prior to final disposal [110], [111], [112]. ED/EDR poses many advantages such as the ability to utilize feedwater with higher suspended and dissolved solids, due to its high tolerance toward fouling, hence lower pretreatment requirements and high recovery [58]. However, ED/EDR has the disadvantage of relatively high direct electrical energy consumption, which is directly proportional to feed salinity and flow capacity [113]. ED/EDR is a straightforward process consisting of two electrodes, i.e., cathode and anode, with alternating chambers in between, with chambers separated by alternating order of anion ion exchange membrane AIX, which allows anions to pass through and retain cations, and cation exchange membranes CIX, which permeate only cations but not anions [114]. Anode attracts negatively charged anions, while cathode attracts positively charged cations upon application of electrical potential. In EDR, the polarity of electrodes is switched, i.e. cathode becomes the anode and vice versa, at certain time periods to lessen scaling and deposited material [58], [115].

2.4.7. Capacitive deionization CDI

CDI is similar to ED/EDR as it is driven by the electrical potential for separation of charged ions but uses electrosorption, i.e. electrostatic adsorption of ions to the electrode surface [116]. In CDI charged ions in feedwater are attracted to oppositely charged electrodes during the desalination cycle, hence producing product water, then the electrode charge is switched during the regeneration cycle to release adsorbed ions into brine [117], [118]. However, during regeneration oppositely charged ions can be adsorbed to the switched polarity electrode; thus ion exchange membrane, like those used in ED/EDR, hence called membrane capacitive deionization MCDI, has been utilized to improve regeneration efficiency [57], [116]. Most of the R&D efforts in CDI are geared to develop efficient electrodes with high electroadsorption capacity [91], [119].

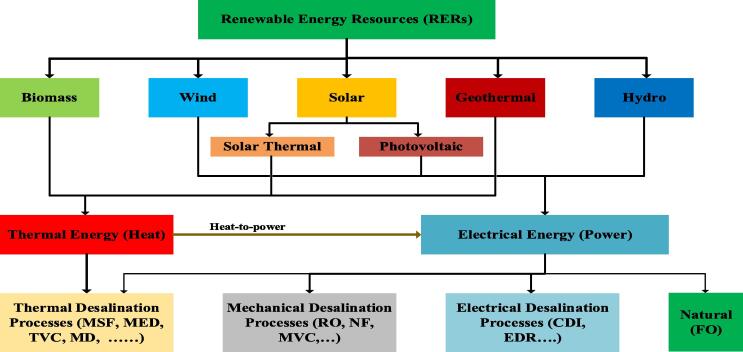

2.4.8. Summary

Table 3 shows a comparison of different desalination processes. In general, the desalination methods that utilize phase change, i.e., thermal processes require high energy. On the other hand, membrane processes have less energy requirements but need adequate feedwater pretreatment. New technologies, such as FO and CDI don’t have fouling or scaling issues, but they have not been commercialized yet. The combination of two desalination technologies together, i.e., hybrid desalination, has the ultimate objective of maximizing water productivity at reduced specific energy consumption. Many configurations have been studied in the literature such as MED-TVC, MED-AD, MED-MD, FO-MD, HDH-AD, and MSF-RO [100], [120], [121], [122], [123], [124]. Desalination is an energy-extensive process that is mainly derived from conventional fossil fuels, with high energy consumption, although utilizing waste heat and energy recovery approaches [16], [125], [126]. Accordingly, desalination using fossil fuels is not considered a sustainable approach, especially with the volatility of fossil fuel prices and their decreasing availability. A key solution to this issue is to utilize renewable energies (REs) to drive desalination processes. Fig. 4 shows proposed combinations of RE with various desalination processes. According to the International Renewable Energy Agency (IRENA), renewables can meet rising energy demand, at low costs, and contribute to limiting global warming [127].

Table 3.

Comparison of various desalination approaches.

| Type | Desalination Process | Advantages | Disadvantages |

|---|---|---|---|

| Thermal | SS: Solar still |

|

|

| MSF: Multistage Flash |

|

|

|

| MED: Multi-Effect Distillation |

|

||

| AD: Adsorption desalination |

|

|

|

| HD: Humidification Dehumidification | |||

| TVC: Thermal Vapor Compression |

|

|

|

| FD: Freeze desalination |

|

|

|

| MD: Membrane Distillation |

|

|

|

| Mechanical | MVC: Mechanical Vapor Compression |

|

|

| RO/NF: Reverse Osmosis/Nanofiltration |

|

|

|

| Electrical | ED: Electrodialysis |

|

|

| CDI: Capacitive Deionization |

|

|

|

| Others | FO: Forward Osmosis |

|

|

Fig. 4.

Incorporation of renewable energy resources and desalination processes.

