Abstract

With the upsurge in the use of disposable masks during the coronavirus disease pandemic, improper disposal of discarded masks and their negative impact on the environment have emerged as major issues. Improperly disposed of masks release various pollutants, particularly microplastic (MP) fibers, which can harm both terrestrial and aquatic ecosystems by interfering with the nutrient cycling, plant growth, and the health and reproductive success of organisms. This study assesses the environmental distribution of polypropylene (PP)-containing MPs, generated from disposable masks, using material flow analysis (MFA). The system flowchart is designed based on the processing efficiency of various compartments in the MFA model. The highest amount of MPs (99.7 %) is found in the landfill and soil compartments. A scenario analysis reveals that waste incineration significantly reduces the amount of MP transferred to landfills. Therefore, considering cogeneration and gradually increasing the incineration treatment rate are crucial to manage the processing load of waste incineration plants and minimize the negative impact of MPs on the environment. The findings provide insights into the potential environmental exposure associated with the improper disposal of waste masks and indicate strategies for sustainable mask disposal and management.

Keywords: Microplastic, Mask, Material flow analysis, Environmental impact, Polypropylene

Graphical abstract

1. Introduction

The coronavirus disease (COVID-19) pandemic has led to a significant increase in the use of disposable masks, thus resulting in an increase in the amount of waste generated from discarded masks (Limon et al., 2022). Despite the recent shift from mandatory to advisory recommendations for wearing masks in many regions, numerous people still choose to wear masks. This behavior can be attributed to various reasons, including personal beliefs regarding the effectiveness of masks in preventing the spread of COVID-19 or a desire to protect themselves and others from potential infection (Ha, 2022). Under these circumstances, mask usage remains high in Korea; thus, improper disposal of masks can significantly impact the environment.

Currently, a large fraction of disposed masks end up in landfills or are incinerated, and in turn some residual wastes become sources of microplastic (MP) fibers and other pollutants, which are harmful to the environment (Ma et al., 2021). Disposable masks contain polypropylene (PP) (Fadare and Okoffo, 2020), which breaks down into small MPs when the disposed masks are to exposed to sunlight (photo-oxidation), wind, and water (shear stress) (Li et al., 2021; Cao et al., 2023; Liang et al., 2022). Bioaccumulation of these MPs can have significant implications for both terrestrial and aquatic ecosystems. For example, MPs released in waterbodies can be ingested by several organisms, such as planktons and fish, and accumulate in the food chain over time (Du et al., 2022). This biological accumulation of MPs may lead to possible biomagnification and ultimately affect the health and reproductive success of organisms belonging to diverse ecosystems. Furthermore, the MPs present in soil can interfere with the nutrient cycling and plant growth and are thus pernicious to both agricultural and natural ecosystems (Dissanayake et al., 2021).

Although the effects of exposure to MP fibers present in disposable masks and their toxicity have been extensively investigated (Li et al., 2021; Li et al., 2022; Sun et al., 2021), studies on their impact on the environment remain exiguous. Specifically, investigations based on material flow analysis (MFA) and life-cycle assessment (LCA) are crucial to determine and visualize the extent of damage caused by environmental exposure to MP-containing PP fibers (Cholewinski et al., 2022; Liu and Nowack, 2022). MFA can be used to determine the amount of substances released into different environmental media, such as air, water, and soil, as well as identify high-exposure areas (Kawecki et al., 2018; Kawecki and Nowack, 2019). By contrast, LCA can be used to propose methods to analyze and reduce the conspicuous adverse effects of PP fibers, present in disposable masks, on the environment; however, this methodology is not suitable for conducting a quantitative analysis of the associated root causes. Therefore, analyzing the exposure and impact of PP fibers in masks throughout their lifecycle, including their use and disposal, is an integral requirement of MFA.

In a previous study, mass flow into water and soil for seven MPs, including PP, were analyzed by MFA, and the mass flow into soil was predicted to be 40 times larger than that into water (Kawecki et al., 2018; Kawecki and Nowack, 2019; Liu and Nowack, 2022). Recently, MFA was employed to quantify the flow of plastics contained in compost and digestate into soil in Switzerland (Kawecki et al., 2021; Kawecki and Nowack, 2020). In addition, the mass flows of rubber particles from tires to roads and further into soil and surface water were determined via a dynamic probabilistic MFA (Sieber et al., 2020). Presently, Nowack and coworkers (Kawecki et al., 2021; Kawecki and Nowack, 2019; Kawecki and Nowack, 2020; Kawecki et al., 2018; Liu and Nowack, 2022; Mueller and Nowack, 2008; Sieber et al., 2020) are conducting leading research in the field of MFA. However, MFA of the amount of PP-contained MPs, emitted from masks, released into different environmental media has not yet been conducted.

To the best of our knowledge, no MFA study has been conducted to quantify the flow of MPs released from improperly disposed masks into the environment and assess their environmental exposure. Therefore, in this study, the environmental exposure of PP-containing MPs obtained from disposable masks is evaluated using MFA. Specifically, the exposure concentration of MPs in each environmental medium was assessed using MFA and the environmental exposure of disposable masks was evaluated by changing the release ratio in each environmental compartment. The results provide insights into the potential environmental exposure associated with improper disposal of disposable masks and suggests strategies for sustainable mask disposal and management.

2. Methods

2.1. Mask type and number of PP in the masks

To understand the mass flow of MPs from discarded masks into environmental media, three types of disposable face masks, namely N95, surgical, and normal medical masks, were selected as type-1, type-2, and type-3 masks, respectively. PP is widely used to fabricate the outer and inner layers of these masks, whereas a melt-blown nonwoven fabric, also composed of PP, is typically used to prepare the middle layer (Fadare and Okoffo, 2020). Therefore, the MP released from the mask into the environment can be considered as PP. The average number of MP-containing PP fibers released from these three mask types (1734 (from 801 ± 71 to 2667 ± 97), 1740 (from 1136 ± 87 to 2343 ± 87), and 1791 (from 1034 ± 119 to 2547 ± 185) MP particles per day for type-1, type-2, and type-3, respectively) was obtained from a previous report (Liang et al., 2022). The three types of masks used in Korea are also widely used in China. Therefore, experimental data from China were used in here.

