Abstract

Gluten-free bread is an important product that is under development using different sources, such as rice and starchy plants. Teosinte seeds are utilized by ethnic groups in Honduras to produce gluten-free flour to prepare traditional baked goods and beverages. The quality of gluten-free products could vary depending on flour properties, such as amylose content, particle size, and water absorption capacity. A good strategy for developing baked goods is to mix different cereal grain sources to optimize their physicochemical properties. As a result, the current study aimed to develop bread from novel flours including teosinte (TF), high-protein brown rice (BRF), and high-protein white rice (WRF). Breads were analyzed for hardness, specific volume, and color utilizing a Simplex-Centroid mixture design coupled with the desirability function. Pasting, and rheological characteristics of the flours, were also analyzed. For flour characteristics, TF addition to BRF or WRF decreased the peak, trough, breakdown, setback, and final viscosities, which would result in a more stable bread and decrease the flow index of rice flour dispersions. BRF and WRF had similar pasting properties, except that BRF had a lower breakdown viscosity. For bread characteristics, TF addition to BRF or WRF increased the specific volume and hardness of the bread compared to rice flour alone. L* of the crust and crumb a* values were increased with greater TF in the mixture, whereas TF decreased the crust a*and b* values and crumb L* values when mixed with BRF or WRF compared to rice flours alone. WRF and BRF were similar in crumb color (L* and a*), except that BRF had greater crumb yellowness (b*). Teosinte flour can be used in combination with rice flour to produce bread with good quality.

Keywords: teosinte, rice, gluten free, bread, mixture design

1. Introduction

Bread uses the ability of hydrated gluten to build a viscoelastic network [1], which causes gas to be trapped, and thus increases its volume. Additionally, gluten in bread plays a key role in moisture control [2]. It is a high-molecular weight protein found in the endosperm of cereals including wheat, barley, and rye. Additionally, it is a storage protein in a group of flowering plants utilized during the growth and germination process that consists of two types of proteins, i.e., a glutenin and a prolamin (gliadin found in wheat), which can be broken down to produce α, β, and γ peptides [3].

However, gluten in bread can cause problems in a group of consumers. Celiac disease is an autoimmune disorder seen in people who genetically have the potential to develop an immune reaction to gluten. The first place affected by this disease is the small intestine; nevertheless, it has a wide distribution that includes both intestinal and extra-intestinal symptoms [4]. Currently, the most effective and safest treatment for people affected by Celiac disease is to use a gluten-free (GF) diet, which causes an improvement of the small intestinal mucosa [5,6].

Gluten helps by forming a sticky, elastic dough with gas retention, as well as shaping the structure [7]. In the absence of gluten in bread, the ability of the bread to hold carbon dioxide produced by yeast is significantly reduced, which results in bread with a firm texture, as well as low specific volume [8].

Gluten-free bread available in the market is usually obtained by replacing wheat flour with rice flour with or without corn starch. Rice flour is known for its low price and mild taste, as well as antiallergenic properties, which is why it is utilized in these products. The rice flour used to prepare gluten-free bread is mostly from white rice [9]. However, gluten-free bread, which is obtained by using white rice flour, is nutritionally imbalanced due to the removal of the entire bran layer, leaving mainly starch and protein. It is expected that the use of brown rice flour in gluten-free bread will compensate for this deficiency because brown rice has non-starch nutrients including dietary fiber, minerals, and bioactive compounds in its bran layer [10].

Teosinte (Dioon mejiae) as an endemic tree in Honduras is one of the dioecious trees and belongs to the category of minor cereals. Minor cereals occur only in a few parts of the world, that is why their use on a large scale is not common. In addition to Teosinte, other plants including teff, millet (pearl, proso, finger, foxtail, and Kodo), fonio (black and white), jungle rice, and Job’s tears are in this category [11,12,13,14]. Teosinte seeds are locally used in the preparation of flour as well as other traditional foods and drinks. The nutritional value of teosinte seed is high with protein and methionine levels higher than maize. However, no difference was reported in the amino acids, such as lysine, tryptophan, or niacin [15]. In the distant past, regional people used the seeds of this plant after washing and drying to prepare foods such as bread, donuts, tamales, and tortillas. Additionally, a type of starch called sago is obtained from this plant, which is used as a food supplement by the natives of that area [16].

Some studies have been conducted in the field of gluten-free bread production and improvement. Some innovative technologies were proposed to improve quality, replace or imitate the gluten network by using exogenous substances including hydrocolloids, emulsifiers, proteins, and cross-linking enzymes [6,17]. As mentioned previously, among the available approaches for gluten-free bread production is the use of alternative plant sources for wheat. Different types of flour and starch (rice, corn, cassava, soybean, and peanut) have been used to produce gluten-free bread [18,19]. For example, active soybean flour improved the volume and structure of gluten-free bread [19]. Bread made with corn flour and chickpea flour became softer with greater levels of chickpea flour, which was thought to be due to greater protein levels [20]. Other flours are used to increase the nutritional quality of gluten free breads [21].