3. Renewable energies

Renewable energies (REs), or renewable energy resources (RERs), or renewables, in short, have fascinated much consideration in the last few decades as substitutes to commonly used conventional fossil energy sources. This is because they are: efficient, eco-friendly, emission-free, locally available, and became recently cost-effective as well. The share of REs in the global energy supply has been progressively increasing over the last three decades, almost doubling from 1.125 to 1.976 gigaton of oil equivalent (Gtoe) [128]. REs are sourced from renewable or continuous unlimited actions, hence can be reused continuously without harm to the environment. Among these renewable sources are the sun’s radiance, i.e., solar energy, the movement of water in rivers and oceans, i.e., hydro and tidal, and wind flow, i.e. wind, or earth internal energy, i.e., geothermal, or from continuing growth living matter, i.e., biomass, and many others [129]. The most important energy generation technologies that use renewable sources are solar photovoltaics (PV), solar thermal energy, hydroelectric energy systems, wind turbines, biomass energy systems, and geothermal energy power plants. These technologies present themselves as potential alternatives to conventional fossil fuel-driven energy generation technologies, along with being more environmentally friendly [31], [32].

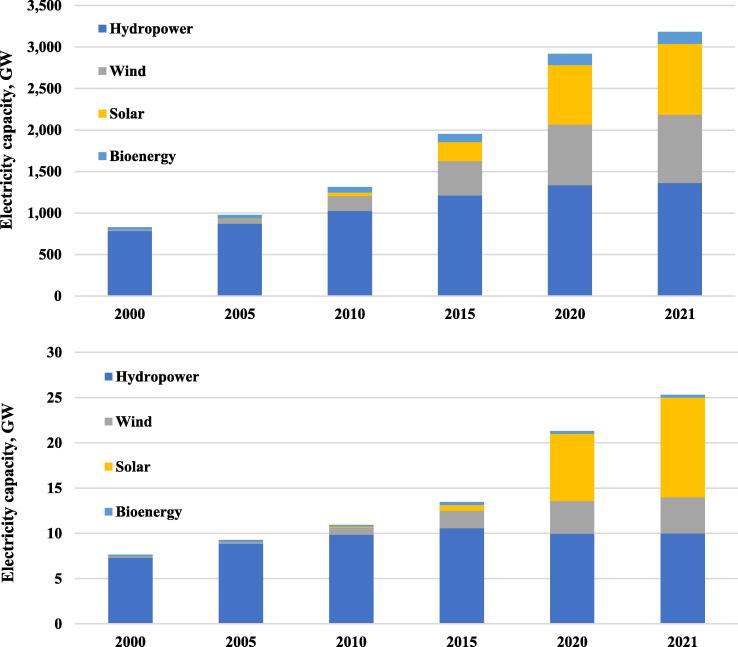

Figure 5 below shows the evolution of REs electricity capacity both worldwide and in the MENA area throughout 2000–2021 showing the capacity to increase almost four times over the last two decades [130]. The increasing capacity is dominated by installations for solar and wind REs, growing from 2 % to 60 % of global RE capacity in 2000 and 2021, respectively, while the share of Hydro dropped from 94 % to 40 % over the same period. The figure shows that although of the huge REs potential in the MENA region it is still very less utilized with less than 1 % of the global REs electricity capacity dominated by hydro and solar REs. This to large extent can be explained by the region is rich with fossil energy resources, hence available at a low cost. However, many countries in the MENA area have set ambitious plans to expand REs capacity within their future development visions due to many environmental and economic drivers [131]. For instance, the KSA has inherited in its 2030 vision to change the energy mix with 50 % of the kingdom’s domestic energy demand, from the current 1 %, to be met by REs, hence displacing ∼1 million barrels of liquid fuel per day, while reducing the carbon emissions by 175 million ton per annuum (Mtpa) [132]. The UAE launched its “Energy Strategy 2050” in 2017 aiming to increase the share of REs up to 50 % of the energy mix, as compared to 7 % in 2020, while increasing energy efficiency by 40 %, hence reducing the associated carbon footprint by 70 % [133]. Similarly, Egypt has set plans for the REs to meet 20 and 42 % of electricity demand by 2022 and 2035 as compared to 10 % in 2020 [134].

Fig. 5.

Electricity capacity from renewable energies (REs) Worldwide (Kopp, #29), and the MENA region (Bottom) [130].

3.1. Solar photovoltaics (Solar PV)

Solar PV is a technology that implements P—N junctions to directly convert energy carried by the sun’s rays into electrical energy as a direct current DC. Since its invention in 1954 [135], solar PV technology has seen a huge development in terms of its efficiency and its applications [136]. There is a clear improvement in the efficiency of different PV technologies over the 1975–2020 period from the early 2–22 % reaching up to 48 % recently [137]. The DC power that is produced by the PV panels can be stored in batteries for future use, used directly to power DC loads, or used to power an AC load first by converting it to AC power, using an inverter. The PV systems’ power can drive electrically-driven desalination processes, such as RO and CDI [138], [139], [140].