According to the data obtained from major domestic sources and reported by the Korean Government and news channels in 2022, the production of the aforementioned three types of masks varied depending on the pandemic situation. On an average, 94.68 million (min–max: 94.20–95.15 million), 590,000 (310,000–870,000), and 5.1 million (4.77–5.43 million) of type-1, type-2, and type-3 masks, respectively, were domestically produced every week (Korean Statistical Information Service, 2022). The size distribution of the MPs released from these mask types was also extracted from previously reported literature; reportedly, MPs with sizes of 100–500 μm and < 100 μm were released in large quantities (Liang et al., 2022). The Feret diameter of the PP fiber was set to exhibit a Gaussian distribution biased to the left of 30–500 μm, with 110 μm as the mode value (Pabortsava and Lampitt, 2020). Further, the fiber diameter (d) of a PP filter membrane can vary up to 20 μm (P.J et al., 2022), and thus, in the present study, d was set to 5–20 μm.

2.2. Weighting factors for MFA

MFA often involves the use of both dynamic and probabilistic models (Liu and Nowack, 2022). In this study, a scenario-based box model was used to simplify the MFA configuration process owing to the absence of sufficiently detailed data (Mueller and Nowack, 2008). As mentioned before, three types of masks were considered as the primary categories. The weighting factors (WFs), used to assign relative importance or value to each mask type, were determined from the total number of masks produced for each mask type and the amount of MP released. The product of these two factors was scaled to 100 % to obtain the distribution of PP by mask type (Table 1 ).

Table 1.

Estimated amount of PP-containing MP released from masks with two weighting factors (WFs) (d = 5 μm).

| Masks | WFs |

Product of two WFs | Amount (kg/y)c | |

|---|---|---|---|---|

| Productiona | MP releasedb | |||

| Type-1 Type-2 Type-3 |

0.943 0.006 0.051 |

0.329 0.330 0.340 |

0.311 0.002 0.017 |

43,586 273 2425 |

On an average, 94.68 million, 590,000, and 5.1 million of type-1, type-2, and type-3 masks, respectively, were domestically produced every week (Korean Statistical Information Service, 2022). The Production values were normalized.

The average number of MP-containing PP fibers released from these three mask types (approximately 1734, 1740, and 1791 MP/d for type-1, type-2, and type-3, respectively) was obtained from a previous report (Liang et al., 2022). The MP released values were normalized.

It was obtained by multiplying the annual emission (46,284 kg/y) of PP discharged from the mask by WFs.

2.3. Predicted environmental concentration

MFA was performed to determine the predicted environmental concentration (PEC) of PP-containing MP in water, air, and soil. All the MPs in air were deposited or washed out of water or soil. The relevant air volume in a 1-km-long terrestrial ecosystem was multiplied by the total area of South Korea (National Geography Information Institute, 2022), and a total air volume of 100,378 km3 was obtained; the concentration of MPs in this air volume was determined. Next, the aquatic compartment was defined as surface water, whose total area (2860 km2) was then multiplied by a relevant mixing depth of 3 m, and the concentration of MPs in this resulting water volume of 8.58 km3 was determined (Mueller and Nowack, 2008). A similar process was implemented for soil. However, because the soil mixing depth depends on its type, mixing depths of 20 and 5 cm were considered for agricultural land (18,833 km2), natural ground (66,854 km2), and urban ground (8524 km2), respectively; the corresponding soil volume (National Geography Information Institute, 2022) was calculated to be 7.54 km3. Subsequently, the concentration of MPs deposited in this volume of soil was determined by MFA.

3. Results and discussion

3.1. Scenario configuration for MFA

In the MFA model, first, flow of materials between different compartments or processes in a system must be established. In this step, the primary movement (i.e., the initial source and destination of the material), secondary movement (i.e., any intermediate step or process applied on the material), and treatment efficiency of each compartment (i.e., the amount of material is lost or transformed during processing) must be considered. When the amount of data on exposure to PP-containing MPs is insufficient, various scenarios are constructed to estimate the potential exposure levels. Such scenarios can be constructed based on the assumptions for sources and pathways of PP-containing MP as well as on the behavior and use patterns of products that contain these fibers. While MFA was performed to analyze the mask itself and the PP exposed from the mask, there is a lack of available data specifically on the exposure of mask-derived PP. This is a common challenge in many MFA analyses, as they rely on existing data sources and may have data gaps. As a result, this study acknowledges these limitations as they are inherent to the current level of available information. Although scenario-based analyses have limitations and uncertainties, they reveal the potential environmental exposure of PP-containing MPs on human health and the environment.

Several methods are typically employed for mask disposal, including general waste disposal, designated waste disposal, and recycling (Sangkham, 2020). In most places, garbage is collected by waste management companies or local government agencies and transported to designated landfills or incineration facilities for disposal. Table 2 indicates that the primary discharge points of the selected masks were set as general waste (94 %), designated waste (4 %), dumping waste (1.9 %), and respiratory exposure during use (0.1 %). A previous study reported that during 24 h of simulated respiration, 110, 137, 264 fiber-like MP particles are exposed to a person wearing type-1, type-2, and type-3 masks, respectively (Li et al., 2021). Additionally, the average number of MP-containing PP fibers released from these mask types was 1734, 1740, and 1791 MP particles per day for type-1, type-2, and type-3, respectively (Liang et al., 2022). Based on these results, it was estimated that when using a mask for 24 h, the maximum exhalation of PP particles ranged from 6.3 % to 14.7 %. The daily average respiratory exposure for the three mask types was determined to be 9.6 %. It is important to note that these values represent the maximum potential detachment of MP particles and not the actual amount directly breathed in. Therefore, in our analysis, a conservative estimate of 0.1 % was set for the direct respiratory exposure of MP particles when wearing a mask for 1 h. Therefore, the likelihood of being exposed to airborne particles through breathing while wearing a mask was estimated to be approximately 0.1 %, which is indicates a relatively small exposure. Further, the primary discharged waste could be moved along secondary discharge routes, including landfills, incineration plants, and wastewater treatment plants, for disposal.

