Abstract

Sour meat is a highly appreciated traditional fermented product, mainly from the Guizhou, Yunnan, and Hunan provinces. The flavor profiles of sour meat from goose and pork were evaluated using gas chromatography–ion mobility spectrometry (GC–IMS) combined with an electronic nose (E-nose) and tongue (E-tongue). A total of 94 volatile compounds were characterized in fermented sour meat from both pork and goose using GC–IMS. A data-mining protocol based on univariate and multivariate analyses revealed that the source of the raw meat plays a crucial role in the formation of flavor compounds during the fermentation process. In detail, sour meat from pork contained higher levels of hexyl acetate, sotolon, heptyl acetate, butyl propanoate, hexanal, and 2-acetylpyrrole than sour goose meat. In parallel, sour meat from goose showed higher levels of 4-methyl-3-penten-2-one, n-butyl lactate, 2-butanol, (E)-2-nonenal, and decalin than sour pork. In terms of the odor and taste response values obtained by the E-nose and E-tongue, a robust principal component model (RPCA) could effectively differentiate sour meat from the two sources. The present work could provide references to investigate the flavor profiles of traditional sour meat products fermented from different raw meats and offer opportunities for a rapid identification method based on flavor profiles.

Keywords: fermented meat, volatile compounds, GC–IMS, intelligent sensory, chemometrics

1. Introduction

Sour meat is a traditional fermented product, mainly from the Guizhou, Yunnan, and Hunan provinces, where it is known as Nanx Wudl [1]. Its manufacture is usually carried out at an artisanal level based on non-standardized production protocols, where salt, rice, and seasonings, such as Chinese prickly ash and chili, are added to the meat. Fermentation is mainly carried out by taking advantage of naturally occurring lactic acid bacteria (LAB) and requires approximately 1–2 months under anaerobic conditions [2]. The meat most often used is pork, but others may be employed, such as the more expensive goose, which plays a special role from the consumer’s perspective because of its strong associations with the traditions of local Chinese communities [3]. From this point of view, it is worth noting that China accounts for as much as 70% of all the goose meat produced and consumed in the world [4].

Independent of the meat source in these fermented products, sour meat has attracted increasing attention outside the typical production areas— mainly due to its unique sensorial characteristics, but also due to its positive compositional traits, such as the richness in probiotics or the absence of nitrites. This brought about an increasing number of scientific works investigating various aspects of its production and characteristics. For instance, Lv et al. investigated the effect of fermentation temperature on the quality, bacterial community, and metabolites of sour meat. Their results showed that reduction in pH, thiobarbituric acid reactive substances (TBARS), and water content and an increase in lactic acid, free amino acids, and the number and amount of volatile compounds occurred as the fermentation temperature and time increased [5,6]. Lv et al. found that sour meat samples inoculated with S. cerevisiae LXPSC1 had better sensory characteristics than their naturally fermented counterparts, together with higher levels of pH, ethanol, free amino acids, and volatile organic compounds [7]. Zhang et al. found that the double-starter culture (Lactobacillus curvatus LAB26 and Pediococcus pentosaceus SWU73571) increased the L* and a* values, amino nitrogen content, and free amino acid content of sour meat significantly while also lowering the b* value; lowering the levels of nitrite, biogenic amines, total volatile basic nitrogen, and malondialdehyde; and restraining the coliform count [8]. Wang et al. found that low-salt fermentation can accelerate sourmeat maturation and facilitate the oxidation and decomposition of protein and fat and that it is more conducive to sour meat fermentation and to distinct fermented flavor production [9].

The main sensory characteristic that has been found to drive consumer preference and acceptance of fermented meat products is flavor [10]. Gas chromatography coupled with mass spectrometry (GC–MS) is considered the technique of choice for the qualitative and quantitative detection of volatile compounds in foods. In recent years, gas chromatography–ion mobility spectrometry (GC–IMS) has been increasingly used for flavor characterization in the food industry, because it can effectively distinguish the differences in flavor between products [11]. GC–IMS is an analytical technique that uses the difference in the migration rate of gas-phase ions in an electric field to characterize chemical substances [12]. It combines the excellent separation capacity of GC with the high sensitivity and fast response of IMS, granting a high accuracy of analysis [13]. To have a comprehensive view of the sensory characteristics of a food, it is ideal to couple this technique with an electronic nose and tongue. These devices are designed to mimic human olfactory and gustatory perception, respectively, without subjective judgements. They consist of a series of sensors designed to gain an overall fingerprint of the molecular profiles that give rise to complex odors and flavors [14]. Their application offers numerous advantages, among them rapidity of response, ease of use, reliability, and accuracy [15].

Despite the importance of aroma in determining consumer preferences for fermented meat foods and the potential of the E-nose, E-tongue, and GC–IMS for the purpose, few studies have evaluated their combination in this area. Moreover, most of the studies have considered products specifically manufactured at a laboratory scale or obtained at the retail level, which were industrially produced [16,17]. Finally, to the best of our knowledge, no studies have investigated the effects of different meat sources on the final product’s flavor profile, even though it has been demonstrated that the action of fermenting microorganisms (particularly LAB), which leads to the final flavor profile, is deeply influenced by the starting raw material [18,19].

To fill these numerous gaps, we attempted, for the first time, to discriminate traditional sour meat based on goose and pork by means of an E-nose and E-tongue, and to obtain their flavor features through a metabolomics approach based on GC–IMS. This work could provide a framework for investigating the flavor profiles of traditional sour meats fermented from pork and goose through GC–IMS and could offer opportunities for a rapid identification method based on overall flavor characteristics by means of an E-nose and E-tongue.

2. Materials and Methods

2.1. Experimental Design

In accordance with the traditional artisanal procedure for producing sour meat (Nanx Wudl) in the Yunnan province, fresh pork (Large White breed) and goose meat (Chinese Goose breed) were cut into small pieces (around 3 cm × 5 cm × 0.6 cm and 200 g each), and then mixed with 3% salt and pickled in a refrigerator at 4 °C for 24 h. Next, 1% pepper was added, along with 7% glutinous rice, fried to golden yellow and ground into coarse-grained, and 1% glutinous rice, fried to golden yellow and steamed. Finally, the ingredients were placed in ten sealed containers (five for pork and five for goose) and spontaneously fermented at room temperature (approximately 15 °C) for 60 days.

2.2. Electronic Nose Analysis

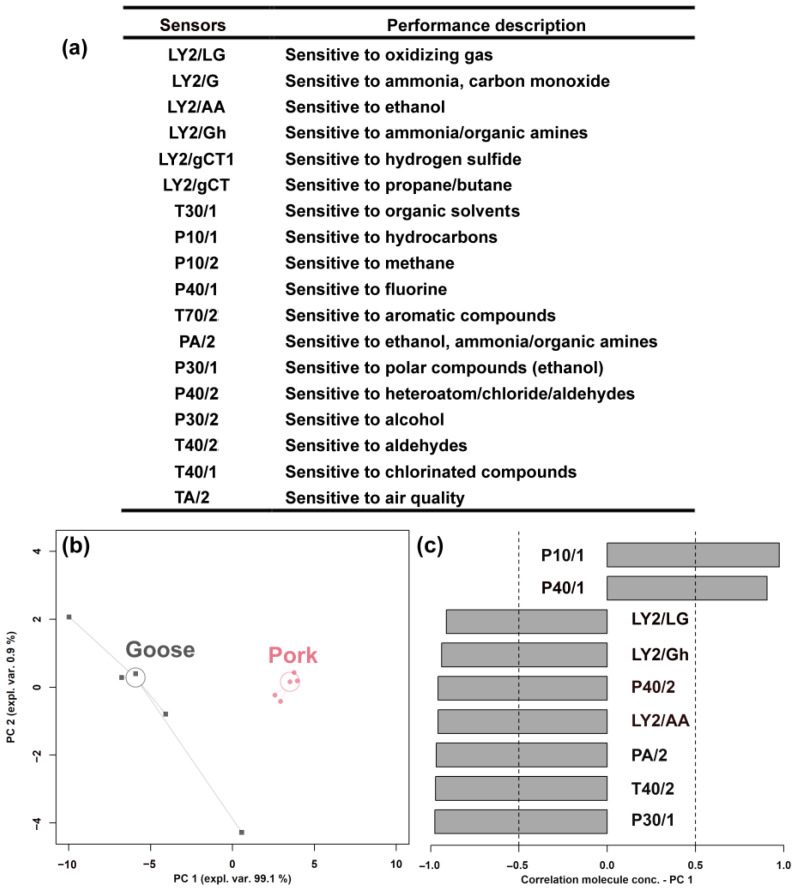

A commercial E-nose (FOX 4000, Alpha MOS, Toulouse, France), equipped with an injection system, 18 sensor chambers, a mass flow controller, and an acquisition board with a microcontroller, was used to discriminate different sour meat samples. The main pieces of information granted by each sensor are shown in Figure 1. In order to fulfill the requirement of E-nose analysis, 0.25 g of sour meat samples was put into a 10 mL headspace bottle, and then the samples were incubated at 70 °C for 5 min and manually injected. The measurement and rinsing phases took 120 s and 240 s, respectively. The observation of each sample was repeated five times, and three stable sets of data were retained. The average value for each sample was included in an RPCA plot.

Figure 1.

Performance description of the E-nose sensors (a); an RPCA model based on the E-nose response data, presented as a score plot (b); and a Pearson correlation plot of the loadings (c).