In this regard, due to the essential need to diversify the diet and for those who have special nutritional requirements, such as celiac patients, it is mandatory to provide an innovative diet. For this purpose, examining the potential of traditional and lesser-known food sources as alternatives and the expansion of their use to produce innovative gluten-free foods that are acceptable to consumers seems promising. Due to the potential for using brown rice flour and teosinte flour in gluten-free foods, and the few studies in this field, this study aims to use these plant resources to develop gluten-free bread.

2. Material and Method

2.1. Experimental Design

Table 1 shows the treatment design for bread production using a Simplex-Centroid Mixture Design (CSMD). The independent variables were the proportions of high-protein brown rice flour (Cahokia), high-protein white rice flour (Cahokia), and teosinte flour, while the dependent variables included specific volume (g/mL), color (L*, b* and a*) and texture (resilience, cohesiveness, hardness, and springiness). The obtained response from each investigated parameter was analyzed using adjusting the cubic model (Y = β1 × 1 + β2 × 2 + β3 × 3 + β12 × 1 × 2 + β13 × 1 × 3 + β23 × 2 × 3 + β123 × 1 × 2 × 3) at p < 0.05 and using regression to determine significant differences in parameters for the level of flour/starch used (dependent variables). The bread formula was optimized using the desirability function methodology (DOM) [22]. The objective of the mixture design is to optimize flour concentrations of high-protein brown rice flour (Cahokia), high-protein white rice flour (Cahokia), and teosinte flour regarding physicochemical characteristics.

Table 1.

Experimental design for bread making with simplex centroid design.

| Treatments | *TF | *BRF | *WRF |

|---|---|---|---|

| ▪ TF alone | 100% | 0% | 0% |

| ▪ BRF alone | 0% | 100% | 0% |

| ▪ WRF alone | 0% | 0% | 100% |

| ▪ TF-BRF | 50% | 50% | 0% |

| ▪ TF-WRF | 50% | 0% | 50% |

| ▪ BRF-WRF | 0% | 50% | 50% |

| ▪ TF-BRF-WRF | 33.337% | 33.337% | 33.337% |

*BRF—High-Protein Brown Rice Flour, *TF—Teosinte Flour, *WRF—High-Protein White Rice.

2.2. Preparing the Bread

The amounts of each ingredient used are shown in Table 2 for gluten-free breads and control breads (the same procedure was used for both type of breads and only the formulation varied). To make the bread, Fleischmann’s activated dry yeast (ACH Food Companies, Inc., Memphis, TN, USA) was mixed with sugar (Great Value, Leander, TX, USA) and distilled water, then rested for 42 h. Subsequently, by using a Globe stand mixer (model SP5 Global Food Equipment, Dayton, OH, USA), the other dry ingredients (Great Value, Leander, TX, USA) were mixed. The mixture was gently stirred for 30 s. Next, in a separate container, room temperature eggs (Great Value, Leander, TX, USA), vegetable oil (Great Value, Leander, TX, USA), and apple cider vinegar (Great Value, Leander, TX, USA) were weighed and added to the dry ingredients and gently mixed for 1 min. Then, the yeast mixture was gradually added and mixed for 7 min. In the production process of gluten-free bread, the consistency is usually similar to batter (instead of dough, which can be kneaded). Vegetable oil was sprayed in a mini loaf pan (15.4 × 8.6 × 4.7 cm) to grease. Next 150 g of standard-loaf batter was weighed in the pan and the surface was smoothed with a spatula. The relative humidity and temperature of a full-size Metro proofing cabinet (C599-SDS-U Intermetro Industries Corporation, Wilkes-Barre, PA, USA) were set to 90% and 100 °F, respectively, then the pan was placed in the cabinet for 30 min. Afterwards the pan was placed in the center of a Baxter mini-rotating rack gas oven (model OV310G) at a temperature of 345 °F and baked for 20 min. At the end of the baking process, the bread was left in the pan for 5 min to cool and then removed from the pan. After an hour of cooling, a sanitized, electric, meat-slicing machine (model S-4 Sanitary Scale Company, Belvidere, IL, USA) was used to prepare slices of 2.5 cm for color and texture analysis.

Table 2.