3.2. Solar thermal energy (Solar-T)

Another RE technology that uses solar irradiance to produce usable power is solar thermal energy. Where the sun’s irradiance is absorbed as thermal energy, i.e., heat, in a heat transfer fluid, commonly water, which can vaporize and be used to drive a turbine producing usable work. To heat the water, various designs of solar collectors are implemented, such as: concentrating, flat plate, and evacuated collectors [43], [141], [142]. In order to use this technology to power desalination plants, two methods can be applied. The first one is using the produced work of the turbine to generate electricity, with electricity then being used to power an electrically driven desalination process, as in solar thermal- RO desalination plant. The second method is using thermal energy as a heat source to directly drive a thermal-driven desalination process such as MSF and MED [143].

3.3. Hydro energy

Hydro energy is based on extracting the kinetic and potential energy carried by a mass of water to produce usable electrical power. There are multiple types of power-generating hydroelectric systems [144]. The first is an impoundment system, in which a dam is used to collect the water of a river so that the water carries a considerable amount of potential energy. After that, the water is left to flow through a turbine that extracts the mechanical energy of water as shaft work. This energy could be transformed into electrical energy through a generator [145]. The second type is known as a run-of-river system. Here, the kinetic energy of water flowing in the rivers is directly extracted using turbines and then converted to power using generators. This electrical energy can be readily used to drive electrically-driven processes. Another type of hydroelectric energy technology is systems that utilize ocean energy. Ocean energy is defined as the kinetic, potential, and chemical energy carried by ocean water, and this energy can be extracted in different ways to produce usable electricity [146]. The four main types of ocean energies are salinity gradient energy (SGE), wave, tidal, and ocean-thermal energies.

Salinity gradient energy (SGE) is the chemical energy stored in seawater, as a result of the difference in salinity between two different bodies of water [147]. When two bodies of water with varying levels of salinity mix, a massive amount of energy is dissipated, which can be partially recovered as electrical energy using technologies such as pressure retarded osmosis (PRO) and reverse electrodialysis (RED) [148], [149]. This technology is of great potential where there is contact between high-salinity and low-salinity water bodies such as the discharge of rivers into seas and oceans, or at the discharge of treated wastewater into open seas [150].

Wave energy is defined as the kinetic energy that is carried by the moving waves of the ocean [151]. This kinetic energy can either be used directly to drive equipment that needs mechanical energy or transformed into electrical energy for use in general applications such as desalination [149]. Tidal energy is a type of ocean energy that is associated with the kinetic and potential energies of ocean water, as they rise and fall during high and low tides, respectively, with tidal generators used to extract tidal’s energy into electrical energy [152].

The ocean-thermal energy is the energy obtained from the temperature difference between the different water layers of the ocean [149]. This temperature difference can be used to run a thermodynamic cycle that produces useful work that can be used to generate electricity. There are two main types of ocean-thermal energy conversion (OTEC) systems, closed-cycle and opened-cycle [153]. In a closed-cycle system, a closed Rankine cycle with ammonia due to its low boiling point is used as the working fluid to produce useful work. In the open-cycle OTEC system, the warmer seawater of the shallow layers is directly used as the working fluid. This produced steam drives a turbine while being condensed to liquid water again [154]. What is special about an open-cycle OTEC, is that the condensed water is desalinated water, so it has a dual production of energy and freshwater [155]. This gives a further advantage of the open-cycle OTEC in comparison with other RE-driven desalination units and makes it a feasible option for countries that have access to oceans with feasible OTEC potentials, however, such energy is not a feasible option for the MENA region.

3.4. Wind energy

Wind energy is the fastest grown RE and represented the highest installed capacities in Europe in 2018. The main principle is to extract the kinetic energy carried by the wind, which can be converted to useful mechanical work, and then to electrical energy using wind turbines [156]. Wind energy is very site-specific as affected by geography and topography, i.e., landscape. Vertical axis wind turbines (VAWT) and horizontal axis wind turbines (HAWT) are the two main types of wind turbines [157]. In VAWT, the rotation axis of the wind turbine’s rotor is vertical, which allows the turbine to make use of wind coming from all directions. However, VAWT has the disadvantages of low efficiency, harder to support, and poor performance and reliability [158]. On the other hand, HAWT with an axis of rotation parallel to the surface of the earth, horizontally oriented, is more advanced, has higher efficiency, more accessible support, better access to higher wind speeds, and better overall performance and reliability. HAWTs can receive wind from a single direction only, hence requiring good and variable alignment to face wind direction which is realized using a yaw mechanism. The power generated from wind energy can be used to derive electrically-driven desalination processes.