Table 2.

Mass flow for the release of PP fibers from masks.

| Masks | 1st releasing points (%) | 2nd releasing points (%) | ||

|---|---|---|---|---|

| Type-1 & 3 | Designated waste | 4 | Landfill | 79 |

| WIP | 12 | |||

| Reuse | 9 | |||

| General waste | 94 | Landfill | 51 | |

| WIP | 49 | |||

| Dumping | 1.9 | Water | 5 | |

| WWTP | 12 | |||

| Air | 6 | |||

| Soil | 77 | |||

| During use | 0.1 | Air | 100 | |

| Type-2 | Designated waste | 99.9 | WIP | 100 |

| During use | 0.1 | Air | 100 | |

According to a previous study, approximately 79 % of the plastic waste associated with the COVID-19 pandemic ended up in landfills or other environmental media, 12 % was incinerated, and only 9 % was recycled (Khoo et al., 2021). Domestic waste disposal is primarily carried out using three methods: recycling (171.61 kt/a), disposal in landfills (10.46 kt/a), and incineration (9.79 kt/a) (Korea Waste Association, 2021). General waste, which includes waste masks, is disposed primarily in landfills and through incineration (ratios, 51 % and 49 %, respectively). Moreover, because masks are also intentionally discarded on streets (France, 2022), the dumping ratio was set to 1.9 %. These discarded masks can break down because of additional weathering and release MPs into various environmental systems. The fractions of MP released into water systems, wastewater treatment plants (WWTPs), soil, and air were estimated to be 5, 12, 77, and 6 %, respectively (Bänsch-Baltruschat et al., 2021; Kole et al., 2017). In principle, surgical masks used in hospitals are incinerated; thus, in this study, all the type-2 masks were considered to be disposed-off in waste incineration plants (WIPs).

Among the nine compartments that constitute the MFA model, treatment efficiencies in air, WIP, and WWTP were considered. MP particles, including tire-wear particles (MPs present on roads), are readily scattered in air (average, 4 t/a), and a large number of these scattered MP particles migrate to soil (average, 58.7 t/a) and some to water systems (average, 8.7 t/a) (Baensh-Baltruschat et al., 2021). Accordingly, 82 and 18 % of the MP particles released into the atmosphere were assumed to be transferred to soil and aquatic systems, respectively.

In the WIP compartment, most of the MP particles decomposed through high-temperature incineration and were thus removed from the system. Additionally, the WIP filters captured 99.9 % of the suspended particles, and the remaining only 0.1 % of the particles entered the atmosphere (Mueller and Nowack, 2008). Incineration can be used to recover energy and reduce the mass and volume of waste by 70 % and 90 %, respectively, and the ash produced can be recycled or disposed in landfills (Li et al., 2007). After the incineration of waste sludge, the generated bottom ash is removed from the system through the landfill; however, according to previous reports, MP particles still remain in the bottom ash. As reported by Shen et al. (2021), the concentrations of MPs in fly ash, bottom ash, and soil were found to be 23, 171, and 86 particles/kg, respectively. Notably, a small ratio of the MP particles presents in the residual bottom ash transferred to the landfill after the incineration of the waste sludge. Therefore, to ensure a conservative estimation, the calculations assumed that 90 % of MP is removed during the incineration process, while 9.9 % of the remaining MP in the sludge is transferred to landfill, and a small portion (0.1 %) may be released into the atmosphere during the transportation process of the sludge to outer system.

WWTP can remove 88–94 % of suspended particles from wastewater before their discharge into the receiving environment (Iyare et al., 2020; Kim et al., 2022). The MP particles were removed from the wastewater and collected in both the sediment and activated sludge during the treatment process. The removal efficiency of MP during wastewater treatment can vary depending on various factors, including the treatment processes employed, operational conditions, and the characteristics of the microplastics themselves. According to data reported by the Korea Institute of Civil Engineering and Building Technology (2019), the removal efficiency of MP in domestic wastewater treatment plants is reported to be over 90 %. Therefore, the treated water contained at least 6 % of MP particles. Waste sludge generated from WWTPs is commonly subjected to dewatering and thickening processes to convert it into solid waste (Zhang et al., 2022); the final destination of waste sludge is typically land. Dewatered sludge can be buried underground in a sanitary landfill as well as spread on agricultural land to act as a soil conditioner and fertilizer. In the WWTPs located in Seoul, South Korea, 24 % of the produced waste sludge is incinerated, 11.5 % is sent to landfills, 9.9 % undergoes fuel conversion, 41.6 % is recycled through various methods, such as composting, soil conversion, construction material conversion, and cement resource conversion, and 13.0 % is categorized as others (Seoul Metropolitan Government, 2019). Therefore, in our analysis, 22.6 % of the waste sludge was set for incineration, 10.8 % for landfill disposal, and 60.6 % was removed from the system through recycling.