Percentages of gluten-free bread ingredients.

| Gluten Free Breads | Control Bread | ||

|---|---|---|---|

| Ingredients | Percentage | Ingredient | Percentage |

| Flour * | 17.09% | All purpose flour | 42.32% |

| Tapioca flour | 14.64% | Whole wheat flour | 10.83% |

| Sugar | 3.33% | Sugar | 6.66% |

| Salt | 0.98% | Salt | 1.50% |

| Active dry yeast | 0.88% | Active dry yeast | 1.17% |

| Water | 32.2% | Water | 30.67% |

| Vegetable oil | 1.47% | Vegetable oil | 4.89% |

| Vanilla | 1.96% | Vanilla | 1.96% |

| Cornstarch | 16.11% | ||

| Egg | 9.76% | ||

| Xanthan gum | 0.78% | ||

| Baking powder | 0.49% | ||

| Apple cider vinegar | 0.29% | ||

* Treatments varied only by mixture design treatments illustrated in Table 1. Control bread = wheat bread.

2.3. Flour Rheological and Pasting Properties

The pasting properties of the flours were evaluated based on the AACC method 61.02.01 [23] by using a Rapid Visco Analyzer (RVA) (RVA-4, Newport Scientific Pty. Ltd., Warriewood, Australia). Rheological properties were evaluated with a rheometer (AR 2000ex, TA Instruments, New Castle, DE, USA) by parallel disc geometry and 40 mm dimensions with a gap of 3 mm. Dispersions of 5% w/w were stirred at medium speed for 15 min and heated for 30 min. Instantly, hot paste (1 mL) was placed in the rheometer. When the sample temperature reached 25 °C, rheological analysis was performed with two types of evaluation (steady shear flow as well frequency sweep) using the method from Ye et al. [24] with slight modifications.

2.4. Bread Physical Features

The specific volume of bread (mL/g) was measured according to the AACC method 10-05 [25] with rapeseed. The texture of the sample was analyzed with a texture analyzer (Texture Technologies Corporation, T.A. XT plus, Scarsdale, NY, USA) based on the AACC method 74-09 (2000) using a two-inch cylinder probe. The bread was cut into to 2.5 cm width slices to examine the bread’s firmness. The parameters were set to a 40% compression at a rate of 1.7 mm/s. With colorimeter equipment (Konica Minolta BC-10 Baking Contrast Meter, Wayne, NJ, USA), L* (brightness/darkness), a* (redness/greenness), and b* (yellow/bluish) samples were analyzed in triplicate.

2.5. Statistical Analysis

For the simplex-centroid design, generation of the corresponding response surfaces and coefficients of the special cubic model was performed in the Minitab 17 program (2014, Minitab LLC, State College, PA, USA) to check the characteristics of bread. One-way analysis of variance (ANOVA) and Tukey’s post-hoc test were conducted.

3. Results and Discussion

3.1. Bread Characteristics

Prepared bread samples are shown in Figure 1 compared to control wheat flour bread.

Figure 1.

Appearance of central slices of breads crumbs. (T1 = TF = Teosinte Flour, T2 = BRF = High-Protein Brown Rice, T3 = WRF = High-Protein White Rice Flour, T4 = TRF-BRF = Teosinte Flour with High-Protein Brown Rice, T5 = TF-WRF = Teosinte Flour with High-Protein White Rice Flour, T6 = BRF-WRF = High-Protein White Rice Flour with High-Protein Brown Rice Flour, T7 = TF-BRF-WRF = Teosinte Flour with High-Protein White Rice Flour and with High-Protein Brown Rice Flour) Control (T8) = bread made with wheat flour.

Figure 2A shows that the bread sample prepared with a combination of TF*BRF presented a greater specific volume compared to BRF and TF individually. Kadan et al. [26] found that rice bread had a lower specific volume than wheat bread; in our study the addition of TF to BRF resulted in a greater specific volume. According to Bastias-Montes et al. [11], protein and total starch contents were 9.67 ± 0.08% and 67.90 ± 0.68% in teosinte flour, and Aleman et al. [27] found that high-protein brown rice flour had 12.2 ± 0.14% protein and 65.4 ± 0.5% starch, while high-protein white rice flour had 10.23 ± 0.26% protein and 75.15 ± 0.20% starch [28]. The specific volume is directly related to water absorption of the network, which affects bread quality, and bread with greater starch content tended to have a greater specific volume [29]. Our study does not show this, as bread with a greater protein, TF*BRF, had a greater specific volume, which could be due to the protein also binding to the water and stabilizing the starch gel [30]. Additionally, the mixture which contained equal percentages of TF, BRF, and WRF showed a lower specific volume similar to bread with WRF or BRF alone. Furthermore, TF alone had the greatest hardness (Figure 2B) compared to other treatments, and Table 3 coefficients indicated that TF had a greater positive effect on the hardness than other flours, which might be due its lower protein content which leads to less water binding and decreased the loaf specific volume [30]. Greater hardness is associated with a lower specific volume, as less water binding could lead to a dryer firmer product with less stable air pockets. WRF alone and BRF alone had the lowest hardness with WRF being lower than BRF. Paz et al. [31] found a similar result for hardness between brown and white rice flour breads.