3.5. Biomass energy

Biomass is defined as any organic material that undergoes photosynthesis. In this, the material uses the energy of the sun’s irradiance to convert water and carbon dioxide (CO2) into carbohydrates. These carbohydrates store energy in the form of chemical energy, known as biomass energy [159]. There are many sources of biomass fuel, such as wood residue, agricultural residue, and combustible trash. The stored biomass energy can be extracted in various methods. The most common and simplest is combustion, in which the biomass fuel is burned to obtain a fraction of its stored chemical energy as heat [160]. Despite its simplicity, this method is the least efficient in heat generation. The second method is co-firing, in which the biomass fuel is added to coal to form a fuel mixture that is less expensive and environmentally harmful than pure coal. This method is more efficient than the direct combustion of biomass and helps to reduce CO2 emissions from coal combustion [161]. The third method is thermal processes, which involve the conversion of biomass by pyrolysis or gasification into other highly combustible fuels such as liquid biofuel and bio-syngas [162], [163]. These various forms of biomass fuels can be used as fuel for thermal power plants, which in turn can be used to drive desalination.

3.6. Geothermal energy

Geothermal energy is simply the thermal energy or heat stored within the Earth. This energy comes from the hot core of the Earth and the decay of radioactive materials buried in the deep layers of the Earth’s rocks, with the Earth’s core at a temperature of about 6,000 °C, which is significantly hotter than its outer layers [164]. This temperature difference, compared to the Earth’s crust, causes heat to flow from the core radially outside. In some places, rainwater passes through the cracks in the Earth’s crust and reaches deeper regions with significantly higher temperatures, hence heated to high temperatures.

In geothermal power plants, this heated water is extracted by digging deep into the rocks and using pipes to carry the hot water to the surface, in what is known as a production well. On the surface, the vapor is produced from this hot mixture of liquid water and water vapor, which is to be used for driving the turbines and generating useful work and electricity. At the end, the remaining brine is returned to the Earth’s deep layers, using injection wells, in a cyclic approach [165]. This ensures the water can be reheated from the hot rocks downwards, and continue the cycle. Geothermal power plants have some unique advantages compared to other REs. These include their high stability, independent of weather conditions, and their lower operating costs [166]. For desalination applications, geothermal energy can drive different desalination processes, either directly as a heat source for thermally-driven processes, or by using the generated work and power to drive other electrically-driven processes [167].

3.7. Summary

To summarize, different types of REs seem to be technically and economically feasible to drive different desalination processes. However, an appropriate selection has to be made for the most technically and economically feasible combination of the specific RE and desalination process to maximize yield at higher energy efficiency. Table 4 shows a comparison between different REs in terms of appropriateness for desalination processes, resource availability in the MENA region, and stability and predictability of the renewable resource.

Table 4.

Comparison of renewable energy technologies.

| Criterion | Solar thermal | Geothermal | Biomass | Photovoltaic | Wind | Hydro |

|---|---|---|---|---|---|---|

| More Appropriate for | Thermal-driven processes | Electrical-driven processes | ||||

| Site constraints and availability in MENA | High availability | Limited availability, site-specific | Medium availability, site-specific | High availability | Medium availability, site-specific | Limited availability, site-specific |

| Continuity of power output | Intermittent power output (requires energy storage) | Continuous power output | Continuous power output | Intermittent power output (requires energy storage) | Mostly continuous, Varies with the location and season | |

| Predictability of power output | Relatively predictable | Predictable | Predictable | Relatively predictable | less predictable | Predictable |

4. Energy storage systems for renewable energy-driven desalination systems

One of the main challenges for expanding the utilization of most REs is the inherited intermittent nature associated with power output [168]. Though many REs are widely available, they cannot be relied on entirely. To increase the reliability of such systems, means of energy storage (ES) have to be employed to smooth power output. ES systems help to store surplus energy during on-peak power output time and release it during off-peak times [169]. An example of this is using batteries to store excess electrical energy that is produced by solar PV panels during the daytime to be used at nighttime. There are a vast variety of ES technologies that are commonly categorized by their mechanism of energy storage [170]. Types of ES approaches include thermal energy storage (TES), electrical energy storage (EES), mechanical energy storage (MES), and chemical energy storage (CES). In the next sections, a detailed description of the ES technologies suitable for REs available in MENA regions will be discussed, while highlighting the future research potential of energy storage technologies.

4.1. Thermal energy storage TES

TES systems, store and release the heat, either as sensible, latent heat, or heat of chemical reaction. This energy storage approach is the best fit for thermal desalination processes such as MSF and MED, hence providing a smooth and stable supply of heat to the process. TES can be categorized according to the storage form to latent heat, sensible heat, and thermochemical TES [171].

4.1.1. Sensible heat thermal energy storage

This type is one of the most commonly used TES technologies. To store sensible heat in a material, the temperature should be in a range away from any phase-change temperatures. An example of this is storing thermal energy in liquid water between temperatures of 5–95 °C. Multiple specifications are needed from the sensible heat storage material, such as high specific heat capacity, being liquid or solid i.e., incompressible material, to avoid pressure increase, and a wide operating temperature range close to that of the desired application [172]. Other important factors include chemical and mechanical stability, good thermophysical properties, efficient reversibility of the heating/cooling, i.e., energy charge/discharge cycles, eco-friendly, and low cost [173].