3.2. System flowchart based on MFA

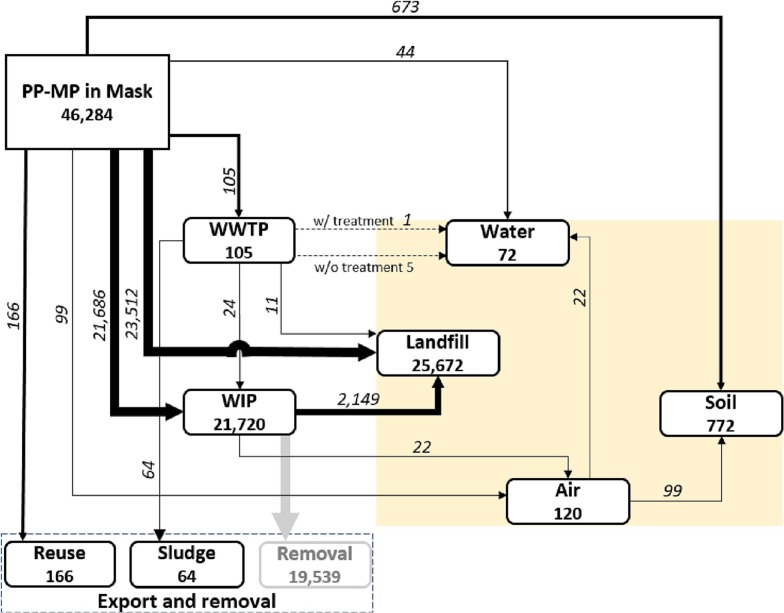

The scenario was designed based on the processing efficiency and ratios of various compartments in the MFA model, and system flow charts were created accordingly. Fig. 1 shows the system flowchart for PP-containing MP particles (diameter, 5 μm) that originate from disposable masks. PP generated from masks was primarily subjected to incineration (21,686 kg/y) and released in landfills (23,512 kg/y), and a certain ratio of the MP particles present in the bottom ash of incineration plants ended up in landfills (2149 kg/y). A small amount of PP-containing MP (105 kg/y) entered the WWTPs and is concentrated primarily in the sludge for recycling (64 kg/y); subsequently, it was removed from the system. A small amount of MP (6 kg/y) was present in the WWTP effluent; 11 kg/y of the MP was treated by landfill sedimentation and waste sludge treatment, whereas 24 kg/y of the MP was treated by incineration. Most MP disappeared from the system in the WIP (19,539 kg/y), whereas some particles present in the bottom and fly ash were released into air (22 kg/y). In addition, PP materials from discarded masks can be recycled and repurposed for other plastic products after undergoing sterilization processes (Yuen et al., 2022). Mask reuse (166 kg/y), sludge recycling (64 kg/y), and removal by incineration (19,539 kg/y) accounted for 42.7 % of the initial PP-containing MP concentration. Of this 42.7 %, 55.5 % of the MP was transported to landfills, which act as major sinks for PP-containing MP. Finally, 72, 120, and 772 kg/y of the generated MP were released into water, air, and soil, respectively, thus indicating that soil is the dominant MP-receiving environmental medium. The results suggest that after subtracting the amount removed from the system, landfills and soil compartments receive the maximum amount (approximately 99.7 %) of MP released from disposable masks. Overall, this scenario highlights the significant impact of landfills and soil as environmental sinks for this type of MP.

Fig. 1.

System flows from PP-containing MP originating from masks to different environmental compartments. Here, diameter of the PP fiber is 5 μm, and all the flows are presented in units of kg/year. The thickness of the arrows is proportional to the amount of MP flowing between the compartments.

The flowchart depicted in Fig. 1 was prepared assuming a diameter of 5 μm for the PP fibers. However, if the diameter of the PP fiber is increased by four times (20 μm), then the total weight increases by 16 times, thus implying that the amount of PP fibers present or emitted from the mask increases from 46,284 kg/y (diameter, 5 μm) to 740,542 kg/y (diameter, 20 μm). The diameter of the PP fibers used to manufacture the previously mentioned three types of disposable masks may not be uniform but rather exhibit a certain distribution. Depending on the specifications of the PP fibers used in these masks, fibers with a small diameter distribution may be present, and these small-diameter fibers are not released into the environment. The diameter of the PP fiber filament used in these masks may vary depending on the mask type. For example, type-1 masks contain microfibers that are 5 μm or less in size, whereas type-2 and type-3 masks use fibers with diameters of 10–20 μm (P.J et al., 2022). The choice of fiber diameter is often based on the filtration efficiency requirements and intended use of the mask. Despite slight variations in the diameters of the fibers used in different respirators, all the outer-layer fiber diameters were larger (approximately 15–30 μm) than those of the inner layer fibers (approximately 1–8 μm) (Ardon-Dryer et al., 2021).

Based on the given information, type-1 masks were assumed to predominantly use PP fibers with a diameter of 5 μm, whereas type-2 and type-3 masks use fibers with a diameter of 20 μm. The WFs for each mask used in Table 1 were 0.942, 0.006, and 0.052 for the type-1, type-2, and type-3 masks, respectively. The number of PP fibers in each compartment was calculated using this information (Table 3 ). The weighted amount increased by 1.87 times compared with the standard of 5 μm but decreased by 8.54 times compared with the standard of 20 μm. During the pandemic, the use of N95 masks accelerated, and therefore, the rate of removal from the system and that of transfer to a landfill remained similar to the weight calculated using the 5 μm standard. Notably, the actual amount of PP fibers released into the environment may vary depending on the diameter distribution of the fibers used in the masks as well as the disposal methods.

Table 3.

Weighted amounts of PP-containing MP in MFA compartments.

| Compartments | Amount (kg/y) |

Weighted amount (kg/y)a | ||

|---|---|---|---|---|

| d = 5 μm | d = 20 μm | |||

| Source Released to |

PP-MP in mask | 46,284 | 740,524 | 86,748 |

| WWTP | 105 | 1678 | 197 | |

| WIP | 21,720 | 347,355 | 40,700 | |

| Landfill | 25,672 | 410,758 | 48,117 | |

| End-point | Water | 72 | 1147 | 135 |

| Air | 120 | 1927 | 225 | |

| Soil | 772 | 12,351 | 1447 | |

| Export | Reuse | 166 | 2650 | 311 |

| Sludge recycling | 64 | 1017 | 120 | |

| Removal of MP | 19,539 | 312,619 | 36,621 | |

Type-1 masks were assumed to predominantly use PP fibers with a diameter of 5 μm, whereas type-2 and type-3 masks use fibers with a diameter of 20 μm. The Weighted amount in each compartments was calculated based on the given information (WFs) in Table 1.