Figure 2.

Contour plot of the breads (A) Specific Volume, (B) Hardness, (C) L* Crust, (D) a* Crust, (E) b* Crust, (F) L* Crumb, (G) a* Crumb, and (H) b* Crumb with *BRF—High-Protein Brown Rice Flour, *TF—Teosinte Flour, and *WRF—High-Protein White Rice.

Crust lightness (L*) was lowest for TF*WRF bread, while TF*WRF*BRF bread had a greater lightness compared to bread made from BRF*TF and BRF*WRF (Figure 2C). Crust redness was the lowest in 100% TF bread (Figure 2D). Bread with TF*WRF and TF*BRF had lower a* compared to BRF*WRF. In another study, the addition of kale to bread decreased a* value due to the addition of the green color [32]. WRF increased the redness in bread which was made from a blend of WRF and BRF. The crust yellowness pattern (Figure 2E) was the same as the redness pattern which means WRF resulted in a greater yellowness in WRF alone, BRF-WRF, and TF-BRF-WRF. TF resulted in a lower yellowness in bread crust for TF alone and TF-WRF.

The crumb color pattern was different from the crust pattern. The lightness of the bread crumb (Figure 2F) was lowest with the use of TF alone, which might be due to the natural, brownish pigments in the seeds [33]. WRF was responsible for lightness in WRF alone, TF-WRF, and BRF-WRF. TF alone had the highest a*, and T3 had the lowest redness (Figure 2G) among breadcrumbs. According to Figure 2H, WRF tended to decrease yellowness (b*) in TF-WRF and BRF-WRF. BRF breadcrumb had the greatest yellowness compared to other treatments, which may be due to the presence of yellow pigments [34].

3.2. Flour Pasting and Rheological Properties

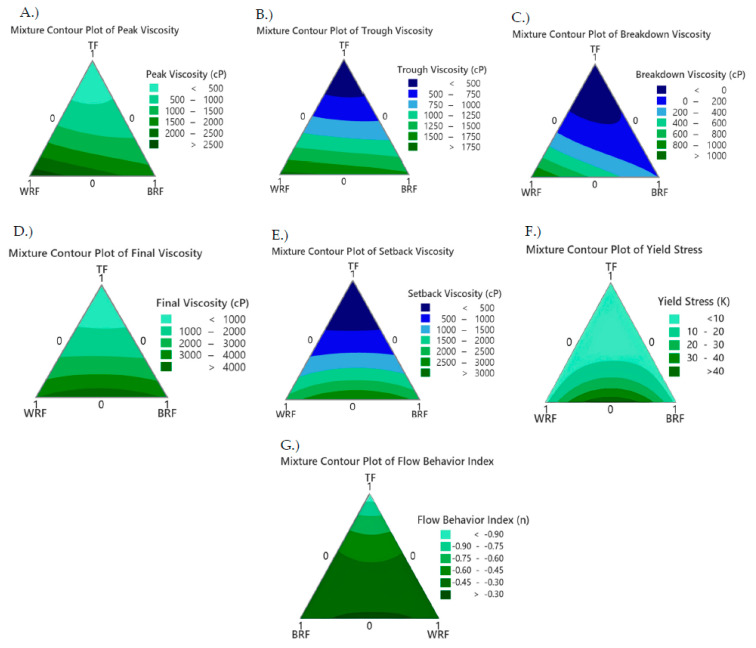

Figure 3 shows peak, trough, breakdown, final, and setback viscosities, as well as yield stress, and flow behavior index with coefficients shown in Table 3. Figure 3A shows that TF alone had the lowest peak viscosity with the lowest coefficient (275) (Table 3) among the flours, while the addition of WRF to the bread blend increased the peak viscosity with a greater coefficient (1739.7), meaning a greater positive effect on peak viscosity (Table 3) than TF. The lower peak viscosity (Figure 3A) of TF resulted in the lowest breakdown viscosity (Figure 3C) coefficient (6.7) (Table 3), and greater past stability compared to BRF and WRF. BRF and WRF showed a greater positive influence on peak, trough final and setback viscosities with greater coefficients than TF (Table 3). Combinations of TF combined with BRF or WRF caused a negative influence resulting in lower pasting viscosities. Other model coefficients did not differ greatly among the individual flours (Table 3). Greater setback viscosity (Figure 2E) in BRF-WRF is associated with a greater retrogradation potential of the starch granules after cooking, which means it might cause a firmer product over time. However, there is no significant correlation between viscosity and starch concentration or distribution of the granules [35].

Figure 3.

Contour plot of the flour dispersions (A) Peak Viscosity, (B) Trough Viscosity, (C) Breakdown Viscosity, (D) Final Viscosity, (E) Setback Viscosity, (F) Yield Stress, and (G) Flow Behavior Index with *BRF—High-Protein Brown Rice Flour, *TF—Teosinte Flour, and *WRF—High-Protein White Rice.