2.3. Electronic Tongue Analysis

E-tongue analysis was performed by the α-ASTREE (equipped with sixteen autosampler carousel positions, Alpha MOS, Toulouse, France), which provided seven sensors for sourness (AHS), saltiness (CTS), umami (NMS), sweetness (ANS), bitterness (SCS), and two reference electrodes (PKS and CPS) [20,21,22]. Sour meat samples (20.0 g) were mixed with 200 mL of deionized water to extract the taste substances. After the mixed solution was centrifuged 2265× g for 10 min at 4 °C, the water phase (100 mL) was obtained for E-tongue analysis. Each collection time was set to 120 s. The stirring rate was set to 60 rpm, and the cleaning time was 30 s. Deionized water was used as a cleaning solution. The average value measured between 100 and 120 s was taken as the output value. Following the suggestion of Li et al. [20], each sample was repeated eight times, and the data of the last 5 stable sets were selected as the original data for analysis. The average value for each sample was included in an RPCA plot.

2.4. GC–IMS Analysis

The volatile compounds in the sour meat samples were analyzed using GC–IMS (Flavorspec, G.A.S. Instrument, Munich, Germany) with an MXT-WAX capillary column (30 m × 0.53 mm × 1 μm) (Restek, Mount Ayr, USA). Without any sample pre-treatment, 0.25 g of meat samples was accurately weighed and put into a 20 mL headspace (HS) vial with a magnetic screw seal cover. Then, the samples were incubated at 50 °C for 10 min. After incubation, 100 μL of the headspace sample was automatically injected into the injector (splitless mode) via a heated syringe at 65 °C. The column was kept at 60 °C, with the drift tube temperature at 45 °C. The drift gas flow was set to a constant flow rate of 150 mL/min. Nitrogen carrier gas (99.999% purity) was used, and the GC column flow rate was programmed as follows: 2 mL/min for 5 min, 10 mL/min for 10 min, 15 mL/min for 5 min, 50 mL/min for 10 min, and 100 mL/min for 10 min. Following the suggestions of previous papers [23,24], the retention index (RI) of volatile compounds was calculated using n-ketones C4–C9 as external references. Volatile compounds were identified by comparing their RI and ions’ drift time— that is, their migration time from the ionization source to the detector in the IMS chamber— with those of the standards in the GC–IMS library. In accordance with Guo et al. [25], the relevant calculation formula is as follows:

RT(x): The retention time of the substance/min;

RT(n): The retention time of the n-ketones/min;

n: The number of carbon atoms in the n-ketones;

x: target to be carried out via qualitative and quantitative analysis;

x − 1: The component peaking before target x;

x + 1: The component peaking after target x.

Each sample was detected once, and the quantification of volatile compounds was based on the peak signal intensity. Using the Laboratory Analytical Viewer, Reporter, and Gallery Plot supported by the GC–IMS instrument, three-dimensional (3D) and two-dimensional (2D) topographic plots and gallery plots of the volatile compounds were constructed.

2.5. Statistical Analysis

Statistical analysis was performed in R computational language. Prior to the univariate analyses, the distribution of the data was brought to normality according to Box and Cox [26]. We used t-tests to look for significant differences between groups (p < 0.05).

Following the suggestions of previous studies [27,28], with the aim of obtaining an overall view of the data, robust principal component analysis (RPCA) models were set up based on the average values of the E-nose and E-tongue sensors and the molecules’ peak signal intensities, respectively. For each RPCA model, a score plot and a Pearson correlation plot of the loadings were calculated, to highlight the structure of the data and to find out the relationships between variables and the model components.

3. Results

3.1. Electronic Nose Analysis

The E-nose analyzer, equipped with 18 sensors, was used to identify different sour meat formulations and to assess their comprehensive flavor characteristics. The main performance of the sensors is described in Figure 1a, as suggested by Wen et al. [29]. The response from nine of the sensors was found to be significantly different between the two groups (p < 0.05). To obtain an overview of the trends of these sensors, their response values were employed as a basis for an RPCA model, shown in Figure 1b,c.

Sour meat samples fermented from goose and pork could be clearly distinguished when observed along PC 1, with goose mainly characterized by higher response values from the sensors LY/LG, LY/Gh, P40/2, LY2/AA, PA/2, T40/2, and P30/1 and by lower response values from the sensors P10/1 and P40/1.

3.2. Electronic Tongue Analysis

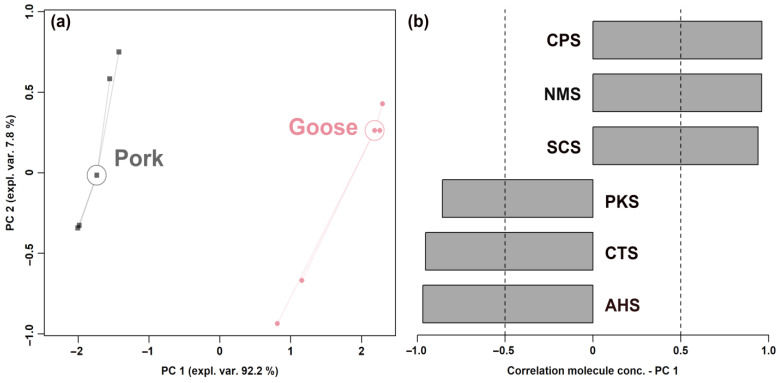

The E-tongue analyzer, equipped with seven sensors, was used to identify different sour meat formulations and to assess their comprehensive taste characteristics. Six of the sensors gave a significantly different response when analyzing the two groups (p < 0.05). In order to obtain an overview of the trends of these sensors, their response values were employed as a basis for an RPCA model, shown in Figure 2.

Figure 2.

Score plot (a) and Pearson correlation plot (b) of the loadings of an RPCA model based on E-tongue response data.

The results showed that sour meat samples fermented from goose and pork were well distinguished along PC 1. Sour meat fermented from goose was mainly characterized by higher response values from the sensors CPS, NMS, and SCS and by lower response values from the sensors PKS, CTS, and AHS.

3.3. GC–IMS Analysis

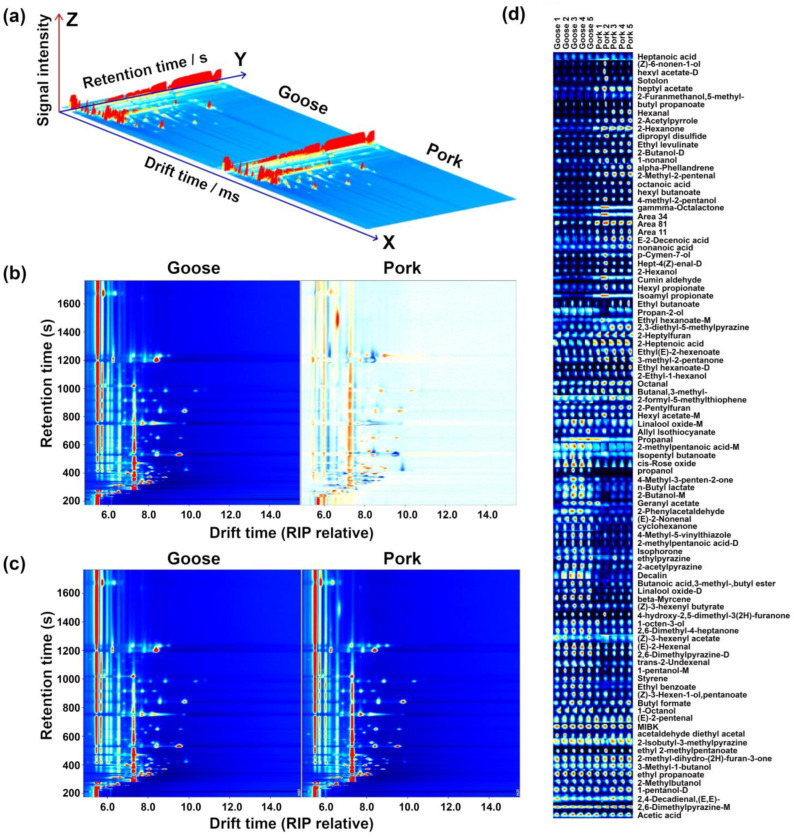

The processing pipeline of the GC–IMS information about the volatile components in the samples from goose and pork meat is summarized by Figure 3.

Figure 3.

GC–IMS observations of sour meat fermented from goose and pork. (a) Their three-dimensional representation. (b) Their bird’s-eye view representation, with spectra from goose meat employed as a reference and the corresponding spectra from pork represented as differences from goose meat. In the latter case, red and blue highlight components that were over- and under-expressed, respectively. (c) Their representation as ion migration spectra, where the ions are numbered and then listed in (d) as gallery plots, in which the color was brighter, the content was higher.

The 3D representation of Figure 3a offers an unbiased visual impression that the samples from the two meat sources differed along large portions of the GC–IMS spectrum. This allows us to establish that GC–IMS is a technique well suited for distinguishing fermented meat from the two studied sources. The point-by-point differences between the two sets of samples in Figure 3b allow us to appreciate in finer detail that most of the peculiarities regarded compounds with retention times between 200 and 1000 s, whose ions showed drift times between 6.0 and 10.0 ms. A total of 94 compounds were identified, including ketones (10), acids (8), alcohols (19), aldehydes (15), esters (27), and others (10). The relevant information about each of them is provided in Table 1.

Table 1.