Among the many promising materials for sensible heat TES, liquid water is one of the most used materials due to its remarkably high specific heat capacity, Cp of 4.19 J/g, along with vast availability [174], [175]. However, one of the main limitations of using liquid water is its limited liquid state temperature range, which ranges from 5 to 95 °C. Also, it would be unfeasible to use it with desalination processes that operate above that range. Accordingly, liquid water can be used efficiently as TES for low-temperature thermal processes, such as HDH, MD, and solar stills (SSs) [176]. For high-temperature applications, using other materials with a wider operating temperature range of stability is recommended. Examples of these materials are solid materials with high melting points and molten salts, as they can efficiently store thermal energy between 200 and 500 °C [174]. In addition, liquids with high boiling temperatures such as oils can be used. To properly size the TES system of a desalination plant, multiple factors must first be considered. These include the type and availability of energy source, the type of desalination technology, the desalination productivity or output required, the thermophysical properties of the storage material, the estimated period of storage i.e., storage capacity, and estimated thermal losses from the TES system [177], [178], [179].

A good example of using sensible heat TES with RE-driven desalination is energy storage in SS desalination systems [180]. SSs use the heat absorbed from the solar radiation to evaporate water, and then recollect it in a freshwater tank via an inclined glass cover. To give the SS a TES’s proficiency, the depth of water in the tank can be increased. In this case, the saline water, with a higher density will be mostly at the bottom and will stay hot for a long time after the sunlight goes, meaning the SS will stay productive for a longer time, but at less production rate [181]. Also, a thin layer of insulation can be placed on top of the water mass to reduce the amount of evaporating water during the daytime [182]. Another method for providing energy storage in SS systems is by putting a layer of solid sensible heat TES material under the water mass to store the heat from solar radiation. In one study, sand was used as TES material laid at the bottom of a SS. It was found that the SS’s productivity had increased the productivity by about 12 % enabling continuous production for almost 4 hr after sunset [183].

Another promising method of implementing sensible heat TES with RE-driven desalination systems is using salinity gradient solar ponds [184]. Solar ponds can be considered large-scale solar collectors. They store solar energy thermally in their layers, especially the lowest layer. Solar ponds are commonly divided into three zones: upper convection zone (UCZ), gradient zone, and lower convection zone (LCZ), which store solar energy as heat. Different types of salts can be used in solar ponds, such as MgCl2 and NaNO3, but NaCl is the most used salt [185]. The thermal energy stored in the solar pond can be used in two ways to drive the desalination processes. The first is, directly using the heat of the LCZ to drive low-temperature thermal desalination processes. The other way is to use such heat to drive a Rankine cycle for power generation, which can be used to drive electrically- and mechanically-driven processes. The brine of these desalination systems can be returned to the pond to help with energy storage [185]. Solar ponds were applied in multiple desalination projects in the MENA region. In Morocco, a solar pond was connected to a multiple distillation and flashing system, a hybrid MED-MSF system [186], [187]. This hybrid system was also connected to a thermal plant nearby, to recover the waste heat of gas exhaust from the thermal power plant [188].

4.1.2. Latent heat thermal energy storage

Latent heat TES refers to storing thermal energy in materials undergoing phase change processes, such as melting/solidification. Materials that are used for latent heat TES are known as phase change materials (PCMs) [189]. The heat absorbed and released during phase-change is much higher than that of a sensible-temperature change, as a result, PCMs can store much thermal energy in a much smaller mass or size, compared to sensible-heat TES materials [190]. There are multiple ways to incorporate PCMs in TES systems. The first method is by encapsulating the PCMs and adding these capsules to a liquid-state sensible heat TES material [191]. In this case, both the PCM and the liquid will contribute to TES. When energy is stored, the capsules will melt the PCM inside them and store latent heat, while the liquid will have its temperature increase. During discharge, the PCM will solidify and the liquid will decrease in temperature, and so forth [192]. Another way of integration is by filling a reservoir with a PCM, where a working fluid is allowed to flow over the PCM to both give and extract the thermal energy in charging and discharging scenarios, respectively.

Some important technical factors must be taken into consideration when designing latent-heat TES devices [189]. PCM selection is the most important criterion as it should well match the intended applications. There is a wide variety of PCMs, and each of them has different specifications. Material selection for a certain application includes high enthalpy of phase change, and its phase change temperature should be close to that of the desired application [193], [194]. For example, if an MSF desalination unit powered by a concentrated solar power (CSP) plant needs to be connected to a latent-heat TES device, the phase change temperature of the PCM must be close to that of the working fluid coming from the CSP plant [195], [196]. This is so that the PCM will undergo phase change as a result of the absorbed heat. As high-temperature TES is possible using PCMs, this type of energy storage can be well implemented with high-temperature thermal processes, such as MSF and MED. Also, the PCM should be of good thermophysical properties as well as be thermally, chemically, and mechanically stable. The thermal performance of PCM should be stable as well over a long lifetime of energy charge/discharge cycles. Furthermore, the TES device should be well insulated, so that the thermal losses to the environment are minimized.