The combination of the WRF and BRF increased the yield stress and flow behavior index and TF had the lowest yield stress and flow behavior index (Figure 3F,G). According to the current study, all flow behavior indices were less than 1.0, indicating that all pastes exhibited pseudoplastic and shear-thinning behavior. WRF and BRF showed results closest to n = 1, which corresponds to a Newtonian fluid [36].

The complex viscosity (Figure 4A) decreases with increasing frequencies representing a shear-thinning flow behavior. The shear stress as a function of the shear rate is indicated in Figure 4B. which shows all treatments had non-Newtonian behavior due to the increase of the shear stress with the shear rate-like [37] pseudoplastic behavior. BRF-WRF had high-shear stress compared to other treatments. The pasting behavior of treatments is exhibited in Figure 4C, and various parameters were measured like peak, trough, breakdown, final, and setback viscosity. The shape of the pasting curve is different for different flour treatments and significant differences can be observed among GF flours, confirming the contour plot illustrations (Figure 3). The pasting curves of WRF alone had the highest value at peak viscosity and WRF-BRF had the highest final viscosity. The pasting process is the absorption of water by starch granules and granules lose their crystalline structure after swelling properly. According to the steady peak of TF for pasting over time and the heating process, amylose double helices were not melted in the cooking process, granules resisted swelling [38], and granules had a lower rate of water absorption and swelling compared to other samples [39]. According to Table 3, a greater influence was observed for BRF on peak viscosity, as well as a trough, breakdown, and final viscosity, than other single flour samples, while TF had a negative effect on these parameters when mixed with BRF. A higher protein could lead to lower peak viscosity, affecting peak time, trough, and breakdown viscosities by lowering the water-holding capacity of the starch during gelatinization [40]. Peak viscosity, trough viscosity, and breakdown viscosity for WRF were greater than BRF, which may be due to the greater starch content in WRF, 75.15 ± 0.20% vs. 65.4 ± 0.5% for BRF [37].

Figure 4.

(A) steady shear flow measurements, (B) frequency sweep analysis, and (C) Viscosity profiles of flour dispersions (TF = Teosinte Flour, BR = High-Protein Brown Rice, WF = High-Protein White Rice Flour, TF-BF = Teosinte Flour with High-Protein Brown Rice, TF-WF = Teosinte Flour with High-Protein White Rice Flour, BF-WF = High-Protein White Rice Flour with High-Protein Brown Rice Flour, TF-BF-WR = Teosinte Flour with High-Protein White Rice Flour and with High-Protein Brown Rice Flour).

Table 3.

Coefficients for the cubic model for bread and flours characteristics.

| Response | TF | BRF | WRF | TF-BRF | TF-WRF | BRF-WRF | TF-BRF-WRF | R 2 |

|---|---|---|---|---|---|---|---|---|

| Specific Volume (mL/g) | 0.01 | 0.01 | 0.01 | >0.01 | >0.01 | >0.01 | >0.01 | 87.0% |

| Hardness (N) | 14.9 | 10.5 | 9.68 | −0.03 | 0.01 | 0.03 | −0.03 | 92.8% |

| L* (Crust) | 0.74 | 0.73 | 0.72 | >−0.01 | >−0.01 | >−0.01 | >0.01 | 80.9% |

| a∗ (Crust) | 0.06 | 0.08 | 0.10 | 0.01 | >−0.01 | >0.01 | >0.01 | 95.6% |

| b∗ (Crust) | 0.20 | 0.22 | 0.24 | >0.01 | >−0.01 | >0.01 | >0.01 | 87.7% |

| L* (Crumb) | 0.69 | 0.77 | 0.79 | >−0.01 | >−0.01 | >−0.01 | >−0.01 | 92.7% |

| a* (Crumb) | 0.03 | >0.01 | >−0.01 | >0.01 | >0.01 | >−0.01 | >−0.01 | 99.4% |

| b* (Crumb) | 0.14 | 0.15 | 0.12 | >−0.01 | >−0.01 | >−0.01 | >−0.01 | 75.5% |

| Peak Viscosity (cP) | 275 | 2848.3 | 1739.7 | −2909 | −1164 | −29 | −2533 | 99.2% |

| Trough Viscosity (cP) | 268.3 | 1811.7 | 1541.3 | −1128 | −814 | 181 | −1253 | 98.6% |

| Breakdown Viscosity (cP) | 6.7 | 1036.7 | 198.3 | −1781.3 | −350 | −210 | −1280 | 99.6% |

| Final Viscosity (cP) | 324 | 3969 | 3854 | −2883 | −2805 | 3370 | −7483 | 98.1% |

| Setback Viscosity (cP) | 56 | 2158 | 2312 | −1755 | −1991 | 3189 | −6230 | 97.7% |