The MFA results revealed that the amount of PP fibers present in each environmental medium was different (72, 120, and 772 kg/year in water, air, and soil, respectively). The size of the PP fiber released from the mask was initially in the range of 30–500 μm, with a mode of 110 μm (Pabortsava and Lampitt, 2020). Fig. 2 shows the number of PP particles present in each environmental medium, determined by MFA. Although the central value of the size distribution was 100 μm, numerous particles with smaller sizes were also present. This size distribution feature suggests that initially, PP fibers with a Feret size of 30–500 μm were discharged from the mask; however, PP particles with a diameter of approximately 100 μm were dominant in the water systems. A similar trend was observed in air and soil. As MFA does not reflect the effect of environmental phenomena, such as weathering, determining whether the PP fibers are fragmented into smaller particles is challenging. However, if weathering is considered in water systems, then fragmentation of large particles can easily occur and result in a high proportion of particles with diameters <100 μm.

Fig. 2.

Numbers of particles with Feret size distribution of PP-containing MP released into environmental media; the values are estimated by MFA (d = 5 μm).

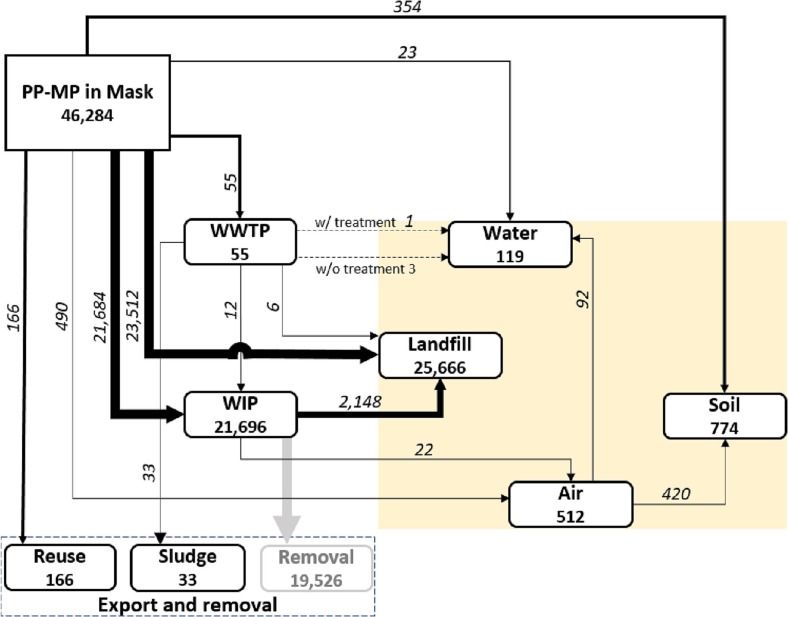

The scenario assumes that there is a risk of respiratory exposure to PP fibers during mask use. To account for this condition, the exposure during use was set at 0.1 %. However, it was also assumed that with long-term use exceeding 10 h, the tendency of PP-containing MP to dislodge increases, leading to an increase in atmospheric exposure. To model this scenario, atmospheric exposure was increased to 1 %, which led to an increase in human breathing and air exposure during mask use by about 5 times, from 99 kg/year to 490 kg/year (Fig. 3 ). The direct transport of air-exposed particles into the soil increased (from 99 kg/year to 420 kg/year). Although the amount of PP-containing MP directly exposed from the mask to the soil decreased by half, the final overall movement of PP to the soil increased to 774 kg/y. In addition, air-to-aquatic transport increased from 72 kg/year to 119 kg/year, while the burden on waste incineration plants and landfills remained almost unchanged. Namely, among the environmental media, water and soil act as final sinks for the particles. This suggests that if MP fibers, including PP, are easily exposed in masks, it can adversely affect human respiration, and ultimately, the exposure in the air and water systems also increases.

Fig. 3.

System flows from PP-containing MP originating from masks to different environmental compartments. Here, the respiratory exposure during use is 1 %.

3.3. Removal and reduction of PP-containing MP

Currently, the use of landfills for domestic waste disposal is gradually reducing owing to the limitations of landfills and complete prohibition of ocean dumping. Incineration is gaining attention as a method for recovering energy from waste, while reducing the amount of waste (Istrate et al., 2023). In the MFA, the endpoints of the mass flows of PP-containing MP, originating from masks, were landfill and soil. Landfill waste generates leachate around the landfill sites, and this leachate can cause secondary pollution in the surrounding areas. Therefore, with the increasing use of incineration, the decrease in the amount of PP-containing MP transferred to the environment must be examined.

The existing material flow for masks were designated as waste and dumped; however, in the treatment method of general waste, including waste masks, the landfill-to-incineration ratio increased from 51:49 to 0:100. In Fig. 1, the diameter of the mask fiber was assumed to be 5 μm. When the incineration ratio was increased, the volumes of the three compartments (reuse of masks, sludge recycling, and MP in the WWTP) remained unchanged, whereas the amount of MP present in the remaining compartments increased. As shown in Fig. 4 , the amount of MP removed from the system increased linearly with increasing incineration rate. If all the general wastes are treated by incineration, then the amount of landfill can be significantly reduced by 4.43 times, from 25,672 to 5798 kg/y, and the throughput of WIP can be increased by 2.02 times, from 21,720 to 43,768 kg/y. By contrast, the amount of MP removed from the system increased from 19,539 to 39,391 kg/y. The final flow of the water system did not increase significantly (from 72 to 76 kg/y). However, it increased by approximately 20 kg/y owing to the increased exposure to air and soil during the post-treatment of the bottom ash and fly ash generated after the incineration.

Fig. 4.

Changes in the amount of MP in WIPs, MP in landfills, and removed MP with increasing landfill-to-incineration MP amount ratio.