Molecules’ peak areas (mean ± sd) characterized by GC–IMS in sour meat fermented from both goose and pork.

| Count | Compound | CAS | Molecule Formula | MW * | RI | RT (s) | DT (ms) | Goose | Pork | p-Value |

|---|---|---|---|---|---|---|---|---|---|---|

| Ketones | 2,6-Dimethyl-4-heptanone | C108838 | C9H18O | 142.2 | 1210.4 | 756.074 | 1.77916 | 1.15 × 103 ± 43.80 | 7.19 × 102 ± 1.13 × 102 | 0.008 |

| 2-Hexanone | C591786 | C6H12O | 100.2 | 1093.1 | 436.042 | 1.49671 | 7.90 × 102 ± 66.90 | 2.23 × 103 ± 2.82 × 102 | 0.000 | |

| 4-Hydroxy-2,5-dimethyl-3(2 H)-furanone | C3658773 | C6H8O3 | 128.1 | 1053.3 | 371.81 | 1.61084 | 3.05 × 103 ± 3.90 × 102 | 2.29 × 103 ± 1.15 × 103 | 0.139 | |

| 4-Methyl-3-penten-2-one | C141797 | C6H10O | 98.1 | 1106.1 | 462.228 | 1.44482 | 7.86 × 102 ± 4.19 × 102 | 3.88 × 102 ± 1.79 × 102 | 0.093 | |

| Isophorone | C78591 | C9H14O | 138.2 | 1115 | 480.134 | 1.25323 | 1.01 × 103 ± 1.40 × 102 | 4.97 × 102 ± 63.20 | 0.000 | |

| 2-Methyl-dihydro-(2 H)-Furan-3-one | C3188009 | C5H8O2 | 100.1 | 1280.5 | 1019.37 | 1.06662 | 1.74 × 103 ± 2.62 × 102 | 2.07 × 103 ± 93.20 | 0.056 | |

| MIBK | C108101 | C6H12O | 100.2 | 1021.3 | 338.292 | 1.47542 | 2.36 × 102 ± 19.10 | 3.54 × 102 ± 50.70 | 0.001 | |

| 3-Methyl-2-pentanone | C565617 | C6H12O | 100.2 | 1056.3 | 374.988 | 1.47533 | 3.54 × 103 ± 7.26 × 102 | 4.16 × 103 ± 2.62 × 102 | 0.155 | |

| 2-Acetylpyrrole | C1072839 | C6H7NO | 109.1 | 1082.5 | 414.813 | 1.49823 | 8.98 × 102 ± 2.03 × 102 | 1.78 × 103 ± 2.21 × 102 | 0.003 | |

| 2-Acetylpyrazine | C22047252 | C6H6N2O | 122.1 | 1017.1 | 333.894 | 1.20618 | 8.62 × 102 ± 1.40 × 102 | 4.40 × 102 ± 85.10 | 0.004 | |

| Acids | Acetic acid | C64197 | C2H4O2 | 60.1 | 1447.3 | 1673.557 | 1.05277 | 1.73 × 104 ± 1.07 × 103 | 1.52 × 104 ± 1.77 × 103 | 0.101 |

| Octanoic acid | C124072 | C8H16O2 | 144.2 | 1174.4 | 628.473 | 1.44089 | 9.98 × 102 ± 1.52 × 102 | 1.87 × 103 ± 3.04 × 102 | 0.002 | |

| 2-Methylpentanoic acid (D) | C97610 | C6H12O2 | 116.2 | 1029.9 | 347.315 | 1.59258 | 2.77 × 102 ± 37.50 | 1.15 × 102 ± 19.90 | 0.000 | |

| 2-Methylpentanoic acid (M) | C97610 | C6H12O2 | 116.2 | 1028.9 | 346.226 | 1.26389 | 4.00 × 102 ± 46.80 | 2.57 × 102 ± 24.30 | 0.001 | |

| Heptanoic acid | C111148 | C7H14O2 | 130.2 | 1082.4 | 414.564 | 1.3611 | 3.66 × 102 ± 12.40 | 4.37 × 102 ± 54.40 | 0.013 | |

| Nonanoic acid | C112050 | C9H18O2 | 158.2 | 1279.5 | 1015.116 | 1.54967 | 1.50 × 103 ± 2.57 × 102 | 2.40 × 103 ± 1.65 × 102 | 0.010 | |

| E-2-Decenoic acid | C334496 | C10H18O2 | 170.3 | 1334.9 | 1232.645 | 1.48495 | 2.12 × 102 ± 40.80 | 3.27 × 102 ± 97.00 | 0.054 | |

| 2-Heptenoic acid | C18999285 | C7H12O2 | 128.2 | 1207 | 744.053 | 1.40605 | 1.26 × 103 ± 2.56 × 102 | 3.10 × 103 ± 2.42 × 102 | 0.001 | |

| Alcohols | 1-Octen-3-ol | C3391864 | C8H16O | 128.2 | 1447.5 | 1674.263 | 1.1622 | 4.63 × 103 ± 6.10 × 102 | 3.62 × 103 ± 9.00 × 102 | 0.096 |

| 1-Pentanol (D) | C71410 | C5H12O | 88.1 | 1253.8 | 914.653 | 1.51902 | 1.83 × 103 ± 1.34 × 102 | 1.52 × 103 ± 4.16 × 102 | 0.257 | |

| 1-Pentanol (M) | C71410 | C5H12O | 88.1 | 1254.1 | 915.518 | 1.25162 | 1.61 × 103 ± 1.27 × 102 | 1.33 × 103 ± 3.01 × 102 | 0.199 | |

| 2-Hexanol | C626937 | C6H14O | 102.2 | 1235.1 | 843.655 | 1.56671 | 4.13 × 103 ± 1.04 × 103 | 7.17 × 103 ± 9.86 × 102 | 0.016 | |

| 3-Methyl-1-butanol | C123513 | C5H12O | 88.1 | 1207.6 | 746.268 | 1.24551 | 1.15 × 103 ± 40.60 | 1.07 × 103 ± 1.03 × 102 | 0.235 | |

| 2-Methylbutanol | C137326 | C5H12O | 88.1 | 1214.5 | 770.435 | 1.24551 | 2.27 × 103 ± 1.71 × 102 | 1.97 × 103 ± 1.23 × 102 | 0.036 | |

| p-Cymen-7-ol | C536607 | C10H14O | 150.2 | 1281.2 | 1021.821 | 1.32996 | 5.51 × 103 ± 1.15 × 103 | 1.03 × 104 ± 1.82 × 103 | 0.006 | |

| (Z)-6-nonen-1-ol | C35854865 | C9H18O | 142.2 | 1181.1 | 652.231 | 1.75376 | 8.75 × 102 ± 30.50 | 1.59 × 103 ± 9.61 × 102 | 0.016 | |

| 4-Methyl-2-pentanol | C108112 | C6H14O | 102.2 | 1180.5 | 650.067 | 1.54657 | 2.02 × 103 ± 5.14 × 102 | 4.15 × 103 ± 1.43 × 103 | 0.009 | |

| 1-Nonanol | C143088 | C9H20O | 144.3 | 1144.7 | 540.011 | 1.53779 | 2.82 × 103 ± 8.05 × 102 | 3.71 × 103 ± 9.29 × 102 | 0.105 | |

| Alcohols | Linalool oxide (D) | C60047178 | C10H18O2 | 170.3 | 1087.7 | 425.155 | 1.80714 | 2.61 × 103 ± 7.70 × 102 | 1.27 × 103 ± 3.23 × 102 | 0.016 |

| Linalool oxide (M) | C60047178 | C10H18O2 | 170.3 | 1082.4 | 414.503 | 1.25444 | 4.16 × 102 ± 64.60 | 3.2 × 6102 ± 68.00 | 0.137 | |

| 2-Ethyl-1-hexanol | C104767 | C8H18O | 130.2 | 1030.4 | 347.834 | 1.4048 | 3.83 × 103 ± 6.13 × 102 | 4.42 × 103 ± 4.86 × 102 | 0.129 | |

| 2-Butanol (D) | C78922 | C4H10O | 74.1 | 1016.3 | 333.005 | 1.33429 | 1.41 × 103 ± 3.90 × 102 | 2.71 × 103 ± 3.06 × 102 | 0.010 | |

| 2-Butanol (M) | C78922 | C4H10O | 74.1 | 1016 | 332.708 | 1.14461 | 6.46 × 102 ± 1.90 × 102 | 2.32 × 102 ± 85.80 | 0.007 | |

| Propanol | C71238 | C3H8O | 60.1 | 976.8 | 295.222 | 1.24209 | 6.75 × 102 ± 2.14 × 102 | 1.54 × 102 ± 37.60 | 0.000 | |

| Propan-2-ol | C67630 | C3H8O | 60.1 | 940.1 | 275.184 | 1.08085 | 7.06 × 102 ± 60.40 | 5.53 × 102 ± 1.74 × 102 | 0.207 | |

| 1-Octanol | C111875 | C8H18O | 130.2 | 1030.2 | 347.582 | 1.46611 | 7.99 × 103 ± 3.00 × 102 | 7.04 × 103 ± 4.65 × 102 | 0.037 | |

| 2-Furanmethanol, 5-methyl- | C3857258 | C6H8O2 | 112.1 | 949.8 | 280.488 | 1.26173 | 1.93 × 102 ± 46.40 | 9.20 × 101 ± 9.12 | 0.001 | |

| Aldehydes | Cumin aldehyde | C122032 | C10H12O | 148.2 | 1240.6 | 862.903 | 1.33504 | 3.60 × 103 ± 1.00 × 103 | 8.59 × 103 ± 2.16 × 103 | 0.005 |

| trans-2-Undecenal | C53448070 | C11H20O | 168.3 | 1335.1 | 1233.494 | 1.56546 | 3.86 × 103 ± 2.27 × 102 | 2.22 × 103 ± 5.03 × 102 | 0.017 | |