| Flow behavior index (n) | 0.85 | 0.31 | 0.44 | 1.31 | 1.27 | 0.41 | 1.12 | 95.8% |

| Yield Stress (K) | 5.72 | 7.19 | 6.83 | −2.92 | 3.65 | 166.90 | −367 | 97.4% |

(p > 0.05) of the independent variables of the cubic model adjusted for cupcake characteristics (TF = Teosinte Flour, BRF = High-Protein Brown Rice, WRF = High-Protein White Rice Flour, TF-BRF = Teosinte Flour with High-Protein Brown Rice, TF-WRF = Teosinte Flour with High-Protein White Rice Flour, BRF-WRF = High-Protein White Rice Flour with High-Protein Brown Rice Flour, TF-BRF-WRF = Teosinte Flour with High-Protein White Rice Flour and with High-Protein Brown Rice Flour).

4. Conclusions

This research examined the development of gluten-free bread by using TF, BRF, and WRF to observe the effects of the different sources on bread properties. Lower pasting properties, such as breakdown and setback viscosity, indicated that TF samples would be more stable. In bread, TF had negative effects on specific volume, texture, and color of breads, resulting in a greater hardness and greater crumb darkness, but these issues can be mitigated by using a combination of brown rice flour or white rice flour with teosinte flour to make the breads.

Author Contributions

R.S.A.: Conceptualization, data analysis and interpretation, writing; F.D.R.: conceptualization, performed most of the research work, M.S.M.; A.M.: data collection; S.K.P.: writing; Y.M.: formulated controls; W.P.: development and design of the experiments; J.M.K.: development and design of the experiments, supervision, project administration, writing and resource/funding acquisition, J.M.F.: supervision, project administration and resource/funding acquisition. All authors have read and agreed to the published version of the manuscript.

Data Availability Statement

Data is contained within the article.

Conflicts of Interest

The authors declare no conflict of interest.

Funding Statement

This work was supported by the Hatch fund at Universidad National de Agriculture (UNAG) with registration # AL-UNAG-028-2020. This work was also supported by the USDA National Institute of Food and Agriculture, Hatch project LAB94466.

Footnotes

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content.

References

- 1.Cappelli A., Cini E., Guerrini L., Masella P., Angeloni G., Parenti A. Predictive models of the rheological properties and optimal water content in doughs: An application to ancient grain flours with different degrees of refining. J. Cereal Sci. 2018;83:229–235. doi: 10.1016/j.jcs.2018.09.006. [DOI] [Google Scholar]

- 2.Ren Y., Linter B.R., Linforth R., Foster T.J. A comprehensive investigation of gluten free bread dough rheology, proving and baking performance and bread qualities by response surface design and principal component analysis. Food Funct. 2020;11:5333–5345. doi: 10.1039/D0FO00115E. [DOI] [PubMed] [Google Scholar]

- 3.Rej A., Aziz I., Sanders D.S. Breaking bread! Proc. Nutr. Soc. 2019;78:118–125. doi: 10.1017/S0029665118002549. [DOI] [PubMed] [Google Scholar]

- 4.Lebwohl B., Sanders D.S., Green P.H.R. Coeliac disease. Lancet. 2018;391:70–81. doi: 10.1016/S0140-6736(17)31796-8. [DOI] [PubMed] [Google Scholar]

- 5.Bender D., Schönlechner R. Innovative approaches towards improved gluten-free bread properties. J. Cereal Sci. 2020;91:102904. doi: 10.1016/j.jcs.2019.102904. [DOI] [Google Scholar]

- 6.Capriles V.D., Arêas J.A.G. Novel Approaches in Gluten-Free Breadmaking: Interface between Food Science, Nutrition, and Health. Compr. Rev. Food Sci. Food Saf. 2014;13:871–890. doi: 10.1111/1541-4337.12091. [DOI] [Google Scholar]

- 7.de la Hera E., Martinez M., Gómez M. Influence of flour particle size on quality of gluten-free rice bread. LWT—Food Sci. Technol. 2013;54:199–206. doi: 10.1016/j.lwt.2013.04.019. [DOI] [Google Scholar]

- 8.Skendi A., Mouselemidou P., Papageorgiou M., Papastergiadis E. Effect of acorn meal-water combinations on technological properties and fine structure of gluten-free bread. Food Chem. 2018;253:119–126. doi: 10.1016/j.foodchem.2018.01.144. [DOI] [PubMed] [Google Scholar]

- 9.Roman L., Belorio M., Gomez M. Gluten-Free Breads: The Gap Between Research and Commercial Reality. Compr. Rev. Food Sci. Food Saf. 2019;18:690–702. doi: 10.1111/1541-4337.12437. [DOI] [PubMed] [Google Scholar]