Overall, although incineration is a promising method for removing PP-containing MP from environmental systems, it may slightly increase the concentration of MP particles in environmental media. If all the general waste is treated by incineration, then the ratio of the amount of MP present in WIPs and landfill sites is expected to increase from 0.85 to a maximum of 7.55. However, this increase in MP concentration ratio can also increase the processing load of the WIPs by maximum two times as well as increase the concentration of MP in the environmental medium. Therefore, drastically increasing the incineration-to-landfill MP concentration ratio is not possible. This scenario analysis suggests that cogeneration must be considered when planning a new incineration facility that produces both electricity and heat from incinerated waste. Cogeneration can help in optimizing the waste management system by reducing the amount of waste transferred to landfills and simultaneously generating energy from the waste. Moreover, the incineration treatment rate must be gradually increased to manage the processing load of WIPs and minimize the adverse environment effects.

In addition, the components of masks are very different by type of mask, and thus some components can produce hazardous substances when they were incinerated. Although modern incineration facilities are designed to operate as zero-emission facilities, minimizing the exposure of hazardous substances to the atmosphere, there is still a possibility of migration of hazardous substances through bottom ash. Therefore, this highlights the importance of implementing proper waste management practices and utilizing appropriate gas treatment systems to mitigate potential environmental risks. Further research and consideration are needed to assess and address the specific challenges associated with the incineration of masks and the potential release of hazardous substances.

Introduction of incineration facilities and increasing the in incineration treatment rates are additional factors that influence the environment. Moreover, considering the environmental impact of masks throughout their lifecycle, i.e., from production to disposal, is crucial. Since the onset of the COVID-19 pandemic, several studies on the LCA of masks have been reported. Reportedly, the carbon footprint of reprocessed face masks is significantly lower than that new face masks; thus, reprocessed face masks are advantageous for a circular economy owing to their relatively less influence on the global climate (van Straten et al., 2021). Recent reports emphasize the importance of considering the environmental impact of masks throughout their lifecycle and highlight the potential benefits of using reusable masks as sustainable alternatives to disposable masks (Lee et al., 2021; Tabatabaei et al., 2021; Türkmen, 2021). However, studies focused on the LCA of MP-containing PP fibers in face masks are scarce. Therefore, impact (toxicity, global warming, terrestrial acidification, and eutrophication) and damage (human health, ecosystems, and resource availability) evaluations via LCAs are required to interpret the environmental impact of a specific target product, such as a mask, on the environment during waste disposal. These assessments will reveal the environmental impact of the entire lifecycle of masks and provide guidance for the development of sustainable waste management strategies.

3.4. PEC of PP-containing MPs in water, air, and soil

The concentration of MP in the environment is typically measured by counting the number of particles per unit volume. MFA can also be used to determine the mass concentrations of MP in a given medium. The PEC of MPs was determined from the sizes of the water, air, and soil compartments within a geographic region as well as the mass of MP in each compartment (as determined by MFA). The calculated PEC of the MPs provide deep insights into the distribution and concentration of MPs in the environment.

Table 4 lists the PEC values calculated for several scenarios, such as changes in the diameter of the PP fibers and complete incineration. The reliability of these PEC values is limited owing to data constraints and the various assumptions made in the scenario-based flowchart composition. For a PP fiber diameter of 5 μm, the corresponding PEC values for air, water, and soil were 0.001 μg/m3, 0.008 μg/L, and 0.102 μg/kg, respectively. It should be noted that the derived PEC value was relatively small because it was calculated for the entire land area. The assessment considered the overall distribution and concentration of MP across the entire land area, leading to a lower PEC value compared to localized or specific areas. Increasing the diameter of the PP fiber by four times resulted in a 19-, 17-, and 16-fold increase in the PEC of MP in air, water, and soil, respectively. However, the calculated PEC values exhibited negligible changes even at an incineration rate of 100 %. This result suggests that the concentration of PP fibers in the environment remain almost the same, even when the waste treatment load in WIPs is increased.

Table 4.

PEC value of PP-containing MP in air, water, and soil.

| Compartments | Diameter of PP fiber |

Incineration 100 % | ||

|---|---|---|---|---|

| d = 5 μm | d = 20 μm | Weighteda | ||

| Air (μg/m3) | 0.001 | 0.019 | 0.002 | 0.001 |

| Water (μg/L) | 0.008 | 0.134 | 0.016 | 0.008 |

| Soil (μg/kg) | 0.102 | 1.639 | 0.192 | 0.105 |

The Weighted value was calculated with WFs in Table 1.

4. Conclusions

In conclusion, the diffusion of PP-containing MP into different environmental media is a global issue that requires immediate attention. The results of the present study indicate that incineration plays a significant role in reducing the concentration and distribution of MP in the environmental medium. In general, increasing the proportion of waste for incineration is an effective method to reduce the concentration of MP in a system as well as decrease the amount of waste transferred to landfills because incineration can destroy most of the MP particles present in waste. However, adopting only waste incineration is not conducive to sustainable waste management and minimizing the amount of MP released into the environment. Energy recovery strategies, such as cogeneration, should be included in the incineration process to maximize the benefits of waste-to-energy conversion. In addition, the diameter of the PP fibers contained in MPs influences the concentration of these fibers in air, water, and soil. These results provide guidance for formulating policies and regulations to minimize the amount of MPs released into the environment.

Apart from the COVID-19 disease, various other respiratory diseases are currently known or may emerge in the future. Therefore, sustainable mask disposal approaches must be developed to combat environmental issues arising from improper disposal of face masks. The scenario-based analysis presented in this study has some limitations owing to insufficient data. However, the results can be used to estimate the potential concentration of MPs in the environment and suggest ways to manage mask disposal. Alternative waste management strategies, such as incineration with energy recovery, are anticipated to minimize the adverse effects of masks and other single-use plastics on the environmental. The results obtained in this study shed light on the importance of further research in this field as well as on developing sustainable solutions to eliminate MP-induced environmental hazards.

CRediT authorship contribution statement

Jaehwan Hong and Ha-neul Park: Methodology and Analysis (MFA).

Seowoo Lee and Min Kyung Song: Data acquisition.