| 2,4-Decadienal,(E,E)- | C25152845 | C10H16O | 152.2 | 1315.6 | 1156.984 | 1.41449 | 3.79 × 102 ± 16.70 | 4.62 × 102 ± 51.90 | 0.005 | |

| (Z)-4-Heptenal | C6728310 | C7H12O | 112.2 | 1272 | 985.747 | 1.62114 | 2.59 × 103 ± 4.75 × 102 | 4.85 × 103 ± 1.84 × 103 | 0.010 | |

| 2-Hexenal | C6728263 | C6H10O | 98.1 | 1210.7 | 757.253 | 1.50243 | 1.28 × 104 ± 8.16 × 102 | 7.70 × 103 ± 1.07 × 103 | 0.006 | |

| 2-Methyl-2-pentenal | C623369 | C6H10O | 98.1 | 1153.1 | 556.885 | 1.5028 | 1.03 × 103 ± 2.27 × 102 | 2.55 × 103 ± 2.73 × 102 | 0.001 | |

| Hexanal | C66251 | C6H12O | 100.2 | 1073.1 | 395.761 | 1.55606 | 5.58 × 102 ± 89.50 | 2.27 × 103 ± 9.09 × 102 | 0.001 | |

| (E)-2-Nonenal | C18829566 | C9H16O | 140.2 | 1144.7 | 540.011 | 1.40541 | 1.37 × 103 ± 1.13 × 102 | 7.37 × 102 ± 58.30 | 0.000 | |

| (E)-2-Pentenal | C1576870 | C5H8O | 84.1 | 1094.4 | 438.764 | 1.36432 | 1.01 × 103 ± 73.90 | 1.05 × 103 ± 1.34 × 102 | 0.975 | |

| 2-Formyl-5-methylthiophene | C13679704 | C6H6OS | 126.2 | 1108.5 | 467.078 | 1.17289 | 3.40 × 102 ± 46.20 | 3.20 × 102 ± 26.50 | 0.838 | |

| Octanal | C124130 | C8H16O | 128.2 | 1006.9 | 323.217 | 1.39288 | 1.13 × 103 ± 2.03 × 102 | 1.54 × 103 ± 75.20 | 0.033 | |

| Butanal, 3-methyl- | C590863 | C5H10O | 86.1 | 909.8 | 258.669 | 1.19285 | 4.51 × 102 ± 38.00 | 5.86 × 102 ± 52.20 | 0.008 | |

| Acetaldehyde diethyl acetal | C105577 | C6H14O2 | 118.2 | 863.4 | 233.347 | 1.13106 | 5.32 × 102 ± 90.20 | 4.71 × 102 ± 21.70 | 0.563 | |

| Propanal | C123386 | C3H6O | 58.1 | 842 | 221.677 | 1.03933 | 5.49 × 102 ± 1.50 × 102 | 4.89 × 102 ± 1.33 × 102 | 0.863 | |

| 2-Phenylacetaldehyde | C122781 | C8H8O | 120.2 | 1013.7 | 330.292 | 1.25765 | 1.95 × 103 ± 3.40 × 102 | 1.87 × 103 ± 56.70 | 0.710 | |

| Esters | Isoamyl propionate | C105680 | C8H16O2 | 144.2 | 1190.1 | 683.977 | 1.33833 | 5.35 × 103 ± 2.37 × 103 | 1.57 × 104 ± 3.81 × 103 | 0.005 |

| Ethyl-(E)-2-hexenoate | C27829727 | C8H14O2 | 142.2 | 1334.8 | 1232.212 | 1.32568 | 3.78 × 103 ± 2.68 × 102 | 6.16 × 103 ± 5.68 × 102 | 0.001 | |

| Hexyl propionate | C2445763 | C9H18O2 | 158.2 | 1329.3 | 1210.43 | 1.43 | 4.53 × 103 ± 6.92 × 102 | 6.47 × 103 ± 6.47 × 102 | 0.021 | |

| (Z)-3-hexenyl acetate | C3681718 | C8H14O2 | 142.2 | 1315.4 | 1155.965 | 1.30104 | 3.60 × 102 ± 23.20 | 2.92 × 102 ± 23.80 | 0.015 | |

| Hexyl acetate (D) | C142927 | C8H16O2 | 144.2 | 1271.7 | 984.728 | 1.88721 | 1.25 × 103 ± 91.60 | 2.58 × 103 ± 2.26 × 103 | 0.044 | |

| (Z)-3-Hexen-1-ol, Pentanoate | C35852461 | C11H20O2 | 184.3 | 1272.2 | 986.766 | 1.48608 | 1.53 × 103 ± 28.50 | 1.26 × 103 ± 3.50 × 102 | 0.122 | |

| Ethyl hexanoate (D) | C123660 | C8H16O2 | 144.2 | 1234.6 | 841.923 | 1.79323 | 6.16 × 103 ± 3.86 × 102 | 9.92 × 103 ± 1.89 × 103 | 0.002 | |

| Hexyl acetate (M) | C142927 | C8H16O2 | 144.2 | 1271.9 | 985.651 | 1.38787 | 1.63 × 103 ± 85.90 | 1.89 × 103 ± 4.85 × 102 | 0.383 | |

| Eesters | Ethyl benzoate | C93890 | C9H10O2 | 150.2 | 1160.1 | 577.835 | 1.26386 | 9.73 × 102 ± 1.61 × 102 | 5.00 × 102 ± 68.00 | 0.001 |

| γ-Octalactone | C104507 | C8H14O2 | 142.2 | 1255.6 | 921.364 | 1.33563 | 4.68 × 103 ± 9.39 × 102 | 1.06 × 104 ± 2.47 × 103 | 0.002 | |

| Ethyl hexanoate (M) | C123660 | C8H16O2 | 144.2 | 1234.7 | 842.104 | 1.34131 | 3.84 × 103 ± 4.45 × 102 | 6.48 × 103 ± 1.12 × 103 | 0.002 | |

| Hexyl butanoate | C2639636 | C10H20O2 | 172.3 | 1188.4 | 678.191 | 1.48375 | 9.06 × 102 ± 87.10 | 1.39 × 103 ± 1.86 × 102 | 0.003 | |

| (Z)-3-hexenyl butyrate | C16491364 | C10H18O2 | 170.3 | 1181.4 | 653.414 | 1.41322 | 9.61 × 102 ± 58.10 | 7.61 × 102 ± 1.07 × 102 | 0.038 | |

| Ethyl 2-methylpentanoate | C39255328 | C8H16O2 | 144.2 | 1141.7 | 534.023 | 1.74779 | 1.12 × 104 ± 1.16 × 102 | 9.35 × 103 ± 3.20 × 103 | 0.137 | |

| Sotolon | C28664359 | C6H8O3 | 128.1 | 1097.4 | 444.752 | 1.61692 | 2.79 × 102 ± 24.50 | 5.70 × 102 ± 2.84 × 102 | 0.007 | |

| Ethyl levulinate | C539888 | C7H12O3 | 144.2 | 1082 | 413.724 | 1.64736 | 4.97 × 102 ± 55.40 | 7.92 × 102 ± 2.66×102 | 0.032 | |

| Butanoic acid, 3-methyl-, Butyl ester | C109193 | C9H18O2 | 158.2 | 1074.2 | 397.938 | 1.38714 | 1.22 × 103 ± 84.70 | 8.69 × 102 ± 91.10 | 0.006 | |

| Isopentyl butanoate | C106274 | C9H18O2 | 158.2 | 1060.1 | 378.974 | 1.40381 | 5.11 × 102 ± 45.20 | 3.71 × 102 ± 57.00 | 0.017 | |

| Butyl formate | C592847 | C5H10O2 | 102.1 | 1014 | 330.632 | 1.5051 | 5.57 × 102 ± 77.30 | 4.87 × 102 ± 1.33×10² | 0.282 | |

| Ethyl propanoate | C105373 | C5H10O2 | 102.1 | 1011.2 | 327.666 | 1.44949 | 6.71 ×103 ± 2.54×102 | 6.11 × 103 ± 2.84×102 | 0.021 | |

| Butyl propanoate | C590012 | C7H14O2 | 130.2 | 908.2 | 257.789 | 1.27492 | 5.02 × 102 ± 69.60 | 8.46 × 102 ± 1.97×102 | 0.005 | |

| Ethyl acetate | C141786 | C4H8O2 | 88.1 | 943.6 | 277.07 | 1.33409 | 3.49 × 102 ± 26.40 | 4.93 × 102 ± 59.90 | 0.003 | |

| Ethyl butanoate | C105544 | C6H12O2 | 116.2 | 1014.5 | 331.173 | 1.5593 | 1.10 × 103 ± 1.46×102 | 7.65 × 102 ± 1.45×102 | 0.020 | |

| n-Butyl lactate | C34451199 | C7H14O3 | 146.2 | 1018.6 | 335.453 | 1.26872 | 2.65 × 102 ± 51.10 | 1.33 × 102 ± 7.96 | 0.000 | |

| Heptyl acetate | C112061 | C9H18O2 | 158.2 | 1073.5 | 396.604 | 1.448 | 5.63 × 103 ± 1.87 × 103 | 4.62 × 103 ± 2.04 × 103 | 0.811 | |

| Geranyl acetate | C105873 | C12H20O2 | 196.3 | 1400 | 1487.894 | 1.21911 | 4.14 × 102 ± 59.60 | 1.83 × 102 ± 32.80 | 0.000 | |

| cis-Rose oxide | C3033236 | C10H18O | 154.3 | 1111.6 | 473.354 | 1.38248 | 3.18 × 103 ± 3.65 × 102 | 1.68 × 103 ± 2.53 × 102 | 0.002 | |