Latent-heat TES devices were implemented in RE-powered desalination systems in the MENA region. A study carried out by Tabrizi et al., compared the productivity of weir-type SSs with and without thermal storage [197]. A latent-heat TES system with paraffin wax as a PCM was incorporated into the system design. The results indicated that the system’s productivity had increased significantly on cloudy days to 3.4 kg/m2d, as compared to 2.1 kg/m2d without energy storage. Another work was carried out in KSA by El-Sebaii et al. investigated the effect of integrating latent-heat TES on single basin SS’s performance [198]. It was found that increasing the mass of the PCM resulted in decreasing daytime productivity, but resulted in a significant increase in nighttime productivity, thereby increasing total daily productivity. The productivity with PCM utilized has reached 9 kg/m2d along with efficiency improvement up to 85 % as compared to 5 kg/m2 day without PCM. These results prove that latent heat TES systems are a very promising energy storage option for renewable energy-powered thermal desalination systems in MENA.

4.1.3. Thermochemical thermal energy storage

Thermochemical TES systems store thermal energy in reversible chemical reactions. In this type of reaction, a change in chemical composition is combined with heat absorption/release, depending on the reaction direction [199]. This kind of TES is similar to latent-heat TES or PCM, as the heat is absorbed/released at little temperature variation. Thermochemical materials have an extremely high enthalpy of reaction, which exceeds that of many PCMs. As a result, thermochemical TES devices are expected to be much smaller in size and with superior TES capabilities [200]. To choose the thermochemical material for ES applications, multiple factors should be addressed. These factors include the material’s cost and availability, reversibility of the chemical reaction, the safety of the chemical process, reaction temperature, and enthalpy of the reaction [201]. However, thermochemical TES devices are still in the early development stage, and a lot of work is still to be done before the commercialization of such devices can occur [202]. Thermochemical TES devices can be a potential energy storage candidate for high-temperature thermal processes, such as MED and MSF.

4.2. Electrical energy storage (EES)

Various types of RE technologies generate electrical energy as a primary output, and this output can be used to drive electrically- and mechanically-driven desalination technologies. Examples of this are systems that rely on solar PV or wind energy to derive RO or ED desalination. For these systems to stay productive in weather conditions where power production is limited, such as cloudy weather or low wind speeds, electrical energy storage (EES) systems must be included in the plant design. There are multiple EES technologies currently available, however, batteries are the most developed and commercially available technology among them. Other EES include capacitors, supercapacitors, and superconducting magnetic (SMES).

Batteries are a type of EES device that stores electrical energy internally as chemical energy [203]. Batteries rely on the mechanism of reduction/oxidation, i.e., redox reactions to convert the electrical energy into chemical energy, and vice versa [204]. Batteries are widely used in many applications starting from smartphones and laptops to large-scale ES in power stations [205]. There are two main types of batteries, i.e., primary and secondary batteries. Primary batteries are non-rechargeable batteries that are usually discarded after getting fully discharged. These include Zn/MnO2 alkaline batteries, Li/FeS2 batteries, and Zn/Air batteries [206]. The second type is secondary batteries, which can be recharged several times before they are discarded such as Li-ion, nickel-metal hydride NiMH, and lead-acid batteries, which are very suitable for the cyclic nature of RE generation [203], [207].

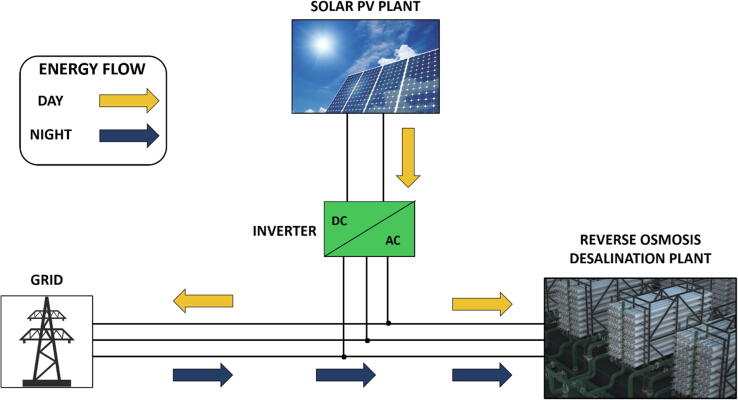

Fig. 6 shows a schematic of a solar PV-driven desalination system, with batteries as the main energy storage tool. In this system, the PV panels will generate electrical power during the daytime, which is used to drive the desalination unit. The excess energy is simultaneously stored in the batteries, which are to be used during cloudy days or at nighttime, to stabilize the water productivity. If a full-day operation of the desalination system is desired, proper sizing of the PV array and the battery system is crucial. A very similar case happens in wind-powered desalination systems. In such systems, not including an EES device will significantly affect the reliability of the desalination unit. However, connecting the system to the power grid is a good alternative to local energy storage depending on its availability.

Fig. 6.

Schematic of solar PV driving desalination system with battery energy storage system.