Younghun Kim: Conceptualization, wiring reviewing, and editing.

Declaration of competing interest

The authors declare that they have no competing financial interests or personal relationships that may have influenced the work reported in this study.

Acknowledgements

This study was supported by the Korea Environmental Industry and Technology Institute (KEITI; MOE-2022003120002).

Editor: Jay Gan

Data availability

Data will be made available on request.

References

- Ardon-Dryer K., Warzywoda J., Tekin R., Biros J., Almodovar S., Weeks B.L., Hoe-Weeks L.J., Sacco A., Jr. Mask material filteration efficiency and mask fitting at the crossroads: implications during pandemic times. Aerosol Air Qual. Res. 2021;21 [Google Scholar]

- Bänsch-Baltruschat B., Kocher B., Kochleus C., Stock F., Reifferscheid G. Tyre and road wear particles—a calculation of generation, transport and release to water and soil with special regard to German roads. Sci. Total Environ. 2021;752 doi: 10.1016/j.scitotenv.2020.141939. [DOI] [PubMed] [Google Scholar]

- Cao J., Shi Y., Yan M., Zhu H., Chen S., Xu K., Wang L., Sun H. Face mask: as a source or protector of human exposure to microplastics and phthalate platicizers? Toxics. 2023;11:87. doi: 10.3390/toxics11020087. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Cholewinski A., Dadzie E., Sherlock C., Anderson W.A., Charles T.C., Habib K., Young S.B., Zho B. A critical review of microplastic degradation and material flow analysis towards a circular economy. Environ. Pollut. 2022;315 doi: 10.1016/j.envpol.2022.120334. [DOI] [PubMed] [Google Scholar]

- Dissanayake J., Torres-Quiroz C., Mahato J., Park J. Facemasks: a looming microplastic crisis. Int. J. Environ. Res. Public Health. 2021;18:7068. doi: 10.3390/ijerph18137068. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Du H., Huang S., Wang J. Environmental risks of polymer materials from disposable face masks linked to the COVID-19 pandemic. Sci. Total Environ. 2022;815 doi: 10.1016/j.scitotenv.2022.152980. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Fadare O.O., Okoffo E.D. Covid-19 face masks: a potential source of microplastic fibers in the environment. Sci. Total Environ. 2020;737 doi: 10.1016/j.scitotenv.2020.140279. [DOI] [PMC free article] [PubMed] [Google Scholar]

- France R.L. First landscape-scale survey of the background level of COVID-19 face mask litter: exploring the potential for citizen science data collection during a ‘pollution pilgrimage’ of walking a 250–km roadside transect. Sci. Total Environ. 2022;816 doi: 10.1016/j.scitotenv.2021.151569. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Ha K.M. Changes in awareness on face mask use in Korea. Public Health Nurs. 2022;39:506–508. doi: 10.1111/phn.12988. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Istrate I.R., Galvez-Martos J.L., Vázquez D., Guillén-Gosálbez G., Dufour J. Prospective analysis of the optimal capacity, economics and carbon footprint of energy recovery from municipal solid waste incineration. Resour. Conserv. Recycl. 2023;193 [Google Scholar]

- Iyare P.U., Ouki S.K., Bond T. Microplastics removal in wastewater treatment plants: a critical review. Environ. Sci. Water Res. Technol. 2020;6:2664. [Google Scholar]

- Kawecki D., Nowack B. Polymer-specific modeling of the environmental emissions of seven commodity plastics as macro- and microplastics. Environ. Sci. Technol. 2019;53:9664–9676. doi: 10.1021/acs.est.9b02900. [DOI] [PubMed] [Google Scholar]

- Kawecki D., Nowack B. A proxy-based approach to predict spatially resolved emissions of macro- and microplastic to the environment. Sci. Total Environ. 2020;748 doi: 10.1016/j.scitotenv.2020.141137. [DOI] [PubMed] [Google Scholar]

- Kawecki D., Scheeder P.R.W., Nowack B. Probabilistic material flow analysis of seven commodity plastics in Europe. Environ. Sci. Technol. 2018;52:9874–9888. doi: 10.1021/acs.est.8b01513. [DOI] [PubMed] [Google Scholar]

- Kawecki D., Goldberg L., Nowack B. Material flow analysis of plastic in organic waste in Switzerland. Soil Use Manag. 2021;37:277–288. [Google Scholar]

- Khoo K.S., Ho L.Y., Lim H.R., Leong H.Y., Chew K.W. Plastic waste associated with the COVID-19 pandemic: crisis or opportunity? J. Hazard. Mater. 2021;417 doi: 10.1016/j.jhazmat.2021.126108. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Kim M.-J., Na S.-H., Batool R., Byun I.-S., Kim E.-J. Seasonal variation and spatial distribution of microplastics in tertiary wastewater treatment plant in South Korea. J. Hazard. Mater. 2022;438 doi: 10.1016/j.jhazmat.2022.129474. [DOI] [PubMed] [Google Scholar]

- Kole P.J., Löhr A.J., Belleghem F.G.A.J.V., Raga A.M.J. Wear and tear of tyres: a stealthy source of microplastics in the environment. Int. J. Environ. Res. Public Health. 2017;14:1265. doi: 10.3390/ijerph14101265. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Korea Institute of Civil Engineering and Building Technology A planning research for microplastics reduction and removal technologies development. KICT. 2019:2019–2246. [Google Scholar]

- Korea Waste Association . 2021. National Waste Generation and Disposal Status; p. 2021.http://kwaste.or.kr [Google Scholar]

- Korean Statistical Information Service Trends in supply and demand, such as mask production. 2022. http://kosis.kr