| Others | Dipropyl disulfide | C629196 | C6H14S2 | 150.3 | 1098.5 | 446.929 | 1.47388 | 1.23 × 103 ± 2.11 × 102 | 2.25 × 103 ± 6.31 × 102 | 0.006 |

| 2,6-Dimethylpyrazine (D) | C108509 | C6H8N2 | 108.1 | 1327.6 | 1204.024 | 1.53744 | 1.76 × 104 ± 7.42 × 102 | 1.03 × 104 ± 1.37 × 103 | 0.004 | |

| 2,6-Dimethylpyrazine (M) | C108509 | C6H8N2 | 108.1 | 1331.2 | 1218.118 | 1.14507 | 3.30 × 103 ± 1.67 × 102 | 3.09 × 103 ± 1.49 × 102 | 0.059 | |

| α-Phellandrene | C99832 | C10H16 | 136.2 | 1152 | 554.708 | 1.67323 | 4.86 × 102 ± 25.00 | 1.34 × 103 ± 4.68 × 102 | 0.000 | |

| 4-Methyl-5-vinylthiazole | C1759280 | C6H7NS | 125.2 | 1029.9 | 347.315 | 1.53323 | 4.62 × 102 ± 32.60 | 1.99 × 102 ± 37.40 | 0.001 | |

| Decalin | C91178 | C10H18 | 138.3 | 1063.2 | 382.237 | 1.23101 | 5.61 × 102 ± 1.44 × 102 | 1.82 × 102 ± 15.10 | 0.000 | |

| β-Myrcene | C123353 | C10H16 | 136.2 | 977.3 | 295.442 | 1.28554 | 2.45 × 103 ± 2.71 × 102 | 1.02 × 103 ± 2.30 × 102 | 0.002 | |

| Ethylpyrazine | C13925003 | C6H8N2 | 108.1 | 933.6 | 271.661 | 1.12623 | 4.13 × 102 ± 81.50 | 3.21 × 102 ± 52.40 | 0.051 | |

| 2,3-Diethyl-5-Methylpyrazine | C18138040 | C9H14N2 | 150.2 | 1154 | 558.675 | 1.27281 | 9.39 × 102 ± 69.70 | 8.97 × 102 ± 65.40 | 0.364 | |

| 2-Isobutyl-3-Methylpyrazine | C13925069 | C9H14N2 | 150.2 | 1142.5 | 535.449 | 1.30033 | 1.78 × 102 ± 44.70 | 1.96 × 102 ± 93.00 | 0.863 | |

| 2-Heptylfuran | C3777717 | C11H18O | 166.3 | 1212.6 | 763.852 | 1.40704 | 3.13 × 103 ± 6.22 × 102 | 4.40 × 103 ± 2.19 × 102 | 0.035 | |

| 2-Pentylfuran | C3777693 | C9H14O | 138.2 | 1230.8 | 828.288 | 1.25257 | 8.35 × 102 ± 77.00 | 8.67 × 102 ± 63.50 | 0.383 |

* Notes: MW—molecular mass; RI—retention index; Rt—retention time; Dt—drift time. p-value was calculated by t-test, and the cutoff value was set as below 0.05.

The topographic plots of Figure 3d allow us to visually appreciate the trends distinguishing the two sets of samples, and they demonstrate that many of the volatile compounds distinguishing fermented goose meat from fermented pork were acids and alcohols. For example, hexyl acetate, sotolon, heptyl acetate, butyl propanoate, hexanal, and 2-acetylpyrrole appeared as more concentrated in sour meat from fermented pork, while levels of 4-methyl-3-penten-2-one, n-butyl lactate, 2-butanol, (E)-2-nonenal, and decalin were higher in the samples from goose meat.

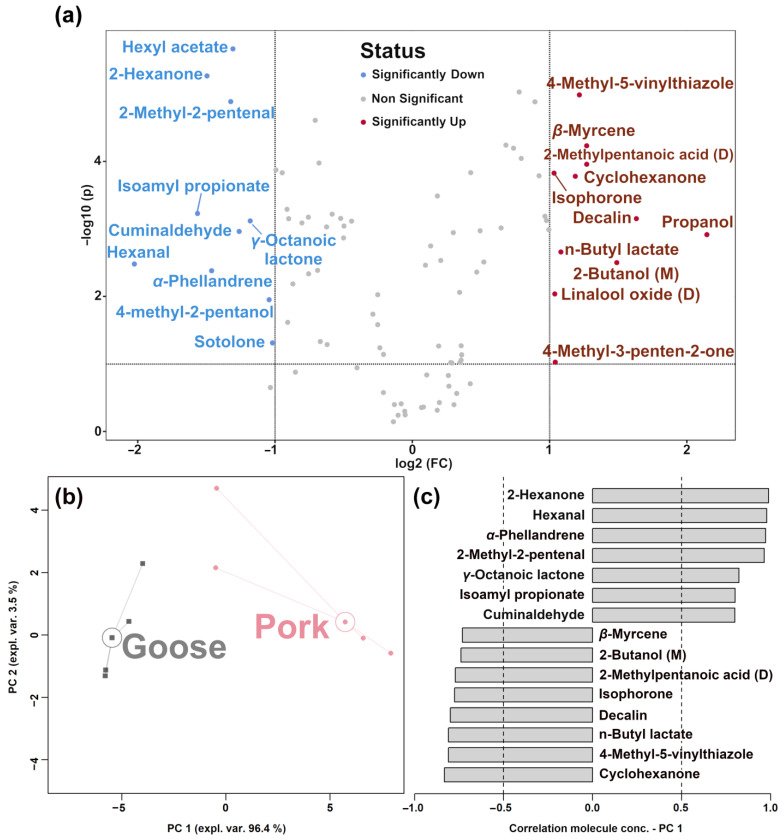

In accordance with Zhu et al., to identify the molecules showing the highest differences between the two types of samples, a volcano plot was set up, which nicely combines the results of the t-test and fold-change analysis on a molecule-by-molecule basis [30]. Significantly different molecules with a fold change higher than 2 are shown in Figure 4a. To obtain an overview of the trends of these molecules, their signal intensities were employed as a basis for an RPCA model, as shown in Figure 4b,c.

Figure 4.

Volcano plot (a) indicating the changes in the concentrations of metabolites in sour meat samples from the two groups. The RPCA model was set up on the basis of the molecules selected by the volcano plot. In the score plot (b), squares and circles indicate goose and pork samples, respectively. The median of each sample group is indicated by wide, empty circles. The Pearson correlation plot of the loadings (c) shows the molecules with significant correlations between concentration and importance over PC 1 (p < 0.05).

In the score plot of Figure 4b, the PC 1 accounted for as much as 96.4% of the samples’ overall variability and perfectly summarized the differences between goose and pork samples, with negative and positive PC 1 scores, respectively. The Pearson correlation plot of the loadings of Figure 4c shows that sour meat fermented from goose has higher amounts of β-myrcene, 2-butanol, 2-methylpentanoic acid, isophorone, decaline, n-butyl lactate, 4-methyl-5-vinylthiazole, and cyclohexanone and lower concentrations of 2-hexanone, hexanal, α-phellandrene, 2-methyl-2-pentenal, γ-octanoic lactone, isoamyl propionate, and cuminaldehyde.

3.4. Correlation between E-Nose and GC–IMS

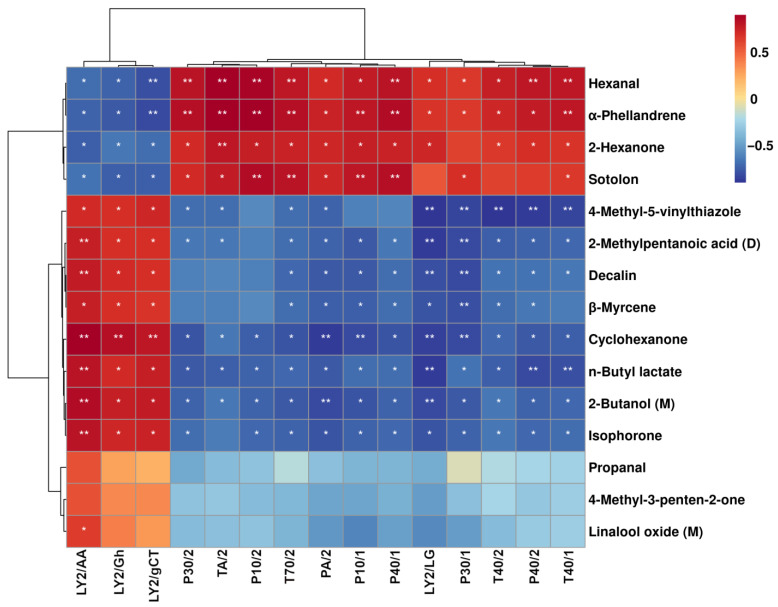

The E-nose and GC–IMS can classify sour meat fermented from pork and goose meat from different points of view. For example, E-nose was able to provide overall information on the volatile compounds in each sample. In contrast, GC–IMS could provide the specific volatile profile of each sour meat. Therefore, in order to promote the overall performance of both techniques, the potential correlation between E-nose sensor responses and volatile compound levels detected by GC–IMS was analyzed, as shown in Figure 5.

Figure 5.

Spearman’s correlation heatmap showing the correlation between the significantly altered volatile compound levels and the electronic nose sensor responses. Colors represent correlation coefficients, with red and blue indicating positive and negative correlation, respectively. Asterisks * and ** stand for significance at p < 0.05 and p < 0.01, respectively.