In KSA, a group from King Abdulaziz City for Science and Technology (KACST) built a PV-driven RO desalination plant, with batteries as an ESS [208]. They used SSs to increase the production of the desalination plant by desalinating the brine of the RO unit. Another study, in KSA, investigated the implementation of a hybrid PV-Wind energy system to drive RO desalination system with battery as an EES system [209]. In the minimum levelized cost of water (LCOW) optimized system, it was found that 6 batteries were needed for a 12-hour operation and 16 batteries were needed for a 24-hour operation.

4.3. Other energy storage technologies

Although energy storage either as TES or EES are the most mature and well-established ES for REs, other types of ESs could be implemented. The interest in other ES technologies comes from the high cost of batteries, along with other technical challenges upon scaling up, which makes building large-scale systems costly and challenging. The most interesting option is mechanical energy storage (MES) technologies, as they are well suited for large-scale applications and can be easily paired with electrical generators to produce the required electricity. These technologies include pumped hydro storage (PHS), compressed air energy storage (CAES), buoyancy work energy storage (BWES), and flywheels. PHS can be used directly to produce freshwater if integrated with an RO unit, which results in decreasing the capital cost of the RO system, and the environmental impact [210]. Also, CAES systems provide a cheap option for energy storage from large PV or wind-powered desalination plants. However, further investigation of the applicability of such devices needs to be carried out, as no actual systems have been tested for RE-driven desalination.

4.4. Summary

In general, ES plays a crucial role in enabling the utilization of REs full potential, hence smoothing the power supply to drive the desalination process to provide a continuous water supply. The ESs in this regard have to be sized in terms of storage capacity, power output, and response/discharge time at rated power, among many other factors [211], [212]. Figure 7 below shows a comparative schematic of different ES technologies relative to these factors.

Fig. 7.

Comparison of different energy storage systems (ESSs), discharge time vs power (Kopp, #29) [212], and power vs energy stored (bottom) [211].

5. Renewable energy resources RERs in the MENA region

The MENA region has a variety of RERs, such as solar, wind, hydro, and biomass, all of which present possible alternatives to conventional fossil fuels. Despite their availability, RERs are not well established as primary energy sources, and the main power supply is met by fossil fuels. In this section, the availability of various RERs in the MENA region is critically discussed, with insight into their potential power supply and implementation levels.

5.1. Solar PV

Due to their distinctive geographic location, most MENA countries have great solar irradiance resources that can be utilized as a primary energy source. This solar irradiance can be very valuable to many MENA countries, as it can be used for power generation, where most MENA countries need a sustainable energy source. The energy carried by solar irradiance can be extracted either using photovoltaics or by using solar thermal systems. For the first option, the MENA region has a very promising solar PV power potential, as shown in Fig. S1. Most MENA countries have agreeable solar power resources that can be utilized for generating power using PV technology. This is illustrated by the good values of specific yields in the range between 4.6 and 5.4 kWh/kWp daily and 1,680–1,972 kWh/kWp yearly [213]. The countries with the highest photovoltaic potential are Algeria, Egypt, Libya, KSA, and Yemen.

5.2. Solar thermal energy

The second method of utilizing solar energy is by using solar-thermal systems, which absorb the thermal energy component of solar irradiance and use it as a source of heat for thermally-driven applications, or indirectly to generate power, which can be used later in many applications. There are two types of solar-thermal systems, with the first is that works on absorbing all incident radiations, i.e., global irradiation, regardless of the irradiances' direction, i.e., horizontal or vertical irradiations, with an example of a flat plate solar collector. To evaluate the suitability of a specific location for such systems, the Global Horizontal Irradiance (GHI) of that location is first evaluated. The GHI is a great tool, used to estimate the solar potential of a given location and compare it to other competitive sites. Fig. S2 shows the GHI values over the MENA region. From the figure, it can be concluded that GHI increases for the regions closer to the equator- in other words- in the South of the MENA region [213].

The second type of solar thermal technology makes use of only one direction of solar irradiance, the irradiance coming directly from the sun to the device, known as the Direct Normal Irradiance (DNI). An example of this technology is the CSP technology, which is designed only to absorb the DNI. Fig. S3 shows the DNI values in the MENA region. Algeria, Egypt, Jordan, Libya, Morocco, KSA, Syria, and Yemen have the highest DNI values [213].

5.3. Wind energy

One of the most attractive RERs is wind energy. The main indicator for the availability of wind energy is the wind speed, as power density is proportional to the cubic power of wind speed, i.e., P/A = 0.5ρυ3, where P is power in W, A is wind turbine rotor area in m2, ρ is air density kg/m3, and υ is the wind speed in m/s. Fig. S4 illustrates the average wind speed in the MENA region. Some locations in the MENA region have a relatively high average wind speed, which exceeds 8 m/s [214]. Fig. S5 shows the wind power density potential in the MENA region in W/m2 of the wind turbine rotor area. Most MENA countries have mediocre wind energy resources, except for some areas mostly in Algeria, Egypt, Iran, Iraq, Libya, Oman, and Syria.