- 10.Wu J., McClements D.J., Chen J., Hu X., Liu C. Improvement in nutritional attributes of rice using superheated steam processing. J. Funct. Foods. 2016;24:338–350. doi: 10.1016/j.jff.2016.04.019. [DOI] [Google Scholar]

- 11.Bastias-Montes J.M., Flores-Varela L.E., Reyes-Calderón O.A., Vidal-San-Martín C., Muñoz-Fariña O., Quevedo-León R., Acuña-Nelson S.M. Teosinte (Dioon mejiae) flour: Nutritional and physicochemical characterization of the seed flour of the living fossil in honduras. Agronomy. 2020;10:481. doi: 10.3390/agronomy10040481. [DOI] [Google Scholar]

- 12.Comino I., de Lourdes Moreno M., Real A., Rodríguez-Herrera A., Barro F., Sousa C. The Gluten-Free Diet: Testing Alternative Cereals Tolerated by Celiac Patients. Nutrients. 2013;5:4250–4268. doi: 10.3390/nu5104250. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 13.Hozyasz K.K. Letter to the Editor Re: Comino, I.; et al. Nutrients 2013, 5, 4250–4268. Nutrients. 2013;5:4964–4965. doi: 10.3390/nu5124964. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 14.Saturni L., Ferretti G., Bacchetti T. The Gluten-Free Diet: Safety and Nutritional Quality. Nutrients. 2010;2:16–34. doi: 10.3390/nu2010016. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 15.Amador M., Montilla I.M.C., Martín C.S. Alternative grains as potential raw material for gluten—Free food development in the diet of celiac and gluten—Sensitive patients. Austin J. Nutr. Metab. 2014;2:1–9. [Google Scholar]

- 16.Bonta M., Pinot O., Graham D., Haynes J., Sandoval G. Ethnobotany and conservation of tiusinte (Dioon mejiae Standl. & LO Williams, Zamiaceae) in northeastern Honduras. J. Ethnobiol. 2006;26:228–257. [Google Scholar]

- 17.Han A., Romero H.M., Nishijima N., Ichimura T., Handa A., Xu C., Zhang Y. Effect of egg white solids on the rheological properties and bread making performance of gluten-free batter. Food Hydrocoll. 2019;87:287–296. doi: 10.1016/j.foodhyd.2018.08.022. [DOI] [Google Scholar]

- 18.Gujral H.S., Guardiola I., Carbonell J.V., Rosell C.M. Effect of cyclodextrinase on dough rheology and bread quality from rice flour. J. Agric. Food Chem. 2003;51:3814–3818. doi: 10.1021/jf034112w. [DOI] [PubMed] [Google Scholar]

- 19.Ribotta P.D., Ausar S.F., Morcillo M.H., Pérez G.T., Beltramo D.M., León A.E. Production of gluten-free bread using soybean flour. J. Sci. Food Agric. 2004;84:1969–1974. doi: 10.1002/jsfa.1915. [DOI] [Google Scholar]

- 20.Rostamian M., Milani J.M., Maleki G. Physical properties of gluten-free bread made of corn and chickpea flour. Int. J. Food Eng. 2014;10:467–472. doi: 10.1515/ijfe-2013-0004. [DOI] [Google Scholar]

- 21.Smidova Z., Rysova J. Gluten-free bread and bakery products technology. Foods. 2022;11:480. doi: 10.3390/foods11030480. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 22.Amdoun R., Khelifi L., Khelifi-Slaoui M., Amroune S., Asch M., Assaf-ducrocq C., Gontier E. The Desirability Optimization Methodology; a Tool to Predict Two Antagonist Responses in Biotechnological Systems: Case of Biomass Growth and Hyoscyamine Content in Elicited Datura starmonium Hairy Roots. Iran. J. Biotechnol. 2018;16:11–19. doi: 10.21859/ijb.1339. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 23.AACC . Approved Methods of the AACC: Method 61.02.01 (Pasting Properties) 11th ed. American Association of Cereal Chemists; St. Paul, MN, USA: 2012. [Google Scholar]

- 24.Ye J., Wang J., Zhu Y., Wei Q., Wang X., Yang J., Tang S., Liu H., Fan J., Zhang F., et al. A thermoresponsive polydiolcitrate-gelatin scaffold and delivery system mediates effective bone formation from BMP9-transduced mesenchymal stem cells. Biomed. Mater. 2016;11:025021. doi: 10.1088/1748-6041/11/2/025021. [DOI] [PubMed] [Google Scholar]

- 25.AACC . Approved Methods of the AACC. 10th ed. American Association of Cereal Chemists; St. Paul, MN, USA: 2000. Methods of 10-05, 10-91, 44-15, and 74-09. [Google Scholar]