As shown in Figure 5, the LY2/AA and LY2/Gh sensors were found to positively correlate with hexanal, α-phellandrene, and 2-hexanone. These compounds were characterized by GC–IMS at high levels in the sour meat fermented from pork. In contrast, the PA/2, P10/1, P40/1, LY2/LG, P30/1, T40/2, and P40/2 sensors were found to positively correlate with 2-methylpentanoic acid (D), decaline, β-myrcene, cyclohexanone, n-butyl lactate, 2-butanol (M), and isophorone. These compounds were characterized by GC–IMS at high levels in the sour meat fermented from goose meat. These results indicate that the E-nose sensor response values and volatile compound quantifications characterized through GC–IMS can discriminate the unique flavors of sour meat fermented from pork versus goose meat.

4. Discussion

Sour meat (Nanx Wudl) is a fermented meat product traditionally manufactured by minorities (the Dong, the Miao, the Dai, the Tujia, the Maonan, etc.) but increasingly appreciated in wider parts of China due to its unique flavor, richness in nutrients, and long shelf life [2,16,31]. However, studies evaluating the effects of different raw meats on the formation of the typical complex flavor during fermentation are still lacking. To shed light on the issue, the present study attempted, for the first time, to comprehensively characterize the flavor profiles of sour meat from goose and pork by means of GC–IMS combined with an electronic nose and tongue—a perfect combination for the purpose, but still rarely employed.

Nine of the eighteen sensors on the E-nose analyzer showed a significantly different response between the samples from goose meat and pork, evidencing that this tool is extremely sensitive to peculiarities in the overall flavor profiles connected to the raw materials for fermented meat. From this point of view, it is worth underlining that this tool is not able to identify the specific volatile compounds giving rise to the overall response; a specific high-throughput technique tailored for the purpose, such as GC–IMS, should be used in parallel to obtain fine-grained information, at least in the first stages of investigation. Six of the seven sensors on the E-tongue showed a significantly different response to the two tested products, demonstrating that, in this context, this technique gives interesting complimentary information from the point of view of taste attributes.

A total of 94 compounds was characterized in each of the tested samples by GC–IMS, by comparing their RI and ion drift time to the standards in the GC–IMS library and references [32,33,34,35], pertaining to ketones (10), acids (8), alcohols (19), aldehydes (15), esters (27), and others (10). Among them, twenty-one compounds exhibited significant differences between the two types of samples, namely hexyl acetate, 2-hexanone, 2-methyl-2-pentenal, isoamyl propionate, cuminaldehyde, hexanal, γ-octanoic lactone, α-phellandrene, 4-methyl-2-pentanol, sotolon, 4-methyl-5-vinylthiazole, β-myrcene, 2-methylpentanoic acid (D), cyclohexanone, isophorone, decaline, propanol, n-butyl lactate, 2-butanol (M), linalool oxide (D), and 4-methyl-3-penten-2-one.

2-Butanol is a flavor-enriching substance with a sweet and pleasant scent [36]. The compound is derived from the reduction of 2-butanone. Moreover, it can also derive from pyruvate, similar to 1-propanol [37]. In turn, pyruvate generation could be attributed to amino acid metabolism, active in lactic acid bacteria, particularly for aspartate [38]. The distinct content of 2-butanol in sour meat fermented from goose meat and pork could be explained, at least in part, by the different amino acid profiles of goose meat versus pork [39,40].

Hexanal and 2-methyl-2-pentenal, belonging to the chemical class of aldehydes, have been found in beef meat [41] and chicken meat [42] and are considered to be useful markers of lipid oxidation [43,44]. Choi et al. found, by studying plant substrates during drying, that hexanal and 2-methyl-2-pentenal are produced from the action of residual enzymes so that, especially at low drying temperatures, their concentration is proportional to the residual humidity of the sample [45]. From these studies, it could be inferred that the different contents of hexanal and 2-methyl-2-pentenal in sour meat fermented from goose meat versus pork could be linked to different activity of residual enzymes, in turn leading to variable extents of lipid oxidation in the final product [46].

2-Hexanone, like many ketones, has an unpleasant, pungent odor [47]. By observing silver carp during chill storage, Jia et al. found that 2-hexanone was initially absent and increased gradually with storage time, showing a good correlation with microbial growth [48]. Similar to 2-hexanone, 2-methyl-2-pentenal, 2-methylpentanoic acid, and 4-methyl-3-penten-2-one were found to be linked to microbiota metabolism, though they were mainly linked to lipid oxidation, carbohydrate fermentation, and amino acid degradation [49,50].

Hexyl acetate is an ester with a pleasant fruity scent, which can usually be found in meat products. Li et al. found that hexanal was first reduced to 1-hexanol by Lb. fermentum and subsequently converted into hexyl acetate by P. kluyveri during pork fermentation [51]. Similarly, Jiang et al. found that there were positive correlations between the levels of Leuconostoc and Lactobacillus versus hexyl acetate in smoked horse meat sausages [52]. Zhang et al. found that hexyl acetate was a crucial positive contributor to the flavor profile of unsmoked bacon [53].

Overall, the trends we observed of the above-mentioned molecules seem to confirm that microorganisms’ role in determining flavor profile is determined by the raw materials, particularly the meat. The trends of other molecules seem to confirm this observation. Linalool oxide can contribute to woody and floral aromas [54]. Sotolon is formed through the aldol condensation of α-ketobutyric acid, produced by threonine and acetaldehyde, which in turn result from the oxidation of ethanol generated, by the glucose metabolism of yeasts during fermentation, among other processes. Confirming this, Ohata et al. used 10% commercial koji and 10% salts to ferment a pork meat sauce for 12 months, and they found that the main odor contributors in their fermented meat sauce were sotolon and ethyl furaneol, which gave the meat sauce a sweet and caramel-like note [55]. Other compounds such as α-phellandrene, β-myrcene, and cuminaldehyde can be considered plant-derived [56,57,58]. The presence of these compounds in the final product is most likely due to the spices added to fresh meat, particularly pepper.

In the present study, it is worth noting that the combination of the E-nose, E-tongue, and GC–IMS could improve the overall performance of all techniques and provide a comprehensive characterization of sour meat fermented from pork and goose meat. In particular, the correlation between E-nose response values and GC–IMS molecule peak areas highlighted that lipid-oxidation-related compounds (such as hexanal and 2-hexanone) played important roles in discriminating sour meat fermented from goose meat and from pork. Moreover, a few of the E-nose sensors (such as PA/2, P10/1, P40/1, LY2/LG, T40/2, and P40/2), which exhibited significantly higher response values for the above compounds, could be considered potential candidates for developing targeted analysis methods by means of an E-nose for practical sample analysis.

5. Conclusions

In this study, for the first time, the flavor features of sour meat traditionally fermented from goose and pork were systematically characterized by means of GC–IMS, an E-nose, and an E-tongue. Taking advantage of a protocol based on univariate and multivariate analyses, we found that the raw material played a crucial role in introducing peculiarities to large portions of the flavor profile, so that sour meat from goose was readily distinguishable from that based on pork. Though the E-nose and E-tongue are able to grant an overall view of the odor and taste features of samples, it is still necessary to apply high-throughput techniques in parallel, to spot the specific volatile compounds conveying the overall response. Notably, none of the tested analyses required sample preparation, which implies that these operations are simple, fast, and nondestructive. Therefore, the present work could provide a basis for investigating the flavor profiles of traditional sour meats fermented from different meat sources and shed light on establishing more comprehensive and rapid methods for identifying flavor characteristics.

Author Contributions

Conceptualization, C.Z.; methodology, C.Z. and J.D.; formal analysis, C.Z., X.Z. and J.F.; investigation, C.Z. and X.Z.; resources, X.D.; writing—original draft preparation, C.Z., X.Z. and L.L.; writing—review and editing, X.Z., J.F., L.L., J.D., X.D., J.T., L.J., C.Z. and G.P.; supervision, C.Z.; funding acquisition, C.Z. All authors have read and agreed to the published version of the manuscript.

Data Availability Statement

The data presented in this study are available on request from the corresponding author.

Conflicts of Interest

The authors declare no conflict of interest.

Funding Statement

This work was funded by the Natural Science Foundation of Sichuan Province (2022NSFSC1652), the Fundamental Research Funds for the Central Universities, Southwest Minzu University (ZYN2022112), Cuisine Science Key Laboratory of Sichuan Province, Sichuan Tourism University (PRKX2022Z03), and Open Fund of Meat Processing Key Lab of Sichuan Province (22-R-21).

Footnotes

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content.