5.4. Hydroelectric energy

Hydroelectric energy, along with its subcategories including ocean thermal, wave, and tidal energies has attracted a drastic increase in attention in recent years. Despite its low energy cost and attractive advantages, hydroelectric energy is heavily reliant on geographic location, and cannot be utilized everywhere on the globe. For example, run-of-river energy can only be obtained when rivers are available in the country, with proper topography. Ocean thermal energy can only be utilized in regions near oceans and with a high ocean temperature gradient. In MENA, not all countries have access to usable hydroelectric sources. However, some countries are already utilizing hydropower successfully, such as Egypt and Iraq. Table S1 presents the total installed hydropower capacity and the total generation amounting to 21,430 MW and 33.6 TWh in 2018 in the MENA region, respectively, out of estimated annual potential of 182 TWh [215].

5.5. Biomass energy

Another promising RER is biomass-based fuels as bioenergy, which come from several sources, such as waste management plants, municipal wastewater treatment plants, agriculture waste treatment, and many other sources. These feedstocks are widely available in most countries, especially in agricultural countries, where agriculture is the steering wheel of the economy [216]. Table S2 shows potential biomass energy resources and estmated power capacity in MENA region countries of 27.4 mtoe and 107 TWh, respectively [217]. Only a few countries have implemented biomass energy as a considerable energy source, while the rest have not yet utilized it.

5.6. Geothermal energy

Geothermal energy is a promising RER that can be utilized in electricity generation, domestic heating and cooling, desalination, and many other applications [127]. In the MENA region, huge energy is used for air conditioning, especially in regions with a hot climate, such as the Arabian Gulf countries, where massive energy is used for desalination as well. In the last few years, increasing consideration has been given to utilizing geothermal energy, especially for desalination, more specifically to drive thermally-driven processes. Table S3 shows the total geothermal installed capacity, energy generation, and generation potential in the MENA region of 390 MWh, 1392 GWh, and 239 TWh, respectively. Despite the huge electricity generation potential in many MENA countries, such as KSA and Yemen, it is evident that in the MENA region, the only uses of geothermal energy are in direct use form and to less extent of the available potential [130]. In these cases, geothermal heat is used directly for heating or cooling purposes, but there are no applications for using geothermal energy to produce electricity.

5.7. Summary

In conclusion, it was found that MENA countries have a wide variety of RERs that can be used effectively to power desalination plants. Table 5 summarizes the availability of such RERs in the MENA region. Despite the availability of many RERs and the huge energy demand, many MENA countries still haven’t utilized most of their RE potential. Examples of this include the geothermal potential of Yemen and the hydropower potential in Iraq, and importantly solar energy over the whole region. This is due to the relatively cheaper prices of fossil fuels, and the high capital costs of RE power plants. The growth of the RE requires advances in RE technologies combined with increased fossil fuel prices. However, the recent advances in REs and ES have encouraged many countries to have REs at the core of their plans for the new installed electricity capacity and as a critical element of the national vision.

Table 5.

Summary of the availability of renewable energy resources in MENA.

| Renewable energy | Availability |

|---|---|

| Solar PV | Abundant in all MENA countries, specifically Egypt, Jordan, Libya, Saudi Arabia, and Yemen. |

| Solar thermal | Abundant in all MENA countries, specifically Egypt, Jordan, Libya, Morocco, Saudi Arabia, and Yemen. |

| Wind | Available mainly in the North Africa region, specifically Algeria, Egypt, Iran, Libya, Morocco, and Syria. |

| Hydroelectric | Only available in countries with specific geographic topography, specifically Egypt, Iran, Iraq, and Morocco. |

| Biomass | Mostly available mostly in agricultural countries, specifically Egypt, Jordan, Iran, Iraq, Morocco, Saudi Arabia, and Syria. |

| Geothermal | Only available in countries with specific geographic topography, specifically Egypt, Jordan, Iran, Saudi Arabia, and Yemen. |

6. Progress of implementing renewable energy-driven desalination in the MENA region

The desalination market has grown considerably in the last few years. In the MENA region, there has been a substantial shift towards renewables in the energy sector. Since desalination is a major energy demanding sector, RE-driven desalination has been studied extensively and implemented in many countries [218]. As a result, REs have become a considerable choice when installing new desalination capacities. Table 6 shows the different configurations of RE-driven desalination systems and their share of total RE-driven desalination installed capacity worldwide. The table shows that almost 1/3 of the capacity is driven by solar PV- RO, followed by wind-RO representing almost 1/5 of the desalination capacity. This can be attributed to the lower energy demand of the RO desalination process along with the generation of direct electrical energy from both solar PV and wind, which is used directly to drive the desalination process [219].

Table 6.

| Renewable energy-desalination system incorporation | Capacity share, % |

|---|---|

| Photovoltaic-Reverse osmosis (PV-RO) | 32 |

| Photovoltaic-Electrodialysis (PV-ED) | 6 |