- 26.Kadan R.S., Robinson M.G., Thibodeaux D.P., Pepperman A.B. Texture and other physicochemical properties of whole rice bread. J. Food Sci. 2001;66:940–944. doi: 10.1111/j.1365-2621.2001.tb08216.x. [DOI] [Google Scholar]

- 27.Aleman R.S., Paz G., Prinyawiwatkul W., Moncada M., King J.M. Comparison of the Thermal and Rheological Properties of Frontière Brown Rice Flour, Tapioca Starch, and Potato Starch and Mixture Effects on Pasting Properties in Aqueous Systems. Starch-Stärke. 2023:2200196. doi: 10.1002/star.202200196. [DOI] [Google Scholar]

- 28.Aleman R.S., Paz G., Morris A., Prinyawiwatkul W., Moncada M., King J.M. High protein brown rice flour, tapioca starch & potato starch in the development of gluten-free cupcakes. LWT. 2021;152:112326. doi: 10.1016/J.LWT.2021.112326. [DOI] [Google Scholar]

- 29.Monteiro J.S., Farage P., Zandonadi R.P., Botelho R.B.A., de Oliveira L.D.L., Raposo A., Shakeel F., Alshehri S., Mahdi W.A., Araújo W.M.C. A systematic review on gluten-free bread formulations using specific volume as a quality indicator. Foods. 2021;10:614. doi: 10.3390/foods10030614. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 30.Ziobro R., Juszczak L., Witczak M., Korus J. Non-gluten proteins as structure forming agents in gluten free bread. J. Food Sci. Technol. 2016;53:571–580. doi: 10.1007/s13197-015-2043-5. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 31.Paz G.M., King J.M., Prinyawiwatkul W. High Protein Rice Flour in the Development of Gluten-Free Bread. J. Culin. Sci. Technol. 2021;19:315–330. doi: 10.1080/15428052.2020.1768994. [DOI] [Google Scholar]

- 32.Korus A., Witczak M., Korus J., Juszczak L. Dough Rheological Properties and Characteristics of Wheat Bread with the Addition of Lyophilized Kale (Brassica oleracea L. var. sabellica) Powder. Appl. Sci. 2022;13:29. doi: 10.3390/app13010029. [DOI] [Google Scholar]

- 33.Sanjyal S., Hampton J.G., Rolston P., Marahatta S. Teosinte (Euchlaena mexicana L.) Seed Production: Effect of Sowing Date, Seed Rate and Cutting Management on Seed Yield. Agronomy. 2022;12:1646. doi: 10.3390/agronomy12071646. [DOI] [Google Scholar]

- 34.Lamberts L., Delcour J.A. Carotenoids in raw and parboiled brown and milled rice. J. Agric. Food Chem. 2008;56:11914–11919. doi: 10.1021/jf802613c. [DOI] [PubMed] [Google Scholar]

- 35.Leon E., Piston F., Aouni R., Shewry P.R., Rosell C.M., Martin A., Barro F. Pasting properties of transgenic lines of a commercial bread wheat expressing combinations of HMW glutenin subunit genes. J. Cereal Sci. 2010;51:344–349. doi: 10.1016/j.jcs.2010.02.002. [DOI] [Google Scholar]

- 36.Zhou D.N., Zhang B., Chen B., Chen H.Q. Effects of oligosaccharides on pasting, thermal and rheological properties of sweet potato starch. Food Chem. 2017;230:516–523. doi: 10.1016/j.foodchem.2017.03.088. [DOI] [PubMed] [Google Scholar]

- 37.Aleman R.S., Morris A., Prinyawiwatkul W., Moncada M., King J.M. Physicochemical properties of Frontière rice flour and its application in a gluten-free cupcake. Cereal Chem. 2022;99:303–315. doi: 10.1002/cche.10484. [DOI] [Google Scholar]

- 38.Singh Sandhu K., Singh N., Lim S.T. A comparison of native and acid thinned normal and waxy corn starches: Physicochemical, thermal, morphological and pasting properties. LWT. 2007;40:1527–1536. doi: 10.1016/j.lwt.2006.12.012. [DOI] [Google Scholar]

- 39.Ragaee S., Abdel-Aal E.S.M. Pasting properties of starch and protein in selected cereals and quality of their food products. Food Chem. 2006;95:9–18. doi: 10.1016/j.foodchem.2004.12.012. [DOI] [Google Scholar]

- 40.Ohizua E.R., Adeola A.A., Idowu M.A., Sobukola O.P., Afolabi T.A., Ishola R.O., Ayansina S.O., Oyekale T.O., Falomo A. Nutrient composition, functional, and pasting properties of unripe cooking banana, pigeon pea, and sweetpotato flour blends. Food Sci. Nutr. 2017;5:750–762. doi: 10.1002/fsn3.455. [DOI] [PMC free article] [PubMed] [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.

Data Availability Statement

Data is contained within the article.