References

- 1.Zhong A., Chen W., Hu L., Wu Z., Xiao Y., Li K., Li Z., Wang Y., Wang C. Characterisation of key volatile compounds in fermented sour meat after fungi growth inhibition. LWT. 2022;165:113662. doi: 10.1016/j.lwt.2022.113662. [DOI] [Google Scholar]

- 2.Chen C., Chen X., Jiang M., Rui X., Li W., Dong M. A newly discovered bacteriocin from Weissella hellenica D1501 associated with Chinese Dong fermented meat (Nanx Wudl) Food Control. 2014;42:116–124. doi: 10.1016/j.foodcont.2014.01.031. [DOI] [Google Scholar]

- 3.Ying W., Ya-Ting J., Jin-Xuan C., Yin-Ji C., Yang-Ying S., Xiao-Qun Z., Dao-Dong P., Chang-Rong O., Ning G. Study on lipolysis-oxidation and volatile flavour compounds of dry-cured goose with different curing salt content during production. Food Chem. 2016;190:33–40. doi: 10.1016/j.foodchem.2015.05.048. [DOI] [PubMed] [Google Scholar]

- 4.Wołoszyn J., Wereńska M., Goluch Z., Haraf G., Okruszek A., Teleszko M., Król B. The selected goose meat quality traits in relation to various types of heat treatment. Poult. Sci. 2020;99:7214–7224. doi: 10.1016/j.psj.2020.09.062. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 5.Lv J., Li C., Li S., Liang H., Ji C., Zhu B., Lin X. Effects of temperature on microbial succession and quality of sour meat during fermentation. LWT. 2019;114:108391. doi: 10.1016/j.lwt.2019.108391. [DOI] [Google Scholar]

- 6.Lv J., Yang Z., Xu W., Li S., Liang H., Ji C., Yu C., Zhu B., Lin X. Relationships between bacterial community and metabolites of sour meat at different temperature during the fermentation. Int. J. Food Microbiol. 2019;307:108286. doi: 10.1016/j.ijfoodmicro.2019.108286. [DOI] [PubMed] [Google Scholar]

- 7.Lv J., Lin X., Liu M., Yan X., Liang H., Ji C., Li S., Zhang S., Chen Y., Zhu B. Effect of Saccharomyces cerevisiae LXPSC1 on microorganisms and metabolites of sour meat during the fermentation. Food Chem. 2023;402:134213. doi: 10.1016/j.foodchem.2022.134213. [DOI] [PubMed] [Google Scholar]

- 8.Zhang Y., Hu P., Xie Y., Wang X. Co-fermentation with Lactobacillus curvatus LAB26 and Pediococcus pentosaceus SWU73571 for improving quality and safety of sour meat. Meat Sci. 2020;170:108240. doi: 10.1016/j.meatsci.2020.108240. [DOI] [PubMed] [Google Scholar]

- 9.Wang Q., Li X., Xue B., Wu Y., Song H., Luo Z., Shang P., Liu Z., Huang Q. Low-salt fermentation improves flavor and quality of sour meat: Microbiology and metabolomics. LWT. 2022;171:114157. doi: 10.1016/j.lwt.2022.114157. [DOI] [Google Scholar]

- 10.Khan M.I., Jo C., Tariq M.R. Meat flavor precursors and factors influencing flavor precursors—A systematic review. Meat Sci. 2015;110:278–284. doi: 10.1016/j.meatsci.2015.08.002. [DOI] [PubMed] [Google Scholar]

- 11.Wang Z., Mi S., Wang X., Mao K., Liu Y., Gao J., Sang Y. Characterization and discrimination of fermented sweet melon juice by different microbial strains via GC–IMS-based volatile profiling and chemometrics. Food Sci. Hum. Wellness. 2023;12:1241–1247. doi: 10.1016/j.fshw.2022.10.006. [DOI] [Google Scholar]

- 12.Guo Y., Chen D., Dong Y., Ju H., Wu C., Lin S. Characteristic volatiles fingerprints and changes of volatile compounds in fresh and dried Tricholoma matsutake Singer by HS-GC–IMS and HS-SPME-GC–MS. J. Chromatogr. B Anal. Technol. Biomed. Life Sci. 2018;1099:46–55. doi: 10.1016/j.jchromb.2018.09.011. [DOI] [PubMed] [Google Scholar]

- 13.Yuan Z.-Y., Li J., Zhou X.-J., Wu M.-H., Li L., Pei G., Chen N.-H., Liu K.-L., Xie M.-Z., Huang H.-Y. HS-GC–IMS-Based metabonomics study of Baihe Jizihuang Tang in a rat model of chronic unpredictable mild stress. J. Chromatogr. B Anal. Technol. Biomed. Life Sci. 2020;1148:122143. doi: 10.1016/j.jchromb.2020.122143. [DOI] [PubMed] [Google Scholar]

- 14.Chen Q., Hu Y., Wen R., Wang Y., Qin L., Kong B. Characterisation of the flavour profile of dry fermented sausages with different NaCl substitutes using HS-SPME-GC-MS combined with electronic nose and electronic tongue. Meat Sci. 2021;172:108338. doi: 10.1016/j.meatsci.2020.108338. [DOI] [PubMed] [Google Scholar]

- 15.Zhu D., Ren X., Wei L., Cao X., Ge Y., Liu H., Li J. Collaborative analysis on difference of apple fruits flavour using electronic nose and electronic tongue. Sci. Hortic. 2020;260:108879. doi: 10.1016/j.scienta.2019.108879. [DOI] [Google Scholar]

- 16.Lv J., Xu W., Ji C., Liang H., Li S., Yang Z., Zhang S., Lin X. Relationships between the bacterial diversity and metabolites of a Chinese fermented pork product, sour meat. Int. J. Food Sci. Technol. 2021;56:2742–2750. doi: 10.1111/ijfs.14905. [DOI] [Google Scholar]

- 17.Zhong A., Chen W., Duan Y., Li K., Tang X., Tian X., Wu Z., Li Z., Wang Y., Wang C. The potential correlation between microbial communities and flavors in traditional fermented sour meat. LWT. 2021;149:111873. doi: 10.1016/j.lwt.2021.111873. [DOI] [Google Scholar]

- 18.Kononiuk A.D., Karwowska M. Comparison of selected parameters related to food safety of fallow deer and beef uncured fermented sausages with freeze-dried acid whey addition. Meat Sci. 2020;161:108015. doi: 10.1016/j.meatsci.2019.108015. [DOI] [PubMed] [Google Scholar]

- 19.Settanni L., Barbaccia P., Bonanno A., Ponte M., Di Gerlando R., Franciosi E., Di Grigoli A., Gaglio R. Evolution of indigenous starter microorganisms and physicochemical parameters in spontaneously fermented beef, horse, wild boar and pork salamis produced under controlled conditions. Food Microbiol. 2020;87:103385. doi: 10.1016/j.fm.2019.103385. [DOI] [PubMed] [Google Scholar]

- 20.Li X., Yang Y., Zhu Y., Ben A., Qi J. A novel strategy for discriminating different cultivation and screening odor and taste flavor compounds in Xinhui tangerine peel using E-nose, E-tongue, and chemometrics. Food Chem. 2022;384:132519. doi: 10.1016/j.foodchem.2022.132519. [DOI] [PubMed] [Google Scholar]

- 21.Yang C., Duan W., Xie K., Ren C., Zhu C., Chen K., Zhang B. Effect of salicylic acid treatment on sensory quality, flavor-related chemicals and gene expression in peach fruit after cold storage. Postharvest Biol. Technol. 2020;161:111089. doi: 10.1016/j.postharvbio.2019.111089. [DOI] [Google Scholar]

- 22.Han D., Zhang C.-H., Fauconnier M.-L., Jia W., Wang J.-F., Hu F.-F., Xie D.-W. Characterization and comparison of flavor compounds in stewed pork with different processing methods. LWT. 2021;144:111229. doi: 10.1016/j.lwt.2021.111229. [DOI] [Google Scholar]

- 23.Wang D., Zhang J., Zhu Z., Lei Y., Huang S., Huang M. Effect of ageing time on the flavour compounds in Nanjing water-boiled salted duck detected by HS-GC–IMS. LWT. 2022;155:112870. doi: 10.1016/j.lwt.2021.112870. [DOI] [Google Scholar]

- 24.Liu H., Yu Y., Zou B., Yu Y., Yang J., Xu Y., Chen X., Yang F. Evaluation of Dynamic Changes and Regularity of Volatile Flavor Compounds for Different Green Plum (Prunus mume Sieb. et Zucc) Varieties during the Ripening Process by HS-GC–IMS with PLS-DA. Foods. 2023;12:551. doi: 10.3390/foods12030551. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 25.Guo S., Zhao X., Ma Y., Wang Y., Wang D. Fingerprints and changes analysis of volatile compounds in fresh-cut yam during yellowing process by using HS-GC–IMS. Food Chem. 2022;369:130939. doi: 10.1016/j.foodchem.2021.130939. [DOI] [PubMed] [Google Scholar]

- 26.Box G.E.P., Cox D.R. An Analysis of Transformations. J. R. Stat. Soc. Ser. B Methodol. 2018;26:211–243. doi: 10.1111/j.2517-6161.1964.tb00553.x. [DOI] [Google Scholar]

- 27.Montanari C., Gatto V., Torriani S., Barbieri F., Bargossi E., Lanciotti R., Grazia L., Magnani R., Tabanelli G., Gardini F. Effects of the diameter on physico-chemical, microbiological and volatile profile in dry fermented sausages produced with two different starter cultures. Food Biosci. 2018;22:9–18. doi: 10.1016/j.fbio.2017.12.013. [DOI] [Google Scholar]

- 28.Karpiński P., Kruszewski B., Stachelska M.A., Szabłowska E. Development of volatile profile of Kumpiak podlaski dry-cured ham during traditional ripening. Int. J. Food Sci. Technol. 2020;55:3630–3638. doi: 10.1111/ijfs.14697. [DOI] [Google Scholar]

- 29.Wen R., Kong B., Yin X., Zhang H., Chen Q. Characterisation of flavour profile of beef jerky inoculated with different autochthonous lactic acid bacteria using electronic nose and gas chromatography–ion mobility spectrometry. Meat Sci. 2022;183:108658. doi: 10.1016/j.meatsci.2021.108658. [DOI] [PubMed] [Google Scholar]

- 30.Zhu C., Yang Z., He L., Lu X., Tang J., Laghi L. The Longer the Storage Time, the Higher the Price, the Better the Quality? A 1H-NMR Based Metabolomic Investigation of Aged Ya’an Tibetan Tea (Camellia sinensis) Foods. 2022;11:2986. doi: 10.3390/foods11192986. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 31.Sidira M., Kandylis P., Kanellaki M., Kourkoutas Y. Effect of immobilized Lactobacillus casei on the evolution of flavor compounds in probiotic dry-fermented sausages during ripening. Meat Sci. 2015;100:41–51. doi: 10.1016/j.meatsci.2014.09.011. [DOI] [PubMed] [Google Scholar]