- Lee A.W.L., Neo E.R.K., Khoo Z.Y., Yeo Z., Tan Y.S., Chng S., Yan W., Lok B.K., Low J.S.C. Life cycle assessment of single-use surgical and embedded filtration layer (EFL) reusable face mask. Resour. Conserv. Recycl. 2021;170 doi: 10.1016/j.resconrec.2021.105580. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Li X., Bertos M.F., Hills C.D., Carey P.J., Simon S. Accelerated carbonation of municipal solid waste incineration fly ashes. Waste Mange. 2007;27:1200–1206. doi: 10.1016/j.wasman.2006.06.011. [DOI] [PubMed] [Google Scholar]

- Li L., Zhao X., Li Z., Song K. COVID-19: performance study of microplastic inhalation risk posed by wearing masks. J. Hazard. Mater. 2021;411 doi: 10.1016/j.jhazmat.2020.124955. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Li M., Hou Z., Meng R., Hao S., Wang B. Unraveling the potential human health risks from used disposable face mask-derived micro/nanoplastics during the COVID-19 pandemic scenario: a critical review. Environ. Int. 2022;170 doi: 10.1016/j.envint.2022.107644. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Liang H., Ji Y., Ge W., Wu J., Song N., Yin Z., Chai C. Release kinetics of microplastics from disposable face masks into the aqueous environment. Sci. Total Environ. 2022;816 doi: 10.1016/j.scitotenv.2021.151650. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Limon M.R., Vallente J.P.C., Cajigal A.R.V., Aquino M.U., Aragon J.A., Acosta R.L. Unmasking emerging issues in solid waste management: knowledge and self-reported practices on the discarded disposal masks during the COVID-19 pandemic in the Philippines. Environ. Chall. 2022;6 doi: 10.1016/j.envc.2021.100435. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Liu Z., Nowack B. Probabilistic material flow analysis and emissions modeling for five commodity plastics (PUR, ABS, PA, PC, and PMMA) as macroplastics and microplastics. Resour. Conserv. Recycl. 2022;179 [Google Scholar]

- Ma J., Chen F., Xu H., Jiang H., Liu J., Li P., Chen C.C., Pan K. Face masks as a source of nanoplastics and microplastics in the environment: quantification, characterization, and potential for bioaccumulation. Environ. Pollut. 2021;288 doi: 10.1016/j.envpol.2021.117748. [DOI] [PubMed] [Google Scholar]

- Mueller N.C., Nowack B. Exposure modeling of engineered nanoparticles in the environment. Environ. Sci. Technol. 2008;42:4447–4453. doi: 10.1021/es7029637. [DOI] [PubMed] [Google Scholar]

- National Geography Information Institute The National Atlas of Korea. 2022. http://nationalatlas.ngii.go.kr

- P.J G.V., David D.A., Karuth A., Jafferali J.F.M., P.M S.B., George J.J., Rasulev B., Raghavan P. Experimental and simulation studies on nonwoven polypropylene-nitrile rubber blend: recycling of medical face masks to an engineering product. ACS Omega. 2022;7:4791–4803. doi: 10.1021/acsomega.1c04913. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Pabortsava K., Lampitt R.S. High concentrations of plastic hidden beneath the surface of the Atlantic Ocean. Nat. Commun. 2020;11:4073. doi: 10.1038/s41467-020-17932-9. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Sangkham S. Face mask and medical waste disposal during the novel COVID-19 pandemic in Asia. Case Stud. Chem. Environ. Eng. 2020;2 doi: 10.1016/j.cscee.2020.100052. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Seoul Metropolitan Government Sewer maintenance basic plan 2030. 2019. http://seoul.go.kr

- Shen M., Hu T., Huang W., Song B., Qin M., Yi H., Zeng G., Zhang Y. Can incineration completely eliminate plastic wastes? An investigation of microplastics and heavy metals in the bottom ash and fly ash from an incineration plant. Sci. Total Environ. 2021;779 doi: 10.1016/j.scitotenv.2021.146528. [DOI] [PubMed] [Google Scholar]

- Sieber R., Kawecki D., Nowack B. Dynamic probabilistic material flow analysis of rubber release from tires into the environment. Environ. Pollut. 2020;258 doi: 10.1016/j.envpol.2019.113573. [DOI] [PubMed] [Google Scholar]

- van Straten B., Ligtelijn S., Droog L., Putman E., Dankelman J., Weiland N.H.S., Horeman T. A life cycle assessment of reprocessing face masks during the Covid-19 pandemic. Sci. Rep. 2021;11:17680. doi: 10.1038/s41598-021-97188-5. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Sun J., Yang S., Zhou G.J., Zhang K., Lu Y., Jin Q., Lam P.K.S., Leung K.M.Y., He Y. Release of microplastics from discarded surgical masks and their adverse impacts on the marine copepod Tigriopus japonicas. Environ. Sci. Technol. Lett. 2021;8:1065–1070. [Google Scholar]

- Tabatabaei M., Hosseinzadeh-Bandbafha H., Yang Y., Aghbashlo M., Lam S.S., Montgomery H., Peng W. Exergy intensity and environmental consequences of the medical face masks curtailing the COVID-19 pandemic: malign bodyguard. J. Clean. Prod. 2021;313 doi: 10.1016/j.jclepro.2021.127880. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Türkmen B.A. Life cycle environmental impacts of disposable medical masks. Environ. Sci. Pollut. Res. 2021;29:25496–25506. doi: 10.1007/s11356-021-17430-5. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Yuen J.G., Marshilok A.C., Benziger P.T., Yan S., Cello J., Stackhouse C.A., Kisslinger K., Bock D.C., Takeuchi E.S., Takeuchi K.J., Wang L., Babu S., Itzkowitz G., Thanassi D., Knopf D.A., Shroyer K.R. Dry heat sterilization as a method to recycle N95 respirator masks: the importance of fit. PLoS One. 2022;17 doi: 10.1371/journal.pone.0257963. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Zhang X., Ye P., Wu Y. Enhanced technology for sewage sludge advanced dewatering from an engineering practice perspective: a review. J. Environ. Manag. 2022;321 doi: 10.1016/j.jenvman.2022.115938. [DOI] [PubMed] [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.

Data Availability Statement

Data will be made available on request.