- 32.Li X., Dong Y., Jiang P., Qi L., Lin S. Identification of changes in volatile compounds in sea cucumber Apostichopus japonicus during seasonings soaking using HS-GC–IMS. LWT. 2022;154:112695. doi: 10.1016/j.lwt.2021.112695. [DOI] [Google Scholar]

- 33.Zhang Q., Ding Y., Gu S., Zhu S., Zhou X., Ding Y. Identification of changes in volatile compounds in dry-cured fish during storage using HS-GC–IMS. Food Res. Int. 2020;137:109339. doi: 10.1016/j.foodres.2020.109339. [DOI] [PubMed] [Google Scholar]

- 34.Wan J., Liu Q., Ma C., Muhoza B., Huang Y., Sun M., Song S., Ho C.-T. Characteristic flavor fingerprint disclosure of dzo beef in Tibet by applying SAFE-GC-O-MS and HS-GC–IMS technology. Food Res. Int. 2023;166:112581. doi: 10.1016/j.foodres.2023.112581. [DOI] [PubMed] [Google Scholar]

- 35.Nie S., Li L., Wang Y., Wu Y., Li C., Chen S., Zhao Y., Wang D., Xiang H., Wei Y. Discrimination and characterization of volatile organic compound fingerprints during sea bass (Lateolabrax japonicas) fermentation by combining GC–IMS and GC-MS. Food Biosci. 2022;50:102048. doi: 10.1016/j.fbio.2022.102048. [DOI] [Google Scholar]

- 36.Kim K.-W., Kim H.-J., Lee E.-D., Kim D.-K., Lee J., Lee S.-S., Jang A., Lee S.-H. Comparison of Meat Quality Characteristics and Aromatic Substances of Korean Native Black Goat Ribs by Different Sex. J. Food Nutr. Res. 2020;8:585–590. doi: 10.12691/jfnr-8-10-7. [DOI] [Google Scholar]

- 37.Montanari C., Bargossi E., Gardini A., Lanciotti R., Magnani R., Gardini F., Tabanelli G. Correlation between volatile profiles of Italian fermented sausages and their size and starter culture. Food Chem. 2016;192:736–744. doi: 10.1016/j.foodchem.2015.07.062. [DOI] [PubMed] [Google Scholar]

- 38.Le Bars D., Yvon M. Formation of diacetyl and acetoin by Lactococcus lactis via aspartate catabolism. J. Appl. Microbiol. 2008;104:171–177. doi: 10.1111/j.1365-2672.2007.03539.x. [DOI] [PubMed] [Google Scholar]

- 39.Moya V.-J., Flores M., Aristoy M.-C., Toldrá F. Pork meat quality affects peptide and amino acid profiles during the ageing process. Meat Sci. 2001;58:197–206. doi: 10.1016/S0309-1740(00)00152-2. [DOI] [PubMed] [Google Scholar]

- 40.Geldenhuys G., Hoffman L.C., Muller N. The fatty acid, amino acid, and mineral composition of Egyptian goose meat as affected by season, gender, and portion. Poult. Sci. 2015;94:1075–1087. doi: 10.3382/ps/pev083. [DOI] [PubMed] [Google Scholar]

- 41.Yim D.-G., Kim H.J., Kim S.-S., Lee H.J., Kim J.-K., Jo C. Effects of different X-ray irradiation doses on quality traits and metabolites of marinated ground beef during storage. Radiat. Phys. Chem. 2023;202:110563. doi: 10.1016/j.radphyschem.2022.110563. [DOI] [Google Scholar]

- 42.Feng X., Ahn D.U. Volatile profile, lipid oxidation and protein oxidation of irradiated ready-to-eat cured turkey meat products. Radiat. Phys. Chem. 2016;127:27–33. doi: 10.1016/j.radphyschem.2016.05.027. [DOI] [Google Scholar]

- 43.Jo Y., An K.-A., Arshad M.S., Kwon J.-H. Effects of e-beam irradiation on amino acids, fatty acids, and volatiles of smoked duck meat during storage. Innov. Food Sci. Emerg. Technol. 2018;47:101–109. doi: 10.1016/j.ifset.2017.12.008. [DOI] [Google Scholar]

- 44.Bak K.H., Rankin S.A., Richards M.P. Hexanal as a marker of oxidation flavour in sliced and uncured deli turkey with and without phosphates using rosemary extracts. Int. J. Food Sci. Technol. 2020;55:3104–3110. doi: 10.1111/ijfs.14574. [DOI] [Google Scholar]

- 45.Choi S.M., Lee D.-J., Kim J.-Y., Lim S.-T. Volatile composition and sensory characteristics of onion powders prepared by convective drying. Food Chem. 2017;231:386–392. doi: 10.1016/j.foodchem.2017.03.129. [DOI] [PubMed] [Google Scholar]

- 46.Xu Y., Shui M., Chen D., Ma X., Feng T. Optimization of Jinhua Ham Classification Method Based on Volatile Flavor Substances and Determination of Key Odor Biomarkers. Molecules. 2022;27:7087. doi: 10.3390/molecules27207087. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 47.Wu W., Wang X., Hu P., Zhang Y., Li J., Jiang J., Zheng R., Zhang L. Research on flavor characteristics of beef cooked in tomato sour soup by gas chromatography–ion mobility spectrometry and electronic nose. LWT. 2023;179:114646. doi: 10.1016/j.lwt.2023.114646. [DOI] [Google Scholar]

- 48.Jia S., Li Y., Zhuang S., Sun X., Zhang L., Shi J., Hong H., Luo Y. Biochemical changes induced by dominant bacteria in chill-stored silver carp (Hypophthalmichthys molitrix) and GC–IMS identification of volatile organic compounds. Food Microbiol. 2019;84:103248. doi: 10.1016/j.fm.2019.103248. [DOI] [PubMed] [Google Scholar]

- 49.Ozturk I., Sagdic O., Yetim H. Effects of Autochthonous Yeast Cultures on Some Quality Characteristics of Traditional Turkish Fermented Sausage “Sucuk”. Food Sci. Anim. Resour. 2021;41:196–213. doi: 10.5851/kosfa.2020.e89. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 50.Qiu Y., Wu Y., Li L., Chen S., Zhao Y., Li C., Xiang H., Wang D., Wei Y., Wang Y. Elucidating the mechanism underlying volatile and non-volatile compound development related to microbial amino acid metabolism during golden pomfret (Trachinotus ovatus) fermentation. Food Res. Int. 2022;162:112095. doi: 10.1016/j.foodres.2022.112095. [DOI] [PubMed] [Google Scholar]

- 51.Li X., Liu S.-Q. Effect of co-inoculation and sequential inoculation of Lactobacillus fermentum and Pichia kluyveri on pork hydrolysates fermentation. Food Biosci. 2021;44:101400. doi: 10.1016/j.fbio.2021.101400. [DOI] [Google Scholar]

- 52.Jiang L., Chen Y., Deng L., Liu F., Wang T., Shi X., Wang B. Bacterial community diversity and its potential contributions to the flavor components of traditional smoked horsemeat sausage in Xinjiang, China. Front. Microbiol. 2022;13:942932. doi: 10.3389/fmicb.2022.942932. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 53.Zhang J., Zhang W., Zhou L., Zhang R. Study on the influences of ultrasound on the flavor profile of unsmoked bacon and its underlying metabolic mechanism by using HS-GC–IMS. Ultrason. Sonochem. 2021;80:105807. doi: 10.1016/j.ultsonch.2021.105807. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 54.Jeong I.-S., Park G.-W., Kim Y.-S., Park K.-H., Hwangbo H., Lee S.-Y., Kim S.-G. Effects of a Novel Convection Heated Roasting Method on Aroma and Umami Taste Components of Vegetable- and Meat-Based Extracts. J. Food Qual. 2022;2022:7690931. doi: 10.1155/2022/7690831. [DOI] [Google Scholar]

- 55.Ohata M., Zhou L., Higuchi K., Nagai T., Kasamatsu H., Arihara K. Investigation of volatile components and identification of the most potent odour-active component in fermented meat sauce. Flavour Fragr. J. 2017;32:171–177. doi: 10.1002/ffj.3371. [DOI] [Google Scholar]

- 56.Soncu E.D., Özdemir N., Arslan B., Küçükkaya S., Soyer A. Contribution of surface application of chitosan–thyme and chitosan–rosemary essential oils to the volatile composition, microbial profile, and physicochemical and sensory quality of dry-fermented sausages during storage. Meat Sci. 2020;166:108127. doi: 10.1016/j.meatsci.2020.108127. [DOI] [PubMed] [Google Scholar]

- 57.Shao Y., Liu X., Zhang Z., Wang P., Li K., Li C. Comparison and discrimination of the terpenoids in 48 species of huajiao according to variety and geographical origin by E-nose coupled with HS-SPME-GC-MS. Food Res. Int. 2023;167:112629. doi: 10.1016/j.foodres.2023.112629. [DOI] [PubMed] [Google Scholar]

- 58.Thangaleela S., Sivamaruthi B.S., Kesika P., Tiyajamorn T., Bharathi M., Chaiyasut C. A Narrative Review on the Bioactivity and Health Benefits of Alpha-Phellandrene. Sci. Pharm. 2022;90:57. doi: 10.3390/scipharm90040057. [DOI] [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.

Data Availability Statement

The data presented in this study are available on request from the corresponding author.